Page 1

David Hewitt

by Alan Babb

T

he DVX Series is the latest

generation of high-performance

woofers from Electro-Voice (EV).

The story begins in spring 2005,

when EV launched its ZX5 as the

“world’s most versatile loudspeaker”:

a 2-way portable powerhouse capable of filling large spaces with concert-quality sound, all while weighing

in at less than 50 pounds.

Word spread quickly. The motor

behind EV’s offering was built into the

ZX5’s sleek molded enclosure: the EV

DVX-3150—a brand-new, 15-inch

woofer, based on the all-new DVX

platform. It’s not often that an experienced team of engineers is given a

blank piece of paper and asked to develop a product that represents the

very best in all aspects, without compromising on a single detail. With

DVX, that was the mission. The DVX3150 features an all-new cone and

surround structure for very low distortion and high excursion, along with

an all-new frame and motor structure

for high output with very low power

compression.

Having impressed everyone who

heard it in the groundbreaking ZX5,

the DVX concept soon materialized

again in the X-Line Very Compact,

the latest and smallest of the EV

line-array family. Shortly after the

launch of X-Line Very Compact and

its 12-inch DVX-3120 wooferequipped, XS212-LF cabinet (the sub

element in the XLVC line), the

phone calls began: “The XS212-LF

sounds incredible for its size, with

tons of power. Are these speakers

going to be available in the XLC

medium-sized line-array format?”

EV has always listened closely to

its customers, and these questions became the impetus for EV’s engineers

to put DVX at front and center in

their transducer program, the result

of which was the development of a

brand-new, 12-inch LF driver, the

DVX-3121, and a new mid-bass driver, the DVN 6.5-inch.

Which brings us up to date. Both

speakers made their debut at InfoComm 2006 inside the XLC127DVX

3-way, full-bandwidth line-array element, based on the world-renowned

XLC127+. The DVX-loaded XLC has

all the sonic signatures that made its

predecessor a favorite, but with extraordinary power handling and performance specs that surpass those on

many full-sized line-array offerings.

So how was all this achieved? Allow me to explain some of the

“sound innovations” behind the

DVX concept, at the drawing board

stage and beyond. Woofers, like all

loudspeakers, are governed by a

complex melding of disciplines: mechanical engineering, electrical engineering, physics and acoustics. The

DVX line has been optimized in all

of these areas using the latest technologies. First of all, the DVX magnet structure, the motor that works

with the voice coil to provide the

drive force to the woofer, was optimized for strength, stability, travel

and linearity. Nonlinearity in a

speaker’s magnetic field or suspension not only leads to added distortion but also greatly impacts the life

expectancy of a speaker.

For example, if you have a speaker motor that is stronger when the

cone is moving out of the basket

than when moving in, the speaker

will tend to offset itself to the outside. Since the suspension of the

speaker (the surround and the spider)

can only move a finite distance in either direction before being damaged,

you are going to stress these components more in one direction than the

other. It also makes the speaker limit

(stop moving) too quickly in one direction, and that means you lose sensitivity and increase distortion. To further compound this problem, the

magnetic field generated by the voice

coil can cause the field of the permanent magnet to modulate. This is the

Efficiency and Accuracy By Design

Electro-Voice DVX Woofers

[59]

soundInnovations:

the manufa

cturer’s view

I

started out as a studio engineer

many years ago, but I was

hijacked by a remote truck and

never looked back. The immediacy

and excitement of live music still

captivates me to this day. One of the

most enjoyable things about working in the field with so many different acts for short periods of time is

the sheer number of great people

you get to meet and work with.

I’ve had the pleasure of hosting

some of the best engineers on the

planet in our remote trucks over

the years. Some of them already

have great chops for live work, and

some have had very little exposure

to the chaos of live work.

What I’d like to do in this article

is encourage everyone to get out

on the road more often. No matter

what your job description might

be, participating in a live show,

even from the sidelines, can be a

real boost to your enthusiasm for

the career you chose.

Especially if you are involved in

post work that has live music content, it behooves you to get out on

location to see how it’s done. This

works to everyone’s advantage because you may be able to impart

some wisdom to the live engineers

about post problems.

There are many ways to do it

right and even more ways to do it

wrong. Besides, it’s fun to see all

the geek gear the video guys bring

to the party. For you studio folks, it

might surprise you how advanced

the audio section is on modern entertainment video trucks. It’s amazing how much gear you can pack

in a space 8x8 feet or less. Watching a pro production mixer, like Ed

Greene at the Oscars, handle several hundred inputs and outputs live

to air will make your hair stand up!

