Page 1

SummitSummit

3208GLD3208GLD

Installation, OperationInstallation, Operation

and Programmingand Programming

Electronics Line (E.L.) Ltd.

www.elecline.com

ELECTRONICS LINE’S TECHNICAL SUPPORT DEPARTMENT: (972)-3-9211110

Electronics Line (E.L.) Ltd. reserves the right to change the information within this manual without prior notice.

ZI0084A (12/98)

Page 2

2

Page 3

TABLE OF CONTENTS

Introduction.................................................................................................................................................. 3

About the Summit 3208GLD Installation, Operation and Programming Manual...................................................3

Publication Information .........................................................................................................................................3

Chapter One: Overview ...............................................................................................................................4

1.1: Specifications ................................................................................................................................................4

1.2: Zones.............................................................................................................................................................5

1.3: Telephone Dialer ...........................................................................................................................................6

1.4: Remote Programming...................................................................................................................................6

1.5: Other Features...............................................................................................................................................7

Chapter Two: Installation.............................................................................................................................. 8

2.1: Parts and Options..........................................................................................................................................8

2.2: Mounting the Keypad.....................................................................................................................................8

2.3: Wiring Diagram............................................................................................................................................10

2.4: Terminal Connections..................................................................................................................................11

2.5: Fuse Replacement ......................................................................................................................................12

2.6: Turning on the System.................................................................................................................................12

2.7: Testing the System......................................................................................................................................12

Chapter Three: System Operation for the 3106 LED and 3108 LCD Keypads.............................................13

3.1: General........................................................................................................................................................13

3.2: Display and Controls....................................................................................................................................13

3.3: System Status Displays...............................................................................................................................14

3.4: Menu Selections/Direct Commands ............................................................................................................15

3.5: Arming/Disarming........................................................................................................................................16

3.6: User Codes..................................................................................................................................................17

3.7: Emergency and Duress...............................................................................................................................17

3.8: Zone Bypassing/Unbypassing......................................................................................................................18

3.9: Event Log ....................................................................................................................................................19

3.10: System Partitioning....................................................................................................................................19

3.11: Tests..........................................................................................................................................................20

3.12: Additional Operations.................................................................................................................................20

Chapter Four: Programming.......................................................................................................................23

4.1: General........................................................................................................................................................23

4.2: Guide to Programming ................................................................................................................................23

4.3: Programming Procedure.............................................................................................................................23

4.4: Programming Parameters...........................................................................................................................24

Appendix A: Troubleshooting .....................................................................................................................45

Appendix B: Hexadecimal Conversion Chart..............................................................................................46

Glossary ....................................................................................................................................................47

INTRODUCTION

About the Summit 3208GLD Installation, Operation and Programming Manual

This manual is designed to help you, the installer, with the installation process for the Summit 3208GLD We

strongly urge you to read through this manual, in its entirety, before beginning the installation process so

that you can best understand all that this security system has to offer your customers. This manual is not

intended for end user use. End users are encouraged to read the Summit 3208GLD User Manual that

accompanies the system. If you have any questions concerning any of the procedures described in this

manual please contact Electronics Line at (972)-3-9211110.

Publication Information

Catalog Number: ZI0084A (12/98)

3

Page 4

CHAPTER ONE: OVERVIEW

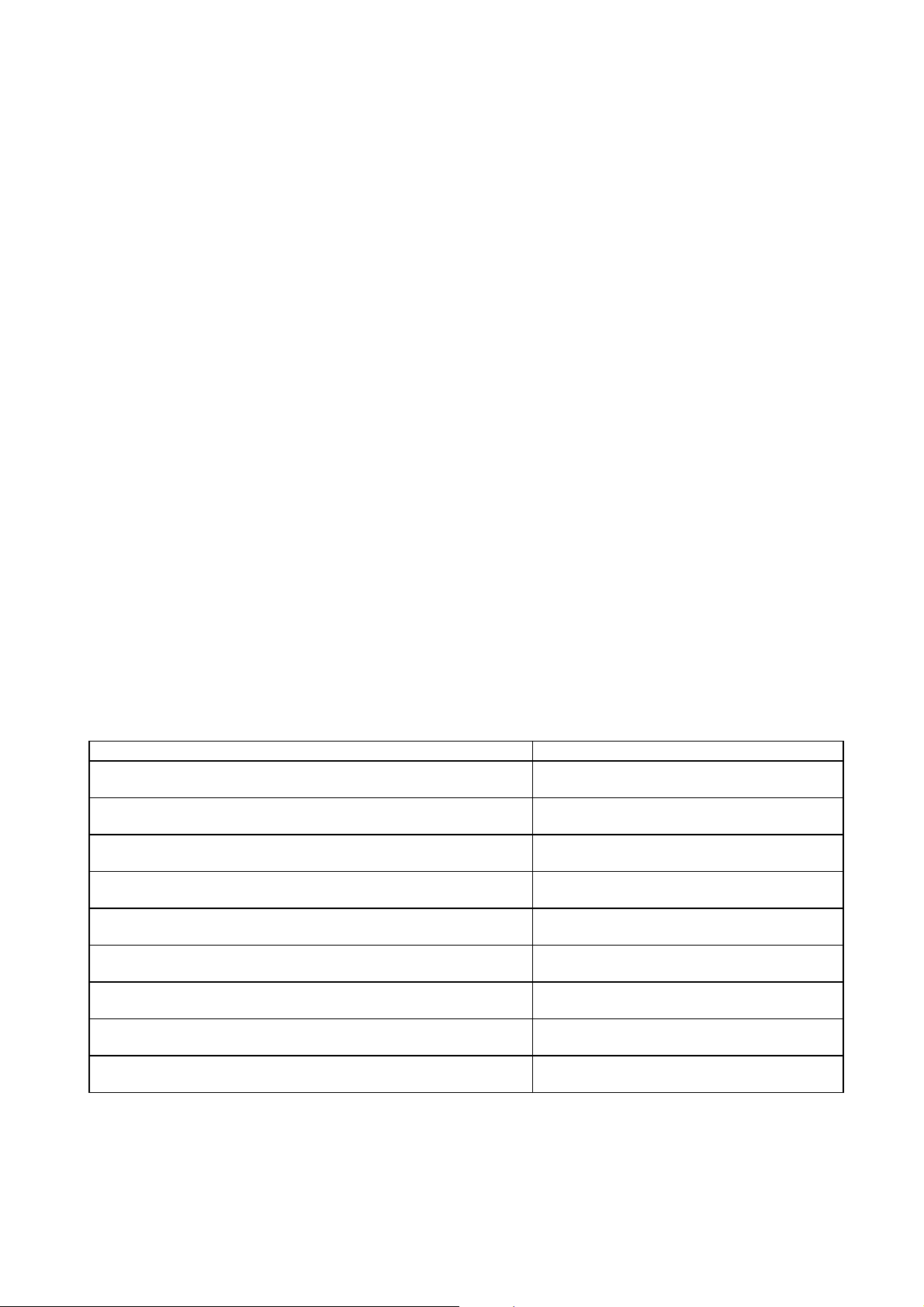

1.1: Specifications

Power Input

Power Output

Zones

Keypads

User Codes

Open/Close

Windows

Remote

Programming

Current

Consumption

Operating

Temperature

Dimensions

Weight

AC: 15Vac, 30VA transformer.

Battery backup: 12Vdc, 6.5 Ah or 7Ah (UL requirement).

Auxiliary power - regulated 12Vdc nominal at 1A max. including keypads and detection

devices for 4 hours standby. (For CSFM Fire applications - 220mA max. including

keypads and smoke detectors for 24 hours standby).

Bell output - regulated 12Vdc nominal from auxiliary power, unregulated 9 – 18 Vdc,

600mA total auxiliary power.

Number of zones - 8 onboard (expandable to 32)

Types - 3108 LCD keypad, 3106 LED keypad

Number of keypads - Up to 8 supervised

Current draw - 40mA without backlight, 60mA with backlight

Distress Keys - 3 user initiated

Number of users – 15

Number of digits per user code - 3 to 6

Authorization levels - 15

Number of windows - 1 opening window + 1 closing window for

each day of the week per sub-system

Window sizes - + 15 min, + 30 min, + 45 min, +60 min.

Equipment - Remote Programmer software package.

Access - Direct (Password), Callback, Off-hook.

Control Panel: Approximately 130mA

3108 LCD Keypad: 20mA without backlight, 60mA with backlight.

3106 LED Keypad: 20mA without backlight, 70mA with backlight.

3508 Zone Expander Module:

10mA

3528 Wireless Zone Expander Module:

10mA

3402 Output Relay Module:

15mA all relays deactivated, 30mA per activated relay.

3407 Output Relay Module:

15mA all relays deactivated, 30mA per activated relay.

3417 Transistor Module:

10 mA all transistors deactivated.

725mA all relays transistors (drawing a max. 100mA each).

0° to 60°C (32° to 140°F).

12” x 12” x 4” (30.5cm x 30.5cm x 10.2 cm).

Approx. 6.5 lbs. (3 Kg).

4

Page 5

1.2: Zones

The Summit 3208GLD comprises 8 on-board zones that are expandable to a total of 32. Both hardwire and

wireless zone expanders are available. Each zone can be precisely configured to suit a wide variety of

applications.

Zone Descriptors

Each zone can be assigned an individual zone descriptor. These can be chosen from the standard zone

descriptor library or from one of the four custom zone descriptors that are programmable by the installer.

Zone Type

One of fifteen zone types can be defined for each zone. The zone type dictates the nature of a specific

zone’s operation. The following is an explanation of each zone type.

Perimeter and Interior Zones

Different methods of arming the system rely on the definition of zones as perimeter or interior. For example,

when the user wishes to remain on the premises, STAY arming secures only perimeter zones allowing free

movement within the protected area. Perimeter and Interior zones can be defined as ‘Normal’, ‘Primary’,

‘Secondary’ or ‘Conditional’.

Normal Zone: A normal zone generates an alarm when opened.

Primary and Secondary Zones: Primary zones never actually generate an alarm; they are always used in

conjunction with secondary zones. A secondary zone will generate an alarm only if opened during the entry

delay of a primary zone. These zones are used when the primary zone is an unprotected area that is

crossed by an intruder to reach the area protected by the secondary zone. This rules out the need to

compromise the sensitivity of the devices installed in the secondary zone to achieve maximum false alarm

immunity.

Conditional Zone: Conditional zones do not generate an alarm when opened during the entry delay otherwise, an alarm is generated instantly. These zones can be used for detectors protecting the area in

which a keypad has been installed or the area crossed in order to reach the keypad.

Common Zone: A common zone belongs to all systems. An alarm will only be generated from a common

zone if all the sub-systems are armed. Common zones are generally used in partitioned systems where a

corridor is shared by more than one protected area.

24hr zones

24hr zones are always operational regardless of system status and will generate an instant alarm when

opened. If an exit/entry delay is defined for a 24hr zone, it will be ignored by the system.

Fire and Verified Fire Zones: Fire zones are designed for use with smoke detectors. A fire zone will

generate an instant alarm when opened. Verified fire zones will not sound an alarm and will not send a

message to the central station unless a second detection has been made within a minute of the first. The

Summit 3208GLD control panel can be programmed to enable automatic or manual power reset for latching

smoke detectors (see address 495).

Emergency/Holdup: Emergency/Holdup zones are 24hr zones designed for use with panic buttons in the

case of holdup situations, medical emergencies etc. It is recommended that glassbreak detectors be

connected to Emergency/Holdup zones.

Tamper: This zone type is used with tamper switches and is designed to prevent unauthorized opening of

the metal housing.

Keyswitch zones

Two zone types offering different operational modes are available for use with a momentary keyswitch.

On/Off STAY and On/Off AWAY: A keyswitch zone can be defined to either STAY or AWAY arm the

system.

Swinger Zones

Swinger zones limit the amount of alarms that can be sent from a specific zone within a predetermined time

period. This feature is designed for use with zones that are highly prone to false alarms. The swinger

parameters are programmed at address 388 and at the second address for each specific zone.

5

Page 6

System Partitioning

The system can be partitioned into a maximum of 4 independent sub-systems with individual account

numbers, keypads, user codes and relays assigned exclusively for each sub-system. A sub-system is

created when at least one zone is assigned to it.

1.3: Telephone Dialer

The Summit 3208GLD allows for up to four different telephone numbers to be programmed into the system

using either pulse or tone dialing. The Summit 3208GLD supports several communication protocols

including pulse protocols enabling communication with most popular central station receivers. Up to 16

digits can be programmed for each telephone number. Different groups of event messages (Burglary, Fire,

Open/Close messages etc.) can be programmed for single or multiple central station notification, enabling

notification of up to four central stations. Message transmission can be programmed as Primary, Backup or

Duplicate.

In some cases the central station handles events reported per zone and in others per event. Additionally, an

event code can comprise of either one or two digits and can include additional information such as the user

number in opening and closing messages or zone ID in event oriented zone messages. These codes are

usually assigned by the central station - consult the central station operator for a listing of the different event

codes.

Follow-me

Using the Follow-me feature, the panel can notify the user that the system has undergone certain events by

sounding a sequence of tones over the telephone. The user acknowledges that the message has been

received by pressing 0, 9 or # on their telephone. If this acknowledgement is not received within the oneminute time window, opened the moment the panel starts dialing, the control panel redials. The number of

dialing attempts made depends on the value programmed at address 197.

