Page 1

1700 Series

Mixer/Power Amplifiers

Operating Instructions

Page 2

TABLE OF CONTENTS

DESCRIPTION................................................................................................................................................................................... 3

INCLUDED ACCESSORIES: ............................................................................................................................................................. 3

OPTIONAL INPUT OUTPUT ACCESSORY MODULES: .................................................................................................................. 3

ELECTRICAL CONNECTIONS FOR THE 1700 SERIES MIXER/POWER AMPLIFIERS ................................................................ 3

Power Connections (120 Volt, 50/60 Hz) .................................................................................................................................... 3

Power Connections (100, 200, 220, or 240 Volt; 50/60 Hz) 1707C/1715C Only ........................................................................ 3

INSTALLING MODULES IN THE MAINFRAME................................................................................................................................. 4

SHELF OR RACK MOUNTING THE ................................................................................................................................................. 4

Ventiliation .................................................................................................................................................................................. 4

OUTPUT CONNECTIONS (1707C/1715C Only) .............................................................................................................................. 6

MUTE/TONE GENERATOR CONNECTIONS ................................................................................................................................... 6

PREAMP OUT/AMP IN CONNECTIONS .......................................................................................................................................... 7

AUX OUT CONNECTIONS................................................................................................................................................................ 7

BATTERY INPUT CONNECTIONS .................................................................................................................................................... 7

FRONT/REAR-PANEL CONTROLS, SWITCHES, INDICATORS, AND CONNECTORS ........................................................... 8

INITIAL SETUP AND OPERATION OF .............................................................................................................................................. 8

MAINFRAME WITH MODULES INSTALLED .................................................................................................................................... 8

Initial Setup of an Input Module .................................................................................................................................................. 8

Initial Setup of an Output Module ............................................................................................................................................... 8

Initial Setup of the Mainframe ..................................................................................................................................................... 8

OPERATING THE 1700 SERIES MIXER/POWER AMPLIFIERS ...................................................................................................... 8

1781 Mic/ Line Input Module......................................................................................................10

DESCRIPTION................................................................................................................................................................................. 10

INSTALLATION OF OPTIONAL 1785A INPUT ISOLATION TRANSFORMER................................................................................ 10

CONFIGURING THE 1781A ............................................................................................................................................................ 10

PROGRAMMING THE 1781A .......................................................................................................................................................... 10

Mute”Priority” Mode of Operation ............................................................................................................................................. 10

Mute “Slave” Mode of Operation ............................................................................................................................................... 10

Mute “Off “ Mode of Operation .................................................................................................................................................. 11

Phantom Power ........................................................................................................................................................................ 11

REMOTE VOLUME CONTROL CONFIGURATIONS ...................................................................................................................... 11

Remote Volume Control Connections ....................................................................................................................................... 11

Alternative Configurations Using the RVC Circuitry for Preset Attenuation ............................................................................. 12

Simultaneous Remote Volume Control of Several Input Modules ............................................................................................ 12

CONNECTOR OPTIONS FOR THE 1781A ..................................................................................................................................... 12

USE OF HIGH LINE LEVEL INPUT SIGNAL SWITCH THE 1781A................................................................................................ 12

ALTERNATIVES TO THE EXTERNAL RESISTIVE PAD ................................................................................................................. 12

SPECIFICATIONS ............................................................................................................................................................................ 13

1783 Line Output Module...........................................................................................................14

CONFIGURING THE 1783 .............................................................................................................................................................. 14

CONNECTOR OPTIONS FOR THE 1783 LINE OUTPUT MODULE .............................................................................................. 14

INCLUDED ACCESSORIES: ........................................................................................................................................................... 14

INSTALLATION OF OPTIONAL 1786 OUTPUT ISOLATION TRANSFORMER .............................................................................. 15

VOX GATE ...................................................................................................................................16

DESCRIPTION................................................................................................................................................................................. 16

MODIFICATION A (REFERENCE FIGURE 1): ................................................................................................................................ 16

MODIFICATION B (REFERENCE FIGURE 1): ................................................................................................................................ 16

2

Page 3

DESCRIPTION

The 1700 Series Mixer/Power Amplifiers offer a highly flexible

integration of a user configurable six input mixer with a fully

protected power amplifier in one convenient cost effective

package.

The six input ports accept any of the several input modules or

output module. The programmable input modules may have their

muting circuitry configured in either “priority”, “slave” mode, or

may be set to ignore muting commands. When a module

configured in the “Priority” mode is activated, modules in the

“slave” mode will be muted.

Circuitry is also provided to allow remote volume control of

individual inputs.

Multiple mainframes may be dynamically linked together.

Separate preamp-out and amplifier-in jacks allow the insertion

of equalizers or other, signal processing between the mixer and

the power amplifier.

A multi-tone generator and a compressor/limiter are also

provided.

INCLUDED ACCESSORIES:

1 - Operating/Service Instruction documents.

1 - Shorting Bar (Installed on Direct Output to OT in).

1 - “U” Shorting Bar (Installed on Preamp Out to Amp In).

4 - Rubber Feet (installed).

1 - System Configuration Label installed on top cover.

1 - International fuse.

1 - International 220/240 VAC voltage sticker.

1 - International Fuse sticker.

1 - Rack mount hardware kit.

OPTIONAL INPUT OUTPUT ACCESSORY

MODULES:

1781A Programmable Input Module.

1781AT Programmable Input Module with 1785A 600 ohm

to 10 kohm isolation transformer installed.

1783 Line Output Module.

1785A 600 ohm to 10 kohm Input Isolation Transformer.

1786 600 ohm to 600 ohm Output Isolation Transformer.

1791 Female XLR Connector.

1792 Male XLR Connector.

1793 Dual RCA Phono Connector.

1794 5-Lug Screw Terminals.

ELECTRICAL CONNECTIONS FOR THE 1700

SERIES MIXER/POWER AMPLIFIERS

Power Connections (120 Volt, 50/60 Hz)

The mainframe configuration for both mixer/ power amplifiers

comes with the power transformer’s primary line voltage

strapped for 120-volt operation from the factory. Refer to Table

1 for exact strapping details and other voltage options.

NOTE:

Make sure the line voltage corresponds with the

selected line voltage power rating BEFORE you

connect the mainframe to the alternating current

line.

Power Connections (100, 200, 220, or 240 Volt; 50/60 Hz)

1700C/1715C Only

trahCgnippartSdnanoitceleSegatloVeniLCA.1elbaT

yramirP

eniL

egatloVetihWwolleYdeReulBegnarO

v001521193

V021251139

V002527018

V022527801

V042257801

roloCdaeLyramirPremrofsnarT

You may change the mixer/power amplifier’s 120-volt power

connection to a 100-, 200-, 220-, or 240-volt power connection

by restrapping the power transformer’s primary line voltage. Use

the following procedure to change the factory strapping to

another line voltage.

1. If you connected the mixer/power amplifier to an

alternating current power source, disconnect it.

