Page 1

Color Printing Guide

RIP STATION 5000

Page 2

Page 3

Copyright © 1998 Electronics for Imaging, Inc. All rights reserved.

This publication is protected by copyright, and all rights are reserved. No part of it may be reproduced or transmitted in any form or by any means for any purpose

without express prior written consent from Electronics for Imaging, Inc., except as expressly permitted herein. Information in this document is subject to change

without notice and does not represent a commitment on the part of Electronics for Imaging, Inc.

The software described in this publication is furnished under license and may only be used or copied in accordance with the terms of such license.

Patents: 5,666,436; 5,553,200; 5,543,940; 5,537,516; 5,517,334; 5,506,946; 5,424,754; 5,343,311; 5,212,546; 4,941,038; 4,837,722; 4,500,919

Trademarks

EFI, the EFI logo, Fiery, the Fiery logo, and Rip-While-Print are trademarks registered in the U.S. Patent and Trademark Office. Fiery ZX, Fiery LX, Fiery Driven,

the Fiery Driven logo, Command WorkStation, AutoCal, Starr Compression, Memory Multiplier, ColorWise, NetWise , and VisualCal are trademarks of

Electronics for Imaging, Inc.

Adobe, the Adobe logo, Adobe Illustrator, PostScript, Adobe Photoshop, Adobe Separator, and Adobe PageMaker are trademarks of Adobe Systems Incorporated,

registered in certain jurisdictions. EPS (Encapsulated PostScript) is a trademark of Altsys Corporation. Apple, the Apple logo, AppleShare, AppleTalk, EtherTalk,

LaserWriter, and Macintosh are registered trademarks, and MultiFinder is a trademark of Apple Computer, Inc. Microsoft, MS, MS-DOS, and Windows are

registered trademarks of Microsoft in the US and other countries. QuarkXPress is a registered trademark of Quark, Inc. Times, Helvetica, and Palatino are

trademarks of Linotype AG and/or its subsidiaries. Corel is a registered trademark and CorelDRAW is a trademark of Corel Corporation in Canada, the United

States, and/or other countries. Macromedia is a registered trademark and FreeHand is a trademark of Macromedia, Inc. ITC Avant Garde, ITC Bookman, ITC

Zapf Chancery, and ITC Zapf Dingbats are registered trademarks of International Typeface Corporation. Ethernet is a registered trademark of Xerox Corporation.

Farallon, PhoneNET PC, and PhoneNET Talk are trademarks of Farallon Computing, Inc. NetWare and Novell are registered trademarks and Internetwork

Packet Exchange (IPX) is a trademark of Novell, Inc. SyQuest is a registered trademark, in the United States and certain other countries, of SyQuest Technology,

Inc. UNIX is a registered trademark of UNIX System Laboratories, a wholly owned subsidiary of Novell, Inc. PANTONE is a registered trademark of Pantone, Inc.

All other terms and product names may be trademarks or registered trademarks of their respective owners, and are hereby acknowledged.

Legal Notices

APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, REGARDING THE APPLE SOFTWARE.

APPLE DOES NOT WARRANT, GUARANTEE, OR MAKE ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE

OF THE APPLE SOFTWARE IN TERMS OF ITS CORRECTNESS, ACCURACY, RELIABILITY, CURRENTNESS, OR OTHERWISE. THE ENTIRE

RISK AS TO THE RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU. THE EXCLUSION OF IMPLIED

WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE TO YOU FOR ANY CONSEQUENTIAL,

INCIDENTAL OR INDIRECT DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF

BUSINESS INFORMATION, AND THE LIKE) ARISING OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF APPLE

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Apple’s liability to you for actual damages from any cause whatsoever, and regardless of the form of the action (whether in contract, tort [including negligence],

product liability or otherwise), will be limited to $50.

Restricted Rights Legends

For defense agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer Software clause at 252.227.7013.

For civilian agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (a) through (d) of the

commercial Computer Software Restricted Rights clause at 52.227-19 and the limitations set forth in Electronics for Imaging, Inc.’s standard commercial

agreement for this software. Unpublished rights reserved under the copyright laws of the United States.

Printed in the United States of America on recycled paper.

Part Number

: 10016208

Page 4

FCC Information

WARNING: FCC Regulations state that any unauthorized changes or modifications to this equipment not expressly approved by the manufacturer could void

the user’s authority to operate this equipment.

Class B Declaration of Conformity

Trade Name—Fiery Server (Printer Controller for Epson)

Model Number—LXFC001

Compliance Test Report Number—M71204A1

Compliance Test Report Date—December 21. 1997

Responsible Party (in USA)—Electronics for Imaging, Inc.

Address—2855 Campus Drive, San Mateo, CA 94403

Telephone—650-524-4300

This equipment has been tested and found to comply with the limits for a class B digital device, pursuant to Part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment. Operation with non-approved equipment or unshielded

cables is likely to result in interference to radio and TV reception. The user is cautioned that changes and modifications made to the equipment without the

approval of manufacturer could void the user’s authority to operate this equipment.

Industry Canada Class B Notice

This Class B digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment Regulations.

Avis de Conformation Classe B de l’Industrie Canada

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

RFI Compliance Notice

This equipment has been tested concerning compliance with the relevant RFI protection requirements both individually and on system level (to simulate normal

operation conditions). However, it is possible that these RFI Requirements are not met under certain unfavorable conditions in other installations. It is the user

who is responsible for compliance of his particular installation.

Dieses Geraet wurde einzeln sowohl als auch in einer Anlage, die einen normalen Anwendungsfall nachbildet, auf die Einhaltung der Funk-entstoerbestimmungen

geprueft. Es ist jedoch moeglich, dass die Funk-enstoerbestimmungen unter unguenstigen Umstaenden bei anderen Geraetekombinationen nicht eingehalten

werden. Fuer die Einhaltung der Funk-entstoerbestimmungen seigner gesamten Anlage, in der dieses Geraet betrieben wird, ist der Betreiber verantwortlich.

Compliance with applicable regulations depends on the use of shielded cables. It is the user who is responsible for procuring the appropriate cables.

Einhaltung mit betreffenden Bestimmungen kommt darauf an, dass geschirmte Ausfuhrungen gebraucht werden. Fuer die beschaffung richtiger Ausfuhrungen

ist der Betreiber verantwortlich.

Page 5

Software License Agreement

Electronics for Imaging, Inc. grants to you a non-exclusive, non-transferable license to use the software and accompanying documentation (“Software”) included

with the RIP Station 5000 you have purchased, including without limitation the PostScript® software provided by Adobe Systems Incorporated.

You may:

a. use the Software solely for your own customary business purposes and solely with RIP Station 5000;

b. use the digitally-encoded machine-readable outline and bitmap programs (“Font Programs”) provided with RIP Station 5000 in a special encrypted format

(“Coded Font Programs”) to reproduce and display designs, styles, weights, and versions of letters, numerals, characters and symbols (“Typefaces”) solely for your

own customary business purposes on the display window of RIP Station 5000 or monitor used with RIP Station 5000;

c. use the trademarks used by Electronics for Imaging to identify the Coded Font Programs and Typefaces reproduced therefrom (“Trademarks”); and

d. assign your rights under this Agreement to a transferee of all of your right, title and interest in and to RIP Station 5000 provided the transferee agrees to be

bound by all of the terms and conditions of this Agreement.

You may not:

a. make use of the Software, directly or indirectly, to print bitmap images with print resolutions of 720 dots per inch or greater, or to generate fonts or typefaces

for use other than with RIP Station 5000;

b. make or have made, or permit to be made, any copies of the Software, Coded Font Programs, accompanying documentation or portions thereof, except as

necessary for use with the RIP Station 5000 unit purchased by you; provided, however, that under no circumstances may you make or have made, or permit to

be made, any copies of that certain portion of the Software which has been included on the RIP Station 5000 hard disk drive. You may not copy the

documentation;

c. attempt to alter, disassemble, decrypt or reverse engineer the Software, Coded Font Programs or accompanying documentation.

d. rent or lease the Software.

Proprietary Rights

You acknowledge that the Software, Coded Font Programs, Typefaces, Trademarks and accompanying documentation are proprietary to Electronics for Imaging

and its suppliers and that title and other intellectual property rights therein remain with Electronics for Imaging and its suppliers. Except as stated above, this

Agreement does not grant you any right to patents, copyrights, trade secrets, trademarks (whether registered or unregistered), or any other rights, franchises or

licenses in respect of the Software, Coded Font Programs, Typefaces, Trademarks or accompanying documentation. You may not adapt or use any trademark or

trade name which is likely to be similar to or confusing with that of Electronics for Imaging or any of its suppliers or take any other action which impairs or reduces

the trademark rights of Electronics for Imaging or its suppliers. The trademarks may only be used to identify printed output produced by the Coded Font

Programs. At the reasonable request of Electronics for Imaging, you must supply samples of any Typeface identified with a trademark.

Confidentiality

You agree to hold the Software and Coded Font Programs in confidence, disclosing the Software and Coded Font Programs only to authorized users having a need

to use the Software and Coded Font Programs as permitted by this Agreement and to take all reasonable precautions to prevent disclosure to other parties.

Remedies

Unauthorized use, copying or disclosure of the Software, Coded Font Programs, Typefaces, Trademarks or accompanying documentation will result in automatic

termination of this license and will make available to Electronics for Imaging other legal remedies.

