Page 1

OWNER‘S MANUAL

BEDIENUNGSANLEITUNG

MODE D‘EMPLOI

Page 2

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ....................... 3

IMPORTANT SERVICE INSTRUCTIONS ....................... 3

DESCRIPTION ....................... 4

UNPACKING & WARRANTY ....................... 5

INSTALLATION NOTES ....................... 5

FRONT VIEW ....................... 6

REAR VIEW ....................... 7

INPUT A / INPUT B ....................... 7

PARALLEL ....................... 7

POWER AMP OUTPUT ....................... 8

BRIDGED MODE ....................... 8

GROUND-LIFT SWITCH ....................... 8

MAINS INPUT ....................... 8

SPECIFICATIONS / TECHNISCHE DATEN ....................... 30

BLOCK DIAGRAM ....................... 32

DIMENSIONS / ABMESSUNGEN ....................... 33

WICHTIGE SICHERHEITSHINWEISE ....................... 13

WICHTIGE SERVICEHINWEISE ....................... 13

BESCHREIBUNG ....................... 14

AUSPACKEN & GARANTIE ....................... 15

INSTALLATIONSHINWEISE ....................... 15

FRONTSEITE ....................... 16

RÜCKSEITE ....................... 17

INPUT A / INPUT B ....................... 17

PARALLEL ....................... 17

ENDSTUFENAUSGÄNGE ....................... 18

BRIDGED MODE ....................... 18

GROUND-LIFT SCHALTER ....................... 18

NETZEINGANG ....................... 18

NETZBETRIEB & WÄRMEENTWICKLUNG ....................... 19

SPECIFICATIONS / TECHNISCHE DATEN ....................... 30

BLOCK DIAGRAM ....................... 32

DIMENSIONS / ABMESSUNGEN ....................... 33

MATIÈRES

IMPORTANTES INFORMATIONS DE SÉCURITÉ ....................... 23

INSTRUCTIONS DE RÉPARATION IMPORTANTES ....................... 23

DESCRIPTION ....................... 24

DÉBALLAGE ET GARANTIE ....................... 25

REMARQUES SUR L’INSTALLATION ....................... 25

FACE AVANT ....................... 26

PANNEAU ARRIÈRE ....................... 27

INPUT A / INPUT B ....................... 27

PARALLEL ....................... 27

SORTIE DE AMPLI DE PUISSANCE ....................... 28

GROUND-LIFT ....................... 28

ENTRÉE SECTEUR ....................... 28

SECTEUR ET TEMPÉRATURE RÉSULTANTE ....................... 29

SPECIFICATIONS ....................... 30

BLOCK DIAGRAM ....................... 32

DIMENSIONS ....................... 33

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

The lightning ash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated „dangerous voltage“ within

the product’s enclosure that may be of sufcient

magnitude to constitute a risk of electric shock to

persons

The exclamation point within an equilateral

triangle is intended to alert the user to

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water. Do not expose this apparatus to dripping or splashing and

ensure that no objects lled with liquids, such as vases, are placed on this apparatus.

6. Clean only with a dry cloth.

7. Do not block any of the ventilation openings. Install in accordance with the manufactures instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including ampliers) that produce heat.

9. Only use attachments/accessories specied by the manufacturer.

10. Refer all servicing to qualied service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped

11. To completely disconnect mains power from this apparatus, the power supply cord must be

unplugged.

For US and CANADA only:

1. Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third

grounding prong. The wide blade or the third prong are provided for your safety. When the provided plug does not t

into your outlet, consult an electrican for replacement of the absolete outlet.

2. Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles,

and the point where they exit the apparatus.

3. Unplug this apparatus during lightning storms or when unused for long periods of time.

the presence of important operating and

maintance (servicing) instructions in the

literature accompanying the appliance.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualied personnel only. To reduce

the risk of electric shock, do not perform any servicing other than that ontained

in the Operating Instructions unless you are qualied to do so. Refer all ervicing

to qualied service personnel.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to

be obeyed when servicing the appliance

2. Use of a mains separator transformer is mandatory during maintenance while the appliance is

opened, needs to be operated and is connected to the mains

3. Switch off the power before retrotting any extensions, changing the mains voltage or the output voltage.

4. The minimum distance between parts carrying mains voltage and any accessible metal piece (metal

enclosure), respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not

connected to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the security symbol (Note) is

only rmissible when using original parts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the location where the appliance is being serviced

have to be strictly obeyed. This applies also to any regulations about the work place itself.

8. All instructions concerning the handling of MOS - circuits have to be observed.

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART )NOTE:

3

Page 4

5

DESCRIPTION

Congratulations! With buying a Electro-Voice CP-SERIES power amplier you have chosen an appliance that employs most advanced technology.

CP-Series power amps combine outstanding audio performance, highest reliability and operational

safety.

The audio performance of CP power amps are simply extraordinary. Optimised power supply units employing low-leakage toroidal transformers and the consistent use of Class-H technology provide extensive headroom far above the stated nominal output. At the same time this contributes to a reduction in

weight and power dissipation.

The CP-Series is designed in Class-H technology, i.e. the power amp provides extremely fast, signaldependent operating voltage switching, which results in doubling the regular supply voltage when needed.

Compared to Class-AB power amps, Class-H power amps generate by far less power dissipation at

identical output. Consequently, reduced leakage power or dissipation is synonymous to less waste heat

– energy is used more efciently. As a result, installing Class-H power amps within rack shelf systems

is possible with less space between appliances. In addition to that and despite offering identical output,

power consumption is a lot less than in Class-AB operation.

Electro-Voice CP-SERIES power amps have been designed to full even the most demanding

requirements of touring applications. CP-Series amps are protected against thermal and electrical

overload, short circuit and the occurrence of HF/DC at the outputs. Back-EMF-Protection eliminates

the risk of the output transistors being damaged by electrical energy back-feed. The power outputs are

switched via relay with a time delay during soft-start. An inrush current limiter prevents mains fuses from

blowing.

Mechanical construction and workmanship also comply with the highest precision manufacturing

standards. The rigid sheet steel chassis even resists the most wearing tour operation. Two three-speed

high performance fans (off/slow/fast) guarantee outstanding thermal stability at absolute low running

noise. The ventilation is directed front-to-rear allowing trouble-free operation even in smaller amp-racks.

The electronically balanced inputs are carried out via XLR-type connectors. Direct-Outs for through

connecting the audio signal are also provided via XLRM-type connectors. Input Routing allows selecting

DUAL (stereo) or PARALLEL (monaural) operation mode. By means of the separate BRIDGED OUTconnector and a Bridged Mode-switch, switching to „Mono Bridged“ operation is truly uncomplicated

as well. The recessed mounted dB-scaled level controls ensure reliable protection against mechanical

damage. These particularly precise, secure to operate detent-potentiometers are located on the front

panel. CP-Series power amps provide the opportunity for retrotting an internal analogue signal

processor board with x-over and lter functions.

The easily readable LED display provides a quick overview of the power amp’s current operational

status. The power outputs CHANNEL A, CHANNEL B and BRIDGED OUT are carried out as extremely

durable SPEAKON-type connectors. Also located on the rear panel is a Ground-lift switch, which helps

eliminating ground-noise loops by separating the power amp’s enclosure from the circuit ground. In

normal operation, all CP-Series power amps are capable of driving loads as low as 2ohms. In MonoBridged mode the allowable minimum load is 4ohms.

This owner’s manual outlines and explains several other features of your CP-Series power amplier.

Please, make sure to carefully read all of it and mind the instructions.

4

Page 5

DESCRIPTION

UNPACKING & WARRANTY

Carefully open t he packaging and take out the power amplier. Next to the power amplier itself, the

package also includes this owner’s manual, a mains cord and the warranty certicate. Keep the original

invoice, which states the purchase/delivery date together with the warranty certicate at a safe place.

INSTALLATION NOTES

Generally, installing or mounting power amps should be carried out in a way that guarantees continuously unopposed front-to-rear air circulation. Installation of appliances with opposite air circulation within

one cabinet or closed rack shelf system is not recommended. When including an appliance in a closed

cabinet or rack shelf system make sure to provide sufcient ventilation. Leave a gap of at least 60mm

x 330mm (up to the cabinet’s top ventilation louvers) for air circulation between the rear of the power

amplier and the cabinet’s/rack’s rear inner wall. Make sure to leave at least 100mm of space above the

cabinet or rack shelf system. Since temperatures inside of the cabinet or rack shelf system can easily

rise up to 40°C during operation, bearing in mind the maximally allowable environmental temperature

during operation for all other appliances installed in the same rack shelf system is mandatory (also refer

to “MAINS OPERATION AND RESULTING TEMPERATURE”).

Caution: For trouble-free operation exceeding the maximally allowable environmental temper-

ature of +40°C is not permissible.

The use of installation rails or optionally available “rear-rack-mount” rails is strongly recommended when

installing the appliance in a rack shelf system or cabinet to prevent the front panel from bending.

The power amplier has to be protected against: dripping or splashing water, direct sunlight, high temperatures or direct inuence of heat sources, high humidity, extensive dust and vibrations.

Condensation on internal parts may occur when transporting the power amplier from a cold into a

warmer environment. In that case operation is only permissible after the appliance has gained the

new temperature (after approximately one hour). If foreign objects or liquids have entered the power

amplier’s enclosure make sure to instantly separate the appliance from the mains power and contact

an authorised service centre for inspection before continuing operation.

5

Page 6

7

FRONT PANEL

Use the POWER switch, located on the front panel’s, right side to switch the appliance’s power on. The

soft-start function limits against current inrush peaks on the mains, which in addition prevents the mains

line protection switch from activating during power-on. The loudspeaker outputs are activated via relay

switching with a delay of approximately 2 seconds to efciently attenuate eventual power-on noise. The

PROTECT LED lights during the delay time and the fans run at maximum speed. This is normal, conrm-

ing the immaculate operation of the protection circuitry.

This indicator lights when the power amplier has been switched on. Causes for the

POWER-indicator not lighting are: the appliance is not connected to the mains

or the primary fuse is defective.

The PROTECT LED indicating that one of the internal protection circuits

against thermal overload, short-circuit, Back-EMF, HF-occurrence at the output,

etc., has been activated. The output relays interrupt the connected loads from

the power amps while input signals are interrupted as well, preventing the connected

loudspeaker systems and the power ampliers themselves from being damaged.

Whatever caused the fault – e.g. a short-circuited speaker cable – needs to be reme-

died. In case of thermal overload you have to wait until the power amplier automatically regains normal operation.

The SIGNAL LED lights as soon as an audio signal of approximately 30dB below full

modulation is present at the output. The LED is dimmed when speaker cables are

short-circuited or a protection circuit has been activated.

The 0dB LED lights whenever the power amplier is driven at its maximum. Higher

input voltage does not result in higher peak output voltage. In addition, the 0dB

indicator comes in handy when adjusting external limiters.

