Page 1

Page 2

Important Notice

***** MUST READ *****

Page 1 of 4

If you think it is not important to read this manual, you’re wrong! This manual

contains important operating information that may affect the safety of you, your

aircraft and passengers.

Read the Warranty / AgreementRead the Warranty / Agreement

Read the Warranty / Agreement. There is information in the Warranty/Agreement that may alter your

Read the Warranty / AgreementRead the Warranty / Agreement

decision to install this product.

not install this productnot install this product

not install this product. This product may be returned for a refund. Contact Electronics International

not install this productnot install this product

inc. for details.

By installing this product, the aircraft owner/pilot and installer agree to hold Electronics International Inc.

harmless and in no way responsible for monetary compensation, including punitive damages for any

incident, harm and/or damage associated with this product. If you do not agree to the above,

INSTALL THIS PRODUCT.INSTALL THIS PRODUCT.

INSTALL THIS PRODUCT. This product may be returned for a refund. Contact Electronics Interna-

INSTALL THIS PRODUCT.INSTALL THIS PRODUCT.

tional inc. for details.

If you do not accept the terms of the Warranty / Agreement, doIf you do not accept the terms of the Warranty / Agreement, do

If you do not accept the terms of the Warranty / Agreement, do

If you do not accept the terms of the Warranty / Agreement, doIf you do not accept the terms of the Warranty / Agreement, do

DO NOTDO NOT

DO NOT

DO NOTDO NOT

mustmust

The pilot

allow anyone to operate the aircraft that does not know how to properly interpret and operate this product.

Keep the Operating Instructions in the aircraft at all times. If you do not thoroughly understand the

operation of this product, contact a knowledgeable flight instructor for training.

The ability for this product to respond to an engine or aircraft system anomaly is directly related to how

that anomaly affects the reading of the function(s) being monitored (i.e.; if an engine fire does not affect

the EGT or CHT, the EGT and CHT readings will not change).

This instrument only displays the parameters for the function(s) being monitored. The pilot is responsible

for interpreting the data and determining if an engine or aircraft system anomaly exists. When using this

instrument, the pilot’s diagnostic ability is limited to his/her interpretation of the displayed data and the

their observation skills. To improve these skills the pilot should seek training from a flight instructor.

If after reading this manual you do not have the knowledge to interpret the displayed data to operate the

aircraft safely or to detect engine and/or aircraft system problems, contact a knowledgeable instructor for

training prior to flying the aircraft with this instrument.

If you detect a problem using this instrument, it is your responsibility to take appropriate action to ensure

the safety of the flight. Practice simulating problems to build your skills and to improve your understand

of the relationships between problems and their affects on the displayed data. To ensure you are taking

appropriate action, contact a knowledgeable flight instructor for training. Inappropriate action can lead to

aircraft and/or engine damage, personal injury or death.

must

understand the operation and limitations of this product before flying the aircraft. Do not

mustmust

This manual does not make any recommendations as to specific operating parameters or controlling

methods. Check the airframe and/or engine manufacturer’s recommendations to properly operate the

aircraft systems and engine. It is the pilot’s responsibility to operate the engine and aircraft safely.

Page 3

Important Notice

***** MUST READ *****

Page 2 of 4

It is possible for any instrument to fail thereby displaying inaccurate high, low or jumpy readings.

Therefore, you

your aircraft safely in spite of an instrument failure. If you do not have this knowledge, contact the FAA

or a knowledgeable flight instructor for training prior to flying the aircraft with this instrument.

Electronics International Inc. is not liable or responsible for a pilot’s action or any situation that results in

personal injury, property damage, missed commitments, lack of use of an aircraft or any expenses

incurred due to: product failure, inaccuracy in displayed data or text files, display or display format

issues, software bugs or problems, upgrade or customization issues, misinterpretation of the display,

warning and/or limit settings, calibration problems, installation issues (leaks, mis-wiring, obstructions,

damage to aircraft or components, incorrect installation of any parts, wrong parts, parts that don’t fit,

etc.) or any other issues related to the installation or operation of this product. All of the above are

solely the pilot’s and/or installer’s responsibility. The pilot

uct before flying the aircraft. The pilot must not allow anyone to operate the aircraft that does not know

the operation of this product. The pilot must keep the instrument Operating Instructions in the aircraft at

all times.

mustmust

must be able to recognize an instrument failure and you

mustmust

mustmust

must

understand the operation of this prod-

mustmust

mustmust

must be proficient in operating

mustmust

Set a unique password to protect all of the calibration and setup data in the CGR-30P. If setup or calibration data is inadvertently or improperly changed, you could get inaccurate readings that may lead to

improper operation of the aircraft or engine. This could result in engine damage and/or an emergency

situation.

Before flying the aircraft verify that the instrument markings displayed on the CGR are accurate with

your POH for every function displayed on the CGR.

The CGR must be calibrated to the aircraft fuel system and the CGR's accuracy must be verified before

flying the aircraft.

Fuel Level Accuracy Limitations:Fuel Level Accuracy Limitations:

Fuel Level Accuracy Limitations:

Fuel Level Accuracy Limitations:Fuel Level Accuracy Limitations:

The accuracy limitations of the CGR are listed below.

anyone flying the aircraft aware of these limitations.anyone flying the aircraft aware of these limitations.

anyone flying the aircraft aware of these limitations.

anyone flying the aircraft aware of these limitations.anyone flying the aircraft aware of these limitations.

1. Angle of Attack -1. Angle of Attack -

1. Angle of Attack - The CGR must be calibrated with the aircraft in a cruise angle of attack. If the

1. Angle of Attack -1. Angle of Attack aircraft is in an angle of attack other than cruise, the CGR may display inaccurate fuel levels (depending

on the mounting location and type of sensor used). If your aircraft does not sit at a cruise angle of attack

when on the ground, it may not display accurate fuel levels.

of attack to determine how the CGR fuel level readings are affected.of attack to determine how the CGR fuel level readings are affected.

of attack to determine how the CGR fuel level readings are affected.

of attack to determine how the CGR fuel level readings are affected.of attack to determine how the CGR fuel level readings are affected.

It is the pilot/owner’s obligation to makeIt is the pilot/owner’s obligation to make

It is the pilot/owner’s obligation to make

It is the pilot/owner’s obligation to makeIt is the pilot/owner’s obligation to make

Test your aircraft at different anglesTest your aircraft at different angles

Test your aircraft at different angles

Test your aircraft at different anglesTest your aircraft at different angles

Full Fuel Readings -Full Fuel Readings -

2.

Full Fuel Readings - As a tank is filled the fuel sensor may be unable to detect the fuel entering

Full Fuel Readings -Full Fuel Readings -

Page 4

Important Notice

***** MUST READ *****

Page 3 of 4

the upper corners of the fuel tank. If this is the case with your sensor, the CGR may display fuel levels

lower than the actual fuel in the tanks when the tanks are full. When the fuel level drops to a point

where the fuel sensor starts to detect a change, the displayed fuel level should be accurate.

accuracy of your system by comparing the displayed fuel levels on the CGR to the fuelaccuracy of your system by comparing the displayed fuel levels on the CGR to the fuel

accuracy of your system by comparing the displayed fuel levels on the CGR to the fuel

accuracy of your system by comparing the displayed fuel levels on the CGR to the fuelaccuracy of your system by comparing the displayed fuel levels on the CGR to the fuel

levels listed in the flight manual at each fill up.levels listed in the flight manual at each fill up.

levels listed in the flight manual at each fill up.

levels listed in the flight manual at each fill up.levels listed in the flight manual at each fill up.

Check the Check the

Check the

Check the Check the

3. Low Fuel Readings -3. Low Fuel Readings -

3. Low Fuel Readings -

3. Low Fuel Readings -3. Low Fuel Readings for an indicated tank level below 1/8for an indicated tank level below 1/8

for an indicated tank level below 1/8. You should always fly the aircraft in such a manner as to

for an indicated tank level below 1/8for an indicated tank level below 1/8

at least maintain the FAA minimum fuel requirements in the aircraft at all times.

mounting location and type of fuel sensor used, the CGR may not be able to accuratelymounting location and type of fuel sensor used, the CGR may not be able to accurately

mounting location and type of fuel sensor used, the CGR may not be able to accurately

mounting location and type of fuel sensor used, the CGR may not be able to accuratelymounting location and type of fuel sensor used, the CGR may not be able to accurately

measure the last few gallons of fuel in the tanks.measure the last few gallons of fuel in the tanks.

measure the last few gallons of fuel in the tanks.

measure the last few gallons of fuel in the tanks.measure the last few gallons of fuel in the tanks.

4. Improper Calibration -4. Improper Calibration -

4. Improper Calibration - If the CGR has not been properly calibrated, it will not display accurate

4. Improper Calibration -4. Improper Calibration fuel levels in the tanks. It is important to verify the accuracy of the CGR.

measured fuel levels in the tanks with the readings on the CGR before each flight.measured fuel levels in the tanks with the readings on the CGR before each flight.

measured fuel levels in the tanks with the readings on the CGR before each flight.

measured fuel levels in the tanks with the readings on the CGR before each flight.measured fuel levels in the tanks with the readings on the CGR before each flight.

5. Poor Connections -5. Poor Connections -

5. Poor Connections - Poor connections between the wires leading from the EDC to the fuel

5. Poor Connections -5. Poor Connections sensors can become intermittent with age. An intermittent connection most likely will show up as

wandering or inaccurate readings on the CGR.

in the tanks with the readings on the CGR before each flight.in the tanks with the readings on the CGR before each flight.

in the tanks with the readings on the CGR before each flight.

in the tanks with the readings on the CGR before each flight.in the tanks with the readings on the CGR before each flight.

6. Defective Fuel Level Sensors -6. Defective Fuel Level Sensors -

6. Defective Fuel Level Sensors - Fuel sensors can become intermittent or change resistance

6. Defective Fuel Level Sensors -6. Defective Fuel Level Sensors with age. It is not uncommon to find intermittent problems even in new resistive sensors. An intermittent problem with a fuel sensor most likely will show up as wandering or inaccurate readings on the

CGR.

CGR at each fill up.CGR at each fill up.

CGR at each fill up.

CGR at each fill up.CGR at each fill up.

Always cross check the measured fuel levels in the tanks with the readings on theAlways cross check the measured fuel levels in the tanks with the readings on the

Always cross check the measured fuel levels in the tanks with the readings on the

Always cross check the measured fuel levels in the tanks with the readings on theAlways cross check the measured fuel levels in the tanks with the readings on the

Do not rely on the CGR to determine the fuel level in the tankDo not rely on the CGR to determine the fuel level in the tank

Do not rely on the CGR to determine the fuel level in the tank

Do not rely on the CGR to determine the fuel level in the tankDo not rely on the CGR to determine the fuel level in the tank

Depending on theDepending on the

Depending on the

Depending on theDepending on the

Always cross check yourAlways cross check your

Always cross check your

Always cross check yourAlways cross check your

Always cross check your measured fuel levelsAlways cross check your measured fuel levels

Always cross check your measured fuel levels

Always cross check your measured fuel levelsAlways cross check your measured fuel levels

Page 5

Important Notice

***** MUST READ *****

Page 4 of 4

Important Fuel Level Considerations:Important Fuel Level Considerations:

Important Fuel Level Considerations:

Important Fuel Level Considerations:Important Fuel Level Considerations:

DO NOT RELY SOLELY ON THE FUEL LEVEL DISPLAYED ON THE CGR TODO NOT RELY SOLELY ON THE FUEL LEVEL DISPLAYED ON THE CGR TO

DO NOT RELY SOLELY ON THE FUEL LEVEL DISPLAYED ON THE CGR TO

DO NOT RELY SOLELY ON THE FUEL LEVEL DISPLAYED ON THE CGR TODO NOT RELY SOLELY ON THE FUEL LEVEL DISPLAYED ON THE CGR TO

DETERMINE THE FUEL LEVELS IN THE AIRCRAFT.DETERMINE THE FUEL LEVELS IN THE AIRCRAFT.

