Electro Steam LB-80 Installation Manual

User Manual

& Installation Instructions

LB-80

IMPORTANT – READ ALL INSTRUCTIONS BEFORE OPERATING

All steam boilers are built in accordance with ASME miniature boiler code.

NOTE: It is the responsibility of the installer to conform to any state or local codes. If further

inspection, following modification by installer, is required under state or local codes, that is

the responsibility of the local installer.

www.electrosteam.com

rev. 12082010

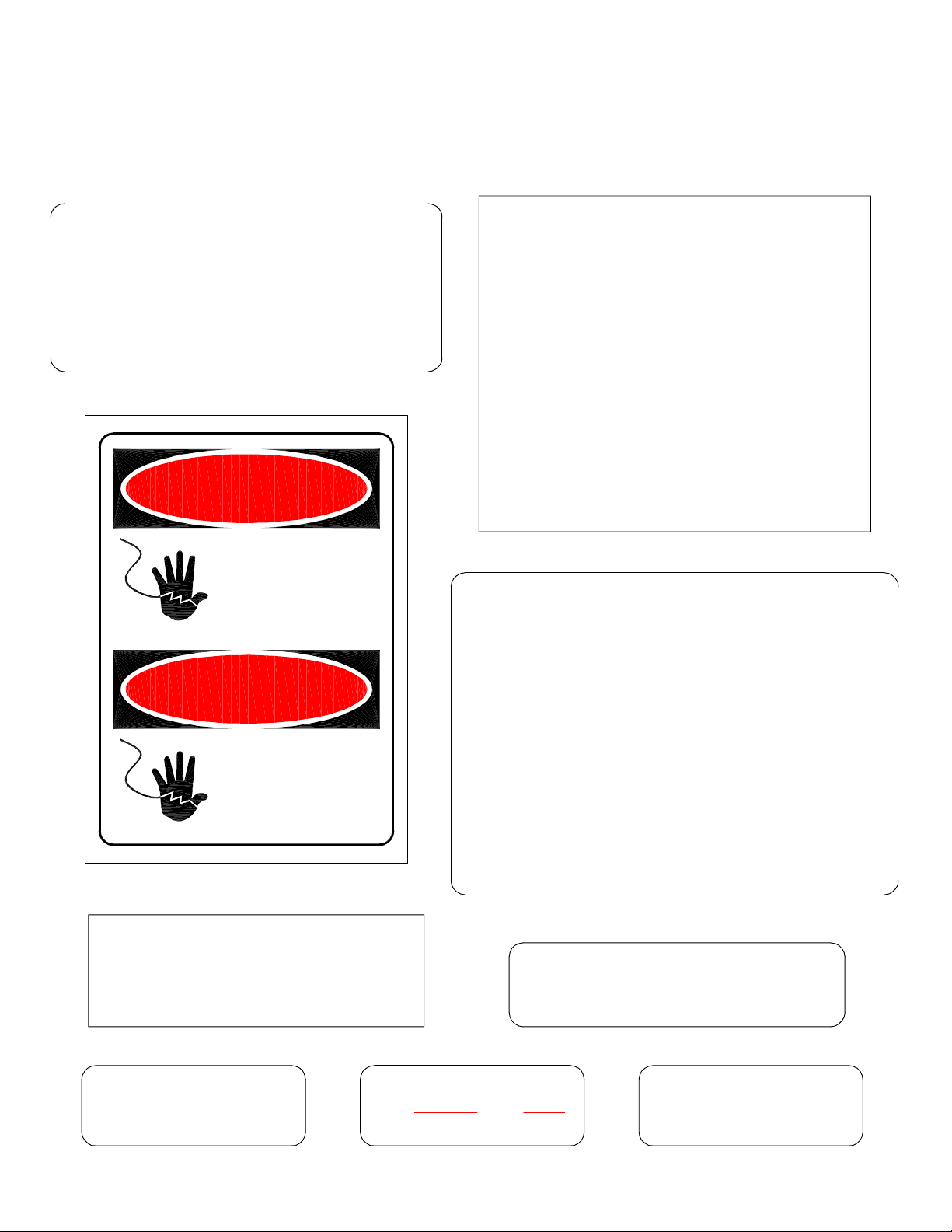

WARNING - The following labels have been placed on this boiler for YOUR SAFETY. Failure

