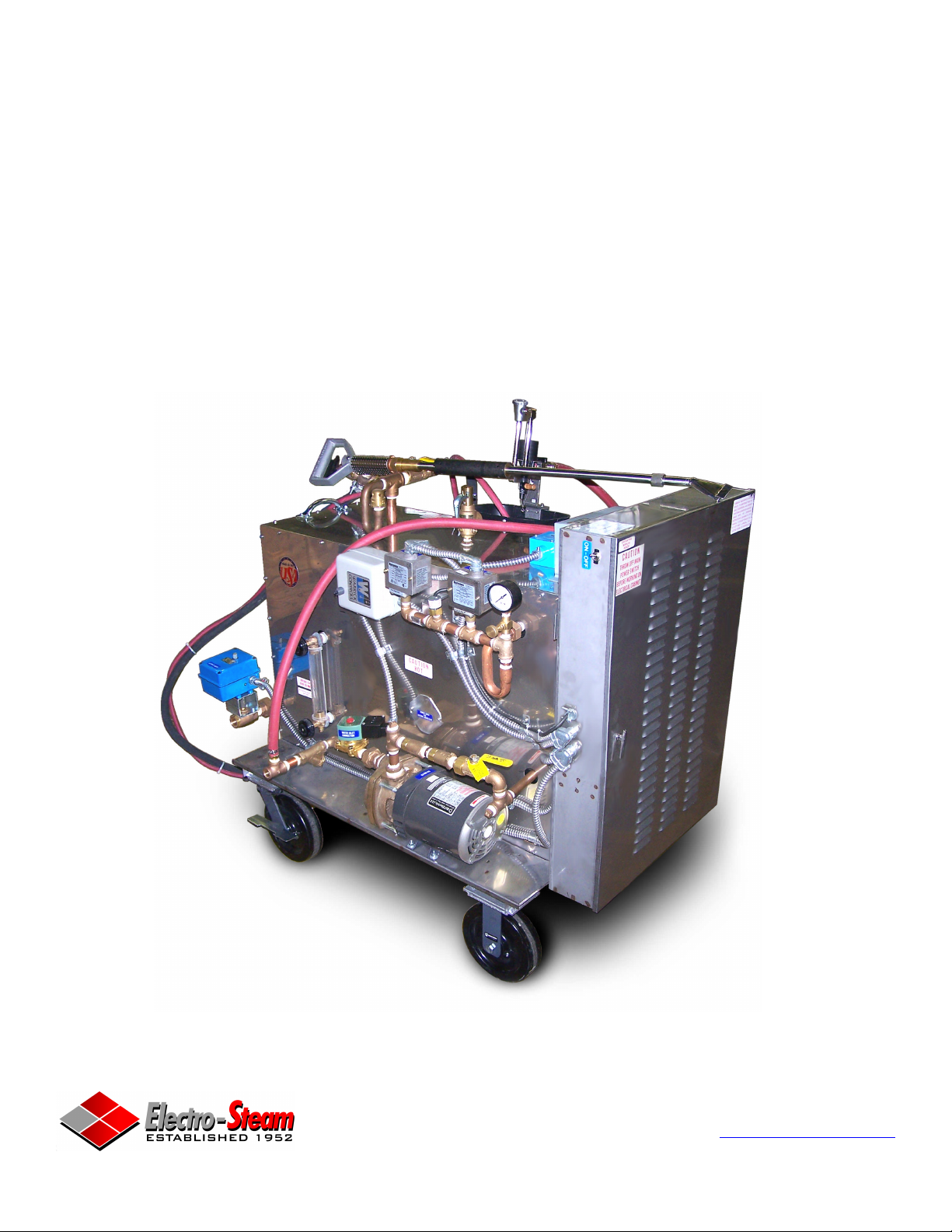

Electro Steam LB-40 Installation Manual

User Manual

& Installation Instructions

LB 40-60 (Cleaner) (Portable)

IMPORTANT – READ ALL INSTRUCTIONS BEFORE OPERATING

All steam boilers are built in accordance with ASME miniature boiler code.