This indicator lights as soon as the integrated dynamic audio signal limiter is

activated and the power amplier is driven at the clipping limit or generally at its

maximum capacity. Short-term blinking is not a problem, because the internal limiter

controlls input levels of up to +21dBu down to a THD of approximately 1%. If, on the

other hand, this LED lights constantly, reducing the volume is recommended to

prevent the loudspeaker systems connected from being damaged by probable

overload.

Detent potentiometers scaled in dB (steps of 1dB) for

adjusting the power amp’s overall volume. To prevent

distortion in mixing consoles connected to your CP-Series

amp, setting these controls to a value between 0dB and -6dB

is generally recommended. The dB-scale provides direct

indication of the control attenuation applied to the xed

internal amplication.

6

Page 7

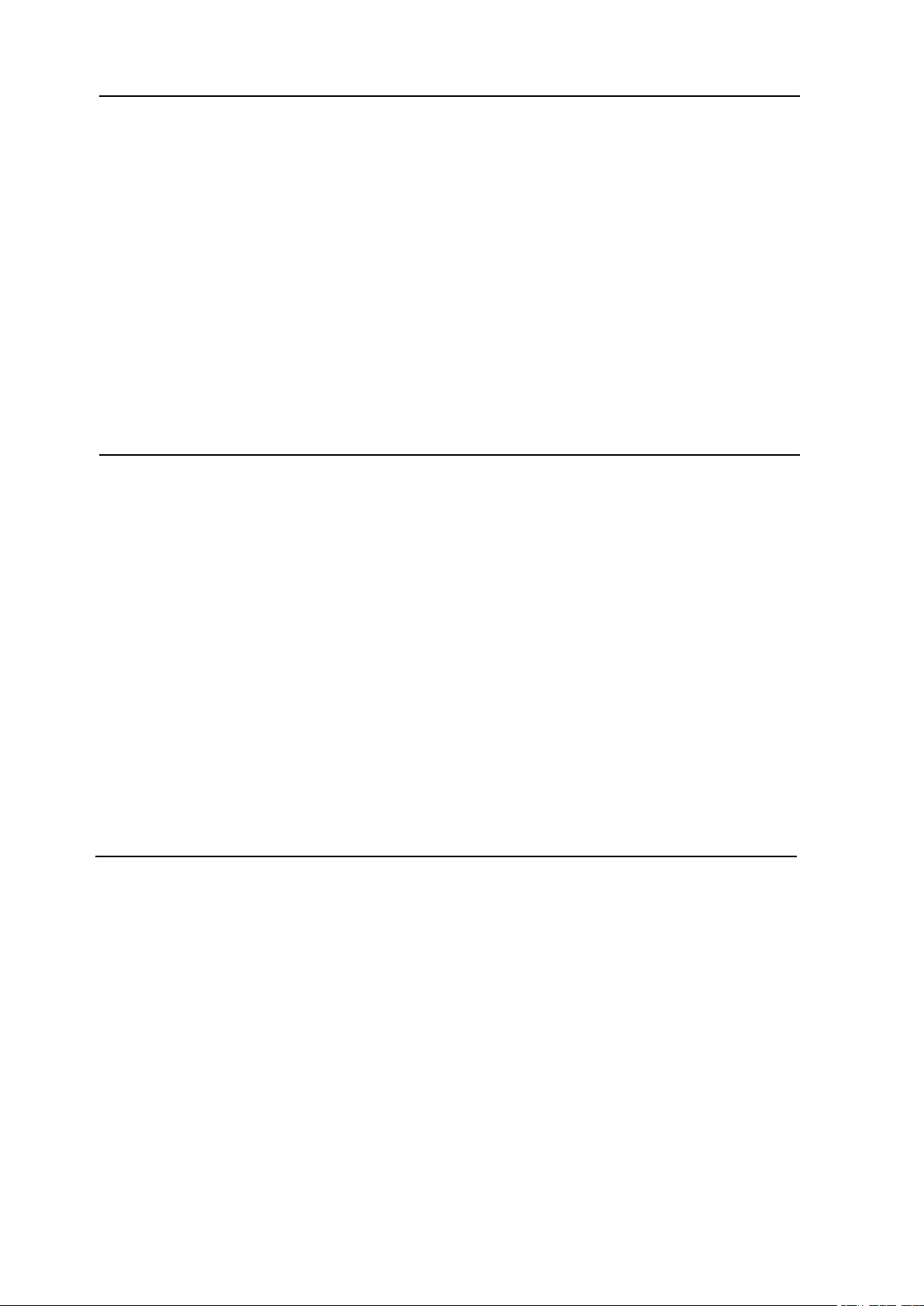

REAR PANEL

INPUT A / INPUT B

The inputs INPUT A & INPUT B are electronically balanced

offering input sensitivity of +4dBu (1.23V) for direct

connection of mixing consoles, signal processors, etc.

The XLR-type connectors OUTPUT A & OUTPUT B are pre-

pared for „through-connecting“ input signals to additional external power amps. The input signal is directly routed to these

output connectors. There are no repeaters or other electronic

components within that signal path. Accordingly, input and output connectors of the corresponding

channel are interconnected in parallel, offering permanent electrical connection, without regard to the

setting of the Power-ON switch.

Although having XLR-type output connectors, some mixing console models provide unbalanced

output connection only. When using mixers with unbalanced outputs, bridging PIN1 and PIN3

of the power amp’s input connectors or leaving PIN3 of the cable’s plugs unconnected is

necessary. Otherwise, when feeding in unbalanced audio signals via PIN3 (b, -, „cold“) and PIN2

(a, +, „hot“), strange humming and HF-interference may occur, which very likely will damage the

power amplier and/or the connected speaker cabinets.

NF-CONNECTION CORDS

Choosing high-quality balanced cables (two conductors for the audio signal plus separate shielding

mesh) with XLR-type connectors is recommended for LF-signal connection. Although connecting unbalanced cables to the power amplier inputs is possible as well, using balanced cables is always preferable. A great number of today’s audio appliances employ balanced outputs. With balanced cabling,

the shield connects all metal enclosure parts and therefore efciently eliminates the introduction of

external interference – mostly noise and hum.

XLR-type connector pin-assignment

XLR (male) XLR (female)

PARALLEL

The input connectors of channel A and channel B are electrically connected

in parallel when the selector switch is set to PARALLEL. However, individually

controlling the volume of both channels is still possible via the corresponding level

controls A and B.

DUAL

If the selector switch is set to DUAL, the audio signals of channels A and B are

independently amplied.

7

Page 8

9

REAR PANEL

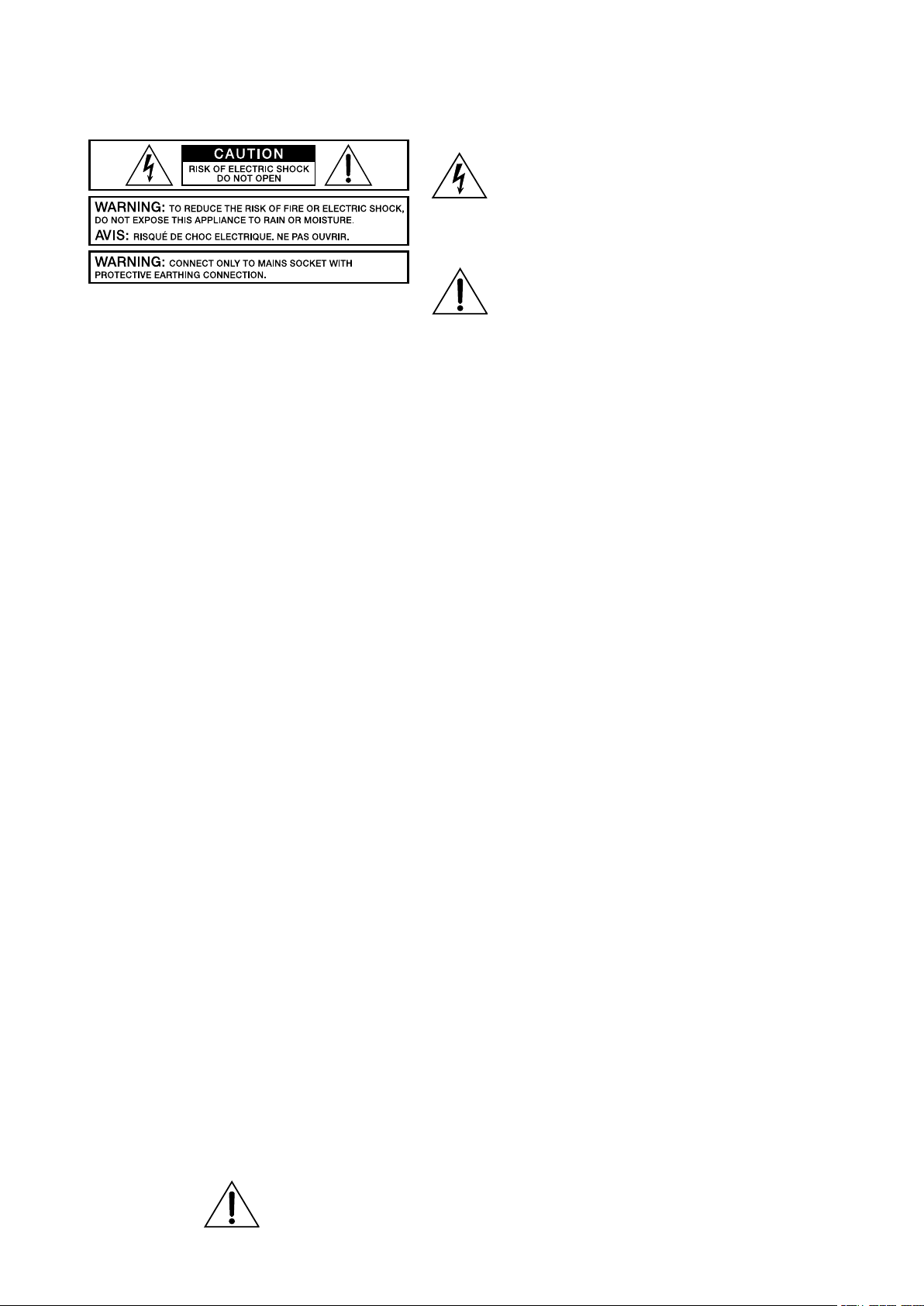

POWER AMP OUTPUT CONNECTORS

Power amp output connection for the two channels A

(left) and B (right) is provided via SPEAKON-type output

connectors.

A plastic cover to prevent inadvertent erroneous

connection protects the BRIDGED OUT connector. Make

sure to remove the cover only when actually operating

the power amplier in Bridged-Mode.

