Electronet ELMAG 200 User Manual

NK Instruments Pvt. Ltd.

B-501/504, 5th floor, Raunak Arcade, Near THC Hospital, Gokhale Road, Naupada,

Thane(W) 400602. Maharashtra INDIA

Telefax Nos.: 91-22-25301330 / 31 / 32

E-Mail: sales@nkinstruments.com

Web: http://www.nkinstruments.com

Skype: nitinkelkarskype

Gtalk: nkinstruments2006

Authorised Dealer

ELECTRONET

USER MANUAL FOR

FULL BORE ELECTROMAGNETIC

FLOW METER

MODEL NO. :- ELMAG 200

ELECTRONET

UM-ELMAG 200-R3

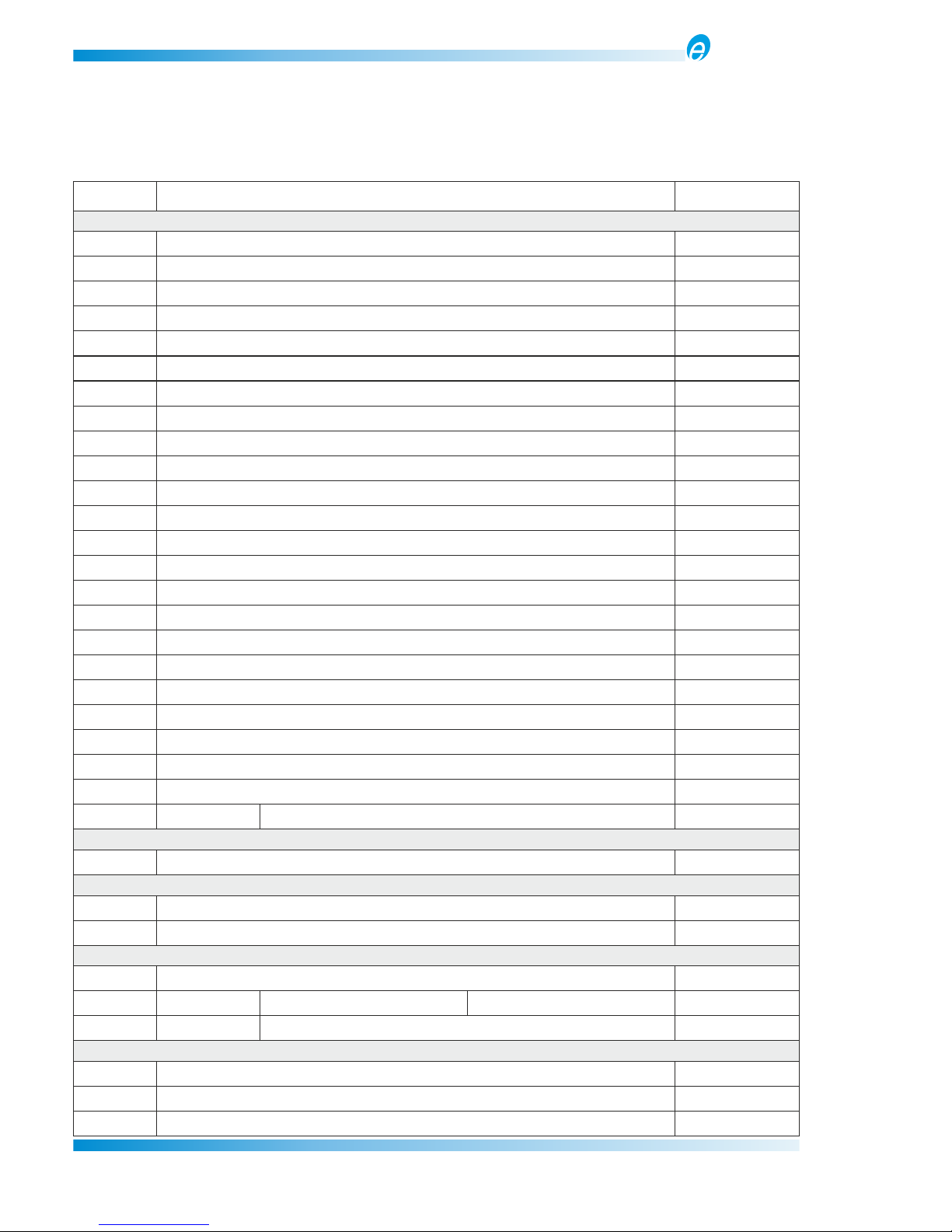

ORDERING DTAILS

Instrument Name : Full Bore Type Electromagnetic Flow Meter

Model No. : ELMAG 200

Serial No. :

Code

Description

As Applicable

Line Size

01

02

03

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

½ Inch (15NB)

¾ Inch (20NB)

1 Inch (25NB)

1½ Inch (40NB)

2 Inch (50NB)

2½ Inch (65NB)

3 Inch (80NB)

4 Inch (100NB)

5 Inch (125NB)

6 Inch (150NB)

8 Inch (200NB)

10 Inch (250NB)

12 Inch (300NB)

14 Inch (350NB)

16 Inch (400NB)

18 Inch (450NB)

20 Inch (500NB)

24 Inch (600NB)

Lining Material

01

02

03

PTFE

Rubber

Other

Flange Material

01

02

03

CS/MS

SS304

SS316

20

28 Inch (700NB)

21

32 Inch (800NB)

22

36 Inch (900NB)

23

40 Inch (1000NB)

24

Other

Calibration Range

01

Flow Direction

01

02

Forward

Reverse

04

1¼ Inch (32NB)

ELECTRONET

UM-ELMAG 200-R3

Code

Description

As Applicable

Electronic Enclosure

01

02

Aluminum die cast

SS304

Output

01

02

03

04

4-20mA DC

4-20mA DC + Pulse Output

4-20mA DC + HART Output

All (4-20mA DC + Pulse Output +HART Output)

Communication Output

01

03

RS485

RS232

04 GSM

Power Supply

01

02

90-260V AC,50Hz

24V DC

03 48V DC

Alarm Output

01

02

Low

High

03 Batch

Cable Gland

01

02

M20 x 1.5 double compression

1/2" NPT(F)

03 3/4 ET

Electrode Material

01

02

03

04

SS316L

Hastalloy C

Platinum

Other

Coil Housing Material

01

02

03

MS

SS304

SS316

Accessories

01

02

Power cable

Cable gland

03 Magnetic key chain

04 ‘U’ clamp

06 Other

05 Grounding Ring

02 Data Logger

ELECTRONET

UM-ELMAG 200-R3

CONTENTS

1. INTRODUCTION.......................................................................................................... 01

1.1 Item Supplied......................................................................................................... 01

1.2 Device Identification............................................................................................... 01

1.3 Reading User Manual............................................................................................. 01

1.4 Warranty Terms...................................................................................................... 01

2. SAFETY INSTRUCTIONS........................................................................................... 02

2.1 General Instructions............................................................................................... 02

2.2 Storage Precautions............................................................................................... 02

2.3 Installation Location Precautions............................................................................ 02

3.APPLICATION.............................................................................................................. 03

4. OPERATING PRINCIPLE............................................................................................ 04

5. TECHNICAL DETAILS................................................................................................ 05

5.1 Electronic Unit Specifications................................................................................. 05

5.2 Flow Sensor Specifications.................................................................................... 05

6. ASSEMBLY OVERVIEW.............................................................................................. 06

7. KEY BOARD DETAILS................................................................................................ 07

8. TERMINATION DETAILS............................................................................................. 07

8.1 HART Communication Details ............................................................................... 08

8.2 GSM Module Details............................................................................................... 08

9. INSTALLATION DETAILS............................................................................................ 10

9.1 How to install Flow Meter...................................................................................... 10

9.2 Cable glanding procedure..................................................................................... 11

9.3 Safety Precautions............................................................................................... 12

9.4 Installation Position............................................................................................... 13