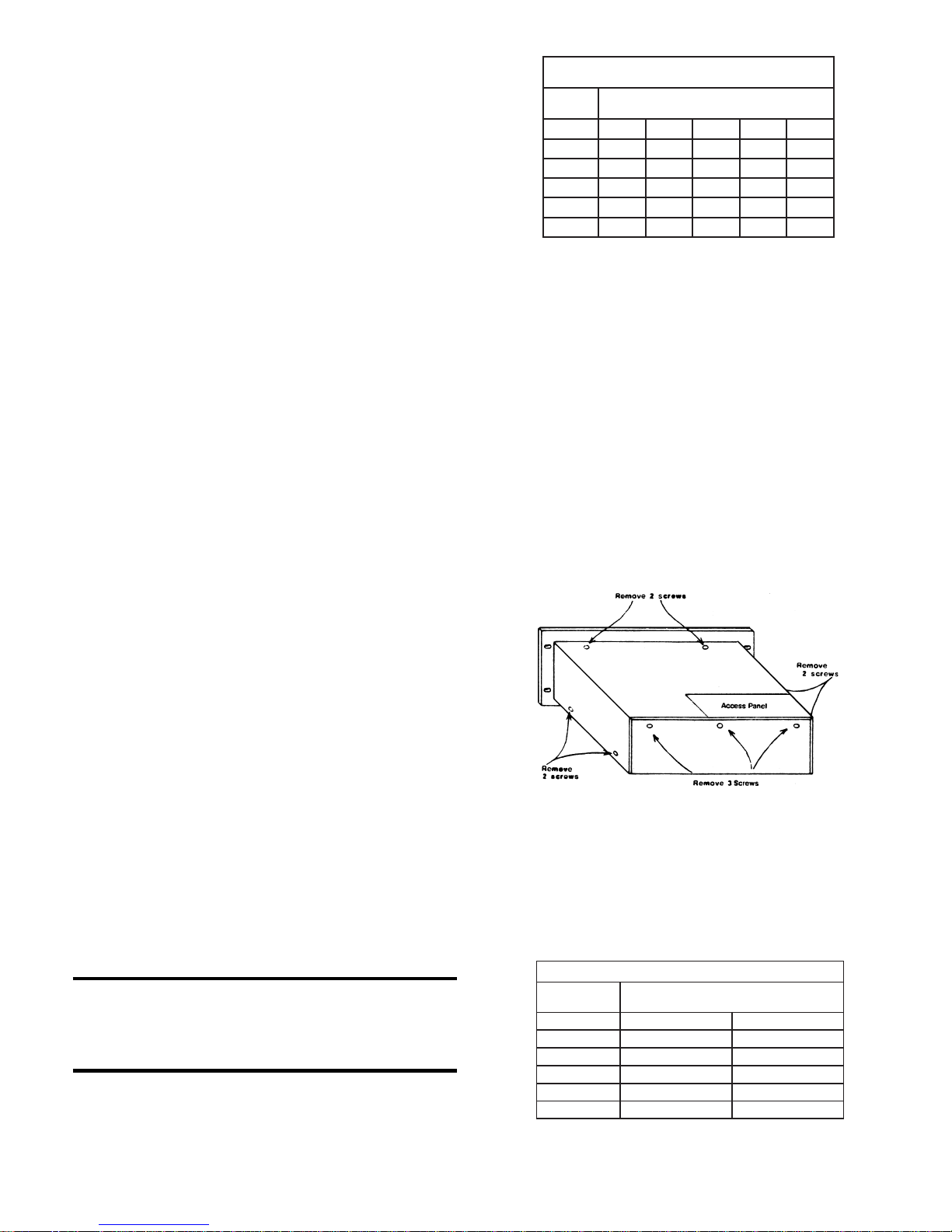

2. Remove and save the nine screws that secure the mixer/

power amplifier’s top cover. There are two screws near

the bottom of each side, two screws on top near the rear

edge of the front panel, and three screws at the top edge

of the rear panel. Refer to Figure 1 for details.

The numbers in Table 1 correspond to the numbered

positions on the alternating current terminal block

connector, which is adjacent to the power transformer. To

select a line voltage, install the colored primary lead wires

into the corresponding numbered positions on the terminal

block.

3. Locate the voltage selection terminal block between the

side of the chassis and the power transformer.

Figure 1. Top Cover Removal

4. While referring to Table 1, disconnect the primary lead

wires from the terminal block. Pull each wire firmly to

disengage the push-on connector. Then reconnect each

lead wire into its designated position on the terminal block

that corresponds to the desired line voltage. Press each

connector to snap into place.

trahCnoitceleSesuFCA.2elbaT

eniLCA

egatloV

C7071

V001V052/A5.3V052/A0.7

V021V052/A5.3V052/A0.7

V002V052/A0.2V052/A0.4

V022V052/A0.2V052/A0.4

V042V052/A0.2V052/A0.4

esuFeniLCA

C5171

3

Page 4

5. Install the appropriate fuse value from Table 2.

NOTE:

Use of fuses other than those listed in Table 2 will

VOID THE W ARRANTY .

6. If you connected the power transformer’s primary leads

for 200-, 220-, or 240-volt operation, perform steps 7, 8,

and 9 below to prevent future confusion and possible

damage to the amplifier. Otherwise, proceed with step

10 below.

7. Affix the supplied 220/240 VAC label above the power

cord and cover the 120 VAC silkscreened designation.

8. Affix the 2-amp fuse/1707C, (4-amp/

original 3.5 amp/1707C, (7-amp/1715C) silkscreened

designation.

1715C) label over the

9. Replace the standard AC line fuse with the 2-amp fuse/

1707C, (4-amp/1715C) supplied. You should find the

labels and the fuse enclosed in the plastic bag with this

manual. Refer to Table 2 for an AC fuse selection chart.

10.If you are not installing additional modules in the

mainframe right now, reinstall and secure the top cover

with the nine screws previously removed in step 2 above.

NOTE:

Y ou can buy and install additional modules into the

mixer/power amplifier , which has six ports that you

can configure as input or output modules.

INSTALLING MODULES IN THE MAINFRAME

1. Remove and save the two screws that secure the access

panel to the top cover. Refer to figure 1 for details.

2. Plug the input or output module into one of the six channel

positions with the controls facing the rear as shown in Figure

Figure 2. Module Installation

2. Secure the module with the two screws provided.

3. Remove the blank cover panel as shown in Figure 3. Install

the selected connector assembly with the screws provided.

Figure 3. Removal of Blank Cover Panel

Figure 4. System Configuration Label

Plug the pigtail connector (from the main connector

assembly) onto its appropriate male mating connector on

the module’s printed circuit board.

4. On the top cover is a System Configuration Label. Use it to

indicate the module type, configuration, and any options for

future reference. Write directly on the label with a permanent

marker. Refer to Figure 4 for a sample of this label.

SHELF OR RACK MOUNTING

You may shelf mount or rack mount the mainframe. For shelf or

countertop applications, four rubber feet on the bottom of the

chassis will protect resting surfaces and provide elevation for

air flow underneath the unit. For rack or cabinet applications,

remove the four rubber feet from the bottom of the chassis. Then

install the unit in the rack with the screws and shoulder washers

provided. The unit must have 1.75" of blank space both above

and below it.

Ventiliation

The mixer/power amplifier generates minimal heat during normal

use. Although the amount of generated heat is low, make sure

the mainframe is property ventilated to prevent an excessive

temperature rise. Because the output power devices (transistors)

are sensitive to heat, you should not place the amplifier between

other heat generating equipment or in areas where the ambient

temperature exceeds 50°C (122°F).

If you mount the mainframe in an equipment rack or cabinet

with other heat producing equipment, provide adequate space

between the units. Otherwise, the equipment may become too

warm.

If a rack or cabinet contains several amplifiers, you may need

to check the ambient air temperature. To determine the ambient

air temperature, operate the system until the temperature

stabilizes. Measure the ambient air with a bulb-type thermometer

held at the bottom of the uppermost amplifier.