BRIDGED MODE

With the BRIDGED-MODE switch being engaged, using the channel A input

for audio signal feed is mandatory, since input B provides no function. While

the amplier of channel A operates as usual, the audio signal is internally

inverted and routed to the amplier of channel B. Both amps – A and B – now

work in push-pull operation to provide doubled output voltage at the

BRIDGED-OUT connector.

The regular output voltage of each amplier channel A / B is still present at the

corresponding output connector CHANNEL A or CHANNEL B. However, using these signals is not recommendable because of the aforementioned phase

inversion. Operating the power amp in Bridged Mode with loads of 2ohms connected is not allowable.

CAUTION: Extremely high voltages might be present at the BRIDGED OUT connector during

Bridged-Mode operation. The connected loudspeaker systems have to be capable of handling

such high voltages. Please make sure that power handling specications as stated in the documentation supplied with your speaker systems match the specications of the power amplier.

GROUND-LIFT SWITCH

The ground-lift switch allows eliminating noise loops. If the power amplier is

operated together with other equipment in a 19“ rack-shelf, setting the switch

to its GROUNDED position is recommended. If the power amplier is operated

together with appliances with differing ground potentials, set the switch to its

UNGROUNDED position.

MAINS INPUT

Under normal circumstances, the mains fuse only blows in case of fault.

Replacing the fuse is only permissible when using a new fuse of the same

type with identical amperage, voltage and blow characteristics. If the mains

fuse blows more often, please contact an authorized service centre.

The high-performance mains cord supplied with your power amplier complies

to applicable safety regulations, plus that its diameter corresponds to the power amp’s power output capacity. Make sure to use the supplied mains cord for connecting the power amp

to the mains, if possible. Using mains cords with smaller diameters results in higher leakage and consequently reduced maximum power output capacity.

At 100V and 120V units the mains fuse is installed internally. This is fore safety reasons. In case of a

blown mains fuse please contact a qualied service personnel for servicing.

8

Page 9

MAINS OPERATION & RESULTING

MAINS OPERATION & RESULTING TEMPERATURE

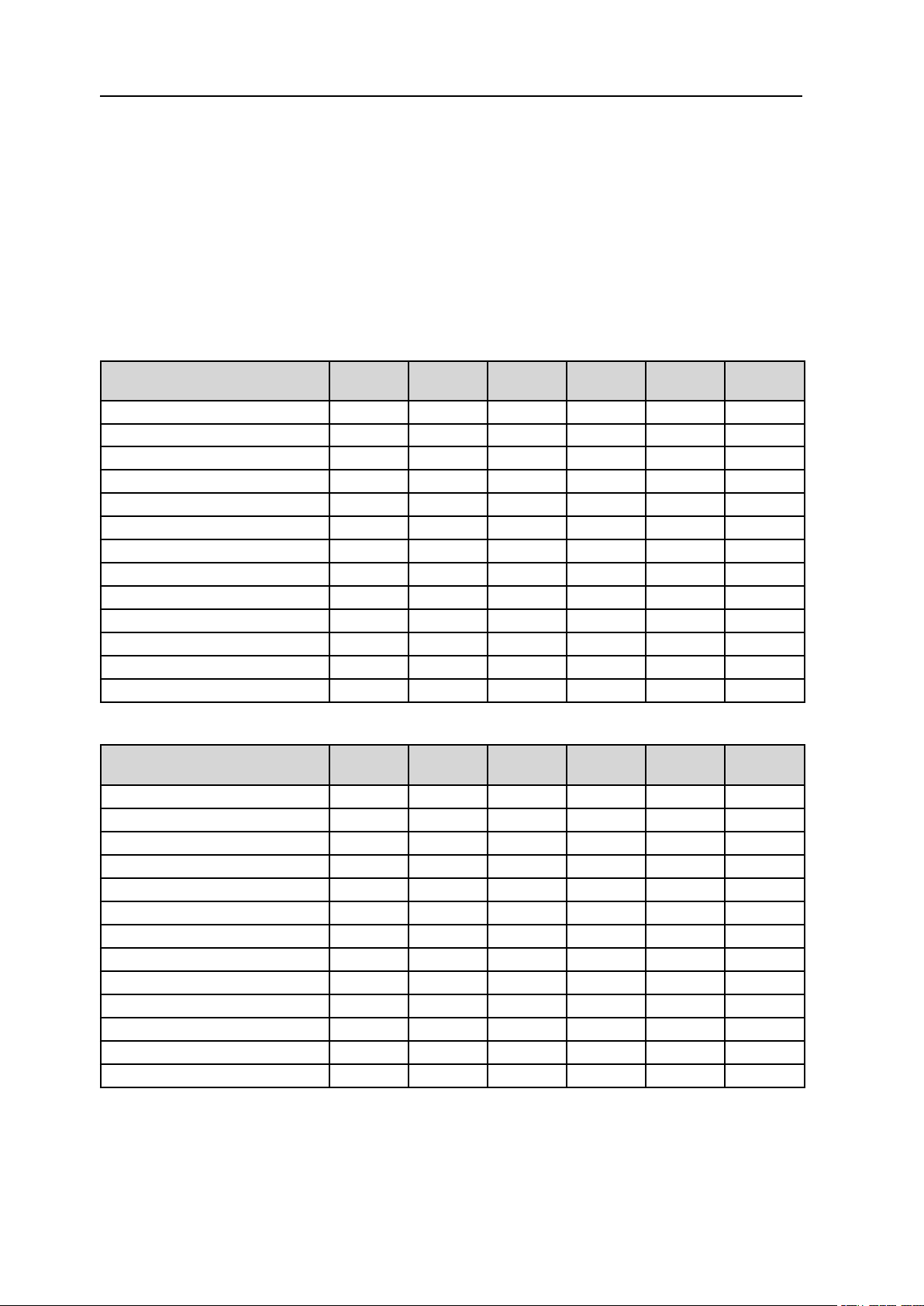

The following tables allow determining power supply and cabling requirements.

The power drawn from the mains network is converted into output power to feed the connected

loudspeaker systems and into heat. The difference between power consumption and dispensed power

is called power dissipation (Pd). The amount of heat resulting from power dissipation might remain

inside of a rack-shelf and needs to be diverted using appropriate measures. The following table is

meant as auxiliary means for calculating temperatures inside of a rack-shelf system/cabinet and the

ventilation efforts necessary.

The column „Pd“ lists the leakage power in relation to different operational states. The column „BTU/hr“

lists the dispensed heat amount per hour.

CP1800

idle

Max. Output Power @ 8Ω

Max. Output Power @ 4Ω

1/3 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

Normal Mode (-10dB) @ 4Ω

Rated Output Power (0dB) @ 4Ω

Alert (Alarm) Mode (-3dB) @ 4Ω

Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

(1)

(1)

(2),(4)

(1)

(1)

CP2200

idle

Max. Output Power @ 8Ω

Max. Output Power @ 4Ω

1/3 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

Normal Mode (-10dB) @ 4Ω

Rated Output Power (0dB) @ 4Ω

Alert (Alarm) Mode (-3dB) @ 4Ω

Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

(1)

(1)

(2),(4)

(1)

(1)

U

mains

[V]

I

mains

[A]

P

mains

[W]

P

out

[W]

Pd

[W]

(5)

BTU/hr

(1)

230V 0,39 46 - 46 155

230V 6,7 1110 2 x 350 410 1400

230V 11,0 1980 2 x 600 780 2660

(1)

(1)

(2)

230V 6,6 1090 2 x 200 690 2355

230V 2,7 410 2 x 75 260 885

230V 3,3 480 2 x 75 330 1125

230V 3,5 500 2 x 84 332 1130

230V 2,5 370 2 x 60 250 855

(1)

230V 10,2 1810 2 x 500 810 2765

(1)

230V 7,4 1250 2 x 250 750 2560

230V 17,0 3290 2 x 900 1490 5085

(1)

(2)

230V 4,0 660 2 x 113 434 1480

230V 4,9 790 2 x 113 564 1925

U

mains

[V]

I

mains

[A]

P

mains

[W]

P

out

[W]

Pd

[W]

(5)

BTU/hr

(3)

230V 0.5 65 - 65 220

230V 8.0 1440 2 x 500 440 1500

230V 13.2 2520 2 x 800 920 3140

(1)

(1)

(2)

230V 7.5 1360 2 x 266 828 2825

230V 3.0 520 2 x 100 320 1090

230V 3.3 570 2 x 100 370 1260

230V 3.6 660 2 x 120 420 1435

230V 2.8 470 2 x 80 310 1060

(1)

230V 12.5 2360 2 x 700 960 3275

(1)

230V 8.8 1610 2 x 350 910 3105

230V 20.0 4000 2 x 1100 1800 6140

(1)

(2)

230V 4.5 815 2 x 138 540 1840

230V 4.5 815 2 x 138 540 1840

(1) Sine Modulation (1kHz) (2) VDE-Noise (3) 1BTU = 1055.06J = 1055.06Ws

(4) 10% Mains Over Voltage (5) Pd = Leakage Power

The following factors allow direct proportional calculation of the mains current Imain for different mains

supply voltages: 100V = 2.3; 120V = 1.9; 240V = 0.96.

9

Page 10

11

10

Page 11

BEDIENUNGSANLEITUNG

Page 12

INHALT

WICHTIGE SICHERHEITSHINWEISE ....................... 13

WICHTIGE SERVICEHINWEISE ....................... 13

BESCHREIBUNG ....................... 14

AUSPACKEN & GARANTIE ....................... 15

INSTALLATIONSHINWEISE ....................... 15

FRONTSEITE ....................... 16

RÜCKSEITE ....................... 17

INPUT A / INPUT B ....................... 17

PARALLEL ....................... 17

ENDSTUFENAUSGÄNGE ....................... 18

BRIDGED MODE ....................... 18

GROUND-LIFT SCHALTER ....................... 18

NETZEINGANG ....................... 18

NETZBETRIEB & WÄRMEENTWICKLUNG ....................... 19

SPECIFICATIONS / TECHNISCHE DATEN ....................... 30

BLOCK DIAGRAM ....................... 32

DIMENSIONS / ABMESSUNGEN ....................... 33

12

Page 13

WICHTIGE SICHERHEITSHINWEISE

Das Blitzsymbol innerhalb eines gleichseitigen Dreiecks soll den Anwender auf nicht isolierte Leitungen

und Kontakte im Geräteinneren hinweisen, an denen

hohe Spannungen anliegen, die im Fall einer

Berührung zu lebensgefährlichen Stromschlägen

führen können.

Das Ausrufezeichen innerhalb eines gleichseitigen

Dreiecks soll den Anwender auf wichtige Bedienungssowie Servicehinweise in der zum Gerät gehörenden Literatur aufmerksam machen.