Limited Warranty And Disclaimer

Electronics for Imaging warrants that, for a period of ninety (90) days from the date of delivery to you, the Software under normal use will perform without

significant errors that make it unusable. Electronics for Imaging’s entire liability and your exclusive remedy under this warranty (which is subject to you returning

RIP Station 5000 to Electronics for Imaging or an authorized dealer) will be, at Electronics for Imaging’s option, to use reasonable commercial efforts to attempt

to correct or work around errors, to replace the Software with functionally equivalent software, or to refund the purchase price and terminate this Agreement.

Some states do not allow limitations on duration of implied warranty, so the above limitation may not apply to you.

Except for the above express limited warranty, Electronics for Imaging makes and you receive no warranties or conditions on the Products, express, implied, or

statutory, and Electronics for Imaging specifically disclaims any implied warranty or condition of merchantability or fitness for a particular purpose.

For warranty service, please contact your authorized service/support center.

Page 6

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, ELECTRONICS FOR IMAGING MAKES AND YOU RECEIVE NO WARRANTIES

OR CONDITIONS ON THE SOFTWARE OR CODED FONT PROGRAMS, EXPRESS, IMPLIED, STATUTORY, OR IN ANY OTHER PROVISION

OF THIS AGREEMENT OR COMMUNICATION WITH YOU, AND ELECTRONICS FOR IMAGING SPECIFICALLY DISCLAIMS ANY IMPLIED

WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Electronics for Imaging does not warrant that

the operation of the software will be uninterrupted or error free or that the Software will meet your specific requirements.

Limitation Of Liability

IN NO EVENT WILL ELECTRONICS FOR IMAGING OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES, INCLUDING LOSS OF DATA, LOST

PROFITS, COST OF COVER OR OTHER SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES ARISING FROM THE USE OF

THE SOFTWARE, CODED FONT PROGRAMS OR ACCOMPANYING DOCUMENTATION, HOWEVER CAUSED AND ON ANY THEORY OF

LIABILITY. THIS LIMITATION WILL APPLY EVEN IF ELECTRONICS FOR IMAGING OR ANY AUTHORIZED DEALER HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGE. YOU ACKNOWLEDGE THAT THE PRICE OF THE UNIT REFLECTS THIS ALLOCATION OF RISK.

BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

Export Controls

You agree that you will not export or re-export the Software or Coded Font Programs in any form without the appropriate United States and foreign government

licenses. Your failure to comply with this provision is a material breach of this Agreement.

Government Use

Use, duplication or disclosure of the Software by the United States Government is subject to restrictions as set forth in subdivision (c) (1) (ii) of the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013 or in subparagraphs (c) (1) and (2) of the Commercial Computer Software—Restricted

Right Clause at 48 CFR 52.227-19, as applicable.

Third Party Beneficiary

You are hereby notified that Adobe Systems Incorporated, a California corporation located at 345 Park Ave., San Jose, CA 95110 (“Adobe”) is a third-party

beneficiary to this Agreement to the extent that this Agreement contains provisions which relate to your use of the Fonts, the Coded Font Programs, the Typefaces

and the Trademarks licensed hereby. Such provisions are made expressly for the benefit of Adobe and are enforceable by Adobe in addition to Electronics for

Imaging.

General

This Agreement will be governed by the laws of the State of California.

This Agreement is the entire agreement held between us and supersedes any other communications or advertising with respect to the Software, Coded Font

Programs and accompanying documentation.

If any provision of this Agreement is held invalid, the remainder of this Agreement shall continue in full force and effect.

If you have any questions concerning this Agreement, please write to Electronics for Imaging, Inc., Attn: Licensing Dept. or see Electronics for Imaging’s web site

at www.efi.com.

Electronics for Imaging, Inc.

2855 Campus Drive

San Mateo, CA 94403

Page 7

Contents

Introduction

About this manual

Tips for success

Chapter 1: Desktop Color Primer

The properties of color

The physics of color 1-1

CIE color model 1-2

Additive and subtractive color systems 1-3

Printing techniques

Halftone and continuous tone devices 1-5

Using color effectively

A few rules of thumb 1-6

Color wheel 1-7

Color and text 1-8

Registration and trapping 1-8

Raster images and vector images

Optimizing files for processing and printing

Resolution of raster images 1-10

Scaling 1-12

xi

xii

1-1

1-4

1-6

1-9

1-10

Workflow scenarios

Short-run color printing 1-12

Offset printing 1-13

1-12

Page 8

viii Contents

Chapter 2: Color Management

Controlling printed color

Maintaining print device consistency 2-2

Print device gamut 2-2

Basics of color management

Color conversion 2-4

RIP Station color management

RGB Source 2-7

Rendering styles 2-8

Pure Black Text/Graphics 2-9

CMYK Simulation 2-9

Optional ICC color management for advanced users

Color management on Macintosh computers 2-10

Color management on Windows computers 2-12

Chapter 3: Working with Color in Applications

Working with color

Color reference pages 3-2

Office applications

Choosing colors in office applications 3-3

2-1

2-3

2-5

2-10

3-1

3-2

PostScript applications

Choosing colors in PostScript applications 3-4

CMYK simulation 3-6

Chapter 4: Printer Drivers and Print Options

What a printer driver does

Adobe PostScript Printer Driver for Macintosh

Setting color management print options 4-2

Adobe PostScript Printer Driver for Windows 95

Setting color management print options 4-5

3-4

4-1

4-2

4-5

Page 9

ix Contents

Adobe PostScript Printer Driver for Windows 3.1x

Setting color management print options 4-7

Microsoft PostScript Printer Driver for Windows NT 4.0

Chapter 5: Adobe Photoshop 4.0

Before you begin

With Windows versions of Photoshop 5-1

With Photoshop 2.5 for Macintosh 5-2

Defining colors

Saving files for importing into other documents

Selecting options when printing

Printing RGB images 5-4

Printing CMYK images 5-5

Chapter 6: Page Layout Applications

Working with page layout applications

Defining colors 6-1

Importing images 6-1

CMYK simulation 6-2

4-7

4-8

5-1

5-2

5-2

5-3

6-1

Adobe PageMaker 6.5 for Macintosh and Windows

Importing images 6-3

Selecting options when printing 6-4

QuarkXPress 3.32 for Macintosh and Windows

Importing images 6-8

Selecting options when printing 6-8

Chapter 7: Illustration Applications

Working with illustration applications

Defining colors 7-1

Importing images 7-2

CMYK simulation 7-3

6-3

6-8

7-1

Page 10

x Contents

Adobe Illustrator 7.0 for Macintosh and Windows

Defining colors 7-3

Importing images 7-5

Selecting options when printing 7-5

Saving files for importing into other documents 7-6

For advanced users: Using Illustrator color management 7-7

Macromedia FreeHand 7.0 for Macintosh and Windows

Defining colors 7-8

Importing images 7-8

Selecting options when printing 7-9

Saving files for importing into other documents 7-10

For advanced users: Using FreeHand color management 7-11

CorelDRAW 7.0 for Windows

Defining colors 7-12

Importing images 7-12

Selecting options when printing 7-13

Saving files for importing into other documents 7-14

For advanced users: Using CorelDRAW color management 7-14

Chapter 8: Office Applications

7-3

7-8

7-12

Working with office applications

Defining colors 8-1

Working with imported files 8-1

Selecting options when printing 8-2

Microsoft Office 97

8-1

8-2

Glossary

Bibliography

Index

Page 11

xi About this manual

Introduction

Welcome to the

issues associated with printing to a RIP Station 5000 print device. It also contains

application notes that explain how to print to the RIP Station from popular Macintosh

and Windows applications.

This manual is one book in a set of documentation that also includes manuals for users

and system administrators. All the other manuals should be available at your site—

refer to them for a complete description of your documentation.

Color Printing Guide

. This manual introduces you to the concepts and

About this manual

This manual is written for anyone who prints to a RIP Station using popular Macintosh and Windows applications. It goes beyond the mechanics of sending a print job

and explains issues that affect the quality of the results, such as:

• Use of color in the document

• Resolution and file formats used for imported images

• Features of ColorWise™ color management performed by the RIP Station

• Effects of print option settings on printed color

Because each application has different options that affect color printing, detailed application notes are included.

Words in bold (for example,

Glossary. The Bibliography at the end of this manual provides sources for further

investigation of color printing issues.

additive color model

), are terms that appear in the

The phrase “RIP Station color management” refers to the ColorWise color

management system built into the RIP Station Color Server.

Page 12

xii Introduction

Tips for success

The built-in ColorWise color management system of the RIP Station ensures that

every color job you print looks good. Regardless of the computer you work on, the

application you use, and the type of color work you do, your RIP Station print device

provides high-quality color output without any special effort on your part.

You can also customize the RIP Station color management system for particular types

of projects or environments. The RIP Station provides total flexibility, allowing you to

specify color settings on a job-by-job basis.

The following list summarizes the issues you should consider when you create and

print a color document.

1. Maintain print device consistency.

(Chapter 2)

2. Use the Color Reference pages when choosing and defining RGB, CMYK, and PANTONE™

colors in applications.

(Chapter 3)

3. Save raster images at the optimal resolution for your print device.

(Chapter 1)

4. Choose the appropriate settings for these print options (described in Chapter 2):

•

RGB Source

(and, for a custom RGB source space, Gamma, Phosphors, and White

Point)—affects the output of all RGB data in your document (see page 2-7)

Rendering Style

•

—determines the type of color effect produced; for example, vibrant

colors (such as for presentations) or accurate-match colors (such as for spot colors in

logos)

Brightness

•

Pure Black Text/Graphics

•

—increases or decreases the brightness of all colors in the document

—determines whether black text and line art in your

document are printed as one-color black or four-color black; can eliminate

misregistration and blasting problems; minimizes the cost of printing mostly black

documents

•

CMYK Simulation

—lets you use your RIP Station print device as a proofing device

for offset press jobs

Page 13

1-1 The properties of color

1

Chapter 1: Desktop Color Primer

This chapter covers concepts that are basic to printing in color, including:

• The properties of color

• Printing techniques

• Using color effectively

• Raster images and vector images

• Optimizing files for processing and printing

• Workflow scenarios

If you are already familiar with color theory and digital color printing, you can skip to

the last section (page 1-10) for tips on optimizing your files for printing.