4

Page 5

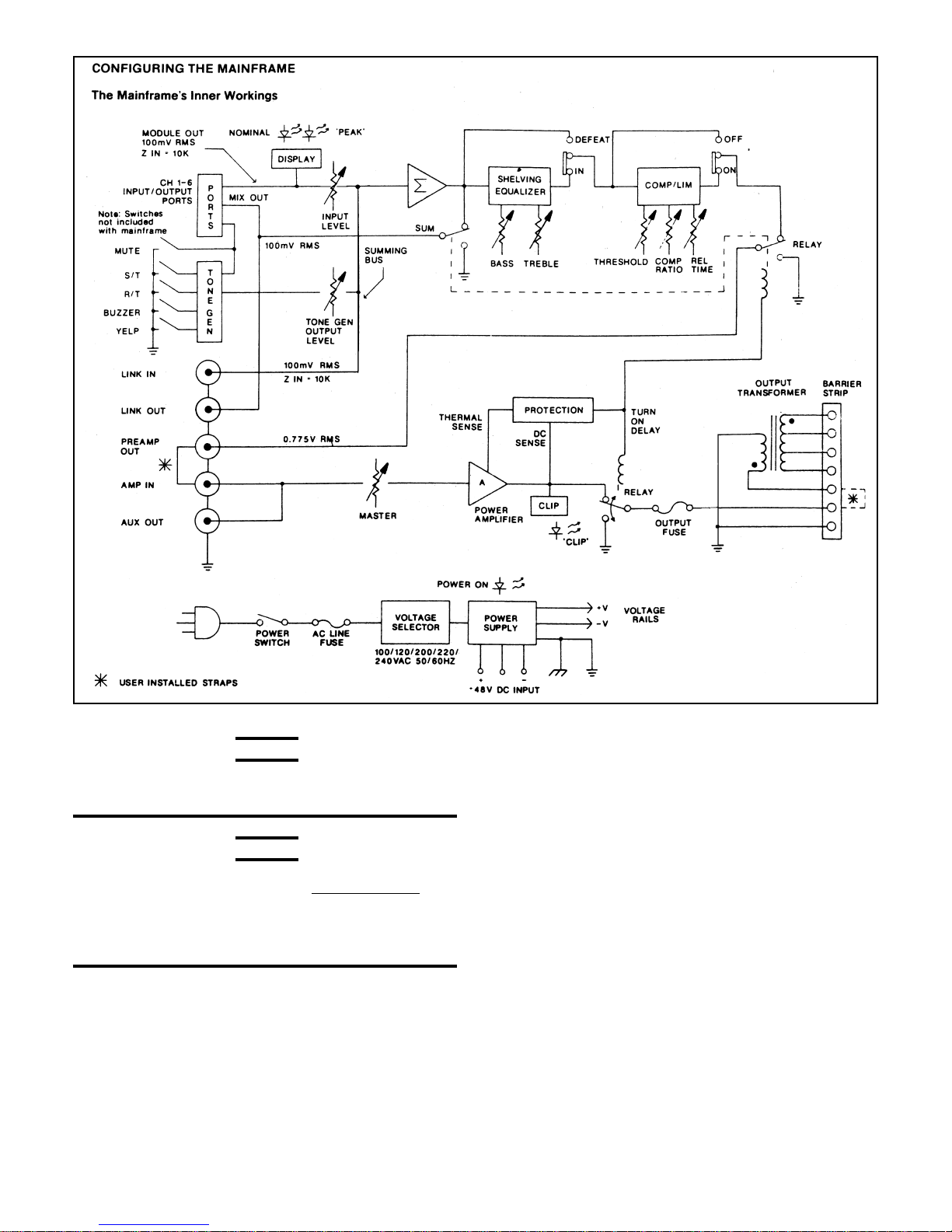

Figure 5. Block Diagram of 1707C / 1715C Mixer/Power Amplifiers

CAUTION

Don’t let the thermometer bulb touch the metal

chassis. The chassis might be hotter than the

ambient air.

CAUTION

If the air temperature exceeds 60°C (140°F), place

the equipment farther apart or install a blower to

provide air movement within the cabinet. Make sure

you don’t block the air intake holes located on the

bottom of the chassis or the exhaust holes on the

top cover.

Figure 5 above displays a block diagram of the mixer/power

amplifier mainframe. Study it carefully. To use the system’s full

capabilities, you’ll need a good understanding of the inner

workings of the mainframe. Brief explanations of how the inside

of the mainframe works follow in the text below.

The signal coming from each additional input module

simultaneously routed to the mixer/power amplifier’s front-panel

nominal/peak LED indicators and to the input channel level

controls. The dual LED nominal/peak displays are pre-fader and

designed to monitor the output level from the corresponding

input module. The nominal (green) LED indicators have an

approximate 10 dB window over which they will illuminate. This

makes it easy to properly adjust the gain for each input module

while efficiently using the rest of the system in terms of

performance and headroom.

The mixer/power amplifier then sums the signal at the wiper of

each input channel level control into a true virtual ground

summing node or bus. The summing amplifier has eight input

channels - input channels one through six on the front panel,

tone generator output, and the link input or LINK IN on the rear

panel. The summing amplifier’s output signal drives the link

output, or LINK OUT, located on the rear panel of the mainframe.

The E.Q. and compressor/limiter sections are in series with each

other, as shown in Figure 5. The compressor/limiter’s output

signal drives the preamplifier output, or PREAMP OUT, located

on the rear panel which then provides the input signal to the

main amplifier section.

The BASS and TREBLE E.Q. controls are ideally suited to make

adjustments to the overall response of the mix. The low and

high frequency shelving equalizers provide ±12 dB of boost

5

Page 6

and cut with the maximum boost occurring at 100 Hz and 10kHz

respectively.

The compressor/limiter section features variable release time,

compression ratio, and threshold. The circuit uses a feed-forward

topology that will minimize level differences for a more nearly

constant output level. The compression ratio can approach ¥ :1,

and the attack time is fixed at approximately 10 ms.

The main amplifier section protects itself and the load against

radio frequency interference, spurious oscillatory waveforms,

excessive temperatures, direct current, turn-on/turn-off

transients, and excess voltage/current phase shift due to reactive

loading.

A signal overload circuit monitors the level at the output stage

of the amplifier section. The front-panel CLIP LED indicator

illuminates when signal levels are high enough to cause

significant output clipping.

A dual slope V-I limiter protects the output devices. It keeps the

output devices operating within their SOA (safe operating area)

as defined by the device manufacturer.

A special integrated circuit function block monitors the heatsink

temperature, powersupply voltage, and the amplifier’s output.

When it detects a problem, it immediately disengages the output

relay.

Output Connections (1707C/1715C Only)

Make output connections to the seven-terminal barrier strip

connector located on the lower-left side of the mainframe’s rear

panel.

The 1707C main output connections include an 8 ohm direct

output (24.5 vrms) and three transformer balanced outputs; 4

ohm (17.4 vrms), 25 vrms (8.3 ohm), and 70.7 vrms (66.6 ohm).

The 1715C main output connections include a 4 ohm direct

output (24.5 vrms) and a 25 vrms (4.2 ohm), an 8 ohm (34.6

vrms), and a 70.7 vrms (33.3 ohm) balanced transformer output.

Refer to Figure 6 for a display of the direct output connections

and Figure 7 to see the transformer output connections.

Figure 6. Direct Output Connections

Output Fuse: A fuse in series with the output of the amplifier

section protects the amplifier from excessive current

consumption by a load. If this output fuse blows, replace it only

with a fuse that matches the same type and rating as

silkscreened on the rear panel of the unit. If the fuse continues

to blow. check the load to see if it shorted or is exceeding the

rated power consumption. If the problem continues, have a

qualified service technician service the unit.

