Page 1

Page 2

Revision A 12/29/04* II 1111981

Page 3

P-110 Standard EGT Probe

1218121

)

ImporImpor

Impor

ImporImpor

All steps All steps

All steps

All steps All steps

3. Both clip rings must be on the

inside of the hose clamp.

The rubber band is used to hold

the washer on during shipping.

tant Installation Inftant Installation Inf

tant Installation Inf

tant Installation Inftant Installation Inf

mustmust

must

mustmust

be read before installing a probe. be read before installing a probe.

be read before installing a probe.

be read before installing a probe. be read before installing a probe.

1. Leave slack in the cable to allow

for engine movement and vibration.

2. Do Not Overtighten.

Over time, tight wire wraps

will cause the wire to break.

ormationormation

ormation

ormationormation

S.S. Washer.

Hose Clamp.

Drill 13/64" Hole

(See II Manual)

(

4. The Type-K thermocouple wire's yellow and red insulation must

be stripped 3/8" for proper overlap in the OLC-1 (Over-Lap Connector). Back out the set screw, insert wires into opposite ends

(matching colors) so wire insulation is just inside the nylon housing

and the ends of the wires are not exposed on the opposite side.

Tighten the set screw until the set screw stops turning and the hex

driver starts to flex (4-5 in-lbs). Tug on the wires (1-2 lbs) to

insure proper connection.

Page 4

P-110 Fast Response EGT Probe

1218122

)

ImporImpor

Impor

ImporImpor

All steps All steps

All steps

All steps All steps

3. The slit in the ferrule must be

placed perpendicular to the hose

clamp band and the spring must

be 3/8" back from the ferrule. If

the probe is placed in a hole

larger than 0.130", use a S.S.

washer between the exhaust pipe

and the ferrule.

tant Installation Inftant Installation Inf

tant Installation Inf

tant Installation Inftant Installation Inf

mustmust

must

mustmust

be read before installing a probe. be read before installing a probe.

be read before installing a probe.

be read before installing a probe. be read before installing a probe.

1. Leave slack in the cable to allow

for engine movement and vibration.

2. Do Not Overtighten.

Over time, tight wire wraps

will cause the wire to break.

3/8"

ormationormation

ormation

ormationormation

Hose Clamp.

Drill 0.130" Hole

(See II Manual)

(

4. The Type-K thermocouple wire's yellow and red insulation must

be stripped 3/8" for proper overlap in the OLC-1 (Over-Lap Connector). Back out the set screw, insert wires into opposite ends

(matching colors) so wire insulation is just inside the nylon housing

and the ends of the wires are not exposed on the opposite side.

Tighten the set screw until the set screw stops turning and the hex

driver starts to flex (4-5 in-lbs). Tug on the wires (1-2 lbs) to

insure proper connection.

Page 5

ContentsContents

Contents

ContentsContents

Warranty ------------------------------------------------------------------------- 2Warranty ------------------------------------------------------------------------- 2

Warranty ------------------------------------------------------------------------- 2

Warranty ------------------------------------------------------------------------- 2Warranty ------------------------------------------------------------------------- 2

Installation Instructions ------------------------------------------------------- 3Installation Instructions ------------------------------------------------------- 3

Installation Instructions ------------------------------------------------------- 3

Installation Instructions ------------------------------------------------------- 3Installation Instructions ------------------------------------------------------- 3

1. UBG-16 Over View ------------------------------------------------------------------------------------- 3

2. Important Information and Initial Check Out --------------------------------------------------- 4

3.

"UBG-16"

4. EGT Probe Installation -------------------------------------------------------------------------------- 6

5. CHT Probe Installation ------------------------------------------------------------------------------- 6

6. TIT Probe Installation --------------------------------------------------------------------------------- 6

7. Oil Temperature Probe Installation ---------------------------------------------------------------- 6

8. Carb. Temp. Probe Installation ---------------------------------------------------------------------- 7

9. OAT Probe Installation -------------------------------------------------------------------------------- 7

10. Other Temperature Probe Installation ------------------------------------------------------------- 7

11. Install Additional Temperature Cables and Mark The Cables for the

12. Route the 16-pin Circular Connectors ------------------------------------------------------------ 9

13. Route Each Extension Cable ------------------------------------------------------------------------ 9

14. Install Functional Modules & Accessories -------------------------------------------------------- 10

15. Route the Power and Ground Wires --------------------------------------------------------------- 10

16. Route the Display Intensity Control Wire -------------------------------------------------------- 10

17. Route the (Optional) External Warning Control Line ----------------------------------------- 1 1

18. Route the (Optional) RS-232 Data Output Line ------------------------------------------------- 1 1

19. Drill Two Holes for the Mode and Step Switch -------------------------------------------------- 1 1

20. Install the Instrument in the Panel ------------------------------------------------------------------ 1 1

21. Configure the UBG-16 for Your Aircraft -------------------------------------------------------- 12

22. System Ground Test ----------------------------------------------------------------------------------- 12

Configuration Form --------------------------------------------------------------------- 5

"UBG-16"

------ 8

Troubleshooting Suggestions ------------------------------------------------Troubleshooting Suggestions ------------------------------------------------

Troubleshooting Suggestions ------------------------------------------------

Troubleshooting Suggestions ------------------------------------------------Troubleshooting Suggestions -----------------------------------------------Specifications and Operating Features ------------------------------------ 15-16Specifications and Operating Features ------------------------------------ 15-16

Specifications and Operating Features ------------------------------------ 15-16

Specifications and Operating Features ------------------------------------ 15-16Specifications and Operating Features ------------------------------------ 15-16

UBG-16 Wiring Diagrams ----------------------------------------------------UBG-16 Wiring Diagrams ----------------------------------------------------

UBG-16 Wiring Diagrams ----------------------------------------------------

UBG-16 Wiring Diagrams ----------------------------------------------------UBG-16 Wiring Diagrams ---------------------------------------------------Appendix A - Adding a Temperature Probe to the UBG-16 ---------Appendix A - Adding a Temperature Probe to the UBG-16 ---------

Appendix A - Adding a Temperature Probe to the UBG-16 ---------

Appendix A - Adding a Temperature Probe to the UBG-16 ---------Appendix A - Adding a Temperature Probe to the UBG-16 --------Appendix B - UBG-16 Circular Connectors -----------------------------Appendix B - UBG-16 Circular Connectors -----------------------------

Appendix B - UBG-16 Circular Connectors -----------------------------

Appendix B - UBG-16 Circular Connectors -----------------------------Appendix B - UBG-16 Circular Connectors ----------------------------Appendix C - UBG-16 Remote Head Wiring Diagram ----------------Appendix C - UBG-16 Remote Head Wiring Diagram ----------------

Appendix C - UBG-16 Remote Head Wiring Diagram ----------------

Appendix C - UBG-16 Remote Head Wiring Diagram ----------------Appendix C - UBG-16 Remote Head Wiring Diagram ---------------STC Information ---------------------------------------------------------- See BackSTC Information ---------------------------------------------------------- See Back

STC Information ---------------------------------------------------------- See Back

STC Information ---------------------------------------------------------- See BackSTC Information ---------------------------------------------------------- See Back

1

1313

13

1313

1717

17

1717

1818

18

1818

1919

19

1919

2020

20

2020

Page 6

WW

arar

W

WW

Electronics International Inc. warrants this instrument and system components to be free from defects in materials and workmanship for a period of one year from the user invoice date. Electronics International Inc. will

repair or replace any item under the terms of this Warranty provided the item is returned to the factory prepaid.