Telephone #4 is designed for use with this feature, as it is the only telephone number that can be easily

programmed by the user, without the need to enter programming mode.

Telephone Line Supervision

Approximately 20 seconds after the telephone line is cut, all keypads sound a trouble beep and the

message “Telephone Comm. Failure” appears on LCD keypads.

1.4: Remote Programming

Electronics Line’s remote programming software enables all programming and operation to be performed

from a PC. This can be done from either a remote location or on-site using the ‘Off-hook’ communication

option. The software provides a comprehensive interface to the Summit 3208GLD control panel facilitating

and cutting down the time taken in programming the system.

A number of programmable options, relating to when and how RP communication is established, are

available at address 496. The tollsaver feature, RP Callback, makes remote programming more costeffective and increases the level of security. Using this feature, the Remote Programmer establishes a

connection with the panel. The panel recognizes the passcode, hangs up and calls the number programmed

at addresses 172-179 within 60 seconds.

Answering Machine Override

Answering machine override enables the control panel to distinguish between regular incoming calls and a

communication attempt by the RP (remote programmer) software. An RP call is identified by the control

panel as a sequence of two calls within a 30-second time window.

1. The control panel does not answer the first incoming call.

2. The control panel opens a 30-second time window from the moment the telephone stops ringing.

3. The control panel answers after 1 ring and RP communication is established.

Note: The 30-second time window will only start if the number of rings in first call exceeds the

number of rings set for the control panel. For example, if the control panel is programmed to pick

up after 3 rings, the time window will not start unless the first call was at least 3 rings.

6

Page 7

1.5: Other Features

Opening and Closing Windows

This feature helps cut down on the amount of opening and closing reports sent to the central station. The

opening and closing windows are programmable windows of time, during which the user usually arms or

disarms the system. Disarming during an opening window or arming during a closing window does not send

a report to the central station. If the system is not disarmed or armed during the appropriate window, a

‘Failed to Open’ or ‘Failed to Close’ message is sent to the central station.

The Summit 3208GLD offers the opportunity to choose from a list comprising three opening and four closing

window times. The times in this list can be programmed according to the user’s entry and exit scheduling

requirements. If required, the user can activate the ‘Late to Close’ command to extend the closing window

period for that day. The user may opt to program an auto arming time at the end of a closing window so that

the system automatically arms itself at a set time. This prevents situations where the system is left unarmed

at the end of the day.

Latch-Key

The latch key feature has been designed to inform parents whether their children have arrived home safely

and on schedule. The panel sends a ‘Failed to Open’/‘Failed to Close’ message to the central station or

follow-me number if the MENU/NEXT key is not pressed during the appropriate window.

Dealer Lockout

The control panel’s parameter settings can be restored during the 60 seconds following power-up using the

unalterable code “123456”. Activating Dealer Lockout disables this feature and the code can only be

restored using the RP software.

7

Page 8

CHAPTER TWO: INSTALLATION

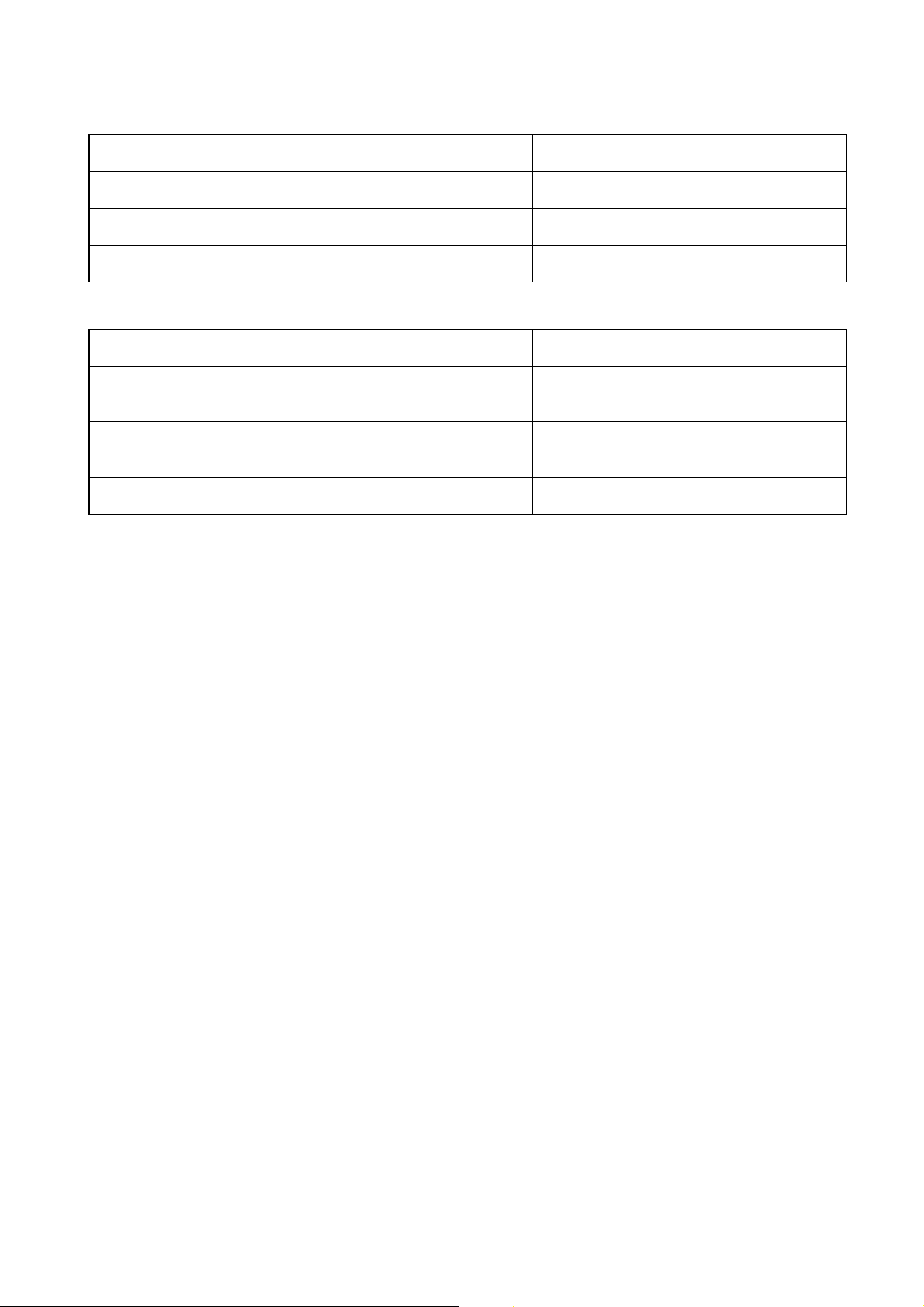

LCD Module

LED /

GND - + VDD

2.1: Parts and Options

Standard Parts

Summit 3208GLD Household Burglary Alarm Control Panel without keypad 1 each

2.2K ohm burglary End Of Line Resistors 8 each

Installation, Operation, and Programming Manual 1 each

User Manual 1 each

Optional Parts List

3106 LED Keypad

3108 LCD Keypad

3407 7 Relay Output Relay Module

3508 8 Zone Expander Module

3528 Wireless Zone Expander

RP3206 Up/Downloading Software

3911 Up/Downloading Remote Programmer & RS232 Cable

12Vdc Adapter for Remote Programmer

12Vdc/7Ah battery

3722 15Vac 30VA Transformer

2.2: Mounting the Keypad

Both the LCD and LED keypads are supplied configured to keypad address 1 in unsupervised mode. To

connect the keypad/s you will need a small flat-head screwdriver. The maximum recommended distance

between the control panel and the keypad is 1,000m (3,000ft.).