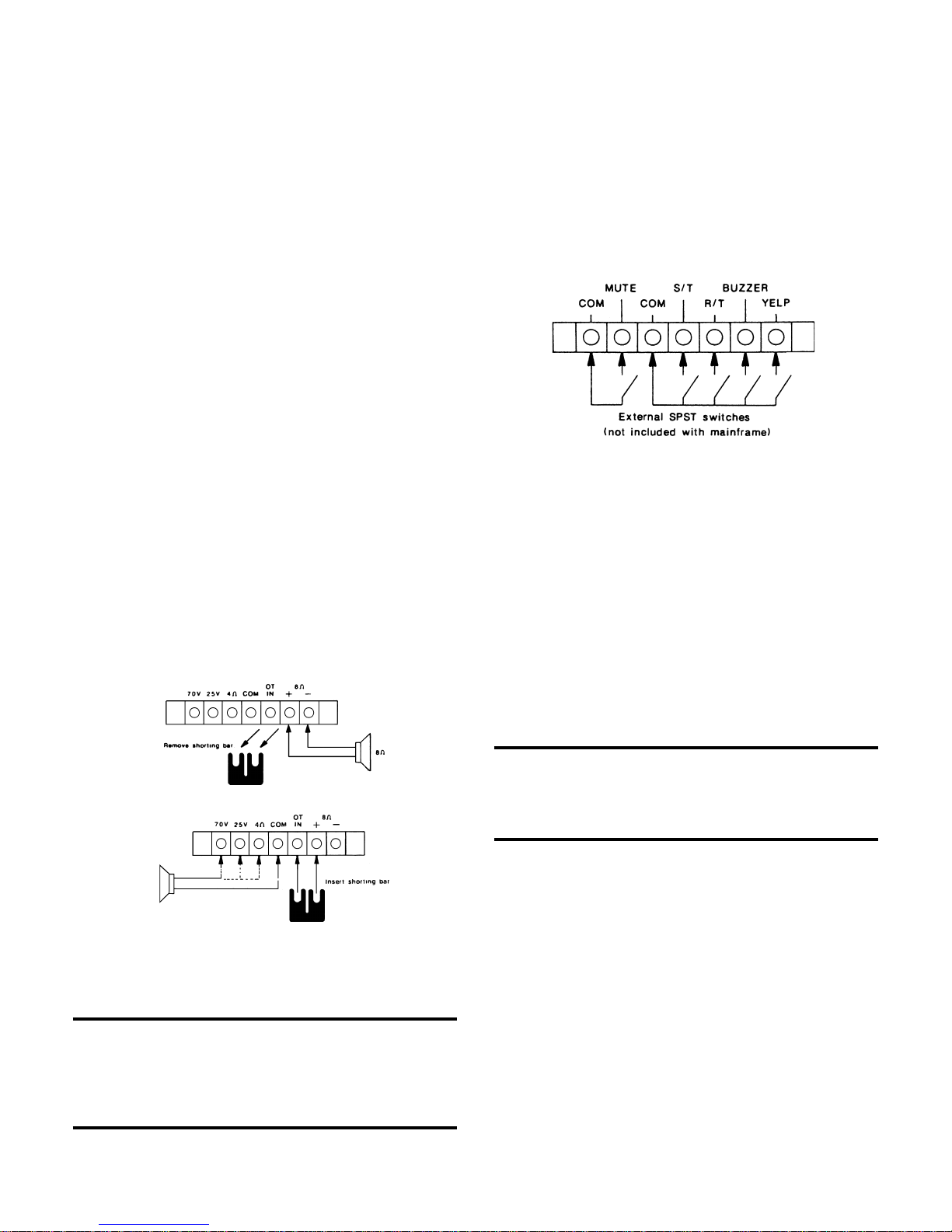

Mute/Tone Generator Connections

The seven-lug screw terminal connector located on the mid-left

rear of the mainframe provides access to the system mute and

tone generator. For connection details, refer to Figure 8.

Figure 8. Mute/Tone Generator Switch Connections

A switch closure between the mute and common (COM)

terminals will mute any input modules configured in the slave

mode. You can use the remaining switches to select one of the

following sounds:

A single-tone chime (S/T),

A repeating-tone chime (R/T),

A buzzer, or

A yelp (siren).

For the duration of a tone, the tone generator automatically

mutes any input modules configured in the slave mode.

Output-Level Control:

The tone generator’s output-level control is conveniently located

on the rear panel of the mainframe. To increase the tone

generator’s output level, rotate the screwdriver-slotted control

shaft clockwise.

NOTE:

Optional External Mute, (connected at the factory)

allows external muting of the tone generator. If

disconnected, the tone generator cannot be

externally muted.

Figure 7. Transformer Output Connections

To use a transformer balanced output, install a U shorting bar

between the direct (+) output and the output transformer’s input

(OT IN).

NOTE:

When using the output transformer, you may use

any combination of output connections as long as

the total connected load does not consume more

than 75 watts for the 1707C or 150 watts for the

1715C.

Resistance Effects of Long-Cable Runs on Mute/Tone

Generator Circuits:

Table 3 shows the maximum allowable cable resistance (total

resistance) that the mixer/power amplifier can support.

Resistances greater than these values, resulting from

excessively long-cable runs or small gauge wire, may cause

the mute or tone generator circuitry to fail to operate. Please

make sure all cable resistances are less than the values shown

in Table 3.

6

Page 7

Table 3. Maximum Allowable Cable Resistances

noitcnuF)smho(ecnatsiseR

emihCT/Sk31

emihCT/Rk8.51

rezzuBk8

pleYk8

etuMk8

LINK IN/LINK OUT Connections

The LINK IN/LINK OUT phono connectors on the mid-rear panel

of the mainframe permit you to dynamically

link

two or more

systems together. If you require more channels, the 1707C/

1715C mixer/power amplifiers are fully compatible with 1700C

mixer/preamplifier.

The signal appearing at the LINK OUT connector is the

summation of all input channels as mixed by the input channel

level controls. LINK IN is a direct input to a system’s mixing

amplifier; it’s also a seventh input channel.

To link two units together, connect LINK OUT of system one to

LINK IN of system two. System two will now control the mix of

up to twelve input channels. Please refer to Figure 9 for typical

linking connections.

NOTE:

The LINK OUT signal is not affected by the

compressor/limiter or the E.Q. circuits.

PREAMP OUT/AMP IN CONNECTIONS

The PREAMP OUT signal is a mix of all input channels

processed by the compressor/limiter and tone control circuits.

Normally, you would insert a U shorting bar between the

PREAMP OUT and AMP IN phono connectors on the rear panel.

However, you can remove the shorting bar to patch in an external

equalizer or other signal processing device with a proper level

match of 0.775 vrms nominal. Figure 10 shows a typical

application using an external equalizer or other signal processing

device.

Figure 10. Patching an External Equalizer or Other Signal

Processing Device

AUX OUT CONNECTIONS

The auxiliary output (AUX OUT) phono connector on the rear

panel is wired directly (internally) to the AMP IN phono connector.

You can use it to drive a second amplifier or a tape recorder.

Please refer to the 1707C/ 1715C mixer/power amplifier’s block

diagram shown in Figure 5.

BA TTERY INPUT CONNECTIONS

You can power a system from the battery input connector for

auxiliary operation or standby switchover. The battery input

connector is the three-terminal barrier strip located on the

upper-left rear panel of the mainframe. The system requires

two ±48V DC battery power sources.

To connect the battery backup system to the three-terminal

barrier strip, follow the three steps shown in Figure 11.

Figure 9. Typical Linking Connections

Figure 11. Battery Input Connections

7

Page 8

FRONT/REAR-PANEL CONTROLS, SWITCHES,

INDICA TORS, AND CONNECTORS

Figure 12 below displays the front panel on the mixer/power

amplifier with numbers that point at each control, indicator, and

switch. You can find the corresponding number and name

description for each control, switch, or indicator in the text below.