1. This Warranty shall not apply to any product that has been repaired or altered by any person other than

Electronics International Inc., or that has been subjected to misuse, accident, incorrect wiring, negligence,

improper or unprofessional assembly or improper installation by any person. This warranty does not cover

any reimbursement for any person’s time for installation, removal, assembly or repair. Electronics

International retains the right to determine the reason or cause for warranty repair.

2. This warranty does not extend to any machine, vehicle, boat, aircraft or any other device to which the

Electronics International Inc. product may be connected, attached, interconnected or used in conjunction with in

any way.

3. The obligation assumed by Electronics International Inc. under this warranty is limited to repair, replacement

or refund of the product, at the sole discretion of Electronics International Inc.

4. Electronics International Inc. is not liable for expenses incurred by the customer or installer due to factory

updates, modifications, improvements, upgrades, changes, or any other alterations to the product that may affect

the form, fit, function or operation of the product.

ranty / ranty /

ar

ranty /

arar

ranty / ranty /

AgrAgr

Agr

AgrAgr

eementeement

eement

eementeement

5. Personal injury or property damage do to misinterpretation or lack of understanding this product is solely the

pilots responsibility. The pilot must understand the operation of this product before flying the aircraft. Do not

allow anyone to operate the aircraft that does not know the operation of this product. Keep the Operating Manual

in the aircraft at all times.

6. Electronics International Inc. is not responsible for shipping charges or damages incurred under this Warranty.

7. No representative is authorized to assume any other liability for Electronics International Inc. in connection

with the sale of Electronics International Inc. products.

8. If you do not agree to and accept the terms of this warranty, you may return the product for a

refund.

This Warranty is made only to the original user. THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL

MANUFACTURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS EXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER

LIABILITY TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE

OR PERFORMANCE OF MANUFACTURER’S PRODUCTS, INCLUDING SPECIFICALLY

LIABILITY IN TORT.

2

Page 7

UBG-16UBG-16

UBG-16

UBG-16UBG-16

INSTINST

INST

INSTINST

1. 1.

"UBG-16""UBG-16"

1.

"UBG-16"

1. 1.

"UBG-16""UBG-16"