9.5 Pipe System.......................................................................................................... 14

10. OPERATIONAL FLOW CHARTS.............................................................................. 17

10.1 General Overview of Operations.......................................................................... 17

10.2 Alarm Setting Mode.............................................................................................. 18

10.3 Configure Mode.................................................................................................... 19

10.4 Alarm Configuration.............................................................................................. 22

10.5 Configure Instrument Method............................................................................... 23

10.6 Real Time Clock Configuration ............................................................................ 27

10.7 View Logged Data................................................................................................. 28

10.8 Batch Mode Opration.......................................................................................... 28

ELECTRONET

UM-ELMAG 200-R3

10.9 Avrage Flow Rate................................................................................................ 29

10.10 SMS Format On Mobile...................................................................................... 29

10.11 Online Diagnostic Features................................................................................ 29

11. MODBUS (RS 485) COMMUNICATION DETAILS.................................................... 30

12. DO'S & DONT'S.......................................................................................................... 34

13. TROUBLE SHOOTING PROCEDURE...................................................................... 34

ELECTRONET

UM-ELMAG 200-R PAGE 01 OF 34

1. INTRODUCTION

1.1 Item Supplied :

ELMAG 200 flow meter

User Manual

Calibration Certificates

User Manual CD

Inspection :

— Check for mechanical damage due to possible improper handling during shipment. All

claims for damage are to be made promptly to the shipper.

— Make sure the scope of delivery and the information on the name plate corresponds to the

ordering information.