Figure 12. Front-Panel Control, Switches,

and Indicators for the 1707C

5

13

4 3 6 9 7 10 11 8 12 1 2

INITIAL SETUP AND OPERA TION OF

metIemaNnoitpircseD/noitcnuF

1hctiwSREWOPhsup-hsupnoitisop-owT.rewopyramirpseilppA

2rotacidnIDELNOnehwhctiwsREWOPnoyalpsiddersetanimullI

3slortnoC6-1HC

4DELlauDdeR/neerG

srotacidnI

5DLOHSERHT

lortnoC

6EMITESAELER

lortnoC

7NOISSERPMOC

OITAR

lortnoC

8hctiwSFFO/NOehtfotuoronitiucricretimil/rosserpmocsecalP

9lortnoCSSAB

01lortnoCELBERTsedivorP.retemoitnetopelbairavylsuounitnoC

11TAEFED/NIQE

hctiwS

21leveLRETSAM

lortnoC

31rotacidnIDELPILCdaolrevolangislanretninanehwsetanimullI

:STUPNI sretemoitnetopelbairavylsuounitnoC

.htaplangis

:TUPTUO .retemoitnetopelbairavylsuounitnoC

.slortnoc

morf ∞ esaercniylsuoenatlumisottiesU.Bd0ot

.level

.edomffo/norofhctiws

.rewopnonrutuoy

morfdetaudarg ∞∞∞∞∞ roesaercninacuoY.Bd0ot

gnidnopserrochcaeroflevelesaerced

levelesaercniotesiwkcolcetatoR.lennahctupni

.levelesaercedotesiwkcolcretnuocdna

:LEVELTUPNI

)der(kaepdna)neerg(lanimonsyalpsiD

.lennahchcaerofnoitacidni

:RETIMIL/ROSSERPMOC elbairavylsuounitnoC

hcihwtalevelehtsenimreteD.retemoitnetop

.snigebgnitimil

lamronotnruterotmetsysehtrofderiuqereht

.dlohserhtwolebsllaflangisretfa

ehtybtessi,dlohserhtehtsdeecxeleveleht

.lortnocDLOHSERHT

nacuoY.esnopserssabnitucrotsoobsedivorP

.gnittesorezataesnopsertalfrolamronniatbo

roesnopsertsoobotesiwkcolcetatoR

.esnopsertucotesiwkcolcretnuoc

niatbonacuoY.esnopserelbertnitucrotsoob

.esnopsertucot

noitisopTAEFED.hctiwsnoitisop-owT

nehwslortnocELBERTdnaSSABstcennocsid

-atsuocAsahcus.noitacilpparofetairporppa

detaudargretemoitnetopelbairavylsuounitnoC

esiwkcolcetatoR.slennahctupnillaesaercedro

yamtahtslevellangistuptuohgihstcetedtiucric

.gnippilctuptuoesuac

MAINFRAME WITH MODULES INSTALLED

Initial Setup of an Input Module

You can buy and install the following input modules from

ElectroVoice:

The 1781A programmable input module. The 1781AT

programmable input module with 1785A input isolation

transformer, and the 1780A and 1780AT mic/line input modules.

To initially set up an input module, follow these steps:

1. Rotate the input module’s gain control to the 12:00 o’clock

(MID) position for planned microphone inputs or to the

MIN (fully counterclockwise) position for line-level inputs.

If the input type is unknown, rotate the gain control to the

MIN position.

2. Rotate the high-cut (HF) filter to the FLAT

position.

3. Rotate the low-cut (LF) filter to the FLAT

position.

Initial Setup of an Output Module

You can buy the 1783 line output module from ElectroVoice.

This module can be installed with or without the optional 1786

output isolation transformer (also available from Altec Lansing).

To initially set up an output module, rotate the output module’s

output level control (labeled GAIN on the rear panel) to the MIN

position.

Initial Setup of the Mainframe

1. Rotate the MASTER output level control on the front panel

of the mainframe to the position (fully counterclockwise).

2. Set the compressor/limiter ON/OFF switch to the OFF

position.

3. Set the tone control EO IN/DEFEAT switch to the DEFEAT

position.

Operating the 1700 Series Mixer/Power Amplifiers

senimreteD.retemoitnetopelbairavylsuounitnoC

senimreteD.retemoitnetopelbairavylsuounitnoC

etatoR?gnittesorezataesnopsertalfrolamron

esiwkcolcretnuocroesnopsertsoobotesiwkcolc

ELBERTdnaSSABehtstcennocNIQE.gnicioV

esaercedotesiwkcolcretnuocrolevelesaercniot

1. Connect a source representative of the type of input signal

to one of the input module positions, if any. Slowly rotate

the input module’s gain control clockwise until the mixer/

power amplifier’s green LED display (-10 dB) on the

input-level front panel section fully illuminates. This is the

nominal level for providing the most efficient performance

and headroom.

The mixer/power amplifier’s red LED display may briefly

illuminate on signal peaks. This is permissible as long as

it does not flash more than fifty percent of the time. If it

does, reduce the gain of the input module by rotating its

gain control counterclockwise or use an external pad.

NOTE:

The LED display precedes each frontpanel

input-level control. As a result, it will alwa ys indicate

the nominal and peak levels regardless of input

channel settings. Please refer to the mainframe

block diagram shown in Figure 5.

8

Page 9

Table 4 below lists the function/descritption of each connector

or control on the rear panel on the mixer/power amplifier.

Table 4. Rear-Panel Control and Connectors for the 1707C

emaNnoitpircseD/noitcnuF

lenaPrevoCknalBtsniagastcetorP.selohgnitnuomrotcennocsrevoC

rotcennoCTUOKNIL foTUOKNILgnitcennocybrehtegotstinuowtenibmoC

rotcennoCNIKNIL -ACRnasisihT.reifilpmaehtottupnitceridasedivorP

TUOPMAERP

rotcennoC

rotcennoCNIPMA -ACRnasisihT.reifilpmaehtottupnitceridasedivorP

TUOXUAlangisehtfotuptuoyrailixuanasedivorProtcennoC

wercSguL-neveS

rotcennoClanimreT

LEVELTUPTUO rotarenegenotehtfoleveltuptuoehtesaercnIlortnoC

lanimreT-neveS

pirtSreirraB

rotcennoC

)yln0C5171/C7071(

pirtSgnitrohSUtuptuofotupniotreifilpmafotuptuostcennoC

ESUFTUPTUO .reifilpmamorftnerrucevissecxetsniagadaolstcetorP

tupnIyrettaB

rotcennoC

ESUFCAnamorfniardtnerrucevissecxetsniagastcetorP

DNGyrailixuatcennocuoystellanimretdnuorgehT

.rotcennoconohpepyt

.rotcennoconohpepyt-ACRna

.rotcennoconohp

.stiucricrotarenegenotdnaetums’metsys

.esiwkcolcretnuoc

.stuptuo

.C5171ehtrofspma3dnaC7071

.gnitarrewopdnaepyt

.emarfniamehtottnempiuqe

.rotcennocdnatropgnisutonnehwsegatlovlanretni

-ACRnasisihT.owtmetsysfoNIKNILotenometsys

.)smrvm001,zHk1.fer(rotcennoconohpepyt

rexims’tinuneewtebtnempiuqeyrailixuahctapotesU

yllamronsiTUOPMAERP.reifilpmarewopdna

rotcennocTUOPMAERPehT.NIPMAotdepparts

sisihT.lortnoclevelRETSAMlenap-tnorfehtsedecerp

.)smrvm577.,zHk1.fer(rotcennoconohpepyt

epyt-ACRnasisihT.tupnis’reifilpmaehttagniraeppa

ehtetarepootsehctiwslanretxefonoitcennocstimreP

tfahslortnocdettols-revirdwercsehtgnitatoryb

tietator,leveltuptuoehtesaercedoT.esiwkcolc

.reifilpmaehtotsdaolsuoiravfonoitcennocstimreP

remrofsnartehtylnoesu,ecalpninehW.remrofsnart

.gnitarrewopdnaepytesufemasehthtiwylnoecalpeR

yrailixuarofylppusyrettabmorfmetsysrewopotesU

V84±enoseriuqeR.revohctiwsybdnatsronoitarepo

ehtrofmumixamspma5.1,ecruosrewopyrettabCD

esufemashtiwylnoecalpeR.ecruostnerrucgnitanretla

2. Once the gain is set for each input module channel, rotate

the front-panel input-level channel controls (CH 1-6) on

the mixer/ power amplifier to their 12:00 o’clock (MID)

position. Slowly increase the MASTER output level control

on the front of the mainframe until you hear a normal

operating level through the loudspeaker system. Then

readjust the input-level channel controls slightly for the

desired mix or blend of signals.

3. Adjust the high-cut (HF) and low-cut (LF) filters on the

input module as needed for the desired response. The

widest possible bandwidth occurs when you rotate both

of these controls to the FLAT position. This is the best

setting for music. However, in speech-only channels, you

should limit the bandwidth to help reduce noise and

system feedback.

4. To use the mixer/power amplifier’s output tone-control

section, move the two-position EQ IN/DEFEAT slide

switch to the EQ IN position. Then adjust the BASS and

TREBLE controls for the desired response. From a center

or 12 o’clock (MID) position, rotate either control clockwise

to boost response or counterclockwise to cut response.

If using the tone-control section is inappropriate for current

applications, such as Acousta-Voicing, move the EQ IN/

DEFEAT slide switch to the DEFEAT position. This

disconnects the BASS and TREBLE controls.

5. To use the compressor/limiter section, follow this

procedure:

Move the slide ON/OFF switch to the ON position.