NOTE: It is the responsibility of the insta ller to confor m to any state or local codes. If further

inspection, following modification by installer, is required under state or local codes, that is

the responsibility of the local installer.

www.electrosteam.com

rev. 01052010

EXCEED 105° F

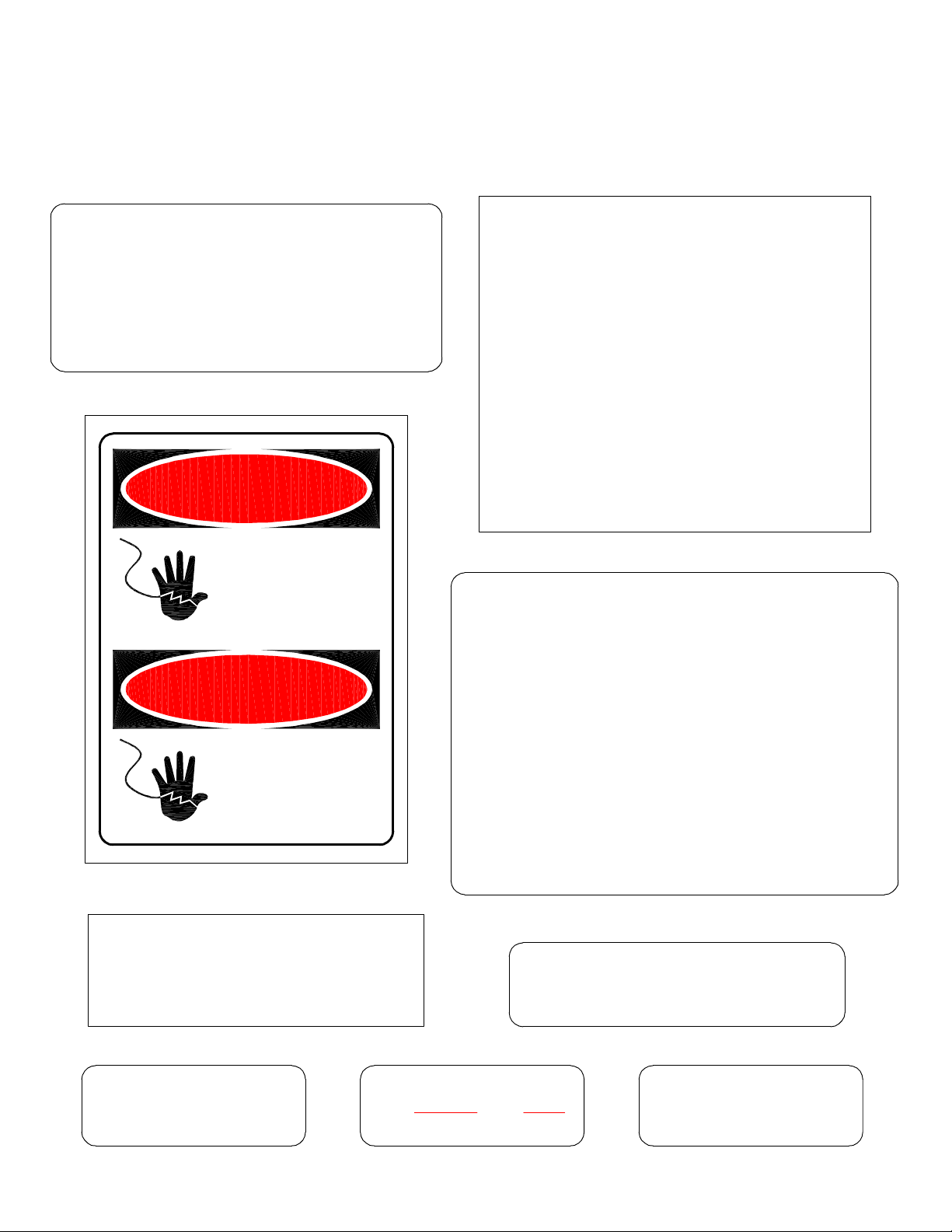

WARNING - The following labels have been placed on this boiler for YOUR SAFETY. Fai lure

