ElectroTherm ThermaCon User manual

EM

GENERAL

The

ThermaCon

materials

instructions,

The

ThermaCon

and

maintaining

transfer

DESCRIPTION

meeting

it

into

the

is a quality

Australian

will

safely

is

designed

the

temperature

portable

(€lectroTherm

ED

‘ThermaCon’

Infusion

Energy

Australian

electrical

and

reliably

to

provide a convenient

of

ThermaBag

Fluid

efficient

made

safety

meet

liquid

for

Standards.

your

specific

infusion

transport

Heater

technology!

product

fluid

in

Ambulance

manufactured

If

used

heating

heating/insulation

requirements.

bags

)

EH

according

at a base

vehicles.

from

to

the

system

depot

high-grade

following

for

raising

ready

for

Development

electric

The

of

lid

ambient

Normal

digital

container.

heating

heating

electric

the

ThermaCon.

minimize

temperatures.

temperature

Controller

element

of

the

elements

heating

energy

with

Abnormal

surface

ThermaCon

that

have

elements

Efficient,

loss

regulation

sensor

temperature

gently

multi-layer

and

form a stand-alone

located

and

connected

is

unique

radiate

in

the

limiting

made

possible

advantages

energy

insulation

ThermaCon

in

one

is

provided

in

series

‘warm

end

with

by

using

over

conventional

into

the

fluid

materials

is

provided

wall

by a thermal

the

inside

room’

sensing

supply

new

carbon-graphite

metal

elements.

through

suitable

by a micro-processor

air

Cutoff

wiring.

the

the

container

for

operation

temperature

located

floor

panels

inside

against

and

radiant

walls

and

in

low

based

the

the

ThermaCon—

Before

GENERAL

Your

care

operating

ThermaCon

in

handling,

OPERATING

your

CARE

is

operating

INSTRUCTIONS

OPERATING

‘ThermaCon’

Date:

ThermaCon,

constructed

and

PLEASE

to

give

storage

INSTRUCTIONS

June

2009

READ

years

is

required.

of

THESE

safe,

trouble

Issue

1

(Page

INSTRUCTIONS!

free

service,

but

2

of

4)

normal

Your

maintaining

powered

DO

outdoors

HANDLING

Care

damage

TESTING

ThermaCon

by

NOT

use

unprotected

must

to

the

the

a

be

is

temperature

240V

a.c.

the

ThermaCon

taken

power

to

socket.

designed

to

12V

weather!

from

avoid

Care

and

warranted

of

up

to

twenty-four

d.c

Power

where

physical

must

Supply.

liquid

damage

also

Electrical

for

DO

spillage

to

be

taken

specific

1

litre

NOT

the

to

use

bags

use

it

may

occur,

ThermaCon

keep

the

CAUTION

appliance - Handle

only

-

of

infusion

for

any

other

in

that

ThermaCon

with

care!

raising

fluid

purpose.

wet

could

dry.

while

areas,

result

and

or

in

|

Periodically,

in

accordance

equipment’,

your

with

or

an

ThermaCon

AS/NZS3760:2003

equivalent

should

safety

be

tested

‘In

service

standard

for

country

for

electrical

safety

safety

inspection

of

operation.

by

and

a

qualified

testing

person

of

electrical

ThermaCon—

OPERATING

Your

ThermaCon

Load

up

to

twenty-four

replaced

regulation,

Connect

Engage

connectors.

Connect

commence

Correct

temperature

The

indicate

and

the

the

the

the

temperature

Red

LED

power,

fitting

lid

Power

connection

Power

heating.

Controller

indicator

and

OPERATING

is

easy

1

litre

flush.

should

be

Supply

with

Supply

is

maintained

fitted

next

heating,

INSTRUCTIONS

to

use!

bags

of

To

maintain

closed

cord

to

to

‘ON’.

except

bayonet

a

clockwise

flexible

the

end

the

power

infusion

optimum

when

plug

quarter-turn

mains

by

wall

socket

cord

a

of

fluid

into

heating

removing

into

into

sensor

the

ThermaCon.

of

the

the

or

the

power

twist.

a

power

connected

ThermaCon

Issue

ThermaCon.

performance

replacing

socket

Do

not

outlet

|

to

a

will

1

(Page

Ensure

and

temperature

liquid

bags.

of

the

ThermaCon.

over-stress

and

turn

digital

light

constantly

3

of

4)

the

lid

is

the

‘ON’

to

electronic

to

A

flashing

by

cycling

The

lf

your

detergent.

NEVER

WARNING!

The

reduced

knowledge.