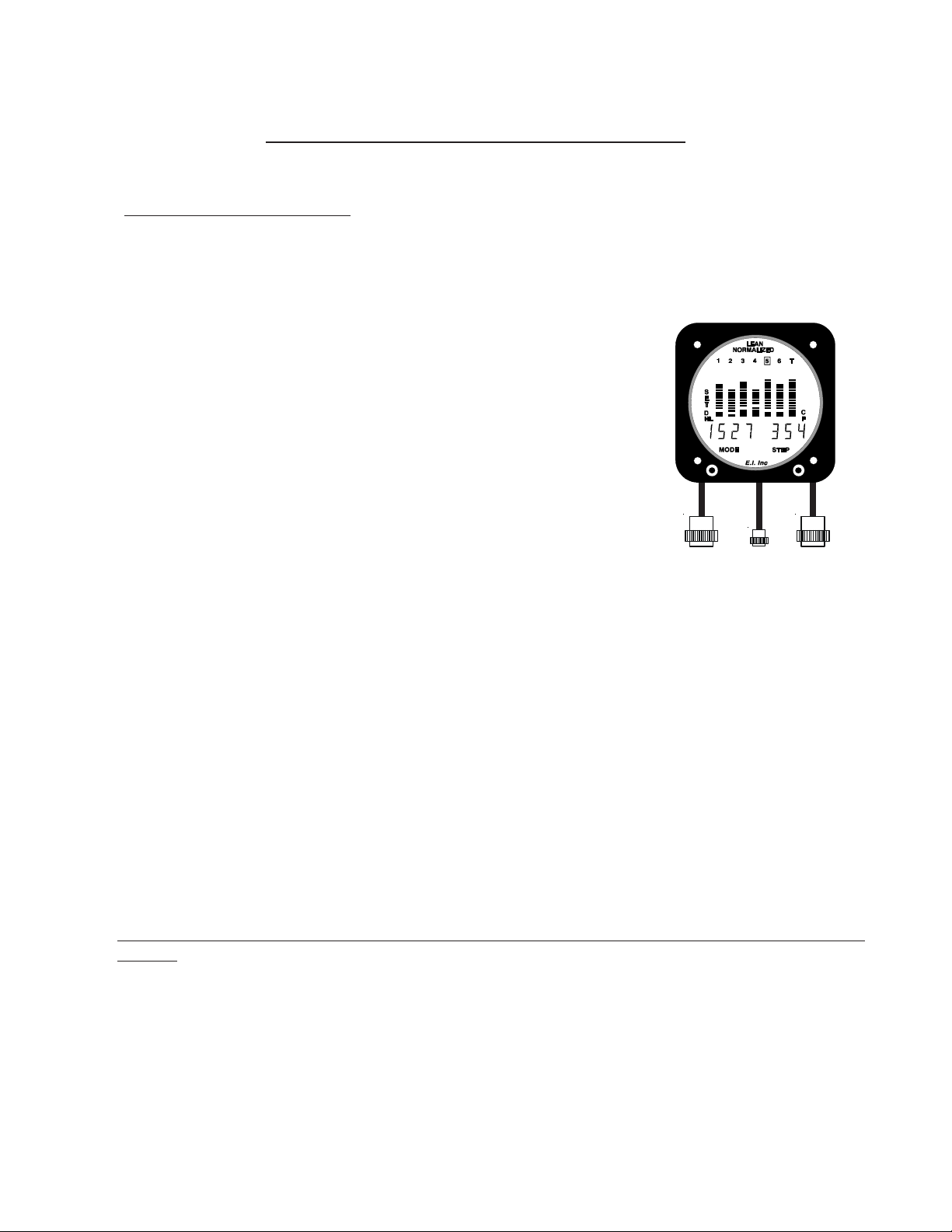

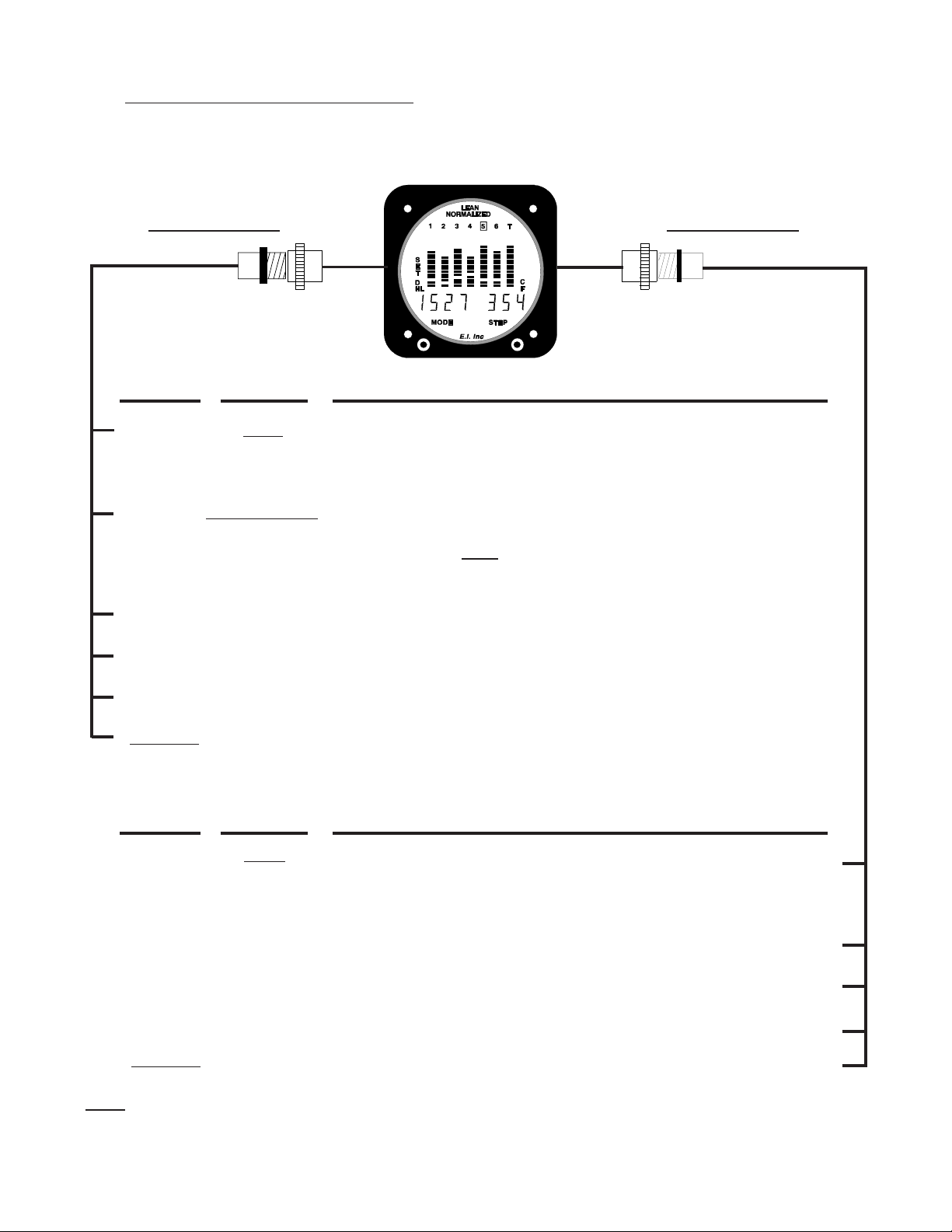

The UBG-16 was designed for use in a single engine aircraft. (For twin engines, use two UBG16’s.)

On the back of the UBG-16 are three circular connectors. As seen in

the diagram to the right:

The first 1 to 7 channels of the LEFT 16-pin connector are used to

monitor EGT’s. Any remaining channels may be used to monitor

other functions.

The first 1 to 7 channels of the RIGHT 16-pin connector are used

to monitor CHT’s. Any remaining channels may be used to

monitor other functions.

The small 9-pin connector connects the instrument to power,

ground, display intensity control, RS232 Recorder and any warning devices.

Over View Over View

Over View

Over View Over View

ALLAALLA

ALLA

ALLAALLA

TION INSTRTION INSTR

TION INSTR

TION INSTRTION INSTR

UCTIONSUCTIONS

UCTIONS

UCTIONSUCTIONS

16-Pin

EGT's

9-Pin 16-Pin

CHT's

The UBG-16 comes with three preassembled wire harnesses which simply plug into the three

circular connectors at the back of the instrument. Two of the wire harnesses are identical. One

will be used to connect the EGT probes to the UBG-16 and the other will be use to connect the

CHT probes to the UBG-16. The wire harnesses were assembled with only enough cables to

accommodate the EGT and CHT channels. Any additional temperature measurement (TIT, OAT,

Carb Temp, Cowl, etc.) requires a Type K thermocouple extension cable be added to the appropriate harness. Any desired function such as RPM, M.P., Oil Pressure, Fuel Pressure, Fuel Flow,

Gyro Vacuum, Volts, Amps, etc., requires an Electronics International Functional Module be

added to the appropriate harness.

The UBG-16 does not require any programming before installation. All setup can be accomplished

on the face of the instrument. The UBG-16 does not use any internal batteries, so once installed

the instrument never has to be removed from the panel.

Read step #2 below then perform only the remaining steps that apply to your configu-Read step #2 below then perform only the remaining steps that apply to your configu-

Read step #2 below then perform only the remaining steps that apply to your configu-

Read step #2 below then perform only the remaining steps that apply to your configu-Read step #2 below then perform only the remaining steps that apply to your configuration.ration.

ration.

ration.ration.

3

Page 8

2. 2.

Important Information and Initial Check OutImportant Information and Initial Check Out

2.

Important Information and Initial Check Out

2. 2.

Important Information and Initial Check OutImportant Information and Initial Check Out

The installer and aircraft owner must read the Warranty before starting the in-The installer and aircraft owner must read the Warranty before starting the in-

The installer and aircraft owner must read the Warranty before starting the in-

A.

The installer and aircraft owner must read the Warranty before starting the in-The installer and aircraft owner must read the Warranty before starting the in-

stallation.stallation.

stallation. There is information in the Warranty that may alter your decision to install this

stallation.stallation.

If you do not accept the terms of the Warranty, do not install this in-If you do not accept the terms of the Warranty, do not install this in-

instrument.

strument.strument.

strument.

strument.strument.

If you are not an FAA Certified Aircraft Mechanic familiar with the issues of If you are not an FAA Certified Aircraft Mechanic familiar with the issues of

B.

If you are not an FAA Certified Aircraft Mechanic familiar with the issues of

If you are not an FAA Certified Aircraft Mechanic familiar with the issues of If you are not an FAA Certified Aircraft Mechanic familiar with the issues of

installing aircraft EGT/CHT instruments, installing aircraft EGT/CHT instruments,

installing aircraft EGT/CHT instruments,

installing aircraft EGT/CHT instruments, installing aircraft EGT/CHT instruments,

The installer should use current aircraft standards and practices to install thisThe installer should use current aircraft standards and practices to install this

The installer should use current aircraft standards and practices to install this

The installer should use current aircraft standards and practices to install thisThe installer should use current aircraft standards and practices to install this

instrument (refer to AC 43.13).instrument (refer to AC 43.13).

instrument (refer to AC 43.13).

instrument (refer to AC 43.13).instrument (refer to AC 43.13).

Check that any necessary FAA Approvals (STC's, etc.) are available for yourCheck that any necessary FAA Approvals (STC's, etc.) are available for your

C.

Check that any necessary FAA Approvals (STC's, etc.) are available for your

Check that any necessary FAA Approvals (STC's, etc.) are available for yourCheck that any necessary FAA Approvals (STC's, etc.) are available for your

aircraft before starting the installation. A copy of the AML is located at the backaircraft before starting the installation. A copy of the AML is located at the back

aircraft before starting the installation. A copy of the AML is located at the back

aircraft before starting the installation. A copy of the AML is located at the backaircraft before starting the installation. A copy of the AML is located at the back

of this manual. of this manual.

of this manual.

of this manual. of this manual.

D. Read the entire Installation Instructions and resolve any issues you may have before starting

the installation. This may eliminate any delays once the installation is started.

Inspect the contents of this package prior to installation.Inspect the contents of this package prior to installation.

E.

Inspect the contents of this package prior to installation. Look for the following items:

Inspect the contents of this package prior to installation.Inspect the contents of this package prior to installation.

1) Proper instrument (UBG-16 for a single engine, UBG-16T for a twin engine).

If you do not accept the terms of the Warranty, do not install this in-

If you do not accept the terms of the Warranty, do not install this in-If you do not accept the terms of the Warranty, do not install this in-

Do Not attempt to install this instrument.Do Not attempt to install this instrument.

Do Not attempt to install this instrument.

Do Not attempt to install this instrument.Do Not attempt to install this instrument.