to observe these instructions could lead to PROPERTY DAMAGE, SEVERE INJURY, or

even DEATH

CA

DANGER

PELIGRO

U

TION

OH T

HIGH VOLTAGE

AUTHORIZED

PERSONNEL

ONLY

CA OTI N

U

THROW OFF MAIN

POWER SWITCH

BEFORE WORKING ON

ELECTRICAL CABINET

A MANUAL WAS SHIPPED WITH THIS

BOILER. IT IS IMPORTANT THAT YOU

READ, UNDERSTAND, AND OPERATE

THIS STEAM GENERATOR IN ACCOR-

ALTO VOLTAJE

SOLAMENTE

PERSONAL

AUTORIZADO

REPLACE GLASS

EVERY SIX MONTHS

CAUTION USE ELECTRICAL

SUPPLY CONDUCTORS RATED

FOR A MINIMUM OF 90°C

DANCE WITH THE OPERATING

INSTRUCTIONS CONTAINED IN THE

MANUAL. IF FOR ANY REASON YOU

DO NOT HAVE A MANUAL, CALL

ELECRTO-STEAM AT 800-634-8177

RETIGHTEN SIGHT GLASS

TERMINALS ARE SUITABLE

FOR COPPER WIRE ONLY

U.L. 834 PAR. 4416

BEFORE USE

AMBIENT TEMPERATURE

AROUND UNIT NOT TO

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

TABLE OF CONTENTS

1.) INSTALLATION INSTRUCTIONS ................................................................ 4-7

1.1) STEAM GENERATOR (CLEANER) (PORTABLE) .............................................. 4

1.2) SOLUT I ON MIXER “OPTIONAL” ..................................................................... 5-7

2.) OPERATION & SEQUENCE OF EVENTS ................................................. 8-9

3.) CLEANING & MAINTENANCE ................................................................. 10-18

3.1) M ANU AL “BLOW DOWN” .................................................................................. 10

3.2) CLEANING WATER LEVEL PROBES .......................................................... 10-11

3.3) CLEANING OR REPLACING HEATERS ............................................................ 11

3.4) REPLACING GLASS GAUGE AND RUBBER WASHERS ......................... 12-13

3.4.1) BRASS SIGHT GLASS (STANDARD) ................................................................ 12

3.4.1) BRASS SIGHT GLASS (SEISMIC) ..................................................................... 13

3.5) CH AMBER CLEANING & CHEMICAL TREATMENT ............................... 14-15

3.6) PRESSURE CONTROL DATA SHEET ................................................................ 16

3.7) SETTING THE PRESSURE CONTROLS ....................................................... 17-18

4.) CALCULATIONS & DATA SHEETS ........................................................ 19-21

4.1) HEATER POWER & VOLTAGE RATINGS ........................................................ 19

4.2) TOTAL POWER RATING CALCULATIONS ...................................................... 19

4.3) AMPE RAGE C ALCULATIONS ............................................................................ 20

4.4) ACTU AL POWER RATING CALCUL ATIONS ................................................... 21

4.5) STEAM CAPACITY CALCULATIONS ............................................................... 21

5.) DRAWINGS & WIRING SCHEMATICS ................................................. 22-28

5.1) PARTS LEGE NDS ............................................................................................ 22-23

5.1.1) LB 40-60 (CLEANER) (PORTABLE) ................................................................... 22

5.1.2) HEAVY DUTY GUN ......................................................................................... 23

5.2) INSTALLATION DATA SHEET ........................................................................... 24

5.3) CONT ROL WIRING SCHEMATIC ....................................................................... 25

5.4) HE ATE R WIRING SCHEMATICS .................................................................. 26-28

5.4.1) LB (40-80KW) (THREE PHASE) (208-240V) ........................................................ 26

5.4.2) LB (40-60KW) (THREE PHASE) (380-425V) ........................................................ 27

5.4.3) LB (40-60KW) (THREE PHASE) (440-600V) ........................................................ 28

6.) TERMS & CONDITIONS ..................................................................................... 29

3 of 29

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

1.) INSTALLATION INSTRUCTIONS

LITTLE GIANT “LG-SERIES” (Cleaner) (Portable)