The

The

Red/Green

power

ThermaCon

ThermaCon

IMMERSE

ThermaCon

physical,

ThermaCon

ThermaCon

LED

to

the

is

designed

becomes

IN

WATER

is

not

sensory

is

to

be

is

to

be

indicates

heating

to

soiled,

intended

or

handled,

tested

that

elements.

be

safely

clean

OR

HOSE

for

use

mental

capabilities,

installed

by

qualified

the.

Controller

operated

inside

DOWN!

by

persons

and

personne!

is

regulating

continuously

and

outside

-

DO

NOT

{including

or

lack

of

operated

by

only.

internal

with

power

with

a

damp

USE

SOLVENTS!

children)

experience

trained

temperature

connected.

cloth

and

with

and

personnel

mild

only.

Operate

Do

not

the

ThermaCon

operate

the

ThermaCon

indoors

only.

it

the

power

connectors

are

damaged.

ThermaCon—

SPECIFICATION

Normal

Abnormal

Manufactured

Proper

Operating

Suppliers

through

Your

months

unserviceable

care

and

Instructions

and

misuse

ThermaCon

from

OPERATING

Temperature

Element

Input:

90-264V

use

of

agents

date

parts

of

these

is

or

do

guaranteed

of

INSTRUCTIONS

Regulation

Temperature

a.c.

Ambient

in

accordance

your

ThermaCon

is

the

responsibility

not

accept

products.

purchase.

replacement

ThermaCon

12V

d.c.

75W

(by

electronic

Limiting

Power

47-63Hz

operating

responsibility

against defects

Guarantee

of

Heater.

Supply

Output:

conditions:

with

AS/NZS

and

ancillary

of

the

is

Controller):

(by

Cutoff):

12V

d.c.

0-40°C

60335.1

equipment

purchaser.

for

any

injury,

in

materials

limited

144°C

6.66A,

and

or

to

repair

Issue

1

40°C

+/-

+0°C

80W

60335.2.15

in

accordance

The

manufacturer

loss

or

workmanship

or

(Page

2°C

4

of

-4°C

with

damages

for

replacement

4)

these

and

its

caused

twelve

of

10

Keppler

Manufactured

ELECTROTHERM

Circuit,

3

61

Tel:

Email:

Design

in

Australia

ABN

12

055

597

Seaford,

1575

9775

sales@electrotherm.com.au

and

Specification

Victoria

Fax:

subject

PTY

058

61

by:

LTD

3198,

9775

3

to

change

Australia

1595

16

July

2009

Page 1 of

8

W

S

Curry

P.

Eng.

Mr

M

Bell

Electrotherm

Unit

4,

10

Keppler

Seaford

Dear

ELECTRICAL

The

the

A3,

This

the

Vic

Michael

following

above

&

appliance

A4

[Part

report

principal

appliance.

Ltd

Court

3198

SAFETY

is

a

report

complied

2]

and

comprises

safety

It

is

not

clauses

purported

INSPECTION

of

an

AS/NZS

of

7

pages

and

REPORT:

inspection

with

the

principal

60335.1:

including

limited

to

be

a

full

testing

carried

2002

+

1

page

test

report

THERMACON

out

on

safety

A1,

A2,

with

to

the

above

to

the

MODEL

a

sample

aspects

4

6

of

A3

[Part

photographs.

standards

above

safety

Electrical

23

Grout

3188

Phone:

Fax:

E

Mail:

920-851

of

the

above

AS/NZS

1].

60335.2.15

It

is

an

relevant

standards.

Consultant

St

Hampton

Australia

61

3

9598

6139597

currelec

INFUSION

@bigpond.net.au

appliance

:

inspection

to

the

Thermacon

0864

0418

FLUID

to

determine

2002

+

report

Vic

HEATER

A1,

A2,

covering

if

MARKINGS.

The

markings

Thermacon:

9775

1575.

Complies

Power

12v

Supply

de,

6.64

DESCRIPTION:

The

above

Supply

litre

sealed

The

Thermacon

electrical

Unit.

plastic

approximate

metal

liner

of

connected

between

electronic

socket.

40°.

144°

the

thermostat

It

is

The

power

intended

of

the

components

Model

920-851

with

Unit:

Amtex

мего.

©

E]

equipment

The

equipment

bags

is

a

rectangular

dimensions

the

Thermacon

“Microtemp”

outer

enclosure

is

to

supply

unit

12V

AS/NZS

Model

comprises

is

intended

of

infusion

of

the

Thermacon

is

wrapped

thermal

and

located

behind

maintain

is

connected

are

as

follows:

dc

72W

Manufactured

60335.1

LFZVC90NS12E

of

for

use

fluid

for

medical

shaped

open

are:

with

fuse

attached

the

inner

metal

the

small

the

temperature

to

the

and

AS/NZS

the

Thermacon

at

an

box

with

640

a

12V

liner

metal

of

Thermacon

in

Australia

60335.2.15.