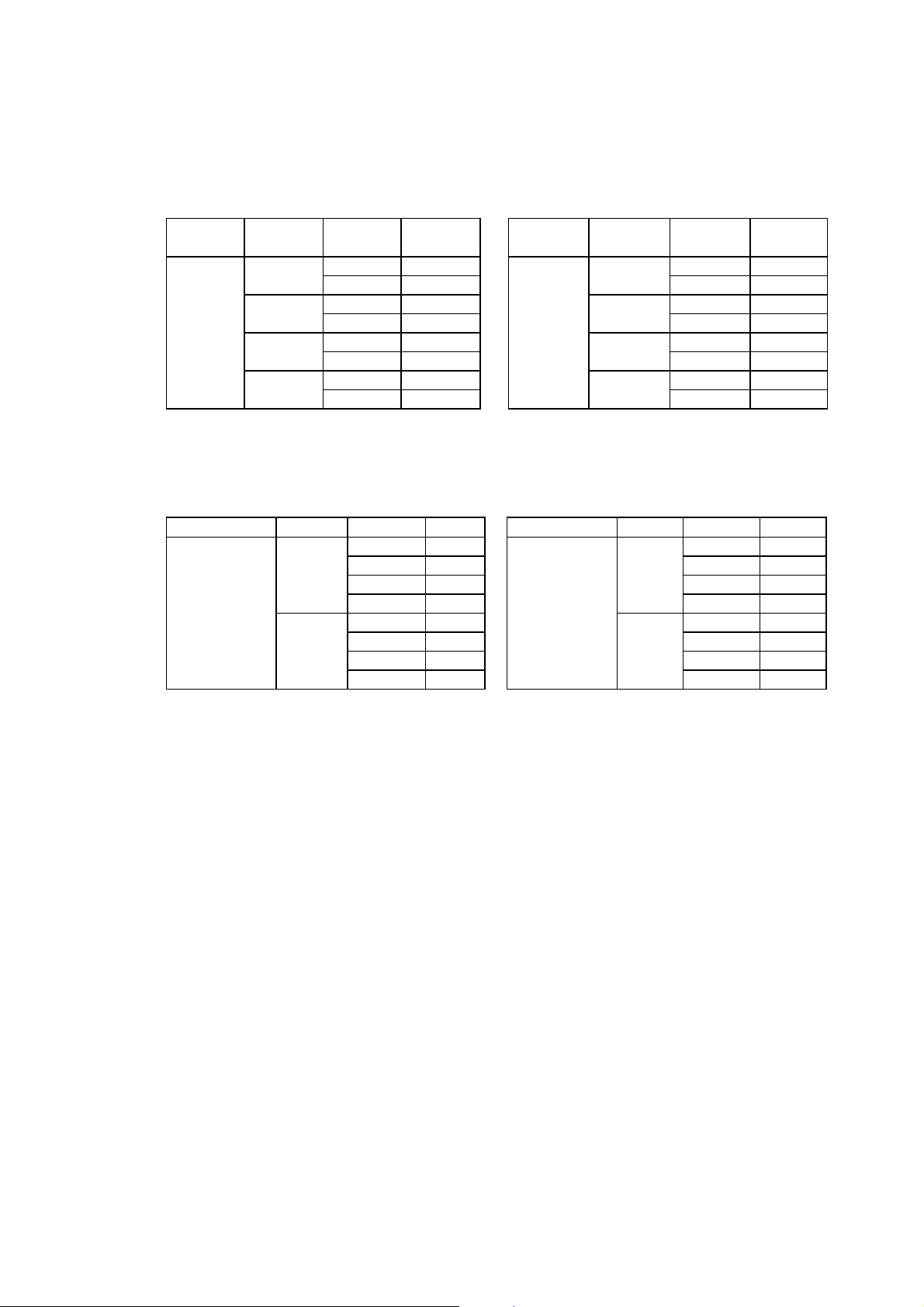

LED / LCD Module - rear view, cover removed

LCSP

terminal block

G

B

R

L

E

A

E

C

N

K

LSCP

W

H

I

R

T

E

E

D

LCD Contrast

trimmer

Buzzer

MicroController

Jumpers

B

S

C

A

Tamper

Switch

8

Page 9

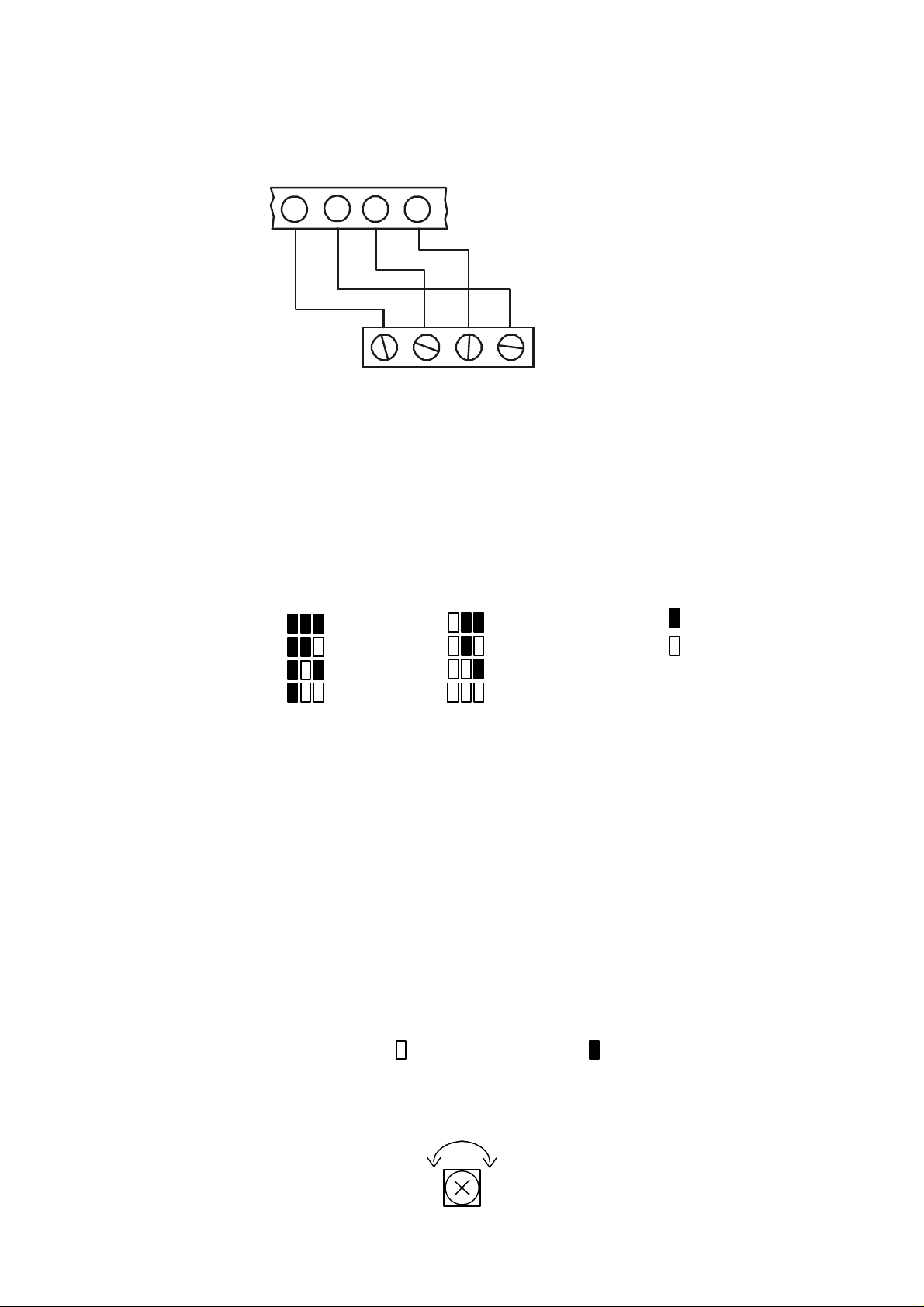

Keypad Wiring Connections

VDD

WHITE

LSCP

CONTROL PANEL

Supervised

Unsupervised

S

GNDVDD

5 6 7

BLACK

LSCP

+

-

8

GREEN

RED

KEYPAD

GND

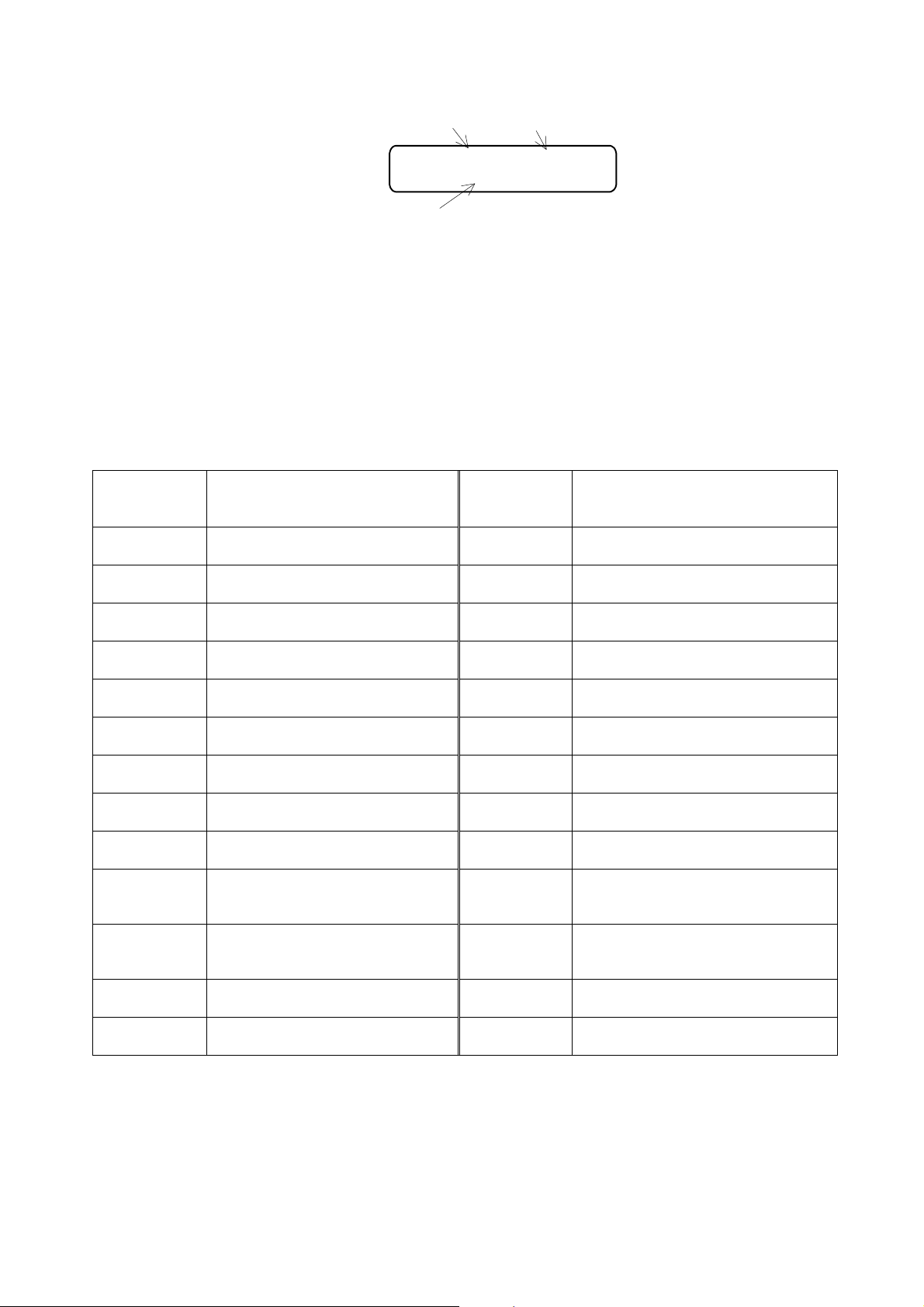

Keypad unit address

Up to eight individually addressed supervised keypads can be installed with the control panel. If more than

one keypad is installed with same unit address, all keypads must be configured as unsupervised.

To configure the keypad unit address:

1. Using a small flat-head screwdriver, open the back cover of the keypad.

2. Locate the jumpers marked “CBA”.

3. Install the jumpers according to the diagram below.

4. Disconnect and reconnect the power supply.

Keypad 1

Keypad 2

Keypad 3

Keypad 4

Keypad 8

-

Keypad 5

Keypad 6

Keypad 7

+

CBACBA

Jumper installed

Jumper removed

On LED keypads, the keypad’s system defines which zone expander is associated with the keypad. See

Addresses 132-139 for keypad system allocation.

System 1: Zone Expander A System 2: Zone Expander B

System 3: Zone Expander C System 4: Zone Expander D

Note: If zone expander A is not in use, the control panel’s 8 onboard zones are displayed from a

System 1 keypad.

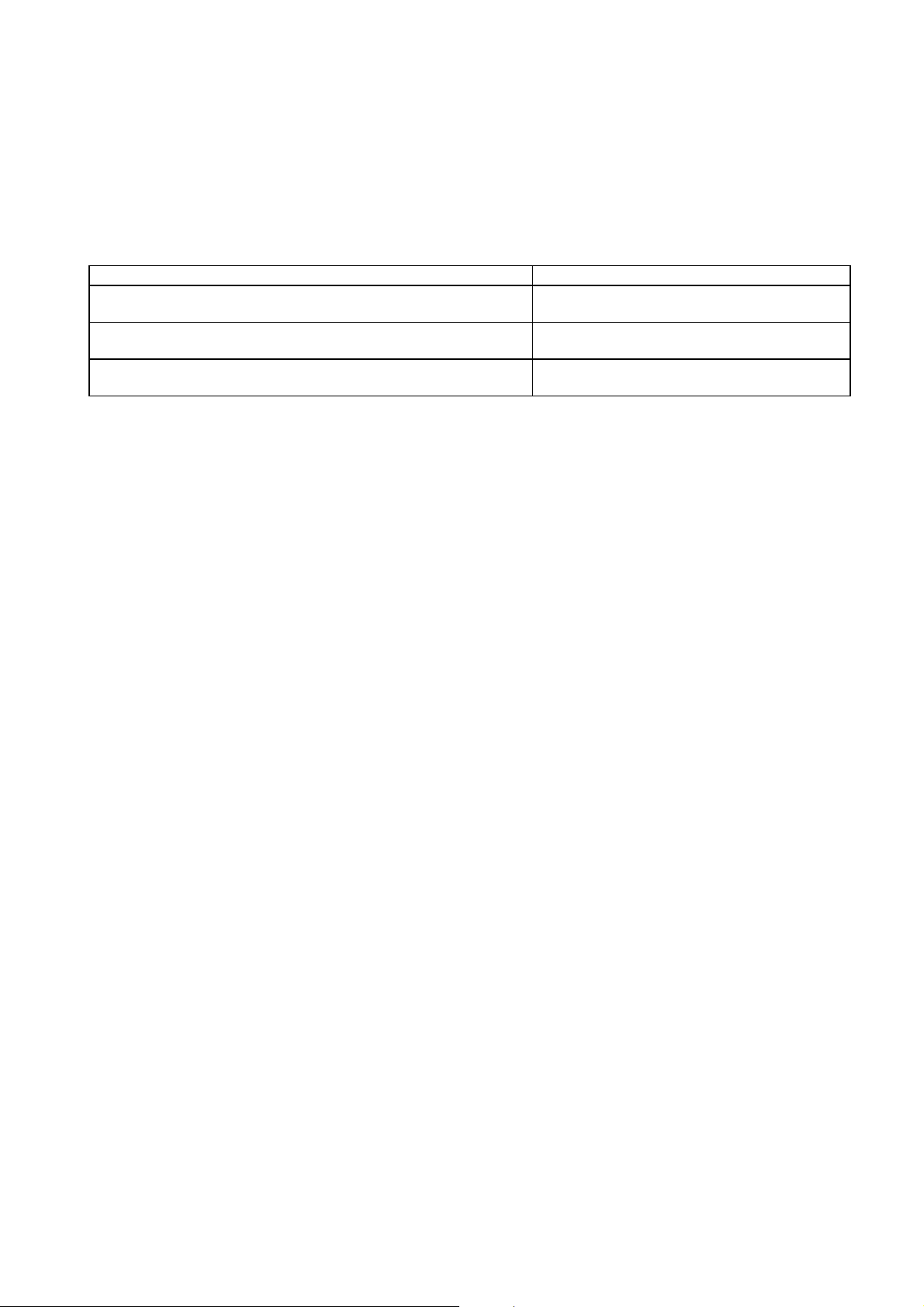

Keypad supervision

A supervised keypad will generate an alarm should it become disconnected from the control panel.

To configure the keypad supervision setting:

1. Using a small flat-head screwdriver, open the back cover of the keypad.

2. Locate the jumper marked S.

3. To configure the keypad in supervised mode, remove the jumper.

S

Adjusting the display contrast on the LCD keypad

If the LCD display is unclear, the contrast may be adjusted using the LCD contrast trimmer.