Rotate the RELEASE TIME control to its maximum

position (full clockwise).

Rotate the COMPRESSION RATIO control to minimum

position (full counterclockwise).

Rotate the THRESHOLD control to its 12 o’clock (MID)

position.

Begin increasing the compressor/limiter by rotating the

COMPRESSION RATIO control clockwise until you

achieve the desired amount of compression or limiting.

Since the amount of compression or limiting depends on

the incoming signal level, you may need to readjust the

THRESHOLD control. To lower the triggering threshold,

rotate the THRESHOLD control counterclockwise. If the

system requires a higher incoming signal level to trigger

the compressor/limiter, raise the threshold by rotating the

THRESHOLD control clockwise.

NOTE:

A high compression ratio and a low threshold

setting may decrease the system’s apparent

loudness since peak signals and parts of the

nominal signal may be above the threshold. You can

correct this by raising the threshold level; just rotate

the THRESHOLD control clockwise.

6. If you installed the 1783 line output module, adjust the

output level control on the 1783 for the desired output

level. The higher the output level, the better the

signal-to-noise ratio. However. too high a level reduces

the available headroom and may cause premature

clipping.

NOTE:

If you set the 1783’s output level control at its MAX

(full clockwise) level, the output level is +8dBm.

However. this level only applies if you use a 100

mvrms reference level on the input of the output

module from the mix output bus. It also only applies

if you have a balanced 600 S2 load.

9

Page 10

1781 Mic/ Line Input Module

DESCRIPTION

The ELECTRO-VOICE 1781A program mable input module

accepts either mic or line level signals through a wide variety of

connector interfaces. Standard features include an electronically

balanced input stage with adjustable gain, continuously variable

high and low pass filters, RFI protection, 36 volt phantom

powering two levels of muting, and remote control capability.

Programming is accomplished with plug-in jumpers which may

select phantom power (on or off), mute priority or slave, or remote

volume control. ELECTRO-VOICE also offers the 1781AT, a

programmable input module with a Transformer installed.

INSTALLATION OF OPTIONAL 1785A INPUT ISOLATION

TRANSFORMER

1. Remove the two wire jumpers with ferrite beads,

designated FB1 and FB2, near the upper right corner of

the module when looking at the component side of the

circuit board. Refer to Figure 1 for details.

2. Thread the four wires from the transformer through the

larger center hole from the component side. Secure the

transformer with the two screws and washers provided.

3. Lay the module on the component side (circuit side up)

and attach the four wires as shown in Figure 2.

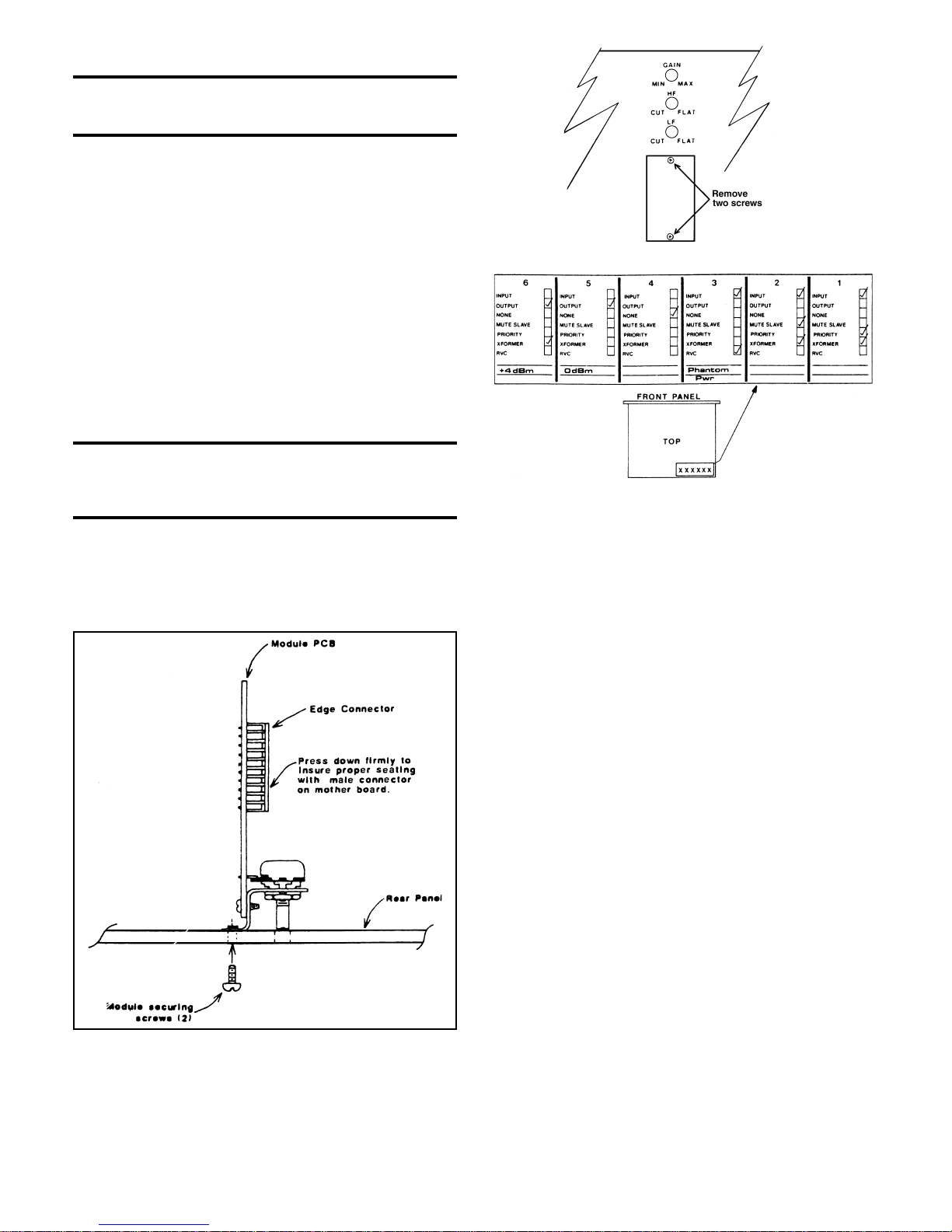

CONFIGURING THE 1781A

A block diagram of the 1781A input module is shown in Figure

3. Study the diagram carefully and refer to it as needed.

PROGRAMMING THE 1781A

Mute”Priority” Mode of Operation

In the priority mode, a signal applied to the designated priority

channel will cause all other input channels configured in the

slave mode to be fully attenuated.

To configure an input module for the priority mode, install a

2-pin female jumper onto J4, the 2-pin male header connector

located near the lower right corner of the module as shown in

Figure 1.

Any number of channels can be configured in the priority mode,

however, activity in one priority channel will not attenuate the

other priority channels.

Mute “Slave” Mode of Operation

In the slave mode, a module (or all slave modules) will be fully

attenuated either during activity in the priority channel, switch

closure between the MUTE and COM (common) terminals of

the 7-lug screw terminal connector located on the rear of the

mainframe, or a switch closure between the common and any

one of the tone generator control inputs (for the duration of the

tone).

Figure 1. Optional 1781A Configuration

10

Page 11

Figure 2. 1785A Input Transformer Connections

To configure the module for the slave mode, install a 2-pin female

connector onto J5, the 2-pin male header connector located

near the right edge of the module as shown in Figure 1.

Mute “Off “ Mode of Operation

By not installing a jumper in either the priority (J4) or slave (J5)

position, the channel can not be muted, or cannot mute other

channels.

Phantom Power

To enable phantom powering of condenser microphones, install

a 2-pin female jumper onto J6, the 2-pin male header connector

located near J1 as shown in Figure 1. This will apply +36 VDC

to each side (“+” and “-”) of the microphone’s signal lines.

Figure 4. Remote Volume Control Applications

REMOTE VOLUME CONTROL CONFIGURA TIONS

Remote V olume Control Connections

A remote volume control (RVC) may be used with the

5-lug screw terminal connector assembly to vary the output level

of the input module. The resistance setting of a potentiometer

determines the amount of attenuation in the voltage -controlled

attenuator (VCA). Since only DC is present on the potentiometer

(no audio signal), the pot may be located long distances from

the mainframe. The RVC function is usable regardless of the

mute circuit’s mode of operation.