DETERMINE THE FUEL LEVELS IN THE AIRCRAFT.

DETERMINE THE FUEL LEVELS IN THE AIRCRAFT.DETERMINE THE FUEL LEVELS IN THE AIRCRAFT.

eliminate or reduce the necessity for the pilot to use good flight planning, preflight andeliminate or reduce the necessity for the pilot to use good flight planning, preflight and

eliminate or reduce the necessity for the pilot to use good flight planning, preflight and

eliminate or reduce the necessity for the pilot to use good flight planning, preflight andeliminate or reduce the necessity for the pilot to use good flight planning, preflight and

in-flight techniques for managing fuel.in-flight techniques for managing fuel.

in-flight techniques for managing fuel. It is important the pilot adopt the practices listed below.

in-flight techniques for managing fuel.in-flight techniques for managing fuel.

If you are not familiar with these techniques, contact the FAA to acquire proper training.

1. 1.

A copy of these Operating Instructions must be in the aircraft at all times.A copy of these Operating Instructions must be in the aircraft at all times.

1.

A copy of these Operating Instructions must be in the aircraft at all times.

1. 1.

A copy of these Operating Instructions must be in the aircraft at all times.A copy of these Operating Instructions must be in the aircraft at all times.

2. Flight Planning -2. Flight Planning -

2. Flight Planning - Always calculate the fuel requirement for each leg of a flight, including any

2. Flight Planning -2. Flight Planning alternate plans for bad weather or other problems. Keep this information available in the aircraft

during the flight. Keep a chart of the published fuel flows for various flight/engine conditions in the

aircraft. Keep a chart of the measured fuel flows for various flights in the aircraft. Measured fuel

flows can be considerably different from published figures.

The use of the CGR does not The use of the CGR does not

The use of the CGR does not

The use of the CGR does not The use of the CGR does not

3. Preflight - Do not rely on the CGR to determine the fuel level in the fuel tanks. The3. Preflight - Do not rely on the CGR to determine the fuel level in the fuel tanks. The

3. Preflight - Do not rely on the CGR to determine the fuel level in the fuel tanks. The

3. Preflight - Do not rely on the CGR to determine the fuel level in the fuel tanks. The3. Preflight - Do not rely on the CGR to determine the fuel level in the fuel tanks. The

pilot must visually check/measure the fuel levels in the tanks before every takeoff.pilot must visually check/measure the fuel levels in the tanks before every takeoff.

pilot must visually check/measure the fuel levels in the tanks before every takeoff. Cross

pilot must visually check/measure the fuel levels in the tanks before every takeoff.pilot must visually check/measure the fuel levels in the tanks before every takeoff.

check the measured fuel levels with the displayed levels on the CGR. Also, cross check these levels

with the fuel requirements for the flight listed in your flight plan.

4. In Flight -4. In Flight -

4. In Flight - Make the CGR part of your normal instrument scan.

4. In Flight -4. In Flight displayed on the CGR with your flight plan at each leg of the flight or every 30 minutesdisplayed on the CGR with your flight plan at each leg of the flight or every 30 minutes

displayed on the CGR with your flight plan at each leg of the flight or every 30 minutes

displayed on the CGR with your flight plan at each leg of the flight or every 30 minutesdisplayed on the CGR with your flight plan at each leg of the flight or every 30 minutes

(if a leg is longer than 30 minutes). Calculate the fuel flows from the CGR displayed fuel levels and

compare them with your charts of measured and published fuel flows for the aircraft. If there is a

discrepancy, land the aircraft at the nearest airport and verify the fuel levels. Discrepancies should be

taken seriously.

5. New Pilot or Owner of the Aircraft -5. New Pilot or Owner of the Aircraft -

5. New Pilot or Owner of the Aircraft -

5. New Pilot or Owner of the Aircraft -5. New Pilot or Owner of the Aircraft aircraft, it is the previous aircraft pilot/owner’s responsibility to insure the new pilot/aircraft, it is the previous aircraft pilot/owner’s responsibility to insure the new pilot/

aircraft, it is the previous aircraft pilot/owner’s responsibility to insure the new pilot/

aircraft, it is the previous aircraft pilot/owner’s responsibility to insure the new pilot/aircraft, it is the previous aircraft pilot/owner’s responsibility to insure the new pilot/

owner has read this manual and is aware of any accuracy limitations and other importantowner has read this manual and is aware of any accuracy limitations and other important

owner has read this manual and is aware of any accuracy limitations and other important

owner has read this manual and is aware of any accuracy limitations and other importantowner has read this manual and is aware of any accuracy limitations and other important

considerations. All limitations and operating characteristics learned from operating theconsiderations. All limitations and operating characteristics learned from operating the

considerations. All limitations and operating characteristics learned from operating the

considerations. All limitations and operating characteristics learned from operating theconsiderations. All limitations and operating characteristics learned from operating the

CGR must be passed on to the new pilot/owner.CGR must be passed on to the new pilot/owner.

CGR must be passed on to the new pilot/owner.

CGR must be passed on to the new pilot/owner.CGR must be passed on to the new pilot/owner.

If there is a new pilot or new owner of theIf there is a new pilot or new owner of the

If there is a new pilot or new owner of the

If there is a new pilot or new owner of theIf there is a new pilot or new owner of the

Crosscheck the fuel levelsCrosscheck the fuel levels

Crosscheck the fuel levels

Crosscheck the fuel levelsCrosscheck the fuel levels

Page 6

Contents

(Page 1 of 2)

Warranty/Agreement----------------------------------------------------------------------------------------- 1

1.0 Introduction: ---------------------------------------------------------------------------------- 3

1.1 Features ------------------------------------------------------------------------------- 5

1.2 Overview of the CGR Screens: -------------------------------------------------------- 5

1.3 System Hardware: --------------------------------------------------------------------- 6

1.4 SELECT Knob and Button Operation: ------------------------------------------------- 7

1.5 Display Dimming: ---------------------------------------------------------------------- 7

1.6 Cleaning the Screen: ------------------------------------------------------------------- 7

2.0 Main Engine Screen: -------------------------------------------------------------------------- 9

2.1 Power-up Add Fuel Message: --------------------------------------------------------- 11

2.2 Main Screen Layout: ------------------------------------------------------------------- 11

2.3 RPM and Maniflod Pressure: ---------------------------------------------------------- 12

2.4 Horizontal Strip Gauges: --------------------------------------------------------------- 12

2.5 Bar Graph Analyzer: ------------------------------------------------------------------- 12

2.6 Main Screen Annunciators: ------------------------------------------------------------ 15

2.7 External Master Caution and Warning Light: ------------------------------------------- 15

2.8 Voice Alarm Control Panel (OEM Only): ---------------------------------------------- 15

3.0 Secondary Screen: --------------------------------------------------------------------------- 17

3.1 RPM and Mainifold pressure Gauges: ------------------------------------------------- 18

3.2 Three Annunciators: ------------------------------------------------------------------- 18

3.3 Six Horizontal Strip and/or Digital Gauges: --------------------------------------------- 18

3.4 EGT/CHT Digital Gauges: ------------------------------------------------------------- 18

4.0 Fuel Qtys Screens: --------------------------------------------------------------------------- 20

4.1 Fuel Quantity: ------------------------------------------------------------------------- 22

4.2 Selecting a Tank: ---------------------------------------------------------------------- 22

4.3 Adding Fuel: -------------------------------------------------------------------------- 22

4.4 K-Factor Adjustments: ---------------------------------------------------------------- 23

5.0 Fuel Data Screen: ---------------------------------------------------------------------------- 24

5.1 Total Fuel Cylinder: ------------------------------------------------------------------- 26

5.2 Fuel: FLOW ------------------------------------------------------------------------- 26

5.3 Fuel: EST DIST ---------------------------------------------------------------------- 26

5.4 Fuel: EST QTYS --------------------------------------------------------------------- 26

5.5 Fuel: EST TIME ---------------------------------------------------------------------- 27

5.6 Fuel: EST AT DEST ------------------------------------------------------------------ 27

5.7 Fuel: EST USED --------------------------------------------------------------------- 27

Page 7

Contents

(Page 2 of 2)

6.0 User Setup Screens: -------------------------------------------------------------------------- 28

6.1 Fuel K-Factor Screen: ----------------------------------------------------------------- 30

6.2 Clock and Hour Meters Screen: ------------------------------------------------------- 31

6.3 EGT/CHT Bar Graph Setup Screen: --------------------------------------------------- 31

6.4 USB and Data Recording Screen: ------------------------------------------------------ 32

6.5 Fuel Alarm and Unit Info Screen: ------------------------------------------------------- 32

6.6 System Config Screens Menu: ---------------------------------------------------------- 33

7.0 System Configuration Screens ---------------------------------------------------------------- 34

7.1 USB Config and SW Prg Manager Screen: -------------------------------------------- 36

7.2 Change Passwords Screen: ------------------------------------------------------------ 36

7.3 Aircraft ID Screen: --------------------------------------------------------------------- 37

7.4 Hour Meters and Flight Timers Screen: ------------------------------------------------ 37

7.5 Serial Port and EDC Setup Screen: ---------------------------------------------------- 37

7.6 Engine and EGT/CHT Bar Graph Setup Screen: --------------------------------------- 38

7.7 Fuel Tank Setup Screen: --------------------------------------------------------------- 38

7.8 Display and Voice Controls Screen: ---------------------------------------------------- 40

7.9 CGR Input/Output Tests Screen: ------------------------------------------------------- 40

7.10 Horsepower Calibration Screen: ------------------------------------------------------ 41

7.11 Function Configuration Screen: ------------------------------------------------------- 41

7.11.1 Probe Calibration Screen: ------------------------------------------------- 44

7.11.2 Function Mapping Screen (Fuel T ank Calibration): ------------------------- 46

Appendix ------------------------------------------------------------------------------------------ 48

A1.0 Specifications / Features:

A2.0 Recorded Flight Data Format

Page 8

Warranty / Agreement

You must read the entire Installation and Operating Instructions. If you do not agree to andYou must read the entire Installation and Operating Instructions. If you do not agree to and

You must read the entire Installation and Operating Instructions. If you do not agree to and

You must read the entire Installation and Operating Instructions. If you do not agree to andYou must read the entire Installation and Operating Instructions. If you do not agree to and

accept the terms of this warranty/agreement and the responsibilities set forth in these manuals,accept the terms of this warranty/agreement and the responsibilities set forth in these manuals,

accept the terms of this warranty/agreement and the responsibilities set forth in these manuals,

accept the terms of this warranty/agreement and the responsibilities set forth in these manuals,accept the terms of this warranty/agreement and the responsibilities set forth in these manuals,

DO NOT install this product. Contact E.I. for a refund.DO NOT install this product. Contact E.I. for a refund.