Things are generally a little

calmer over in our audio-only remote trucks. We usually deal only

with the music elements. Of

course, that may mean 10 bands in

a row! You do have to scramble to

keep up. Our Classic Silver Studio

has the big Neve VR with recall and

Flying Faders snapshots, and that

works well when you have time to

reset. But if you want instant global reset, our new White Truck with

a pair of Yamaha DM-2000s is the

ticket. The Neve works best for

projects like Neil Young’s recent

film, Heart of Gold, and the Yama-

has for TV shoots like Jazz at Lincoln Center’s Gala, where you have

maybe a dozen different sets.

One of my concerns over the

years has been proper documentation of the media. At Remote

Recording, our trucks are equipped

with software to quickly document

all the relevant information for

(continued on page 66) (continued on page 66)

[59]

September 2006 prosoundnews.com

Come Out on the Road

sparstech

Page 2

equivalent of your car motor losing power many

times a second. It would be difficult to have a

smooth, controlled speed ride.

To solve this problem, the woofers in the

DVX line have been optimized via extensive

computer FEA (Finite Element Analysis) to have

linear magnetic fields that do not overly modulate. With the aid of a laser displacement measurement system, we can also optimize the suspension to not only have the right stiffness but

also to stop the cone motion in a smooth and

controlled fashion when the speaker is pushed

to extremes. What does all this mean to the

prospective customer? Quite bluntly, it means

less distortion under normal conditions and no

rude noises when the speaker is overdriven.

Another problem common to woofers is

that the voice coil of the speaker, like any coil

of wire, has an inductance. Place a hunk of iron

inside a coil and you get even larger inductance. In speaker terminology, we call that

hunk of iron a “pole piece”; every speaker has

one. Most people understand the problems

caused by inductance at high frequencies. Engi-

neers take advantage of inductance all the time

in crossover design. The problem with inductance in a speaker is as follows: As the cone

moves outward, it moves out of the magnetic

circuit and the pole piece is no longer inside as

much of the coil as when the cone is moving

inward. This asymmetry in the inductance also

causes an offset of the speaker’s center position, just like a nonlinear magnetic field or suspension. Besides negatively impacting the life

expectancy of a speaker, this asymmetry causes

distortions that are particularly audible and

offensive.

To combat this problem, the DVX woofer

uses multiple approaches. First, we computermodeled the magnetic structure and optimized

the geometry to eliminate asymmetries. After

the FEA phase prototyping, the tests and measurements began. The use of multidimensional

measurements using acoustic and laser data

further sped perfecting the design so we could

very quickly identify areas to improve and the

solutions. This enabled a final design that is far

superior to using traditional design methods.

Unfortunately, you cannot simply eliminate

the pole piece from the equation, so we did the

next best thing. We have put a conductive but

non-magnetic ring inside the magnet structure.

Sometimes called a Faraday Loop, this shorting

ring blocks the field from the coil that would interact with the iron core, without affecting the

DC or static field generated by the large ceramic magnet of the motor structure. Another benefit is that is also counteracts the modulation of

the static field that can be caused by the field

generated by the voice coil.

At the end of the day, of course, all this adds

up to a superior-sounding loudspeaker. DVX goes

to show that there is still room for improvement

in the world of loudspeaker design. It’s not just

about the greater overall output. In DVX, the level of sonic clarity—even for an arena-size system

running extremely high SPLs—is unprecedented.

Alan Babb is a transducer engineer for

Electro-Voice.

For a more highly illustrated version of this

story, visit www.prosoundnews.com and click on

“web bonus.”

many different formats. These days that’s a lot,

and it’s getting increasingly difficult to find a

place to store a paper trail of data. Our technician, Phil Gitomer, insists on having track

sheets and take sheets for every drive or disc.

How many times have you had a hard drive or

tape show up with no documentation? Without wasting time mounting it and playing the

material, you have no idea what’s there.

Sometimes it’s hard to get accurate information to document. Rehearsal time for live

shows can be short or nonexistent. Getting titles for classical music movements without a

score, improvisational jazz, or artists and production people that won’t give up a set list (or

who even change it without telling audio), and

these days, even guns on stage are all elements

that make obtaining this information difficult. I

would be very interested to hear from you post

guys about what you like to see for documentation. What happens to the paper documentation? Does it get used or tossed? Would you

like to have a CD with the docs on it?