to observe these instructions could lead to PROPERTY DAMAGE, SEVERE INJURY, or

even DEATH

CA

DANGER

PELIGRO

U

TION

OHT

HIGH VOLTAGE

AUTHORIZED

PERSONNEL

ONLY

CA OTI N

U

THROW OFF MAIN

POWER SWITCH

BEFORE WORKING ON

ELECTRICAL CABINET

A MANUAL WAS SHIPPED WITH THIS

BOILER. IT IS IMPORTANT THAT YOU

READ, UNDERSTAND, AND OPERATE

THIS STEAM GENERATOR IN ACCOR-

ALTO VOLTAJE

SOLAMENTE

PERSONAL

AUTORIZADO

REPLACE GLASS

EVERY SIX MONTHS

CAUTION USE ELECTRICAL

SUPPLY CONDUCTORS RATED

FOR A MINIMUM OF 90°C

DANCE WITH THE OPERATING

INSTRUCTIONS CONTAINED IN THE

MANUAL. IF FOR ANY REASON YOU

DO NOT HAVE A MANUAL, CALL

ELECRTO-STEAM AT 800-634-8177

RETIGHTEN SIGHT GLASS

TERMINALS ARE SUITABLE

FOR

COPPER WIRE ONLY

U.L. 834 PAR. 4416

BEFORE USE

AMBIENT TEMPERATURE

AROUND UNIT NOT TO

EXCEED 105° F

LB-80 - User Manual Electro-Steam Generator Corp.

TABLE OF CONTENTS

1.) INSTALLATION INSTRUCTIONS .................................................................... 4

2.) OPERATION & SEQUENCE OF EVENTS ..................................................... 5

3.) CLEANING & MAINTENANCE .................................................................... 6-14

3.1) MANUAL “BLOW DOWN” ..................................................................................... 6

3.2) CLEANING WATER LEVEL PROBES ............................................................... 6-7

3.3) CLEANING OR REPLACING HEATERS ............................................................... 7

3.4) REPLACING GLASS GAUGE AND RUBBER WASHERS ............................... 8-9

3.4.1) BRASS SIGHT GLASS (STANDARD) ................................................................... 8

3.4.1) BRASS SIGHT GLASS (SEISMIC) ........................................................................ 9

3.5) CHAMBER CLEANING & CHEMICAL TREATMENT ................................ 10-11

3.6) PRESSURE CONTROL DATA SHEET ................................................................. 12

3.7) SETTING THE PRESSURE CONTROLS ....................................................... 13-14

4.) CALCULATIONS & DATA SHEETS ........................................................ 15-17

4.1) HEATER POWER & VOLTAGE RATINGS ......................................................... 15

4.2) TOTAL POWER RATING CALCULATIONS ...................................................... 15

4.3) AMPERAGE CALCULATIONS ............................................................................ 16

4.4) ACTUAL POWER RATING CALCULATIONS ................................................... 16

4.5) STEAM CAPACITY & WATER CONSUMPTION CALCULATIONS ............... 17

5.) DRAWINGS & WIRING SCHEMATICS ................................................. 18-31

5.1) PARTS LEGENDS ............................................................................................ 18-21

5.1.1) LB (80KW) (LOW PRESSURE) (0-15PSI) ............................................................ 18

5.1.2) LB (80KW) (LOW PRESSURE)(MAFD) (0-15PSI) ................................................ 19

5.1.3) LB (80KW) (HIGH PRESSURE)(0-30, 0-100PSI) ................................................... 20

5.1.4) LB (80KW) (HIGH PRESSURE)(MAFD) (0-30, 0-100PSI) ...................................... 21

5.2) INSTALLATION DATA SHEETS .................................................................. 22-25

5.2.1) LB (80KW) (LOW PRESSURE) (0-15PSI) ............................................................ 22

5.2.2) LB (80KW) (LOW PRESSURE)(MAFD) (0-15PSI) ................................................ 23

5.2.3) LB (80KW) (HIGH PRESSURE)(0-30, 0-100PSI) ................................................... 24

5.2.4) LB (80KW) (HIGH PRESSURE)(MAFD) (0-30, 0-100PSI) ...................................... 25

5.3) CONTROL WIRING SCHEMATICS .............................................................. 26-29

5.3.1) LB (LOW PRESSURE) (0-15PSI) ........................................................................ 26

5.3.2) LB (LOW PRESSURE)(MAFD) (0-15PSI) ............................................................ 27

5.3.3) LB (HIGH PRESSURE)(0-30, 0-100PSI) .............................................................. 28

5.3.4) LB (HIGH PRESSURE)(MAFD) (0-30, 0-100PSI) .................................................. 29

5.4) HEATER WIRING SCHEMATICS .................................................................. 30-31

5.4.1) LB (40-80KW) (THREE PHASE) (208-240V) ....................................................... 30

5.4.2) LB (80KW) (THREE PHASE) (380-600V) ............................................................ 31

6.) TERMS & CONDITIONS ..................................................................................... 32

3 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

1.) INSTALLATION INSTRUCTIONS

LITTLE BOILER “LB-SERIES”

The Electro-Steam Generator design consists essentially of a high pressure chamber filled with water

that is heated by one or more submerged resistance type electric heating elements. Automatic controls

are provided to maintain the pre-set operating pressure and water level. Safety features include:

automatic low-water cutoff (manual low-water reset optional), dual pressure controls, safety valve, and

visible water level gauge. All of our generators are built in accordance with A.S.M.E. Miniature Boiler

Code and are individually inspected and stamped by an Authorized National Board Insurance Inspector.