DO NOT install this product. Contact E.I. for a refund.

DO NOT install this product. Contact E.I. for a refund.DO NOT install this product. Contact E.I. for a refund.

Electronics International Inc. (EI) warrants this instrument and system components to be free from defects in

materials and workmanship for a period of one year from the purchase date. EI will repair or replace any item

under the terms of this Warranty provided the item is returned to the factory prepaid.

Electronics International Inc. is not liable or responsible for a pilot’s action or any situation that results in

personal injury, property damage, missed commitments, lack of use of an aircraft or any expenses incurred due

to: product failure, inaccuracy in displayed data or text files, display or display format issues, software bugs or

problems, upgrade or customization issues, misinterpretation of the display, warning and/or limit settings,

calibration problems, installation issues (leaks, mis-wiring, obstructions, damage to aircraft or components,

incorrect installation of any parts, wrong parts, parts that don’t fit, etc.) or any other issues related to the installation or operation of this product. All of the above are solely the pilot’s and/or installer’s responsibility. The

mustmust

pilot

to operate the aircraft that does not know the operation of this product. The pilot will keep the instrument

Operating Instructions in the aircraft at all times.

By installing this product, the aircraft owner/pilot and installer agree to hold Electronics International Inc.

harmless and in no way responsible for monetary compensation, including punitive damages for any incident,

harm and/or damage associated with this product (including but not limited to the ones listed above). If you do

not agree to the above,

must

understand the operation of this product before flying the aircraft. The pilot will not allow anyone

mustmust

DO NOT INSTALL THIS PRODUCT.DO NOT INSTALL THIS PRODUCT.

DO NOT INSTALL THIS PRODUCT.

DO NOT INSTALL THIS PRODUCT.DO NOT INSTALL THIS PRODUCT.

This Warranty shall not apply to any product that has been repaired or altered by any person other than Electronics International Inc., or that has been subjected to misuse, accident, incorrect wiring, negligence, improper

or unprofessional assembly or improper installation by any person.

reimbursement for any person’s time for installation, removal, assembly or repair.reimbursement for any person’s time for installation, removal, assembly or repair.

reimbursement for any person’s time for installation, removal, assembly or repair. Electronics

reimbursement for any person’s time for installation, removal, assembly or repair.reimbursement for any person’s time for installation, removal, assembly or repair.

International retains the right to determine the reason or cause for warranty repair and if the product will be

covered.

Personal injury or property damage due to misinterpretation or lack of understanding of this product is solely

mustmust

the pilot’s responsibility. The pilot

the aircraft. If he/she does not, he/she agrees to seek training from a knowledgeable instructor. Do not allow

anyone to operate the aircraft that does not know the operation of this product. Keep the Operating Instructions in the aircraft at all times.

This warranty does not extend to any machine, vehicle, boat, aircraft or any other device to which the Electronics International Inc. product may be connected, attached, interconnected or used in conjunction with in any

way.

The obligation assumed by Electronics International Inc. under this warranty is limited to repair, replacement or

refund of the product, at the sole discretion of Electronics International Inc.

Electronics International Inc. is not liable for expenses incurred by the customer or installer due to factory

updates, modifications, improvements, changes, or any other alterations to the product that may affect the

form, fit, function or operation of the product.

must

understand all aspects of the operation of this product before flying

mustmust

This warranty does not cover anyThis warranty does not cover any

This warranty does not cover any

This warranty does not cover anyThis warranty does not cover any

More On Next PageMore On Next Page

More On Next Page

More On Next PageMore On Next Page

1

Page 9

Electronics International is not responsible for shipping charges or damages incurred under this Warranty.

No representative is authorized to assume any other liability for Electronics International Inc. in connection

with the sale of Electronics International Inc. products.

This Warranty is made only to the original user.

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLYWARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLYWARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ADISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ADISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFAC-PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFAC-

PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFAC-

PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFAC-PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, IN-TURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, IN-

TURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, IN-

TURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, IN-TURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT ASCLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS

CLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS

CLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT ASCLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS

EXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITYEXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY

EXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY

EXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITYEXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY

TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE OR PERFOR-TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE OR PERFOR-

TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE OR PERFOR-

TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE OR PERFOR-TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURER’S PRODUCTS, INCLUDING SPECIFICALLY LIABILITY INMANCE OF MANUFACTURER’S PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN

MANCE OF MANUFACTURER’S PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN

MANCE OF MANUFACTURER’S PRODUCTS, INCLUDING SPECIFICALLY LIABILITY INMANCE OF MANUFACTURER’S PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN

TORT.TORT.

TORT.

TORT.TORT.

