Table of Contents

Terms and Conditions......................................................................... 5

Electromotive Product Warranty ...............................................................................................5

Warranty Replacement ..............................................................................................................5

Warranty Coverage....................................................................................................................5

Length of Warranty....................................................................................................................5

Who the Warranty Protects........................................................................................................5

Warranty Exclusions..................................................................................................................6

How to Obtain Warranty Service ..............................................................................................6

Limitation of Implied Warranties ..............................................................................................7

Exclusion of Damages ...............................................................................................................7

Forward................................................................................................ 8

A. Installing the TECgt System.......................................................... 9

A.1. How it All Works: The Two Pages You Need to Read ....................................................9

A.2. Pre-Installation Checklist................................................................................................10

A.3. Mounting the Main Computer and DFU.........................................................................11

A.4. Trigger Wheel and Sensor Installation ...........................................................................12

A.4.a. Crankshaft Trigger Installation for 60(-2) Tooth Wheel .............................................12

A.4.b. Magnetic Crank Sensor Installation.............................................................................13

A.4.c. Wiring the Magnetic Sensor ........................................................................................15

A.4.d. Verifying Trigger Wheel Timing.................................................................................15

A.4.e. Camshaft- & Distributor-Mounted Trigger Setups......................................................17

A.4.f. Full Sequential Applications – Cam Synchronization..................................................17

A.4.g. TDC Tooth Setup Software Adjustment Parameters...................................................19

A.5. Wiring the TECgt............................................................................................................21

A.5.a. TECgt - Main Power Connections ...............................................................................21

A.5.b. Power Harness Installation ..........................................................................................21

A.5.c. Wiring the Fuel Injectors .............................................................................................23

A.5.d. Wiring the DFU’s ........................................................................................................24

A.5.e. Wiring the Engine Sensors...........................................................................................24

B. Tuning Guide ............................................................................... 25

Introduction..............................................................................................................................25

B.1. Adjusting the Timing Advance .......................................................................................25

B.2. Establishing Proper Starting Enrichments ......................................................................26

B.3. Getting the Engine to Idle ...............................................................................................27

B.4. Establishing Proper Acceleration Enrichments...............................................................27

B.5. Adjusting the VE Table...................................................................................................28

B.6. Using TPS/MAP Blend...................................................................................................29

B.7. Tuning for Cold Engines and Cold Weather...................................................................29

B.8. Tuning the Idle Air Control Motor .................................................................................30

B.8.a Configuring the New Electromotive Idle Speed Control .............................................30

B.8.b. Idle Speed primer ........................................................................................................31

B.8.c. Getting Started..............................................................................................................31

B.8.d. Error Sensitivity ...........................................................................................................32

B.8.e. RPM Rate-of-Change Sensitivity.................................................................................32

B.8.f. Wiring a 2-wire IAC:....................................................................................................33

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 1 - ©2008 Electromotive, Inc.

B.8.g. Wiring a 3-wire IAC: ...................................................................................................33

B.9. Tuning the Knock Control ..............................................................................................34

B.10. Using the Injector Trims ...............................................................................................34

B.11. Using the Ignition Advance Trims................................................................................35

B.12. Tuning the EGO Sensor ................................................................................................35

C. Direct Fire Units (DFU’s) ........................................................... 36

Introduction..............................................................................................................................36

C.1. Wiring the DFU’s............................................................................................................37

C.2. DFU to Spark Plugs ........................................................................................................38

C.3. Spark Plug Wire Routing ................................................................................................40

C.3.a. Common Engine Setups ...............................................................................................41

C.3.b. Special Note for Coil-Per-Plug Applications...............................................................41

C.4. Coil and Injector Firing Schemes....................................................................................42

C.4.a. Injector and Coil Firing Patterns for EVEN-FIRE Engines.........................................42

C.4.b. Injector and Coil Firing Patterns for ROTARY Engines.............................................43

C.4.c. Injector and Coil Firing Patterns for 2-CYCLE Engines .............................................43

C.4.d. Injector and Coil Firing Patterns for ODD-FIRE Engines...........................................43

C.4.e. Examples of Typical Engine Setups.............................................................................44

C.5. Common Firing Orders ...................................................................................................46

C.5.a. To find the TDC Event Order : ....................................................................................47

C.5.b. TDC Tooth for DFU “2” needed for an Odd-Fire Engine: ..........................................47

C.5.c. Harley-Davidson Applications.....................................................................................47

C.6. Rotary Engines................................................................................................................47

C.7. Dual Plug Engines...........................................................................................................48

C.8. Spark Plug Wire Selection ..............................................................................................48

C.9. Spark Plug Selection .......................................................................................................49

D. Fuel Injector Configurations ...................................................... 50

D.1. High vs. Low Impedance Injectors .................................................................................50

D.2. Injector Firing Schemes ..................................................................................................52

D.2.a. Staged Injection............................................................................................................52

D.2.b. Throttle Body Injection (TBI)......................................................................................53

D.2.c. Phase-Sequential Injection...........................................................................................54

D.2.d. Full Sequential Injection..............................................................................................55

D.2.e. Rotary Engine Injection ...............................................................................................56

D.3. Injector Wiring................................................................................................................56

D.4. Fuel Injector Pulse Width Derivation .............................................................................57

D.4.a. Introduction..................................................................................................................57

D.4.b. Time on for One Gama (TOG) ....................................................................................59

D.4.c. Injector Offset Time (IOT) ..........................................................................................62

D.4.d. Volumetric Efficiency Table Corrections....................................................................64

D.4.e. TPS/MAP Blend Corrections.......................................................................................65

D.4.f. Oxygen Sensor Corrections..........................................................................................67

D.4.g. Warm-Up Enrichments (Coolant Temperature-Based) ...............................................69

D.4.h. Manifold Air Temperature Enrichments......................................................................70

D.4.i. Throttle Position Sensor and MAP Enrichments..........................................................70

D.4.j. Starting Enrichments ....................................................................................................72

D.4.k. Battery Voltage Compensation....................................................................................73

D.4.l. Deceleration Fuel Cut-Off ............................................................................................73

D.4.m. Summary.....................................................................................................................74

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 2 - ©2008 Electromotive, Inc.

E. Fuel System .................................................................................. 74

E.1. Injector Sizing .................................................................................................................75

E.2. Fuel Pump Selection........................................................................................................79

E.3. Fuel Pressure Regulator Selection...................................................................................79

F. TECgt Output Functions and Wiring ....................................... 80

F.1 Idle Air Control Motor .....................................................................................................80

F.2. Tachometer Output..........................................................................................................82

F.3. The Fuel Pump Relay Output ..........................................................................................82

CAUTION: ..............................................................................................................................83

G. TECgt Input Functions and Wiring ........................................ 84

G.1. The Manifold Air Pressure (MAP) Sensor C B A .......................................................84

G.2. Throttle Position Sensor..................................................................................................87

TPS Functionality and Wiring.................................................................................................88

G.3. Coolant Temperature Sensor ..........................................................................................89

G.4. Manifold Air Temperature Sensor..................................................................................91

G.5. The Exhaust Gas Oxygen Sensor....................................................................................92

Mounting the Sensor................................................................................................................92

G.6. Wideband O2 Sensor ......................................................................................................94

FAQ’s and Troubleshooting Tips: ...........................................................................................95

G.7. Knock Sensor..................................................................................................................96

H.1. The General Purpose Inputs (GPI’s) and General Purpose Outputs

(GPO’s) or GP I/O’s.......................................................................... 97

H.1.a. Available General Purpose Input (GPI) Functions : ...................................................98

H.1.b. Wiring the GPI’s..........................................................................................................99

H.1.c. GP I/O Wiring Harness Layout..................................................................................100

H.2. General Purpose Output (GPO) functions : ..................................................................101

H.2.a. Available GPO Functions ..........................................................................................101

H.2.b. Wiring the GPO’s: .....................................................................................................102

I. Diagnostics................................................................................... 104

I.1. Trouble Codes from the LED’s Mounted on the TECgt ................................................104

I.2. Trouble Codes from the Check Engine Output ..............................................................105

Trouble Code Descriptions ....................................................................................................106

I.2.a. Using the Trouble Codes .............................................................................................107

I.2.b. Wiring the Check Engine Light...................................................................................108

J. Data logging with the TECgt..................................................... 108

J.1. PC-Based Data logging ..................................................................................................109

J.2. On-Board Data logging ...................................................................................................109

K. Rev Limiters .............................................................................. 109

K.1. Valet Mode Rev Limiter...............................................................................................110

K.2. Secondary Rev Limiter : ...............................................................................................110

K.3. Primary Rev Limiter :...................................................................................................110

L. Timing Control ........................................................................... 110

L.1. Zero degree advance......................................................................................................110

L.2. 3-stage coil cut ..............................................................................................................110

L.3. FUEL CONTROL .........................................................................................................111

L.3.a. No Fuel Cut ................................................................................................................111

L.3.b. Fuel Cut ......................................................................................................................111

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 3 - ©2008 Electromotive, Inc.

L.3.c. Progressive Fuel Cut...................................................................................................111

M. Troubleshooting........................................................................ 111

M.1. Air, Fuel, and Spark .....................................................................................................111

M.2. Starting Problems.........................................................................................................111

M.2.a. Air-Related Starting Problems ..................................................................................111

M.2.b. Fuel-Related Starting Problems ................................................................................112

M.2.c. Spark-Related Starting Problems ..............................................................................112

N.1. Idling Problems.............................................................................................................113

N.1.a. Air-Related Idling Problems ......................................................................................113

N.1.b. Fuel-Related Idling Problems ....................................................................................113

N.1.c. Spark-Related Idling Problems ..................................................................................113

O.1. Low-, Medium-, and High-Load Problems ..................................................................113

O.1.a. Air-Related Load Problems .......................................................................................113

O.1.b. Fuel-Related Load Problems .....................................................................................114

O.1.c. Spark-Related Load Problems ...................................................................................114

P.1. Summary of Troubleshooting Topics............................................................................114

Appendix I. Electromotive TECgt ECU Specifications .......................................................114

OUTPUTS .............................................................................................................................114

INPUTS .................................................................................................................................115

Tuning Features .....................................................................................................................116

Supported Engine Management Configurations....................................................................117

Data logging Features............................................................................................................117

Physical Dimensions..............................................................................................................117

Environmental Considerations...............................................................................................118

PC Requirements ...................................................................................................................118

Appendix II. Electromotive Trigger Wheel Availability......................................................118

Appendix III. Secondary Coil Polarity for Redundant Ignition Applications......................120

Appendix IV. TECgt Custom Harness Specification Sheet .............................................121

Appendix V. TECgt Custom Harness Spec. Sheet continued : ........................................122

Software Coding Information ................................................................................................123

Firmware Coding Information...............................................................................................123

Software Upgrade Procedure.................................................................................................123

Firmware Upgrade Procedure................................................................................................124

Appendix VI. TECgt

Gray Connector......................................................................................................................125

Appendix VII. TECgt Wiring Harness Layout.................................................................127

Appendix VIII. TECgt Power Harness Schematic ..........................................................128

Connector Pin Out Summary.............................................................125

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 4 - ©2008 Electromotive, Inc.