The properties of color

What we call “color” is really a perceptual ability unique to humans and a small

number of animal species. Color theory is an attempt to systematize the properties of

color perception, which by nature is relative and changeable. A color appears different

depending on the other colors around it, and individuals vary in their abilities to

perceive color.

This section introduces concepts that are basic to color theory. You will encounter

some of these concepts (such as hue, saturation, and brightness) when you work with

color in applications; others provide useful background information. Color is a

complex topic, so consider this a starting point for experimentation and further

research.

The physics of color

The human eye can see electromagnetic radiation at wavelengths between 400

nanometers (purplish blue) and 700 nanometers (red). This range is called the visible

spectrum of light. We see pure

Sunlight at midday, which we perceive as white or neutral light, is composed of light

from across the visible spectrum in more or less equal proportions. Shining sunlight

spectral light

as intensely saturated or pure colors.

Page 14

1-2 Desktop Color Primer

1

through a prism separates it into its spectral components, resulting in the familiar

rainbow of colors (plate 1).

Like the sun, most light sources we encounter in our daily environment emit a mixture

of many light wavelengths, although the particular distribution of wavelengths can

vary considerably. Light from a tungsten light bulb, for example, contains much less

blue light than sunlight. Tungsten light appears white to the human eye which, up to a

point, can adjust to the different light sources. However, color objects appear different

under tungsten light than they do under sunlight because of the different spectral

makeup of the two light sources.

The mixture of light wavelengths emitted by a light source is reflected selectively by

different objects. Different mixtures of reflected light appear as different colors. Some

of these mixtures appear as relatively saturated colors, but most appear to us as grays or

impure hues of a color.

CIE color model

In the 1930s, the Commission Internationale de l’Eclairage (CIE) defined a standard

color space

communication of color information. This color space is based on research on the

nature of color perception. The CIE chromaticity diagram (plate 2) is a twodimensional model of color vision. The arc around the top of the horseshoe

encompasses the pure, or spectral, colors from blue-violet to red. Although the CIE

chromaticity diagram is not perceptually uniform—some areas of the diagram seem to

compress color differences relative to others—it is a good tool for illustrating some

interesting aspects of color vision.

, a way of defining colors in mathematical terms, to help in the

By mixing any two spectral colors in different proportions, we can create all the colors

found on the straight line drawn between them in the diagram. It is possible to create

the same gray by mixing blue-green and red light or by mixing yellow-green and blueviolet light. This is possible because of a phenomenon peculiar to color vision called

metamerism

different combinations of spectral light can produce the same perceived color.

Purple colors, which do not exist in the spectrum of pure light, are found at the

bottom of the diagram. Purples are mixtures of red and blue light—the opposite ends

of the spectrum.

. The eye does not distinguish individual wavelengths of light. Therefore,

Page 15

1-3 The properties of color

1

Hue, saturation, and brightness

A color can be described in terms of three varying characteristics:

• Hue, or tint (the qualitative aspect of a color—red, green, or orange)

• Saturation, or the purity of the color

• Brightness, or relative position between white and black.

While the CIE chromaticity diagram (plate 2) conveys hue and saturation, a threedimensional color model is required to add the brightness component (plate 3).

Many computer applications include dialog boxes in which you choose colors by

manipulating hue, saturation, and brightness. For example, Photoshop uses a square

Color Picker (plate 4) which can be reconfigured according to your preference.

Additive and subtractive color systems

Color devices used in desktop publishing and printing

colors using a set of primary colors that are combined to create other colors. There are

two methods of creating a range of colors from a set of primary colors. Computer

monitors and scanners use the additive color model. Printing technologies, including

RIP Station print devices and offset presses, use the

simulate

subtractive color model

the range of visible

.

Additive (RGB) color

Color devices that use the additive color model make a range of colors by combining

varying amounts of red, green, and blue light. These colors are called the

primaries

and blue light available. Black occurs wherever all three colors are absent. Grays are

created by adding varying amounts of all three colors together. Combining varying

amounts of any two of the additive primaries creates a third, saturated hue.

A familiar device that uses this color model is the computer monitor (plate 6).

Monitors have red, green, and blue

display a given color. Scanners create digital representations of colors by measuring

their red, green, and blue components through colored filters.

(plate 5). White is created by adding the maximum amount of red, green,

phosphors

that emit varying amounts of light to

additive

Page 16

1-4 Desktop Color Primer

1

Subtractive (CMY and CMYK) color

The subtractive color model is used in color printing, and in color photographic prints

and transparencies. While the additive color model simulates the visible spectrum of

color by adding light of three primary hues, the subtractive color model uses a “white”

or neutral light source containing light of many wavelengths. Inks, toners, or other

colorants

otherwise would be reflected or transmitted by the media in question.

The

blue light, respectively (plate 7). Combining any two subtractive primaries creates a

new color that is relatively pure or saturated. For example, you can make red by

combining magenta and yellow, which absorb green and blue light, respectively. White

occurs when no colorant is applied. Combining all three subtractive primaries in

theory yields black, but due to deficiencies of cyan, magenta, and yellow colorants,

combining these three primaries actually yields a muddy brown. Black colorant is

added to compensate for the deficiencies of cyan, magenta, and yellow colorants, and

consequently color printing uses four process colors: Cyan, Magenta, Yellow, and

blacK (CMYK). The use of black ink helps in producing rich solid blacks and also

allows for improved rendition of black text.

are used to selectively absorb (subtract) certain wavelengths of light that

subtractive primaries

are cyan, magenta, and yellow; they absorb red, green, and

The CMYK colorants used in offset printing and by your RIP Station print device are

to some degree transparent. When one layer of colorant is applied on top of another,

you see the effect of both. To create a range of intermediary colors, a method is

required for varying the amount of each colorant that is applied. A technique called

halftoning is used in offset printing, while color print devices typically use a

proprietary system for applying ink or toner colors that is similar to halftoning.

Printing techniques

Until recently, most color printing was done on printing presses using one of several

printing techniques—offset lithography, flexography, and gravure, to name a few.

All traditional printing techniques require lengthy preparation before a print run can

take place. Short-run color printing, including RIP Station printing, eliminates most

of this preparation. By streamlining the process of color printing, the RIP Station

makes short print runs economically feasible.

Page 17

1-5 Printing techniques

1

In contemporary offset lithographic printing, digital files from desktop computers are

output to an imagesetter, which creates film separations. The film is used to make a

prepress proof, which is an accurate predictor of the final print job, allowing an

opportunity to make corrections before going to press. Once the proof is approved, the

printer makes plates from the film and runs the print job on the press.

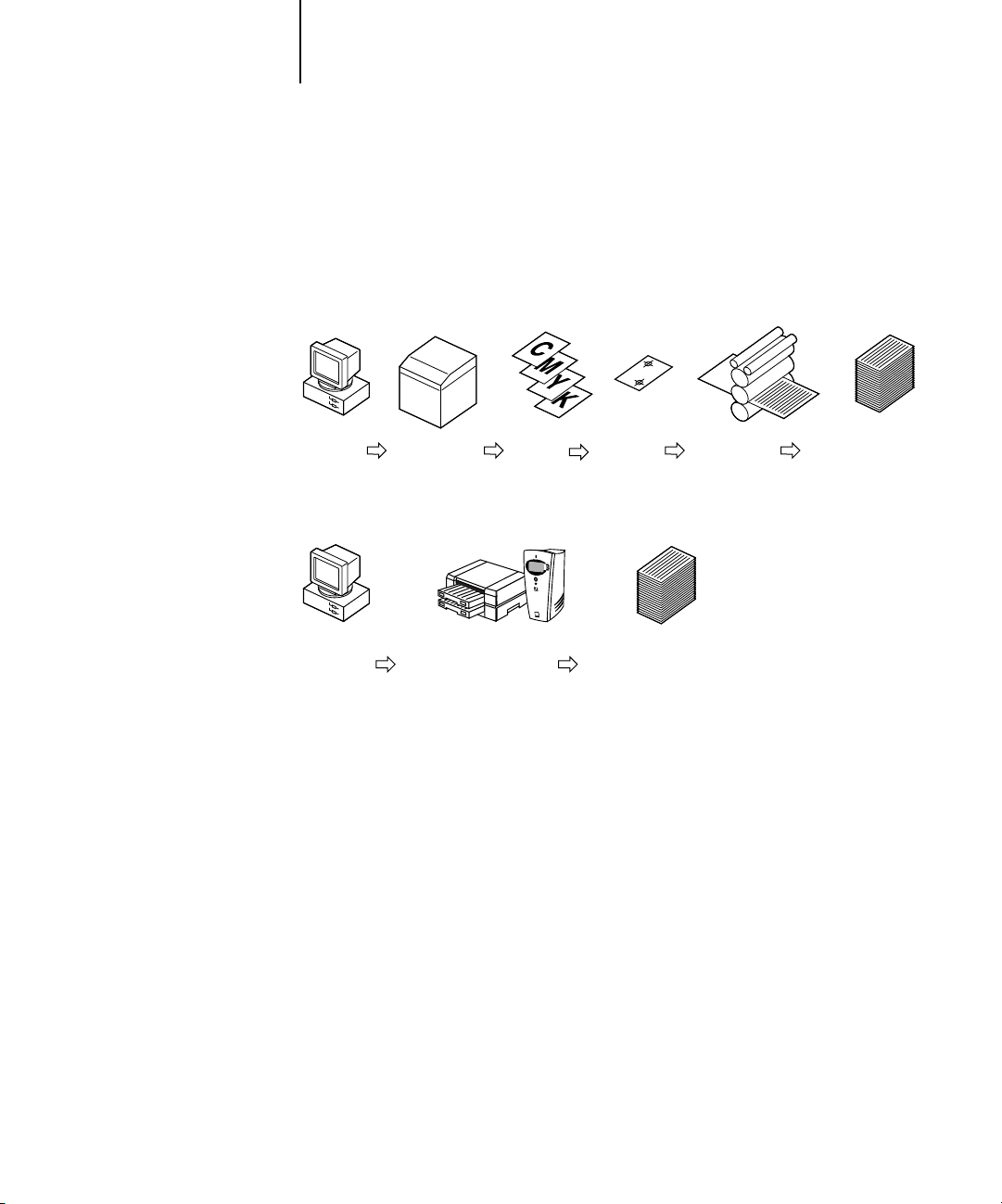

computer

Desktop

computer

With a RIP Station, you simply print the file. The RIP Station processes the PostScript information in the file and sends bitmaps to the print engine. The ease of