THIS WARRANTY IS IN LIEU OF ALL OTHERTHIS WARRANTY IS IN LIEU OF ALL OTHER

THIS WARRANTY IS IN LIEU OF ALL OTHER

THIS WARRANTY IS IN LIEU OF ALL OTHERTHIS WARRANTY IS IN LIEU OF ALL OTHER

2

Page 10

IntroductionIntroduction

Introduction

IntroductionIntroduction

1.1 Features:

1.2 Overview of the CGR Screens:

1.3 System Hardware:

1.4 SELECT Knob and Button Operation:

1.5 Display Dimming:

1.6 Cleaning the Screen:

1.01.0

1.0

1.01.0

3

Page 11

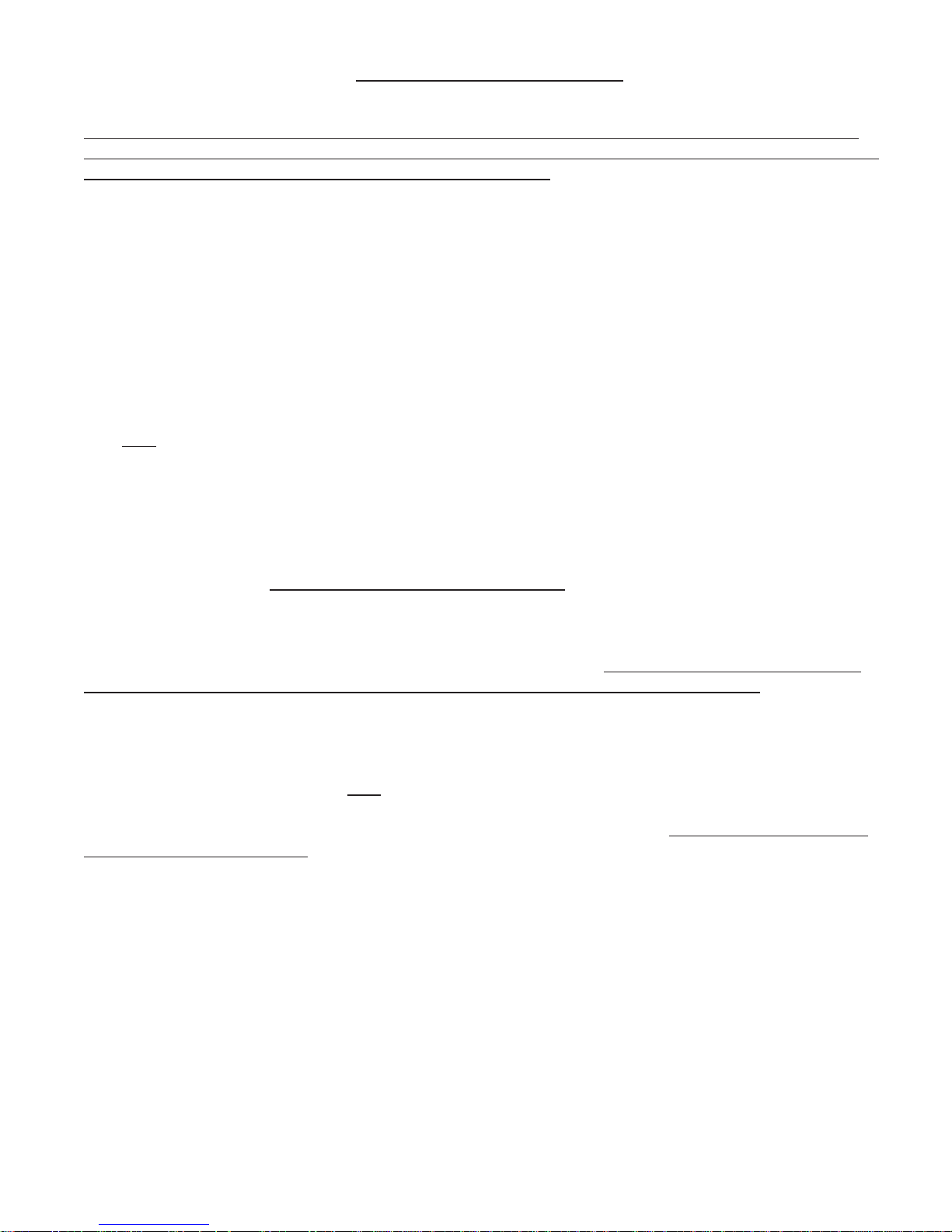

1.1 Features:

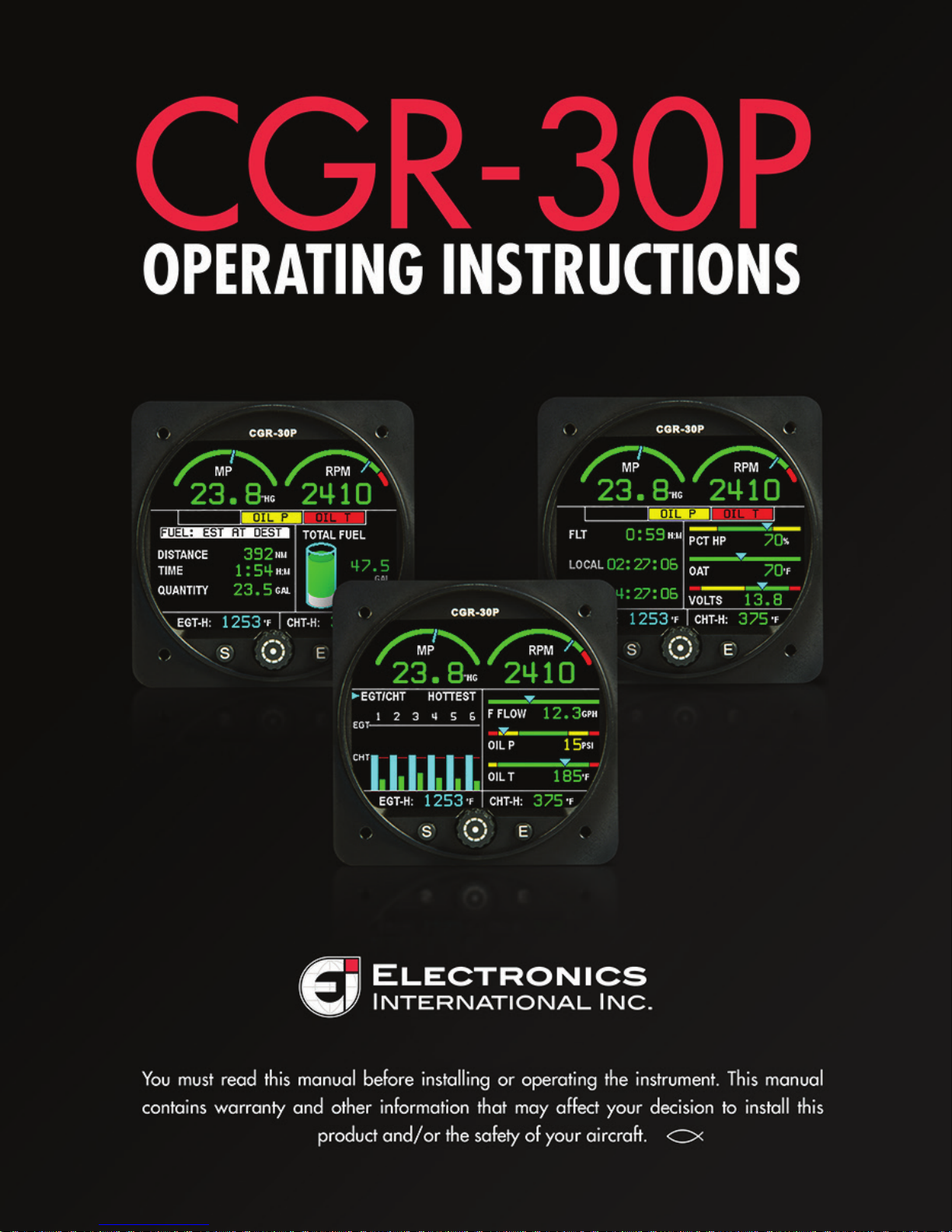

The CGR-30P is a state-of-the-art Glass Panel Engine Monitor that

provides many of the engine and system instruments found in an aircraft

panel. Each of the instruments displayed on the CGR’ s Main Engine

Screen provides features not found in most multifunctional displays or

traditional gauges.

Aircraft panels equipped with individual instruments require a pilot to

scan and interpret a multitude of gauges spread across an entire panel.

By providing a single location for viewing the engine and many aircraft

system instruments, the CGR reduces a pilot’s workload and the chance

of missing a problem. Additionally , the CGR provides both analog and

digital displays with digits that blink and change colors when yellow or

red operating ranges are reached. Also, an external Caution and

Main Screen

W arning Light can be placed in front of the pilot. All of these features are

designed to alert the pilot the moment any monitored function enters a red or yellow operating range.

1.2 Overview of the CGR Screens:

Main Screen (see section 2.0): The Main Screen displays most of the

engine and aircraft instruments monitored by the CGR. This is the screen

the CGR displays after power-up and is the screen the pilot will view for

most of the flight.

Secondary Screen (see section 3.0): The Secondary screen is

intended to display functions that do not need to be displayed

continuously . Although, one function with a red (warning) and/or yellow

(caution) can be placed on the Secondary screen.

If a primary function on the Secondary screen reaches a red or yellow

operating range, an annunciator located between the two arc gauges

located at the top of the Main Screen will blink. In this way the pilot is

alerted of a potential problem and should view the Secondary screen for

further information.

Fuel Qtys Screens (see section 4.0): Depending on the way the

CGR-30P is setup, the Fuel Qtys Screen will display the estimated fuel

levels for the different aircraft fuel tanks or it will display the total fuel

onboard. The setup depends on how the aircraft handles fuel to the

engine (i.e.; if the engine returns fuel to a single fuel tank or if you can

select both tanks, then only total fuel will be displayed). Also, the Fuel

Qtys Screen allows the pilot to add fuel to a tank.

Secondary Screen

Fuel Qtys Screen

5

Page 12

Fuel Data Screen (see section 5.0): The Fuel Data Screen provides

six sets of data based on Fuel Flow and GPS information. This data

includes Range, Distance to Destination, Range after reaching your

Destination, Fuel Remaining, Fuel to Destination, Fuel Reserve, Time to

Empty , Time to Destination, T ime Reserve, Fuel Used for the Flight, Fuel

Used since fuel was Added, Economy (MPGs) and T otal Fuel onboard.

Much of this data depends on an RS232 connection to your GPS.

User Setup Screens (see section 6.0): The User Setup Screen Menu

provides a list of setup screens for setting the K-Factor, setting clocks,

viewing the T ach and Engine Hours, setting the display range for the bar

graph, downloading recorded data and setting up the Recurring Fuel

Alarm.

Fuel Data Screen

System Config Screens (see section 7.0): The System Config

Screens allows Electronics International to setup the CGR-30P for almost any function for any aircraft. These

screens are password protected.

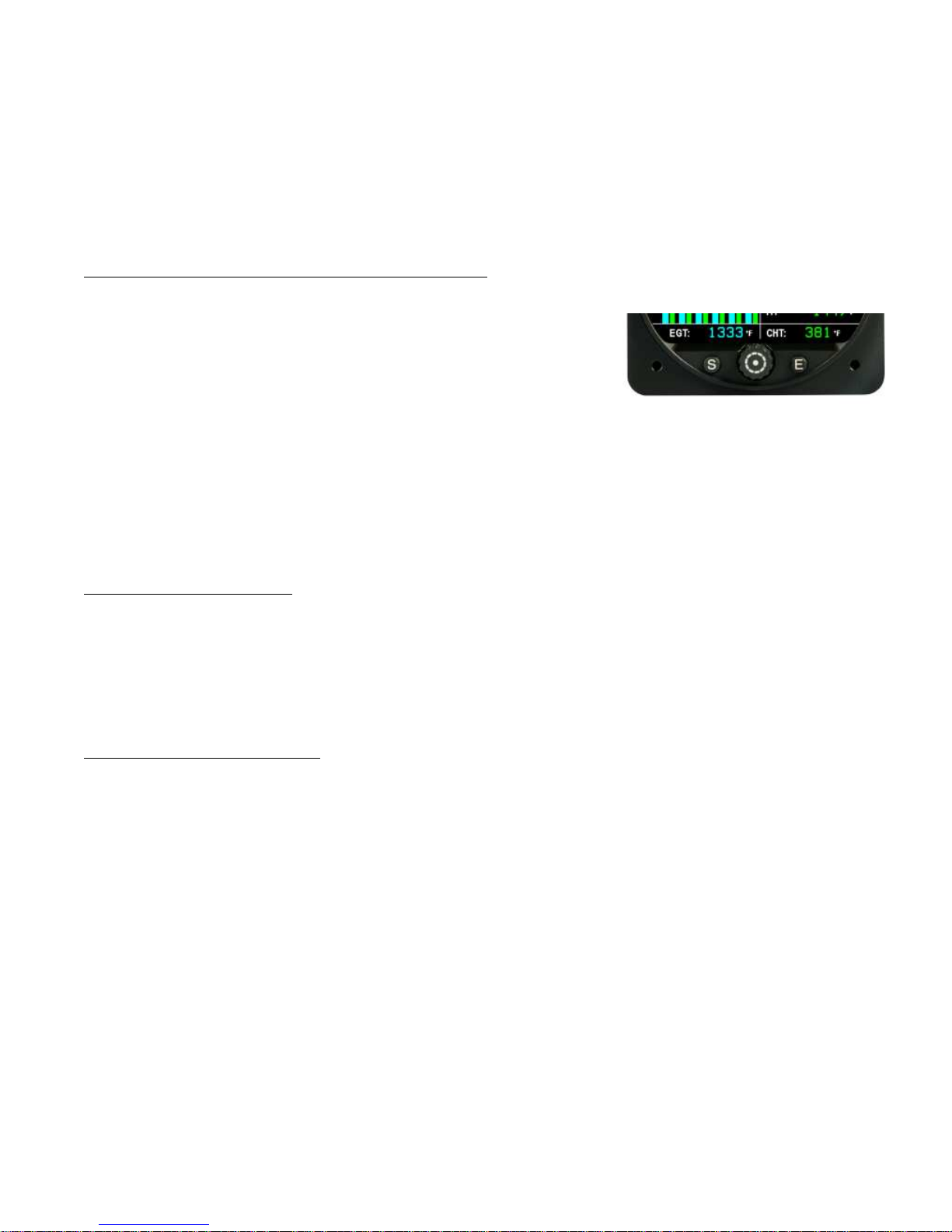

1.3 System Hardware:

The CGR-30P hardware consists of the following three groups of components:

A. Probes, T ransducers and Extension Cables – These components are used to measure pressures,

temperatures, fuel flow , volts, amps, fuel levels and many other engine and aircraft system functions. The

analog signals produced by the transducers and probes are routed through the Extension Cables to

various EDC inputs.

B. EDC (Engine Data Converter) – The EDC-33P converts the analog signals from the probes and

transducers to a digital format. This data is transmitted via a one-wire +5V Serial cable to the CGR

Display .

6

Page 13

C. CGR Display – The CGR receives, processes and displays the Serial EDC data on its TFT color

display . In addition, the CGR receives GPS data, interfaces with the Voice W arning Control Panel and

monitors the external back light control line. Also, the CGR transmits fuel data to the GPS and controls

the external Caution and W arning Lights.

The CGR reduces the number of panel-mounted instruments from around 12 to only 1. The EDC can reduce the

total number of wires routed to the aircraft instrument panel by 50 or more.

1.4 SELECT Knob and Button Operation:

SELECT Knob: The SELECT knob can be rotated or pressed.

Depending on the screen and field being viewed, rotating the knob can

move an arrow , select a digit, or change a digit’s value. Pressing the

SELECT knob will choose the highlighted item.

SCREENS Button: Pressing the SCREENS button sequences the

CGR through the four display screens (Main, Secondary , Fuel Qty and Fuel Data).

EXIT Button: Pressing the EXIT button will exit you out of a specific operation. Repeated presses will exit you

out of the current screen and return you to the Main Screen.

1.5 Display Dimming:

The CGR provides an external dimming control line to dim the display . The CGR can be set to dim on any input

voltage swing. Dimming calibration is setup in the Display & Voice Controls screen found in section 7 of this

manual.

1.6 Cleaning the Screen:

The CGR incorporates a flat panel full color TFT display , which should be protected from scratches. The TFT

display should be cleaned using only isopropyl alcohol and a soft cleaning cloth. Individually wrapped lens-cleaning

tissue (used to clean glasses or plastic lenses) works best.

7

Page 14

Main Engine ScreenMain Engine Screen

Main Engine Screen

Main Engine ScreenMain Engine Screen

2.1 Power-up Add Fuel Message:

2.2 Main Screen Layout:

2.3 RPM and Manifold Pressure:

2.4 Horizontal Strip Gauges:

2.5 Bar Graph Analyzer:

2.5.1 “EGT/CHT” Operating Mode:

2.5.2 “Normalized” Operating Mode:

2.02.0

2.0

2.02.0

2.5.3 “Lean - ROP” Operating Mode:

2.5.4 “Lean - LOP” Operating Mode:

2.5.5 “EGT” Digital Operating Mode:

2.5.6 “CHT” Digital Operation Mode:

2.6 Main Screen Annunciators:

2.7 External Master Caution and Warning Lights:

2.8 Voice Alarm Control Panel (OEM Only):

9

Page 15

The Main Engine Screen displays the aircraft system and engine instruments you will view most frequently during a

flight. There is important information published in the Important Notice section (found in the front of this

manual) that must be read before operating this instrument. Please read the Important Notice section at this

time.