Terms and Conditions

Electromotive Product Warranty

Only products Manufactured by Electromotive are covered by Electromotive’s limited warranty for

a period of one-year from date of shipment by Electromotive.

Products not manufactured by Electromotive are expressly excluded from any consideration under these

terms – for information regarding products not manufactured by Electromotive you must contact the

specific product’s manufacturer.

Whenever possible, Electromotive attempts to replace defective products rather than repair them.

Replacement puts the "Customer First" and offers many benefits over repair; the greatest benefit being the

timeliness of the replacement process. However, in some cases, replacement with a ‘like new’ refurbished

product is not possible, and a warranty repair situation occurs. In these situations, Electromotive strives to

keep our repair times to a minimum (on average 2 to 3 business days upon receipt - excluding the necessary

shipping time). Customers should follow the appropriate steps outlined below to initiate a warranty

replacement or repair.

Warranty Replacement

Contact Electromotive Technical Support at 1-703-331-0100 9am to 5pm Eastern Time. The

customer must have the serial number and original proof-of-purchase available. Electromotive’s Technical

Support staff will attempt to help you correct any minor issues that might be causing the problem. If we are

unable to fix the issue to your satisfaction, a return merchandise authorization (RMA) number will be

issued. Under our Warranty program, Electromotive will typically ship the customer a replacement unit on

the same day the defective product arrives.

The replacement product will assume the remainder of your original product's warranty or 90 days,

whichever is greater.

Warranty Coverage

Electromotive warrants its products to be free from defects in material and workmanship during the

warranty period. If a product proves to be defective in material or workmanship during the warranty period,

Electromotive will, at its sole option, repair or replace the product with a similar product. Replacement

product or parts may include remanufactured or refurbished parts or components.

Length of Warranty

Electromotive products are warranted for one (1) year parts and one (1) year labor. Warranty begins

upon date of shipment from Electromotive.

Who the Warranty Protects

This warranty is valid only for the purchaser from Electromotive.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 5 - ©2008 Electromotive, Inc.

Warranty Exclusions

1. Any product, on which the serial number has been defaced, modified or removed.

2. Damage, deterioration or malfunction resulting from:

A. Accident, misuse, neglect, fire, water, lightning, or other acts of nature, unauthorized

product modification, or failure to follow instructions supplied with the product.

B. Repair or attempted repair by anyone not authorized by Electromotive.

C. Any damage of the product due to shipment.

D. Removal or installation of the product.

E. Causes external to the product, such as electric power fluctuations or failure.

F. Use of supplies or parts not meeting Electromotive’s specifications.

G. Any other cause, which does not relate to a product defect.

3. Removal, installation, and set-up service charges.

4. Shipping Charges.

5. Any warranty of merchantability, express or implied, is excluded except as otherwise set forth

herein.

6. There are no warranties that extend beyond the description on the face of this document.

7. There are no warranties of fitness for a particular purpose except as stated on the face of this

“Electromotive Product Warranty”.

8. Any and all oral warranties are excluded and will not be honored.

9. Consequential damages will not be covered by this warranty.

How to Obtain Warranty Service

1. For information on warranty service, contact your Electromotive Value Added Dealer or call

Electromotive Technical Support at 1-703-331-0100 from 9am to 5pm Eastern Time Monday

through Friday - e-mail [support@electromotive-inc.com]. To obtain warranty service, you will

be required to provide:

a. Original dated sales receipt

b. Your name

c. Your address

d. The serial number of the product

e. A description of the problem

f. Contact information (daytime phone number or email address)

2. Take or ship the product in the original or a suitable replacement container to:

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 6 - ©2008 Electromotive, Inc.

Electromotive, Inc.

9131 Centreville Road

Manassas VA 20110

Limitation of Implied Warranties

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, WHICH EXTEND BEYOND

THE DESCRIPTION CONTAINED HEREIN INCLUDING THE IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusion of Damages

ELECTROMOTIVE’S LIABILITY IS LIMITED TO THE COST OF REPAIR OR

REPLACEMENT OF THE PRODUCT. ELECTROMOTIVE SHALL NOT BE LIABLE FOR:

1. DAMAGE TO OTHER PROPERTY CAUSED BY ANY DEFECTS IN THE

PRODUCT, DAMAGES BASED UPON INCONVENIENCE, LOSS OF USE OF

THE PRODUCT, LOSS OF TIME, LOSS OF PROFITS, LOSS OF BUSINESS

OPPURTUNITY, LOSS OF GOODWILL, INTERFERENCE WITH BUSINESS

RELATIONSHIPS, OR OTHER COMMERCIAL LOSS, EVEN IF ADVISED OF

THEIR POSSIBILITY OF SUCH DAMAGES.

2. ANY OTHER DAMAGES, WHETHER INCIDENTAL, CONSEQUENTIAL OR

OTHERWISE.

3. ANY CLAIM AGAINST THE CUSTOMER BY ANY OTHER PARTY.

4. SHIPPING CHARGES.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 7 - ©2008 Electromotive, Inc.

Forward

The TECgt Total Engine Control system is the latest ignition system in the expanded line of ultrahigh resolution engine management systems from the company that revolutionized engine management

over twenty years ago. The TECgt can be configured to control virtually any 1-, 2-, 3-, 4-, 6-, or 8

cylinder engine, as well as 1 or 2-rotor rotary engines, and dual plug 4 cylinder. The heart of the TEC

series of engine management systems has always been a high-resolution ignition, which offers incredibly

precise ignition timing even at the highest acceleration rates. The TECgt continues this tradition; only

what was once done with an analog ignition circuit is now done with a high-speed microprocessor. Direct

Fire Units (DFU’s) with twin-tower coils are available from Electromotive in 2- and 3-coil versions. Single

tower coils are available as well. These DFU’s are completely weather proof, and feature sealed electrical

connectors. Additionally, the DFU’s are impedance matched for optimum performance with our TECgt.

The TECgt with six dedicated fuel channels and drivers also covers fuel control. This allows up to

12 low or high impedance injectors to be driven. Staged injector firing is a built-in option on the TECgt

for most engine configurations. Sequential operation is also available through the use of a cam position

sensor but sequential operation is not available for the 8 cylinder engine option on the TECgt.

There are Nine dedicated, user-definable, general-purpose inputs / outputs (GP I/O’s) included with

the TECgt to make your high-tech engine setup a snap. The GP I/O’s can be used to control anything from

wastegates for turbo setups to simple electric radiator or intercooler fans. The possibilities are nearly

limitless.

One of the GPI’s has a frequency-based input capability, which can process data from wheel a

speed sensor or similar device. The other GPI’s are analog inputs only, and do not feature frequency-based

capabilities. These channels can perform fuel trims, timing trims, and many other functions.

Besides the GP I/O’s, several functions are built-in to the TECgt that are quite useful on most

applications. The following outputs are standard on the TECgt:

Tachometer (configurable to drive most modern tachs)

Check Engine Light

Fuel Pump Relay Ground (activated at appropriate times by the TECgt)

Idle Speed Motor control (stepper motor style or 2-wire style)

The TECgt uses the following inputs to perform engine management:

Crank Trigger

Cam Trigger (optional)

Manifold Air Pressure

Coolant Temperature Sensor

Manifold Air Temperature Sensor

Throttle Position Sensor

Knock Sensor (optional)

Exhaust Gas Oxygen Sensor (O

sensor)

2

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 8 - ©2008 Electromotive, Inc.

A. Installing the TECgt System

A.1. How it All Works: The Two Pages You Need to Read

The goal behind Electromotive’s Total Engine Control product line is to provide complete, highresolution control of all functions of the modern engine, and to do so with a user-friendly interface.

Consequently, the TECgt is designed to easily control a huge number of complex engine management

functions through the hands of a user who is new at the game.

Engine Speed & Position = Crank Sensor…

What separates our engine management systems from those of our competitors is the fact that our

products are all designed around an ultra high-resolution ignition. For this reason, we use a 60(-2) tooth

crank trigger wheel to give the computer an extremely accurate engine position input. This is also the

reason that we do not support any other types of trigger inputs. Take, for instance, the flying magnet

trigger input used by some manufacturers: 8 cylinder engines have 4 magnets mounted to the crank trigger

wheel. Our 60(-2) tooth trigger has 15 TIMES MORE RESOLUTION! From a magnetic sensor aimed at

the trigger wheel, the TECgt receives its input for engine speed and position.

Engine Load = MAP Sensor…

As nice as the 60(-2) tooth trigger wheel is for determining engine speed and position, more is

necessary to perform ignition and fuel control; namely a load input. While many OEM’s use Mass Airflow

(MAF) sensors to determine the airflow (and thus the load) of an engine, Electromotive systems are

designed around Manifold Air Pressure (MAP) sensors as the load-determining device. MAP sensors

simply plug into the intake manifold of the engine (after the throttle), and are inherently easier to install

than MAF sensors since they are not sensitive to vacuum leaks or engine airflow requirements. A 1-Bar

MAP sensor is designed for naturally aspirated engines. A 2-Bar sensor is used for turbo/supercharged

engines with up to 15psi (about 200kPa absolute) manifold boost. A 3-Bar sensor is good for up to 30psi

(300kPa), while a 4-Bar is good for up to 45psi (400kPa). Choose the appropriate sensor for the

application, and you are done.

Ignition Advance Control…

Once the MAP sensor and crank sensor are installed, the TECgt has inputs for RPM and load.

Under steady-state conditions on a fully warmed-up engine, these are the only necessary inputs for the

TECgt to control the fuel and ignition curves. Control of the ignition advance curve is quite simple: there

is a table of RPM vs. MAP in which the desired ignition advance angle is entered for every point. The

table can be made in any size from 8

interpolation occurring. This keeps the advance curve from “stepping” from point-to-point. Additionally,

it means that the engine can be tuned with only a few input numbers; some other systems on the market

rely on the tedious input of hundreds of numbers to obtain an ignition advance curve that is still not as

smooth between data points as ours.

Fuel Injector Control…

Control of the fuel curve is very simple as well. When the user first sets up a calibration, the

Tuning Wizard is generally used. The Wizard asks for the engine horsepower, peak RPM, number of

injectors, and the amount of manifold boost. From these, a raw fuel curve is established. Most

importantly, the User Adjustable Pulse Width (UAP/TOG) is established. UAP/TOG is the fuel injector

pulse width when the MAP sensor reading is full-scale (wide-open throttle on a 1-Bar MAP sensor, 15psi

boost on a 2-Bar sensor, etc.). The second variable that is established is the Injector Offset Time (IOT).