RIP Station printing makes possible experimentation that would be too costly on

press, allowing unlimited fine-tuning of color and design elements.

Imagesetter Film Proof PressDesktop Print run

E

P

S

O

N

Print device Color prints

Halftone and continuous tone devices

Halftoning is used in offset printing to print each process color at a different intensity,

allowing millions of different colors to be reproduced using only the four process

colors. Depending on the required intensity of a given color, ink is placed on paper in

dots of different size. The grid of dots used for each ink color is called a screen.

Halftone screens are aligned to unique angles designed to eliminate interference

patterns called moiré that can arise with halftoning.

Page 18

1-6 Desktop Color Primer

1

Some color print devices are commonly referred to as continuous tone (or “contone”)

devices. They do not use traditional halftone screen patterns and angles. However, they

do apply dots (in some cases very elongated dots or lines) of different sizes to paper in a

process similar to halftoning.

Even if your color printing is done exclusively on the RIP Station, you will encounter

concepts from offset printing if you use high-end graphics applications. For example,

color controls in illustration applications such as Illustrator are geared toward

specifying color for offset printing using process and spot colors. Many applications

allow you to specify the screening used for each printing plate.

Using color effectively

The ability to print in color can greatly increase the effectiveness of your message,

whether you are printing a presentation or a newsletter, or proofing an ad concept that

will later be printed on press. Some potential benefits of using color include:

• Conveying information rapidly by using color cues

• Making use of the emotive aspects of different colors

• Increasing impact and message retention

Color can also be a source of distraction and discord if it is used poorly. This section

outlines some tips and concepts that will prove useful as you approach designing color

materials.

A few rules of thumb

Try some of the following strategies for creating successful color materials:

• Rather than applying colors indiscriminately, use color to aid comprehension. In

presentations, graphs, and charts, use color to highlight patterns and emphasize

differences.

• In general, fewer colors work better than many colors.

• Use red as an accent color. Red is particularly effective when used in otherwise

monochromatic materials.

• Consider the tastes of your target audience when choosing colors.

• Keep a file of printed color pieces that appeal to you or strike you as effective. Refer

to it for ideas when designing your own documents.

Page 19

1-7 Using color effectively

1

Color wheel

A color wheel (plate 8) is a helpful tool for understanding the interrelation of colors.

The colors on one side of the color wheel, from magenta to yellow, appear to most

people to be warm colors, while those on the other side, from green to blue, appear to

be cool. The distance between two colors on the color wheel can help predict how they

will appear when seen side by side.

Colors opposite one another on the wheel are called complements (plate 9), and create

a striking contrast side by side. This can be the basis for a bold graphical design, but it

is an effect you should use with discretion since it can be visually fatiguing. Other bold

combinations to consider are split complements (a color and the two colors adjacent to

its complement) and triads (three colors evenly spaced on the color wheel). Colors

adjacent to one another on the color wheel result in subtle harmonies.

The color wheel simplifies color relationships for the purpose of clarity, showing only

saturated or pure colors. Adding the myriad variations of each hue to the palette (more

or less saturated, darker or lighter) creates a wealth of possibilities. Taking a pair of

complements from the color wheel and varying the saturation and brightness of one or

both colors produces a very different result from the pure complements. Combining a

light tint of a warm color with a darker shade of its cooler complement often gives

pleasing results. Combining a darker shade of a warm color with a light tint of its

cooler complement produces an unusual effect you may like.

Once you have mastered the concept of the color wheel, you have a good framework

for experimenting with color combinations. Many books targeted at graphic designers

show groups of preselected color combinations. Some are organized by themes or

moods, and some are based on a custom color system such as PANTONE. The more

you develop a critical facility for judging color combinations, the more you will be able

to trust your own eye for color. The Bibliography at the back of this manual includes

books on design.

Page 20

1-8 Desktop Color Primer

1

Color and text

It is not a coincidence that the overwhelming majority of text you see is printed in

black on white paper. Text in black on white is highly legible and is not fatiguing to

read for extended periods. For many color materials, using black text on a white

background and confining color to graphic elements and headings is a good choice.

Color text can add flair to documents printed on paper when used skillfully, and is

widely used in presentations. When using color text, avoid dazzling text and

background combinations created from primary complements, especially red and cyan

or red and blue; they are visually fatiguing and hard to read. Color text is more legible

when distinguished from its background by a difference in lightness—for example,

dark blue text on a light beige background. In addition, using many different colors in

a string of text makes for a confused appearance and is hard to read. However, using a

single highlight color is an effective way to draw the reader’s eye to selected words. See

plate 10 for color text samples.

When using color text, keep in mind that small font sizes typically do not print in

color with the same sharpness as in black. In most applications, black text prints

exclusively in black ink, while color text usually prints with two or more inks. Any

misregistration between the different inks on paper causes color text to lose definition.

You can make test prints to find the smallest point size at which color text prints

clearly. When using high-end graphics applications that allow you to specify color as

percentages of cyan, magenta, yellow, and black, you can create pure cyan or pure

magenta text that prints with the same sharpness as black text. (Pure yellow text is

extremely hard to read on anything but a dark or complementary background.)

Registration and trapping

With any print device, there is the possibility that the different inks may print slightly

out of register, producing distracting gaps between objects. Trapping is the process of

spreading one color slightly into adjacent colors to compensate for any misregistration

that might occur when the file is printed. Depending on the job’s makeup, you may

need to take trapping into consideration for best printed results. See the Bibliography

for sources of information on trapping.

Page 21

1-9 Raster images and vector images

1

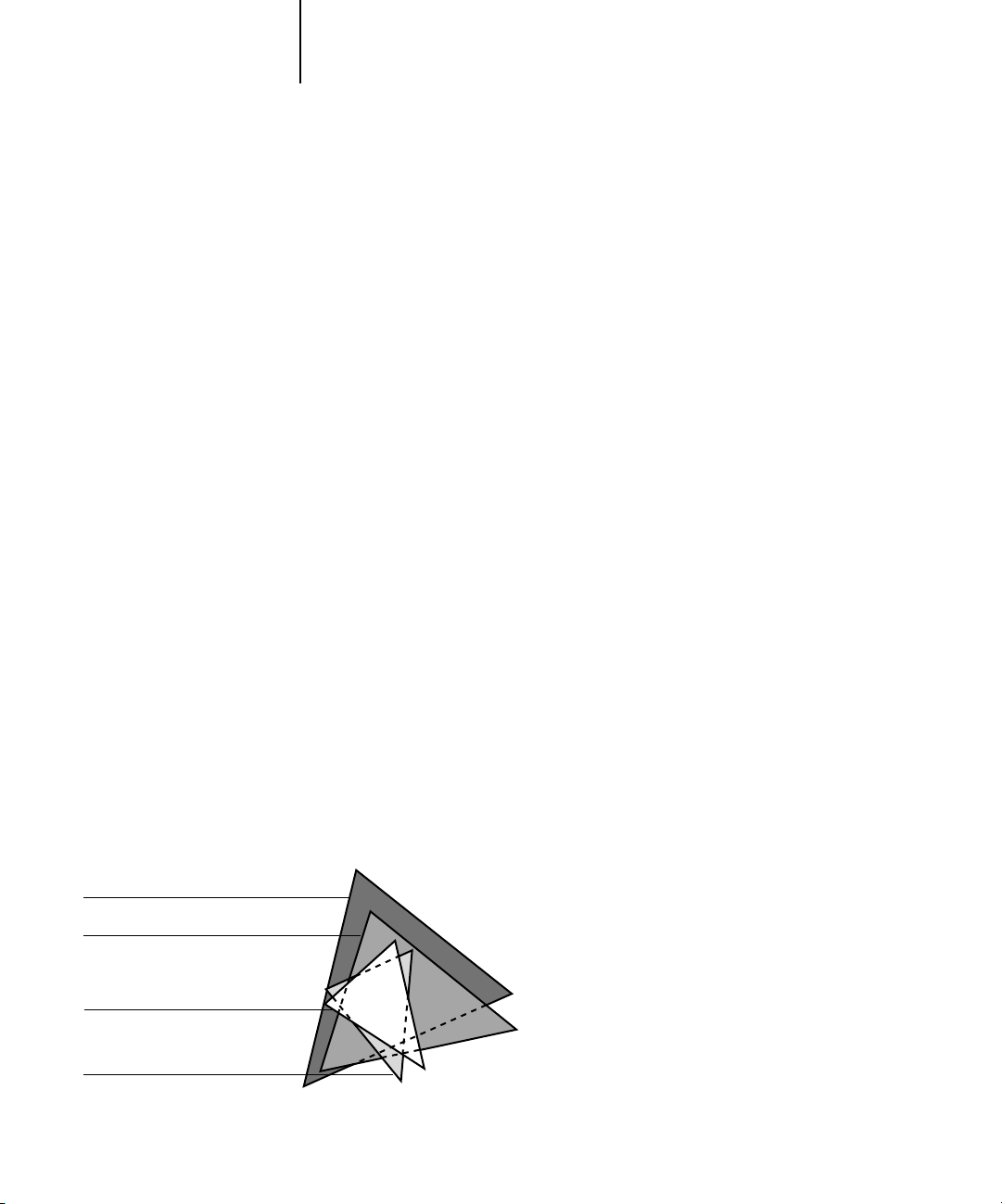

Raster images and vector images

Two broad categories of artwork can be printed from a personal computer to a color

printer: raster and vector images (plate 11).