AC

Adaptor

ambulance

purposes.

a

lid

and

mm

long,

72W

thin

to

it

on

one

which

is

panel

the

infusion

via

by

220-240V,

and

a

240/12V

station

is

made

345

mm

sheet

flexible

side.

fixed

which

incorporates

fluid

a

plastic

Electrotherm

90-100VA,

Extra

to

warm

from

aluminium

wide

and

heating

Thermal

inside

in

the

the

enclosure

“in

line”

insulation

outer

Pty

50-60H2;

Low

and

store

275

mm

element

enclosure.

the

12V

at

two

pole

Ltd.

Tel.

+61

Output

Voltage

sheet.

high.

is

Power

up

to

24

The

The

with

a

series

provided

inner

An

supply

inlet

approximately

ELV

connector.

3

one

Note:

The

and

testing

appliance

information

to

the

relevant

are

not

addressed

contained

safety

in

this

in

this

report

standard

report.

may

is

based

reveal

|

on

inspection

additional

of

points

a

sample

with

of

non-compliance.

limited

Health

testing

aspects

being

performed.

related

to

Full

the

medical

examination

use

of

the

Page 2 of

8

INSPECTION

The

details

Standards

assessed

of

are

as

being

CONCLUSION.

It

is

noted

that

operation

the

insulation.

because

LFZVC90NS12E

which

Accordingly

power

and

manufacturer.

If

you

Best

with

all

is

protected

supply

are

safe

have

regards

electrical

in

unit

products

any

REPORT

the

compliance

provided

safe

the

temperature

the

thermostat

The

heater

components

ELV

against

my

opinion

comply

when

queries

DETAILS.

in

the

or

not

operates

power

overload

the

with

about

of

the

Thermacon

following

applicable

rise

of

rendered

at

are

supply

unit

and

Thermacon

the

essential

used

in

accordance

this

report,

equipment

table.

the

All

relevant

in

the

decision

electrical

inoperative,

a

safe

voltage

located

is

an

short

Model

within

Australian

circuit.

920-851

safety

with

please

do

with

safety

column

insulation

are

well

of

12V

the

metal

safety

Infusion

aspects

not

of

the

instructions

hesitate

the

relevant

clauses

of

the

during

within

dc

the

and

presents

enclosure.

approved

Fluid

AS/NZS

to

contact

clauses

are

noted

table.

normal

operation

continuous

no

Also

type

Heater

60335.2.15

for

use

provided

me.

of

the

as

complying,

and

temperature

electrical

the

Amtex

[Approval

and

its

associated

and

AS/NZS

by

above

abnormal

or

fire

Model

No:

NSW23963]

the

safety

rating

of

hazards

ELV

60335.1

WS

Curry

William

Curry

Note:

The

and

testing

appliance

information

to

the

relevant

are

not

addressed

contained

safety

in

this

in

this

report

standard

report.

may

is

based

reveal

on

inspection

additional

of

points

a

sample

with

of

non-compliance.

limited

Health

testing

aspects

being

performed.