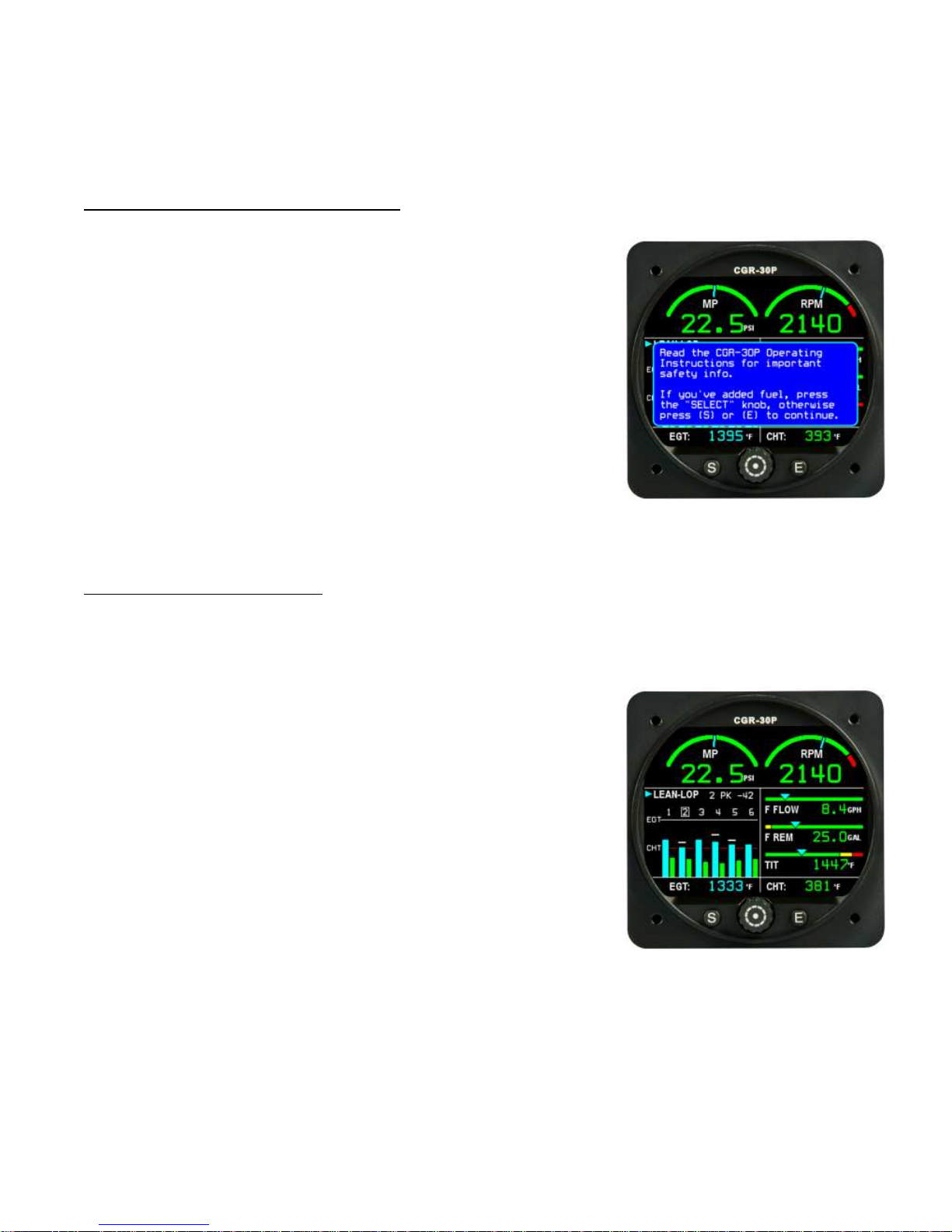

2.1 Power-up Add Fuel Message:

The CGR requires approximately 15 seconds to power-up. Y ou may

want to switch on the Master Switch when first entering the aircraft to

insure the CGR is powered up when you are ready to start the engine.

An “Important Safety Info” and “Add Fuel Message” will appear when

the CGR is fully powered up. The purpose of this message is to remind

you to read the important information and to update the fuel computer if

you have added fuel to the aircraft. The CGR can display the estimated

fuel on-board the aircraft calculated from the fuel flow. This allows you

to cross check the fuel readings on your fuel level gauge to ensure

accuracy. The “Add Fuel Message” can be acknowledged by pressing

the “Exit” button or (if you have added fuel to the aircraft) you can

change the displayed fuel quantity by pressing the “Select” knob.

2.2 Main Screen Layout:

The Main Screen is laid out in the following four areas:

RPM and Manifold Pressure (see section 2.3): The RPM and

Manifold Pressure instruments are located at the top of the Main

screen. Each of these instruments incorporates a large arc and

digital display . Other functions may be placed in this location.

Three Horizontal S trip Gauges (see section 2.4): A series of

three Horizontal Strip Gauges (with digital readouts) are located on

the right side of the screen. A number of different functions may be

placed in this location.

Bar Graph (see section 2.5): The Bar Graph is located in the

lower left portion of the Main screen. The Bar Graph monitors

both EGT s and CHT s. The Bar Graph provides both bar graph

and digital formats and incorporates features for leaning, detecting

and diagnosing engine problems. The “SELECT knob controls the display and operation of the Bar Graph

portion of the screen.

EGT/CHT Digital Gauges (see section 2.5): The two digital displays located at the bottom of the Main

screen provides EGT and CHT data based on the bar graph operating mode selected.

11

Page 16

2.3 RPM and Manifold Pressure:

The RPM and M.P. instruments incorporate a digital readout and an

analog arc. The color of the digital readout will reflect the current range

in which the function is operating (i.e., if the RPM is operating in the red,

the digital readout will be displayed in red).

The digital display will blink when the RPM or M.P. operating level

reaches a yellow or red operating range. To stop the blinking, push the

Exit button. Also (if so equipped), acknowledging a voice warning using

the external “Voice Alarm Control Panel” will stop the blinking of any

digital display.

The CGR’s RPM Instrument provides a Mag Out feature in addition to

the arc and digital display. The CGR continually monitors both mag

signals. If one mag fails or is turned off, an appropriate “Mag Out”

warning will be displayed on the appropriate side of the RPM digital display.

2.4 Horizontal Strip Gauges:

L. Mag

Out

The three Horizontal Strip gauges provide the following features:

A. The colored operating ranges shown on the Horizontal Strip can be set up for any aircraft.

B. Each Horizontal Strip Gauge features a pointer (triangle) marking the current operating level. Also, the

pointer allows the pilot to interpret rate and trend information and provides field of vision.

C. A digital display is provided with each Horizontal Strip Gauge.

D. The digits on the digital display will blink when a function’ s operating level reaches a yellow or red

operating range. T o stop the blinking, push the Exit button. Also (if so equipped), acknowledging a voice

warning using the external “V oice Alarm Control Panel” will stop the blinking of any digital display .

2.5 Bar Graph Analyzer:

The Bar Graph Analyzer has six operating modes: EGT/CHT, Normalized, Lean ROP , Lean LOP , EGT and

CHT. The CGR’ s current mode of operation is displayed in the top left portion of the Bar Graph Display. The

SELECT knob may be used to change operating modes.

2.5.1 “EGT/CHT” Operating Mode: The vertical bars are arranged to show the EGT and CHT for

each cylinder. The operating ranges for the EGT bars may be set to match your engine’ s operating

temperatures (i.e.; if your full rich low power EGT readings are around 1100’F , set your Low EGT Range

for 1000’F . If your peak EGT readings are around 1500’F , set your High EGT Range for 1525’F). The

high and low EGT ranges may be set in the “EGT/CHT Bar Graph Setup” screen (see section 6).

12

Page 17

If the EGT for a cylinder exceeds the pilot set High EGT Range,

the bar for that cylinder will turn white and blink. This feature

provides the pilot with a warning of a high EGT . The F AA does

not allow exceedance of user set EGT s to display in red or

yellow .

If the CHT for a cylinder exceeds the set limit, the bar for that

cylinder will turn red and blink.

The current Digital Display Mode of operation is designated in

the top right portion of the Engine Analyzer display . The

selections are Select, Diff, Scan and Hottest. The Digital Display

Mode controls what will be displayed in the digital section at the

bottom of the Bar Graph display .

Select Mode: The Select Mode allows the pilot to select a cylinder (displayed with a box around the

cylinder number). The EGT and CHT for the cylinder selected are shown in the bottom portion of the

display .

Diff Mode: The Diff Mode displays the difference between the hottest and coldest EGT and CHT .

The values are displayed at the bottom of the Bar Graph and are designated by EGT -D and CHT -D

If a differential limit is exceeded, the digital values will be displayed in white. The differential limits are

set in the “EGT/CHT Bar Graph Setup” screen (see section 6). The differential limits allow the CGR

to detect developing engine problems before they become expensive repair bills.

Scan Mode: The Scan Mode automatically scans through all of the cylinders. As it scans through the

cylinders, the EGT and CHT numeric values are displayed in the bottom portion of the Bar Graph

display . The scan rate can be set in the “EGT/CHT Bar Graph Setup” screen.

Hottest Mode: The Hottest Mode displays the hottest EGT and CHT in the digital display below

the bars. This is the favorite mode of operation for most pilots.

2.5.2 “Normalized” Operating Mode: The Normalized Mode of operation is an engine diagnostic tool

that allows comparison of the current EGT s and CHT s to a reference (past flight). By normalizing the EGTs

and CHT s the vertical bars are brought to the same level, creating a reference baseline.

The EGT and CHT bars may be normalized (leveled) at any time by pushing and holding the Select Knob

for four seconds and following the instruction in the pop-up window .

The offset data to level the bars is stored in CGR permanent memory . The Normalized Mode allows

changes that have occurred in the engine to be spotted easily . This makes it possible to detect trends over

several flights, days, weeks, and even years.

13

Page 18

2.5.3 “Lean-ROP” Operating Mode: This operating mode was designed to assist the pilot in leaning

the engine Rich-of-Peak EGT . As you lean, the EGT bars for all cylinders will rise. When the first cylinder

reaches peak EGT a tattletale marker will appear at the top of that cylinder’s bar . Enrichen the mixture and

the first cylinder to reach peak and the T emp Below Peak (on the rich side) will be displayed at the top right

of the bar graph display area.