IOT and TOG can be thought of as the idle adjustment screw and the main power jet of a carburetor,

x8 to 16x16 data points. Between each data point, there is a 256 point

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 9 - ©2008 Electromotive, Inc.

respectively. From these two numbers, a fundamental fuel curve is established. However, the

fundamental fuel curve only works on a thermodynamically linear engine. A thermodynamically linear

engine would have a torque curve that is a flat horizontal line from idle to redline. In reality, engines stray

from this straight line, sometimes dramatically, as in the case of motorcycle engines. To compensate for

non-linear fuel consumptions, a Volumetric Efficiency (VE) table is included in the software. The VE

table is based on RPM and MAP readings (like the Advance Table) to provide fuel injector pulse width

offsets for various loads and engine speeds that stray from linear.

Compensations…

Having a warmed-up engine running under steady-state conditions is all well and good, but in the

real world, we must deal with cold weather starting, engine accelerations and decelerations, etc. For these

scenarios, engines need fuel and spark compensations. The coolant temperature sensor (CLT) provides an

input for the TECgt to measure the engine temperature. Since cold engines need more fuel than hot

engines, tables are provided in the software to allow fuel flow increases as a function of engine

temperature. Other parameters related to the coolant temperature are cold starting (cranking) enrichments

and throttle movement enrichments when cold. A Manifold air temperature (MAT) sensor is mounted in

the intake tract to measure incoming air temperature. This reading is used to supply additional fuel for cold

weather, or to take away some fuel on hot days. The throttle position sensor (TPS) is used for functions

similar to the accelerator pump on a carburetor. Also, the TPS reading is used in the TPS-MAP Blend

routine, which is very useful for multiple throttle setups and radically-cammed engines.

Additional Features…

Once all the necessary input sensors are in place, and the software is tuned, the engine will run quite

well. However, to further refine the control of the engine, a few additional features are included. The idle

air control motor (IAC) is used to meter air into the engine at idle. This helps maintain a smooth idle,

regardless of operating conditions. It can also be used to increase the idle for cold temperatures, or air

conditioner activation. A fuel pump output is also included, which allows the user to turn on the fuel pump

relay for a set amount of time when the ignition is turned on. This primes the fuel system, and powers the

fuel pump once the engine is cranked and running. A tachometer output is included, which will drive most

modern tachometers, and a check engine output is included to keep track of failed engine sensors. A host

of other engine input and output options are included as well, and are outlined in other areas of this manual.

A.2. Pre-Installation Checklist

To perform a complete TECgt installation, the following items are required:

1. TECgt Computer

2. DFU(s)

3. Resistor Core Spark Plug Wires (see notes on Spark Plug Wires)

4. TECgt Wiring Harness w/ Power Harness

5. Windows-based PC-type Computer (see notes on Computer Requirements)

6. Serial Connector Cable (DB9) for PC

7. Crank Position Sensor (Magnetic Sensor)

8. 60 (-2) Tooth Crank Trigger Wheel or 120 (-4) Tooth Cam Trigger Wheel

9. Coolant Temperature Sensor (CLT)

10. Manifold Air Temperature Sensor (MAT)

11. Manifold Air Pressure Sensor (MAP)

12. Throttle Position Sensor (TPS)

13. Exhaust Gas Oxygen Sensor (EGO)

14. Idle Air Control Motor (IAC)

15. Knock Sensor (KNK)

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 10 - ©2008 Electromotive, Inc.

16. Fuel Rail(s) and Fuel Pressure Regulator (see notes on Fuel Pressure Regulator)

17. High Pressure Electric Fuel Pump (see notes on Fuel Pump)

18. Fuel Injectors (see notes on Fuel Injectors)

19. Fuel Injector Wiring Harness

20. Throttle

21. Wire Terminal Crimping Tool (available from Electromotive)

22. Shrink Tubing

23. Assorted Wire Crimp Terminals

24. Drill

25. ¼” Bolts for DFU(s) & TECgt ECU

26. Soldering Gun

A.3. Mounting the Main Computer and DFU

For utmost reliability, install the TECgt computer where temperatures will not exceed 150

o

(65

C). It is recommended that the TECgt computer be installed in the passenger compartment of the

vehicle where it will not be exposed to the elements. A good location is in the kick panel of a vehicle

originally equipped with a factory ECU. If the TECgt must be mounted in an area that is partially exposed

to the elements, there should not be a problem; the circuit board is completely sealed for harsh environment

installations. A well vented area is recommended, particularly in engines utilizing most of the injector

channels and operating at sustained high speeds. It should be noted that the TECgt might get hot under

prolonged high-rpm operation. As long as air is moving around the ECU, there is no risk of damage to the

TECgt; just be careful not to burn yourself on the unit! Secure the TECgt ECU with four ¼” socket head

cap screws. The wiring harness should be passed through the firewall using a suitable grommet to avoid

chafing.

The DFU(s) can be placed nearly anywhere under the hood of the vehicle where the temperatures

are below 250

o

F (120oC). Since they are entirely sealed, exposure to the elements is not an issue. The

DFU Ground Wire MUST be installed to vehicle ground.

It is recommended that the ECU and DFU be separated by at least six inches for the purpose of

reducing electrical noise in the ECU.

o

F

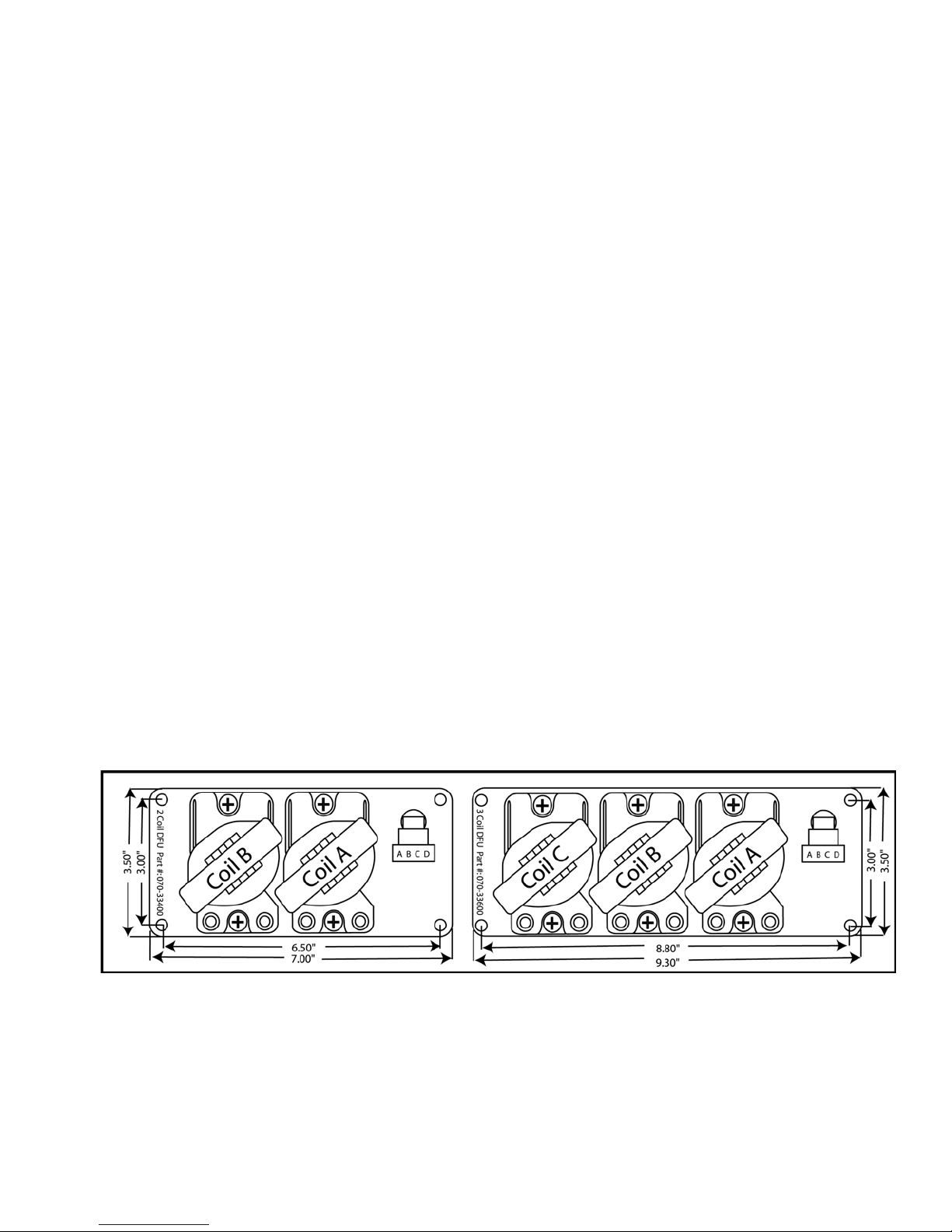

2-Coil DFU Dimensions 3-Coil DFU Dimensions

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 11 - ©2008 Electromotive, Inc.