related

to

Full

the

medical

examination

use

of

the

Page 3 of

8

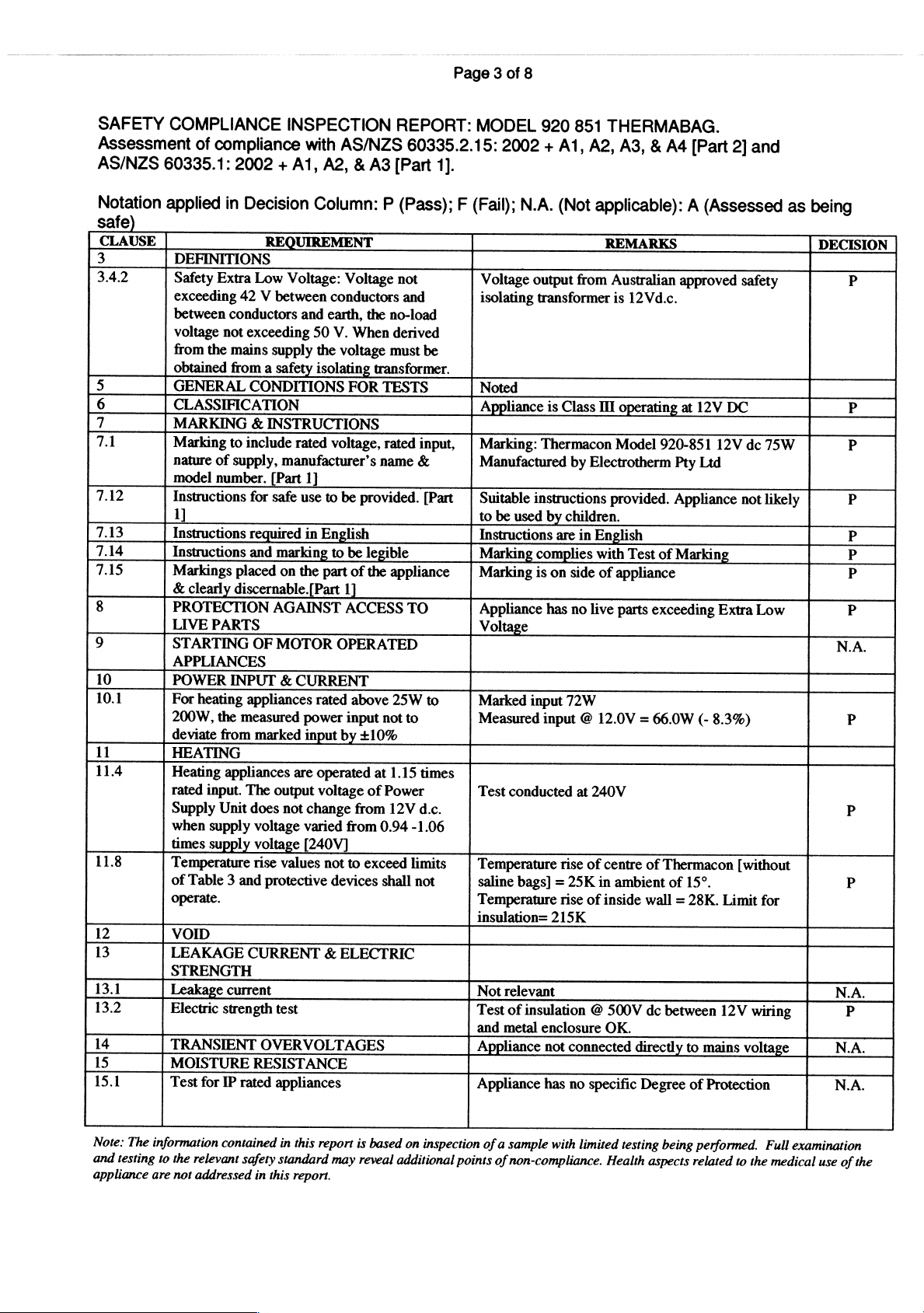

SAFETY

Assessment

AS/NZS

Notation

safe)

CLAUSE

3

3.4.2

5

6

7

7.1

7.12

7.13

7.14

7.15

8

9

10

10.1

11

11.4

11.8

12

13

13.1

13.2

14

15

15.1

COMPLIANCE

of

compliance

60335.1:

applied

DEFINITIONS

Safety

exceeding

between

voltage

from

obtained

GENERAL

CLASSIFICATION

MARKING & INSTRUCTIONS

Marking

nature

model

Instructions

1]

Instructions

Instructions

Markings

&

clearly

PROTECTION

LIVE

STARTING

APPLIANCES

POWER

For

200W,

deviate

HEATING

Heating

rated

Supply

when

times

Temperature

of

Table

operate.

VOID

LEAKAGE

STRENGTH

Leakage

Electric

TRANSIENT

MOISTURE

Test

2002 + A1,

in

Extra

42 V between

conductors

not

the

mains

from a safety

to

of

supply,

number.

placed

discernable.[Part

PARTS

INPUT & CURRENT

heating

the

measured

from

appliances

input.

Unit

supply

supply

3

and

current

strength

for

IP

rated

INSPECTION

with

A2, & A3

Decision

REQUIREMENT

Low

exceeding

CONDITIONS

include

for

required

and

OF

appliances

marked

The

does

voltage

voltage

rise

protective

CURRENT & ELECTRIC

OVERVOLTAGES

RESISTANCE

Column:

Voltage:

conductors

and

earth,

50

V.

supply

the

isolating

rated

voltage,

manufacturer’s

[Part

1]

safe

use

to

in

English

marking

on

AGAINST

MOTOR

output

not

values

test

appliances

the

rated

power

input

are

operated

voltage

change

varied

[240V]

to

part

not

devices

AS/NZS

P

Voltage

the

no-load

When

derived

voltage

be

OPERATED

by

must

transformer.