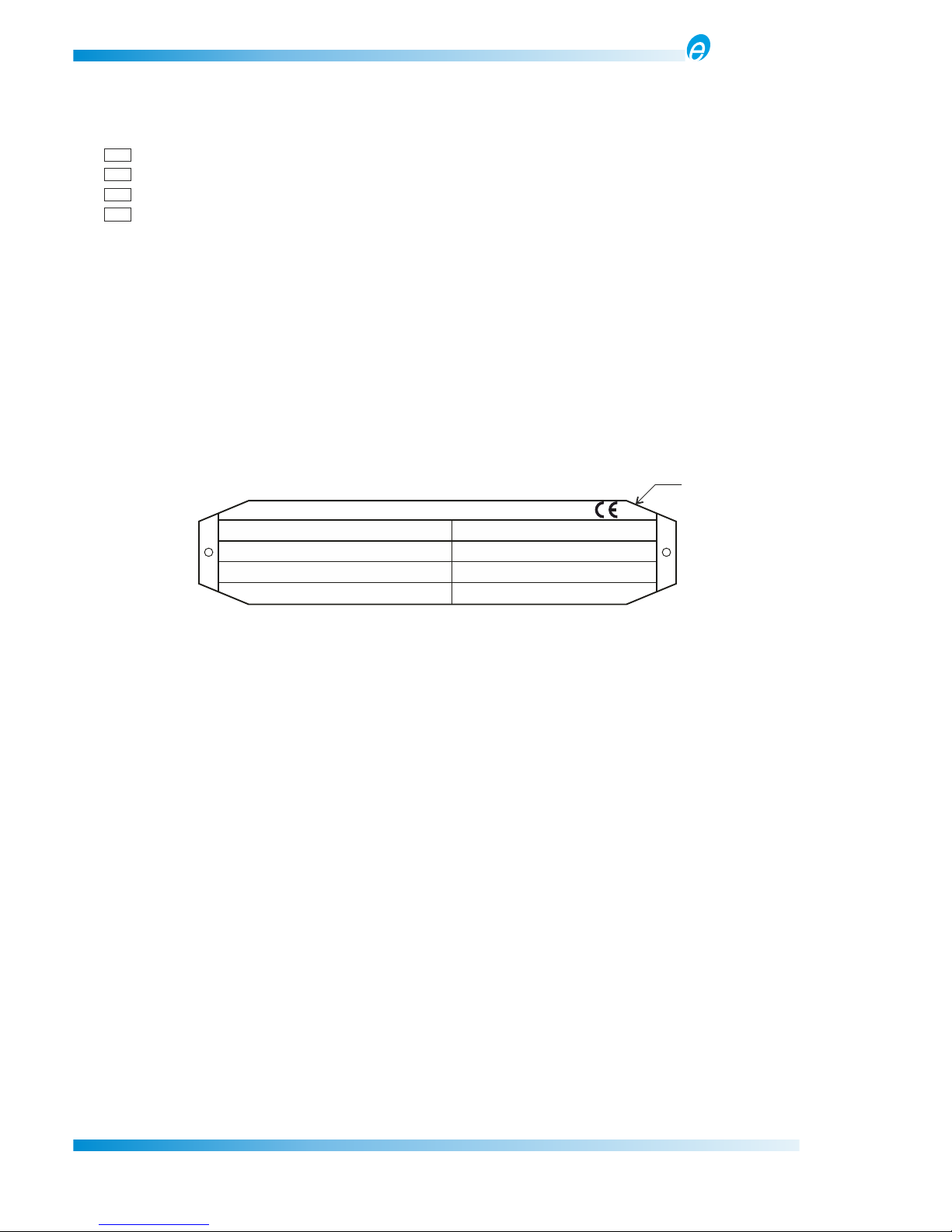

1.2 Device Identification :

The Model no. and Specification are found on name plate, located on top of electronic

housing. Check the Model no. & Specifications you have ordered.

1.3 Reading User Manual :

— This manual should be provided to the end user.

— Before use, read this manual carefully and compare the instrument specification.

— The contents of this manual may be changed without prior notice.

1.4 Warranty terms :

— The terms of this instrument that are guaranteed are described in the quotation. We will

make any repairs that may become necessary during the guaranteed term free of

charge.

— Please contact our sales office if this instrument requires repair.

— If the instrument is faulty, contact us with concrete details about the problem and the

length of time it has been faulty, and state the model and serial number. We would

appreciate the inclusion of images or additional information.

— The results of our examination will determine whether the meter will be repaired free of

charge or on an at-cost basis.

ELECTROMAGNETIC FLOW METER

MODEL NO.:

SUPPLY :

RANGE :

SR. NO.:

LINE SIZE :

OUTPUT :

MAX. W. P.:

TAG NO.:

Electronic Unit

name plate

ELECTRONET

UM-ELMAG 200-R3 PAGE 02 OF 34

2. SAFETY INSTRUCTIONS

2.1 General Instructions:

— This flow meter was carefully calibrated at the factory before shipment. When meter is

delivered, visually check that no damage has occurred during transportation

— Read User manual carefully and understand instructions & directions provided in this

manual.

— In general, devices from the manufacturer may only be installed, commissioned, operated

and maintained by properly trained and authorized personnel.

— Look at the ordering detail to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

— Before powering up the meter, consider the following:

– Is the meter installed according to the direction of flow as marked on the meter.

– Has the wiring been carried out correctly and have all safety procedures been adhered to.

Is the supply voltage correct.

– Has the flow meter been properly earth.

– Lethal power supply voltages may be present, do not apply power with the signal

converter cover or terminal box cover removed.

— The following principles should be considered during installation:

– If there is a noisy power supply voltage (especially peaks generated, usually by motors),

use an external power supply filter between the flow meter and power supply.

– Protect the flow meter and the internal lining of the sensor pipe from mechanical damage,

especially during installation or cleaning.

– Do not expose the flow meter to intense vibration.

2.2 Storage Precautions:

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store the device in its original packing.