A raster image, also referred to as a bitmap, is composed of a grid of pixels, each

assigned a particular color value. The grid, when sufficiently enlarged, resembles a

mosaic made from square tiles. Examples of raster images include scans and images

created in painting or pixel-editing applications, such as Photoshop and Painter.

The amount of information found in a raster depends on its resolution and bit depth.

The resolution of a raster describes the density of the pixels and is specified in pixels

per inch (ppi). The bit depth is the number of bits of information assigned to each

pixel. Black and white rasters require only one bit of information per pixel. For

photographic quality color, 24 bits of RGB color information are required per pixel,

yielding 256 separate levels of red, green, and blue. For CMYK images, 32 bits per

pixel are required.

When printing raster artwork, the quality of the output depends on the resolution of

the raster. If the raster’s resolution is too low, individual pixels become visible in the

printed output as small squares. This effect is sometimes called “pixelation.”

In vector images, picture elements are defined mathematically as lines or curves

between points—hence the term “vector.” Picture elements can have solid, gradient,

or patterned color fills. Vector artwork is created in illustration and drawing

applications such as Illustrator and CorelDRAW. Page layout applications such as

QuarkXPress also allow you to create simple vector artwork with their drawing tools.

PostScript fonts are vector-based as well.

Vector artwork is resolution-independent; it can be scaled to any size without danger of

pixels becoming visible in printed output.

Page 22

1-10 Desktop Color Primer

1

Optimizing files for processing and printing

The following sections provide tips on how to create image files that produce the

highest possible print quality while minimizing the processing time and disk space they

require.

Resolution of raster images

While a 72 ppi raster image appears sharp on a monitor, the same image would likely

appear pixelated when printed to the RIP Station. Color print devices are capable of

much greater detail than monitors, and require correspondingly higher resolution

image files. However, high-resolution files can be large, and therefore cumbersome to

transmit over a network, process for printing, store on disk, and edit.

Beyond a certain threshold, a higher image resolution greatly increases file size while

having a minimal effect on output quality. The optimal image resolution depends on

the resolution of the final print device. Aim for the resolution that optimizes both file

size and output quality.

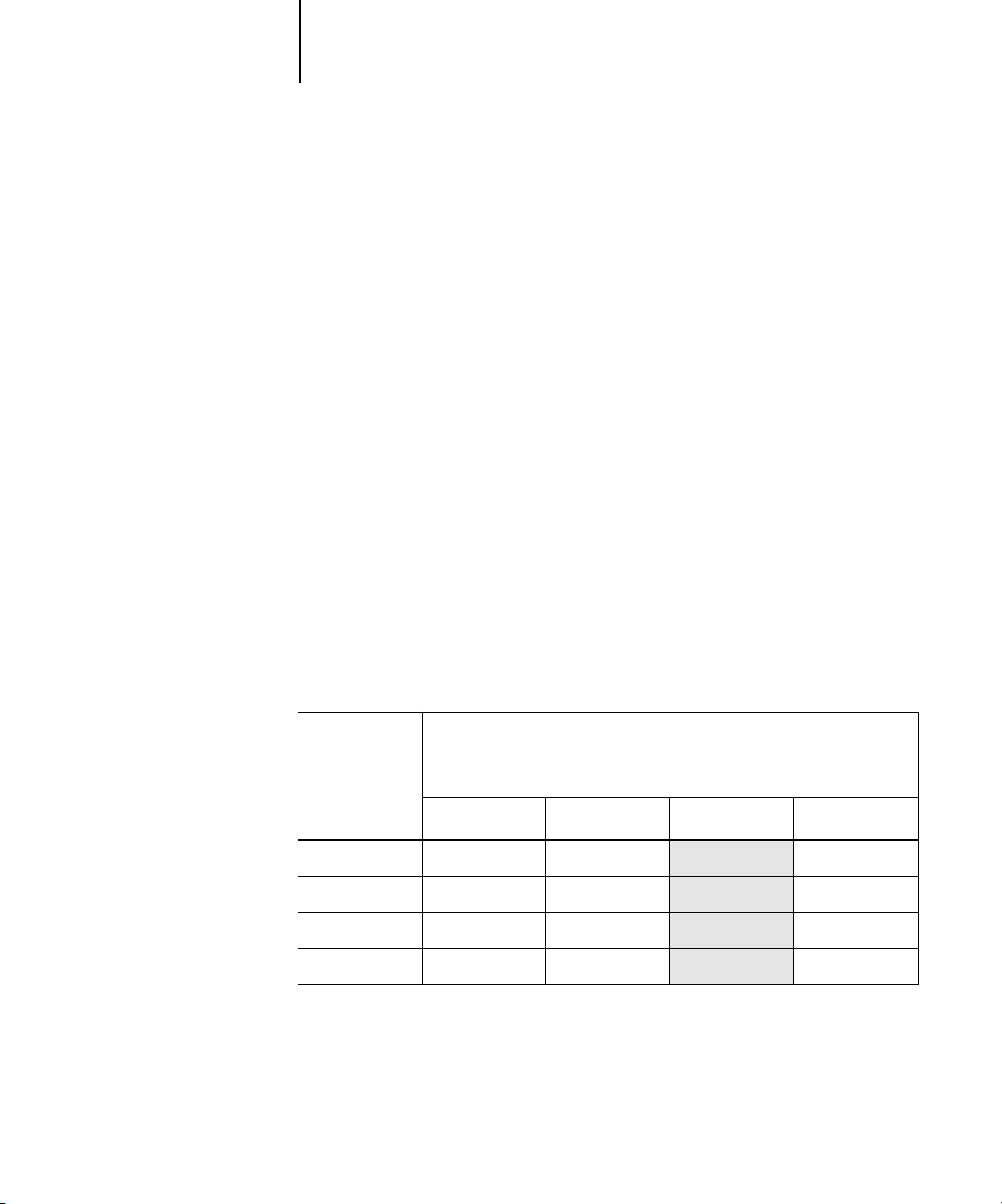

The resolution of a raster, along with its bit depth and physical dimensions, determine

its file size. The following table shows the file sizes of color raster images at different

dimensions and resolutions.

File size at:

Image size 100 ppi 150 ppi 200 ppi 400 ppi

RGB/CMYK RGB/CMYK RGB/CMYK RGB/CMYK

3"

x 4"

x 7"

5"

x 11"

8.5"

x 17"

11"

In this table, the shaded areas indicate that 200 ppi is typically the best trade-off

between image quality and file size. However, higher resolutions (e.g., 250 to 300 ppi)

may be needed for offset printing, when quality is of the utmost importance, or for

images containing sharp diagonal lines.