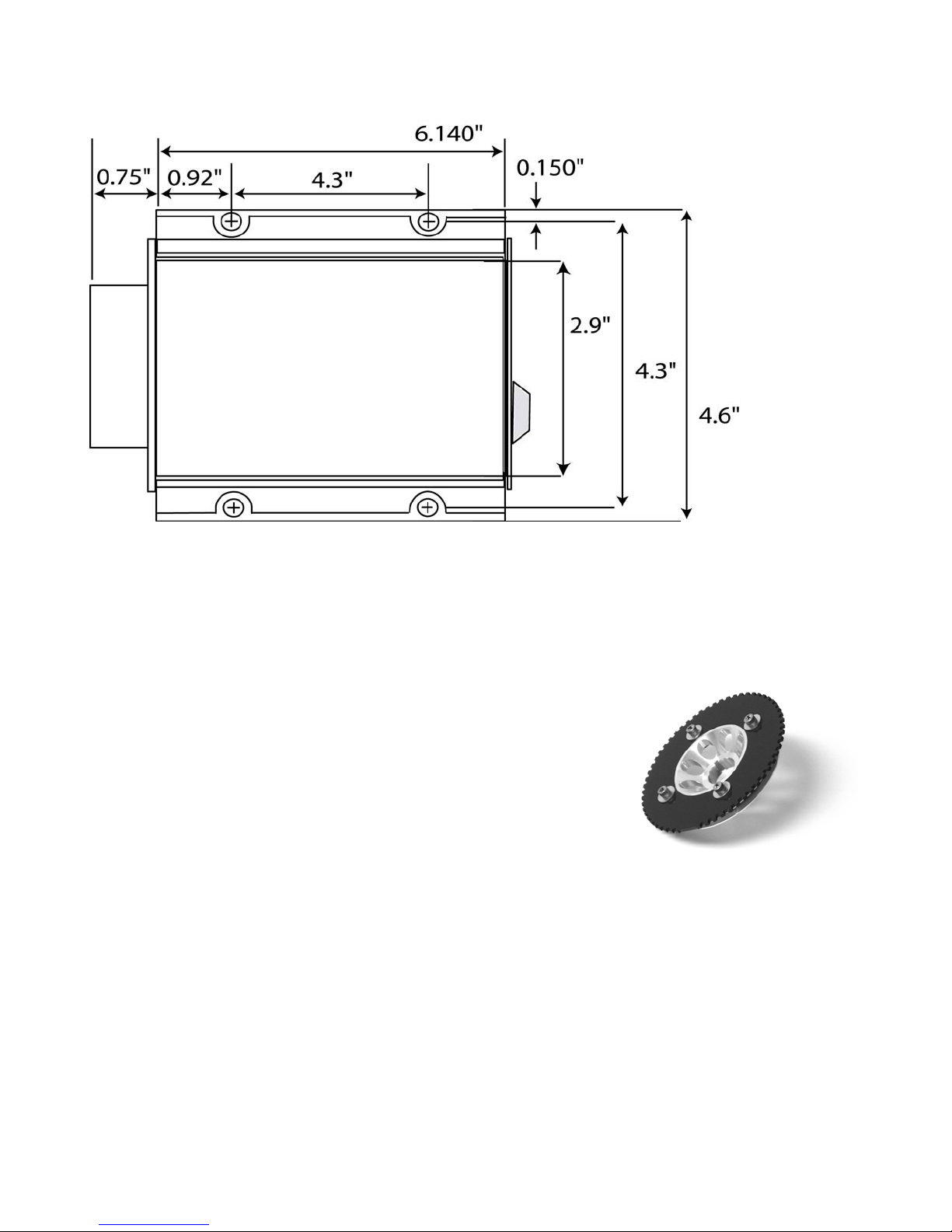

TECgt ECU Dimensions (bolt pattern is 4.3” x 4.3”)

A.4. Trigger Wheel and Sensor Installation

The foundation of the TECgt ultra-high resolution ignition is

the 60(-2) tooth trigger wheel. The trigger wheel is designed to give

uncompromising timing accuracy at the highest engine acceleration

rates. As such, Electromotive does not support other triggering

systems, particularly those of the “flying magnet” variety. These

systems can lead to vastly inaccurate spark timing, and can contribute

to engine damage. For most applications, the 60(-2) tooth trigger

wheel is mounted on the crankshaft damper or pulley. Some

applications may warrant the use of a camshaft- or distributor-mounted trigger wheel. With this setup, a

120(-4) tooth trigger wheel is necessary, since the camshaft turns at half the speed of the crank.

A.4.a. Crankshaft Trigger Installation for 60(-2) Tooth Wheel

For a crankshaft-mounted trigger wheel setup, an appropriate place must be found to mount the

wheel and trigger. Typically, the easiest place to mount a trigger wheel is on the harmonic damper or

pulley. If it is mounted on a damper, it should be mounted on the inner hub rather than the outer

dampening ring. The damper/pulley should be keyed to the crankshaft so that it cannot spin on the

crankshaft, as this would cause an ignition timing error. When using a damper that has bolt-on pulleys, the

trigger wheel can usually be mounted between the pulleys and the damper. However, the accessory pulleys

will need to be shimmed out by 1/8” (the thickness of the trigger wheel). A variety of application-specific

trigger wheels are available. See Appendix II for a listing of applications. Universal trigger wheels are

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 12 - ©2008 Electromotive, Inc.

also available in a variety of sizes, and are listed in Appendix II as well. Electromotive can custom-make

trigger wheels in nearly any configuration for a one-time tooling fee.

To choose the proper size trigger wheel, find the diameter of the pulley or damper on which the

wheel is to be mounted. The trigger wheel diameter should be about ½” larger than this diameter. It should

also be noted that the trigger wheel should be at least ¼” from any moving magnetic pieces, such as bolts

or other fasteners, to avoid interference and false triggering. It is important that the trigger wheel be

perfectly concentric with the crankshaft centerline. To achieve concentricity, a shallow cut can be

machined in the front or rear face of the damper to create a centering ledge, and a hole can be created in the

trigger wheel to match the ledge diameter. The trigger wheel can then be drilled to bolt it to the damper.

See Table A.4.1 below to determine the tolerances that must be maintained when mounting the

trigger wheel. These tolerances may require the use of a lathe to true the trigger wheel with the crankshaft

centerline, which can be accomplished by putting the entire damper/trigger wheel assembly on the lathe.

Note that the maximum out-of-round is the distance between the lowest and highest teeth and the crank

sensor. That is, if a feeler gauge is used between the sensor and the wheel to measure the out-of-round, the

reading between the lowest and highest teeth should not exceed the guidelines in the table.

Table A.4. 1: Crank Trigger Specifications

Trigger

Wheel

Size

2.5" 0.025" max 0.002"

3.5" 0.035" max 0.003"

5" 0.050" max 0.005"

6" 0.060" max 0.006"

7.25" 0.070” max 0.007"

8.25" 0.080” max 0.008"

Air Gap

Maximum

Out-of-

Round

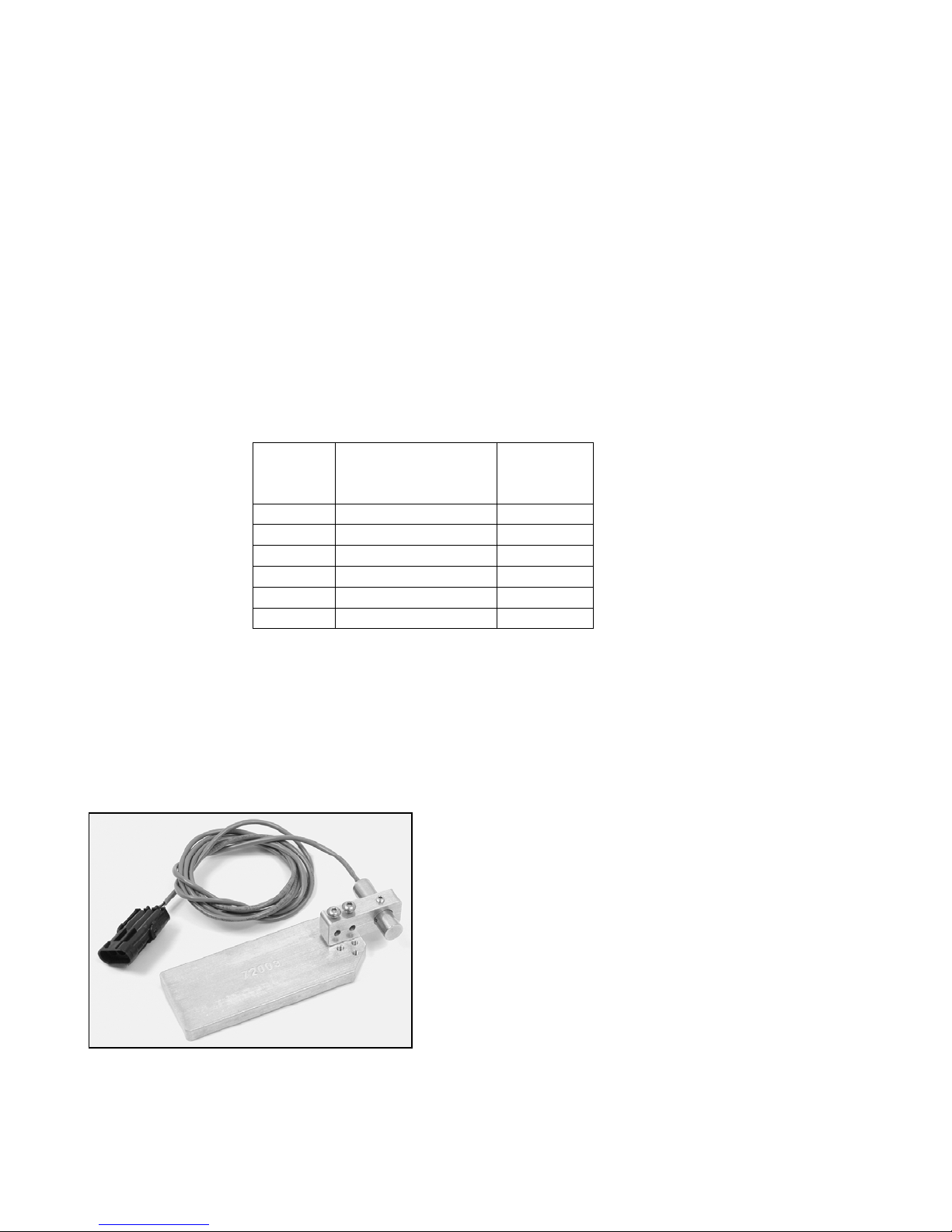

A.4.b. Magnetic Crank Sensor Installation

When installing the magnetic sensor, an appropriate bracket must be made to aim the sensor at the

trigger wheel. A good starting point for a magnetic sensor bracket is Electromotive part number 21072003, which is our universal sensor bracket (See Figure A.4. 1). If this part is not used as a starting point,

a custom bracket can easily be made. The most important things to remember when fabricating a

bracket are that it should be bolted directly to the engine block, away from rotating steel or magnetic

pieces, and should be nonferrous (not attracted to magnets). This will keep the sensor and trigger

wheel vibrating together so the gap between the two always

stays the same. Variations in sensor gap may cause erratic

timing or false triggering of the ignition. (This is the reason

for not mounting the trigger wheel to the outer ring of a

harmonic damper.) As such, any custom magnetic sensor

bracket should be very rigid. The sensor can be secured with

either a set screw or a clamping arrangement, as long as the

1/2” sensor is utilized (part number 250-72218). If the smaller

3/8” sensor is utilized, a clamping arrangement should be

employed rather than a setscrew, as the setscrews may crush

the sensor. See Table A.4. 2 for the appropriate magnetic

Fig A.4. 1: Universal Crank

Sensor Bracket

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 13 - ©2008 Electromotive, Inc.

sensor/trigger wheel combinations.