• Storage temperature: 0 to 55°C

2.3 Installation Location Precautions:

— Installation of the Electromagnetic flow meter must be performed by expert engineer or

skilled personnel. No operator shall be permitted to perform procedures relating to

installation.

— The Electromagnetic flow meter is a heavy instrument. Be careful that no damage is

caused to personnel through accidentally dropping it, or by exerting excessive force on the

electromagnetic flow meter. When moving the electromagnetic flow meter, always use a

trolley .

— When the electromagnetic flow meter is processing hot fluids, the instrument itself may

become extremely hot. Take sufficient care not to get burnt.

Note : IP68 Certification is valid if cable glanding is done as per mentioned cable

glanding procedure (Point no. 9.2, page no.11&12) also safety precautions must

be strictly maintained

ELECTRONET

UM-ELMAG 200-R3 PAGE 03 OF 34

ELMAG 200 is microprocessor based full bore type electromagnetic flow meter specially used

for various industrial applications. This flow meter accurately measures the flow rate of

conductive liquids & slurries in closed pipes. Due to simple, rigid & obstruction less design the

flow meter is a maintenance free instrument in place of conventional mechanical flow measuring

device. ELMAG 200 standard configuration is a sensor with transmitter integrated in one unit. It’s

performance is independent of temperature, pressure, density and viscosity of the medium.

ELMAG 200 is a flanged meter available in sizes from DN 10 to DN 1000. The rugged flow sensor

is constructed from completely welded construction. In the instrument, the sensor and the

electronics form one mechanical entity. A retransmission output of 4-20 mA is provided. The use

of ‘Pulsed DC ’ excitation technology offers highest ability & better measuring accuracy in the

form of electrical signal 4 - 20 mA DC linearly proportional to volumetric flow.

Sensor : The sensor consists of metering pipe; electrodes and coils. It is accommodated in

welded and a fully encapsulated steel enclosure.

Electronics :The conditioning electronics circuitry is housed in a cast aluminum connection box.

The termination of this electronics is given in the same housing through cable glands for the

required connecting cables.

Applications:

CApplications include measurement of flow on conducting liquids and slurries (even

highly corrosive and abrasive) in chemical and petrochemicals, pharmaceutical, fertilizers,

foodstuffs, dairy, sugar, breweries, paper, steel, mining industries etc.

CMonitoring water flow in cooling systems in steel plants, power plants etc.

CMeasuring flow of clean water, effluent, sludge etc. In pollution and environmental control.

CThe isolated 4-20 mA output proportional to flow can be fed to PLCs, DCS or remote mounted

indicator.

3. APPLICATION

ELECTRONET

UM-ELMAG 200-R3 PAGE 04 OF 34

4. OPERATING PRINCIPLE

The flow meter is designed for electrically conductive fluids. Measurement is based on Faraday’s

law of induction, according to which a voltage is induced in an electrically conductive body, which

passes through a magnetic field.

The following expression is applicable to the voltage:

U = K x B x v x D

Where:

U = induced voltage

K = an instrument constant

B = magnetic field strength

v = mean velocity

D = pipe diameter

Thus the induced voltage is proportional to the mean flow velocity, when the field strength is

constant. Inside the electromagnetic flow meter, the fluid passes through a magnetic field applied

perpendicular to the direction of flow. An electric voltage is induced by the movement of the fluid

(which must have a minimum electrical conductivity). This is proportional to the mean flow

velocity and thus to the volume of flow. The induced voltage signal is picked up by two electrodes,

Which are in contact with conductive fluid and transmitted to the signal converter.This method of

measurement offers the following advantages:

1) No pressure loss through pipe.

2) Since the magnetic field passes through the entire flow area, the signal represents a mean

value over the pipe cross-section; therefore, only relatively short straight inlet pipes x DN from

the electrode axis are required upstream of the primary head.

3) Only the tube liner and the electrodes are in contact with the fluid.

4) The signal produced is an electrical voltage, which is an exact linear function of the mean flow

velocity.