FOR

TESTS

rated

name

provided.

be

legible

of

the

appliance

1]

ACCESS

above

25W

input

not

+10%

at

1.15

of

Power

from

12V

from

0.94

to

exceed

shall

REPORT:

60335.2.15:

[Part

1].

(Pass);

not

and

TO

to

limits

be

input,

&

[Part

to

times

d.c.

-1.06

not

F

|

|

MODEL

(Fail);

Voltage

isolating

Noted

Appliance

Marking:

Manufactured

Suitable

to

Instructions

Marking

Marking

Appliance

Voltage

Marked

Measured

Test

Temperature

saline

Temperature

insulation=

Not

Test

and

Appliance

Appliance

920

2002

+

N.A.

output

transformer

Thermacon

instructions

be

used

by

complies

is

has

input

input

conducted

bags]

relevant

of

insulation

metal

enclosure

not

has

is

on

215K

851

THERMABAG.

A1,

A2,

(Not

applicable):

REMARKS

from

Australian

is

Class

III

by

Electrotherm

provided.

children.

are

in

English

with

side

of

no

live

72W

@

12.0V

at

240V

rise

of

centre

=

25K

in

rise

of

inside

@

500V

OK.

connected

no

specific

A3,

&

A4

12Vd.c.

operating

Model

920-851

Test

of

appliance

parts

exceeding

=

66.0W

of

Thermacon

ambient

of

wall = 28K.

dc

between

directly

Degree

[Part

A

(Assessed

approved

at

12V

DC

12V

Pty

Ltd

Appliance

Marking

Extra

(-

8.3%)

15°.

Limit

12V

to

mains

of

Protection

2]

and

safety

dc

75W

not

likely

Low

[without

for

wiring

voltage

as

being

DECISION

P

P

P

P

P

P

P

P

Ν.Α.

P

P

P

N.A.

P

N.A.

N.A.

Note:

and

appliance

The

information

testing

are

to

the

not

contained

relevant

addressed

safety

this

in

in

standard

this

report.

report

may

is

based

reveal

on

inspection

additional

of

a

sample

with

limited

points

of

non-compliance.

testing

Health

aspects

being

performed.