Bright

Dim

9

Page 10

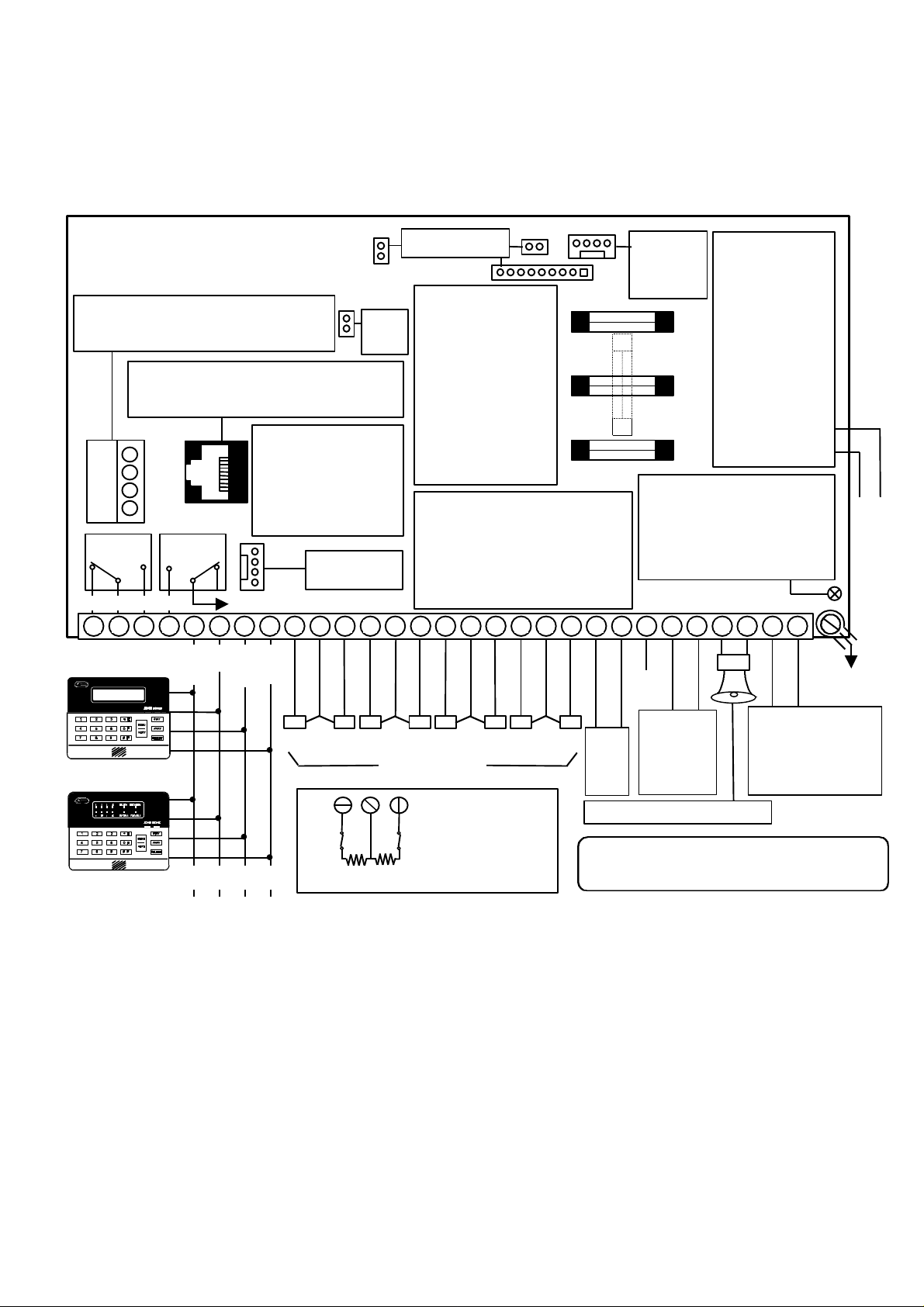

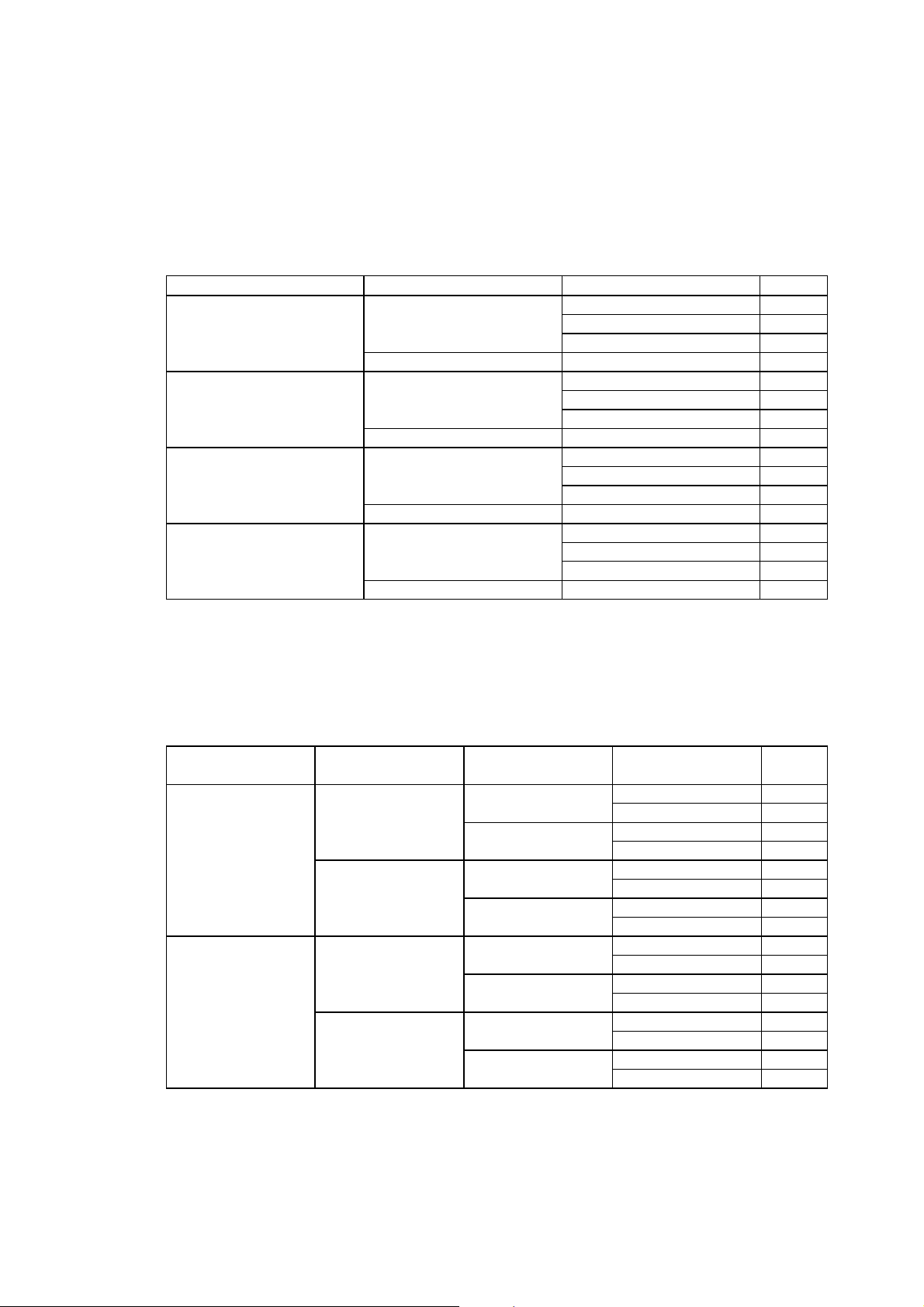

2.3: Wiring Diagram

BLACK

RED

4

terminals 24 and 25)

the Installation manual

to Earth

+

-

2.2K

N.C.

2.2K

BLACK

RED

GREEN

WHITE

+ -

Electronics Line (E.L.) Ltd.

SUMMIT 3208GLD

Household Burglary and Fire Alarm Panel

TELCOM

1 & 2: Outgoing line to telephone

3 & 4: Incoming line from telephone company

TELCOM

4 & 5: Incoming line from telephone company

3 & 6: Outgoing line to telephone

1

2

3

J4

-or-

K5

N.C. C. N.O. N.O.

1

8

K6

Internally connected to + AUX Power

8-POSITION

TELEPHONE SOCKET

Attach the incoming

telephone line and

telephone according to the

instructions provided in

Factory

LSCP Bus

Connector

Test

Point

For Future Use

PROTECTION FUSES

F1 (BATT): 3A/250V

(bel 5MF3)

F2 (AUX): 1.6A/250V

(bel 5MF1.6)

F3 (BELL): 3A/250V

(bel 5MF3)

Install F3 horizontally to

supply 12V nominal

regulated power to bell.

Install vertically to supply

9-18V unregulated to

AUXILIARY POWER OUTPUT

Regulated 12Vdc nominal.

Fire: In accordance with CSFM (Fire)

supplies 220mA for 24 hours.

Burglary: Supplies 1A for 4 hours

(including 100mA to smoke detector,

Long Range

Radio

Interface

Connector

F1

12V/7Ah

BATTERY

Use

POWERSONIC

PS-1270 or

YUASA NP7-12

Replace the battery

every 3 - 5 years

F3

F2

LED SYSTEM

STATUS INDICATOR

On = Telephone Tone Detection

Off = System in Communication

Flashing = Dialing

Flashing (1 pulse/sec) = Standby

Mic

2928272625242322212019181716151413121110987654321

Connect

Use Electronics Line

3108 LCD Keypad

Use Electronics Line

3106 LED Keypad

LSCP Bus

Z1 Z2 Z3 Z4 Z5 Z6 Z7 Z8

Zone Connections

Typical End of

Line Resistor

N.C.

Zone

Connections

(EOLR)

Smoke

(+) (-)

AUX

Power

Output

Siren Audio Output: 8Ω, 8W

OBSERVE PROPER WIRING CONNECTIONS!

Refer to the Installation manual for further information

Detector

Output

12V nominal

max. 100mA

Transformer

15Vac/30VA

Do not connect to a

switch-controlled

receptacle

Label Part Number:

ML0032A (1/99)

Page 11

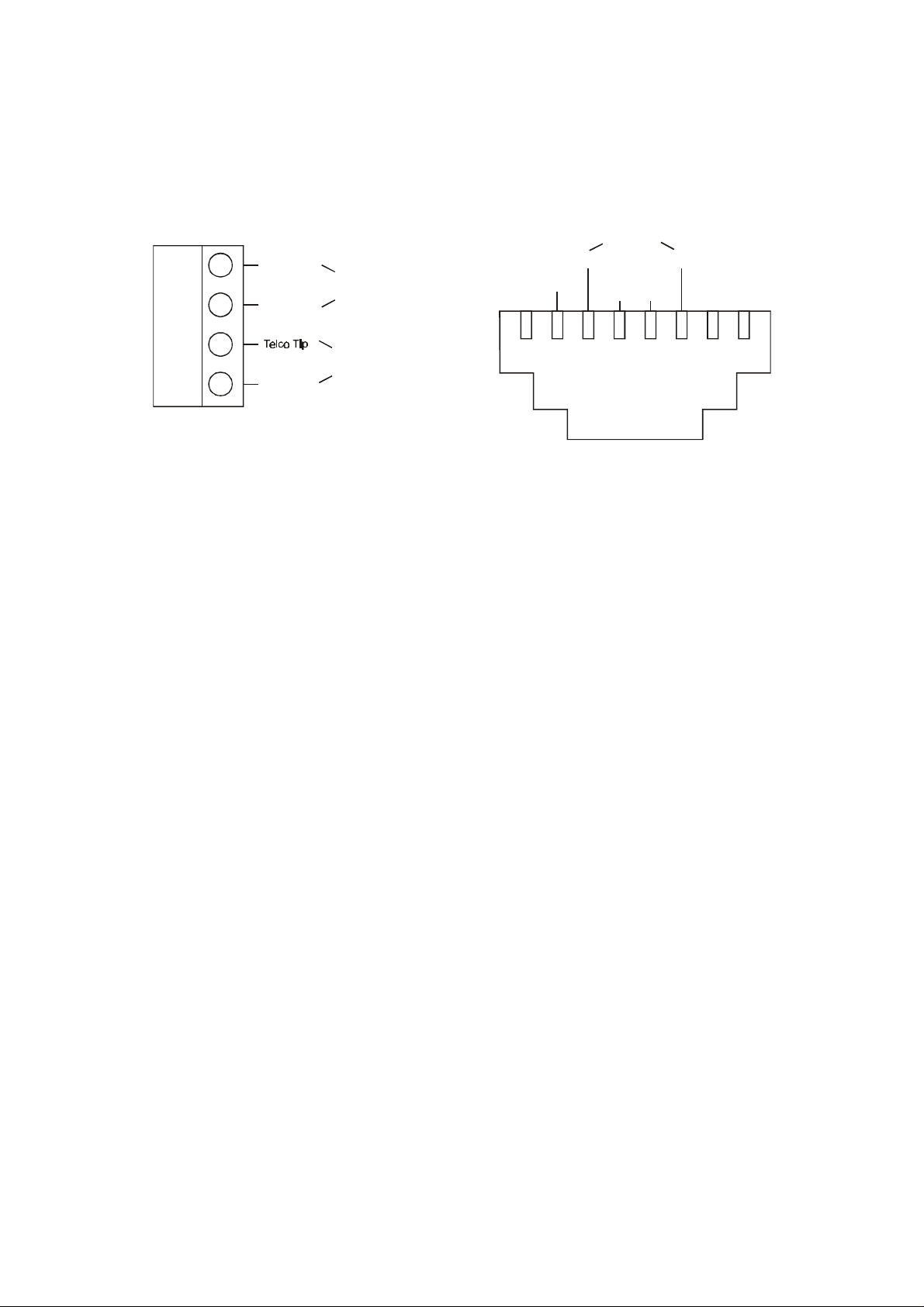

2.4: Terminal Connections

1

2

3

4

5

6

7

8

Earth

Incoming Line

from Telephone

Telephone Connections

Connector J4:

The telephone line should be connected as follows:

Company

1

2

Home Tip

Home Ring

Outgoing Line

to Telephone

L-

Outgoing Line

to Telephone

L-

-Or-

3

4

On-Board Relay Contacts

Terminals 1, 2, 3 and 4:

K5: 1 - N.C., 2 - Common, 3 - N.O.

K6: 4 - N.O. (Relay K6 is internally connected to + AUX power supply)

Keypad Connections

Terminals 5(-), 6(+), 7(LSCP-), 8(LSCP+):

5 (Black) Common Ground -, 6 (Red) AUX power +, 7 (Green) LSCP - signal, and 8 (White) LSCP + signal.

Make sure that the wires are connected to the same connections on the keypad.