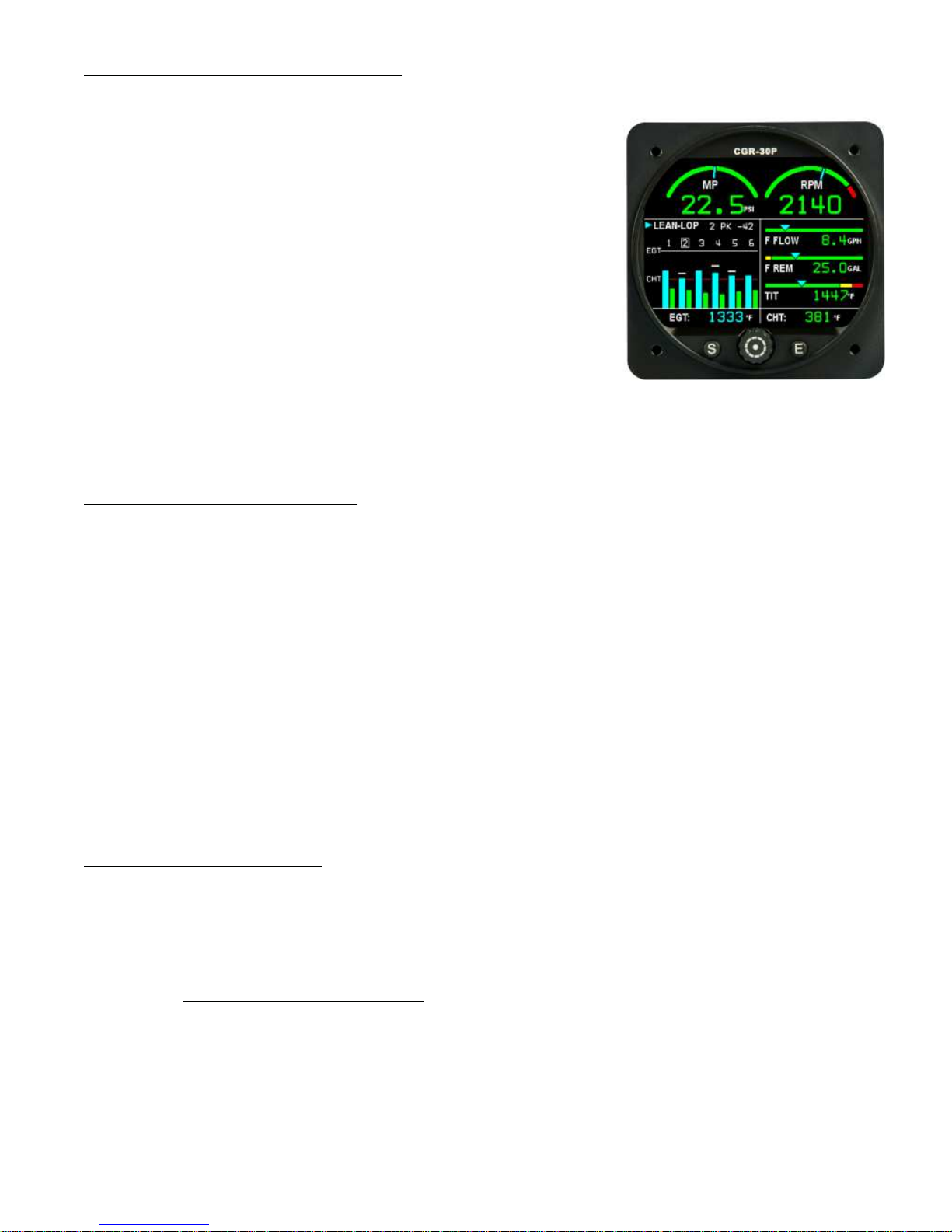

2.5.4 “Lean-LOP” Operating Mode:

Important Notice: The engine must be leaned and operated in

accordance with the POH and engine manufactures

recommendations. Information in this manual is for reference

only and does not make any recommendations.

This operating mode was designed to assist the pilot in leaning

the engine Lean-of-Peak EGT . As you lean, the EGT bars for all

cylinders will rise. When the first cylinder reaches peak EGT a

tattletale marker will appear at the top of that cylinder’s bar . As

you continue to lean, additional tattletale markers will be placed

at the top of the appropriate bar as each cylinder reaches peak

EGT . This gives a quick visual reference as to which cylinders

have reached peak EGT and at what temperature each cylinder

peaked. If a false peak is detected (an EGT dips and then starts

increasing again), the CGR will reset the tattletale marker for that cylinder and once again look for the true

peak.

The data provided in the top portion of the display will show the first cylinder to reach peak EGT and the

current temperature below peak for that cylinder.

2.5.5 “EGT” Digital Operating Mode: The EGT Digital Operating Mode provides a pictorial

representation of the engine and the EGT s for each cylinder in a digital format. The Digital Display Modes

available are: “Actual” and “Diff.”

Actual: In the Actual Mode the current EGTs for each cylinder are displayed. The data at the

bottom of the display provides the difference (or spread) between the hottest and coldest EGT and

CHT.

Diff: In this Mode, the coldest cylinder is indicated by a reading of “0.” Each of the other cylinders

will display the difference between its temperature and the temperature of the coldest cylinder. The

data at the bottom of the display provides the temperature of the hottest EGT and CHT. Differential

readings provide valuable diagnostic information.

2.5.6 “CHT” Digital Operating Mode: The CHT Digital Operating Mode provides a pictorial

representation of the engine and the CHT s for each cylinder in a digital format. The Digital Display Modes

available are: “Actual” and “Diff.”

14

Page 19

2.6 Main Screen Annunciators:

Located between the RPM and M.P. instruments on the Main Screen

are the following annunciators:

Fuel - When the estimated total fuel drops below approximately

45 minutes the “FUEL” annunciator will blink. The trigger level is based on 75% engine power and a fuel

specific of .08 gal/hr/Hp. The Low Fuel Trigger is set by Electronics International based on the aircraft data

provided.

Switch – When the “Recurring Fuel Alarm Qty” has been burned the “SWITCH” annunciator will blink.

This provides a reminder for the pilot to switch fuel tanks. The “Recurring Fuel Alarm Qty” can be set or

disabled in the “Fuel Alarm and Unit Info”screen, found in the User Setup Screens Menu (see section 6).

Secondary Screen Annunciator – If a function with a red and/or yellow limit is placed on the Secondary

Screen and the function is operating in a yellow or red range, the name of the function (in this case VOLTS)

will blink in the color of its operation. All functions monitored by the CGR-30P with yellow and/or red

range markings are either viewed or annunciated on the Main screen.

2.7 External Master Caution and Warning Lights:

A red external W arning Light and a yellow Caution Light (provided with the CGR) may be mounted in front of the

pilot, high on the aircraft instrument panel. These lights provide a heads-up visual warning. The red W arning Light

will blink any time the operating level of any monitored function reaches a red operating limit and the

yellow Caution Light will blink any time the operating level of any monitored function reaches a

yellow operating limit.

Pushing the Exit Button while viewing the Main screen will acknowledge the blinking and the blinking

will stop. Also, acknowledging a voice warning using the external “Voice Alarm Control Panel” will

stop the blinking of the Caution and W arning Lights.

Acknowledging a yellow blinking display will cause the yellow Caution Light to go out. Acknowledging a red

blinking display will cause the red W arning Light to stop blinking and go solid red. If at any time another function

reaches a red and/or yellow operating limit, the approprate Caution or W arning Light will once again blink.

R

CGR-30

Y

2.8 Voice Alarm Control Panel (OEM Only):

The Voice Alarm Control Panel is an external panel used to control the voice warnings provided by the CGR. The

CGR voice warning system is a powerful system that provides an immediate and intelligent audible warning

regardless of the pilot’s head position or focus. The instant an operating level of any function reaches a red and/or

yellow operating limit, a chime will sound in the headset and a pleasant female voice will annunciate a phrase, such

as: “Check Oil Pressure,” or “Check Fuel Pressure.”

15

Page 20

Secondary ScreenSecondary Screen

Secondary Screen

Secondary ScreenSecondary Screen

3.1 RPM and Manifold Pressure Gauges:

3.2 Three Annunciators:

3.3 Six Horizontal Strip and/or Digital Gauges:

3.4 EGT/CHT Digital Gauges:

3.03.0

3.0

3.03.0

17

Page 21

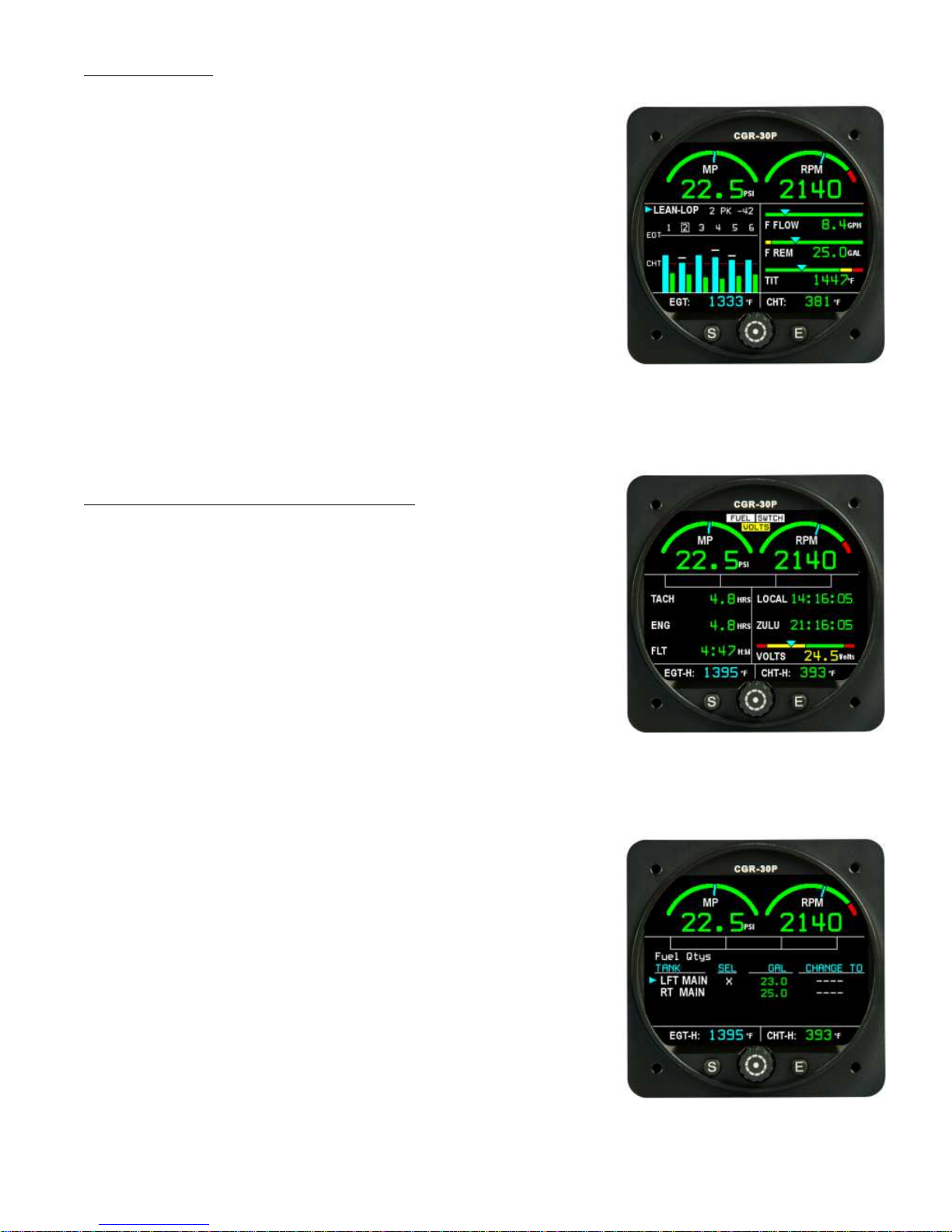

The Secondary screen is divided into the following four areas; RPM and

M.P gauges, three Annunciators, six Horizontal Strip gauges and the

EGT/CHT digital gauges.