IMPORTANT – READ ALL INSTRUCTIONS BEFORE OPERATING

Important – Set unit perfectly level, and as close as possible to the steam vessel or appliance it

will operate. For generator measurements, refer to Installation Data Drawing attached. For

interpretation of numbered items, refer to Parts Legend Drawing attached. NOTE: Ambient

temperature around this unit must not exceed 105°F.

CONNECTIONS:

Periodically check all plumbing and electrical connections for tightness; this should also be done

before initial start-up.

ELECTRICAL:

This generator must be connected to a disconnect switch protected by fuses or

circuit breakers with the proper size wire by a licensed electrician in

accordance with N.E.C. and your local codes – Voltage, KW, and Phase

requirement are marked on the nameplate.

WATER SUPPLY:

Connect city water line to Y-Strainer (#6).

Purity: NOT to exceed 26,000 OHMS per CM

Temperature Range: 32°F – 140°F or 0°C – 60°C.

Pressure Range: 20PSI – 150PSI.

*CAUTION: The Pump (#8) requires clean tap water. If the water is not free of foreign matter, a 5

micron cartridge filter should be installed in the water supply line.

STEAM OUTLET:

Connect Steam Outlet Valve (#16) to piece of equipment, vessel, room, or area to be operated by

the Electro Steam Generator.

SAFETY VALVE & DRAIN:

Separately route the Safety Valve (#18) & Drain (#23) to a high temperature drain *NO PVC.

Discharging pipe of the Safety Valve (#18) should never be smaller than the valve outlet and

should be rigidly supported, placing no weight on the safety valve itself. If equipped with

Motorized Auto-Flush & Drain “MAFD” (#20), it should be routed with the Drain (#23).

4 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

2.) OPERATION & SEQUENCE OF EVENTS

IMPORTANT – READ INSTALLATION INSTRUCTIONS BEFORE OPERATING

1. Turn on water supply from the source to the Generator.

2. OPEN all valves on the Generator except for the Manual Drain (#19).

3. Place main disconnect switch in ON position.

4. Place ON/OFF Switch (#2) in ON position.

x The Water Solenoid (#7) [and Pump (#8), if high pressure] will engage and the

chamber will begin to fill with water. As the water level rises, it will make contact

with the (G OR D) and (A) probes, indicating the heaters are safely submerged. At

this time the contactor(s) will engage, supplying power to the heaters, causing

steam pressure to accumulate.

x The chamber will continue to fill with water until 1 second after the water makes

contact with the (C) probe, causing the Water Solenoid (#7) [and Pump (#8), if

high pressure] to turn off.

x If the contactor(s) still have not engaged at this time, you may need to press the

Safety Reset (#13) on the “Safety” Pressure Control (#12). If your generator is

equipped with a Manual Low-Water Reset (MLWR) (#3), it must be pressed at

this time to engage the contactor(s). If your generator is equipped with a Motorized

Auto-Flush & Drain (MAFD) (#20), you must wait until it closes before the

contactor(s) will engage. (approximately 3 minutes)

x Steam pressure will continue to rise until is reaches its set operating pressure. This

may take up to 25 minutes. At this time, the “Control” Pressure Control (#12)

will cause the contactor(s) to disengage. The pressure will drop approximately 2-8

PSI until the “Control” Pressure Control (#12) causes the contactor(s) to

reengage, causing the pressure to rise again. The contactor(s) will continue to cycle

on and off during operation.

5. The Generator is now fully operational and will produce steam until it is turned off.

x As steam is exhausted, the water level will drop until 3 seconds after it breaks

contact with the (C) probe. At this time, the Water Solenoid (#7) [and Pump (#8),

if high pressure] will engage and the chamber will again fill with water. The

chamber will continue filling until 1 second after the water makes contact with the

(C) probe. The Water Solenoid (#7) [and Pump (#8), if high pressure] will

continue to cycle on and off during operation.