1. Lesen Sie diese Hinweise.

2. Heben Sie diese Hinweise auf.

3. Beachten Sie alle Warnungen.

4. Richten Sie sich nach den Anweisungen.

5. Betreiben Sie dieses Gerät nicht in unmittelbarer Nähe von Wasser. Stellen Sie bitte sicher, dass kein Tropf- oder

Spritzwasser ins Geräteinnere eindringen kann. Platzieren Sie keine mit Flüssigkeiten gefüllte Objekte, wie Vasen

oder Trinkgefässe, auf dem Gerät ab.

6. Verwenden Sie zum Reinigen des Gerätes ausschliesslich ein trockenes Tuch.

7. Verdecken Sie keine Lüftungsschlitze. Beachten Sie bei der Installation des Gerätes stets die entsprechenden

Hinweise des Herstellers.

8. Vermeiden Sie die Installation des Gerätes in der Nähe von Heizkörpern, Wärmespeichern, Öfen oder anderer

Wärmequellen.

9. Verwenden Sie mit dem Gerät ausschliesslich Zubehör/ Erweiterungen, die vom Hersteller hierzu vorgesehen sind.

10. Überlassen Sie sämtliche Servicearbeiten und Reparaturen einem ausgebildeten Kundendiensttechniker.

Bringen Sie das Gerät direkt zu unserem Kundendienst, wenn es beschädigt wurde oder eine Funktionsstörung zeigt.

11. Um das Gerät komplett spannungsfrei zu schalten, muss der Netzstecker gezogen werden.

WICHTIGE SERVICEHINWEISE

ACHTUNG: Diese Servicehinweise sind ausschliesslich zur Verwendung durch qualiziertes Servicepersonal.

Um die Gefahr eines elektrischen Schlages zu vermeiden, führen Sie keine Wartungsarbeiten durch,

die nicht in der Bedienungsanleitung beschrieben sind, ausser Sie sind hierfür qualiziert. Überlassen

Sie sämtliche Servicearbeiten und Reparaturen einem ausgebildeten Kundendiensttechniker.

1. Bei Reparaturarbeiten im Gerät sind die Sicherheitsbestimmungen nach EN 60065 ( VDE 0860 ) einzuhalten.

2. Bei allen Arbeiten, bei denen das geöffnete Gerät mit Netzspannung verbunden ist und betrieben wird, ist ein Netz Trenntransformator zu verwenden.

3. Vor einem Umbau mit Nachrüstsätzen, Umschaltung der Netzspannung oder sonstigen Modikationen ist das Gerät

stromlos zu schalten.

4. Die Mindestabstände zwischen netzspannungsführenden Teilen und berührbaren Metallteilen

(Metallgehäuse) bzw. zwischen den Netzpolen betragen 3 mm und sind unbedingt einzuhalten.

Die Mindestabstände zwischen netzspannungsführenden Teilen und Schaltungsteilen, die nicht mit dem Netz

verbunden sind (sekundär), betragen 6mm und sind unbedingt einzuhalten.

5. Spezielle Bauteile, die im Stromlaufplan mit dem Sicherheitssymbol gekennzeichnet sind, (Note) dürfen nur durch

Originalteile ersetzt werden.

6. Eigenmächtige Schaltungsänderungen dürfen nicht vorgenommen werden.

7. Die am Reparaturort gültigen Schutzbestimmungen der Berufsgenossenschaften sind einzuhalten. Hierzu gehört

auch die Beschaffenheit des Arbeitsplatzes.

8. Die Vorschriften im Umgang mit MOS - Bauteilen sind zu beachten.

NOTE:

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART )

13

Page 14

15

BESCHREIBUNG

Herzlichen Glückwunsch! Sie haben sich mit einer Endstufe der CP-SERIE von Electro-Voice für ein

Gerät modernster Technologie entschieden.

Die Endstufen der CP-Serie vereinen überragende Audio-Performance mit höchster Zuverlässigkeit und Betriebssicherheit.

Die Übertragungseigenschaften der CP-Endstufen sind hervorragend. Durch optimierte Netzteile mit

streuarmen Ringkerntransformatoren und die konsequente Anwendung der Class H Technik wird ein

großer Headroom weit oberhalb der ausgewiesenen Nennleistung erzielt und gleichzeitig eine deutliche

Reduzierung von Gewicht und Verlustleistung erreicht.

Die CP-Serie ist in Class H Technik aufgebaut. D.h. die Endstufe verfügt über eine extrem schnelle,

signalabhängige Umschaltung der Betriebsspannung, die im Bedarfsfall eine Verdopplung der normalen

Versorgungsspannung bewirkt. Im Vergleich zu Class AB Endstufen wird bei Endstufen mit Class H

Technik erheblich weniger Verlustleistung bei gleicher Ausgangsleistung erzeugt. Weniger Verlustleistung

ist gleichbedeutend mit weniger Abwärme oder besser gesagt mit einer besseren Efzienz bzw.

Energiebilanz des Gerätes. Endstufen in Class H Technik lassen sich daher mit einer entsprechend

höheren Packungsdichte im Rack bzw. Gestellschrank verbauen. Darüber hinaus ist die netzseitige

Stromaufnahme wesentlich geringer als im Class AB Betrieb, bei gleicher Ausgangsleistung.

Die Electro-Voice - Endstufen der CP- SERIE erfüllen auch die extremen Anforderungen des

harten Tour-Betriebs. Sie sind gegen Überhitzung, Überlast, Kurzschluß sowie Hochfrequenz

und Gleichspannung am Ausgang geschützt. Eine Beschädigung der Endtransistoren durch

Rückeinspeisung elektrischer Energie wird durch die Back-EMF Schutzschaltung verhindert. Beim

Softstart werden die Leistungsausgänge über Relais verzögert zugeschaltet. Zusätzlich verhindert eine

Einschaltstrombegrenzung das Ansprechen von Netzsicherungen.

Höchste Präzision ist auch in der mechanischen Konstruktion und Verarbeitung gewährleistet. Das

robuste Stahlblech-Chassis ist besonders verwindungssteif und speziell auf die Belastungen des harten

Tourbetriebs ausgelegt. Die thermische Stabilität wird durch zwei 3-Stufen Lüfter (off/slow/fast) mit sehr

niedrigem Geräuschpegel gewährleistet. Die Front-to-Rear Luftführung, erlaubt den Betrieb auch in

großen und schmalen Endstufen-Racks. Die Eingänge sind elektronisch symmetrisch auf XLR-Buchsen

geführt. Direct-Outs zum Durchschleifen des Signals sind ebenfalls in Form von XLR-Buchsen (male)

praktischer Standard. Über das Input Routing können die Betriebsarten DUAL (Stereo) oder PARALLEL

(Mono) gewählt werden. Außerdem ist der „Mono Bridged“ –Betrieb über die separate BRIDGED OUT

Buchse und den Bridged Mode Umschalter sehr einfach zu realisieren. Auf der Frontblende sitzen die in dB

skalierten Levelregler, die als besonders präzise, bediensichere Rastpotis ausgeführt und zum Schutz vor

mechanischer Beschädigung in der Frontblende versenkt sind. Die CP-Serie bietet intern die Möglichkeit

zur Nachrüstung einer analogen Signalprozessorkarte mit Frequenzweichen- und Filterfunktionen.

Eine schnelle Übersicht über den aktuellen Betriebszustand der Endstufen vermittelt das leicht

ablesbare LED-Display. Die Leistungsausgänge CHANNEL A, CHANNEL B und BRIDGED OUT sind

als extrem zuverlässige SPEAKON-Buchsen ausgeführt. Ebenfalls auf der Rückwand benden sich

ein Groundlift-Schalter, der bei Bedarf das Gehäuse der Endstufe von der Schaltungsmasse trennt und

somit Brummschleifen verhindern hilft. Alle CP- Endstufen können im Normalbetrieb an Lasten bis hinab

zu 2 Ohm und im Brückenbetrieb bis zu minimal 4 Ohm eingesetzt werden.

Mit dieser Bedienungsanleitung werden Sie noch viele weitere Eigenschaften der Endstufen aus der

CP-SERIE kennenlernen. Lesen Sie deshalb bitte aufmerksam weiter.

14

Page 15

BESCHREIBUNG

AUSPACKEN & GARANTIE

Öffnen Sie die Verpackung und entnehmen Sie die Endstufe. Zusätzlich zu dieser Bedienungsanleitung

liegen dem Gerät ein Netzkabel, und die Garantiekarte bei. Bewahren Sie zur Garantiekarte auch den

Kaufbeleg, der den Termin der Übergabe festlegt, auf.

INSTALLATIONSHINWEISE

Generell sind die Endstufen so aufzustellen oder zu montieren, dass die Luftzufuhr an der Frontseite

und die Entlüftung an der Geräterückseite nicht behindert wird. Die Belüftungsrichtung ist also „Frontto-Rear“. Geräte mit umgekehrter Luftführung sollen möglichst nicht im gleichen Rack/Schrank verbaut

werden. Für den Einbau in Gehäuse und Gestellschränke ist zu beachten, dass eine ausreichende

Belüftung der Geräte möglich ist. Zwischen der Endstufen Rückseite und der Schrank/Rack-Innenseite

ist ein freier Luftkanal bis zur oberen Rack- oder Schrankentlüftung von mindestens 60mm x 330mm

vorzusehen. Oberhalb des Schrankes soll ein freier Raum von mindestens 100mm für die Entlüftung zur

Verfügung stehen. Da beim Betrieb die Temperatur im Gehäuse- oder Schrank bis zu 40°C ansteigen

kann, muss die maximal zulässige Umgebungstemperatur der übrigen im Gestellschrank bendlichen

Geräte beachtet werden (siehe auch Kapitel: NETZBETRIEB UND WÄRMEENTWICKLUNG ).

Achtung: Die max. Umgebungstemperatur von +40°C soll für störungsfreien Betrieb nicht

überschritten werden.

Beim Einbau in Gestellschränken oder Transportracks, sollen in jedem Fall handelsübliche Einbauschienen oder die optional erhältlichen „Rear-rackmount“ Schienen verwendet werden, um ein Verwinden

der Frontblende zu verhindern.

Die Endstufe ist zu schützen vor: Tropf- oder Spritzwasser, direkter Sonnenbestrahlung, hoher

Umgebungstemperatur oder unmittelbarer Einwirkung von Wärmequellen, hoher Luftfeuchtigkeit,

starken Staubablagerungen und starken Vibrationen.

Wenn die Endstufe direkt von einem kalten an einen warmen Ort gebracht wird, kann sich Feuchtigkeit

auf Innenteilen niederschlagen. Das Gerät darf erst in Betrieb genommen werden, wenn es sich auf die

geänderte Temperatur erwärmt hat (nach etwa einer Stunde). Sollte ein fester Gegenstand oder Flüssigkeit in das Gehäuse gelangen, trennen Sie sofort das Gerät vom Netz und lassen Sie das Gerät von

einer autorisierten Servicestelle überprüfen, bevor Sie es weiterverwenden.