3.1 RPM and Manifold Pressure Gauges:

The RPM and Manifold Pressure gauges are located at the top of the

Secondary screen. Each of these instruments are carried over from the

Main screen.

3.2 Three Annunciators:

The three annunciators located just below the RPM and M.P. gauges

provide a status indicator for the three horizontal strip gauges found on the Main screen. If any one (or all) of the

strip gauges on the Main screen transition into a yellow or red operating area, the appropriate annunciator on the

Secondary screen will blink the name of the function in yellow or red. To acknowledge and stop the blinking, press

the Exit button while viewing the Main screen. All functions monitored by the CGR-30P with yellow and/or red

range markings are either viewed or annunciated on the Secondary screen.

3.3 Six Horizontal Strip and/or Digital Gauges:

Six additional gauges (horizontal Strip and/or Digital) are provided on the Secondary screen. Only one of these

gauges should have yellow and/or red range markings. The function with the yellow and/or red range markings will

be annunciated on the Main screen. The CGR-30P has a number of derived functions (HP, Flight Time, Tach

Time, Local Time, Zulu Time, etc.) that can be placed on the Secondary screen.

3.4 EGT/CHT Digital Gauges:

The digital display located at the bottom of the Secondary screen provides the hottest EGT (EGT-H) and hottest

CHT (CHT-H). This displayed data is carried over from the Main screen.

18

Page 22

4.1 Fuel Quantity:

4.2 Selecting a Tank:

4.3 Adding Fuel:

4.4 K-Factor Adjustments:

FUEL QTYS ScreenFUEL QTYS Screen

FUEL QTYS Screen

FUEL QTYS ScreenFUEL QTYS Screen

4.04.0

4.0

4.04.0

20

Page 23

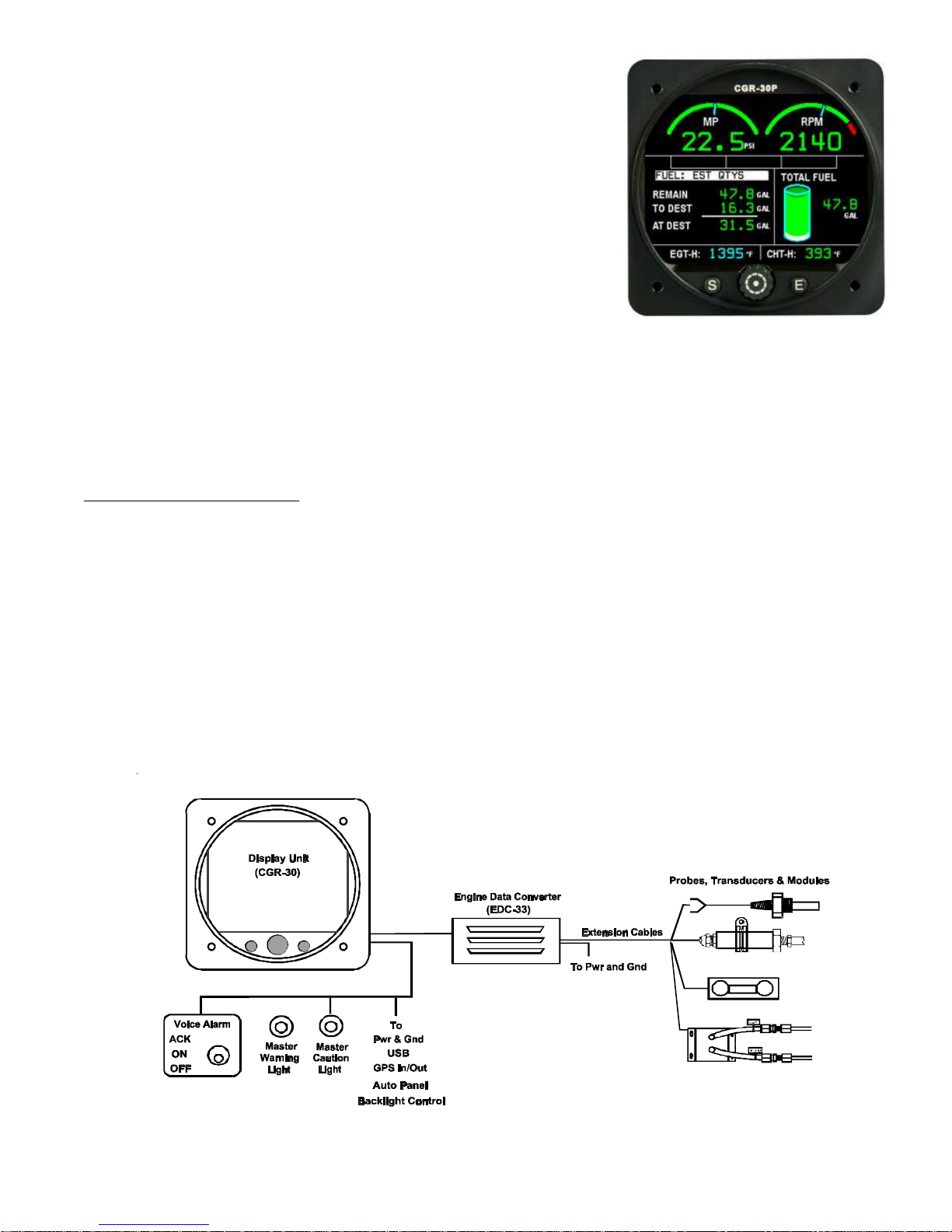

4.1 Fuel Quantity:

The Fuel Qtys screen provides the current estimated fuel level for each

fuel tank or the estimated total fuel on-board the aircraft. Estimated

individual fuel tank levels may or may not be displayed depending on the

configuration of the fuel system for the aircraft (i.e.; the CGR-30P will

only show Total Fuel on-board for an aircraft that feeds the engine from

one tank and returns the fuel to another tank or where both tanks can be

selected).

WARNING: The estimated fuel levels are only estimates and should

not be the only means of determining the fuel level in a fuel tank.

4.2 Selecting a Tank:

If the estimated fuel level for each tank is displayed, you are required to select the appropriate tank in the CGR-30P

at the same time you physically select the tank in the aircraft. In this way the CGR-30P provides an estimate of the

fuel in each tank of the aircraft. This is accomplished with the Select Knob. If only the total fuel on-board is

displayed, synchronizing the selection of tanks in the CGR-30P with the physical selection of tanks in the aircraft is

not required.

4.3 Adding Fuel:

To provide an estimate of the fuel on-board the aircraft the fuel levels shown in the CGR-30P must be updated

when fuel is added to the aircraft. A blue add fuel screen is displayed at every power-up to remind the pilot to

update the fuel levels displayed in the CGR-30P.

To add fuel, navigate to the “Change To” column in the Fuel Qty screen using the Select Knob. There are two

default fuel levels (set in the Fuel Tank Setup screen) and an add amount feature available.

22

Page 24

4.4 K-Factor Adjustments:

Fuel levels are only estimates of the fuel on-board the aircraft and are

derived from fuel flow. Accurate fuel flows depend on an accurate KFactor. If after filling the fuel tanks you find an error in the Fuel Qty

“SINCE ADD” (as shown on the “Fuel: Est Used” screen) when compared to the actual fuel used (as read off the fuel pump), you can manually or automatically adjust the K Factor. The K-Factor is a measurement of the pulses per gallon that the flow transducer outputs. Due to

variations in the installation of the flow transducer, it may be necessary to

adjust the K-Factor for the first few flights in order to get an accurate fuel

remaining, fuel used and flow reading.

The K-Factor should be changed only when the fuel tanks have been

filled accurately on level ground. After a few adjustments of the KFactor, the fuel remaining and the fuel used as calculated by the CGR30P should be within a few gallons (or less) of actual and should not need further adjustment. Navigate to the “Fuel

K-Factor” screen to change the K-Factor (see section 6.1).

23

Page 25

5.1 Total Fuel Cylinder:

5.2 Fuel: FLOW

5.3 Fuel: EST DIST

5.4 Fuel: EST QTYS

5.5 Fuel: EST TIME

5.6 Fuel: EST AT DEST

5.7 Fuel: EST USED

FUEL Data ScreenFUEL Data Screen

FUEL Data Screen

FUEL Data ScreenFUEL Data Screen

5.05.0

5.0

5.05.0

24

Page 26

The Fuel Data screens provide flight data based on fuel flow, fuel remaining, fuel used and GPS data. The screens provide the follow data:

5.1 Total Fuel Cylinder:

For all the fuel data screens the estimated Total Fuel is provided in the

right hand portion of the display. The bottom white portion of the

displayed cylinder represents the last 45 minutes of fuel on-board. The

fuel above this amount will be displayed in green.

When the estimated Total Fuel drops below approximately 45 minutes

(white area), the “FUEL” annunciator on the Main screen will blink. The

45 minute trigger level is based on 75% engine power and a fuel specific

of .08 gal/hr/Hp. This tigger is set by Electronics International based on

aircraft data provided in the worksheet.

5.2 Fuel: FLOW

This screen provides the current Fuel Flow for the engine and if the Recurring Fuel Alarm is set, the quantity or time

before the next alarm (see section 6.5)

5.3 Fuel: EST DIST

This screen provides the following Distance data:

RANGE – This is the distance the aircraft can travel based on the current fuel flow, fuel remaining and GPS

ground speed.

To DEST – This is the distance to the destination based on GPS data.

At DEST – This is the calculated distance in reserve after the aircraft reaches its destination

(Range – Distance to Destination).

5.4 Fuel: EST QTYS

This screen provides the following calculated Fuel Quantity data:

REMAIN – This is the total estimated fuel remaining on-board

the aircraft.

To DEST – This is the estimated fuel required to reach the GPS

Destination.

At DEST – This is the calculated fuel in reserve after you reach

your destination (Fuel Remain – Fuel required to reach your

Destination).

26

Page 27

5.5 Fuel: EST TIME

This screen provides the following calculated Time data:

To EMPTY – This is the estimated time to empty based on the

fuel remaining and the current fuel flow.

To DEST – This is the time required to reach your destination

based on GPS data received.

At DEST – This is the reserve time after you reach your destination (Time to Empty – Time to Destination).

5.6 Fuel: EST AT DEST

This is a display of all the estimated reserves (after you reach your destination). The CGR-30P calculates the

Distance, Time and Fuel Qty in reserve early in the flight allowing the pilot to manage fuel and make critical decisions as the flight progresses.

5.7 Fuel: EST USED

This screen provides the following calculated Fuel Used data:

Flight – This is the fuel used for the current flight. When the

flight timer starts, this field is reset to zero and fuel accumulates as

the flight progresses.

Since ADD – This is the fuel used since your last fill-up or if you

did not fill-up, since you added fuel.

Economy – This is your current economy in nautical miles per

gallon. It is calculated from the current fuel flow and GPS

ground speed. This can be very helpful in dealing with winds

aloft and leaning.