6. To shut off the Generator, place ON/OFF Switch (#2) in OFF position. Pressure will

drop naturally as the chamber cools, or the Generator may be drained manually through

Manual Drain (#19). (See Manual Blow Down 3.1)

WARNING – HOT WATER and STEAM under HIGH PRESSURE can lift drain pipes

right off the ground and cause SERIOUS INJURY. Make sure drain pipe is SECURE

and CANNOT move. The drain must be directed into a HIGH TEMPERATURE drain

(NO PVC) or outside.

5 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

3.) CLEANING & MAINTENANCE

The following cleaning procedures are HIGHLY RECOMMENDED in order to keep your

Steam Generator in the best operating condition at all times.

3.1) MANUAL “BLOW DOWN”

A Manual “Blow Down” is an easy way to GREATLY extend the life of your Steam

Generator. Using a Motorized Auto-Flush & Drain (MAFD) of course helps, but is not a “Cure

all”. The following is the LEAST amount of times recommended to blow down your generator:

NORMAL WATER AREAS – Should be done ONCE A WEEK.

BAD WATER AREAS – Should be done ONCE A DAY.

NORMAL WATER AREAS WITH MAFD – Should be done TWICE A MONTH.

BAD WATER AREAS WITH MAFD – Should be done ONCE A WEEK.

NOTE: The best time to Blow Down your generator is after it has been running for some time,

while it is still hot.

1. Place Toggle Switch (#2) and Main Disconnect Box in OFF position.

2. Allow pressure to drop between 10 and 20 PSI.

3. Open Manual Drain (#19) slowly, allowing HOT WATER and STEAM to blow out

into the drain, cleaning out the generator.

NOTE: Blow Down your generator at any pressure you feel comfortable with. 10 to 20 PSI is

only a recommendation. You may go higher or lower, but higher is always better.

WARNING – HOT WATER and STEAM under HIGH PRESSURE can lift drain pipes right

off the ground and cause SERIOUS INJURY. Make sure drain pipe is SECURE and

CANNOT move. The drain must be directed into a HIGH TEMPERATURE drain (NO

PVC).

3.2) CLEANING WATER LEVEL PROBES

Water Level Probes are the heart of your generator. Almost all steam generator malfunctions

are caused by dirty water level probes. CLEANING your PROBES is by far the MOST

IMPORTANT maintenance step to keep your generator running properly. The following is the

LEAST amount of times recommended to clean your probes:

NORMAL WATER AREAS – Should be done TWICE A YEAR.

BAD WATER AREAS – Should be done 3-4 TIMES A YEAR.

NOTE: The best time to clean your probes is before you turn your generator on, while it is still

cool.

1. Place Toggle Switch (#2) and Main Disconnect Box in OFF position.

2. Make sure generator is cool and the Pressure Gauge (#15) reads 0 PSI.

3. Locate the blue box on top of generator and remove cover plate, exposing the Water

Level Probes (#5).

4. Use 5/16” Socket to remove wires from probes.

5. Use 13/16” Spark Plug Socket to remove probes from chamber.

6 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

3.2) CLEANING WATER LEVEL PROBES (Continued)

6. Clean probes to remove rust and scaling.

NOTE: To clean probes you may use wire wheel, wire brush, steal wool, or Scotch-Brite.

(Wire wheel works the best) You may also want to try some sort of chemical like CLR

remover or LIME-A-WAY.

7. Reinstall probes assuring each probe’s length is assigned to its proper letter.

8. Reconnect wires to probes assuring each color is also assigned to its proper letter.

NOTE: DO NOT make wires too tight. Just tighten enough to make contact. Over

tightening can cause probe plugs to pull apart over time.

9. Reinstall cover plate.

Water Level Probe Specifications:

Letter Assignment on Chamber A B C D/G

Water Level Probe Length 5 ¼” Not Used 3 ¾” 5 ½”

Wire Color Assignment RED Not Used BLACK GREEN

Assignment on Dual Function Board LLCO Not Used H G

NOTE: The (B) Probe is not used.

WARNING – There MUST be NO PRESSURE in the chamber when removing probes. If you

must change probes while chamber is HOT, make sure the steam out and drain valves are open

to assure chamber will remain depressurized. DO NOT touch probes with your bare hands

while HOT, and be cautious of escaping steam from probe holes while probes are removed.

3.3) CLEANING OR REPLACING HEATERS

Heaters are located inside the control panel (#1) below the insulation barrier, bolted into the

chamber. If (3.5) Chamber Chemical/Acid Treatments are not regularly done, heaters must be

taken out at least ONCE A YEAR, cleaned with wire brush and reinstalled using a new gasket.