Telco Ring

Incoming Line

from Telephone

Company

8-Position Telephone Socke

L+

L+

t

Zone Connections

Terminals 9(+), 10(-), 11(+), 12(+), 13(-), 14(+), 15(+), 16(-), 17(+), 18(+), 19(-), 20(+):

Zone 1:

Zone 2:

Zone 3:

Zone 4:

Terminals 9 and 10

Terminals 11 and 10

Terminals 12 and 13

Terminals 14 and 13

Zone 5:

Zone 6:

Zone 7:

Zone 8:

Terminals 15 and 16

Terminals 17 and 16

Terminals 18 and 19

Terminals 20 and 19 (Fire by default)

Auxiliary Power Output

Terminals 21(+), 22(-):

Regulated 12Vdc nominal at 1A max. including keypads and detection devices for 4 hours standby. (For

CSFM Fire applications - 220mA max. including keypads and smoke detectors for 24 hours standby).

Microphone

Terminal 23

Microphone input for listen-in applications (software dependant).

Smoke Detector Power Output

Terminals 24(+), 25(-):

These terminals provide up to 100mA for powering latching smoke detectors. The smoke detector output is

active low and is restored either automatically or manually.

Bell Power Output

Terminals 26(+), 27(-):

Connect these terminals to supply power to the bell. The power requirements are as follows: AUX power

(12Vdc nominal regulated; 9 - 18Vdc unregulated), rated at 600mA. with 40VA transformer.

AC Power Input

Terminals 28, 29:

Connect a 16.5Vac Class II transformer rated at 40VA, using 18AWG wire.

11

Page 12

2.5: Fuse Replacement

There are 3 protection fuses on the Summit 3208GLD control panel board, the layout of the fuses is shown

in the following diagram:

Battery

Protection Fuse

3 Amp / 250V

Bell Power Output

Protection Fuse

3 Amp / 250V

AUX Power Output

Protection Fuse

1.6 Amp / 250V

F1 (Battery Protection Fuse): Protects the battery charger circuit and the control panel from a short circuit.

To replace this fuse use a bel 5MF3 or other 3A/250V fuse.

F2 (Bell Power Protection Fuse): Protects the active bell output (terminal 26). When the fuse is installed

in the horizontal position 12Vdc nominal regulated power is supplied to the bell. When the fuse is installed

in the vertical position, unregulated (approx. 9 to 18Vdc) power is supplied to the bell and terminal 28. To

replace this fuse use a bel 5MF3 or other 3A/250V fuse.

F1

F3

F2

F3 (AUX Power Output Protection Fuse): Protects terminals 6 (keypad power), 21 (AUX output) and 24

(smoke detector power output). To replace this fuse use a bel 5MF1.6 or other 1.6A/250V fuse.

MAKE SURE YOU REPLACE A FUSE WITH THE CORRECT RATING !

2.6: Turning on the System

Once all of the systems components are properly connected to their destination terminals, the Summit

3208GLD is ready to be turned on. To avoid the risk of electrical shock or damage to the control panel,

make sure that both the AC supplier and the battery are connected properly before plugging in the system.

If you experience any difficulties in applying power to the unit, please contact Electronics Line’s Technical

Support Department.

2.7: Testing the System

All system functions can be tested manually using the LED or LCD keypads. Additionally, circuit tests also

performed automatically by the control panel. For further information on testing using the keypads, see

3.11: Tests.

12

Page 13

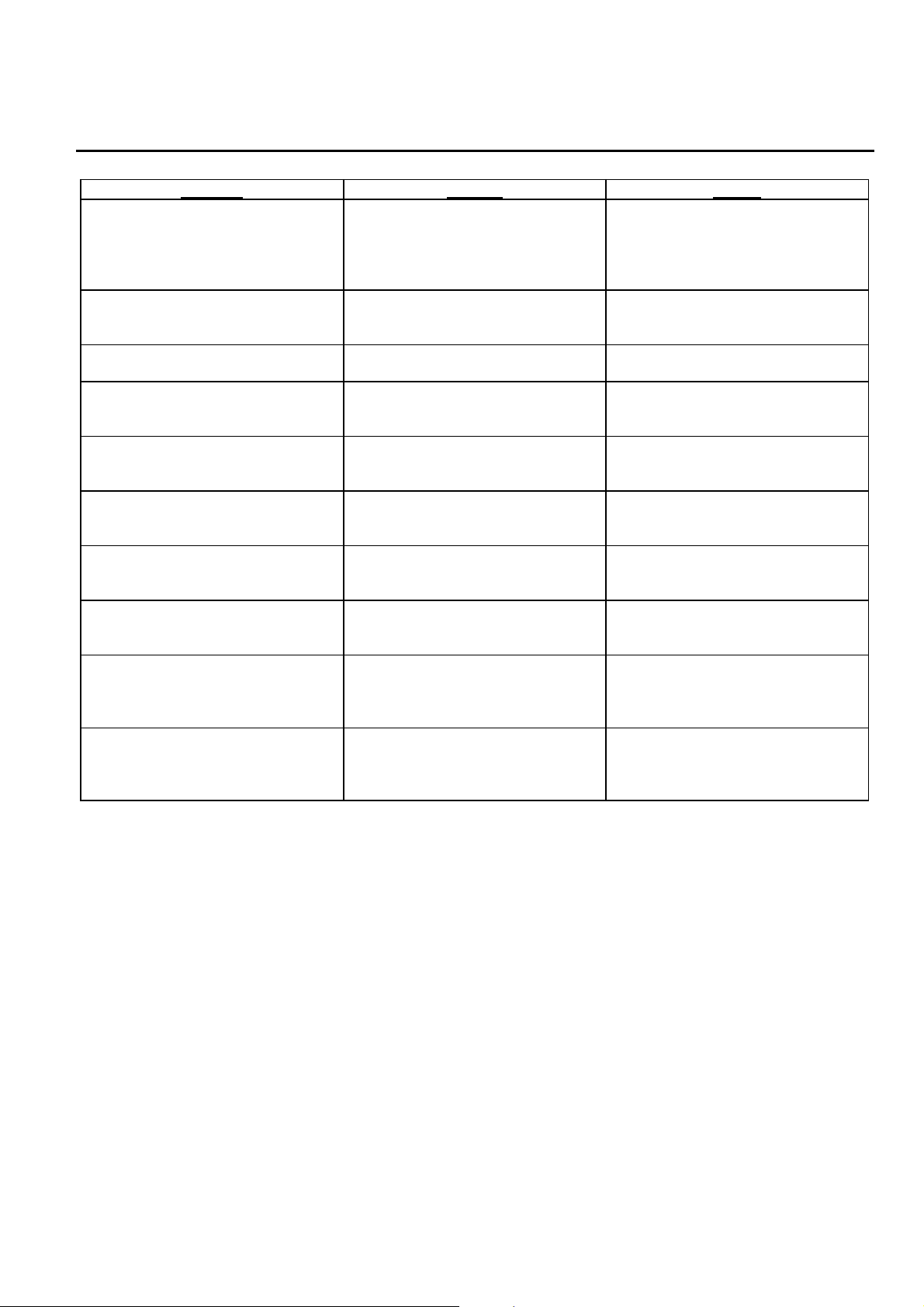

CHAPTER THREE: SYSTEM OPERATION FOR THE 3106 LED AND 3108 LCD KEYPADS

Display

Display

Indicators

Key

LED Keypad

LCD Keypad

3.1: General

The Summit 3208GLD can be operated by using either the 3108 LCD or 3106 LED keypads. All the parameters

can be programmed using either the LCD keypad or the Remote Programmer software. Refer to Chapter Four:

Programming, page 23, for instructions relating to programming the system.

3.2: Display and Controls

Keypad Layout

LED

Numeric

Keypad

Buzzer

LCD

Status

Arming

Keys

Select

LED Display

1 - 8: Used to display zone status and system status.

READY: Indicates if the system is ready to perform functions.

PROGRAM: Indicates if the system is in programming mode. The Program LED lights up if SELECT is pressed

and blinks to indicate that the system is waiting for an authorized user code to be entered.

BYPASS: Indicates if zones have been bypassed. The Bypass LED and the relevant zone LEDs blink to

indicate that zones have been bypassed.

TROUBLE: Blinks if a trouble situation exists within the system (telephone communication failure).

Status Indicators

ARMED: On when the system is armed, off when the system is disarmed.

Note: If the keypad is programmed to display all systems, the Armed LED lights up only when all

systems are armed.

POWER: On when both the AC and the backup battery are connected, provided that the voltage supplied by

the battery is over 10.8V and AC power supply is between 50 - 60 Hz. The indicator blinks slowly when the

battery is low and turns off to indicate AC power loss.

System Trouble Chimes

The keypad indicates certain trouble situations, such as AC loss and low battery by chiming. Pressing any

key on the keypad terminates these chimes.

13

Page 14

Keys and Keypad Functions

0 - 9: The numeric keys are used to enter user codes, telephone numbers, to issue commands and for numeric

programming.

Q , #: These keys are used in programming the control panel. Pressing the Q key during the exit delay cancels

the delay, immediately arming the system. On the LCD keypad, the Q key is used for scrolling back during

operation and programming. The # key is used for entering hexadecimal digits (A - F) during programming.

MENU/NEXT: On the LCD keypad, pressing the MENU/NEXT key displays the main menu and is used to scroll

through the menu items. On both the LCD and LED keypads the MENU/NEXT key is used to log in an arrival

when using the latch key feature. Additionally, the MENU/NEXT key generates an emergency alarm when held

down simultaneously with one of the distress keys (E, F or P).

SELECT: Pressing SELECT followed by a command code causes a system function to occur. On the LCD

keypad, pressing this key when a menu is open results in the selection of the menu item.

STAY: Pressing STAY, when the system is ready to arm, arms only the system's perimeter zones.

AWAY: Pressing the AWAY key, when the system is ready to arm, arms both the perimeter and interior zones.

On the LCD keypad, pressing AWAY returns the display back to the main menu when scrolling or

programming.

Note: If one-key arming is enabled, the user can arm the system using the STAY and AWAY keys

without having to enter a user code.

3.3: System Status Displays

On the LED keypad system status is displayed using the eight zone LEDs as well as the Ready, Program,

Bypass and Trouble LEDs. LEDs 1 - 8 represent alarm situations from the corresponding zone. The other LEDs

show if the system is ready, whether zones are bypassed, if the system is in programming mode and if a trouble

condition exists.

The LCD display of the system status includes descriptions of open zones, alarms, etc. The following are

typical LCD displays:

Arming Display

Description Display

System ready to arm SYSTEM 1 READY

System ready to arm with bypassed zones SYSTEM 1 READY

(BYPASSED)

System not ready to arm due to open perimeter zones SYSTEM NOT RDY

(OPEN ZONES)

System armed, exit delay counting SYSTEM 1 ARMED

011 SEC TO EXIT

System ready for perimeter arming (interior zones open) SYSTEM 1 READY

FOR STAY ARMING

System ready for perimeter arming with perimeter bypassed

zones

System armed, exit delay ended - system is fully armed SYSTEM 1 ARMED

SYSTEM 1 READY

FOR STAY (BYPASSED)

14

System Perimeter armed, exit delay ended (STAY pressed) SYSTEM 1 ARMED/P

System armed, immediate mode SYSTEM 1 ARMED

IMMEDIATE

Page 15

Zone Status Display

Zone status will only be displayed if detailed display is selected

Zone 1, Bedroom, is open ZONE 1 OPEN

BEDROOM

Zone 3, Front Door, has been bypassed ZONE 3 BYPASSED

FRONT DOOR

Zone 4 has been tampered with ZONE 4 TAMPER

Zone 4, bedroom, is in alarm ZONE 4 IN ALARM

BEDROOM

System Status Display

AC power has been disconnected: SYSTEM AC LOSS

Backup battery is low (under 10.8V) or has been

disconnected:

Communication failure or the telephone has been

disconnected:

Time and Date display (scrolls every few seconds): THU, 28 JUL 94

Refer to Appendix A for information on returning system status display to normal.

SYSTEM LOW BATT

TELEPHONE COMM.

FAILURE

12:37 PM

3.4: Menu Selections/Direct Commands

There are two ways to perform a command on the control panel:

• Direct commands (LCD and LED keypads)

• Menu selections (LCD keypad only)

Direct Command Codes

To perform a direct command:

1. Press “SELECT”.

2. Enter the operation code for the desired command (refer to the “Command Codes” table below).

3. If prompted to, enter an authorized user code; an acknowledgment tone is sounded to indicate that the

command has been performed.

Command Codes

Disarm System X (1 - 4)

1X

Perimeter Arm System X (1 - 4)

21X

Normal Arm System X (1 - 4)

22X

Late to Close HHMM

23X

Bypass Zone X (1 - 32)

31X

Unbypass Zone X (1 - 32)

32X

Chime On

33

Chime Off

34

Unbypass All zones

39

Set Time HHMM, DDMMYY

41

Walk Test

421

Bell Test

422

Telephone Test

423

System Test

425

Battery Test

426

Fire Sensor Reset

43

Bell Cancel

44

Stop Telephone Call

45

Follow Me

46

User Codes

5

View Log

61

Clear Log

62

Show Versions

64

Manual Programming

71

Default Programming 1

72

Default Programming 2

73

Remote Programming: off hook

741

Remote Programming: Callback

742

Reset Relay X

83X

Set Relay X

84X

Access Control

9

15

Page 16

Menu Selections Using the LCD Keypad

To make a menu selection from the menu:

1. Press MENU/NEXT; the main menu will be displayed and the selection pointed to by >.

2. Press MENU/NEXT to scroll through the menu items. Pressing “Q“scrolls backwards and pressing any

numeric key displays that number’s associated menu item. To abort at any time, press AWAY.