0.4/0.5 MB 0.8/1.0 MB 1.4/1.8 MB 5.5/7.3 MB

1.0/1.3 MB 2.3/3.0 MB 4.0/5.3 MB 16.0/21.4 MB

2.7/3.6 MB 6.0/8.0 MB 10.7/14.3 MB 42.8/57.1 MB

5.4/7.1 MB 12.0/16.1 MB 21.4/28.5 MB 85.6/114.1 MB

Page 23

1

Image quality

1-11 Optimizing files for processing and printing

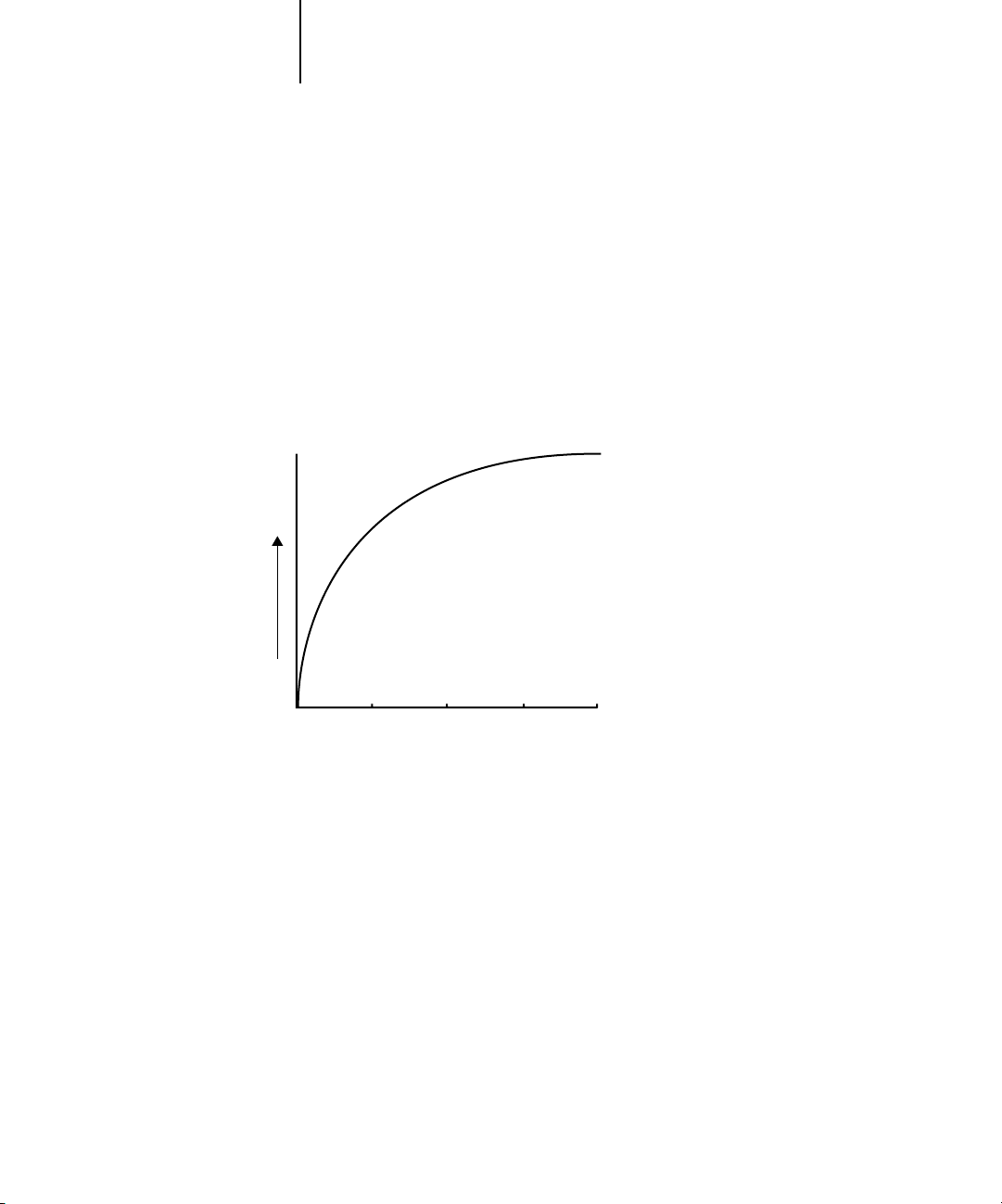

To find the best image resolution for your purposes, make test prints of some raster

artwork at different resolutions. Start with a high-resolution image (400 ppi) and save

versions at progressively lower resolutions, down to 100 ppi, using a pixel-editing

application such as Photoshop. Always save a copy of the original high-resolution

version in case you need to revert to it. The high-resolution data cannot be recreated

from a lower resolution version.

Print the files and examine the output. You will likely begin to see a marked

deterioration in output quality at resolutions below 200 ppi, while above 200 ppi the

improvement may be very subtle.

100 ppi 200 ppi 300 ppi 400 ppi

Image resolution

Raster images prepared for offset printing may need to be at higher resolutions than

needed for proofing on your RIP Station.

Page 24

1-12 Desktop Color Primer

1

Scaling

Ideally, each raster image should be saved at the actual size it will be placed into the

document and at the optimal resolution for the print device. If the image resolution is

correct for the print device, there is no quality advantage to be gained by scaling an

image down to a percentage of its actual size. If you scale a large image down to a

percentage of its actual size, you incur unnecessary file transfer time because the image

data for the entire large image is sent to the printer. If an image is placed multiple times

at a markedly different sizes in a document, save a separate version of the image at the

correct size for each placement.

If you need to place an image at greater than 100% in a document, remember that the

output image resolution is affected. For example, if you scale a 200 ppi image to

200%, the image is printed at 100 ppi.

Workflow scenarios

Color print jobs can be divided into two categories:

• Short-run print jobs for which the RIP Station is the final print device

• Offset print jobs being proofed on the RIP Station

For either type of job, issues of effective color usage, trapping, file optimization, and

scaling are important ones. The areas of difference between the workflows for these two

types of jobs are outlined in the following sections.

Short-run color printing

For short-run color jobs printed to the RIP Station:

• You can work in either the RGB color model or the CMYK color model (see the

application notes). When working with RGB colors, you should take advantage of

the color rendering capabilities of the RIP Station (see Chapter 2).

• When choosing or defining colors in your application, use the RIP Station color

reference pages to be assured of predictable results (see Chapter 3).

• When printing, choose the appropriate settings for print options that affect color

output (see Chapter 2).

Page 25

1-13 Workflow scenarios

1

Offset printing

For jobs that will be proofed on the RIP Station in preparation for being printed on an

offset press:

• Work in the CMYK color model only (see the application notes). All elements in

your document, including placed images, must be in the CMYK color model to

create film separations for printing.

• When choosing or defining colors in your application, use the RIP Station color

reference pages to be assured of predictable results (see Chapter 3).

• If cost is a factor and the document does not contain CMYK images, consider using

two or three PANTONE colors, instead of the standard four process colors (see

Chapter 3). This reduces the number of film separations and printing plates needed

to print the job. Use the PANTONE reference pages to define RGB-equivalents of

the PANTONE colors you want to print (see Chapter 3). These color definitions are

used only for proofing the job on the RIP Station.

• Choose the appropriate CMYK Simulation setting (see Chapter 2).

Page 26

Page 27

2-1 Controlling printed color

2

Chapter 2: Color Management

This chapter provides information on the factors involved in controlling and managing

color output with the objective of achieving predictable color results, including:

• Controlling printed color

• Basics of color management

• RIP Station color management

• Optional ICC color management on Macintosh and Windows computers

Controlling printed color

When working with color materials, whether they be presentations, illustrations, or

complicated page designs, you make aesthetic decisions about the colors you use. Once

you have decided on your goal, you then need to realize it in print. Your color printing

system becomes an ally in this creative process to the extent that you can get results

that are predictable.

• If you have designed a brochure to print on the RIP Station, you want the printed

colors to match the design specification.

• If you are printing presentations on the RIP Station, you want to preserve the vivid

colors in the monitor display.

• If you are working with color that will print on press, you want the RIP Station

output to match prepress proofs or PANTONE color swatch books.

The type of print job and the final print device, RIP Station or offset press, determine

the methodology you use to achieve optimal results.

No matter what your goals are, two hardware factors always impact color print output:

print device consistency and the range of colors the print device can print, known as its

gamut. These factors are covered briefly in this chapter. Creating successful color

documents and presentations also requires an understanding of color management

software as it is implemented by the RIP Station and on your desktop computer. Most

of this chapter is devoted to discussing the various elements of color management that

contribute to predictable color results.

Page 28

2-2 Color Management

2

Maintaining print device consistency

The factors described below affect print device consistency, as well as color fidelity and

overall output quality.

Paper stock and ink

The paper and ink used by your print device can greatly affect printed color. For best

results, use the supplies recommended in the Printer Guide.

Maintenance

Problems such as banding and insufficient amounts of one or more inks may arise if

the print device does not receive periodic print head cleaning and alignment. In

addition to having it serviced regularly, monitor the condition of your print device by

making standard test prints at regular intervals. You can do this easily by printing the

RIP Station Test Page. Save the prints and show them to the service technician

whenever output densities vary from the norm or other problems appear.

Color transparency film

RGB monitor

Offset press (white)

Other print device

Print device gamut

Different color reproduction techniques have different color capabilities, or gamuts.

Color transparency films have comparatively large gamuts, as do color monitors. The

color gamut that can be produced using process inks or CMYK inks on paper is

smaller. This is why some colors that can be displayed on a color monitor, especially

bright saturated colors, cannot be reproduced exactly by your RIP Station print

device—nor, for that matter, can they be reproduced on press using process colors.

Moreover, different print devices have different gamuts—some colors that your print

device can produce cannot be reproduced on an offset press, and vice versa. The

following illustration provides a graphical representation of this concept.

Page 29

2-3 Basics of color management

2

You need to account for the gamut of your print device when designing on a color

monitor. When printed, colors that fall outside the print device’s gamut are “mapped”

to printable colors. This process, referred to as gamut mapping, takes place when

color data is converted or adjusted to meet the color space and gamut requirements of

a print device.

The RIP Station is specially designed to perform gamut mapping at high speed with

high quality results. It provides these color management features automatically, using

either built-in default settings or settings that you specify for a particular print job. For

added flexibility, the RIP Station color management system can also be used in

combination with color management systems on Macintosh and Windows computers

(see page 2-10).

Basics of color management

The past several years have seen progress toward standardization in the field of digital

color management systems. Both the Macintosh and Windows 95 operating systems

now support a standard format developed by the International Color Consortium

(ICC). This ICC format is implemented on Macintosh computers in ColorSync™ 2.x

and on Windows 95 and Windows NT 4.0 computers in Image Color Matching

(ICM). More and more software developers are also incorporating color management

systems into high-end applications. The RIP Station provides a custom color

management system that can be used independent of, or together with, platform-based

and application-based color management tools.

A color management system, or CMS, is a “translator” between the color space of the

image source (the monitor, or a scanner, for example) and the color space of the target

print device. The CMS uses a device-independent color space, such as CIELAB, as its

reference point (see page 1-2). To perform its translation, the CMS needs information

about the color space of the image source and the color space and gamut of the print

device. This information is provided in the form of profiles, often created by the

makers of the monitor or print device. The end product of a CMS conversion is a

printed document or an image file in the color space and gamut needed for a particular

print device.