Fig.1

ELECTRONET

UM-ELMAG 200-R3 PAGE 05 OF 34

5. TECHNICAL DETAILS

5.1 Specifications:

Instrument Name : Full Bore Type Electromagnetic Flow Meter

Model No. : ELMAG 200

Media : Conductive Liquids & slurries

Calibration Range : As per customer requirement

Display : 16X2 Alphanumeric LCD, 6 digit for flow rate & 8 digit

for totaliser

Power Supply : 1) 90-260V AC, 50Hz

2) 24V DC

3) 48V DC

Power Consumption : Less than 10VA

Response Time : 2Sec.

Accuracy : +/-0.5% of full scale

Linearity : +/-0.5% of full scale

Isolation : 1.4KV Between input & Power supply

Output : 1) 4-20mA DC

2) Pulse output (Open collector OR 12V DC

Amplitude)

3) Relay O/P(1c/o,1Amp @ 230V AC for

Low/High/Batch alarm)

Communication Output : 1) 4-20mA DC with HART

2) RS485 supporting MODBUS RTU Protocol

3) RS232

4) GSM

Flow Direction : 1) Forward 2) Reverse

0

Temperature : 1) Ambient : 0 to 55 C

0

2) Storage : 0 to 55 C

Relative Humidity : 10-95% RH, non condensing

Cable Entry : M20 x1.5 Double Compression Cable Gland,

½” NPT

Mounting : In Line - Horizontal / Vertical

Transmitter Enclosure : Aluminum Die cast

Protection Class : IP66

5.1.1 Electronics Unit Specifications:

5.1.2 Flow Sensor Specifications:

Line Size : 15NB to 1000NB

Material of Construction : 1) Coil housing : MS / SS

2) Electrode : SS 316L / Hastalloy C / Platinum

3) Flange : CS / MS / SS 304 / SS 316

4) Lining : Rubber / PTFE

Mechanical Connections : Flange / SMS union / Threaded / Tri clover

Media conductivity : > 20 μs/cm

Limit flow velocities of measured liquid : 6 m/s

Viscosity : 200cp (max.)

Direction of Flow : Direction of Arrow on Meter

Protection class : IP68

Process Temperature : 1) 0 to 85° C(For Rubber Lining)

2) 0 to 120° C(For PTFE Lining)

2

Operating Pressure : 0 to10Kg/cm

ELECTRONET

UM-ELMAG 200-R3 PAGE 06 OF 34

6. ASSEMBLY OVERVIEW

DIMENSIONAL DETAILS OF FLANGE(AS PER ASA150 # B-16.5):

Fig.2 FRONT VIEW

Fig.3 SIDE VIEW WITH FLANGE DETAILS

Ø DBC

Ø Bolt Hole

Lining

R

D

FD

Note : All dimensions are in ‘mm’

Line Size

Inch

NB

Flange

Diameter

D (mm)

Diameter of

Raised Face

R (mm)

200

2 ½ ”

65 177.8

4

104.8 19.0

22.2

½”

15

88.9

4

34.9

20015.9

11.1

3/4”

20

98.4

4

42.9 20015.9

12.7

1 ”

25 107.9

4

50.8 20015.9

14.3

200

1 ½ ”

40 127.0

4

73

15.9

17.5

2”

50

152.4

4

92.1 20019.0

19.0

Diameter of

Bolt Hole

(mm)

No.

of

Holes

Flange to Flange

Distance (FD)

(mm)

Thickness

of

Flange

3 ”

80 190.5

4

127.0 20019.0

23.8

4”

100

228.5 8157.2 25019.0

23.8

250

5 ”

125 254.0 8185.7

22.2

23.8

6”

150 279.4 8215.9

300

22.2

25.4

8”

200

342.9

8269.9

350

22.2

28.3

10”

250 406.4

12

323.8

45025.4

30.2

12”

300

482.6

12

381.0

50025.4

31.8

14”