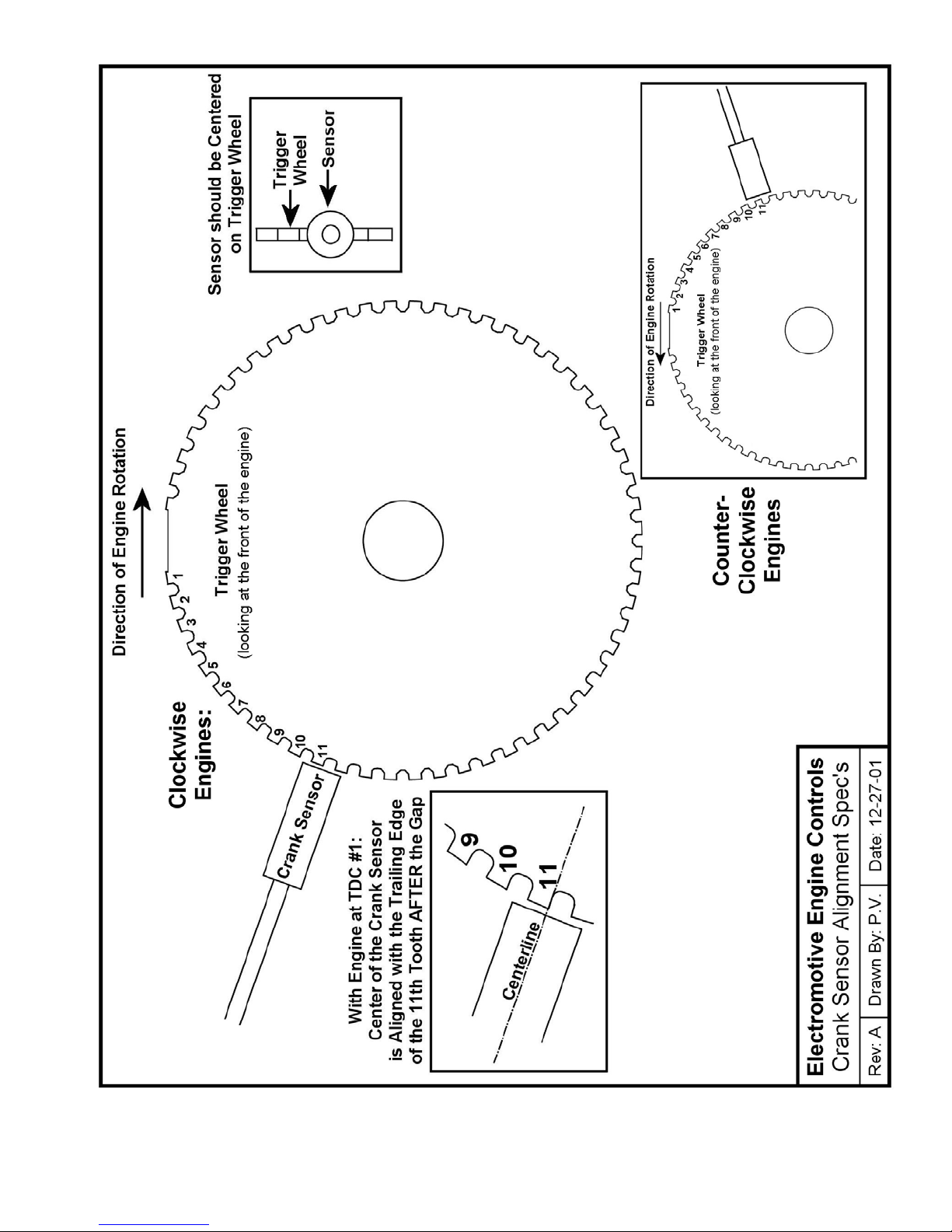

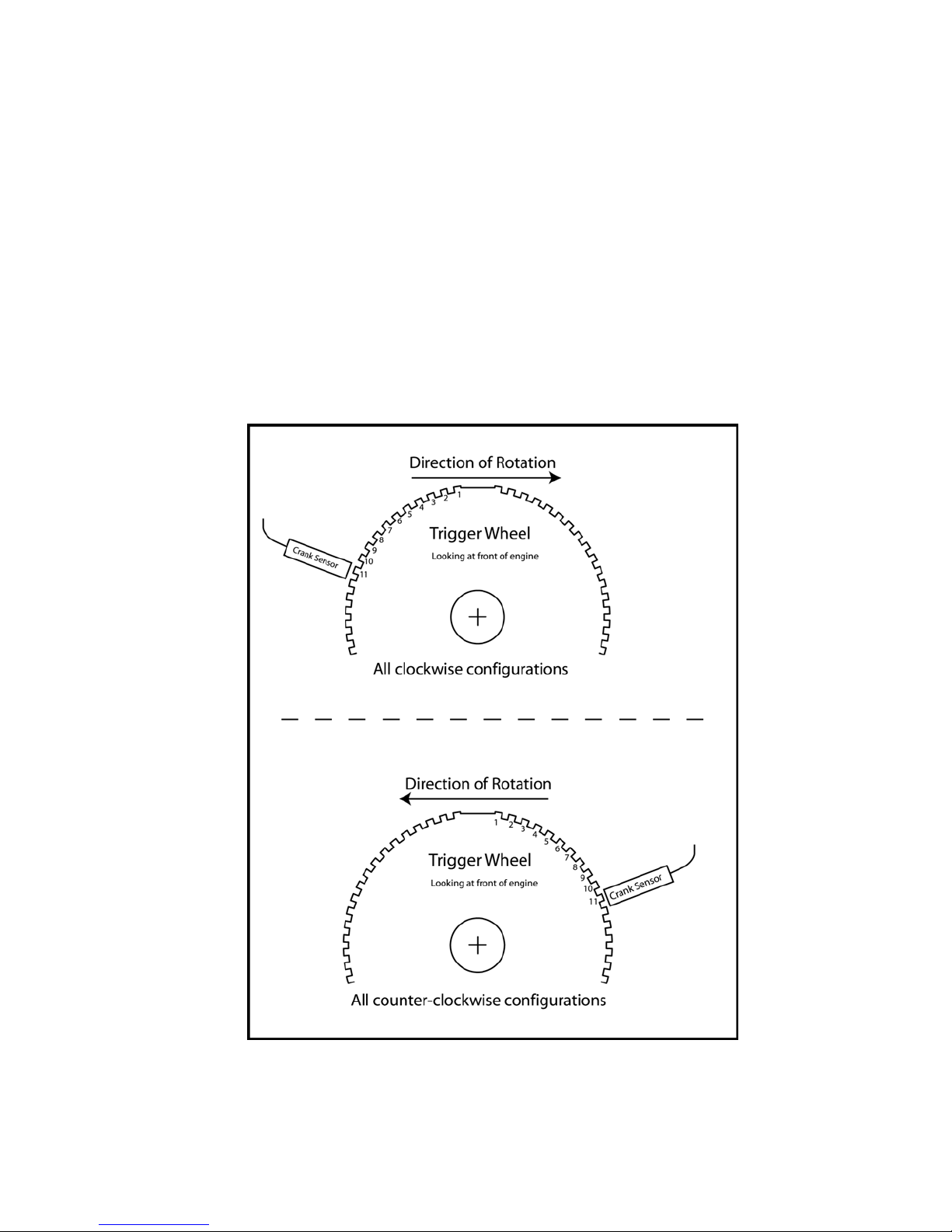

Once a magnetic sensor and trigger wheel are installed, they must be aligned such that the TECgt

computer knows where to locate Top Dead Center of the #1 cylinder (referred to as TDC #1). Correct

alignment necessitates that the center of the sensor must be aligned with the trailing edge of the 11th

tooth after the two missing teeth when the engine is at TDC #1 (see the drawing at the end of this

section). Aligning the magnetic sensor with anything other than the 11

th

tooth will cause an ignition timing

retard or advance, depending on the direction of the misalignment. Each tooth represents six degrees, so if

the sensor is aligned with the trailing edge of the 12

Conversely, if the sensor is aligned with the trailing edge of the 10

th

tooth, the timing will be advanced by six degrees.

th

tooth, the timing will be retarded by

six degrees. In the event that the sensor is not aligned correctly, the WinTec software can be made to

compensate by manipulating the Tooth Offset Parameter, as outlined in Section A.4.g of this manual.

IMPORTANT NOTE :

Make sure that the Mag. Sensor harness is NOT routed near battery cables or other high

current leads or devices such as cooling fans, starter or alternator. Coil wires, injector leads also

should be avoided.

Table A.4. 2: Magnetic crank sensor selection. Note: use a clamping arrangement for securing 3/8”

sensors, rather than a setscrew. The ½” sensors can be secured with any clamping method.

All 120 (-4) Tooth

2-3/8” & 2-1/2”

60 (-2) Tooth

3-1/2” 60 (-2) Tooth

(below 6000rpm)

3-1/2” 60 (-2) Tooth

(Above 6000rpm)

Greater than 3-1/2”

60 (-2) Tooth wheels

3/8” Diameter

Chisel Point

Sensor

PN: 250-72212

X

X

X

X

X

1/2” Diameter

Flat Tip

Sensor

PN: 255-72218

X

X

X

Fig A.4. 2: Electromotive ½” (12.7mm)

crank sensor

”

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 14 - ©2008 Electromotive, Inc.

