EVX-155

General Product Description

The EVX-155 low-frequency transducer is designed for professional

sound reinforcement or studio monitoring applications that require

maximum output with low distortion.

The EVX-155 woofer provides unprecedented power capacity, linearity

and excursion, made possible by the HeatWick™ total-thermalengineering design. The proprietary HeatWick design actually “wicks”

heat away from the voice coil, significantly increasing power handling

and long-term reliability. A special frame extension and elongated pole

piece provide a metal surface with close proximity to the entire length

of the voice coil, providing a major heat-transfer path. Also, the 100mm

(4-in.) diameter voice coil is longer than conventional medium efficiency

woofers to give additional power handling and virtually eliminate

dynamic-range power compression.

Additionally, a Flux Demodulation Device (FDD™) reduces distortion in

the critical mid band by providing a “short-circuit” effect to prevent

amplifier signal modulation of the static magnetic field. To further increase

reliability, PROTEF

diameter of the FDD™ and top plate. PROTEF™ lubricates any rubbing

contact and electrically insulates the coil from the FDD™ and top plate

to guard against violent short-term power peaks.

A ribbed, Kevlar

stiffness-to-weight ratio and exceptional strength gives the EVX-155

increased resistance to cone collapse and deformation, without

sacrificing efficiency. A rubber mounting flange gasket provides a

reusable seal for front or rear mounting, completely surrounding the

frame flange.

™

, a Teflon® based coating, is applied to the internal

®

fiber composite cone with an extremely high

Architects’ and Engineers’ Specifications

The low-frequency transducer shall have a nominal diameter of 381

mm (15 in.), overall depth not greater than 168 mm (6.61 in.), and weigh

no more than 10 kg (22 lb). The frame shall be made of die-cast aluminum

to resist deformation. The magnetic assembly shall have an extended

pole piece to reduce inductive variances with excursion, and provide a

symmetrical magnetic field at the voice-coil gap. Two aluminum rings

shall encircle the pole piece above and below the magnetic gap, and

shall have internal diameters concentric with the internal diameter of

the steel top plate. The upper ring shall be part of the loudspeaker

frame. Both rings act to reduce flux modulation and provide a

heat-transfer path from the outer diameter of the voice coil. The inner

diameter of the steel top plate and the lower aluminum ring shall be

Teflon® coated.

The voice coil shall be 100 mm (4 in.) in diameter and 20 mm (0.8 in.)

in winding length, and shall be made of edge-wound aluminum ribbon.

When centered in the magnetic gap, the voice coil shall produce a

force of not less than 20.4 newtons (tesla-ampere-meters) with a dc

current of 1 ampere.

Performance specifications of a typical production unit shall be as

follows: measured sensitivity (SPL at 1 m (3.3 ft) with 1 watt input, 100

to 800 Hz pink noise) shall be at least 98 dB. The half-space reference

efficiency shall be at least 4.3%. The usable frequency response shall

be 30 Hz to 1,800 Hz, and the nominal impedance shall be 8 ohms. The

rated power for the loudspeaker shall be 1,000 watts continuous program

power.

The low-frequency transducer shall be the Electro-Voice® EVX-155.