Resolve any issues you may have before starting the installation.Resolve any issues you may have before starting the installation.

Resolve any issues you may have before starting the installation.

Resolve any issues you may have before starting the installation.Resolve any issues you may have before starting the installation.

2) Correct length and number of extension cables (one for each temperature probe).

3) Correct number and type of temperature probes.

4) Correct Functional Modules (if required).

If you did not receive the proper instrument, probes, cables, functional modules or hardware

for your installation, contact either the dealer you purchased the instrument from or Electronics International Inc. for assistance. In most cases E.I. can exchange parts for only the

cost of shipping. Please have the purchase date, dealer name and serial number of the unit

available when you call.

Before starting the installation make sure the instrument will fit in the locationBefore starting the installation make sure the instrument will fit in the location

F.

Before starting the installation make sure the instrument will fit in the location

Before starting the installation make sure the instrument will fit in the locationBefore starting the installation make sure the instrument will fit in the location

you intend to install it without obstructing the operation of any controls. Note:you intend to install it without obstructing the operation of any controls. Note:

you intend to install it without obstructing the operation of any controls. Note:

you intend to install it without obstructing the operation of any controls. Note:you intend to install it without obstructing the operation of any controls. Note:

The UBG requires two non-standard holes be drilled in the aircraft instrumentThe UBG requires two non-standard holes be drilled in the aircraft instrument

The UBG requires two non-standard holes be drilled in the aircraft instrument

The UBG requires two non-standard holes be drilled in the aircraft instrumentThe UBG requires two non-standard holes be drilled in the aircraft instrument

panel outside the bezel area.panel outside the bezel area.

panel outside the bezel area.

panel outside the bezel area.panel outside the bezel area.

G. If this instrument is to replace an existing gauge in the aircraft, it is the installer's responsibil-

ity to move or replace any existing instruments or components in accordance with FAA approved methods and procedures.

WARNINGWARNING

WARNING

WARNINGWARNING

Do Not use screws that penetrate

the instrument face more than

.125". Display damage may result.

4

Page 9

3. 3.

"UBG-16""UBG-16"

3.

"UBG-16"

3. 3.

"UBG-16""UBG-16"

If you are installing the UBG-16, fill out the following configuration form. This form will document

which Temperature probes or Functional Modules will be connected to specific input channels on the

UBG-16.

8-Input Channels

LEFT

Channels: Function: Comments:

Configuration Form Configuration Form

Configuration Form

Configuration Form Configuration Form

LEFT

RIGHT

8-Input Channels

1 to ______ EGTs

(BAR 7) TIT, Oil T, OFF

L________ __________

L________ __________

L________ __________

L 8 __________

Right

Channels: Function: Comments:

1 to ______ CHTs

Up to 7 channels may be used to monitor EGTs. Each channel will be

displayed on a column of bars. A total of 7 columns are available. Enter

the number of EGTs you will be monitoring.

The 7th column of bars is intended to display EGT (on a 7-cylinder engine)

or TIT or Oil Temp or it may be turned off (circle one). However, the TIT

or Oil Temp probe

EGT channel (e.g., #5 on a 4-cylinder engine or #7 on a 6-cylinder engine).

In order, list the unused channels on the LEFT connector and indicate the

functions to be monitored on each channel. OAT or Carb Temp must only

be connected to channel L7, L8, R7 or R8 (these are precision channels). If

a channel is not used, write "OFF" in the Function Column for that channel.

Channel 8 is the last available channel on the left.

The number of CHTs monitored must be the same as the number of

EGT's monitored. The CHTs are monitored on the RIGHT Channels.

Enter the number of CHTs you will be monitoring.

must be connected to the next channel after the last

R________ __________

R________ __________

R________ __________

R 8 __________

Note: The UBG-16 digital display steps through the channels starting with number one on the LEFT and ending

with number 8 on the RIGHT.

In order, list the unused channels on the RIGHT connector and indicate

the functions to be monitored on each channel. OAT or Carb Temp

must only be connected to channel L7, L8, R7 or R8 (these are precision

channels). If a channel is not used, write "OFF" in the Function Column

for that channel.

Channel 8 is the last available channel on the Right.

5

Page 10

4. 4.

EGT Probe InstallationEGT Probe Installation

4.

EGT Probe Installation

4. 4.

EGT Probe InstallationEGT Probe Installation

Look at each exhaust stack and determine the best location at which all of the EGT probes can be

mounted at the same distance down from the exhaust ports. The ideal location is 1 1/2", but ease

of installation should prevail. Drill a 13/64" diameter hole in each exhaust stack. Insert the probe

and tighten the hose clamp. As the hose clamp is heated and cooled, it will become loose as it

conforms to the exhaust stack. After the first 10 hours of operation, each hose clamp should be

retightened.

IMPORTANT NOTE: For Cessna 210’s or any aircraft using a slip joint in the exhaust system,

install the EGT probes

slip joint can damage the probe.

5. 5.

CHT Probe InstallationCHT Probe Installation

5.

CHT Probe Installation

5. 5.

CHT Probe InstallationCHT Probe Installation

A single CHT probe should be placed on the hottest cylinder. In a 6-cylinder engine this would be

one of the center cylinders. On a 4-cylinder engine this would be one of the back cylinders.

If a second CHT probe is to be installed it should be placed on one of the front unobstructed

cylinders. This will allow the UBG-16 to detect shock-cooling automatically.

ABOVE OR BELOW THE SLIP JOINT. Installing a EGT probe in the

Most engines have a port just below the lower spark plug for the CHT probe.

primary CHT probe in one of the cylinders, do not remove it. The UBG-16 is not STC'd as a

primary replacement instrument. Select another cylinder for your probe. If you’re putting a

CHT probe on every cylinder use our P-102 Gasket CHT Probe for your primary cylinder.

6. 6.

TIT Probe InstallationTIT Probe Installation

6.

TIT Probe Installation

6. 6.

TIT Probe InstallationTIT Probe Installation

If you currently have a TIT gauge mounted in the aircraft it may be a primary engine instrument.

If this is the case you will need to install a secondary TIT probe. The TIT probe should be installed on the inlet of the Turbo-charger one to two inches before the Turbo-charger flange. Drill

a 13/64" diameter hole in the exhaust stack. Insert the probe and tighten the hose clamp. As the

hose clamp is heated and cooled, it will become loose as it conforms to the exhaust stack. After the

first 10 hours of operation, each hose clamp should be retightened.

7. 7.

OIL Temperature Probe InstallationOIL Temperature Probe Installation

7.

OIL Temperature Probe Installation

7. 7.

OIL Temperature Probe InstallationOIL Temperature Probe Installation

Sometimes finding a location for a secondary oil temperature probe can be a problem. The P-120,

P-100, P-111, P-112, P-114 and P-128 are all sealed probes appropriate for measuring oil temperature. See the "Probes" section of the price sheet for dimension information.

If your engine has a

6

Page 11

LYCOMING

IO 320, IO 360 and IO 540

Remove the 5/8" - 18 plug located on the rear engine accessory case above and forward of the oil

filter adaptor or oil screen as applicable. Install E.I.’s P-120 Oil Probe with a new oil seal and

torque to Lycoming’s specifications. Check for oil leaks after the first flight.

All Other Engines

Equipped with a 5/8"-18 Secondary Oil Drain Plug

Remove the 5/8"-18 Secondary oil drain plug located on the bottom of the engine. Install E.I.’s P120 Oil Probe with a new oil seal and torque to specifications.

flight.

If another location is used to measure oil temperature, make sure the probe does not interfere with

the operation of the engine.