15

Page 16

17

FRONTSEITE

Mit dem POWER Schalter rechts auf der Frontblende wird das Gerät eingeschaltet. Eine Softstart-

Schaltung vermeidet dabei Einschaltstromspitzen auf der Netzleitung. Dadurch wird verhindert, dass

der Leitungsschutzschalter des Stromnetzes beim Einschalten der Endstufe anspricht. Die Lautspre-

cher werden über die Ausgangsrelais um ca. 2 Sekunden verzögert zugeschaltet, wodurch etwaige

Einschaltgeräusche effektiv unterdrückt werden, die ansonsten in den Lautsprechern hörbar wären.

Während dieser Verzögerung leuchtet die PROTECT LED und die Lüfter laufen mit maximaler Ge-

schwindigkeit. Dies ist normal und bestätigt die einwandfreie Funktion der Schutzschaltungen.

Diese LED leuchtet auf, wenn die Endstufe eingeschaltet ist. Falls die POWER An-

zeige nicht leuchtet, ist das Gerät nicht mit dem Stromnetz verbunden, oder die

Primärsicherung defekt.

Wenn die PROTECT-Anzeige aueuchtet, hat eine der internen Schutzschaltungen

wie Übertemperatur, Kurzschluss, Back-EMF, Hochfrequenz am Ausgang.... ange-

sprochen. Die Endstufen werden in diesem Fall über die Ausgangsrelais von der Last

getrennt, und die Signalzufuhr unterbrochen um etwaige Schäden an den Laut-

sprechern oder der Endstufe selbst zu verhindern.

Die Fehlerursache, beispielsweise eine kurzgeschlossene Lautsprecherleitung muss

beseitigt werden. Bei Überhitzung muss einige Zeit gewartet werden, bis die Endstu-

fe sich selbständig wieder in den normalen Betriebszustand schaltet.

Die SIGNAL-LED beginnt ca. 30dB unter Vollaussteuerung zu leuchten

und zeigt an, dass generell ein Signal am Ausgang vorhanden ist. Bei Kurzschluss

von Lautsprecherleitungen oder Ansprechen einer Schutzschaltung verlischt diese

Anzeige.

Die 0dB Anzeige leuchtet auf, wenn die Endstufe an der Aussteuergrenze be-

trieben wird. Eine höhere Eingangsspannung hat keine Erhöhung der Spitzenausgangs-

spannung zur Folge. Die 0dB Anzeige kann auch bei der Einstellung von externen

Limitern sehr hilfreich sein.

Diese Anzeige leuchtet auf, sobald einer der eingebauten dynamische Audio-Limiter

anspricht und die Endstufe über der Aussteuerungsgrenze oder generell im Grenz-

bereich betrieben wird. Kurzzeitiges Aueuchten ist dabei unproblematisch, da der

interne Limiter Eingangspegel bis zu +21dBu auf einen akustisch unkritischen Klirr-

faktor von ca. 1% ausregeln kann. Leuchtet diese LED jedoch dauerhaft, sollte die

Lautstärke reduziert werden, um etwaige Überlastungsschäden der angeschlossenen

Lautsprecherboxen zu vermeiden.

In dB-skalierte Rastpotis ( 1 dB Schritte ) zur Anpassung der

Gesamtverstärkung der Endstufe. Zur Vermeidung von Ver zerrungen in vorgeschalteten Mischpulten sollten diese

Regler normalerweise zwischen 0dB und -6dB eingestellt

werden. Die Beschriftung zeigt unmittelbar die Reglerdämp fung mit der die intern festgelegte Verstärkung verändert wird.

16

Page 17

RÜCKSEITE

INPUT A / INPUT B

Die Eingänge INPUT A & INPUT B sind elektronisch symmetrisch

mit einer Eingangsempndlichkeit von +4dBu (1.23V) für den

direkten Betrieb mit Mischpulten, Signalprozessoren usw. aus gelegt.

Die XLR-Ausgangsbuchsen OUTPUT A & OUTPUT B

sind zum „Durchschleifen“ des Eingangssignals zu weiteren

Endstufen vorgesehen. Das Eingangssignal wird dabei direkt

auf die Ausgangsbuchsen gelegt, es benden sich keine Zwischenverstärker oder andere elektronischen Bauteile in diesem Pfad. Die Eingangs- und Ausgangsbuchsen des jeweiligen Kanals sind also

direkt elektrisch parallel geschaltet und damit unabhängig von der Stellung des Power-ON-Schalters

permanent miteinander verbunden.

Einige Mischpulte sind ausgangsseitig unsymmetrisch beschaltet obwohl als Ausgangssteckverbindung XLR Stecker vorgesehen sind. Falls ein Mischpult mit unsymmetrischen Ausgängen

verwendet wird, müssen an den Endstufeneingangsbuchsen PIN1 und PIN3 miteinander über

eine Brücke verbunden werden, oder der PIN3 am Verbindungskabel muß unbeschaltet bleiben.

Wird aus unsymmetrisch beschalteten Geräten über PIN3 (b, -, „kalt“) und PIN2 (a, +, „heiß“)

eingespeist, so können eigenartige Brummstörungen und hochfrequente Schwingungen

auftreten, die zu Endstufen- und Lautsprecherdefekten führen können.

NF-VERBINDUNGSKABEL

Als NF-Verbindung wählen Sie am besten symmetrisch ausgelegte Kabel (2 Signaladern + Schirmgeecht) mit XLR-Stecker. Obwohl alle Endstufeneingänge auch unsymmetrisch beleget werden können, stellt ein symmetrisch ausgeführtes NF-Verbindungskabel die bessere Alternative dar. Die meisten Audiogeräte verfügen über symmetrisch aufgebaute Ausgänge. Der Schirm im Kabel verbindet bei

symmetrischer Signalführung alle metallischen Gehäuse und verhindert dadurch lückenlos ein Einkoppeln von externen Störsignalen, im wesentlichen Brummen, auf den Audiosignalpfad.

XLR-Steckerbelegung

XLR (male) XLR (female)

PARALLEL

Steht der Wahlschalter in Position PARALLEL sind die Eingangsbuchsen Kanal A

und B elektrisch direkt parallel geschaltet. Die Lautstärke für Kanal A oder B kann

aber unabhängig voneinander mit den Levelreglern A oder B eingestellt werden.

DUAL

Steht der Wahlschalter in Stellung DUAL werden Kanal A und B getrennt verstärkt.

17

Page 18

19

RÜCKSEITE

ENDSTUFENAUSGANGSBUCHSEN

Für die Endstufenkanäle A (Links) und B (Rechts) sind

jeweils SPEAKON Ausgangsbuchsen vorhanden.

Die BRIDGED OUT Buchse für den Brückenbetrieb

ist mit einem Kunststoffdeckel geschlossen, um

Anschlußfehler zu vermeiden. Entfernen Sie den Deckel

nur, wenn Sie die Endstufe tatsächlich im Brückenbetrieb

verwenden wollen.

BRIDGED MODE

Ist der Schalter BRIDGED-MODE gedrückt muß in den Kanal A eingespeist

werden. Der Input B hat dann keine Funktion.Die Endstufe im Kanal A wird

ganz normal angesteuert. Zusätzlich wird das Signal intern invertiert und

auf die Endstufe im Kanal B gelegt. Die Endstufen A und B arbeiten dann im

Gegentakt mit verdoppelter Ausgangsspannung auf die Ausgangsbuchse

BRIDGED-OUT.

Die Ausgangsspannung jeder einzelnen Endstufe A+B steht zwar noch an den

Ausgangsbuchsen CHANNEL A und CHANNEL B, soll aber wegen der Pha sendrehung nicht weiter benutzt werden.

Der Betrieb von 2 Ohm Lasten ist im Bridged Mode nicht zulässig.

ACHTUNG: Im Bridged-Betrieb können sehr hohe Spannungen am BRIDGED OUT Ausgang

produziert werden. Die angeschlossenen Lautsprecher müssen für derart hohe Spannungen

ausgelegt sein. Beachten Sie unbedingt die Leistungsangaben im Datenblatt des jeweiligen

Lautsprechers und vergleichen Sie diese mit der entsprechenden Ausgangsleistung der Endstufe.

GROUND-LIFT SCHALTER

Mit dem Groundlift-Schalter können Sie Brummschleifen verhindern. Wenn

die Endstufe zusammen mit anderen Geräten in einem 19“-Rack betrieben

wird, sollte der Schalter in Stellung GROUNDED stehen. Wird die Endstufe

mit Geräten mit unterschiedlichem Erdungspotenzial betrieben, sollte der

Schalter in Stellung UNGROUNDED stehen.

NETZEINGANG

Die Netzsicherung löst unter normalen Umständen nur bei einem Fehlerfall

aus. Die Sicherung darf nur gegen eine gleichwertige Sicherung mit

gleicher Strom-, Spannungs- und Auslösecharakteristik getauscht werden.

Sollte die Netzsicherung wiederholt durchbrennen, kontaktieren Sie bitte die

nächstgelegene Servicestelle.

Die Endstufe wird mit einem qualitativ hochwertigen Netzkabel ausgeliefert,

das über ausreichend hohen Leiterquerschnitt verfügt und den sicherheitstechnischen Anforderungen genügt. Verwenden Sie möglichst nur dieses Kabel zum Anschluß der Endstufe ans Netz. Kabel mit dünneren Querschnitten haben erhöhte Verluste und entsprechend geringere

maximale Ausgangsleistung zur Folge.

18

Page 19

NETZBETRIEB & WÄRMEENTWICKLUNG

NETZBETRIEB & WÄRMEENTWICKLUNG IN DER ENDSTUFE

Mit Hilfe der folgenden Tabellen können die Anforderungen für Stromversorgung und Zuleitungen

bestimmt werden.

Die vom Stromnetz aufgenommene Leistung wird in Ausgangsleistung für die Lautsprecher und in

Wärme umgewandelt. Die Differenz aus aufgenommener Leistung und abgegebener Leistung nennt

man Verlustleistung (Pd). Die durch Verluste entstehende Wärme verbleibt u.U. im Rack und muss durch ge-

eignete Massnahmen abgeleitet werden. Zur Berechnung der Wärmeverhältnisse im Rack/Schrank bzw. zur

Dimensionierung eventuell benötigter Abluftmassnahmen kann die nachfolgende Tabelle benutzt werden.

Die Spalte Pd zeigt die Verlustleistung bei verschiedenen Betriebszuständen. Die Spalte BTU/hr

zeigt die abgegebene Wärmemenge je Stunde.