Anyway, back to the theme about getting

more people involved in the production of live

shows and the business of recording them.

One of the ways might be for you to attend a

SPARS meeting in your area. I try to make them

all, gigs permitting. You might just meet some

interesting people and learn something from

their forums. Karen Brinton is more than just

Remote Recording’s boss; she is the current

president of SPARS.

David Hewitt is chief engineer and president of Remote Recording in New York City.

Membership in SPARS, the Society of Professional Audio Recording Services, is open to

studio owners, producers, engineers and anyone else involved in professional recording. For

more information, contact the organization at

800-771-7727, or visit www.spars.com.

[66]

prosoundnews.com September 2006

SPARS

(continued from page 59)

Innovations

(continued from page 59)

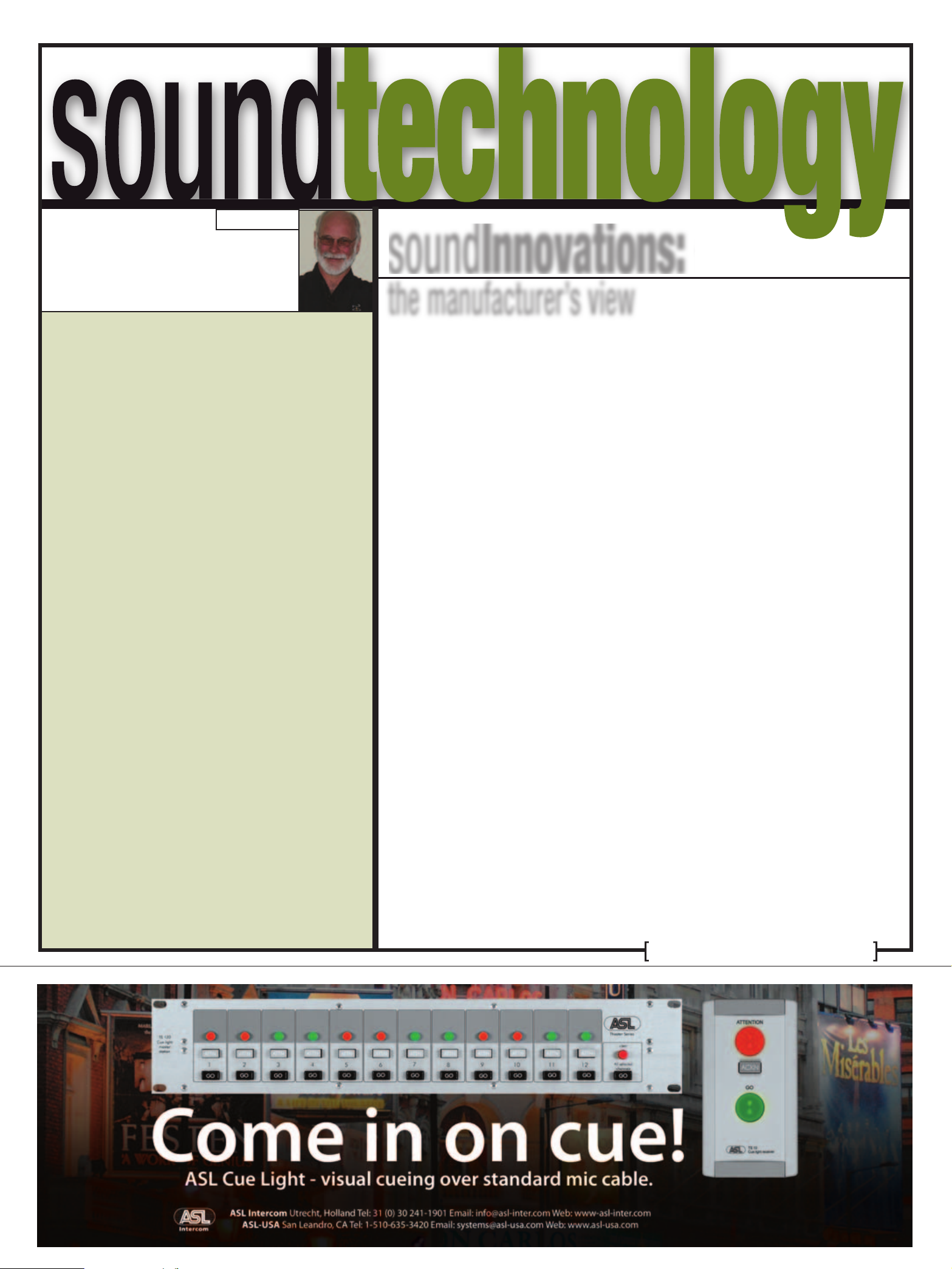

Graph plotting the variation in the strength of the magnetic field in the motor gap

vs. time, using a DVX motor structure and a conventional ceramic motor structure.