8. 8.

Carb Temp Probe InstallationCarb Temp Probe Installation

8.

Carb Temp Probe Installation

8. 8.

Carb Temp Probe InstallationCarb Temp Probe Installation

Remove the threaded plug located in the carburetor housing just below the throttle valve. Install

the Carburetor Temperature Probe (P-128) in this hole using a lock washer. Care should be taken

not to over-tighten the probe and strip the threads in the carburetor housing.

Check for oil leaks after the first

NOTE:NOTE:

NOTE: A Carb Temp Probe should be connected to a precision channel on the UBG. That would

NOTE:NOTE:

be channel 7 or 8 on the left and right Circular Connector. A three to four degree F error can

occur in some instances if the Carburetor Probe is not connected to a precision channel.

9. 9.

OAT Probe InstallationOAT Probe Installation

9.

OAT Probe Installation

9. 9.

OAT Probe InstallationOAT Probe Installation

Mount the OAT Probe in an appropriate location on the aircraft, using the hardware supplied.

The OAT Probe is sensitive to air temperature changes. For this reason, do not mount the OAT

probe in the path of the cowl or engine exiting air (i.e., on the belly of the aircraft). Also, if the

probe is mounted in the cowling area near a turbo or hot cylinder head, radiant heat may influence the probe temperature. Other than these consideration the OAT Probe may be mounted in

an air intake vent, on the side of the cowling or anywhere else on the aircraft.

NOTE:NOTE:

NOTE: An OAT Probe should be connected to a precision channel on the UBG. That would be

NOTE:NOTE:

channel 7 or 8 on the left and right Circular Connector. A three to four degree F error can occur

in some instances if the OAT Probe is not connected to a precision channel.

10. 10.

10.

10. 10.

Other Temperature Probe InstallationOther Temperature Probe Installation

Other Temperature Probe Installation

Other Temperature Probe InstallationOther Temperature Probe Installation

Other temperature probes (Cowl Temp, CDI Temp, Water Temp, etc.) may be installed using

current aircraft standards and practices (refer to AC 43.13). Make sure these probes do not

interfere with the operation of the engine or aircraft.

7

Page 12

11. 11.

11.

11. 11.

for the for the

for the

for the for the

Install Additional Temperature Cables and Mark The CablesInstall Additional Temperature Cables and Mark The Cables

Install Additional Temperature Cables and Mark The Cables

Install Additional Temperature Cables and Mark The CablesInstall Additional Temperature Cables and Mark The Cables

"UBG-16""UBG-16"

"UBG-16"

"UBG-16""UBG-16"

There are two identical pre-wired Extension Cable Harnesses in the installation kit. One end of

each harness has a 16-pin Circular Connector and the other end has red Slip-on connectors on the

individual extension cables (see the Wiring Diagram at the back of this manual). There is a type K

thermocouple extension cable for each EGT and CHT temperature to be measured. The end of

each extension cable in the harness has a piece of yellow heat shrink marked with its channel

number. One of these harnesses is to be connected to the EGT probes (and LEFT connector on the

UBG-16) and the other is to be connected to the CHT probes (and the RIGHT connector on the

UBG-16). Refer to step 4 (Configuration Form) to identify which harness will be used for EGT's

and which will be used for CHT's.

Mark the Circular Connector that will be connected to the EGT probes. The first 4 or 6 channels

(starting with channel #1) are used to monitor EGT's. Any additional channels may be used to

monitor other temperatures or functions. There are 8 channels available on each 16-pin Circular

Connector. Any channel used to measure a temperature other than EGT or CHT (TIT, OAT,

Carb Temp, etc.) will have a type K thermocouple extension cable lose in the kit. Plug any additional extension cables into the appropriate pins of the Circular Connector (see "Appendix A" at

the back of this manual).

Any channel used to monitor functions other than temperature (RPM, M.P., Oil Pressure, Volts,

Amps, etc.) will require a Functional Module. Installation of a Functional Module will be covered

later in this manual.

Mark each of the Type K thermocouple extension cables in this harness (on the yellow heat shrink)

with the temperature function for which it will be used (i.e., CHT, EGT, Oil, etc.). An ink pen or

marker works well.

Note:Note:

Note: If a cable needs to be removed from a connector, you

Note:Note:

tool may be purchased from E.I.

Mark the Circular Connector that will be connected to the CHT probes. The first 4 or 6 channels

(starting with channel #1) are used to monitor CHT's. Any additional channels may be used to

monitor other functions. There are 8 channels available on each 16-pin Circular Connector. Any

channel used to measure a temperature other than EGT or CHT (TIT, OAT, Carb Temp, etc.)

will have a type K thermocouple extension cable lose in the kit. Plug any additional extension

cables into the appropriate pins of the Circular Connector (see "Appendix A" at the back of this

manual).

Any channel used to monitor a function other than temperature (RPM, M.P., Oil Pressure, Volts,

Amps, etc.) will require a Functional Module. Installation of a Functional Module will be covered

later in this manual.

Mark each of the Type K thermocouple extension cables in this harness (on the yellow heat shrink)

with the temperature function for which it will be used (i.e., CHT, EGT, Oil, etc.). An ink pen or

marker works well.

mustmust

must use an extraction tool. This

mustmust

Note: Note:

Note: Any channel will accept any one of E.I.’s probes or Functional Module.

Note: Note:

8

Page 13

12. 12.

12.

12. 12.

Route the 16-pin Circular ConnectorsRoute the 16-pin Circular Connectors

Route the 16-pin Circular Connectors

Route the 16-pin Circular ConnectorsRoute the 16-pin Circular Connectors

Do not continue with this step unless each Extension Cable has been marked as previously described.

Starting from under the instrument panel, route the 16-pin circular connector wire harness up to

the instrument mounting location. (See the wiring diagram at the back of this manual). Place the

circular connector about 9 inches back from the panel. Tie wrap the harness in place approximately 1 foot back from the circular connector. This will allow the harness to be flexible and

accommodate varying lengths in instrument wires.

freedom of travel of any controls.freedom of travel of any controls.

freedom of travel of any controls.

freedom of travel of any controls.freedom of travel of any controls.

Be sure these wires do not obstruct theBe sure these wires do not obstruct the

Be sure these wires do not obstruct the

Be sure these wires do not obstruct theBe sure these wires do not obstruct the

13. 13.

13.

13. 13.

Route Each Extension CableRoute Each Extension Cable

Route Each Extension Cable

Route Each Extension CableRoute Each Extension Cable

Starting from under the instrument panel, route each Extension Cable to its appropriate probe. If

new connectors are to be installed on the ends of the cables, you may want to pull any excess cable

length through the fire wall and cut it off at this time. However, it is recommended you leave some

extra wire length under the instrument panel in case you choose to move the UBG to a different

location at a later date.

strument.strument.

strument. The Extension Cables and Probe Wires are made of type K thermocouple wire that

strument.strument.

must not be substituted or extended with regular copper wire. Also, it is important these wires not

be kinked (i.e.,

Connect each probe to its associated Extension Cable using the supplied OLC-1 Overlap Connectors. See OLC-1 Installation Instructions for details.

sure there is no strain or pull on the cable against the probe or connectors. Dress each cable up to

the instrument keeping them away from any hot areas such as exhaust stacks, cylinder heads, etc.