related

to

Full

the

examination

medical

use

of

the

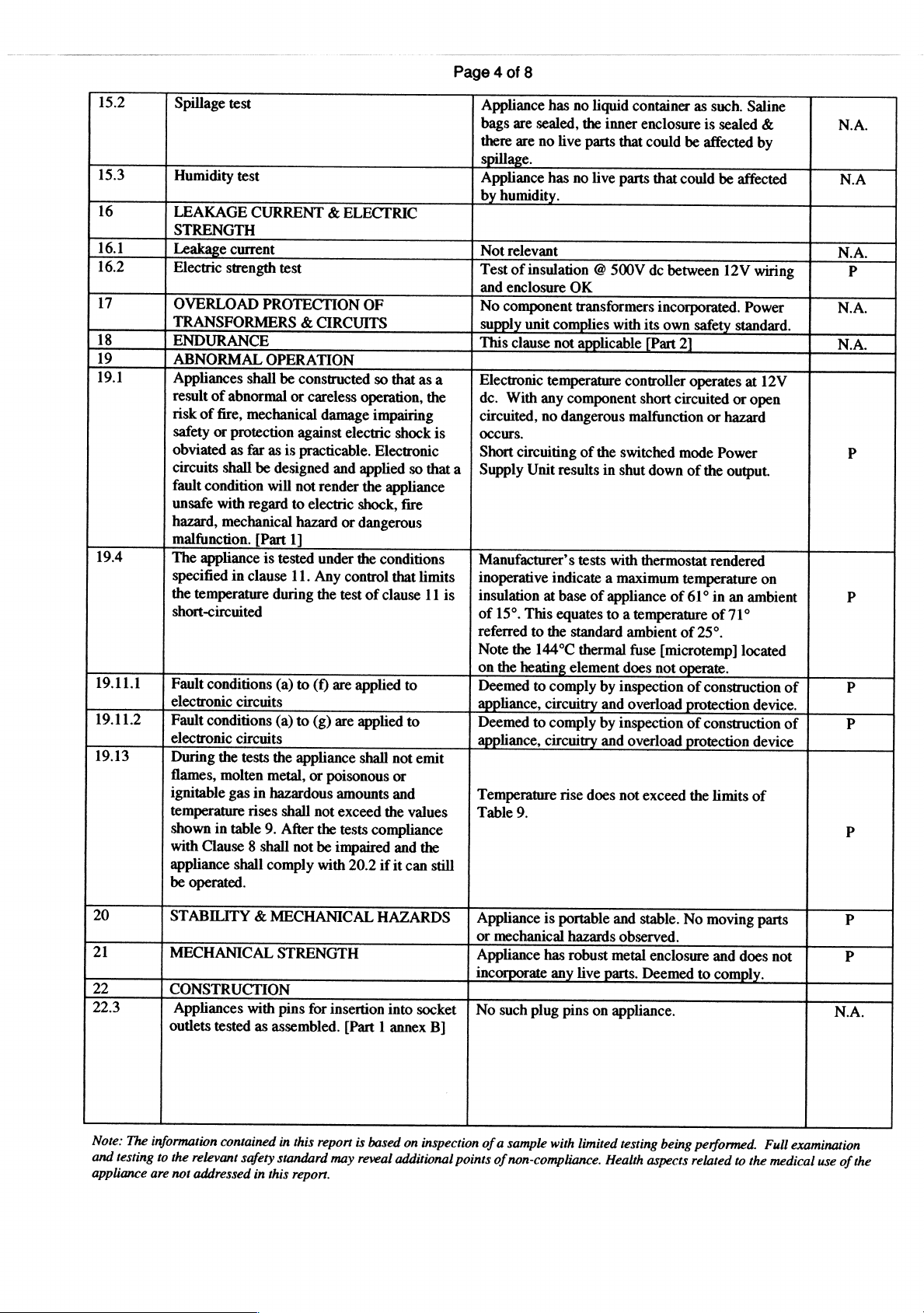

15.2

15.3

16

16.1

16.2

17

18

19

19.1

19.4

19.11.1

19.11.2

19.13

20

21

22

223

Spillage

Humidity

LEAKAGE

STRENGTH

Leakage

Electric

OVERLOAD

TRANSFORMERS

ENDURANCE

ABNORMAL

Appliances

result

risk

safety

obviated

circuits

fault

unsafe

hazard,

malfunction.

The

specified

the

short-circuited

Fault

electronic

Fault

electronic

During

flames,

ignitable

temperature

shown

with

appliance

be

STABILITY

MECHANICAL

CONSTRUCTION

Appliances

outlets

test

test

CURRENT

current

strength

shall

of

abnormal

of

fire,

mechanical

protection

or

as

far

shall

be

condition

regard

with

mechanical

appliance

in

clause

temperature

conditions

circuits

conditions

circuits

tests

the

molten

gas

in

rises

in

table

8

Clause

shall

operated.

&

with

tested

as

test

PROTECTION

OPERATION

be

as

designed

will

[Part

is

tested

during

(a)

(a)

the

metal,

hazardous

9.

shall

comply

MECHANICAL

STRENGTH

pins

assembled.

&

&

CIRCUITS

constructed

or

careless

damage

against

is

practicable.

and

render

not

electric

to

hazard

1]

under

11.

Any

the

test

to

(f)

are

to

(g)

are

appliance

poisonous

or

amounts

exceed

not

shall

After

the

tests

impaired

be

not

with

for

insertion

ELECTRIC

OF

so

that

operation,

impairing

electric

or

control

[Part 1 annex

shock

Electronic

applied

appliance

the

shock,

dangerous

the

conditions

that

of

clause

applied

applied

not

shall

or

and

the

compliance

and

it

if

20.2

HAZARDS

into

so

fire

to

to

values

can

Page 4 of

as

a

the

is

that

a

limits

11

is

emit

the

still

socket

B]

|

|

|

Deemed

appliance,

Temperature

Table

|

Appliance

or

Appliance

incorporate

|

No

8

Appliance

bags

there

spillage.

Appliance

humidity.

by

Not

Test

and

No

supply

This

Electronic

dc.

circuited,

occurs.

Short

Supply

Manufacturer’s

inoperative

insulation

of

15°.

referred

Note

the

on

Deemed

appliance,

mechanical

such

has

sealed,

are

live

no

are

has

relevant

of

insulation

enclosure

component

unit

complies

clause

not

temperature

With

any

no

dangerous

circuiting

Unit

results

indicate

at

base

This

equates

the

to

144°C

the

heating

to

comply

circuitry

to

comply

circuitry

rise

9.

is

portable

has

any

plug

no

the

no

OK

transformers

applicable

component

of

tests

standard

thermal

element

hazards

robust

live

pins

liquid

inner

that

parts

live

parts

@

500V

with

the

in

shut

with

a

maximum

of

appliance

to

by

inspection

and

by

inspection

and

does

not

and

observed.

metal

parts.

on

appliance.

container

enclosure

be

could

that

could

dc

between

incorporated.

its

own

[Part

2]

controller

short

malfunction

switched

thermostat

a

temperature

ambient

fuse

does

overload

overload

stable.