If you are replacing or cleaning your heater elements:

1. Place Toggle Switch (#2) and Main Disconnect Box in OFF position.

2. Make sure generator is cool and the Pressure Gauge (#15) reads 0 PSI.

3. Remove heater wires from heater(s), using a 3/8” Socket.

4. Unbolt and remove heater(s) using a 1 1/16” Socket.

NOTE: Heater(s) may be difficult to get out; you may need to use some sort of pry bar to

get them loose.

5. Clean heater(s) with wire brush. If replacing, dispose of old heater(s).

6. Reinstall heater(s) with new gasket(s).

7. Attach heater wires assuring proper wiring. *Refer to Heater Wiring Schematics

attached*

NOTE: If you are replacing a heater because of a heater failure, you must also clean the probes

and clean out the chamber, or you may have another heater failure within 48 hours.

7 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

3.4) REPLACING GLASS GAUGE & RUBBER WASHERS OR

GLASS PACKINGS

The Sight Glass (#10) gives the operator the ability to easily monitor the actual water level

inside the chamber. If the Sight Glass (#10) gets clogged or is no longer functional, it can be very

difficult to troubleshoot a problem.

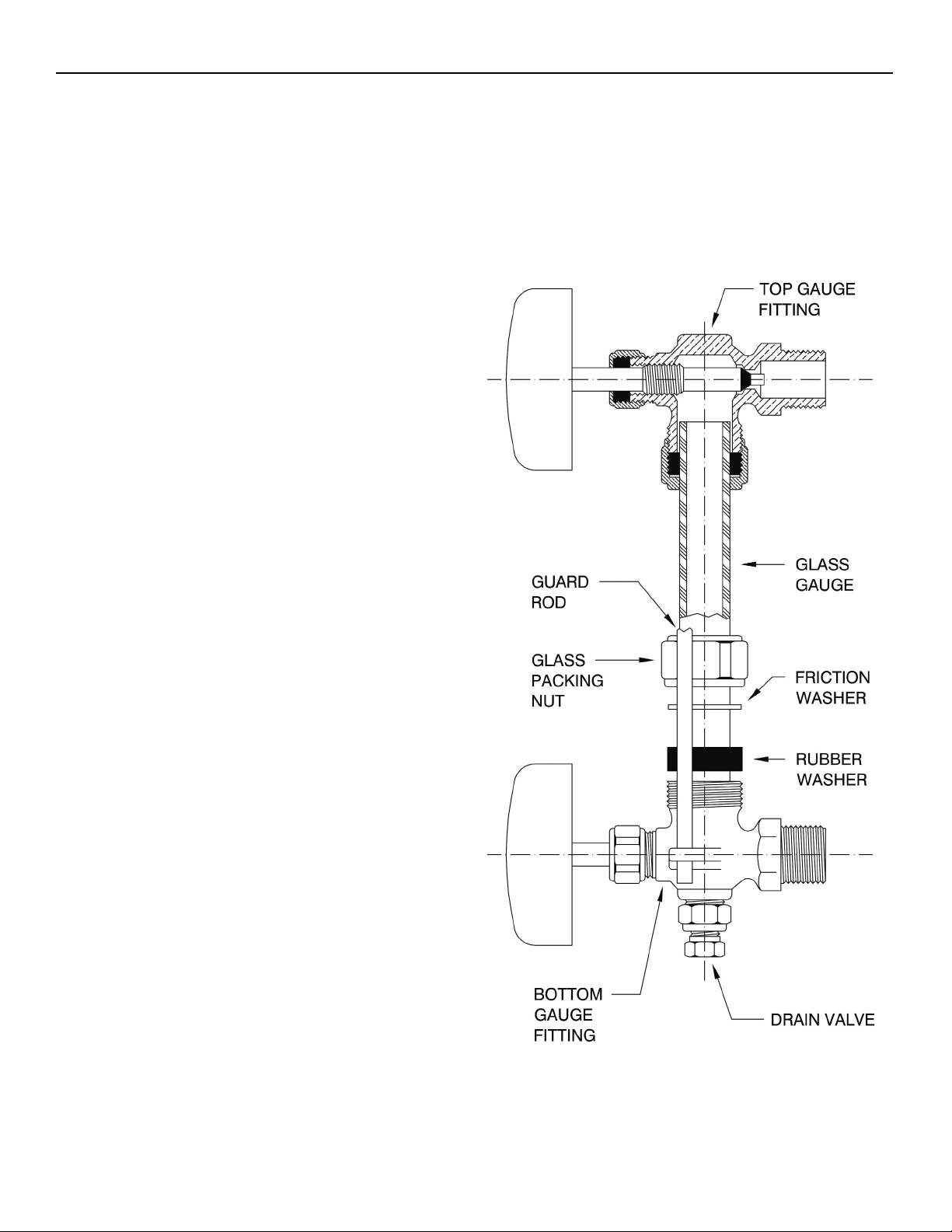

3.4.1) BRASS SIGHT GLASS (STANDARD)

GLASS GAUGE and RUBBER WASHERS

MUST be replaced EVERY SIX MONTHS

INSTALLATION:

Only properly trained personnel should install and

maintain water gauge glass and connections.