Page 30

2-4 Color Management

2

NOTE: If color matching between computer display and printed output is critical,

calibrate your monitor as closely as possible to the printed output. For most users,

predictability of printed color output is adequate and monitor calibration is not

necessary. For information on monitor calibration, see your Photoshop or Illustrator

documentation.

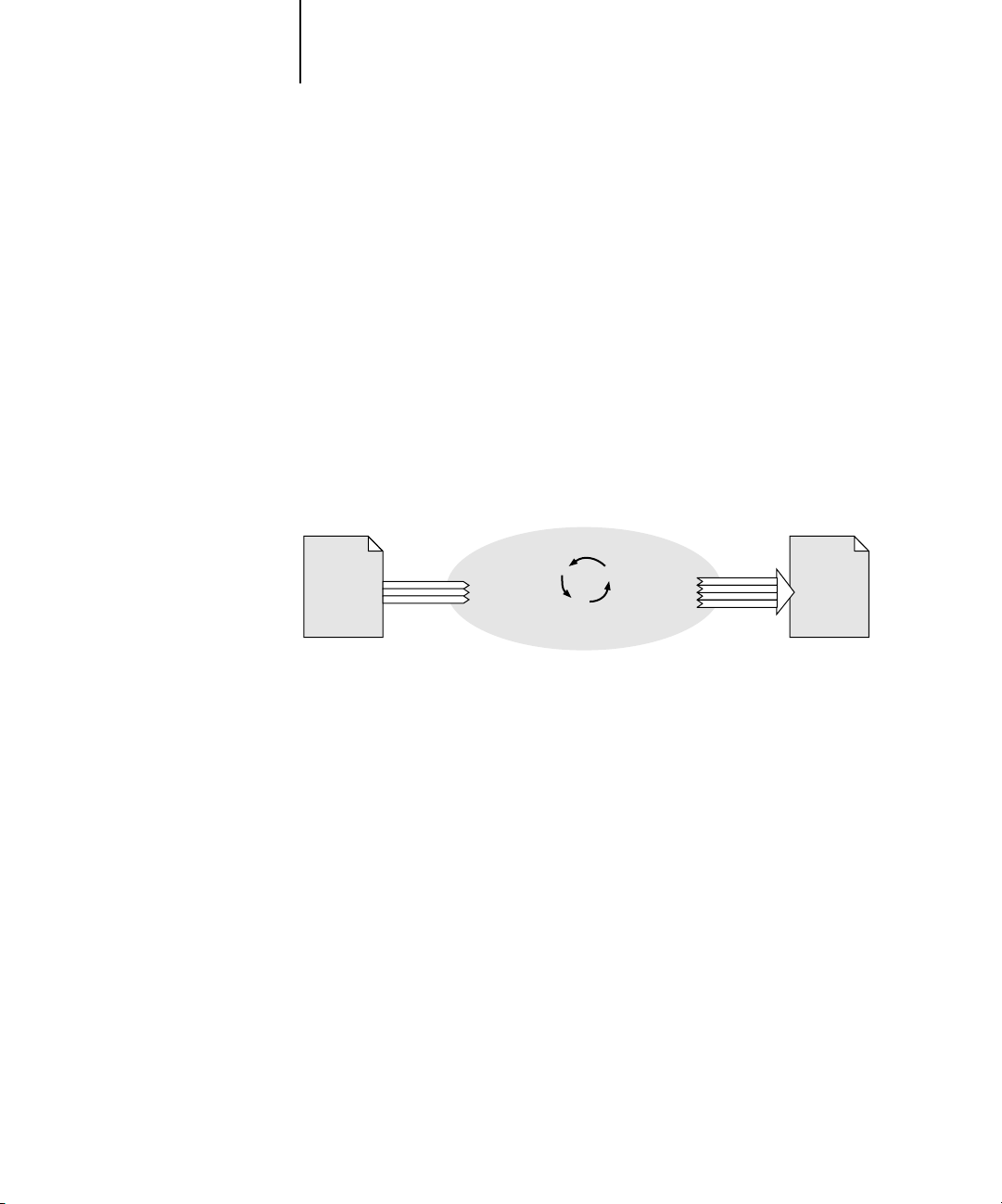

Color conversion

Before a color document can be printed, the color data in it must be converted to the

color space and gamut of the print device. Whether performed by RIP Station color

management or by an ICC CMS, the process of converting color data for a print

device is the same: the CMS interprets RGB image data according to a specified source

profile and adjusts both RGB and CMYK data according to a specified target profile.

Color management system

Source

profile

Device-independent

color standard

Input data

The source profile defines the RGB color space characteristics of the image’s source—

characteristics such as the white point, the gamma, and the type of phosphors used.

The target profile defines the color space characteristics and gamut of the target print

device. The RIP Station (or the ICC CMS) uses a device-independent color standard

to translate between the source color space and the target color space.

The RIP Station allows you to specify default and override settings for the source color

space information and the target profile information (see “RIP Station color

management” on page 2-5). When you use these settings, you do not need to use the

features of other color management systems. Your RIP Station user software includes

ICC profiles for use with other color management systems if you choose to use them.

Color management systems can also be used to adjust color data to conform to the

gamut of a print device other than the one to which you are printing. This process of

simulating another print device is commonly used for proofing jobs that will print on

an offset press. The RIP Station simulation feature is described on page 2-9.

Target

profile

Printed data

or file

Page 31

2-5 RIP Station color management

2

RIP Station color management

The RIP Station uses a simple and flexible color architecture that produces excellent

color results with default settings. It also allows you to customize your color results

using various color controls.

The diagram below illustrates the controls in the RIP Station color management

process that affect color data conversions. You access these controls via print options

when you send a print job. Most of these options and their settings are described in

subsequent sections of this chapter.

The output of the RIP Station color management process is color data that is ready to

be sent to the print device. Additional processing may be performed on board the print

device before printing begins.

RGB data

CMYK data

RGB Source

Gamma

Phosphors

White Point

Rendering Style (CRD)

Brightness

CMYK Simulation

Rendering Style (CRD)

Brightness

Pure Black Text/Graphics

RIP Station

color

processor

Color data sent

to print device

Page 32

2-6 Color Management

2

Settings for the following RIP Station options can be specified via print options when

you send a job. Some can also be set as defaults by the administrator during

RIP Station Setup. Settings specified via print options override the defaults set at

Setup.

RIP Station color print option

and settings

RGB Source

EFIRGB/sRGB (PC)/Apple Standard/Other/Off

(Default set at Setup)

(Other) Gamma

1.0/1.2/1.4/1.6/1.8/2.0/2.2/2.4/2.6/2.8/3.0

(Other) Phosphors

Hitachi EBU/Hitachi-Ikegami/NTSC/Radius

Pivot/SMPTE/Trinitron

(Other) White Point

5000 K (D50)/5500 K/6500 K (D65)/7500 K/

9300 K

Rendering Style

Photographic/Presentation/Solid Color

(Default set at Setup)

Brightness

85% to 115%

Pure Black Text/Graphics

On/Off

What it does

Applies an RGB source space definition to RGB data (see page 2-7). If

you choose the Other setting, you can specify particular settings for

gamma, phosphors, and white point with the following three options

Applies the specified gamma value to the RGB source space definition

(see page 2-7). To use this print option, you must choose Other as the

RGB Source setting.

Applies the specified phosphor (monitor type) information to the RGB

source space definition (see page 2-7). To use this print option, you must

choose Other as the RGB Source setting.

Applies the specified white point value to the RGB source space

definition (see page 2-7). To use this print option, you must choose

Other as the RGB Source setting.

Applies a RIP Station color rendering style (CRD) to RGB data (see

page 2-8). This setting is also applied to CMYK data when a CMYK

Simulation setting other than None is specified (see page 2-9).

Performs a color adjustment on all color channels to make the printed

output lighter or darker.

The On setting optimizes the quality of black text and line art output

(see page 2-9).

CMYK Simulation

SWOP-COM-M/SWOP-COM-F/

Cromalin EuroSTD/DuPont WaterProof/DIC/

Euroscale/Custom-1 through Custom-5/None

(Default set at Setup)

Explanations of how these settings affect your print jobs are provided in subsequent

sections of this chapter.

Adjusts CMYK color data to simulate an offset press standard or a

custom color gamut defined at your site. Choosing None bypasses

simulation (see page 2-9). If you choose any setting other than None,

specify Solid Color as the Rendering Style setting.

Page 33

2-7 RIP Station color management

2

RGB Source

The RGB Source option is used to provide a source color space definition for RGB

data in your document. The setting you specify for this option overrides any source

color space profiles you may have specified with other color management systems. For

example, if you specified a ColorSync System Profile on your Macintosh computer (see

page 2-10), the RGB Source setting overrides it. In cases where you don’t want this

setting to override another specified source color space, choose the Off setting.

• EFIRGB specifies a ColorWise-specific source space that can be used to ensure

consistent results across different computer platforms.

• sRGB (PC) specifies the source space of a generic Windows computer monitor.

• Apple Standard specifies the source space of all standard Macintosh computer

monitors.

• Other allows you to specify custom RGB source settings. If you choose Other as the

RGB Source setting, you can choose settings for the Gamma, Phosphors, and White

Point options.

If you set RGB Source to Off, PostScript RGB data (such as RGB EPS images) and

non-PostScript RGB data (such as RGB TIFF images) are converted differently by the

RIP Station color management system.

• PostScript RGB data is converted using the CRD specified by the Rendering Style

option (see page 2-8). PostScript RGB data contains its own source color space

information which is used as a reference point for the conversion.