Tie off any excess cable under the instrument panel.

freedom of travel of any controlsfreedom of travel of any controls

freedom of travel of any controls

freedom of travel of any controlsfreedom of travel of any controls

do not bend the wires on a radius less than 1 inchdo not bend the wires on a radius less than 1 inch

do not bend the wires on a radius less than 1 inch

do not bend the wires on a radius less than 1 inchdo not bend the wires on a radius less than 1 inch

Varying cable lengths will not affect the accuracy of this in-Varying cable lengths will not affect the accuracy of this in-

Varying cable lengths will not affect the accuracy of this in-

Varying cable lengths will not affect the accuracy of this in-Varying cable lengths will not affect the accuracy of this in-

).).

).

).).

When tie wrapping these cables down, be

Be sure these cables do not obstruct theBe sure these cables do not obstruct the

Be sure these cables do not obstruct the

Be sure these cables do not obstruct theBe sure these cables do not obstruct the

..

.

..

9

Page 14

14. 14.

14.

14. 14.

Install UBG-16 Functional Modules & AccessoriesInstall UBG-16 Functional Modules & Accessories

Install UBG-16 Functional Modules & Accessories

Install UBG-16 Functional Modules & AccessoriesInstall UBG-16 Functional Modules & Accessories

If a channel on the UBG-16 is to be used to monitor a function other than temperature, an appropriate Functional Module must be installed. A Functional Module is a small box with circuitry

used to convert pressure, RPM, Voltage, Amps, etc. to an appropriate signal the UBG can display.

This signal can be connected to any unused channel on the UBG-16. These modules are small and

light and are tie wrapped under the instrument panel. They come with a Circular Connector so

they may be installed and removed easily. Below is a list of the functional modules available:

FM-OP - Oil Pressure FM-FP - Fuel Pressure

FM-MP - Manifold Pressure FM-Gyro - Gyro Vacuum

FM-RPM - RPM FM-VA - Volts/Amps

FM-Flow - Fuel Flow (Flow only)

You may install any Functional Modules at any time. Installation Instructions for the various

Functional Modules are included with the modules.

The UBG-16 has optional items that may be installed. These items are listed below.

MUX-8A - Data Recorder AV-17 - Voice Annunciator

AP-7V - Vertical Annunciator Panel AP-7H - Horizontal Annunicator Panel

ATG-1 - Annunciator Tone Generator CP-1 - LED Intensity Control Pot

AL-1(x) - Chrome Annunciator Light A-103 - 3 1/8" Adaptor Plate

You may install any of the options at any time. Installation Instructions for the various options

are included with the options.

15. 15.

15.

15. 15.

16. 16.

16.

16. 16.

Route the Power and Ground WiresRoute the Power and Ground Wires

Route the Power and Ground Wires

Route the Power and Ground WiresRoute the Power and Ground Wires

Route the red wire in the 9-pin wire harness to the aircraft’s 12 or 24 volt

applicable via an independent five amp circuit breaker,

engine startengine start

engine start. An alternate method would be to route the red lead to the bus via a five amp in-line

engine startengine start

fuse. If the latter method is used, a spare fuse should be kept in the aircraft.

Route the black wire in the harness to a good ground .

obstruct the freedom of travel of any controls.obstruct the freedom of travel of any controls.

obstruct the freedom of travel of any controls.

obstruct the freedom of travel of any controls.obstruct the freedom of travel of any controls.

Route the Display Intensity Control WireRoute the Display Intensity Control Wire

Route the Display Intensity Control Wire

Route the Display Intensity Control WireRoute the Display Intensity Control Wire

Connect the white/orange wire to Electronics International's Intensity Control Pot (CP-1). If a

CP-1 has not been previously installed in the aircraft panel, do so at this time. This CP-1 will dim

the display on the UBG for night operation. If this line is left open, the display will remain at full

intensity at all times.

the UBG-16 must be OFF duringthe UBG-16 must be OFF during

the UBG-16 must be OFF during

the UBG-16 must be OFF duringthe UBG-16 must be OFF during

Tie wrap these wires so they do notTie wrap these wires so they do not

Tie wrap these wires so they do not

Tie wrap these wires so they do notTie wrap these wires so they do not

RADIO BUSRADIO BUS

RADIO BUS as

RADIO BUSRADIO BUS

10

Page 15

An alternate method is to connect the white/orange wire to the panel light rheostat. When the

panel lights are turned on for night operation the UBG display will dim. With this method their is

no guarantee that the panel lights and UBG display intensity will match.

Tie wrap all wires so they do not obstruct the freedom of travel of any controls.Tie wrap all wires so they do not obstruct the freedom of travel of any controls.

Tie wrap all wires so they do not obstruct the freedom of travel of any controls.

Tie wrap all wires so they do not obstruct the freedom of travel of any controls.Tie wrap all wires so they do not obstruct the freedom of travel of any controls.

17. 17.

17.

17. 17.

18. 18.

18.

18. 18.

19. 19.

19.

19. 19.

Route the (Optional) External Warning Control LineRoute the (Optional) External Warning Control Line

Route the (Optional) External Warning Control Line

Route the (Optional) External Warning Control LineRoute the (Optional) External Warning Control Line

The white/yellow wire can be connected to an external light (an AL-1 is supplied in this kit), buzzer

(ATG-1), voice annunciator (AV-17), a relay, etc. This wire grounds when a warning is activated

in the UBG. The current in this line must be limited to 1/10 of an amp maximum. Exceeding this

Tie wrap this wire soTie wrap this wire so

limit will damage the unit. If this feature is not used, leave this line open.

it does not obstruct the freedom of travel of any controls.it does not obstruct the freedom of travel of any controls.

it does not obstruct the freedom of travel of any controls.

it does not obstruct the freedom of travel of any controls.it does not obstruct the freedom of travel of any controls.

Route the (Optional) RS-232 Data Output LineRoute the (Optional) RS-232 Data Output Line

Route the (Optional) RS-232 Data Output Line

Route the (Optional) RS-232 Data Output LineRoute the (Optional) RS-232 Data Output Line

The white/green wire can be connected to Electronics International's MUX-8A for data recording.

Refer to the MUX-8A Operating and Installation Instructions for details.

Drill Two Holes for the Mode and Step SwitchDrill Two Holes for the Mode and Step Switch

Drill Two Holes for the Mode and Step Switch

Drill Two Holes for the Mode and Step SwitchDrill Two Holes for the Mode and Step Switch

A drill template is enclosed in the kit. Mount the drill template to the front of the aircraft instrument panel. Punch the two holes in the drill template for the Mode and Step Switch. Remove the

drill template and drill the two holes using a 1/4" drill bit. You may want to drill a pilot hole first.

Tie wrap this wire so

Tie wrap this wire soTie wrap this wire so

20. 20.

20.

20. 20.

Install the Instrument in the PanelInstall the Instrument in the Panel

Install the Instrument in the Panel

Install the Instrument in the PanelInstall the Instrument in the Panel

Install the instrument from behind the instrument panel using 6 x 32 screws.

SCREWS THAT PENETRATE THE INSTRUMENT FRONT PANEL MORE THANSCREWS THAT PENETRATE THE INSTRUMENT FRONT PANEL MORE THAN

SCREWS THAT PENETRATE THE INSTRUMENT FRONT PANEL MORE THAN

SCREWS THAT PENETRATE THE INSTRUMENT FRONT PANEL MORE THANSCREWS THAT PENETRATE THE INSTRUMENT FRONT PANEL MORE THAN

1/8" -- DOING SO WILL BREAK THE GLASS DISPLAY.1/8" -- DOING SO WILL BREAK THE GLASS DISPLAY.

1/8" -- DOING SO WILL BREAK THE GLASS DISPLAY.

1/8" -- DOING SO WILL BREAK THE GLASS DISPLAY.1/8" -- DOING SO WILL BREAK THE GLASS DISPLAY.