CP1800

idle

Max. Output Power @ 8Ω

Max. Output Power @ 4Ω

1/3 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

Normal Mode (-10dB) @ 4Ω

Rated Output Power (0dB) @ 4Ω

Alert (Alarm) Mode (-3dB) @ 4Ω

Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

(1)

(1)

(2),(4)

(1)

(1)

CP2200

idle

Max. Output Power @ 8Ω

Max. Output Power @ 4Ω

1/3 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

Normal Mode (-10dB) @ 4Ω

Rated Output Power (0dB) @ 4Ω

Alert (Alarm) Mode (-3dB) @ 4Ω

Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

(1)

(1)

(2),(4)

(1)

(1)

U

mains

[V]

I

mains

[A]

P

mains

[W]

P

out

[W]

Pd

[W]

(5)

BTU/hr

(1)

230V 0,39 46 - 46 155

230V 6,7 1110 2 x 350 410 1400

230V 11,0 1980 2 x 600 780 2660

(1)

(1)

(2)

230V 6,6 1090 2 x 200 690 2355

230V 2,7 410 2 x 75 260 885

230V 3,3 480 2 x 75 330 1125

230V 3,5 500 2 x 84 332 1130

230V 2,5 370 2 x 60 250 855

(1)

230V 10,2 1810 2 x 500 810 2765

(1)

230V 7,4 1250 2 x 250 750 2560

230V 17,0 3290 2 x 900 1490 5085

(1)

(2)

230V 4,0 660 2 x 113 434 1480

230V 4,9 790 2 x 113 564 1925

U

mains

[V]

I

mains

[A]

P

mains

[W]

P

out

[W]

Pd

[W]

(5)

BTU/hr

(3)

230V 0.5 65 - 65 220

230V 8.0 1440 2 x 500 440 1500

230V 13.2 2520 2 x 800 920 3140

(1)

(1)

(2)

230V 7.5 1360 2 x 266 828 2825

230V 3.0 520 2 x 100 320 1090

230V 3.3 570 2 x 100 370 1260

230V 3.6 660 2 x 120 420 1435

230V 2.8 470 2 x 80 310 1060

(1)

230V 12.5 2360 2 x 700 960 3275

(1)

230V 8.8 1610 2 x 350 910 3105

230V 20.0 4000 2 x 1100 1800 6140

(1)

(2)

230V 4.5 815 2 x 138 540 1840

230V 4.5 815 2 x 138 540 1840

(1) Sinusaussteuerung (1kHz) (2) VDE-Rauschen (3) 1BTU = 1055.06J = 1055.06Ws

(4) 10% Netzüberspannung (5) Pd = Verlustleistung

Die Stromaufnahmen für andere Netze können mit folgenden Faktoren direkt proportional

umgerechnet werden: 100V = 2.3; 120V = 1.9; 240V = 0.96

19

Page 20

21

20

Page 21

MODE D‘EMPLOI

Page 22

MATIÈRES

IMPORTANTES INFORMATIONS DE SÉCURITÉ ....................... 23

INSTRUCTIONS DE RÉPARATION IMPORTANTES ....................... 23

DESCRIPTION ....................... 24

DÉBALLAGE ET GARANTIE ....................... 25

REMARQUES SUR L’INSTALLATION ....................... 25

FACE AVANT ....................... 26

PANNEAU ARRIÈRE ....................... 27

INPUT A / INPUT B ....................... 27

PARALLEL ....................... 27

SORTIE DE AMPLI DE PUISSANCE ....................... 28

GROUND-LIFT ....................... 28

ENTRÉE SECTEUR ....................... 28

SECTEUR ET TEMPÉRATURE RÉSULTANTE ....................... 29

SPECIFICATIONS ....................... 30

BLOCK DIAGRAM ....................... 32

DIMENSIONS ....................... 33

22

Page 23

IMPORTANTES INFORMATIONS DE SÉCURITÉ

Le symbole «éclair» à l’intérieur d’un triangle signale

à l’utilisateur la présence dans l’appareil de câbles et

de contacts qui ne sont pas isolés, dans lesquels circule un courant électrique à haute tension, et qu’on

ne doit en aucun cas toucher an d’éviter de recevoir

une décharge électrique qui pourrait être mortelle.

Le symbole «point d’exclamation» à l’intérieur d’un

triangle signale à l’utilisateur les consignes importantes concernant la maintenance et l’emploi de

l’appareil, il vous invite à lire le mode d’emploi accompagnant cet appareil.

1. Lisez ces instructions.

2. Conservez ces instructions.

3. Tenez compte des avertissements.

4. Respectez toutes les instructions.

5. Ne pas utiliser cet appareil près d’un point d’eau. Ne pas exposer cet appareil à la pluie ni aux éclaboussures et

veiller à ce qu’aucun récipient, tel que vase, verre, etc., ne soit posé sur cet appareil.

6. Nettoyer uniquement à l’aide d’un chiffon sec.

7. Ne bloquez aucun des orices de ventilation. Installez-le en respectant les instructions du fabricant.

8. Ne l’installez pas près de sources de chaleur telles que radiateurs, poêles, ou autres appareils produisant de la

chaleur.

9. Utilisez uniquement les accessoires spéciés par le fabricant.

10. Adressez-vous toujours à un personnel qualié pour toutes les réparations. Une révision est nécessair lorsque

l’appareil a été endommagé d’une manière quelconque : sa prise ou son cordon d’alimentation sont abimés,

du liquide a été renversé ou des objets sont tombés à l‘intérieur, l’appareil a été exposé à la pluie ou à l’humidité,

son fonctionnement est anormal ou il a subit une chute.

11. Pour déconnecter complètement cet appareil du secteur, il faut débrancher le cordon d’alimentation.

INSTRUCTIONS DE RÉPARATION IMPORTANTES

ATTENTION : Ces instructions de maintenance s’adressent uniquement à des techniciens qualiés.

Pour réduire le risque d’électrocution, n’effectuez aucune opération de maintenance autre que

celles contenues dans les instructions d’utilisation, à moins d’être qualié pour le faire. Conez

toutes ces interventions à un personnel qualié.

1. Les règles de sécurité telles qu’elles sont spéciées par les directives EN 60065 (VDE 0860 / IEC 65) et

CSA E65 - 94 doivent être observées lors de la réparation de l’appareil.

2. L’usage d’un transformateur d’isolation est obligatoire pendant la maintenance lorsque l’appareil est ouvert,

qu’il doit fonctionner et est branché sur le secteur.

3. Mettez hors tension avant de brancher toute extension, changer la tension secteur ou celle de sortie en fonction.

4. La distance minimum entre les éléments sous tension secteur et toute pièce de métal accessible (boîtier métallique),

doit être de 3 mm entre phase. Ceci doit être respecté en permanence. La distance minimum entre les éléments

sous tension secteur et tout commutateur ou interrupteur non connecté au secteur (éléments secondaires) doit

être de 6 mm. Ceci doit être respecté en permanence.

5. Le remplacement de composants spéciaux qui sont marqués d’un symbole de sécurité (Remarque) sur le schéma

de principe n’est autorisé qu’en utilisant des pièces d’origine.

6. La modication des circuits sans autorisation ou avis préalable n’est pas permise.

7. Toutes les règlementations concernant la sécurité du travail en vigueur dans le pays où l’appareil est réparé doivent

être strictement observées. Ceci s’applique également aux règlementations concernant le lieu de travail lui-même.

8. Toutes les instructions concernant la manipulation de ircuits MOS doivent être respectées.

REMARQUE:

COMPOSANT DE SÉCURITÉ (NE DOIT ÊTRE REMPLACÉ QUE PART

UNE PIÈCE D’ORIGINE)

23

Page 24

25

DESCRIPTION

Félicitations ! En achetant un amplicateur de puissance Electro-Voice CP-SERIES, vous avez choisi

un appareil qui emploie les technologies les plus modernes.

Les performances audio des amplis de puissance CP sont tout simplement extraordinaires. Les

alimentations secteur ont été optimisées et emploient des transformateurs toroïdaux à faibles pertes et

grâce à un usage cohérent de la technologie Classe H ils disposent d’une réserve de puissance, très

au-dessus de la puissance nominale de sortie. Ceci permet une réduction du poids et de la puissance

dissipée.

Le CP-Series est basé sur la technologie Classe H, ce qui veut dire que l’alimentation peut doubler

sa puissance extrêmement rapidement en fonction du signal, et de la puissance demandée par

l’amplicateur. Comparé aux amplicateurs de Classe A-B, les amplis Classe H génèrent donc

beaucoup moins de puissance dissipée, à sortie identique. En conséquence, ceci entraîne de moins

de déperdition en chaleur, l’énergie est donc utilisée de manière plus efcace. Résultat : il est possible

d’installer des amplis de puissance Classe H dans une armoire de rack en laissant moins de place

entre les appareils. De plus, pour une même puissance en sortie, la consommation électrique est bien

moindre que celle d’un ampli de Classe A-B. Les amplicateurs de puissance Electro-Voice CP-SERIES

ont été conçus pour satisfaire aux conditions de tournée les plus exigeantes. Les amplis de puissance

CP sont protégés contre les chocs thermiques et les surcharges électriques, les courts-circuits et la

présence de hautes fréquences et de courant continu sur les sorties. Une protection contre la force

contre-électromotrice supprime le risque que les transistors de sortie ne soient endommagés par un

retour d’énergie électrique. Les sorties de puissance sont commutées via un relais avec temporisation

lors du démarrage (Soft-Start). Un limiteur d’appel de courant évite que les fusibles secteur ne sautent.

Leur construction mécanique et quasiment artisanale achève de parfaire une fabrication de haute

précision. Le châssis en acier est conçu pour résister aux conditions de tournées les plus difciles. Deux

ventilateurs à trois vitesses (arrêt/lente/rapide) très performants garantissent une stabilité thermique

constante avec un bruit de fonctionnement très faible. La ventilation est dirigée de l’avant vers l’arrière,

ce qui permet un fonctionnement able, même dans de petits racks d’amplis. Les entrées symétrisées

électroniquement sont équipées de connecteurs de type XLR. Des sorties directes pour la connexion

d’un signal audio sont également disponibles sur des connecteurs de type XLRM. La sélection du

mode de fonctionnement permet de choisir entre les modes DUAL (stéréo) ou PARALLEL (mono).

Grâce au connecteur séparé BRIDGED OUT et au commutateur Bridged Mode, le passage au mode

Dérivation (ou „Mono Bridged“) est vraiment très simplié. Les contrôles de niveau, gradués en dB, sont

encastrés dans la face avant, ce qui assure une protection able contre les dommages mécaniques ; ces

potentiomètres crantés sont particulièrement précis. Les amplis de puissance CP peuvent être équipés

d’une carte interne processeur de signal analogique avec fonction de crossover et de ltre.

L’afchage à LED très lisible fournit un aperçu rapide de l’état de fonctionnement de l’ampli de puissance.