The Electro-Steam Generator design consists essentially of a high pressure chamber filled with water

that is heated by one or more submerged resistance type electric heating elements. Automatic controls

are provided to maintain the pre-set operating pressure and water level. Safety features include:

automatic low-water cutoff (manual low-water reset optional), dual pressure controls, safety valve, and

visible water level gauge. All of our generators are built in accordance with A.S.M.E . Miniature Boiler

Code and are individually inspected and stamped by an Authorized National Board Insurance Inspector.

IMPORTANT – READ ALL INSTRUCTIONS BEFORE OPERATING

NOTE: For generator measurements, refer to Installation Data Drawing attached. For

interpretation of numbered items, refer to Parts Legend Drawing attached. Ambient

temperature around this unit must not exceed 105°F.

1.1) INSTALLATION INSTRUCTIONS: (CLEANER) (PORTABLE)

Set STEAM GENERATOR on level floor and attach Solution Bucket (#25) into the 2 predrilled holes on right side of generator.

CONNECTIONS:

Periodically check all plumbing and electrical connections for tightness; this should also be done

before initial start-up.

ELECTRICAL:

This generator must be connected to a disconnect switch protected by fuses or

a circuit breaker with the proper size wire by a licensed electricia n in

accordance with N.E.C. and your local codes – Voltage, KW, and Phase

requirement are marked on the nameplate.

WATER SUPPLY:

Connect city water line to Y-Strainer (#6).

Purity: NOT to exceed 26,000 OHMS per CM

Temperature Range: 32°F – 140°F or 0°C – 60°C.

Pressure Range: 20PSI – 150PSI.

*CAUTION: The Pump (#8) requires clean tap water. If the water is not free of foreign matter, a 5

micron cartridge filter shou ld be installed in the water supply line.

STEAM OUTLET:

Connect the 1/4” Union “Female End” (A) on the Steam Hose (I) from the Steam Gun to the

Steam Outlet (1/4” Union “Male End”) (#16).

SAFETY VALVE & DRAIN:

Route Safety Valve (#18) and Manual Drain (#19) separately towards the floor.