Connect all the Circular Connectors to the UBG in the following manner:

A)A)

A) Push the two mating connectors together and twist them until they snap into position.

A)A)

B)B)

B) Turn the locking ring on the instrument connector clockwise (1 1/2 turns) until it locks

B)B)

into position.

If you are using the optional remote head for the UBG-16, secure the body of the UBG-16 underneath the instrument panel in a location that will not obstruct the freedom of travel of any controls. Route the wires from the body to the remote head making sure that the wires do not obstruct the freedom of travel of any controls. Connect the cable from the head to the body.

11

DO NOT USEDO NOT USE

DO NOT USE

DO NOT USEDO NOT USE

Page 16

21. 21.

21.

21. 21.

Configure the UBG for Your AircraftConfigure the UBG for Your Aircraft

Configure the UBG for Your Aircraft

Configure the UBG for Your AircraftConfigure the UBG for Your Aircraft

To configure the UBG to operate with the temperature probes and Functional modules installed in

your aircraft, refer to the Power-up Programming section in the Operating Instructions. Use the

Configuration Form found in this manual as a reference.

22. 22.

22.

22. 22.

System Ground TestSystem Ground Test

System Ground Test

System Ground TestSystem Ground Test

A. Turn the master switch on and look for a near ambient temperature reading on each tempera-

ture channel. If the instrument does not power-up (display a reading), check the power and

ground leads (red and black leads) for an open, loose or poor connection.

If you suspect that any channel is not receiving a signal, remove the probe from the engine

(leaving it connected to the Extension Cable) and apply a temperature to it. Look for an increase in reading on the display for that channel. Check the other channels for an increase in

reading. You may have connected the probe to the wrong Extension Cable. If the reading is

decreasing, you may have reversed the connectors on the Extension Cable leads (the yellow

wire on the probe must connect to the yellow wire on the Extension Cable).

B. Start the engine and check each channel for a proper reading. On the ground (after a few

minutes) EGT’s will read around 900°F and CHT’s will read around 200°F. If you suspect any

channel is not receiving a signal properly, see step A of the “Troubleshooting” section of this

manual.

12

Page 17

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

Because high reliability is designed into Electronics International’s equipment, there is no reason to put

up with poor operation. We have few problems with our probes, cables and units and installation is

simple. Usually fixing a problem is just a matter of inspecting the installation at a few key points.

StrategyStrategy

Strategy

StrategyStrategy

TING SUGGESTIONSTING SUGGESTIONS

TING SUGGESTIONS

TING SUGGESTIONSTING SUGGESTIONS

If you have more than one problem,

them at once can be confusing and misleading. In many cases fixing one problem first will lead you

to the solution for fixing all of the problems. Therefore, take one problem on one channel and

proceed with the following:

A. A.

Instrument Check OutInstrument Check Out

A.

Instrument Check Out

A. A.

Instrument Check OutInstrument Check Out

If there is an identical symptom on each channel, then the instrument may have a problem. But if

even one channel of the instrument is operating properly, the instrument probably does not have a

problem. A good method to test the instrument is to remove all the Extension Cables by disconnecting the Extension Cable Circular Connector. Then look for a reading on all channels to be

near cabin temperature for temperature channels or zero for channels measuring functions other

than temperature (RPM, Oil Pressure, etc.). The only inputs the UBG requires to operate properly and measure cabin temperature is power (red lead) and ground (black lead). Check the

power and ground leads for proper connection (pull on the wire at each connector).

Note:Note:

Note: Few problems turn out to be the instrument.

Note:Note:

B. B.

Probe Check OutProbe Check Out

B.

Probe Check Out

B. B.

Probe Check OutProbe Check Out

FIX ONE PROBLEM AT A TIMEFIX ONE PROBLEM AT A TIME

FIX ONE PROBLEM AT A TIME

FIX ONE PROBLEM AT A TIMEFIX ONE PROBLEM AT A TIME

. .

. Trying to fix all of

. .

There are two good methods of testing a probe. Perform one or both of the following:

1.1.

1. A probe can be tested with an ohmmeter. Disconnect the probe from the Extension Cable.

1.1.

When testing the resistance between the connectors, the probe should measure a “short” (less

than 5 ohms). When measuring from one lead (either lead) of the probe to the probe sheath

(metal tip), there should be an “open” (10k or greater).

2.2.

2. Another method of checking a probe is to plug the suspected bad probe into a channel that is

2.2.

working properly. If the problem follows the probe, you have a defective probe.

C. C.

Extension Cable Check OutExtension Cable Check Out

C.

Extension Cable Check Out

C. C.

Extension Cable Check OutExtension Cable Check Out

With the Extension Cable connected to the UBG, remove the probe from the suspected bad Extension Cable. Set the UBG to the proper channel and look for a near cabin temperature reading. A

very high or low reading indicates a short to ground in the cable. Next, connect an ohmmeter, set

13

Page 18

to 10K range, to the open probe ends of the suspected bad Extension Cable. Set the UBG to the

proper channel and look for a high (+ or -) reading. A near cabin temperature reading or no

change in reading indicates an open in the cable or its connectors. Most problems of this kind are

usually one of the following:

Improper OLC-1 Connections:Improper OLC-1 Connections:

1. 1.

Improper OLC-1 Connections: Pull on wires installed in the Over-Lap Connector to

1.

Improper OLC-1 Connections:Improper OLC-1 Connections:

1. 1.

check the connection. You may have insulation in the overlap area. Remove the wires from

the OLC-1 and inspect.

Broken Wire:Broken Wire:

2. 2.

Broken Wire: A wire can be broken from a too-tight tie-wrap or by repeatedly flexing

2.

Broken Wire:Broken Wire:

2. 2.

the wire. Inspect the wires for a break. Note: A wire can be broken while the insualtion is

still intact.

Cable Chafed to Ground:Cable Chafed to Ground:

3. 3.

Cable Chafed to Ground: If a cable is routed around a metal object, it will over time

3.

Cable Chafed to Ground:Cable Chafed to Ground:

3. 3.

chafe the wire and short to the object. Inspect the wires for chafing.

14

Page 19

SPECIFICSPECIFIC

SPECIFIC

SPECIFICSPECIFIC

Model:Model:

Model: UBG-16

Model:Model:

Weight:Weight:

Weight: Unit only: 22 oz., One probe and 6 foot cable: 3.5 oz., One Probe and 20 foot cable: 7 oz.

Weight:Weight:

Environmental:Environmental:

Environmental: Meets TSO C43a

Environmental:Environmental:

Power Requirements:Power Requirements:

Power Requirements: 10.5 to 30 Volts, 3/10 Amp.

Power Requirements:Power Requirements:

Display:Display:

Display: Plasma (viewable in direct sunlight). Display dims for night operation.

Display:Display:

Accuracy:Accuracy:

Accuracy: 1/2% in accordance with TSO C43a.

Accuracy:Accuracy:

Power-up Test:Power-up Test:

Power-up Test: Flashes all bars, segments and nomenclature.

Power-up Test:Power-up Test:

Probes:Probes:

Probes: Type K, Ungrounded (for improved accuracy, stability and reliability).

Probes:Probes:

Extension Cables:Extension Cables:

Extension Cables: Type K, any length or size. Non-Temp cables are tin/copper.

Extension Cables:Extension Cables:

Channels:Channels:

Channels: Maximum of 16 Channels.