1

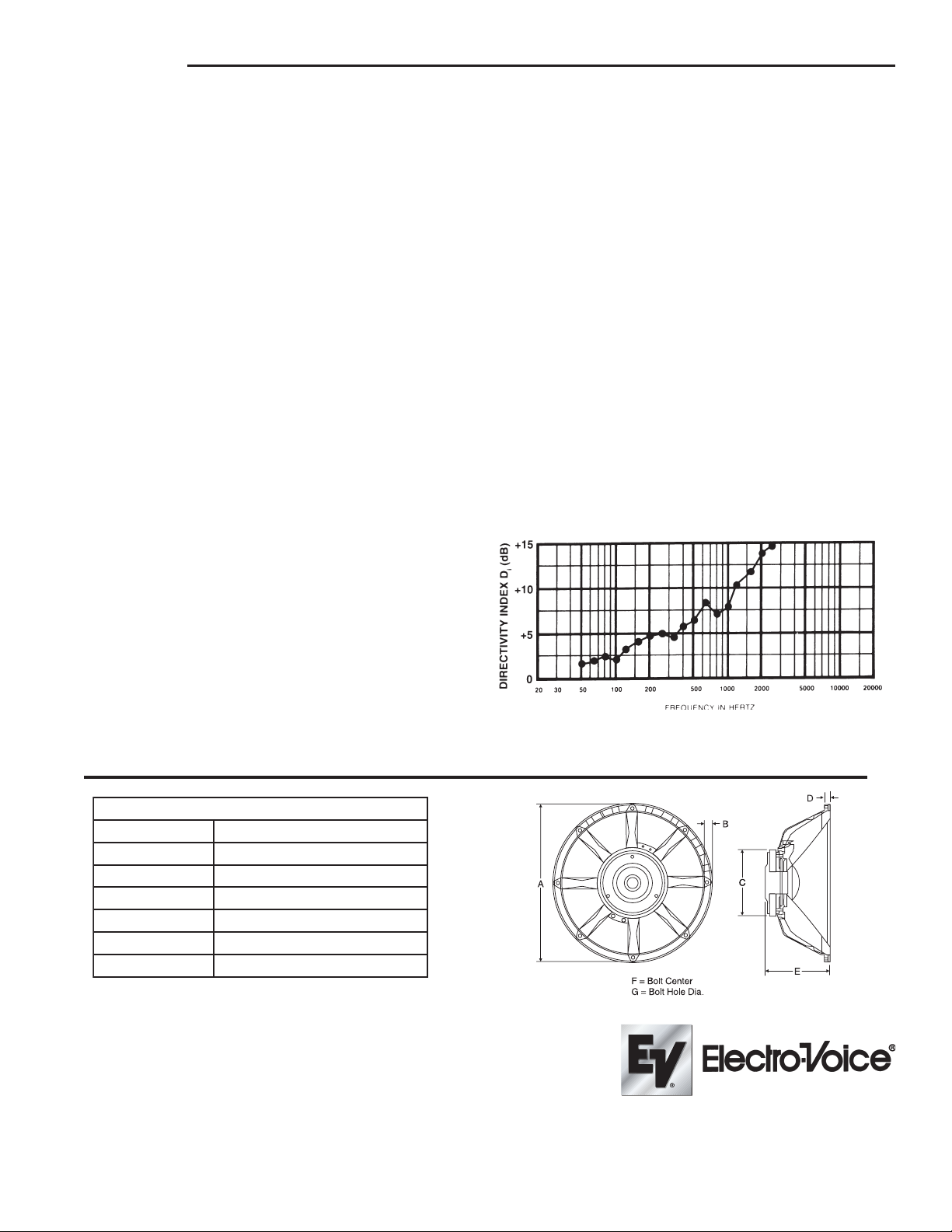

Directional Characteristics

The directional characteristics of the EVX-155 in the TL606A 90-liter

(3.2-ft³) vented enclosure were measured by running a set of polar

responses in EV’s large anechoic chamber. The test signal was

octave-band-limited pseudo-random pink noise centered at the ISO

standard frequencies.

15 Inch Low-Frequency

Reproducer

The curves show horizontal (side-to-side) dispersion when the

enclosure’s long axis is vertical. The vertical (up-and-down) polar

responses deviate only slightly from the horizontal responses due to

box geometry. Typical data is provided in Figures 1 and 2, which indicate

6-dB-down beamwidth versus frequency and directivity factor,

respectively, for an EVX-155 in the TL606A enclosure.

Electrical Connections

The EVX-155 is fitted with a pair of chrome-plated, frame-mounted

connectors with color-coded ends. Electrical connection is made by

pushing down, inserting wire completely through the rectangular slot

and releasing pressure. One conductor of #9 AWG stranded, #8 AWG

solid, a pair of twisted #15 AWG stranded or a pair of #14 AWG solid

conductors will fit. A positive electrical signal applied to the red (+)

terminal will displace the cone away from the magnet, thus producing a

positive acoustic pressure.

Recommended Enclosures

The most extended bass, lowest distortion and best control is usually

realized in properly designed vented enclosures. In such designs, the

vent, or port, actually provides the lowest octave of output. The vent is

driven to full acoustic output by a relatively small motion of the speaker

cone itself, acting through the air contained within the enclosure. The

excursion of the EVX-155 at these frequencies is much reduced

compared to sealed or open-back enclosures, directly reducing harmonic

distortion and the possibility of speaker “bottoming.” Several specific

vented-enclosure recommendations are shown on the previous page.

The maximum output is limited by either: (1) the long-term thermal power

handling capacity or (2) the speaker’s maximum cone-excursion

capability, whichever occurs first.

Figure 1. Beamwidth vs. Frequency

EVX-155/TL606A In a 90-Liter (3.2-ft³) Enclosure

1

PROTEF- is covered by U.S. Patent No. 4,547,632;

Teflon® and Kevlar® are registered trademarks of DuPont.

Specifications:

Power Handling:.................................................... 1000 watts continuous

Per AES2-1984/ANSI S4.26-1984:

50-500 Hz: ........................................................................... 600 watts

Sensitivity (SPL at 1 W/1 m), 100-800-Hz average: ...................... 98 dB

Impedance Response:

Minimum (Zmin): ..................................................................... 7 ohms

Nominal: .................................................................................. 8 ohms

Distortion Response (on axis in standard baffle, 10% rated input

power):

Second Harmonic:

100 Hz: ......................................................................... -45 dB (0.6%)

1,000 Hz: ...................................................................... -41 dB (0.9%)

Third Harmonic:

100 Hz: ......................................................................... -41 dB (0.9%)

1,000 Hz: ...................................................................... -38 dB (1.3%)

Beamwidth (angle included by 6-dB-down points on polar

responses for octave bands of pink noise):

500 Hz: .......................................................................................... 90°

1,000 Hz: ....................................................................................... 70°

2,000 Hz: ....................................................................................... 45°

Physical Constants,

Effective Piston Diameter: ................................... 318.0 mm (12.5 in.)

Moving Mass (MMo): .............................................. 0.069 kg (0.152 lb)

Voice-Coil Winding Depth: ....................................... 20.3 mm (0.8 in.)