3. Press SELECT to select the displayed menu item (indicated by the arrow). Certain menu items may require

an authorized passcode.

Example:

Selection Display

Pressing MENU/NEXT for the first time displays >1 OPEN / DISARM

NEXT. . .

Pressing MENU/NEXT displays the next menu item in the

same menu:

Pressing SELECT when the CLOSE/ARM menu is selected

displays

Note: The selection numbers are the direct command numbers for specific menu items. These commands can be performed without having to scroll through the menus. For further information, refer to

the direct command operating procedure.

>2 CLOSE / ARM

NEXT. . .

>21 PERIM ARM

NEXT. . .

Main Menu

1 - DISARM 421 - WALK TEST 7 - PROG.

2 - ARM 422 - BELL TEST 71 - MANUAL PROGRAMMING

21 - PERIMETER ARM 423 - TELEPHONE TEST 72 - LOAD DEFAULT PROG. #1

22 - NORMAL ARM 425 - SYSTEM TEST 73 - LOAD DEFAULT PROG. #2

23 - LATE TO CLOSE 426 - BATTERY TEST 74 - REMOTE PROGRAMMING

3 - BYPASS 43 - FIRE SENSOR RESET 741 - OFF HOOK

31 - BYPASS ZONE 44 - BELL CANCEL 742 - CALLBACK

32 - UNBYPASS ZONE 45 - STOP COMMUNICATIONS 8 - AUX RELAY

33 - CHIME ON 46 - FOLLOW ME 83 - RESET RELAY

34 - CHIME OFF 5 - USER CODES 84 - SET RELAY

39 - UNBYPASS ALL 6 - VIEW/LOG 9 - ACCESS CONTROL

4 - SERVICE 61 - VIEW LOG

41 - SET TIME & DATE 62 - CLEAR LOG

42 - TEST 64 - SHOW VERSIONS

3.5: Arming/Disarming

Arming & Disarming

To arm the system:

• Press AWAY to arm both the perimeter and interior or STAY to arm the perimeter only; the Armed LED

lights up to indicate that the system is armed.

The system can also be armed by entering an authorized passcode or by selecting one of the arming options

from the Arm menu.

To disarm the system:

• Enter an authorized passcode. If the system is in alarm, entering an authorized passcode will disarm the

system and terminate the alarm.

Forced Arming

Forced arming enables the user to arm the system even if all zones are not secured. If zones are still not

secured after the exit delay has ended, an alarm will be generated. The ability to force arm the system is

optional and is selected at address 494.

Note: Electronics Line recommends waiting until all of the zones are secured and the system can be

armed normally.

16

Page 17

Immediate Arming

The system can be immediately armed, canceling the entry or exit delay for the arming period.

To arm the system immediately:

• Press Q during the exit delay; the delay is cancelled and the system is armed immediately.

Note: Immediate arming disables both the exit and entry delays for the arming period.

3.6: User Codes

Most operations executed from the control panel require a user code. Different user code authorization levels

restrict certain functions to specific users. That is to say, of the 15 users that are able to operate the system, not

all of them have access to all system operations. For example, an installer with a level 12 user code can only

test and program the system. The installer does not have the ability to arm and disarm the system, which

maintains a high level of security for the user. Each of the 15 user codes can be programmed with 3 to 6 digits.

Each user code has an authorization level and can be assigned to either a specific sub-system or to all

systems.

The following list explains each of the authorization levels:

Level 0 No functions are assigned to the user code

Level 1 Allows only normal arming (AWAY), interior & perimeter zones

Level 2 Operations of Level 1 + Perimeter arming (STAY)

Level 3 Same as Level 2

Level 4 Operations of Level 3 + Disarming, bell cancel, chime on/off, fire sensor reset and auxiliary relay

operations

Level 5 Operations of Level 4 + view log, Follow-me telephone number programming and access control

Level 6 Operations of Level 5 + Zone bypass/unbypass, clock setting, late to close, clear log, remote

programming and stop call

Level 7 Operations of Level 6 + User code programming

Level 8 Same as Level 7

Level 9 Operations of Level 7 + Tests

Level 10 Operations of Level 9 + Programming

Level 11 Not available at this time

Level 12 Allows only tests & programming

Level 13 Allows only view & clear log

Level 14 Allows only tests

Level 15 Duress code level allows arm, disarm, stop call, bell cancel and fire sensor reset

3.7: Emergency and Duress

Distress Keys

In the case of an emergency, 3 types of alarm can be generated from the keypad.

To generate a distress key alarm.

1. Press and hold down the MENU/NEXT key.

2. Keeping the MENU/NEXT key held down, press the required distress key, for more than 1 second; the

relevant event code is reported to the central station and, if programmed, the bell is activated.

The distress key combinations are:

• MENU/NEXT and E - Emergency (Event code at address 255 or 289)

• MENU/NEXT and F - Fire alarm emergency (Event code at address 256 or 290)

• MENU/NEXT and P - Police emergency (Event code at address 257 or 291)

DuressCode

The duress code is a user code designed for situations where the user is being forced to operate the system.

This user code performs the selected operation, while sending the duress event message (address 259 or 293)

to the central station. A duress code has an authorization level of 15. For further information on programming

user codes see 3.6: User Codes.

17

Page 18

Note: In the message to the central station, the control panel always indicates the system of the keypad

from which the duress code was entered.

User codes and system partitioning

When the Summit 3208GLD is partitioned into several sub-systems, user codes can be associated either with a

specific sub-system or with the entire system. Assigning a user code to only one system will default all

operations to that system. For example, if a user code is assigned to system 3, entering the code arms system

3 without the need to indicate the system number. A user code authorized to all of the subsystems can perform

functions affecting the entire system, such as arming and disarming. To assign a user code to all of the

systems, program the code as belonging to system 5.

Programming User Codes

To program user codes (LCD keypad only):

1. Select User Codes from main menu or press SELECT, 5; the LCD display requests a user code.

2. Enter an authorized user code; the display reads:

In the above example: The code displayed is for User 1. The user code is “1234” - 4 digits with “..” following,

signifying that two digits were not used in this user code. The user code is assigned to system 1. The user code

authorization level is 10. The current field is indicated by “>”.

3. To scroll through the user codes, press MENU/NEXT to scroll forward and Q to scroll back.

4. To scroll through the different fields, press SELECT.

5. To change the value of the current field, enter the required value.

6. Press AWAY to exit user code programming or MENU/NEXT to program the next user code.

USER 01 : > 1234. .

SYS. : 1 LEVEL: 10

Note: A user cannot program a code to a higher access level or to a sub-system other than the one to

which their code belongs. Additionally, a user cannot view user codes assigned to a higher access

level. The system accepts the first user code it recognizes. To prevent being locked out of the system,

do not program user codes beginning with the same numeric combination. For example, the 3 digit

user code “123” and the 4 digit code “1234” are programmed in the same system. Any attempt to enter

“1234” is impossible as the system recognizes “123” the moment the third digit is entered.

3.8: Zone Bypassing/Unbypassing

A bypassed zone is ignored by the system when arming. Bypassing and unbypassing can only be performed if

the system is disarmed.

To bypass a zone:

1. From the Bypass menu, select Bypass or press SELECT 3, 1.

2. Enter an authorized user code and a zone number.

To unbypass a zone:

1. From the Bypass menu, select Unbypass or press SELECT 3, 2.

2. Enter an authorized user code and the bypassed zone number.

To unbypass all zones:

1. From the Bypass menu, select Unbypass All or press SELECT 3, 9.

2. Enter an authorized user code.

Note: On a control panel with zone expanders, the control panel waits for an extra digit when zones 1,

2 or 3 are bypassed. This allows bypassing of the additional zones (for example, 11, 24, or 32). In this

case, when enter the zone number and press MENU/NEXT to indicate that no additional digit is

necessary.

18

Page 19

3.9: Event Log

The event log records the last 100 events the system has undergone. The event log uses the FIFO (first in, first

out) method. Once the log is full, the oldest event will automatically be erased. The event log can only be

viewed with the LCD keypad.

View Event Log

To view the event log:

1. From the View/Log menu select View Log or press SELECT 6, 1.

2. Enter an authorized user code.

3. Scroll through the log by pressing the MENU/NEXT key. The events are displayed starting with the most

recent event registered in the log.

4. Press AWAY to exit the log.

The following table shows examples of typical event log displays.

Event Display

Day 23 in month, time 12:45, alarm from zone 2,

Bathroom

Day 23 in month, time 12:50, system 1 was armed

(perimeter) by user 11.

System message: Last message was successfully sent

to the central station.

Log viewing completed. *** END OF LOG ***

23 12:45 ALARM

BATHROOM, 02

23 12:50 STAY

SYS.1 BY USER 11

23 13:56 SYSTEM

REPORT SENT

Clear Event Log

To clear the log:

1. From the View/Log menu, select Clear Log or press SELECT 6, 2.

2. Enter an authorized user code; the log is erased and the message “***END OF LOG***” is displayed. Clear

Log also causes the Armed LED to stop flashing and zone in alarm messages to be cleared.

3.10: System Partitioning

The Summit 3208GLD can be operated in partitioned mode where the system is separated into a maximum of

four sub-systems. A sub-system is created when at least one zone has been assigned to it. The following

section describes how certain elements of the system are affected by system partitioning.

Zones

Each zone can be assigned to a one of the four sub-systems. A common zone is assigned to all sub-systems

and will only be armed in the event that all systems are armed.

User Codes

User codes are assigned to any sub-system or to the entire system during user code programming. For more

information on the programming of user codes refer to page 18.

Keypad Display

The keypad can display either the entire system or a specific sub-system. This is programmed at parameter

addresses 132 - 139.

Arming & Disarming

Pressing STAY or AWAY on a keypad assigned to a specific sub-system arms only that sub-system. Entering a

user code assigned to a specific sub-system arms the system to which the user code has been assigned. To

disarm a sub-system, the user code entered must be assigned to either that sub-system or to all systems. All

arming methods are available for each sub-system.

Note: If the user code entered is assigned to all systems, the panel asks which system to arm. Entering

System 5 arms all the sub-systems that are ready.

19

Page 20

3.11: Tests

Walk Test

The walk test allows detection devices to be tested without generating an alarm.

To perform a walk test:

1. Press SELECT 4, 2, 1 or select Walk Test from the Test menu.

2. Test the control panel’s detection devices; an opened zone causes the keypad to beep.

3. To end the walk test, press AWAY.

Walk test mode is automatically terminated after 4 minutes and 15 seconds.

Note: During a walk test, an open zone will not create an alarm. However, this does not apply to

zones programmed as tamper zones and 24hr zones (Emergency/Holdup, Fire and Verified Fire)

opening these zones will create an alarm.

Bell Test

To perform a bell test:

• Press SELECT 4, 2, 2 or select Bell Test from the Test menu; a 1 second ring is heard and the test is

terminated automatically.

Telephone Communicator Test

To perform a telephone communicator test:

• Press SELECT 4, 2, 3 or select Telephone Test from the Test menu; a test message is sent to all

central stations that are programmed to receive communications from the control panel. The control

panel returns to normal operation after the telephone communication test is initiated. The report code

for this message is at address 251 or 285.

Note: The control panel seizes the telephone line to run this test.

System Test

To perform a system test:

• Press “SELECT” 4, 2, 5 or select System Test from the Test menu; the system tests the control panel’s

electronic circuitry. Should the LCD display the message “System Failure”, contact our technical

support department.

Battery Test

To perform a battery test:

• Press “SELECT” 4, 2, 6 or select Batt. from the Test menu; the battery is tested under loading

conditions, the control panel returns to normal operation and the battery status display is updated. For

the test to be successful the voltage must not be lower than 10.8V under loading conditions. This test is

automatically executed by the system every 30 seconds.

3.12: Additional Operations

Set Time & Date

To set the time and date:

1. On the LCD keypad, press SELECT 4, 1; the panel prompts you to enter a user code.

2. Enter an authorized user code; the panel prompts you to set the date.

3. Enter the date (DDMMYY).

4. Enter the time in 24 hour format (HHMM).

5. Press AWAY; the panel returns to normal operation.

or

1. On the LED keypad, press SELECT 4, 1; the Program LED lights up.

2. Enter an authorized user code.

3. Enter the date (DDMMYY).

4. Enter the time in 24 hour format (HHMM).

5. Press AWAY; the Program LED turns off.

20

Page 21

Bell Cancel

The bell is automatically stopped when the system is disarmed. To stop the bell manually:

1. On the LCD keypad, press SELECT 4, 4; the panel prompts you to enter a user code.

2. Enter an authorized user code; the bell stops ringing immediately and the system sends a Bell Cancel

event code to the central station.

or

1. On the LED keypad, press SELECT 4, 4; the Program LED lights up.

2. Enter an authorized user code; the bell stops ringing immediately, the Program LED turns off and the

system sends a Bell Cancel event code to the central station.