350 533.4

12

469.9 50028.6

34.9

16”

400 596.9 16

533.4

60028.6

36.5

18”

450

635.0

16584.2 600

31.7

39.7

20”

24”

500

600

698.5

812.8

20

20

139.7

60.3

69.8

79.4

98.4

120.6

Diameter of

Bolt Hole Circle

DBC (mm)

152.4

190.5

215.9

241.3

298.4

361.9

431.8

476.2

539.7

577.8

635.0

749.3

692.1

692.1

600

600

31.7

34.9

42.9

47.6

125

125

155

265

605

555

605

355

605

405

605

205

245

285

485

185

165

145

Housing

OD

(mm)

Grounding

Ring

* Note : Flange to flange distance (FD) Tolerance : 1) 1/2"(15NB) to 6"(150NB) : +/-3mm

2) 8"(200NB) to 24"(600NB) : +/-5mm

ELECTRONET

ELECTROMAGNETIC FLOW METER

ELMAG-200

0000.00 m3/Hr

000000.02 m3 L

200

1 ¼ ”

32 117.5

4

63.5

15.9

15.9

88.9

155

ELECTRONET

UM-ELMAG 200-R3 PAGE 07 OF 34

7. KEY BOARD DETAILS

8. TERMINATION DETAILS

P

Program Key : This key is used to toggle between Run mode and Program mode.

Increment Key : This key is used to :-

1) Increment the numerical value of any digit, from 0 to 9, by one at

each time.

2) Go to the next parameter in Program mode.

3) To start Batch operation

Shift Key : This key is used to :-

1) Shift the cursor to the next digit.

2) To stop Batch operation

Enter Key : This key is used to :-

1) Validate the function or value of parameter.

2) To toggle between totaliser & batch totaliser in batch mode.

3) Press this key for 5 to 6 sec. to reset totaliser

Fig 5 . 24V DC operated flowmeter Rear View

Fig 4 . 230V AC operated flowmeter Rear View

P

NO

NC

1

8

2

9

3

10

4

11

13

7

5

12

14

4-20 mA DC

RET. OUTPUT

L

N

E

230V AC

Power Supply

6

NA

Not Applicable

T1

T2

T3

R

S

4

8

5

R

S

2

3

2

G

S

M

Relay O/P

For

Alarm

I+

+

I-

GND

OC

PULSE

O/P OF

12V DC

AMPLITUDE

Open

Collector

Output

T1

A TXD

T2

B RXD

T3

GND GND

RS 485

RS 232 /

GSM

P

NO

NC

1

8

2

9

3

10

4

11

13

7

5

12

14

4-20 mA DC

RET. OUTPUT

+

-

NA

24V DC

Power Supply

6

NA

Not Applicable

T1

T2

T3

R

S

4

8

5

R

S

2

3

2

G

S

M

Relay O/P

For

Alarm

I+

+

I-

GND

OC

PULSE

O/P OF

12V DC

AMPLITUDE

Open

Collector

Output

T1

A TXD

T2

B RXD

T3

GND GND

RS 485

RS 232 /

GSM

NONCNA

P

NOT

APPLICABLE

T2T3T1

RS485

RS232

GSM

I-I+

GND

+

OC

PULSE O/P

OF12V DC

AMPLITUDE

T1

T2

T3

RS485

RS232

GSM

A

B

GND

TXD

RXD

GND

230V AC

POWER

SUPPLY

L

N E

1 2

3

4

5

6 7 98 10

11 121314

NONCNA

P

NOT

APPLICABLE

T2T3T1

RS485

RS232

GSM

I-I+

GND

+

OC

PULSE O/P

OF12V DC

AMPLITUDE

T1

T2

T3

RS485

RS232

GSM

A

B

GND

TXD

RXD

GND

24V DC

POWER

SUPPLY

+

-

NA

1 2

3

4

5

6 7 98 10

11 121314

Loading...

Loading...