To implement a remote volume control, connect an audio taper

potentiometer (10 kohm or greater) between pins 4 and 5 of the

1794. Refer to Figure 4a.

1794

Figure 3. Block Diagram of the 1781A Input Module

11

Page 12

Alternative Configurations Using the RVC Circuitry for

Preset Attenuation

A variation of the remote volume control is shown in Figure 4b.

A switch in series with a fixed value resistor “R” may be used to

attenuate (or mute) the channel to a predetermined level. If the

resistor is removed and replaced with a zero ohm jumper, a

switch closure will fully attenuate the channel. Table 1 shows

typical attenuation values expected for various values of resistor

“R”.

NOTE:

VR001

(located near J1) calibrated for 60 dB of

attenuation, with pins 4 & 5 of the 1794 shorted.

Simultaneous Remote Volume Control of Several Input

Modules

It is possible to parallel pins 4 and 5 of several 1794 5-lug screw

terminal connectors to permit one potentiometer (connected

between the pins 4 and 5) to control the modules simultaneously.

This technique works reasonably well with an audio taper

potentiometer 10 kohm or greater). To insure that the channels

track throughout the range of attenuation, each module’s

attenuation-adjust potentiometer, VR001, should be adjusted

for the same maximum attenuation.

Table 1. Resistance Table for Fixed Attenuation

noitaunettAfotnuomA

).pyTBd2±(

Bd01mhok08.2mhok7.2

Bd02mhok05.1mhok5.1

Bd03mho788mho019

Bd04mho115mho015

Bd05mho191mho002

Bd06mho0mho0

Connector Options for the

The

1781A

programmable input module has two 5-pin male

%1%5

1781A

)W4/1(RfoeulaVetamixorppA

header connectors (J1 and J2) which are used to interface the

1790-series of connector assemblies. Due to circuit differences

between a balanced mic input (“+” and “-”) and a tape input (L

and R), use J1 with the

should only be used with the

1791, 1792,

1793

dual phono connector. Please

or

1794.

Connector J2

refer to Figures 1 and 3 for additional information.

NOTE:

When using the 1793 dual phono connector

assembly , insure that the phantom po werjumper is

removed from J6.

The pinouts of the connectors are shown in Table 2. Figure 5

shows how external equipment may be connected to the 1781A

through the various connector choices.

Table 2. Connector Assembly Wiring

197129714971

.oNniPF-RLXM-RLX.mretwercsgul-5

1)dleihS(dnG)dleihS(dnG)dleihS(dnG

2)iH(ni+)iH(ni+)iH(ni+

3)oL(ni-)o,.I(ni-)oL(ni-

4)sahC(llehS)sahC(llehSCVR

5A/NA/NdnGCVR

NOTE:

Only one input connector assembly may be used

with the 1781A programmable input module at a

time.

Use of High Line Level Input Signal switch the 1781A

The sensitivity of the electronically balanced input stage at

minimum gain is approximately 100 mVrms. Therefore it may

be necessary to pad the incoming line if its nominal level exceeds

-18 dBu 100 mVrms), or -28 dBu (30 mVrms) when usIng the

1781AT refer to Table IV for a suggested pad and the required

attenuation for various input levels.

Alternatives to the External Resistive Pad

The ferrite beads, FB1 and FB2, can be replaced by resistors.

For example, replacing the ferrite beads with 91 kohm resistors

will reduce the sensitivity by nearly 20 times (at minimurn gain)

enabling a nominal level of +8 dBu. (1.95 Vrms) to produce

rated output from the module (100 mVrms). Refer to Table 3 for

the approximate resistor values required for other input levels.

Table 3. Resistor Replacements for FB1 & FB2

to Reduce Sensitivity of 1781A

)ubd(leveLtupnIlanimoN

8+mhok19

2+mhok74

2-mhok03

6-mhok1.5

01-mho3.4

2BF&1BFecalpeR

wolebseulavhtiw

If the 1781AT is used, it is also possible to select a resistor from

Table IV and connect it between pins 4 and 5 of the 1794 5-lug

screw terminal connector (or directly to J1-4 and J1-5 on the

printed circuit board). This technique works by increasing the

attenuation in the VCA. It should not, however, be used on input

signal levels above -2 dBu. With higher levels (requiring more

attenuation in the VCA), the distortion through the VCA

increases. Therefore, if the application requires that the input

module handle nominal line levels in excess of -2 dBu, the

external resistive pad offers the best performance.

12

Page 13

Figure 5. Typical Input Module Connections

Table IV Attenuator Pad Resistance Values

)smhoni(daProfseulaVrotsiseR

langiS

leveL

uBd81-enoN-----------------uBd8-Bd01451051224034406026

uBd4-Bd41002002942042406026

uBd0Bd81232042451051406026

uBd01+Bd824720725.7474406026

langiS

leveL

uBd82-enoN------------------

uBd81-Bd01451051224034406026

uBd8-Bd02342042121021406026

uBd4-Bd421620725757406026

uBd0Bd824720725.7474406026

uBd01+Bd834920035151406026

fotnuomA

noitaunettA

fotnuomA

noitaunettA

1R2R3R

%1%5%1%5%1%5

)smhoni(daProfseulaVrotsiseR

1R2R3R

%1%5%1%5%1%5

SPECIFICATIONS

A1871tupnIdecnalaByllacinortcelE

1781A PROGRAMMABLE INPUT MODULE

Gain: ..............................0 dB to 50 dB, continuously variable

10 dB to 60 dB w/1785A

Input Sensitivity:

(Ref. 1 kHz, 0 dBr = 100 mVrms output, 10 kQ load)

Without 1785A: ....................... 0.3 mVrms to 100 mVrms

(-50 dBr to 0 dBr)

With 1785A: .............................. 0.1 mVrms to 30 mVrms

(-60 dBr or -10 dBr)

Input Impedance: (Ref. 1 kHz)

TA1871tupnIdecnalaByllacinortcelE

Electronically balanced: ..................................... >8 kohm

Transformer balanced: .................... 200 ohm to 600 ohm

With 1793 installed: ......................................... >39 kohm

Frequency Response: (Ref. 1 kHz, 100 mVrms output, 10

kohm load)

Without 1785A:

±1 dB (Minimum gain): .......................... 20 Hz to 40 kHz

±1 dB (Maximum gain): ......................... 50 Hz to 40 kHz

±3 dB (Minimum gain): .......................... 10 Hz to 80 kHz

±3 dB (Maximum gain): ......................... 25 Hz to 80 kHz

With 1785A:

±1 dB (Minimum gain): .......................... 20 Hz to 25 kHz

±1 dB (Maxim.um gain): ........................ 40 Hz to 15 kHz

±3 dB (Minimum gain): .......................... 10 Hz to 50 kHz

±3 dB (Maximum gain): ......................... 20 Hz to 30 kHz

Total Harmonic Distortion (THD):

(Ref. I kHz, 100 mVrms output, minimum gain, 10 kL2 load, 30

kHz low pass filter)

20 Hz to 20 kHz: .................................................. <0.03%

Equivalent Input Noise: ........................................ <-120 dBr

(Ref. 0 dBr = 100 mVrms output, 10 kohm load, 2000 ohm input

termination maximum gain, A-weighted)

13

Page 14

High Pass Filter (Low Cut):

(Ref., 100 mVrms output, minimum gain, 10 kQ load)

Fl: .......................................... 320 Hz (>10 dB at 100 Hz)

Slope: ............................................... 6 db/oct (20 db/dec)

Low Pass Filter (High Cut):

(Ref. 100 mVrms output, minimum gain, 10 kQ load)

Fl: ............................................... 5 kHz (>6 dB at 10 kHz)

Slope: .............................................. 6 dB/oct (20 dB/dec)

Attenuation:

(Ref. 1 kHz, 100 mVrms output, 10 kohm load)

Mute: ..................................................................... >60 dB

10 kohm remote

Optional Accessories:

1785A Input Isolation Transformer

1785A INPUT ISOLATION TRANSFORMER

V oltage Gain:................................................................. 10 dB

1783 Line Output Module

CONFIGURING THE 1783

A block diagram of the 1783 line output module is shown in

Figure 1. Study and refer to the diagram as needed during the

following sections.