4 of 29

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

5 of 29

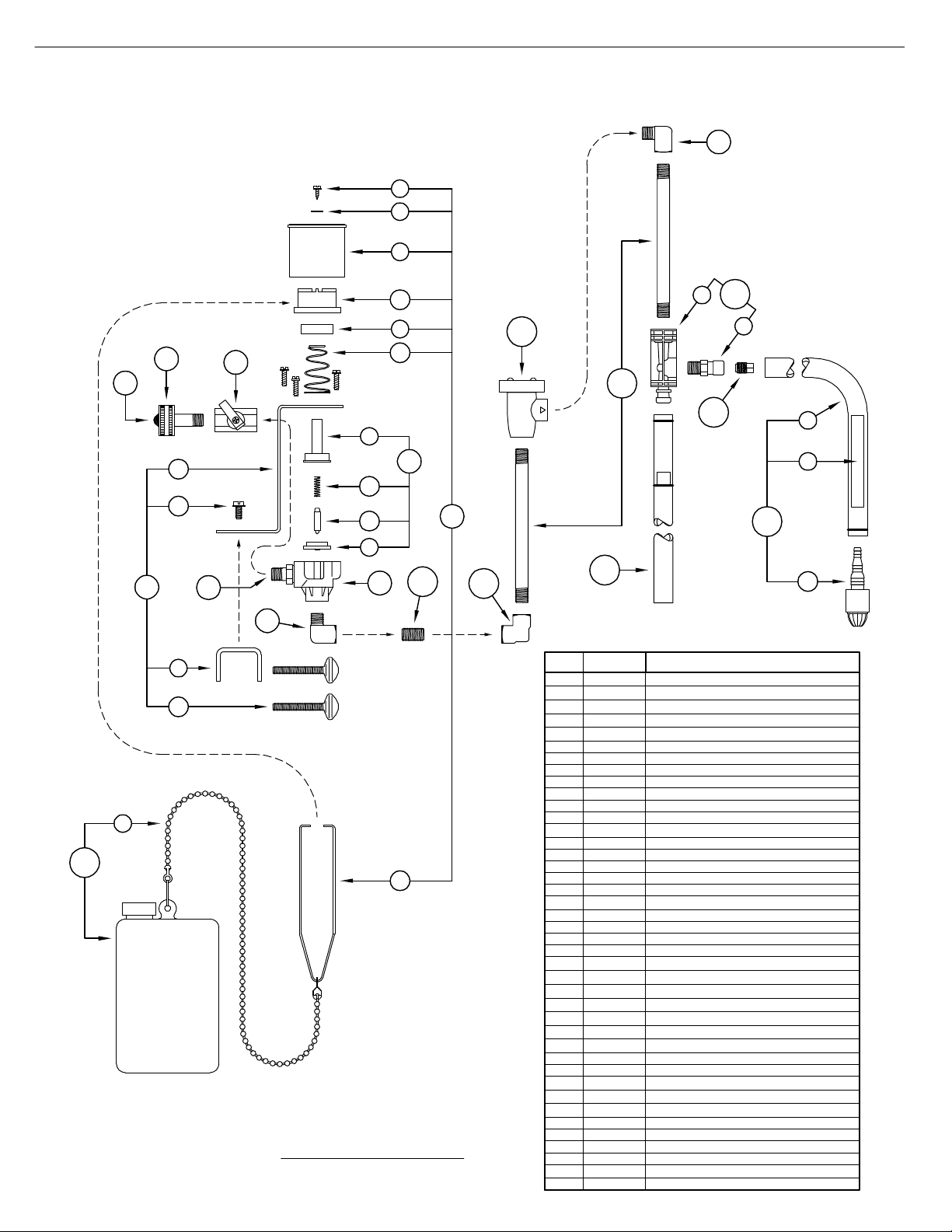

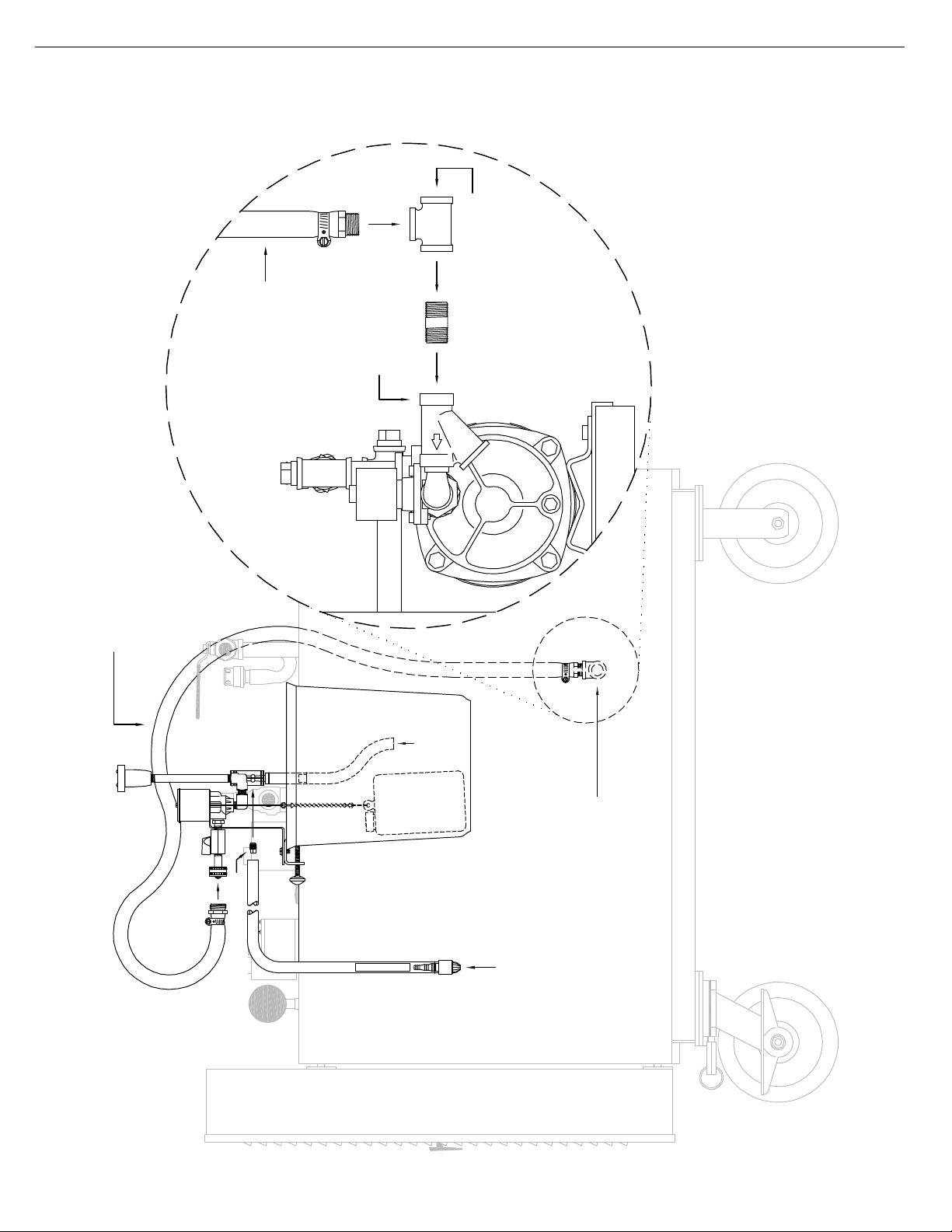

1.2) INSTALLATION INSTRUCTIONS - SOLUTION MIXER

HydroMinder Model 511 Parts

Diagram/List "OPTIONAL"

a

b

c

d

e

2

3

1

h

k

6

4

f

n

7

p

q

r

8

5

10

11

13

16

12

s

15

9

14

t

u

v

17

w

9

i

m

x

18

g

Hydro Systems Phone: (513) 271-8800

3798 Round Bottom Road Fax: (513) 271-0160

Cincinnati, OH 45244 www.hydrosystemsco.com

KEY PART NO.

238100

1.

506500

2.

5020003.

4. 360900

10080500

5.

a.

g.

m.

n.

p.

q.

9. 505600

10.

11.

12.

13.

14.

s.

16.

17.

u.

v.

w.

-

-c.

-d.

-e.

-f.

-

5030-K6.

i.

j. Lock Washer (Not Shown)

r.

5200008.

519000

506000

505900

506300

440121

440100

440101

t.

69001515.

5057-A

5058-9A

505809

250006

10076301

250700

-

5043-A18.

507200x.

Mounting Bracket Kit (speci fy model 5 11)

-h.

-

-

-k.

-

-

-

-

-

DESCRIPTION

Strainer Washer

Hose Swivel

Ball Valve, 1/4"

Nipple, 1/4"

Magnet Parts Kit

Screw

Washer-b.

Magnet Cover

Magnet Cap

Magnet

Magnet Spring

Magnet Yoke

Z Bracket

U Clamp

Screw

Thumb Screw

Valve Parts List6655207.