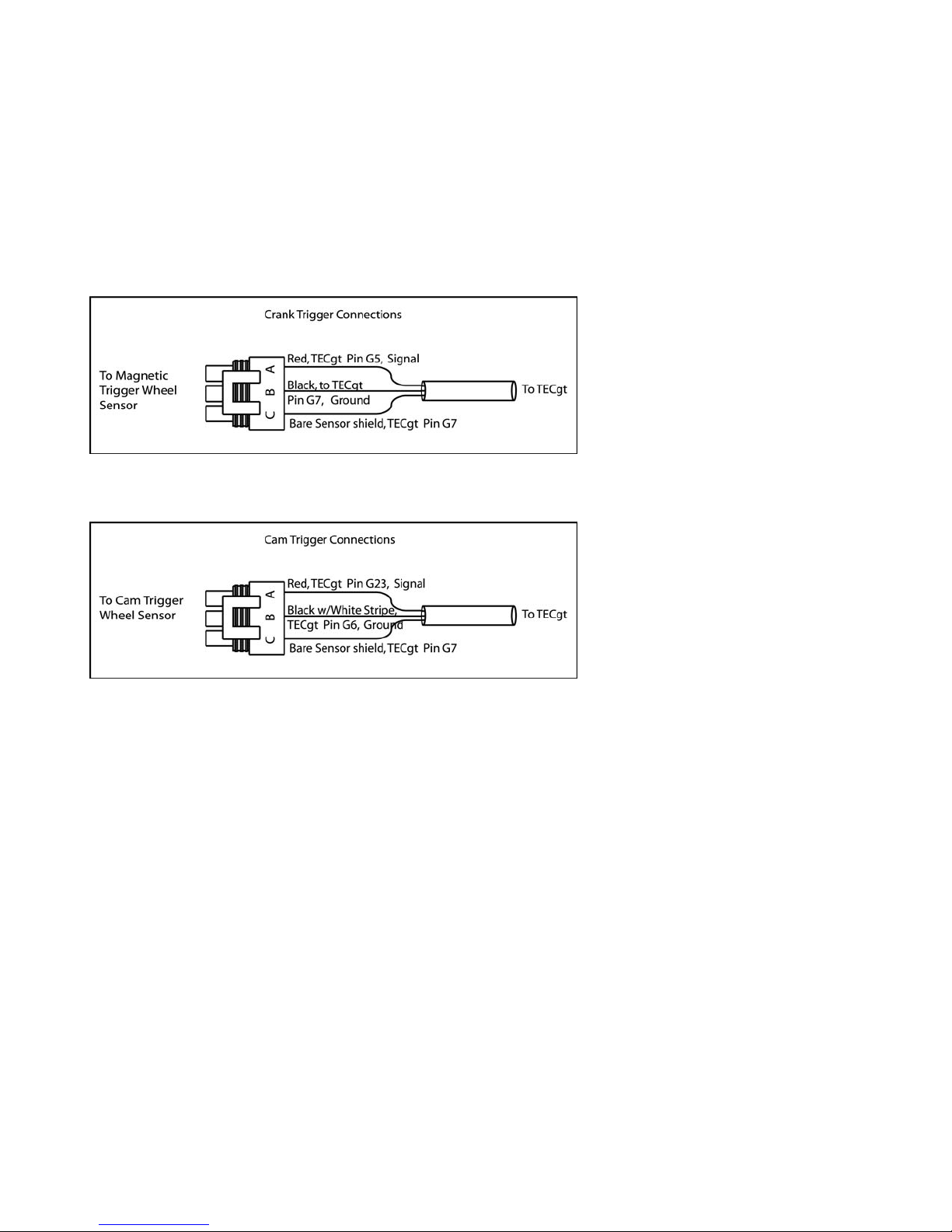

A.4.c. Wiring the Magnetic Sensor

The crank sensor has three wires. The red wire is the signal from the sensor, the black wire is the

signal ground, and the bare wire is the shield. The harness has provisions for both a crank and a cam

sensor. The crank sensor cable must be used for all 60 (-2) or 120 (-4) tooth trigger wheel inputs. The

cam sensor cable should only be used for the “sync” pulse from the cam-mounted trigger wheel on

sequential applications. If you are unsure which cable is for the crank sensor, measure the resistance

between pin G5 on the TECgt harness and the red wire coming out of both the crank and cam cables. The

wire that reads zero resistance to pin G5 is the crank sensor wire. See Figure A.4. 4 for details. Consult

the end of this section for details on sequential applications.

Figure A.4. 4: Wiring layout for crank G5 and cam G23 sensors. Note that the Cam Sensor is only used

on full sequential applications. It is NOT used on applications using the 120(-4) tooth cam trigger wheel

with no crank trigger.

A.4.d. Verifying Trigger Wheel Timing

The most important step in the trigger wheel installation process is to check the ignition advance

with a timing light. A timing indicator (pointer) should be attached to the engine block, and it should point

at a line on the crankshaft pulley or trigger wheel when the engine is at TDC #1. When running the engine,

verify that the timing value read by the timing light corresponds to the timing value in the software’s

engine monitor screen.

Use of a good-quality inductive timing light is recommended. DO NOT use a timing light that goes

between the spark plug and spark plug wire with a clamp probe. Dial-Back inductive timing lights can be

used, but will need to be dialed to DOUBLE the actual desired timing value due to the waste-spark firing of

the DFU coils. They are fooled into thinking that the timing is twice as advanced as it actually is.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 15 - ©2008 Electromotive, Inc.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 16 - ©2008 Electromotive, Inc.

A.4.e. Camshaft- & Distributor-Mounted Trigger Setups

While crankshaft mounted triggers are preferred, it is sometimes easier to install a camshaft- or

distributor-mounted trigger wheel. For these cases in which the trigger wheel is spinning at half the

engine speed, a 120(-4) tooth trigger wheel is necessary. This wheel has two sets of two missing teeth,

spaced 180 degrees apart. As such, the input to the TECgt is identical to that of the crank-mounted 60(-2)

tooth trigger wheel. Electromotive offers 120 (-4) tooth wheels in 3.25” and 2.75” diameters.

It is often easy to use an old distributor rotor to serve as the mount for a 120(-4) tooth trigger wheel.

A simple nonferrous bracket would need to be fabricated to hold the sensor. The 3/8” chisel point sensor

(PN: 250-72219) must be used on 120(-4) trigger wheels. As such, the bracket for the sensor should use a

clamping arrangement rather than a setscrew to hold the magnetic sensor. Just like the crank-mounted

trigger, the distributor/cam-mounted triggers require the sensor to be aligned with the trailing edge

of the 11

th

tooth after the two missing teeth when the engine is at TDC #1. The same tolerances that

apply to the crankshaft-mounted trigger wheels (Table A.4. 1) apply to the camshaft-mounted trigger

wheels as well.

A Note on Engines with High-Overlap Camshafts:

If your engine is equipped with a camshaft that has early intake valve openings or very long

duration, you may experience backfiring through the throttle during starting. This is caused by the intake

valves beginning to open on the exhaust stroke. Since the spark plugs fire on both the compression and the

exhaust strokes, the spark on the exhaust stroke may cause unburned fuel in the intake manifold to ignite,

resulting in a backfire.

To remedy this situation, advance the “mechanical” timing by manipulating the DFU “A” Trigger

Wheel TDC Parameter. If your crank sensor is aligned with the 11

th

tooth of the trigger wheel at TDC #1,

setting the Tooth Offset to a number LOWER than 11 will add mechanical advance. If the number “10”

was set for the Tooth Offset, the mechanical timing would be ADVANCED by 6 degrees (6 degrees per

tooth). This would require that you subtract 6 degrees from the values in your ignition advance table in

WinTec to obtain your desired advance value. That is, the timing table will have to read 30 degrees in

order for the engine to operate at 36 degrees advance. See Section A.4.g. for more details.

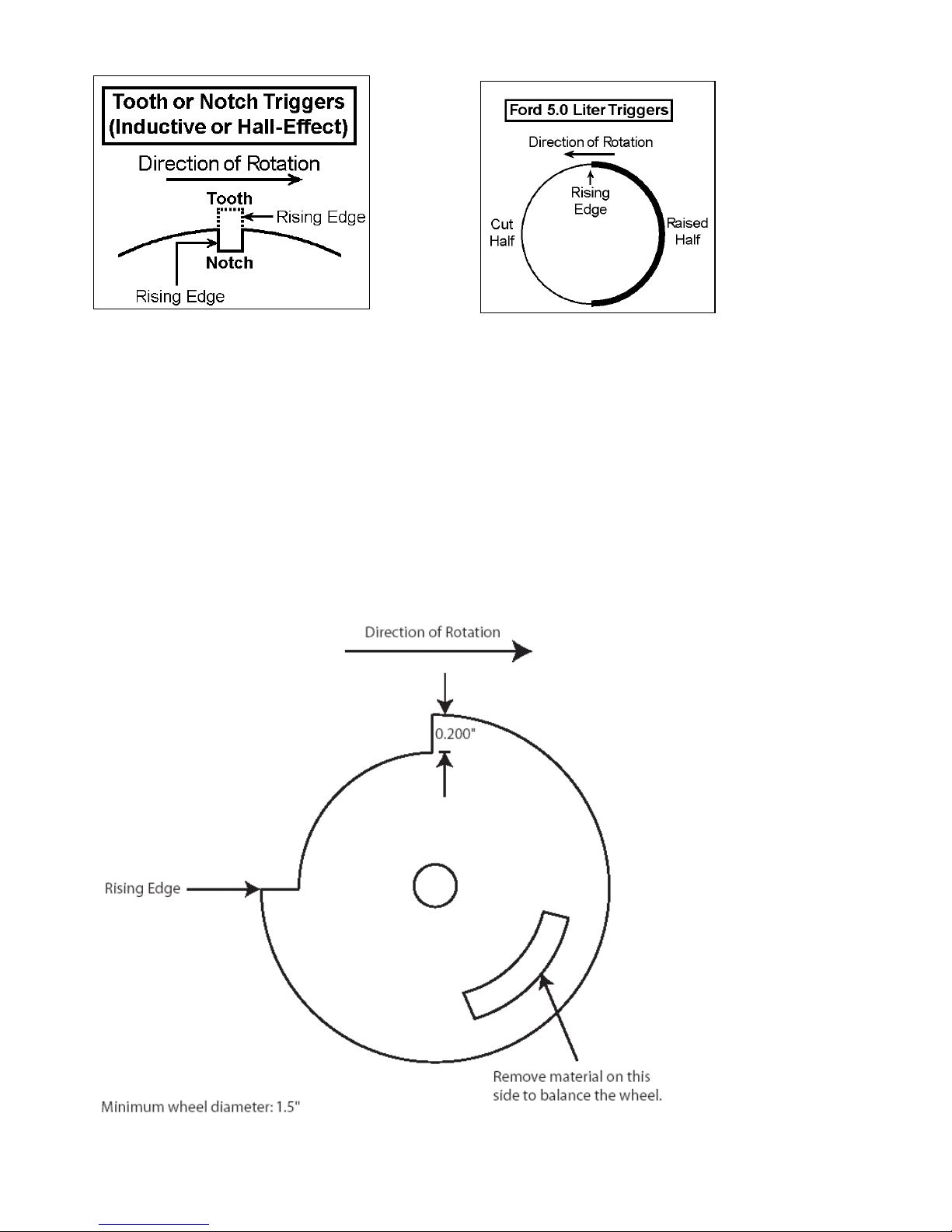

A.4.f. Full Sequential Applications – Cam Synchronization

When full sequential fuel operation is desired, a once-per-engine-cycle synchronization, or “sync,”

pulse must be received by the ECU. Typically, the sync pulse is generated by the installation of a 1-notch

(or 1-tooth) trigger wheel onto the camshaft. A standard Electromotive magnetic (inductive) sensor can

then be used to obtain the reading from this trigger wheel. A Hall effect sensor could also be used as a

triggering method instead of a magnetic sensor setup. With either method, the tooth must pass by the

magnetic sensor between 180

See Figure A.4. 7 for installation details.

The TECgt will only trigger off a rising edge during the synchronization period (between 180o

o

and 6

BTDC compression). A rising edge occurs when the metal on the cam trigger wheel becomes

closer to the sensor over a very short period of time. See Figures A.4. 6 and 7 for representative examples

and different cam trigger wheel designs, and their rising edge location.

o

and 6o before TDC Compression (not exhaust) of the number one cylinder.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 17 - ©2008 Electromotive, Inc.

Figure A.4. 6: Tooth/Notch Triggers Figure A.4. 7: Ford “Half-Moon” Trigger

Most types of sensors are compatible with the TECgt’s sync pulse requirement. This would

include most Hall effect, flying magnet, and reluctor sensors. As long as the sensor outputs a rising voltage

to the TECgt between 180

o

and 6o before TDC compression for the number one cylinder, it should work

perfectly.