CONNECTOR OPTIONS FOR THE 1783 LINE

OUTPUT MODULE

The 1783 line output module can use any of the 1790-series

connector assemblies. The connector assembly wiring is shown

in Table 1. A detailed drawing showing typical output module

connections to external equipment is shown in Figure 2.

Impedance Ratio: ................................................ 600il: 10 kil

(Primary: Secondary)

Frequency Response (Ref. I kHz, 100 mVrms output)

±1 dB: .................................................... 40 Hz to 20 kHz

±3 dB:..................................................... 20 Hz to 40 kHz

Total Harmonic Distortion (THD): (Ref 1 kHz, 100 mVnns

output)

50 Hz - 20 kHz: ...................................................... <0.2%

Insertion Loss: .............................................................<1 dB

(Ref. 1 kHz, 100 mVrms output)

Included Accessories:

2 - Mounting screws

1 - Flat washer

Table 1. Connector Assembly Wiring

197129714971

.oNniPF-RLXM-RLXmretwercsgul-5

1)dleihS(dnG)dleihS(dnG)dleihS(dnG

2)iH(nI+)iH(nI+)iH(nI+

3)oL(nI-)oL(nI-)oL(nI-

4)sahC(llehS)sahC(llehSCVR

5A/NA/NdnGCVR

Figure 1. Block Diagram of the 1783 Line Output Module

14

Page 15

Figure 2. Block Diagram of the 1783 Line Output Module

The 1783 line output module has an electronically-balanced

(differential) output providing high drive capability with low

distortion.

It resembles a power amplifier’s output in the bridge mode. If

the output module is required to drive an unbalanced load, DO

NOT strap the low side of the output (Pin 3 of 1791, 1792 and

1794) to ground. This could cause overheating and possible

damage to the integrated circuit. Connect only between the “+”

output (Pin 2) and ground (Pin 1). This will result in a 6 dB

decrease in output level (or a 3 dB decrease in output power).

However, the output level control can easily compensate for the

loss.

When using the 1793 dual phono connector, it is necessary to

restrap the inverting “-” output jumper wire (connected to the

operational amplifier’s inverting output) to the amp’s

non-inverting output. This will put the same polarity signal on

both phono connectors. Refer to Figures 1 and 3 for additional

information.

INSTALLATION OF OPTIONAL 1786 OUTPUT

ISOLA TION TRANSFORMER

The following outlines the installation of the 1786 transformer:

1. Remove the two wire jumpers near the lower left corner

of the module. Refer to Figure 3.

2. Install the 1786 output isolation transformer in the position

shown in Figure 3.

3. Lay the module on the component side (circuit side up)

and solder the transformer in place.

Figure 3. Optional 1783 Configuration Layout Guide

15

Page 16

VOX GATE

DESCRIPTION

The ELECTRO-VOICE 1781A programmable input module can

be modified to become a current controlled gate with a adjustable

threshold. There are two applicable modifications, A and B. The

A modification will stand alone (gated only by its input). The B

modification will be gated by the external mute, and/or other B

modified modules.

The advantages to using the VOX GATE modification is to reduce

or eliminate noise on open microphone lines. The VOX GATE

supresses extraneous noise from entering mixer inputs from

open microphone lines or from inactive microphones. This results

in increased quietness of sound systems of all sizes. After

installation of the VOX GATE modification a 1781A or 1781AT

will operate within all of the original specifications.

MODIFICATION A (refer to Figure 1):

1. Remove capacitor C001 (47 mF) and C002 (.01 mF).

2. Remove resistor R101 (47 kohm).

3. Remove resistor R113 (10 kohm)

4. Connect a resistor from the junction of C102/R101 and

the junction of C224 (negative side) and MCL703C

(resistor value will depend on the required threshold, from

5 kohms to 50 kohms, refer to Figure 1 and Table 1).

5. Place a jumper trace across transistors Q103 and Q105

(PNP 2SC1815Y) collectors.

6. Priority jumper must be removed.

modification B (reference Figure 1):

1. Remove capacitor C001 (47 mF) and C002 (.01 mF).

2. Remove resistor R101 (47 kohm).

3. Remove resistor R113 (10 kohm).

4. Connect a resistor from the junction of C102/R101 and

the junction of C224 (negative side) and MCL703C

(resistor value will depend on the required threshold, from

5 kohm to 50 kohm, refer to Figure 1 and Table 1).

5. Place a jumper trace across transistors Q103 and Q105

(PNP 2SC1815Y) collectors.

6. Priority jumper must be in place.

Table 1. Threshold Sensitivity Resistive Value Reference: 1 kHz,

1781A (-18 dBu = 0 dBr In, Linkout 100 mVrms 10 kohm Load).

1781AT (28 dBu = 0 dBr In, Linkout 100 mVrms 10 kohm Load.

ytivitisneSdlohserhT

Bd1±rBd

rBd05.12mhok99.4

rBd57.71mhok0.01

rBd52.31mhok0.02

rBd52.01mhok1.03

rBd00.8mhok2.04

nieulaV101R

bd1±smhO

rBd52.6mhok9.94

Figure 1. Optional VOX GATE Modification Layout

16

Page 17

USA 12000 Portland Ave South, Bur nsville, MN 55337, Phone: 952-884-4051, Fax: 952-884-0043

Canada 705 Progress Avenue, Unit 46, Scarborough, Ontario, Canada, M1H2X1, Phone: 416-431-4975, 800-881-1685, Fax: 416-431-4588

Germany Hirschberger Ring 45, D94315, Straubing, Germany, Phone: +49 9421-706 0, Fax: +49 9421-706 287

France Parc de Courcerin, Allee Lech Walesa, Lognes, 77185 Marne la Vallee, France, Phone: +33 1 6480-0090, Fax: +33 1 6480-4538

Australia Unit 23, Block C, Slough Business Park, Slough Avenue, Silverwater, N.S.W. 2128, Australia, Phone: +61 2-9648-3455, Fax: +61 2-9648-5585

Hong Kong Unit E & F, 21/F, Luk Hop Industrial Bldg., 8 Luk Hop St., San PO Kong, Kowloon, Hong Kong, Phone: +852-2351-3628, Fax: +852-2351-3329

Japan 5-3-8 Funabashi, Setagaya-ku, Tokyo, 156-0055 Japan, Phone: +81 3-5316-5020, Fax: +81 3-5316-5031

Singapore 3015A Ubi Rd 1,05-10, Kampong Ubi Industr ial Estate, Singapore 408705,Phone: +65-746-8760, Fax: +65-746-1206

Mexico Av. Parque Chapultepec #66-201, Col. EI Parque Edo. De Mexico 53390, Mexico, Phone: +52 5358-5434, Fax: +52 5358-5588

UK 4, The Willows Centre, Willow Lane, Mitcham,Surrey CR4 4NX, UK, Phone: +44 181 640 9600, Fax: +44 181 646 7084

Africa,Mid-East Hirschberger Ring 45, D94315, Straubing, Germany, Phone: +49 9421-706 0, Fax: 49 9421-706 287

Latin America 12000 Portland Ave South, Bur nsville, MN 55337, Phone: 952-887-7491, Fax: 952-887-9212

www.electrovoice.com Telex Communications, Inc. www.telex.com

© Telex Communications, Inc. 08/2001

Part Number 38110-030 Rev B

For customer orders, contact the Customer Service department at

U.S.A. and Canada only.

800/392-3497 Fax: 800/955-6831

For warranty repair or service information, contact the Service

Repair department at 800/685-2606

For technical assistance, contact Technical Support at 866/78AUDIO

Please refer to the Engineering Data Sheet for warranty information.

Specifications subject to change without notice.

Loading...

Loading...