Valve Guide ("Bonnet")

Armature Spring

Armature

Diaphram

Water Valve Body

Street Elbow, 1/4"

Nipple, 1/4" x Close

Elbow, 1/4"

Nipple, 1/4" x 6"

Vacuum Breaker

Eductor Assembly

Eductor Body Only

Suction Stub Only

Metering Tip (Kit)

Discharge Tube Assembly

Suction Tube Assembly

Tubing, 1/2" x 9'

Ceramic Weight

Foot Valve, Viton

(Foot Valve & Weight)

Float & Chain Assembly

Bead Chain Only

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

1.2) INSTALLATION INSTRUCTIONS – SOLUTION MIXER

“OPTIONAL” (Continued)

NOTE: Refer to “HydroM inder Model 511 Parts Diagr am” on previous page fo r interpretation of

numbered & lettered items. For interpret ation of numbered items with “#”, refer to Parts Legend

Drawing attached. For better understanding of installation of Solution Mixer, refer to dr awing on

next page.

1. A 4’ Red Hose should be enclosed to attach the incoming water connection to the Solution Mixer.

Attach tee end of hose to Water Inlet (#6).

2. Remove the 2 Screws (6k) holding U-Clamp (6i) and reverse U-Clamp (6i) to where

Thumbscrews (6m) are on outside of Solution Bucket (#25). This allows Solution Mixer to fit

more vertical and Magnet Yoke (5g) moves more free ly.

3. Attach Solution Mixer on side of Solution Bucket (*25) opposite the Steam Out (*16). Tighten

Thumbscrews (6m).

4. Attach Discharge Tube Assembly (16) to botto m of Eductor Body Only (14s). Push tight on

flange.

5. Remove Metering Tip (15) of your choice from enclosed packet and hand screw into Suction Stub

Only (14t). (Green tip is suggested for initial start up. The Solution Mixer should be titrated, at end

of gun, or wand, with valve fully open by chemical supplier. Larger or s maller Metering Tips (15)

may be required to achieve proper working concentrat ion.)

NOTE: For better understanding of metering tip selection, refer to section “Metering Tip Selection:”

in the HydroMinder Model 511 Manual enclosed with Solution Mixer.

6. Attach Tubing 1/2” x 9’ (17u) to Suction Stub Only (14t). Push tight on flange.

7. Place Viton Foot Valve (17w) into solution supply.

8. Thread Bead Chain Only (18x) t hrough loop on Magnetic Yoke (5g). Pull Bead Chain (18x) close

so that Float & Chain Assembly (18) is suspended in Solution Bucket (#25). If not suspended,

Solution Bucket (#25) will never fill.

9. Attach the other end of the 4’ Red Hose to the Hose Swivel (2).

10. Verify that the Ball Valve (3) is completely open.

11. Solution Mixer is now ready for use.

6 of 29

7 of 29

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

1.2) INSTALLATION INSTRUCTIONS - SOLUTION MIXER

"O PTIONAL" (Continued)

NEW WATER INLET

WATER INLET

GENERATOR'S

4' HOSE USED TO

CONNECT WATER INLET

4' HOSE USED TO CONNECT WATER INLET OF

SOLUTION MIXER TO INCOMING WATER CONNECTION"

CONNECTION"

INCOMING WATER

OF SOLUTION MIXER TO

WATER &

SOLUTION

OUTLET

METERING TIP

INLET

SOLUTION

WATER INLET

OF GENERATOR)

(ON OPPOSITE SIDE

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

2.) OPERATION & SEQUENCE OF EVENTS

IMPORTANT – READ INSTALLATION INSTRUCTIONS BEFORE OPERATING

START UP:

1. Turn on water supply from the source to the generator.

2. OPEN all valves on generator except for the Manual Drain (#19).

3. Place Main Disconnect Box in ON position and/or Plug In.

4. Hold in the Lever Handle (D) on the Steam Gun.

5. Place toggle Switch (#2) in ON position.

• The Water Solenoid (#7) and Pump (#8) will engage and the chamber will begin

to fill with water. As the water level rises, it will make cont act with the (G/D) and

(A) probes, indicating the heaters are safely submerged. At this t ime the

contactor(s) will engage, supplying power to t he heaters, causing steam pressure to

accumulate.