Terminal G23 on the ECU is used for cam sync inputs (as shown in Figure A.4. 4). If using a Hall

effect or other sensor type that is powered by +5Volts, be sure that the output signal from the sensor is

going into terminal G23. If using a magnetic sensor with a custom steel trigger wheel, we recommend

using our magnetic sensors. The red wire from the sensor should go to terminal G23. Keep in mind that

when adapting an OEM cam trigger setup to a TECgt, the wheel may need to be rotated to place the rising

edge in the appropriate degree window for the TECgt.

Figure A.4. 8:

Proper cam

trigger

installation. This

cam trigger

occurs approx.

o

90

BTDC

Compression on

the #1 cylinder

(as measured at

the crank). Note

the 87 degree

(as measured on

the cam wheel)

“window” in

which the rising

edge must occur.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 18 - ©2008 Electromotive, Inc.

A.4.g. TDC Tooth Setup Software Adjustment Parameters

So, you took a lot of time to install your trigger wheel, and now you realize that you didn’t get the

trailing edge of the 11

th

tooth to align with the center of the magnetic sensor with the engine at TDC #1.

What to do?

The WinTec software features a TDC setup parameter that allows users to manipulate the TDC

point for the trigger wheel. There are two adjustable parameters:

Change DFU “A” Trigger Wheel TDC

Change DFU “B” Trigger Wheel TDC

For all but the odd-fire applications, the adjustment is only present for the DFU “A” TDC. The

default setting for DFU “A” TDC is 11, signifying TDC alignments with the 11

with the 13

th

tooth at TDC, change this number to 13. Several late-model Bosch-equipped applications use

th

tooth. If you are aligned

our 60 (-2) tooth trigger wheel, but come from the factory with a different TDC tooth alignment. Typically,

these setups are referenced to the 14

th

tooth for TDC, but you MUST confirm this on your application,

since Bosch used a few different offsets through the years.

Odd-Fire applications have the ability to move the TDC reference for the second DFU (using the

parameter “DFU “B” Trigger Wheel TDC”). This allows the user to define the odd-fire ignition split that is

present on the engine. Refer to Section C.5 to determine the proper settings for this value.

Some applications may require more “mechanical timing” to compensate for large, high-overlap

cams. Assuming the crank sensor is aligned with the 11

th

tooth at TDC, this can be done by entering a

value for the “Change DFU “A” Trigger Wheel TDC” that is LESS than 11. Each tooth less than 11

represents 6 degrees of advance that is added to the Ignition Advance Table.

Some applications may require less “mechanical timing” (some rotary users may wish to do this).

Assuming the crank sensor is aligned with the 11

th

tooth at TDC, this can be done by entering a value for

the “Change DFU “A” Trigger Wheel TDC” that is MORE than 11. Each tooth more that 11 represents 6

degrees of retard that is subtracted from the Ignition Advance Table.

If an odd-fire engine has the trigger wheel installed incorrectly, and the DFU “A” TDC parameter is

changed to compensate for the error, the “DFU “B” Trigger Wheel TDC” parameter needs to be

manipulated in the same amount. As an example, if the TDC for DFU “A” is at 11 and is moved to 10, the

TDC for DFU “B” would need to be moved from 16 to 15.

The following pages outline the various situations that can be addressed through the TDC software

parameters.

Situation A

Problem:

Incorrect trigger wheel alignment results in undesired mechanical timing.

Solution:

With the engine at TDC #1, find the trigger wheel tooth that is aligned with the crank sensor. Enter the

number of this tooth into the TDC Tooth Alignment Parameter. The timing will be shifted to make the

Ignition Advance Table accurate.

Method:

The software will automatically RETARD the timing when a number GREATER THAN 11 is entered into

the TDC Tooth Alignment Parameter. The timing will be automatically ADVANCED when a number

LESS THAN 11 is entered.

Situation B

Problem:

The engine needs less mechanical advance, and the crank sensor is aligned with the 11

th

tooth.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 19 - ©2008 Electromotive, Inc.

Solution:

Enter in the number “12” to the TDC Tooth Alignment Parameter. The timing values will be automatically

RETARDED by 6 degrees. The Ignition Advance Table values will now be incorrect (the displayed values

will be 6 degrees higher than the actual advance).

Situation C

Problem:

The engine needs more mechanical advance, and the crank sensor is aligned with the 12th tooth instead of

th

the 11

Solution:

Enter in the number “11” to the TDC Tooth Alignment Parameter. The timing values will be automatically

ADVANCED by 6 degrees. The Ignition Advance Table values will now be incorrect (the displayed

values will be 6 degrees lower than the actual advance).

Note:

In the past, aligning the sensor with the 12th tooth would advance the mechanical timing by 6 degrees.

.

Figure A.4. 9 - TDC tooth for two possible scenarios.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 20 - ©2008 Electromotive, Inc.

In a normal scenario, not considering software manipulation, aligning the magnetic sensor with

anything other than the 11

direction of the misalignment. Each tooth represents six degrees, so if the sensor is aligned with the trailing

edge of the 12

the trailing edge of the 10

required for easier starting (high compression/radical cam timing engines, for example), aligning the sensor

with the 12th or 13th tooth will yield 6° or 12° (respectively) of advance during cranking. Also check that

the sensor is centered over the edge of the wheel.

th

tooth, the timing will be advanced by six degrees. Conversely, if the sensor is aligned with

th

tooth will cause an ignition timing retard or advance, depending on the

th

tooth, the timing will be retarded by six degrees. If some ignition advance is

A.5. Wiring the TECgt

Introduction

The task of installing a TECgt wiring harness may seem a bit intimidating at first. However, by

dividing the wiring installation into a few small jobs, it can be accomplished by most installers in a

reasonable amount of time.

WARNING: Always disconnect the battery when doing ANY electrical work on a

vehicle. Use common sense when working around electrical systems, particularly the

TECgt DFU coils. The voltage output of the coils can be well over 40,000 Volts at a

given instant.

A.5.a. TECgt - Main Power Connections

The two wires (with their own connector) that protrude from the TECgt ECU are the main ground

and switched ignition power. The ground wire is 10awg. The reason for the larger/thicker size of the wire

is that the ECU is mainly in charge of switching the GROUNDS, not the +12 Volt power. As an example,

the fuel injector and coil outputs are all pull-to-grounds. The +12 Volt power is supplied on a harness that

is external to the TECgt.

The red 12awg wire in position (A) on the 2-position connector should be connected to Switched

+12 Volt Input. This wire is used to turn the unit on and off as well as supply power to the ECU. As such

it only flows a very small amount of current (less than 1 amp). This wire can be placed on the ignition

switch circuit. The black 10awg wire in position (B) of the connector should be connected to full time

battery negative. The TECgt is shipped with the corresponding connector with five feet of wire. See

Figure A.5. 1 for a wiring diagram.

If you are using the TECgt Power Harness, refer to the next section on installing the Switched +12

Volt Input into the Power Harness.

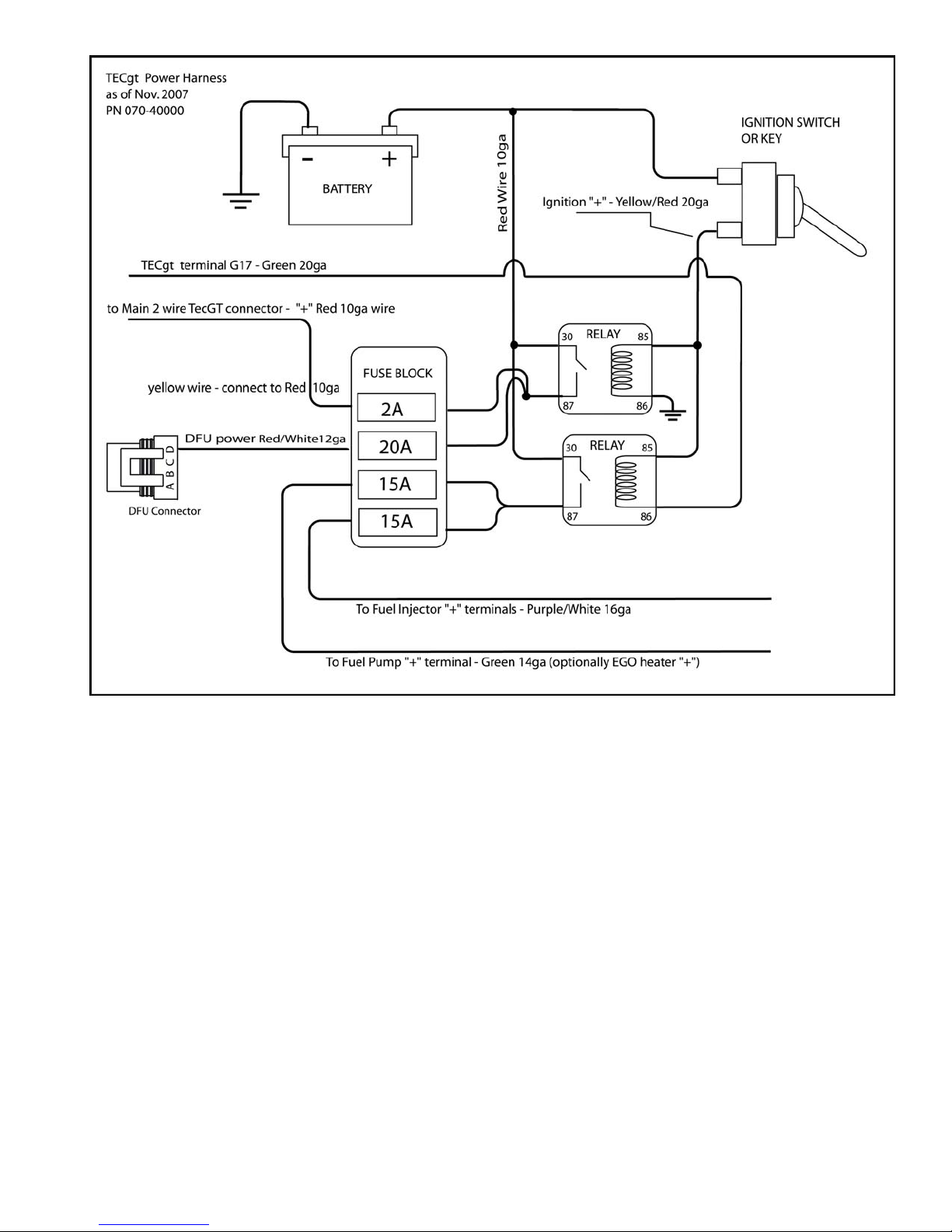

A.5.b. Power Harness Installation

Electromotive’s Power Harness (PN 070-40000) for the TECgt is capable of supplying the +12Volt

high-amperage power required to run the DFU’s, injectors, EGO sensor heater and fuel pump. Included in

the harness is a fuse block with four fuses (ignition, DFU’s, Injectors and Fuel Pump are fused) and two

relays to switch the power. Our custom harnesses are all built with the power harness pre-installed, so

wiring them is even more straightforward. Figure A.5. 1 gives an example of a typical Power Harness

installation.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 21 - ©2008 Electromotive, Inc.