Deemed

operates

circuited

mode

down

of

temperature

of

61°

of

[microtemp]

operate.

not

of

protection

of

protection

exceed

the

No

enclosure

as

such.

Saline

&

sealed

is

be

affected

12V

Power

standard.

at

or

open

hazard

Power

output.

in

an

ambient

of

71°

located

limits

and

does

comply.

by

wiring

12V

on

device.

device

of

parts

affected

safety

or

the

rendered

25°.

construction

construction

moving

to

of

of

not

N.A.

N.A

Ν.Α.

P

N.A.

N.A.

P

P

P

P

P

P

P

N.A.

Note:

and

appliance

The

information

testing

are

to

the

not

contained

relevant

addressed

safety

this

in

in

this

report

standard

report.

may

is

based

reveal

on

inspection

additional

of

a

sample

with

limited

testing

points

of

non-compliance.

Health

being

aspects

related

performed.

to

the

Full

examination

medical

use

of

the

22.6

22.8

22.21

22.22

22.26

22.41

23

23.1

23.8

23.9

24

Appliances

electrical

water

by

liquid

After

is

no

that

could

distances

For

appliances

access

and

that

the

electrical

that

they

cleaning

Wood,

fibrous

used

Appliances

Appliances

construction

insulation

extra-low

complies

insulation

Appliances

other

INTERNAL

Wireways

edges.

Aluminium

internal

Stranded

by

lead-tin

to

contact

means

bad

contact

COMPONENTS

shall

insulation

that

could

that

this

test,

trace

of

result

below

can

be

are

likely

are

not

cotton,

or

hygroscopic

as

insulation,

shall

having

shall

between

voltage

with

or

reinforced

shall

than

lamps,

WIRING

shall

wires

wiring.

conductors

soldering

pressure,

is

constructed

due

be

constructed

cannot

condense

could

leak

inspection

liquid

on

windings

in a reduction

the

values

having

compartments

gained

without

to

be

connections

subject

silk,

ordinary

material

unless

not

contain

parts

be

constructed

parts

and

other

the

reguirements

insulation.

not

incorporate

containing

be

smooth

shall

not

shall

where

unless

so

that

to

cold

flow

so

that

be

affected

on

cold

surfaces

from

containers

shall

show

or

insulation

of

creepage

specified

cleaned

shall

to

pulling

paper

impregnated.

asbestos

of

class

operating

live

mercury.

and

be

not

they

the

there

of

in

the

aid

of a tool

in

normal

be

arranged

during

and

shall

III

so

that

at

parts

for

double

components,

free

from

used

for

be

consolidated

are

subjected

clamping

is

no

the

solder.

their

by

etc.

that

there

29.2.

to

which

similar

not

be

the

safety

sharp

risk

Page 5 of

Insulation

dc.

or

distances

with

circuited.

element

comply.

No

use,

so

No

No

No

No

Complies

No

No

of

8

is

In

accordance

may

clause

No

is

subjected

such

wiring.

such

insulation

asbestos

live

parts

mercury

aluminium

such

consolidation

functional

with

be

reduced

19

with

the

hazard

will

to

in

appliance

in

appliance

in

appliance.

wires

used

of

insulation

29.2.4

if

functional

arise

spillage.

conductors

these

the

appliance

if

the

Deemed

operating

insulation

creepage

complies

heating

to

at

12V

short-

24.1

25

25.1

25.8

25.17

26

26.11

27

Note:

and

testing

appliance

Components

requirements

Standard

SUPPLY

FLEXIBLE

Appliances

connection

Conductors

cross

sectional

Cord

anchorage

TERMINALS

CONDUCTORS

For

appliances

type Z attachment,

or

similar

connection

PROVISION

shall

comply

specified

as

far

as

they

CONNECTION

CORDS

shall

be

to

supply

of

supply

area

per

to

be

FOR

having

soldered,

connections

of

external

FOR

EARTHING

in

the

reasonably

provided

mains.

cords

Table

adequate

EXTERNAL

type Y attachment

may

conductors.

The

information

to

the

are

not

contained

relevant

addressed

safety

in

this

in

this

report

standard

report.

may

with

the

relevant

&

EXTERNAL

with

to

have

11

welded,

be

used

is

based

reveal

safety

IEC

apply.

means

of

adequate

or

crimped

for

the

on

inspection

additional

Microtemp

is

not

60335.1.