Stop Communications

To stop all communications and clear communication message buffers:

1. On the LCD keypad, press SELECT 4, 5; the panel prompts you to enter a user code.

2. Enter an authorized user code; all communication buffers are cleared and all communications stop

immediately.

or

1. On the LED keypad, press SELECT 4, 5; the Program LED flashes.

2. Enter an authorized user code; the Program LED turns off, all communication buffers are cleared and all

communications stop immediately.

Follow-me

To program a telephone number (telephone #4) for the Follow-me feature:

1. On the LCD keypad, press SELECT 4, 6; the panel prompts you to enter a user code.

2. Enter an authorized user code; the panel prompts you to enter the telephone number.

3. Enter the required telephone number using keys 0 - 9, # to include a three second pause and Q to switch to

tone dialing (DTMF).

or

1. On the LED keypad, press SELECT 4, 6; the Program LED flashes.

2. Enter an authorized user code; the Program LED lights up.

3. Enter the desired telephone number, using keys 0 - 9, # to include a three second pause and Q to switch to

tone dialing (DTMF); after a short delay the Program LED turns off.

Examples: To program telephone number 921-1110 using DTMF dialing, enter Q9211110. To dial telephone

number 9211110 in pulse dialing, and then switch to tone dialing to access extension 231 after a pause, key in

9211110#Q231. Up to 16 digits can be entered, including pauses (#) and tone dialing switches (Q). The Q key

will appear on the display as “T” and the # will appear as “,”.

To disable the Follow-me number enter # (“,”) as the first digit of the number.

Note: Make sure all types of messages that need to be passed to the “follow me” number are routed

correctly (see Chapter Four: Programming). A follow me number can be set on any phone number,

however, only telephone number 4 can be changed through “SELECT” 4, 6.

Late To Close

When using opening/closing windows, the control panel must be armed within the programmed time frame for

the closing window. If the user wishes to stay on the premises and arm the system at a later time, a “Late to

Close” condition can be activated in order to extend the window and prevent a message being sent to the

central station.

To activate a “Late to Close” condition:

1. On the LCD keypad, press SELECT 2, 3; the system prompts you to enter the system number.

2. Enter the system number; the system prompts you to enter a user code.

3. Enter an authorized user code; the system prompts you to set a time.

4. Enter the new closing hour in 24-hour format (HH); the command is acknowledged and the system returns

to normal operation.

or

1. On the LED keypad, press SELECT 2, 3. The Program LED turns on.

2. Enter the system number; the Program LED begins flashing

3. Enter an authorized user code.

4. Enter the new closing hour in 24-hour format (HH). The command is acknowledged, the system returns to

normal operation and the Program LED turns off.

21

Page 22

Latch Key

When the latch key feature is activated (address 411), the MENU/NEXT key is used to acknowledge arrivals or

departures from the system during opening or closing windows. If MENU/NEXT is not pressed after the user

code is entered, a ‘Failed to Open’ or ‘Failed to Close’ event code is sent to the central station.

Zone Chime

A zone can be programmed to chime when opened.

To program a zone to chime:

1. Press SELECT 3,3.

2. Enter an authorized user code.

3. Enter a zone number; the zone is programmed to chime when opened.

To deactivate a zone chime:

1. Press SELECT 3, 4.

2. Enter an authorized user code.

3. Enter the zone number; the zone will not chime when opened.

Access Control

This feature is designed for use with an electric door latch. The user is able to release the door latch from the

keypad by activating a relay programmed to “Access Control” mode – see address 477. A relay is controlled by

its corresponding keypad. For example, ‘Keypad 1’ controls ‘Relay 1’, ‘Keypad 2’ controls ‘Relay 2’ and so on.

Note: Keypad 8 cannot be used to operate this feature, as it has no relay assigned.

To activate an access control relay:

1. Press SELECT 9.

2. Enter an authorized user code; the relay is activated for the programmed cutoff time.

Set Relay

Relays can be manually activated and deactivated using this operation. A relay activated in this way is not

dependent on system status and stays activated until manually reset.

To manually activate a relay:

1. Press SELECT 8,4.

2. Enter the number of the relay you want to activate (1-7).

3. Enter an authorized user code; the relay is activated.

To manually reset a relay:

1. Press SELECT 8,3.

2. Enter the number of the relay you want to reset (1-7).

3. Enter an authorized user code; the relay is deactivated.

22

Page 23

CHAPTER FOUR: PROGRAMMING

4.1: General

The Summit 3208GLD control panel can be programmed using either the 3108 LCD keypad or the Remote

Programmer, Electronics Line’s up/downloading software. For keypad operation refer to Chapter 3.

For programming using the Remote Programmer refer to the instructions provided with the software. Contact

your nearest Electronics Line office or agent to obtain a copy of the software.

4.2: Guide to Programming

The control panel has 500 parameter addresses. All the programmed data is stored in the EEPROM memory

and is saved even if both AC and battery power are disconnected. To make programming easier, the Summit

3208GLD includes a default program including typical values for most installations. This means that, in most

cases, only the programming of customer specific parameters (such as telephone numbers, account numbers,

etc.) is required. Programming changes are made by entering a new value at the appropriate address. This

chapter includes a complete list of parameter addresses and the options available for each address.

4.3: Programming Procedure

Electronics Line suggests the following:

• Always load a default program when receiving a new panel by pressing SELECT 7, 2 (Default Program 1)

or SELECT 7, 3 (Default Program 2 - if available).

• Before installation and programming, plan the application well using the programming form provided.

• Use the following procedure to program the data from the programming form into the control panel.

To program the Summit 3208GLD using the 3108 LCD keypad:

1. Press SELECT 7, 1 to enter programming mode.

2. Enter an authorized user code.

3. Enter a 3-digit parameter address; the keypad displays the selected address within a group of related

parameters (zones, telephone numbers, routing etc.). For example, if a zone parameter address is

selected, the four parameters relating to that specific zone are displayed and the first digit of the selected

address flashes.

4. Pressing MENU/NEXT or entering data moves the cursor to the next parameter digit. To move back to the

previous digit press the Q.

5. To move to another item within the current group, press SELECT and then MENU/NEXT or Q to scroll

forwards and backwards through the available options. For example, if zone 1 is selected, the zone number

flashes when SELECT is pressed. MENU/NEXT and Q enable you to scroll forward and backwards through

the zones.

6. To exit programming mode, press AWAY.

7. For the modifications to take effect, disconnect and reconnect both AC and battery power supplies.

Note: The system allows two minutes to begin programming before automatically exiting programming

mode. Programming mode is immediately aborted if the control panel is in communication (both

incoming and outgoing calls).

LCD Keypad Programming Display

Entering programming mode

SELECT ADDR : 0 0 0

( 0 0 0 - 4 9 9 )

First digit blinking, any key will change this digit

Press:

Q

to move to the

previous digit

SELECT to select

another address or

group of parameters

MENU/NEXT to move

to the next digit or

group

AWAY to exit

programming mode

23

Page 24

After entering parameter changes

Parameter address

ADDR: 000 ZONE 01

VAL=> 58 08 12 05

First digit blinking

Group ID

Upon entering a digit, the display automatically moves to the next digit. To move to the next digit without

entering a modification, press MENU/NEXT. To move back to the previous digit, press Q.

Entering Hex data

Pressing # scrolls through the hexadecimal digits A, B, C, D, E and F. If the original digit is decimal (0-9),

press # to change the digit to A. If the original digit is hexadecimal (A-F), press # to move to the next

hexadecimal digit in sequence.

4.4: Programming Parameters

This section comprises a complete listing of the Summit 3208GLD control panel’s programming parameters.

The following table lists the addresses for each group of programming parameters.

ADDRESSES PARAMETERS ADDRESSES PARAMETERS

000-127

128-131

132-139

140-179

180-195

196-197

198-201

202-261

262-295

296-310

378-381

Zone Parameters

System Parameters

Keypad Parameters

Telephone Numbers

Account Numbers

Telephone Line Parameters

Communication Protocols

Zone Oriented Event Codes

Event Oriented Event Codes

Event & Message Routing

Exit Timers

388

389-409

410

411

412-475

476

477-490

491-493

494

495

496

Swinger Parameters

Opening & Closing Windows

Bell Cut-Off

Dealer Lockout & Latchkey

Custom LCD Zone Descriptors

Zone Expanders

Relay Parameters

Periodic Test

Arming Options & Arming Ring

Detailed Display, Bell Muting

& Fire Sensor Reset

Police Key Operation

& RP Communication Options

24

382-384

385-387

Entry Timers

Pulse Counters

497-498

499

AC Loss & Restore

Listen-In Time Out

Page 25

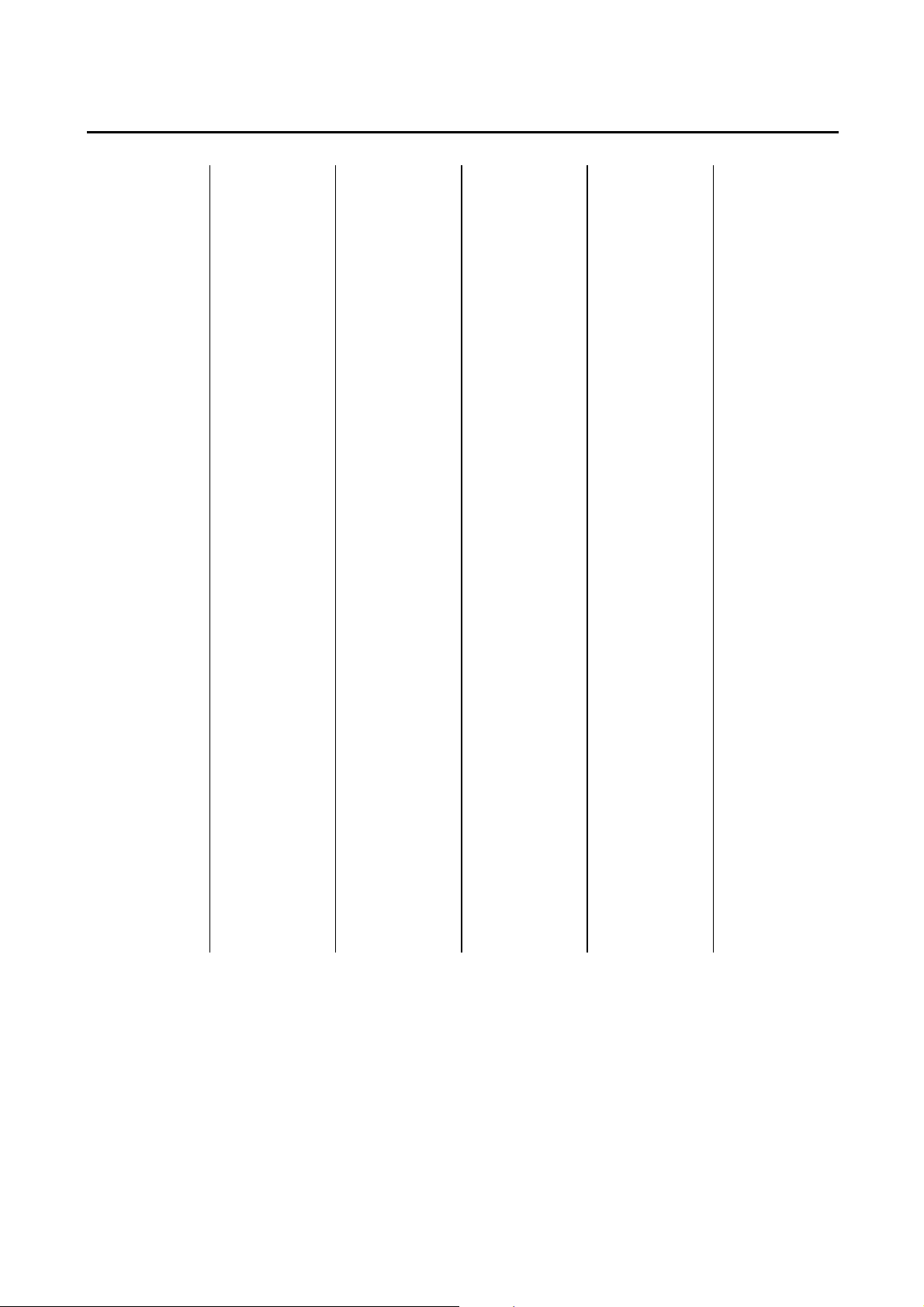

ADDRESSES 000-127: ZONE PARAMETERS

000-003: Zone # 1 Parameters

Each zone is individually defined in four parameter addresses. The following four addresses relate to

zone 1 but the method of programming zones 2 - 32 is identical.

000 LCD Zone Descriptor and Entry Delay for Zone #1

Select a zone descriptor and entry delay for zone 1 from the table below. Entry delay options

#1, #2 and #3 are set at addresses 382, 383 and 384, respectively. The four custom LCD

messages can be programmed at addresses 412-475.