Leaning past 100 degrees rich of peak EGT reduces horsepower and therefore airspeed. It also reduces

fuel flow. The displayed Economy allows you to determine if continuing to lean produces a true fuel savings

and how much. Also, different altitudes can have different winds aloft. In this case the displayed Economy

allows you to determine if one altitude provides a fuel saving over another.

27

Page 28

User Setup ScreensUser Setup Screens

User Setup Screens

User Setup ScreensUser Setup Screens

6.1 Fuel K-Factor Screen:

6.2 Clock and Hour Meters Screen:

6.3 EGT/CHT Bar Graph Setup Screen:

6.4 USB and Data Recording Screen:

6.5 Fuel Alarm and Unit Info Screen:

6.6 System Config Screens Menu:

6.06.0

6.0

6.06.0

28

Page 29

The User Setup screens are provided to allow the pilot to adjust the KFactor, setup the Local and Zulu clocks, setup the EGT/CHT Bar

Graph, setup Data Recording, and activate the Recurring Fuel Alarm.

To display the User Setup Screens Menu, push and hold the

Select Knob for approximately 3 seconds while viewing the Main

screen. The following is a list of the User screens available:

6.1 Fuel K-Factor Screen:

Note: This screen is not accessible during engine operation.

If after filling the fuel tanks you find an error between the fuel displayed in

the “Calc-Fill” column (as shown on the screen) and the actual fuel used (as read off the fuel pump), you can

manually or automatically adjust the K-Factor. The K-Factor is a measurement of the pulses per gallon that the

flow transducer outputs. Due to variations in the installation of the flow transducer, it may be necessary to adjust the

K-Factor for the first few flights in order to get an accurate fuel remaining, fuel used and fuel flow reading.

The K-Factor should be changed only when the fuel tanks have been

filled accurately on level ground. After a few fill-ups and adjustments of

the K-Factor, the fuel remaining and the fuel used as calculated by the

CGR-30P should be within a few gallons (or less) of actual and should

not need further adjustment. Use the following fields, as necessary, to

correct the K-Factor.

Note: The Fuel K-Factor Screen is not accessible while in flight.

CALC-FILL – This column is calculated by the CGR-30P and

is the fuel used since the last fill-up and the calculated fuel necessary to fill the tank.

ACT-FILL – Enter the fuel from the fuel pump required to fill the fuel tank(s) into this field. The difference

between the CALC-FILL and the ACT-FILL is the error. Adjusting the K-Factor will correct this error.

Feed K-Factor – This field provides the current K-Factor and the percentage error between the calculated

fuel to fill the tank(s) (CALC-FILL) and the measure fuel to fill the tank(s) (ACT-FILL).

Return K-Factor - This field is used to adjust the K-Factor for a flow transducer in the fuel return line.

Normally this field will not be used.

30

Page 30

Auto Adjust K-Factor – This field activates the automatic calculation of the new K-Factor to remove the

error in the Fuel Remaining and Fuel Used. The K-Factor can be adjusted manually by using the following

formula:

(Calc’d Used Since Fill up) x (current K-Factor)

New K-Factor = —————————————————————

Actual Fuel Used (Pump Reading at Fill up)

WARNING: When you change the K-Factor, the accuracy of the CGR-30P’s estimated Fuel Remaining,

Fuel Used and Fuel Flow readings will change.

6.2 Clock and Hour Meters Screen:

This screen allows you to set today’s date, Local and Zulu time and view

the current Tach Time and Engine Hours. The date and time is used to

stamp each record in the flight logs. The Tach Time is the total time the

engine has been operated over 1300 RPM. The Eng Time is the total

time the engine has been operated. Eng Time is is used for TC work or

logging flight hours.

6.3 EGT/CHT Bar Graph Setup Screen:

The Bar Graph may be setup using the following fields:

EGT Range Low & High – The Low and High EGT Range settings determine the operating range of the

bar graph display . The goal is to set the range so the bars are

low in the display during full rich low power operation and high in

the display during lean cruise operation. It will then be possible

(at a glance) to see how rich or lean your engine is running.

Set the “High EGT Range” field for 30°F above peak EGT for

the hottest cylinder.

Set the “Low EGT Range” field for 50°F below the coldest EGT

when operating full rich low power.

When an EGT reaches a High Range limit, the bar for that

cylinder will blink in white alerting the pilot of a possible over

temp condition.

Hottest to Coldest Difference (EGT and CHT) – This field allow you to set the maximum spread

between the hottest and coldest EGT and CHT. This provides a tool to help detect engine problems early.

False warnings are annoying and can create complacency towards alarms in general. EGT and CHT

spreads will vary with engine power, mixture settings and different altitudes. To protect against false alarms

31

Page 31

while maintaining good EGT and CHT Differential Limits, fly with the CGR-30P and note the maximum

spread for both EGTs and CHTs for all stages of flight. Set the EGT and CHT “Hottest to Coldest Difference” field to 35’F above the maximum spread.

EGT/CHT Scan Rate – This field sets the rate at which the digital EGT and CHT readout (at the bottom

of the bar graph display) will scan from one cylinder to the next, when in the Scan Mode.

6.4 USB and Data Recording Screen:

Note: This screen is not accessible during engine operation.

This screen allows you to download flight data to the USB Data Stick

and set the Data Sample Rate. The Data Sample Rate is the time interval

between recorded data. The CGR-30P can record up to 1500 flights

before it records over the oldest flight first. The USB port may be found

mounted in the instrument panel or hanging under it.

Flight data is recorded and downloaded in a comma delimited format.

This allows the file to be ported directly into Excel. The file names are

formatted as follows (see Appendix A2.0 for more information):

Flt0001_20130123P.csv

Flt0001 - This is Flight Number 1.

_2013 - This is the Year.

01 - This is the Month (January)

23 - This is the Day (23rd)

P - P = Instrument was only powered-up, E = The instrument was powered-up and the

engine was running, F = The aircraft was flown (the flight timer started).

The current Flight Number is shown at the bottom of the screen. This number increments each time the CGR-30P

is powered-up.

6.5 Fuel Alarm and Unit Info Screen:

This screen provides the following features:

Recurring Fuel Alarm – A recurring fuel alarm may be set to

alert the pilot each time a set amount of fuel is consumed. For

example; if the aircraft has 40 gallons of fuel on-board and the

alarm was set for 10 gallons, when the fuel remaining dropped to

30 gallons you would get an alarm. Also, the alarm will recur at

20, 10 and 0 gallons. The word “SWITCH” between the RPM

and M.P. gauges will blink in white when the Recurring Fuel

Alarm is activated. The alarm is intended to help the pilot

manage fuel by reminding him/her to switch fuel tanks. The alarm

32

Page 32

can be used for other purposes. To turn off the alarm, press the Exit button while viewing the Main screen.

The time or fuel quantity to the next alarm is displayed on one of the Fuel Data screens (see section 5.2).

Aircraft and CGR-30P Data – The lower section of this screen provides aircraft and CGR data. The

Aircraft ID is the aircraft for which the CGR-30P was configured.

6.6 System Config Screens Menu:

The “System Config Screens Menu” provides a list of screens that are

used to configure the CGR-30P for a specific aircraft. These screens are

password protected. To display the “System Config Screens

Menu,” push and hold the Select Knob for approximately 3 seconds while viewing the Main screen. Next, select the “System

Config Screens Menu” at the bottom of the screen. Section 7

provides a list of the available screens.

If you have access but do not have the knowledge to properly change an

item, seek help. All changes must be verified that they provide proper

CGR-30P operation for your aircraft/engine.

WARNING: The System Configuration Screens allow you to

change important setup and calibration data that may affect the

way the aircraft is operated. If any data is changed in any one of the System Configuration Screens, it is

important to verify that the change is proper for your aircraft. If any changes have been made, backup

the CGR-30P configuration files to a USB Data Stick.

You must set a unique password to protect all of the calibration and setup data in the CGR-30P. If setup

or calibration data is inadvertently or improperly changed, the CGR-30P could display inaccurate readings that may lead to improper operation of the aircraft or engine. This could result in engine damage

and/or an emergency situation. Verify that the CGR-30P is working properly for the aircraft and engine

for which it is intended BEFORE the aircraft is released for normal operation.

33

Page 33

System Configuration ScreensSystem Configuration Screens

System Configuration Screens

System Configuration ScreensSystem Configuration Screens

7.1 USB Config and SW Prg Manager Screen:

7.2 Change Passwords Screen:

7.3 Aircraft ID Screen:

7.4 Hour Meters and Flight Timers Screen:

7.5 Serial Port and EDC Setup Screen:

7.6 Engine and EGT/CHT Bar Graph Setup Screen:

7.7 Fuel Tank Setup Screen:

7.07.0

7.0

7.07.0

7.8 Display and Voice Controls Screen:

7.9 CGR Input/Output Tests Screen:

7.10 Horsepower Calibration Screen:

7.11 Function Configuration Screen:

34

Page 34

7.1 USB Config and SW Prg Manager Screen:

This screen provides a method to update the software and backup and

retrieve configuration data. The data fields operate as follows:

Update The SW Program (3 Steps) - This section allows you

to update the main CGR-30P software program. Your CGR’s

current software version is listed on this screen under “Curr

Revision.” The new software program must be placed in the

“sw” directory on the USB Data Stick and must be the only file

in that directory.

Config Files (Limits, Redlines, etc.) - This section allows you

to backup configuration files to the USB Data Stick, or retrieve

configuration files from the USB Data Stick. The configuration

files contain all of the data necessary to set up the CGR-30P for

your aircraft and engine (engine type, GPS interface, all instrument and bar graph limits, fuel tank cal data, EDC mapping, screen layout, all calibration data for all probes

and transducers, etc.).

The “Retrieve ALL Backup Config Files” command reads all the stored configuration data on the USB Data

Stick. If the configuration data was NOT stored to the USB Data Stick by the same CGR-30P that is

retrieving it, the command will fail. Each CGR-30P system has the following unique calibration data:

A. Temp Comp Diode offset (this diode is located on the middle connector of the EDC).

B. PT-30ABS, Manifold Pressure offset.

C. PT-30Alt, Pressure or Cabin Altitude calibration data.

D. Horsepower calibration data.

E. Fuel Tank calibration data.

F. G-Meter

Certified Unit Field – If this field is set to “Yes” and the EGT’s are set to Primary in the “Engine & Bar

Graph Setup” screen, the EGT Low and High Ranges cannot be set by the user.

Reserved for EI use Field – This field is for E.I. support personel only.

Button Board Trk Num – This field provides Button Board software information for E.I. support

personel.

7.2 Change Passwords Screen:

The CGR-30P provides a number of screens for the pilot to use during flight, none of which require a password. It

also provides many System Configuration Screens that are used to configure the CGR-30P for a specific aircraft.

Some of the aircraft functions (fuel level, engine hours, GPS port setup, etc.) must be calibrated or setup during

installation and some are setup at the factory or by an OEM.

36

Page 35

The CGR-30P provides four levels of passwords for configuring, setting

up and calibrating the unit. During ground operation all of the System

Configuration Screens and data may be viewed without a password, but

a password is required to change data.

User Password – The User Password allows the pilot to

lockout any changes to fields in the User Setup Screens. The

password is set to “blank” when the system is setup at the

factory. This allows easy access for simple changes. To lock

these screens, set a User Password. Be sure to record this