No

supply

connects

Rated

are

18AWG

Appliance

Appliance

thermal

relied

mains

to

input

inlet

is

upon

for

connection.

12V

PSU

current

(0.82

mm”)

device

Class

cut

out

safety

via 2 pole

6.0A

rated

fitted.

II;

no

is

UL

Listed

in

respect

Flexible

connector.

Conductors

at

7.5A

earthing

required

of

a

sample

with

limited

testing

being

points

of

non-compliance.

Health

aspects

performed.

related

however

of

AS/NZS

cord

of

ELVPSU

to

Full

the

medical

it

N.A.

N.A

N.A

N.A.

examination

use

of

the

28

28.1

29

29.1

29.2

30

30.1

30.2.1

30.2.2

30.2.4

31

32

SCREWS

Fixings,

connections

shall

occurring

these

soft

aluminium.

CLEARANCES,

AND

Clearances

specified

rated

categories

Appliances

creepage

appropriate

into

pollution

RESISTANCE

Ball

live

550°C

750°

that

Needle

material

[Part

RESISTANCE

RADIATION,

HAZARDS

AND

electrical

withstand

in

purposes

or

liable

SOLID

shall

in

Table

impulse

of

shall

distances

for

account

degree.

Pressure

parts

etc.

Glow

GW

test

carry

a

current

Flame

is

classified

1]

CONNECTIONS

connections

providing

normal

shall

to

INSULATION

voltage

Table

the

the

TO

Test

Wire

on

Test

TO

TOXICITY

earthing

the

mechanical

use.

not

creep,

such

CREEPAGE

not

be

16,

taking

for

15.

be

constructed

are

not

working

material

HEAT

on

insulation

test

on

insulation

>

0.5A.

on

PCBs

V-0

RUSTING

be

less

to

and

continuity

stresses

Screws

group

used

of

metal

as

zinc

DISTANCES

than

the

into

account

the

overvoltage

so

less

than

voltage,

and

AND

FIRE

supporting

non

metallic

supporting

unless

IEC

60695-11-10.

&

SIMILAR

or

that

those

the

base

for

which

values

the

taking

parts

parts

Page 6 of

is

8

Connections

Clearances

Creepage

circuits

No

live

Test

not

impregnated

wiring

comply.

Test

not

unable

insulation

within

fuse

considered

ignition.

Base

material

|

classified

equivalent.

enclosure.

No

metallic

No

radiation

comply.

adequate

distances

parts

in

appliance

conducted.

fiberglass]

fully

within

conducted.

to

cause

an

[PTFE

metal

enclosure.

to

Deemed

of

UL94

V-0

Also

Deemed

parts

or

toxic

for

on

All

metal

12V

arcing

impregnated

be

satisfactory

to

comply.

thermostat

which

located

to

comply

subject

hazards.

12V

circuits

PCB

adequate

electrical

&

enclosure;

circuitry

fault.

Provision

within

to

insulation

Silicon

All

fiberglass]

protection

PCB

[fiberglass]

is

considered

full

rusting.

for

12V

[PTFE

rubber

insulated

deemed

considered

electrical

of

metal

_

144°

to

to

fully

thermal

against

is

to

be

P

P

P

N.A.

P

be

P

P

P

P

Note:

The

and

testing

appliance

information

to

the

relevant

are not

addressed

contained

safety

in

this

in

this

report

standard

report.

may

is

based

reveal

on

inspection

additional

of

points

a

sample

of

non

with

limited

-compliance.

testing

Health

being

aspects

performed.

related

to

Full

the

examination

medical

use

of

the

PHOTOS

Page 7 of

8

Thermacon

Infus

10n

Fluid

Heater.

Thermacon

electronic

thermostat

PCB.

9

V

1ew

insi

de

Thermacon

with

Thermacon

element

with

Inner

thermal

me

tal

enclosure

fuse

on

lid

side

removed.

show

ing

+

of

inner

.

flexi

liner.

ble

h

ns

Amtex

ELV

Note

The

and

testing

appliance

43)

È

i

i

i

Power

informat

are not

to

ton

the

relevant

addressed

|

<

|

Supply

conta

1

safety

in

U

nit

d

in

standard

th

is

report

th

.

is

report

may

is

based

reveal

on

inspection

additional

of

points

Thermacon

a

sample

of

non-compli

with

unit

showing

limited

e.

Health

testing

aspects

marking

being

performed.

related

label

to

and

Full

the

12V

supply

examination

medical

use

inlet.

of

the

Loading...

Loading...