Remember to wear safety gloves and glasses

during installation. Before installing, make sure

all parts are free of chips and debris.

1. Uninstall GUARD RODS, GLASS GAUGE, and

RUBBER WASHERS. (You may need to rotate one of the

GAUGE FITTINGS to remove GLASS GAUGE)

2. Slip a new RUBBER WASHER on the new GLASS

GAUGE about an inch from the bottom.

3. Now slip the following items through the top of GLASS

GAUGE in the following order:

• FRICTION WASHER

• GLASS PACKING NUT (facing down)

• GLASS PACKING NUT (facing up)

• FRICTION WASHER

• RUBBER WASHER (inch down from top)

4. Gently insert GLASS GAUGE into GAUGE FITTINGS.

You may need to rotate GAUGE FITTINGS until

vertically aligned, after GLASS GAUGE is in.

5. Carefully raise GLASS GAUGE about 1/16” from bottom

and slide lower RUBBER WASHER down until it makes

contact with the BOTTOM GAUGE FITTING. (DO NOT

allow GLASS GAUGE to remain in contact with any metal)

6. Carefully slide upper RUBBER WASHER up as far as

possible.

7. Hand tighten both GLASS PACKING NUTS, then tighten

1/2 turn more by wrench. Tighten only enough to prevent

leakage. DO NOT OVER TIGHTEN! If any leakage

should occur, tighten slightly, a quarter turn at a time,

checking for leakage after each turn.

8. Reinstall GUARD RODS.

8 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

3.4) REPLACING GLASS GAUGE & RUBBER WASHERS OR

GLASS PACKINGS (Continued)

The Sight Glass (#10) gives the operator the ability to easily monitor the actual water level inside the

chamber. If the Sight Glass (#10) gets clogged or is no longer functional, it can be very difficult to

troubleshoot a problem.