• NonPostScript RGB data is converted using a general under-color-removal

conversion method. Non-PostScript RGB data does not contain source color space

information and so cannot be converted using a CRD.

Page 34

2-8 Color Management

2

Rendering styles

The Rendering Style option is used to specify a CRD for color conversions. The

following table describes the various color rendering styles (CRDs) provided with

RIP Station software and provides guidelines on when to use each one. Each color

rendering style uses a different gamut mapping method, such as Photographic or Solid,

designed for a particular kind of color usage.

The ICC rendering styles referred to in the table are settings you can choose when

specifying a target profile with an ICC color management system (see the application

notes.)

NOTE: Your version of RIP Station software may not include all these color rendering

styles, or may include others.

RIP Station rendering style Best used for

Photographic—Preserves tonal relationships in

images rather than exact colors. This rendering style

maps out-of-gamut RGB colors to printable colors in

a way that retains differences in lightness. Color

accuracy is sacrificed slightly in favor of presenting

color relationships in the way the human eye perceives

them. Photographic rendering typically gives less

saturated output when printing out-of-gamut RGB

colors than Solid Color rendering does.

Presentation—Creates bright saturated colors. This

rendering style does not try to match printed colors

precisely to displayed colors but instead provides

vibrant, dense colors. Photographic images, however,

are treated the same way as by the Photographic

rendering style.

Solid Color—Provides best color accuracy and

preserves the saturation of displayed colors. This

rendering style matches RGB colors to printable

equivalents wherever possible and maps out-of-gamut

RGB colors to the closest printable colors.

Continuous tone photographs,

including scans and images from

stock photography CDs

Artwork and graphs in presentations

and continuous tone photographs

Spot colors and graphic images

(Solid Color rendering may not be

appropriate for printing saturated

RGB color blends, since artifacts such

as banding may occur)

Equivalent ICC

rendering style

Image and Contrast and

Perceptual

Saturation and Graphics

Colorimetric

Page 35

2-9 RIP Station color management

2

Pure Black Text/Graphics

The Pure Black Text/Graphics option provides a way to optimize the quality of black

text and line art by printing one-color black at the full density of your print device.

This option can also be used to minimize the amount of ink used when printing

documents consisting of a mixture of color and black-only pages.

• With On, black text and line art are printed using only black ink. This setting

eliminates the potential for blasting and misregistration of colors that exists when

using a four-color black.

• With Off, black text and line art are printed using all four colors of ink. This setting

should be used when a rich black is desired.

The Pure Black Text/Graphics option affects only black text and line art elements

defined in RGB as R0%, G0%, B0%, or in CMYK as C0%, M0%, Y0%, K100%. It

does not affect colors in continuous tone images.

The Pure Black Text/Graphics option can be used only when printing composites, not

when printing separations.

CMYK Simulation

The CMYK Simulation print option allows you to print press proofs or simulations.

This option affects CMYK data only.

The CMYK Simulation setting specifies the offset press standard or other color gamut

that you want to simulate. You can also create up to five custom simulations using the

Fiery Print Calibrator (see the User Guide). For details on the various CMYK

Simulation settings, see the User Guide.

The CMYK Simulation setting you should specify depends on the press standard for

which the CMYK data was separated. For example, for images that were separated for

SWOP, choose SWOP-Coated as the CMYK Simulation setting. For images that were

separated using a custom separation (such as a device-specific separation or a

separation produced with an ICC-profile), choose None as the CMYK Simulation

setting.

Page 36

2-10 Color Management

2

The CMYK Simulation setting also determines whether or not CMYK data is affected

by the Rendering Style setting (see page 2-5).

• With a CMYK Simulation other than None, choose Solid Color as the Rendering

Style setting.

• With None as the CMYK Simulation, the CMYK data is converted to device-ready

color data using a default PostScript conversion scheme.

Optional ICC color management for advanced users

This section describes how the ICC color management systems implemented on

Macintosh and Windows platforms can be used in combination with RIP Station color

management. You do not need to use the Macintosh or Windows color management

systems to get good color printing results—the RIP Station provides its own built-in

color management. This information is provided for advanced users with particular

customization requirements.

Color management on Macintosh computers

The Macintosh operating system includes the ICC ColorSync 2.x color management

system. The AdobePS 8.5.1 printer driver (included in the RIP Station user software)

supports ColorSync 2.x features and all other PostScript Level 2 and 3 printing

features. You can use the AdobePS printer driver to control color conversions of RGB

data with ColorSync profiles. Some PostScript applications also provide independent

color management features that use ColorSync profiles.

To use the AdobePS driver to perform color management, choose the ColorSync Color

Matching setting and specify a ColorSync printer profile when you print (see

page 4-2). With these settings, the AdobePS driver performs color conversions and

sends the resulting color data to the RIP Station. For information on color

management tools provided with applications, see the application notes.

Page 37

2-11 Optional ICC color management for advanced users

2

Source color space profiles

You can specify a ColorSync source color profile for your Macintosh computer with

the ColorSync System Profile Control Panel (see the Setup Guide). The recommended

source color profile for printing to your RIP Station print device is the EFIRGB ICC

profile included in your RIP Station user software. The source color space defined by

this profile is the same as that defined by the EFIRGB setting of the RGB Source

option (see page 2-7).

The RGB Source setting overrides the ColorSync System Profile setting for RGB data

sent to the RIP Station. If you do not want the ColorSync profile setting to be

overridden, set the RGB Source print option to Off.

The RGB Source setting does not override other source profile settings in cases where

you use the printer driver or your application’s color management system to perform

color conversions. For example, if you print using the ColorSync Color Matching

setting (as described above), the printer driver performs the color conversion and sends

CMYK data to the RIP Station. In another example, if you assign a ColorSync source

profile to an RGB image placed in a document, the application performs the

conversion to CMYK and the assigned source profile is not overridden by the RGB

Source setting.

Target profiles

The target profile, or printer profile, contains information about the color space and

gamut of the target print device. If you use the ColorSync Color Matching setting of

the AdobePS driver, you must specify the printer profile that ColorSync will use to

perform its color conversions.

Some applications let you assign ColorSync target profiles to RGB images you place in

a document (see the application notes). When you print the document, the application

performs color conversions on the placed images, using the profiles you specified, and

embeds the resulting color data in the document. Three rendering styles are included

in a ColorSync profile, each tailored for a specific type of color output (see page 2-8).

See Chapter 4 for information on setting print option settings that affect printed color.

Page 38

2-12 Color Management

2

Color management on Windows computers

The Windows 95 and Windows NT 4.0 operating systems include the Image Color

Matching (ICM) color management system.

• The AdobePS4 printer driver for Windows 95 (included in your RIP Station user

software) supports ICM features and all PostScript Level 2 and 3 printing features.

With Windows 95, you can instruct the Adobe PS4 driver to perform color

management using ICM. To do this, you select the “Use image color matching”

option in the Graphics tab of the printer’s Properties dialog box. (See your

Windows 95 documentation for more information.) With the proper ICM settings,

the printer driver performs color conversions and sends the resulting color data to

the RIP Station.

• The Microsoft PostScript Level 2 Printer Driver for Windows NT 4.0 does not

currently support all ICM features.

• The Windows 3.1x and Windows NT 3.51 operating systems do not support ICM.

• Some PostScript applications also provide independent color management features

that use ICM profiles (see the application notes).

Source color space profile

A default source color space is defined for every Windows computer monitor. The

RGB Source setting overrides this default source color space (see page 2-7). If you do

not want the monitor’s default source color space to be overridden, set the RGB Source

print option to Off.

The RGB Source setting does not override other source profile settings in cases where

you use the printer driver or your application’s color management system to perform

color conversions. For example, if you print with Windows 95 using Image Color

Matching (as described above), the printer driver performs the color conversion and

sends CMYK data to the RIP Station. In another example, if you assign an ICM

source profile to an RGB image placed in a document, the application performs the

conversion to CMYK and the assigned source profile is not overridden by the RGB

Source setting. (See the application notes for information on the color management

tools available with different applications.)

Page 39

2-13 Optional ICC color management for advanced users

2

Target profiles

The target profile, or printer profile, contains information about the color space and

gamut of the target print device. If you use the “Use image color matching” option of

the Adobe driver for Window 95, you must install the printer profile that ICM will use

to perform its color conversions.

Some applications let you assign ICM target profiles to RGB images that you place in a

document (see the application notes). When you print the document, the application

performs color conversions on the placed images, using the profiles you specified, and

embeds the resulting color data in the document. Three rendering styles are included

in an ICM profile, each tailored for a specific type of color output (see page 2-8).

See Chapter 4 for information on print option settings that affect printed color.

Page 40

Page 41

3-1 Working with color

3

Chapter 3: Working with Color in Applications

This chapter provides guidelines for defining colors in your documents to produce the

results you want. The following topics are covered:

• Factors affecting how you work with color

• Choosing colors with QuickDraw and GDI applications, such as presentation

applications and word processing programs

• Choosing colors with PostScript applications, such as page layout programs,

illustration programs, and pixel-editing applications

Working with color

The two main factors that influence how you work with color in your documents are

the application you use and the final print device.

Applications vary in the methods they provide for choosing colors and in the way they

transmit color data to the print device.

• Office applications such as presentation software, spreadsheets, and word processing

programs use the RGB color model.

• PostScript applications such as illustration, pixel-editing, and page layout

applications use the CMYK color model.

The type of printing you plan for the document—short-run printing on the

RIP Station versus offset press printing—determines the way you define colors as well

as the print option settings you choose.

• For short-run printing on the RIP Station, use any type of application and define

colors in either RGB or CMYK. Choose the appropriate settings for print options