There are three breakouts in the Power Harness:

• TECgt Connections

• Power Inputs

• Power Outputs (w/ switched voltage input)

• TECgt Connections

The TECgt Connections are color-matched to the TECgt harness.

Light Green 20awg Wire: Connects to Pin G17 (Fuel Pump Relay Ground)

Yellow (from power harness) 20awg Wire: Connects to 2 wire (separate connector- Pin A, red wire

10awg) = Switched +12v input

• Power Inputs

The Power Inputs are color coded in standard fashion:

Red 12awg Wire: Connect to (Switched +12V input)

Black 10awg Wire: Connect to Vehicle Ground

• Power Outputs (w/ switched voltage input)

The power outputs provide power for the DFU’s, injectors, EGO sensor heater, and Fuel Pump. The

switched voltage input is used to turn on the TECgt ECU, and should be wired to a +12Volt source that is

activated with the ignition key.

Purple/White Stripe 16awg: Injector Power (runs to all injectors)

Red/White Stripe: DFU Power (pin “D” on DFU’s)

Green 16awg: Fuel Pump Positive and EGO Sensor Heater Positive

Yellow 18awg: Switched +12 Volt Input (for TECgt turn-on request)

The Wiring Diagrams in the DFU and Injector wiring sections of this manual show the terminals on which

the power should be brought in. Any reference to fusing the power source in these sections is unnecessary

when using the Power Harness, since the connections are already fused.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 22 - ©2008 Electromotive, Inc.

Figure A.5.1: TECgt Power Harness (PN: 070-40000).

A.5.c. Wiring the Fuel Injectors

The Injector connectors use pull-to-seat terminals. DO NOT crimp the terminals onto the wires until

you have fed the wires through the connector!

When wiring the injectors, Section D must be referenced to determine the correct wiring for your

application. To summarize the main wiring points from Section D:

• Injector drivers 1-4 use a Yellow base color. The stripe color indicates the channel (Black-RedGreen-Blue = Channel 1-2-3-4).

• Injector drivers 5-6 use a Light Blue base color. The stripe color indicates the channel (Black-Red

= Channel 1-2).

• All injectors need a +12Volt connection on one terminal and a TECgt Injector Output on the other

terminal.

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 23 - ©2008 Electromotive, Inc.

• Low Impedance injectors should be wired in pairs (in parallel), and should not be used on a oneper-driver basis.

• High Impedance injectors can be used with either 1 or 2 per channel. When using two per channel,

wire them in parallel.

When using the Power Harness, refer to Figure A.5. 1 to obtain the fused +12Volt source for the

fuel injectors. It is the Purple w/ White stripe wire coming out of the Power Harness.

A.5.d. Wiring the DFU’s

The DFU connectors use pull-to-seat terminals. DO NOT crimp the terminals onto the wires until

you have fed the wires through the connector!

When wiring the DFU’s, Section C must be referenced to determine the correct wiring for your

application. To summarize the main wiring points from Section C:

• Terminal “D” on the DFU connector is the +12Volt connection.

• The TECgt harness has two cables for the DFUs. The first cable has three 16awg wires with a

shield. The second cable has two 16awg wires with a shield.

• The 3-wire DFU cable has the outputs for A, B, and C channels.

• The 2-wire DFU cable has the outputs for C and D channels. Channel C is in the second cable for

ease of wiring 8-cylinder and 2-rotor engines.

A.5.e. Wiring the Engine Sensors

The TECgt harness has provisions to connect all of the engine devices outlined in Sections G and F

of this manual. Refer to this section to wire your sensors appropriately.

• The following sensors use pull-to-seat connectors (feed the wire through the connector before crimping

the terminal!):

Coolant Temperature

Manifold Air Temperature

Some Throttle Position Sensors

Idle Air Control Motor

• The following sensors use push-to-seat connectors (crimp the terminal to the wire before inserting into

the connector!):

Crank Sensor

Cam Sensor (if used)

MAP sensor (1-Bar sensors use green connector. 2-& 3-Bar use orange connector)

Some Throttle Position Sensors

EGO Sensor

Knock Sensor

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 24 - ©2008 Electromotive, Inc.

• A brief word on Crimp Terminals…

When crimping terminals to the sensor wires, care must be taken to ensure that a proper crimp is

made. Improper crimps can lead to terminal failure and wire fatigue. To crimp properly, we recommend

using a high-quality ratcheting crimp tool (such a tool is available from Electromotive). In the absence of a

good crimp tool, the terminals can be soldered. Care should be taken to make absolutely certain that the

solder penetrates the terminal and gets to the wire.

There are two main crimp styles used with the TECgt sensors: Metri-Pack and Weather-Pack.

Metri-Pack terminals have two crimp areas. One area crimps to the bare (stripped) wire and provides the

electrical connection, and the other area crimps to the un-stripped wire housing to provide a strain relief.

Metri-Pack connectors are pull-to-seat.

Weather-Pack terminals also have two crimp areas, but instead of one area acting as a strain relief, it

is used to hold the connector seal in place. Therefore, when crimping a Weather-Pack terminal, always

insert the cable seal before crimping. Weather-pack connectors are push-to-seat.

Note : Soldered terminals will not tolerate much flexing. They may break if too much movement is

allowed.

B. Tuning Guide

Introduction

This section focuses on the tuning of a TECgt equipped engine. The tuning procedures outlined

here are based on an engine that has been wired correctly, has proper injector sizes, and has gone through

the Tuning Wizard with the engine parameters to establish a base program. Failure to meet any of these

criteria will make the tuning procedure difficult. Refer to section D.4 for terminology used in this section.

B.1. Adjusting the Timing Advance

Perhaps the most important step in tuning an engine is establishing the required ignition advance.

An engine with too much timing will detonate, regardless of how much fuel is thrown at it. An engine with

too little timing will perform poorly, and overheat the exhaust in short order. We are looking for the happy

medium here. Keep in mind that the timing settings are solely dependent on the crank trigger installation

angle. If the crank sensor is aligned with the 13

the engine timing will be mechanically advanced by two teeth (12 degrees). When this occurs, the timing

values in the Ignition Advance Table will be 12 degrees LESS THAN the actual engine timing. If the

crank sensor is aligned with the 10

th

tooth at TDC#1, the timing will be mechanically retarded by one tooth

(6 degrees). When this happens, the timing values in the Ignition Advance Table will be 6 degrees MORE

than the actual engine timing. Always confirm your timing values in the software with a timing light!

Remember that dial-type timing lights will not read correctly with the TECgt due to the waste-spark. See

Section A.4.d for more information on this topic. To avoid potential engine damage, it is best to check

engine timing with a timing light when first starting the tuning process.

As a guideline, most piston engines, regardless of compression ratio, will require anywhere from 820 degrees of advance when the engine is idling. Rotary engines require little or no timing at idle (some

even idle with negative advance!), so an ignition advance of zero may work best at low engine speeds.

Less timing makes the combustion process occur later, and thus makes the exhaust temperatures higher. It

also usually makes an engine idle somewhat rough. If your exhaust manifold is glowing red at idle, you

know one thing: there is not enough timing. NO

th

tooth of the trigger wheel when the engine is at TDC #1,

emissions will typically be low with too little timing.

x

______________________________________________________________________________________

TECgt Manual Version 2.0 - Page 25 - ©2008 Electromotive, Inc.

More timing makes the combustion process occur sooner, and will decrease exhaust temperature. It also

makes an engine idle smoother. NO

emissions will rise with too much timing.

x

With increasing RPM, the timing needs to be advanced for optimum power. This is a result of the

available time for combustion decreasing with increasing RPM. The peak cylinder pressure needs to occur

between 10 and 15 degrees after TDC compression for optimum power production, so the timing must be

tuned to allow this to happen. As a rule of thumb, engines with slow-burning (large) combustion chambers,

and/or low dynamic compression (low volumetric efficiency) typically need more timing advance, since the

flame front moves slowly. Engines with fast-burning (usually small) combustion chambers and/or high

dynamic compression ratios need less timing for optimum power, since the flame front moves faster.

Peak timing usually should occur by 3000 rpm on most engines. Load-dependent timing should

always be used, especially on turbo/supercharged engines. With increasing load (i.e. full-throttle or fullboost), less timing is needed. With decreasing load (i.e. cruising), increased timing is needed.

Rotary engines (particularly the turbocharged rotaries) do not give the tuner a margin of error when

it comes to ignition timing. They will detonate ONE TIME only, and will then be broken. The apex seals

cannot stand up to the huge shockwave generated by detonation. Tune these engines extremely

conservatively!! Start with the least amount of timing possible and the most amount of fuel possible. A

huge power-to-weight advantage is present on the rotary turbo engines, but it will only come to a tuner who

is cautious and patient.

B.2. Establishing Proper Starting Enrichments

When setting up the Starting Enrichments, it is generally best to first use the default settings from

WinTec. If these settings cannot start your engine, there would only be two possible causes: either the

enrichments are not adding enough fuel, or they are flooding the engine with too much fuel. Flooded

engines are easy to spot, since there will be a strong fuel odor in the air around the engine. Alternatively,

the spark plugs can be removed to check for flooding. Flooded spark plugs will be wet with fuel when they

are removed. If an engine is not flooded but still will not start, it is most likely not getting enough fuel.

For engines that will not start when cold, look to SE0 (the Temperature-Based One Second Starting

Enrichment). If the engine is flooding out during cold starting, decrease this number. If this number is

already zeroed out, and the engine is flooding, look to SE1 (the Constant One Second Starting Enrichment).

If SE1 is too high, the engine will flood out during cold AND hot cranking, since its value is added

regardless of temperature. If both of these values are set very low, and the engine still floods during

starting, look to PW0 (the Fixed One Second Starting Pulse Width). Most engines will not need PW0, so it

is generally best to set this to zero. ASE-0 and ASE-1 can also contribute to a flooding problem. If these

values are set too high, there may be too much fuel present at cranking.

An injector that is stuck open can sometimes cause a scenario that can be confused with engine

flooding on start-up. An injector that is stuck open will spray fuel into its respective cylinder as long as

there is fuel pressure. This will fill a cylinder with fuel in short order and effectively lock the engine. The

starter motor won’t be able to turn the engine over, since an engine cannot compress liquid fuel very easily.