Drive signal: 75V pk at 100 Hz.

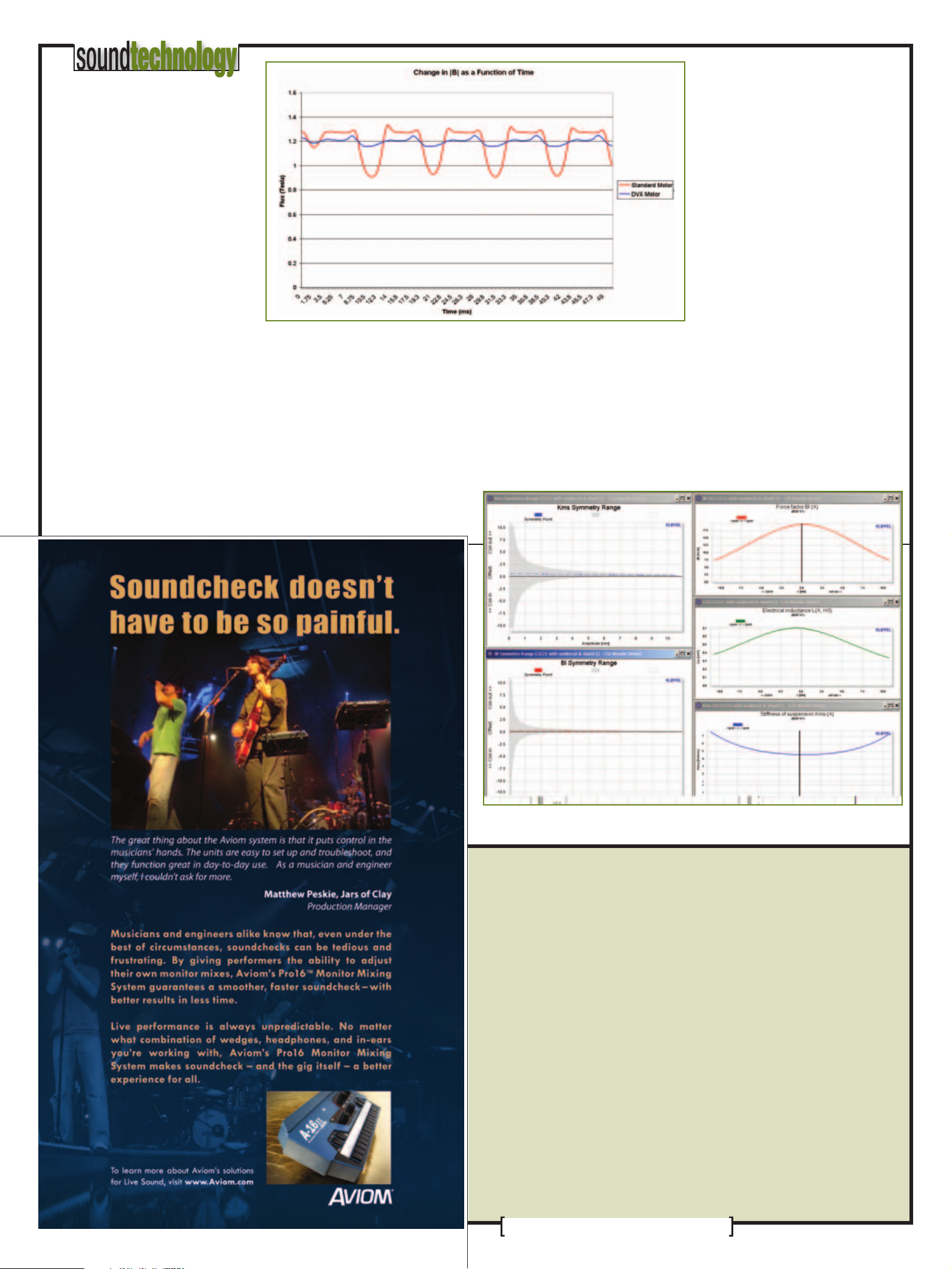

The Klippel measurement system is used to measure the symmetry of the magnetic

field, the compliance of the suspension and the inductance.

Loading...

Loading...