Les sorties de puissance CHANNEL A, CHANNEL B et BRIDGED OUT sont équipées de connecteurs

de type SPEAKON. Toujours à l’arrière, se trouve un sélecteur de masse (Ground-Lift), qui aide à éliminer

les boucles de masse en séparant le châssis de l’ampli de puissance du circuit de masse. En mode de

fonctionnement normal, tous les amplis de puissance CP peuvent gérer des charges aussi faibles que

2 ohms. En mode Mono-Bridged, la charge minimum possible est de 4 ohms.

Ce mode d’emploi décrit et explique les différentes fonctions de votre amplicateur de puissance Série

CP. Veuillez le lire attentivement et tenir compte des instructions mentionnées.

24

Page 25

DESCRIPTION

DÉBALLAGE ET GARANTIE

Ouvrez avec précautions le carton d’emballage et sortez votre amplicateur de puissance. En plus de

l’amplicateur de puissance lui-même, le carton contient également le présent mode d’emploi, le cordon

secteur et le certicat de garantie. Conservez en lieu sûr, l’original de la facture, qui mentionne la date

d’achat et de livraison, ainsi que le certicat de garantie.

REMARQUES SUR L’INSTALLATION

Généralement, l’installation ou le montage en rack des amplicateurs de puissance doit être effectué

de manière à garantir continuellement une circulation libre de l’air de l’avant vers l’arrière de l’appareil.

L’installation de ces appareils avec une circulation d’air insufsante, dans un meuble ou dans une armoire

de rack fermé n’est pas recommandée. Si vous devez installer cet appareil dans de telles conditions,

veillez à lui fournir une ventilation sufsante. Laissez un espace d’au moins 60 mm x 300 mm (jusqu’aux

ouies de ventilation situées en haut du meuble) pour permettre la circulation de l’air entre l’arrière de

l’amplicateur de puissance et la paroi arrière du meuble ou du rack. Veillez à laisser au moins 100 mm

au-dessus du meuble ou du rack lui-même. Comme la température à l’intérieur du meuble ou du rack

peut monter facilement à 40°C pendant le fonctionnement, vériez que la température ambiante

maximale autorisée en fonctionnement pour tous les autres appareils présents dans ce rack est dans

les normes admises (reportez-vous également au § „ALIMENTATION SECTEUR ET TEMPÉRATURE

RÉSULTANTE“).

Attention : Pour un fonctionnement able, la température ambiante autorisée ne doit pas

dépasser +40°C.

L’usage de rails d’installation ou de glissières optionnelles est fortement recommandé, lorsque l’appareil

doit être installé dans une armoire de racks ou un meuble an d’éviter toute déformation du panneau

arrière.

L’amplicateur de puissance doit être protégé contre : les éclaboussures ou les fuites d’eau, les rayons

directs du soleil, les températures élevées ou l’inuence directe de sources de chaleur, une humidité

trop élevée, les excès de poussière et les vibrations.

De la condensation peut se former sur les éléments internes, lors du transport de l’amplicateur d’un

endroit froid à un environnement plus chaud. Dans ce cas, sa mise en route n’est possible qu’après avoir

laissé l’appareil se réchauffer à la température ambiante (pendant environ une heure). Si des objets

ou du liquide pénètrent dans le boîtier de l’amplicateur de puissance, débranchez immédiatement

l’appareil du secteur et contactez le service après-vente agréé pour procéder à une inspection avant de

le remettre en marche.

25

Page 26

27

FACE AVANT

Utilisez l’interrupteur secteur, situé en face avant, du côté droit, pour mettre l’appareil sous tension. La

fonction Soft-Start élimine les crêtes provoquées par l’appel de courant à l’allumage, ce qui par la même

évite que le commutateur de protection secteur ne s’enclenche lors de la mise sous tension. Les sorties

haut-parleur sont activées via la commutation d’un relais avec une temporisation d’environ 2 secondes

de façon à atténuer efcacement d’éventuels bruits de mise sous tension. Le témoin PROTECT s’allume

pendant cette temporisation et les ventilateurs tournent à la vitesse maximum. C’est tout à fait normal,

et conrme un parfait fonctionnement du circuit de protection.

Ce témoin s’allume lorsque l’amplicateur de puissance a été mis sous tension.

Les causes pour lesquelles le témoin POWER ne s’allume pas sont les suivantes :

l’appareil n’est pas branché sur le secteur ou le fusible secteur est défectueux.

Le témoin PROTECT indique qu’un des circuits de protection interne contre la surchauffe,

les courts-circuits, la force contre-électromotrice, la présence de HF à la sortie, etc. s’est

activé. Les relais de sortie coupent les charges connectées aux amplis de

puissance alors que les signaux entrant sont également interrompus, évitant

ainsi d’endommager les systèmes de haut-parleurs connectés ainsi que les

amplicateurs de puissance eux-mêmes. Quelle que soit la raison de la panne, par ex. un

court-circuit dans un câble du haut-parleur, celle-ci doit être résolue. Dans le cas

d’une surchauffe, il vous faudra attendre que l’amplicateur de puissance revienne

automatiquement à un fonctionnement normal.

Le témoin SIGNAL s’allume dès qu’un signal audio inférieur d’environ 30 dB à la

modulation maximum est présent en sortie. Ce témoin est éteint lorsque les câbles

de haut-parleurs sont en court-circuit ou lorsqu’un des circuits de protection a été

activé.

Le témoin 0 dB s’allume chaque fois que l’amplicateur de puissance fonctionne à sa

puissance maximum. Des tensions d’entrée plus élevées ne provoqueront pas des

tensions de sorties plus fortes. De plus, ce témoin est très pratique lors du réglage

de limiteurs externes.

Ce témoin s’allume dès que le limiteur de signal audio dynamique intégré entre en

action et que l’amplicateur de puissance arrive à la limite de l’écrêtage ou plus

généralement à sa capacité maximum. Un bref clignotement n’est pas un problème,

car le limiteur interne contrôle des niveaux d’entrée pouvant dépasser les +21 dB

jusqu’à une THD (Distorsion harmonique totale) d’approximativement 1%. Par contre,

si ce témoin est constamment allumé, il faut réduire le volume pour éviter que les

haut-parleurs connectés ne soient endommagés par une probable saturation.

Les potentiomètres crantés, gradués en dB (par pas de 1 dB)

servent à régler le volume général de l’amplicateur de

puissance. Pour éviter toute distorsion dans les consoles de

mixage connectées à votre ampli Série CP, il est

recommandé de régler ces potentiomètres entre 0 dB et

–6 dB. La graduation en dB donne une indication immédiate

de l’atténuation appliquée.

26

Page 27

PANNEAU ARRIÈRE

INPUT A / INPUT B

INPUT A / INPUT B (Entrées A & B)

Les entrées, INPUT A & INPUT B sont symétrisées

électroniquement et offrent une sensibilité de +4 dBu (1,23 V)

pour le branchement direct de consoles de mixage,

processeurs de signal, etc.

Les connecteurs de sortie de type XLR OUTPUT A & OUTPUT B

sont prévus pour un branchement „transparent“ des signaux

d’entrée vers d’autres amplicateurs de puissance. Le signal

d’entrée est directement dirigé vers ces connecteurs de sortie. Il ne s’agit pas de répétiteurs ou autres

composants électroniques intégrés dans le trajet du signal. Donc, les connecteurs d’entrée et de sortie

d’un même canal sont reliés en parallèle, offrant une connexion électrique permanente, quel que

soit le réglage de l’interrupteur secteur (Power).

Bien qu’elles soient équipées de connecteurs de sortie de type XLR, certaines consoles de

mixage disposent uniquement d’une connexion de sortie asymétrique. Si vous employez de

telles consoles, il est nécessaire de raccorder les broches 1 et 3 des connecte urs d’entrée

de l’ampli de puissance ou de laisser la broche 3 de la prise du câble non connectée. Sinon,

des signaux audio asymétriques arriveront via la broche 3 (b, -, point froid) et la broche 2 (a, +,

point chaud), produisant un ronement et des interférences HF, qui risquent d’endommager

l’amplicateur de puissance et/ou les enceintes connectées.

CORDONS DE CONNEXION NF

Il est recommandé de choisir des câbles symétrisés de qualité (deux conducteurs pour le signal audio,

plus une tresse de masse) munis de prises de type XLR. Bien que le branchement de câbles non

symétrisés à l’amplicateur de puissance soit possible, il est toujours préférable d’utiliser des câbles

symétrisés. La plupart des équipements audio actuels sont équipés de sorties symétrisées. Avec un

câblage symétrisé, toutes les parties métalliques des boîtiers sont reliées la masse, ce qui élimine

efcacement l’apparition d’interférences externes, se traduisant par des bruits de fond et des parasites.

Câblage interne d’un connecteur de type XLR

XLR (mâle) XLR (femelle)

PARALLEL

Les connecteurs d’entrée des canaux A et B sont reliés électriquement en parallèle

lorsque le sélecteur est réglé sur PARALLEL. Toutefois, le contrôle séparé des deux

canaux est toujours possible via le contrôle de niveau A ou B.

DUAL

Si le sélecteur est réglé sur DUAL, les signaux audio des canaux et A et B sont

ampliés indépendamment.

27

Page 28

29

PANNEAU ARRIÈRE

CONNECTEURS DE SORTIE DE AMPLI DE PUISSANCE

Les connecteurs de sortie de l’ampli de puissance pour

les deux canaux A (gauche) et B (droit) sont des prises

de type SPEAKON.

Un cache en plastique protège le connecteur BRIDGED

OUT de tout branchement erroné. N’enlevez ce cache

que lorsque vous souhaitez réellement faire fonctionner

l’amplicateur de puissance en mode Dérivation

(Bridged).

MODE BRIDGED (Dérivation)

Si le bouton BRIDGED MODE est engagé, l’utilisation de l’entrée du canal A

pour le signal audio est obligatoire, puisque l’entrée B ne fonctionne pas. Alors

que l’amplicateur du canal A fonctionne normalement, le signal audio est

inversé en interne et dirigé vers l’amplicateur du canal B. Les deux amplis,

A et B, fonctionnent alors en push-pull pour fournir une tension de sortie

double sur le connecteur BRIDGED OUT.

La tension de sortie normale de chaque canal A/B de l’amplicateur est

toujours présent sur le connecteur de sortie correspondant CHANNEL A

ou CHANNEL B. Cependant, il n’est pas recommandé d’utiliser ces signaux

à cause de l’inversion de phase susmentionnée. Le fonctionnement de l’ampli

de puissance en mode Bridged avec des charges de 2 ohms connectées n’

est pas recommandé non plus.

ATTENTION : Des tensions très fortes peuvent être présentes sur le connecteur BRIDGED

OUT durant le fonctionnement en mode Dérivation. Les systèmes de haut-parleurs connectés

doivent être capables de supporter de telles tensions. Veuillez vérier que les caractéristiques de

puissance mentionnées dans la documentation fournie avec vos haut-parleurs correspondent à

celles de l’amplicateur de puissance.