• The chamber will continue to fill with water until 1 second after the water makes

contact with the (C) probe, causing the Water Solenoid (#7) and Pump (#8) to turn

off.

• If the contactor(s) still have not engaged at this time, you may need to press the

Safety Reset (#13). If your generator is required to have a Manual Low-Water

Reset (MLWR) (#3), it must be pushed it at this time to engage the contactor(s).

6. Once generator is full of water, release the Lever Handle (D) on the Steam Gun.

• Steam pressure will continue to rise until is reaches 85 PSI. At this time, the

pressure control labeled “Control” will cause the contactor(s) to disengage. The

pressure will drop approximately 5-8 PSI until the “Control” causes the

contactor(s) to reengage, causing the pressure to rise again. The contactor(s) will

continue to cycle on and off during operation.

NOTE: Just because generato r is up to pressure does not necessarily mean it is up to

temperature. When first starting generator, before using the gun for operation, you

should use the gun to exhaust pressure, allowing the heaters to r emain on longer,

thus increasing the temperature inside the chamber and increasing its ability to

recover from loss of steam.

WARNING – Steam hose and gun will always be hot while generat or is on, even when

gun is not is use.

7. The generator is now fully operational and w il l produce steam until it is turned off.

8 of 29

LB-40(C) thru LB-60(C) (Portable) - User Manual Electro-Steam Generator Corp.

2.) OPERATION & SEQUENCE OF EVENTS (Continued)

• As steam is exhausted, the water level will drop until 3 seconds after it breaks

contact with the (C) probe. At this time, the Water Solenoid (#7) and Pump (#8)

will engage and the chamber will again fill with water. The chamber will continue

filling until 1 second after the water makes contact with the (C) probe. The Water

Solenoid (#7) and Pump (#8) will continue to cycle o n and off during operation.

NOTE: If at anytime the “Control” fails and the pressure exceeds 85 PSI, the “Safety”

will cause the contactor(s) to disengage at 90 PSI and will not allow the

contactor(s) to reengage until the Safety Reset (#13) is manually pushed. I f this

happens, the “Control” needs to be set lower or must be replaced. If the “Control”

and “Safety” happen to fail, and the pressure reaches 100 PSI, the Safety Valve

(#18) will pop, releasing the pressurized steam. I f this happens, a ll three

components may need to be replaced.

STEAM GUN OPERATION:

NOTE: Refer to Steam Gun Parts Legend for interpretation of lettered items.

1. The special Siphon Heavy Duty Steam Gun is equipped with Steam (I) and Detergent

(J) Hoses with valves for steam and detergent control.

2. The Suction Strainer (B) at the end of the detergent hose shou ld be placed in the

Solution Bucket (#25). Chemicals should be mixed in the bucket in proport ions as

recommended by chemical supplier. (Solution Mixer “Optional”)

3. Steam flow is obtained by pressing on the Lever Handle (D) located direct ly in front of

the handle. A mixture of steam and detergent is obtained by regulating the small

Detergent Valve (H) while operating the Lever Handle (D).

SHUT DOWN:

4. To shut off generator, place Toggle Switch (#2) and Main Disconnect Box in OFF

position and/or unplug the machine. Pressure will drop naturally as the generator cools,

or generator may be drained manually through Manual Drain (#19). (See Manual Blow

Down 3.1)

WARNING – HOT WATER and STEAM under HIGH PRESSURE can lift dra in pipes

right off the ground and cause SERIOUS INJURY. Make sure drain pipe is SECURE

and CANNOT move. The drain must be directed into a HIGH TEMPERATURE drain

(NO PVC).

9 of 29

Loading...

Loading...