Channels:Channels:

AA

TIONS and OPERATIONS and OPERA

A

TIONS and OPERA

AA

TIONS and OPERATIONS and OPERA

S1111981

TING FEATING FEA

TING FEA

TING FEATING FEA

TURESTURES

TURES

TURESTURES

11/11/98

EGT and CHT Analyzer Channels:EGT and CHT Analyzer Channels:

EGT and CHT Analyzer Channels: 1 to 7, programmable from front panel (left channels for

EGT and CHT Analyzer Channels:EGT and CHT Analyzer Channels:

EGTs and right channels for CHTs).

EGT Bar Resolution:EGT Bar Resolution:

EGT Bar Resolution: 1 to 104°F per Bar, programmable from front panel.

EGT Bar Resolution:EGT Bar Resolution:

CHT Bar Resolution:CHT Bar Resolution:

CHT Bar Resolution: 33°F per Bar.

CHT Bar Resolution:CHT Bar Resolution:

Lean Operating Mode:Lean Operating Mode:

Lean Operating Mode:

Lean Operating Mode:Lean Operating Mode:

A. Activated after 10°F rise in hottest EGT.

B. Peak detected when 5°F decrease in any EGT or TIT.

Scan Rate:Scan Rate:

Scan Rate: Programmable from 1 to 9 second per channel.

Scan Rate:Scan Rate:

15

Page 20

UBG-16

RS-232 (5-volt) Output

0721991

7/21/99

1. General Description1. General Description

1. General Description

1. General Description1. General Description

The UBG transmits serial RS-232 (5-volt) data on the white/green wire (pin 9). The serial data transmitted is the same as that shown on the digital display as each channel is selected. The white/green wire may

be connected to a PC through Electronics International’s 8 Channel Multiplexer Unit (MUX-8). If the

transmitted signal is inverted, it may be connected directly to a PC. The serial data is transmitted in a

comma delimited format, suitable for importing into most spreadsheet and data base programs.

2. Instrument Operation2. Instrument Operation

2. Instrument Operation

2. Instrument Operation2. Instrument Operation

The UBG outputs RS232 (5-volt) data in all operating modes.

3.3.

TT

ransmit Specificationsransmit Specifications

3.

T

ransmit Specifications

3.3.

TT

ransmit Specificationsransmit Specifications

* Baud Rate: 9600

* Data Bits: 8

* Start Bit: 1 (Logic Low)

* Stop Bit: 1 (Logic High 5-volts)

* Parity: None

* Transmit Rate: 5 seconds to transmit all 16 channels.

4.4.

TT

ransmit Fransmit F

4.

T

ransmit F

4.4.

TT

ransmit Fransmit F

The UBG transmits the following record:The UBG transmits the following record:

The UBG transmits the following record:

The UBG transmits the following record:The UBG transmits the following record:

UBG,L1,R1,L2,R2,L3,R3,L4,R4,L5,R5,L6,R6,L7,R7,L8,R8CrLf

UBG Instrument identifier.

, A comma separates data fields.

L1 Left channel 1 reading (-999 to 1999 decimal points are not transmitted).

R 1 Right channel 1 reading (-999 to 1999 decimal points are not transmitted).

Cr Carriage return (0Dh)

Lf Line feed (0Ah)

ormatormat

ormat

ormatormat

Other left channels are L2, L3, etc.

Other right channels are R2, R3, etc.

16

Page 21

WARNINGWARNING

WARNING

WARNINGWARNING

Do Not use screws that penetrate

the instrument face more than

.125". Display damage may result.

UBG-16

Wiring Diagram

Right Channels

For monitoring CHT's and other

temperatures or functions.

Channel #1.

Channel #2.

Channel #3.

Channel #4.

Channel #5,

Channel #6.

Channel #7.

Channel #8.

1

2

3

4

5

6

7

8

Right Extension Cable Harness. Left Extension Cable Harness.

UBG-16

Back View

Left Channels

For monitoring EGT's and other

temperatures or functions.

1

Channel #1.

2

Channel #2.

3

Channel #3.

4

Channel #4.

5

Channel #5,

6

Channel #6.

7

Channel #7.

8

Channel #8.

Note: Any channel used to measure a temperature must

be connected to a Type K thermocouple extension cable.

Note: The first 4 or 6 channels on the left and right must

be used to monitor EGT and CHT respectively.

Note: If using the 7th column of bars to display TIT or

Oil Temp, the probe must be connected to the next LEFT

channel after the last EGT channel.

Note: OAT or Carb Temp must be connected to channel

7 or 8 on the left or right. These are "precision" channels.

Note: Any left or right channel will accept any one of

E.I.'s probes or Functional Modules.

Note: Varying cable lengths will not affect accuracy.

Connecting Wire Harness.

White/Orange

Red

Black

White/Grn

White/Yel

17

Description Connects To:

Display Dimming.

Power Lead.

Ground Lead.

(Optional) RS232 Data Output Line.

Connect to MUX-8 to record data.

(Optional) External Warning Control

Line. Can be connected to a relay to

control an external light, buzzer, etc.

This line grounds when a warning is

blinking on the display. Current must

be limited to 1/10 amp maximum.

CP-1 Intensity

Control Pot.

12/24 Volt, Radio

Bus. via 5 amp fuse.

Ground

Page 22

Appendix A

Adding a Temperature Probe to the UBG-16

If you have an unused channel and would like to add an extension cable and probe to your instrument, perform

the following steps:

1. Order an XCS Extension Cable (at the proper length) and appropriate probe from Electronics

International Inc.

2. Disconnect the cable harness at the Circular Connector on the back of the UBG.

3. Insert the the XCS Extension Cable into the Circular Connector at the proper location (see below).

Once these connectors are installed

extraction tool is used you can damage the Circular Connector. An extraction tool may be purchased from Electronics International Inc.

4. Follow the appropriate steps in the Installation Instructions for mounting the probes and routing the

Extension Cables.

5. Reconnect the cable harness to the Circular Connector at the back of the UBG.

do not try to remove them without an extraction tool. Unless an

Extension Cable Harness

Back View (wire side)

2

1

Yel

Yel

3

Red

16

5

Red

7

Red

8

Yel

5

3

6

Yel

10

7

Yel

14

Yel

Yel

2

6

18

1

Red

4

Yel

Red

Note: 1 Red = Channel #1 Red wire.

1

3

2

Red

4

7

Red

6

11

Red

8

15

1 Yel = Channel #1 Yel wire.

Page 23

Appendix B

UBG-16

Circular Connectors

Extension Cable Harness, Back View (wire side)

OR

Instrument Connector, Front View

Note: 1 Red = Channel #1 Red wire (Gnd)

2

1

Yel

3

6

Yel

3

Red

2

Yel

1

Red

2

Red

1

3

1 Yel = Channel #1 Yel wire (Signal)

Yel

4

Yel

6

8

Red

6

Red

15

4

Red

7

11

14

10

Yel

5

Yel

7

16

5

Red

7

Red

8

Yel

Connecting Cable Harness, Back View (wire side)

OR

Instrument Connector, Front View

W/

3

Yel

W/

6

Org

Blk

Red

1

4

Note: See Wiring Diagram for

hook up information.

W/

9

Grn

7

19

Page 24

Cable

UBG-16 Head

Side View

WARNINGWARNING

WARNING

WARNINGWARNING

Do Not use screws that penetrate

the remote face more than .125".

Display damage may result.

Appendix C

UBG-16 Remote Head

Wiring Diagram

UBG-16 Body

Side View

UBG-16 Body

Back View

Right Extension Cable Harness. Left Extension Cable Harness.

Connecting Wire Harness.

20

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Loading...

Loading...