COMMUTATEUR DE MASSE (GROUND-LIFT)

Ce commutateur permet d’éliminer les boucles de masse. Si l’amplicateur de

puissance fonctionne avec un autre équipement dans un rack 19“, il est

recommandé de régler ce commutateur sur la position GROUNDED (à la

masse). Si l’amplicateur de puissance fonctionne en étant associé à des

appareils ayant des potentiels de masse différents, réglez-le sur la position

UNGROUNDED (pas de masse).

ENTRÉE SECTEUR

Dans des circonstances normales, le fusible secteur ne saute qu’en cas de

panne. Ne remplacer ce fusible que par un nouveau fusible de même type,

ayant le même ampérage, la même tension et les mêmes caractéristiques.

Si le fusible secteur saute fréquemment, veuillez contacter un service après vente agréé. Le cordon secteur hautes-performances fourni avec votre

amplicateur de puissance satisfait aux normes de sécurité en vigueur, de

plus son diamètre est adapté à la puissance de sortie de l’amplicateur. Veuillez n’utiliser que le cordon

secteur fourni pour brancher l’ampli de puissance sur le secteur, si c’est possible. L’utilisation d’un cordon secteur de diamètre inférieur peut provoquer des pertes d’énergie et par la même réduire la capacité de puissance de sortie maximum.

Sur les appareils en 100 V et 120 V, le fusible secteur est installé à l’intérieur. Ceci pour des raisons de

sécurité. Si un fusible saute, il faudra contacter un service après-vente agréé pour le faire remplacer.

28

Page 29

ALIMENTATION SECTEUR ET TEMPÉRATURE RÉSULTANTE

ALIMENTATION SECTEUR ET TEMPÉRATURE RÉSULTANTE

Le tableau suivant indique les normes d’alimentation secteur et de câblage.

Le courant d’alimentation secteur est converti en puissance de sortie pour alimenter les haut-parleurs

connectés et en chaleur. La différence entre la consommation électrique et la puissance dispensée est

appelée puissance dissipée (Pd). La chaleur résultant de la puissance dissipée s’accumule à l’intérieur

de l’armoire de rack et doit donc être évacuée par des moyens appropriés. Le tableau suivant permet

de calculer les températures à l’intérieur d’une armoire de rack ou d’un meuble, ainsi que la capacité

de ventilation à mettre en œuvre.

La colonne „Pd“ indique la perte de puissance (puissance dissipée) en fonction des différents états de

fonctionnement. La colonne „BTU/h“ indique la chaleur diffusée par heure.

CP1800

idle

Max. Output Power @ 8Ω

Max. Output Power @ 4Ω

1/3 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

Normal Mode (-10dB) @ 4Ω

Rated Output Power (0dB) @ 4Ω

Alert (Alarm) Mode (-3dB) @ 4Ω

Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

(1)

(1)

(2),(4)

(1)

(1)

CP2200

idle

Max. Output Power @ 8Ω

Max. Output Power @ 4Ω

1/3 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

1/8 Max. Output Power @ 4Ω

Normal Mode (-10dB) @ 4Ω

Rated Output Power (0dB) @ 4Ω

Alert (Alarm) Mode (-3dB) @ 4Ω

Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

1/8 Max. Output Power @ 2Ω

(1)

(1)

(2),(4)

(1)

(1)

U

mains

[V]

I

mains

[A]

P

mains

[W]

P

out

[W]

Pd

[W]

(5)

BTU/hr

(1)

230V 0,39 46 - 46 155

230V 6,7 1110 2 x 350 410 1400

230V 11,0 1980 2 x 600 780 2660

(1)

(1)

(2)

230V 6,6 1090 2 x 200 690 2355

230V 2,7 410 2 x 75 260 885

230V 3,3 480 2 x 75 330 1125

230V 3,5 500 2 x 84 332 1130

230V 2,5 370 2 x 60 250 855

(1)

230V 10,2 1810 2 x 500 810 2765

(1)

230V 7,4 1250 2 x 250 750 2560

230V 17,0 3290 2 x 900 1490 5085

(1)

(2)

230V 4,0 660 2 x 113 434 1480

230V 4,9 790 2 x 113 564 1925

U

mains

[V]

I

mains

[A]

P

mains

[W]

P

out

[W]

Pd

[W]

(5)

BTU/hr

(3)

230V 0.5 65 - 65 220

230V 8.0 1440 2 x 500 440 1500

230V 13.2 2520 2 x 800 920 3140

(1)

(1)

(2)

230V 7.5 1360 2 x 266 828 2825

230V 3.0 520 2 x 100 320 1090

230V 3.3 570 2 x 100 370 1260

230V 3.6 660 2 x 120 420 1435

230V 2.8 470 2 x 80 310 1060

(1)

230V 12.5 2360 2 x 700 960 3275

(1)

230V 8.8 1610 2 x 350 910 3105

230V 20.0 4000 2 x 1100 1800 6140

(1)

(2)

230V 4.5 815 2 x 138 540 1840

230V 4.5 815 2 x 138 540 1840

(1) Modulation sinusoïdale (1 kHz) (2) Bruit VDE (3) 1BTU = 1055,06 J = 1055,06 W/s

(4) 10% au-dessus de la tension secteur (5) Pd = Puissance dissipée

Les facteurs suivants permettent un calcul proportionnel direct du courant secteur (Imain) pour

différentes alimentations secteur : 100 V = 2,3 ; 120 V = 1,9 ; 240 V = 0,96.

29

Page 30

31

SPECIFICATIONS

- Amplier at rated conditions, both channels driven, 8Ω loads, unless otherwise specied.

CP 1800

Load Impedance 2Ω 4Ω 8Ω

Maximum Midband Output Power

THD = 1%, 1kHz, Dual Channel

Rated Output Power

THD < 0.1%, 20Hz ... 20kHz

Max. Single Channel Output Power

IHF-A

Max. Single Channel Output Power

Continuous, 1kHz, THD-1%

Max. Bridged Output Power

THD = 1%, 1kHz

Maximum RMS Voltage Swing

THD = 1%, 1kHz

Power Bandwith

THD = 1%, ref. 1kHz, half power @ 4Ω

Voltage Gain

ref. 1kHz

Input Sensitivity

at rated output power

THD at rated output power,

MBW = 80kHz, 1kHz

IMD-SMPTE

60Hz, 7kHz

DIM30

3.15kHz, 15kHz

Maximum Input Level

900W 600W 350W

-- 500W 250W

1450W 850W 450W

1200W 720W 410W

-- 1800W 1200W

62V

10Hz ... 60kHz

32,0 dB

+3.2 dBu (1.12 Vrms)

< 0.05%

< 0.02%

< 0.01%

+22dBu (9.76 Vrms)

Crosstalk

ref. 1kHz, at rated output power

Frequency Response

ref. 1kHz

Damping Factor

1kHz

Slew Rate

Signal to Noise Ratio, Amplier

A-weighted

Output Stage Topology

Power Requirements

Power Consumption

1/8 maximum output power @ 4Ω

Protection

Cooling

Safety Class

Dimensions

(W x H x D), mm

Weight

<- 80dB

15Hz ... 40kHz (+/- 1dB)

> 300

30 V/ms

105.5dB

Class H

240, 230, 120V or 100V; 50 ... 60 Hz (factory congured)

500W

Audio limiters, High temperature, DC, HF, Back-EMF,

Peak current limiters, Inrush current limiters, Turn-on delay

Front-to rear, 3stage-fans

I

483 x 88,1 x 386,8

15 kg (33 Ibs)

Optional

Rear-rackmount 15,5“ (NRS 90262) 112930

Rear-rackmount 18“ (NRS 90264) 112933

- Depending on the ambient temperature, the unit might not operate continuously at 2 ohms load in Dual

Mode or 4 ohms load in Bridged Mode.

30

Page 31

SPECIFICATIONS

- Amplier at rated conditions, both channels driven, 8Ω loads, unless otherwise specied.

CP 2200

Load Impedance 2Ω 4Ω 8Ω

Maximum Midband Output Power

THD = 1%, 1kHz, Dual Channel

Rated Output Power

THD < 0.1%, 20Hz ... 20kHz

Max. Single Channel Output Power

IHF-A

Max. Single Channel Output Power

Continuous, 1kHz, THD-1%

Max. Bridged Output Power

THD = 1%, 1kHz

Maximum RMS Voltage Swing

THD = 1%, 1kHz

Power Bandwith

THD = 1%, ref. 1kHz, half power @ 4Ω

Voltage Gain

ref. 1kHz

Input Sensitivity

at rated output power

THD at rated output power,

MBW = 80kHz, 1kHz

IMD-SMPTE

60Hz, 7kHz

DIM30

3.15kHz, 15kHz

Maximum Input Level

1100W 800W 500W

-- 700W 350W

2200W 1200W 625W

1500W 950W 550W

-- 2200W 1600W

72V

10Hz ... 60kHz

32,0 dB

+4.7 dBu (1.33V rms)

< 0.05%

< 0.02%

< 0.01%

+22dBu (9.76 Vrms)

Crosstalk

ref. 1kHz, at rated output power

Frequency Response

1dB, ref. 1kHz

-

Damping Factor

1kHz

Slew Rate

Signal to Noise Ratio, Amplier

A-weighted

Output Stage Topology

Power Requirements

Power Consumption

1/8 maximum output power @ 4Ω

Protection

Cooling

Safety Class

Dimensions

(W x H x D), mm

Weight

<- 80dB

15Hz ... 40kHz

> 300

35 V/ms

107dB

Class H

240, 230, 120V or 100V; 50 ... 60 Hz (factory congured)

660W

Audio limiters, High temperature, DC, HF, Back-EMF,

Peak current limiters, Inrush current limiters, Turn-on delay

Front-to rear, 3stage-fans

I

483 x 88,1 x 386,8

16 kg (35.2 Ibs)

Optional

Rear-rackmount 15,5“ (NRS 90262) 112930

Rear-rackmount 18“ (NRS 90264) 112933

- Depending on the ambient temperature, the unit might not operate continuously at 2 ohms load in Dual

Mode or 4 ohms load in Bridged Mode.

31

Page 32

33

BLOCK DIAGRAM

32

Page 33

DIMENSIONS /ABMESSUNGEN

33

Page 34

NOTES

34

Page 35

NOTES

Page 36

USA Telex Communications Inc., 12000 Portland Ave. South, Burnsville, MN 55337, Phone: +1 952-884-4051, FAX: +1 952-884-0043

Germany EVI AUDIO GmbH, Hirschberger Ring 45, D 94315, Straubing, Germany Phone: 49 9421-706 0, FAX: 49 9421-706 265

Subject to change without prior notice. Printed in Germany 10/09/2003 / 361 858

www.electro-voice.com

Loading...

Loading...