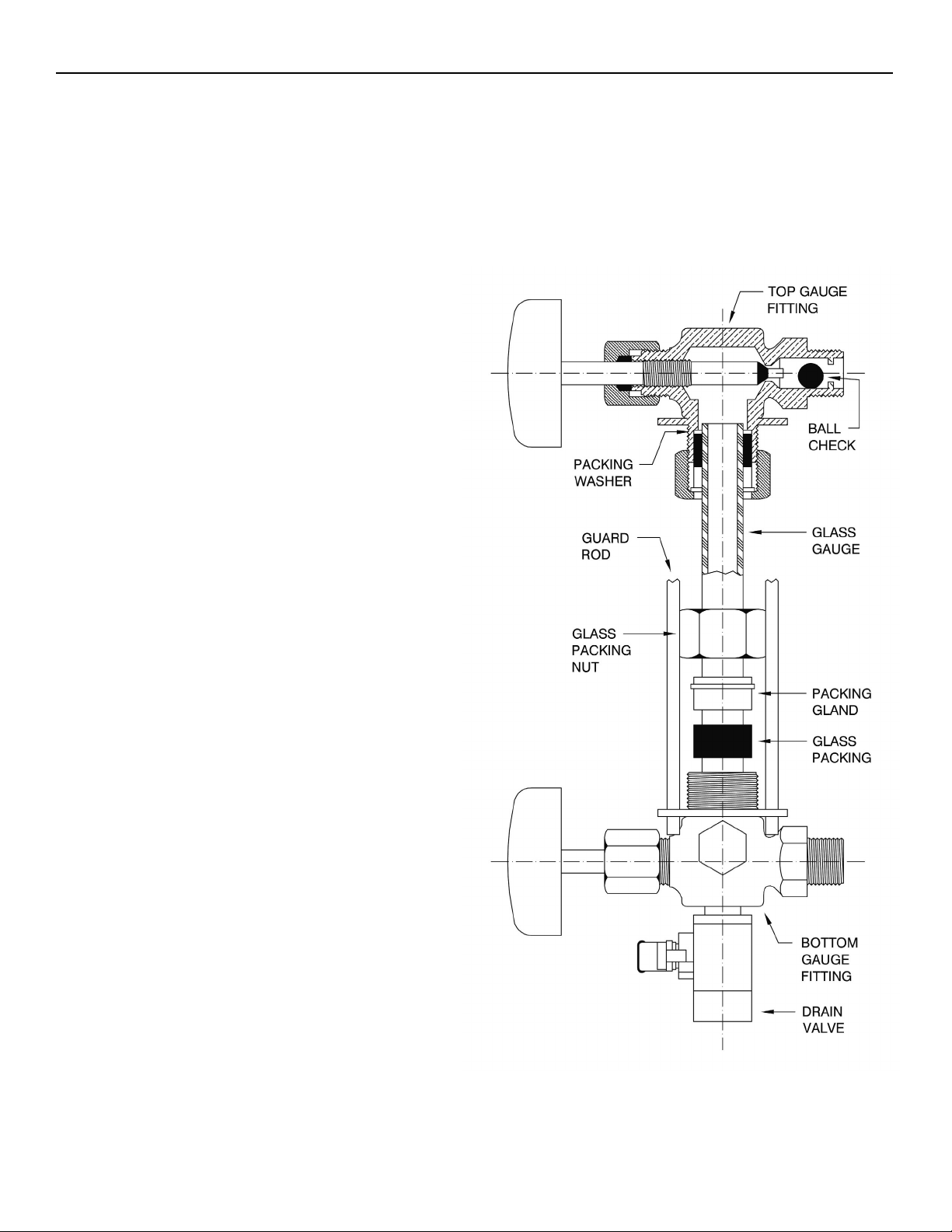

3.4.2) BRASS SIGHT GLASS (SEISMIC)

GLASS GAUGE and GLASS PACKINGS MUST be

replaced EVERY SIX MONTHS

The Seismic Sight Glass is equipped with BALL

CHECKS in each GAUGE FITTING.

Only properly trained personnel should install and

maintain water gauge glass and connections. Remember

to wear safety gloves and glasses during installation.

Before installing, make sure all parts are free of chips

and debris.

1. Uninstall GUARD RODS, GLASS GAUGE, and GLASS

PACKINGS. (You may need to rotate one of the GAUGE

FITTINGS to remove GLASS GAUGE)

2. Slip a new GLASS PACKINGS on the new GLASS

GAUGE about an inch from the bottom.

3. Now slip the following items through the top of GLASS

GAUGE in the following order:

• PACKING GLAND (facing down)

• GLASS PACKING NUT (facing down)

• GLASS PACKING NUT (facing up)

• PACKING GLAND (facing up)

• GLASS PACKINGS (inch down from top)

4. Gently insert GLASS GAUGE into GAUGE FITTINGS.

5. Carefully raise GLASS GAUGE about 1/16” from bottom

6. Carefully slide upper GLASS PACKINGS up as far as

7. Hand tighten both GLASS PACKING NUTS, then tighten

8. Reinstall GUARD RODS.

• PACKING WASHER

You may need to rotate GAUGE FITTINGS until

vertically aligned, after GLASS GAUGE is in.

and slide lower GLASS PACKINGS down until it makes

contact with the BOTTOM GAUGE FITTING. (DO NOT

allow GLASS GAUGE to remain in contact with any

metal)

possible.

1/2 turn more by wrench. Tighten only enough to prevent

leakage. DO NOT OVER TIGHTEN! If any leakage

should occur, tighten slightly, a quarter turn at a time,

checking for leakage after each turn.

INSTALLATION:

9 of 32

LB-80 - User Manual Electro-Steam Generator Corp.

3.5) CHAMBER CHEMICAL/ACID TREATMENT

All Electric Steam Generator should be cleaned regularly. The following is the least amount of

times recommended to clean out your chamber:

NORMAL WATER AREAS – Should be done ONCE A YEAR.

BAD WATER AREAS – Should be done TWICE A YEAR.