Voice-Coil Diameter: ............................................... 63.5 mm (2.5 in.)

Voice-Coil Winding Length: ...................................... 20.3 m (0.80 in.)

Top Plate Thickness at Voice Coil: .......................... 8.9 mm (0.35 in.)

BL Factor: ................................................................. 20.4 tesla meter

Thiele-Small Parameters (broken in):

fS : ........................................................................................... 35.4 Hz

VAS: ......................................................................... 220 liters (7.77 ft3)

QES: ............................................................................................. 0.216

O

: ...............................................................................................

MS

QTS: ............................................................................................. 0.208

RE: ......................................................................................... 5.0 ohms

η0: ............................................................................................. 4.32%

SD: .......................................................................... 0.079 m2 (123 in.2)

MMD: ...................................................................... 0.127 kg (0.280 lb)

LE : ........................................................................................... 1.6 mH

5.56

CMS: ................................................................................. .0.200 mm/N

: ................................................................. 6.86 mechanical ohms

R

MS

P

: .................................................................................. 600 watts

E(max)

1

X

: ........................................................................ 6.4 mm (0.25 in.)

MAX

2

X

: .......................................................................... 25 mm (0.98 in.)

lim

Connector Type:

Push Terminals for bare wires.

Polarity:

A positive voltage applies to the positive (red) terminal produces a

positive pressure at the front of the cone.

Additional Descriptive Information:

Magnet Weight: ............................................................ 3.2 kg (7.0 lb)

Magnet Material: ............................................................ Barium ferrite

Frame: ........................................................................ Cast aluminum

Frame Finish: ..................................................... Textured black epoxy

Plating of Steel Parts: .............................................. Bright Cadmium

Voice-Coil Material: ............................................................ Aluminum

Voice-Coil Insulation:...................................... Polyimide 220°C rating

Voice-Coil Form: .................................................................. Polyimide

Back Cover: ............................. Black, advanced synthetic elastomer

Net Weight: ............................................................................ 10 kg (22 lb)

1. X

is the one-way peak excursion which produces 10% THD of

max

the current waveform when driven at fs.

2. Displacement limit is the one-way peak excursion which, when

exceeded, will cause physical damage to the drive mechanism.

Figure 2.

Directivity Index vs. Frequency

EVX-155/TL606A In a 90-Liter (3.2-ft³) Enclosure

)ni(:snoisnemiD

A82.51

B585.0

C881.8

D05.0

E17.6

F06.41

G8x182.0

Dimensions

USA 12000 Portland Ave South, Burnsville, MN 55337, Phone: 952-884-4051, FAX: 952-884-0043

Canada 705 Progress Avenue, Unit 46,Scarborough, Ontario, Canada, M1H2X1,Phone: 416-431-4975, 800-881-1685, FAX: 416-431-4588

Germany Hirschberger Ring 45, D94315, Straubing, Germany, Phone: 49 9421-706 0, FAX: 49 9421-706 287

France Parc de Courcerin, Alle Lech Walesa, Lognes, 77185 Marne La Vallee, France, Phone: 33/1-6480-0090, FAX: 33/1-6480-4538

Australia Unit 23, Block C, Slough Business Park, Slough Avenue, Silverwater, N.S.W. 2128, Australia, Phone: 61/2-9648-3455, FAX: 61/2-9648-5585

Hong Kong Unit E & F, 21/F, Luk Hop Industrial Bldg., 8 Luk Hop St., San PO Kong, Kowloon, Hong Kong, Phone: 852-2351-3628, FAX: 852-2351-3329

Japan 5-3-8 Funabashi, Setagaya-ku, Tokyo, 156-0055 Japan, Phone: +81 (0) 3-5316-5020, FAX: +81 (0) 3-5316-5031

Singapore 3015A Ubi Rd 1, 05-10, Kampong Ubi Industrial Estate, Singapore 408705, Phone: 65-746-8760, FAX: 65-746-1206

Mexico Av. Parque Chapultepec #66-201, Col. EI. Parque Edo. Mex. 53390, Phone: (52) 5358-5434, FAX: (52) 5358-5588

UK 4, The Willows Centre, Willow Lane, Mitcham, Surrey CR4 4NX, UK, Phone: 44 181 640 9600, FAX: 44 181 646 7084

Africa, Mid-East 12000 Portland Ave South, Burnsville, MN 55337, Phone: 952-887-7424, FAX: 952-887-9212

Latin America 12000 Portland Ave South, Burnsville, MN 55337, Phone: 952-887-7491, FAX: 952-887-9212

www.electrovoice.com Telex Communications, Inc. www.telex.com

© Telex Communications, Inc. 11/2006

Part Number 38109-949 Rev B

For customer orders, contact the Customer Service department at

For warranty repair or service information, contact the Service

For technical assistance, contact Technical Support at 866/78AUDIO

Please refer to the Engineering Data Sheet for warranty information.

Specifications subject to change without notice.

U.S.A. and Canada only.

800/392-3497 Fax: 800/955-6831

Repair department at 800/685-2606

Loading...

Loading...