No

Delay

00 40 80 C0 no message 20 60 A0 E0 LOBBY

01 41 81 C1 1ST FLOOR 21 61 A1 E1 LIVNG ROOM

02 42 82 C2 2ND FLOOR 22 62 A2 E2 MSTR BEDRM

03 43 83 C3 3RD FLOOR 23 63 A3 E3 MAT

04 44 84 C4 4TH FLOOR 24 64 A4 E4 MOTION

05 45 85 C5 BACK DOOR 25 65 A5 E5 NORTH

06 46 86 C6 BASEMENT 26 66 A6 E6 NURSERY

07 47 87 C7 BATHROOM 27 67 A7 E7 OFFICE

08 48 88 C8 BEDROOM 28 68 A8 E8 PANIC

09 49 89 C9 BEDROOM 1 29 69 A9 E9 PERIMETER

0A 4A 8A CA BEDROOM 2 2A 6A AA EA POOL

0B 4B 8B CB BEDROOM 3 2B 6B AB EB ROOF

0C 4C 8C CC COMPUTER 2C 6C AC EC ROOM

0D 4D 8D CD CONFERENCE 2D 6D AD ED ROOM 1

0E 4E 8E CE CORRIDOR 2E 6E AE EE ROOM 2

0F 4F 8F CF DINING 2F 6F AF EF ROOM 3

10 50 90 D0 DOOR 30 70 B0 F0 ROOM 4

11 51 91 D1 EAST 31 71 B1 F1 SHIPPING

12 52 92 D2 EMERGENCY 32 72 B2 F2 SHOP

13 53 93 D3 ENTRANCE 33 73 B3 F3 SLIDE DOOR

14 54 94 D4 EXIT 34 74 B4 F4 SOUTH

15 55 95 D5 EXTERIOR 35 75 B5 F5 STAIRS

16 56 96 D6 FAMILY 36 76 B6 F6 STORAGE

17 57 97 D7 FIRE 37 77 B7 F7 STUDY

18 58 98 D8 FRONT DOOR 38 78 B8 F8 VAULT

19 59 99 D9 GARAGE 39 79 B9 F9 WAREHOUSE

1A 5A 9A DA GUEST ROOM 3A 7A BA FA WEST

1B 5B 9B DB HALL 3B 7B BB FB WINDOW

1C 5C 9C DC HOLDUP 3C 7C BC FC (custom #1)

1D 5D 9D DD INTERIOR 3D 7D BD FD (custom #2)

1E 5E 9E DE KITCHEN 3E 7E BE FE (custom #3)

1F 5F 9F DF LAUNDRY 3F 7F BF FF (custom #4)

Delay#1Delay#2Delay

#3

Descriptor No

Delay

Delay#1Delay#2Delay

#3

Descriptor

25

Page 26

001 First Digit: Loop Speed, Pulse Count and Swinger Setting for zone # 1

The following table lists the options for the loop speed, pulse count and swinger setting. A slow

loop response (150ms) should be entered for motion sensors and contacts. Enter a fast loop

response (50ms) for shock sensors. The three optional pulse count settings can be

programmed at addresses 385-387 and the swinger setting is programmed at address 388. A

full explanation of these features can be found in this section at their respective addresses.

First digit value:

Loop

Speed

Slow Active 3 Fast Active B

Second Digit: Bypassability, Zone Chime and System ID

The second digit of this address deals with a number of options. Select whether the zone is

bypassable, if the zone chime feature is enabled and to which system the zone is assigned

from the table below.

Second digit value:

Bypassable Chime System Value Bypassable Chime System Value

No 4 3 Yes 4 B

Pulse

Count

None - 0 None - 8

#1 - 2 #1 - A

#2 - 4 #2 - C

#3 - 6 #3 - E

Swinger

Setting

Active 1 Active 9

Active 5 Active D

Active 7 Active F

No 2 1 No 2 9

Yes 2 5 Yes 2 D

Value Loop

Speed

1 0 1 8

3 2 3 A

1 4 1 C

3 6 3 E

4 7 4 F

Pulse

Count

Swinger

Setting

Value

002 First Digit: Zone ID for zone#1

Zone ID is the number that can be sent to identify the zone in event code messages to the

central station (event oriented event code table). Generally, the zone ID is the same as the

zone number.

First digit value:

Enter a value between 0 – F for Zone ID

Second Digit: Loop type for zone #1

Select the loop type for this zone from the following list.

Second digit value:

0 – N.C. restore on short, alarm on open.

1 – N.O. alarm on short, restore on open.

2 – EOLR alarm on short, restore on normal, alarm on open.

003 First Digit: Zone type for zone #1

Select a zone type from the following list. For a full explanation of each zone type, see 1.2:

Zones.

First digit value:

0 – Perimeter normal zone. 9 – Verified Fire Zone.

1 – Perimeter primary zone. A – Fire Zone.

2 – Perimeter secondary zone. B – Common Zone.

3 – Perimeter conditional zone. C – Emergency/Holdup (24 Hour).

4 – Interior normal zone. D – Tamper.

5 – Interior primary zone. E – On/Off STAY.

6 – Interior secondary zone. F – On/Off key switch AWAY.

7 – Interior conditional zone.

Note: Zones defined as Emergency/Hold-up, Tamper, Fire and Verified Fire will ignore

the entry/exit delay even if defined.

26

Page 27

Second Digit: Listen-In, Event Code Transmission to the Central Station and Bell

Activation

Select the type of output for this zone in the event of an alarm.

Second digit value:

Listen-In

Activated

No Yes 1

Yes No 8

004-007 Same as above for zone #2

008-011 Same as above for zone #3

012-015 Same as above for zone #4

016-019 Same as above for zone #5

020-023 Same as above for zone #6

024-027 Same as above for zone #7

028-031 Same as above for zone #8

ADDRESSES 032-063: Zones 9 - 16 These addresses are added to the control panel with either the

3508 or 3528 zone expanders (zone expander jumper setting B). Zone expanders are programmed at

address 476.

032-035 Same as above for zone #9

036-039 Same as above for zone #10

040-043 Same as above for zone #11

044-047 Same as above for zone #12

048-051 Same as above for zone #13

052-055 Same as above for zone #14

056-059 Same as above for zone #15

060-063 Same as above for zone #16

Send Message to

Central Station

No No 0

Yes Yes 5

Activate

Bell

No 4

Yes 9

Value

ADDRESSES 064 – 095: Zones 17 - 24 These addresses are added to the control panel with either the

3508 or 3528 zone expanders (zone expander jumper setting C). Zone expanders are programmed at

address 476.

064-067 Same as above for zone #17

068-071 Same as above for zone #18

072-075 Same as above for zone #19

076-079 Same as above for zone #20

080-083 Same as above for zone #21

084-087 Same as above for zone #22

088-091 Same as above for zone #23

092-095 Same as above for zone #24

ADDRESSES 096-127: Zones 25 - 32 These addresses are added to the control panel with either the

3508 or 3528 zone expanders (zone expander jumper setting D). Zone expanders are programmed at

address 476.

096-099 Same as above for zone #25

100-103 Same as above for zone #26

104-107 Same as above for zone #27

108-111 Same as above for zone #28

112-115 Same as above for zone #29

116-119 Same as above for zone #30

120-123 Same as above for zone #31

124-127 Same as above for zone #32

27

Page 28

ADDRESSES 128 – 131: SYSTEM PARAMETERS

These addresses offer a number of options for each sub-system. The keypad tones (beeps) and one-key

arming feature for each sub-system can be set at these addresses. Program only system 1 for

unpartitioned systems.

128 First Digit: Keypad Arming/Disarming Tones for System #1

Each sub-system’s keypads can be programmed to beep during arming, disarming and during

the entry delay. Select the keypad tones for system #1 from the table below.

First digit value:

Arm Beep Continuous on Entry Disarm Beep Value

No 0

No No 1 1

3 2

Yes No 3

No 4

1 No 1 5

3 6

Yes No 7

No 8

3 No 1 9

3 A

Yes No B

No C

Continuous No 1 D

3 E

Yes No F

Second Digit: Display, Power Trouble Tones and One Key Arming for System #1

The second digit of this address offers options for the display type of each sub-system’s

keypads and the tones sounded for power related trouble conditions. One-Key Arming allows

the user the capability to arm the system, using either the STAY or AWAY keys, without

needing to enter a user code. Select these options for system #1 from the table below.

Second digit value:

Display

Type

Summarized Yes 3

Detailed Yes B

One Key

Arming

Disabled Yes 1

Enabled Yes 5

Disabled Yes 9

Enabled Yes D

Beep for

AC Loss

No No 0

Yes No 2

No No 4

Yes No 6

No No 8

Yes No A

No No C

Yes No E

Beep for

Low Battery

Yes 7

Yes F

Value

28

129 Same as above for System #2

130 Same as above for System #3

131 Same as above for System #4

Page 29

ADDRESSES 132 – 139: KEYPAD PARAMETERS

The following addresses offer options for the configuration of each keypad.

132 First Digit: Backlight and Buzzer Operation for Keypad # 1

Select the backlight and buzzer options from the following table.

First digit value:

Buzzer Backlight Value

On after keystroke for 1 minute 0

On for opening windows 1

Audible On for closing windows 2

On for opening/closing windows 3

On at all times 4

On after keystroke for 1 minute 8

On for opening windows 9

Silent On for closing windows A

On for opening/closing windows B

On at all times C

Second Digit: Keypad Supervision, System Operation and Display for keypad #1

In partitioned systems, each keypad is associated with a specific sub-system and can be

programmed to display only its own sub-system or all the sub-systems. Keypad supervision is

selected at this address and on the keypad itself - see 2.2: Mounting the Keypad.

Second digit value:

Supervision

No 4 4 3 Yes 4 4 B

Display

System

1 1 0 1 1 8

2 2 1 2 2 9

3 3 2 3 3 A

All 2 5 All 2 D

Operate

System

1 4 1 C

3 6 3 E

4 7 4 F

Value Supervision

Display

System

Operate

System

Value

133 Same as above keypad #2

134 Same as above keypad #3

135 Same as above keypad #4

136 Same as above keypad #5

137 Same as above keypad #6

138 Same as above keypad #7

139 Same as above keypad #8

ADDRESSES 140 - 179: TELEPHONE NUMBERS

Consecutive addresses are used to enter telephone numbers up to 16 digits. Indicate the end of the

telephone number with the hex digit F. To enter a 3 second pause enter C, for a 7 second pause enter D,

to switch from pulse to tone dialing, enter E. Other telephone data and parameters are entered at later

addresses.

Note: The emergency telephone numbers shall not be set or programmed to place a call to a

police station that has not been specifically assigned by that police station for such service.

140-147 Telephone #1(primary)

148-155 Telephone #2(backup)

156-163 Telephone #3

164-171 Telephone #4 Note: Usually used with the Follow-me feature (SELECT, 4, 6).

172-179 Telephone number for Remote Programmer Callback.

The Remote Programmer Callback telephone number is programmed using the same method

as telephone numbers 1 - 4.

29

Page 30

ADDRESSES 180 - 195: ACCOUNT NUMBERS

Account numbers are transmitted to the central station with the event code to identify the source of the

event. Each system can be given a separate account number. If the system is not partitioned, only enter

the account number for System 1. For partitioned systems, program account numbers for all subsystems. Account numbers are entered in four consecutive addresses. To enter an account number

always enter 8 digits in sequence (if the number is less than 8 digits, use leading zeros).

Certain protocols can handle more than one transmission length. This means that in some protocols

either 5 or 8 digit account numbers, for example, can be sent. The following example illustrates how to

program account numbers for a protocol that handles 3 or 4 digit account numbers.

When transmitting an account number to the central station, the control panel automatically ignores any

sequence of zeros at the beginning of the number.

Enter the following to program a 3 digit account number for System 1:

Address →

Value →

180 181 182 183

00 00 01 23

In the above example the account number will be regarded as “123”. If a 4 digit account number “0123” is

required, enter the following:

Address →

Value →

180 181 182 183

10 00 01 23

The first digit indicates to the control panel that the zero is to be considered as part of the 4 digit account

number.

180-183 Account # for System 1

184-187 Account # for System 2

188-191 Account # for System 3

192-195 Account # for System 4

ADDRESSES 196-197: TELEPHONE LINE PARAMETERS

196 First Digit: Dialing Options and Telephone Event Message Enable/Disable

The first digit of this address comprises the following options.

• Dialing Initiation – the control panel only dials if a dial tone is detected within the time-out

(programmed at address 197) or allowed anyway after the second time-out.

• Dialing Mode – the panel can be programmed to use either pulse or tone (DTMF) dialing.

• Telephone Event Message Enable/Disable – this option enables or disables telephone

communications to the central station and follow-me number. If disabled, there is no need

to program any of the other parameters regarding central station communications

(telephone numbers, event codes etc.).

Note: This option does not affect RP communications. The RP Callback number,

addresses 172-179, may still be programmed.

First digit value:

Dialing Initiation Dialing Mode Telephone Event Message Value

Pulse No 0

Dial Anyway Yes 2

DTMF No 4

Yes 6

Pulse No 8

Do not Dial Yes A

Without Tone DTMF No C

Yes E

30

Second Digit: Time-Outs for Acknowledgment

Acknowledgments are tones transmitted from the central station to the control panel to confirm

successful transmission of event codes. There are 2 acknowledgment tones, Ack1 and Ack2.

Ack1 is the tone that confirms that the central station has recognized that the panel is

attempting to send an event code. Time-Out for Ack1 is the amount of time the panel waits for

Ack1 to be sent after the central station picks up. If Ack1 is not received within this time period,

the panel makes another dialing attempt (if programmed at address 197). Ack2 is the tone that

confirms that the central station has received and understood the message. Time-Out for Ack2