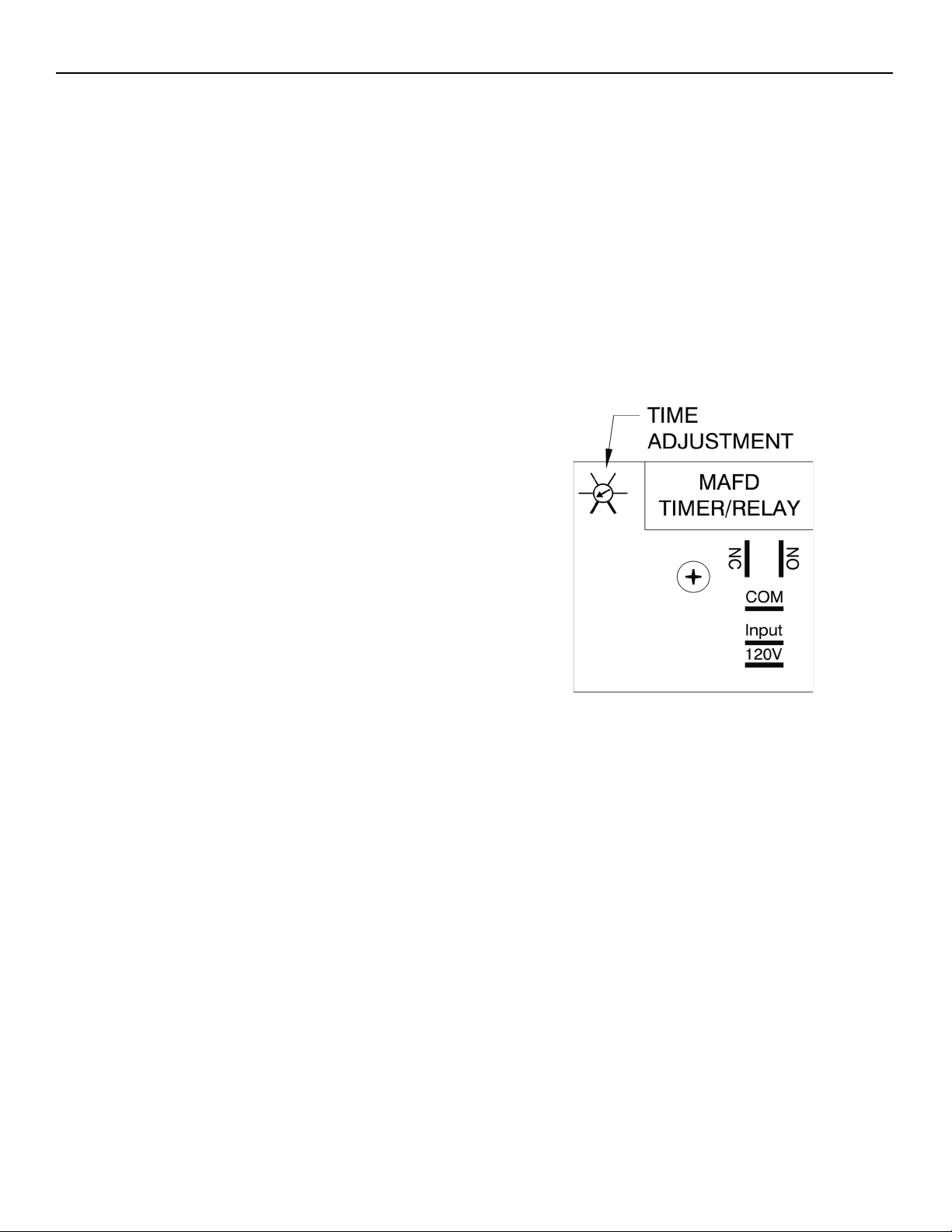

If equipped with Motorized Auto-Flush & Drain “MAFD” (#20), locate the MAFD

TIMER/RELAY in the Control Panel (#1) and do steps 1-3 before the chamber treatment and

steps 4-5 after chamber treatment is done:

WARNING – Before opening Control Panel (#1), TO AVOID ELECTRICAL SHOCK, place

Main Disconnect Box and the Toggle Switch (#2) in the OFF position.

BEFORE:

1. Dial TIME ADJUSTMENT on MAFD

TIMER/RELAY all the way down to 15 seconds.

2. Make sure MAFD (#20) in the closed position.

3. Disconnect the orange wire from the normally open

(NO) terminal on the MAFD TIMER/RELAY.

AFTER:

4. Reconnect the orange wire to the normally open

(NO) terminal on the MAFD TIMER/RELAY.

5. Dial TIME ADJUSTMENT on MAFD

TIMER/RELAY up to the desired flush time (Most

commonly 3 minutes)

Chamber Treatment Instructions:

1. Turn on generator, allowing pressure to climb to 10 to 20 PSI on Pressure Gauge (#15),

and then shut off.

2. “Blow Down” Open Manual Drain (#19) slowly, allowing HOT WATER and STEAM

to blow out into the drain.

NOTE: You may Blow Down your generator at any pressure you feel comfortable with. 10

to 20 PSI is only a recommendation. You may go higher or lower, but higher is always

better.

WARNING – HOT WATER and STEAM under HIGH PRESSURE can lift drain pipes

right off the ground and cause SERIOUS INJURY. Make sure drain pipe is SECURE and

CANNOT move. The drain must be directed into a HIGH TEMPERATURE drain (NO

PVC).

3. Remove Safety Valve (#18).

WARNING – There MUST be NO PRESSURE in the chamber when removing the Safety

Valve (#18), make sure the steam out and drain are open to assure chamber will remain

depressurized. Be cautious of escaping steam from chamber while Safety Valve (#18) is

removed.

10 of 32

Loading...

Loading...