– 1 –

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

2.0 Unpacking and Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

3.0 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

4.0 Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

5.0 AC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

6.0 Overview of Keypad and LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

7.0 Overview of Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

8.0 Changing Units of Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

9.0 General Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

9.1 Additional Operating Information

10.0 Adjusting Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

10.1 Temperature Compensation

10.2 Selecting the Baud Rate of the RS232 Interface

10.3 Switching off the Auto-Power Off Function

10.4 Change the Refresh Rate of the Display

10.5 Flow Chart: Steps Required To Change Advanced Settings

11.0 Data Transfer (Model WT-110RS only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 013

11.1 RS-232 Interface

11.2 Analog Output

12.0 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 015

13.0 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 017

14.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 018

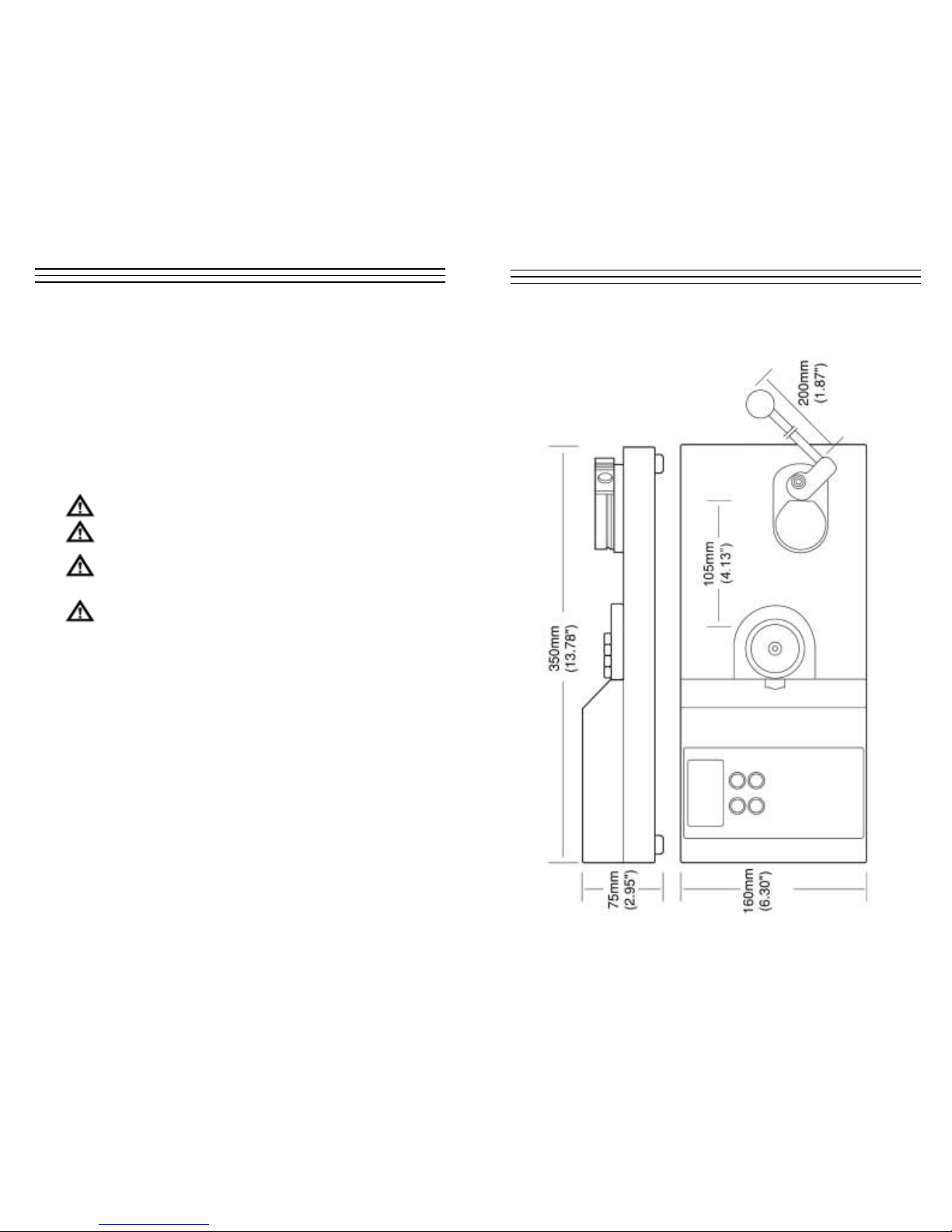

15.0 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 019

16.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 020

TABLE OF CONTENTS

– 20 –

16.0 Warranty

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the

original purchaser that this product is of merchantable quality and confirms in kind

and quality with the descriptions and specifications thereof. Product failure or malfunction arising out of any defect in workmanship or material in the product existing at

the time of delivery thereof which manifests itself within one year from the sale of

such product, shall be remedied by repair or replacement of such product, at

ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering,

abuse or misapplications has taken place, as determined by ELECTROMATIC. All

returns for warranty or non-warranty repairs and/or replacement must be authorized by

ELECTROMATIC, in advance, with all repacking and shipping expenses to the

address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR

SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to the

duration of the foregoing warranty. Some states do not allow limitations on how long

an implied warranty lasts but, not withstanding, this warranty, in the absence of such

limitations, shall extend for one year from the date of invoice.

ELECTROMACTIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

– 2 –

1.0 INTRODUCTION

Thank you for selecting the CHECK•LINE WTT-110 Wire Terminal Pull Tester for

your requirements. With correct use and proper care this product should provide

many years of precise and accurate testing. Please read the entire operation manual

thoroughly before using this instrument for the first time. The information contained

herein will help assist users to achieve accurate and repeatable results as well as

prevent damage with improper set-up or operation.

This instrument is designed for measuring tensile strength of soldered or solder-free

cable joints with end sleeves, pins, solder pins or similar wire terminal components

in the field of quality control or design validation.

Safety Precautions

Wear appropriate eye protection at all times.

The load cell can be damaged if the internal measuring system is overloaded.

Do not exceed the maximum measuring limit of 50 Kg (110 lbs. or 500N).

Transport and store the instrument with great care. This reduces the risk of

damage to the load cell or other minor mechanical problems which can result

in inaccurate measurement results.

Operate the instrument in appropriate environments only. The instrument

is equipped with a temperature compensation for a temperature range of

32 to 120 °F (0° to 40°C) and should be used in this temperature range only.

Do not expose this device to liquid or operate in high-humidity environments.

– 19 –

15.0 Dimensions

– 3 –

2.0 UNPACKING & CONTENTS

Remove the unit carefully and check the unit appears undamaged in shipment.

Check to see that all of the supplied items are contained in the box (see below).

Retain packaging materials in the case that the unit needs to be returned to the manufacturer or distributor.

■ Main instrument table

■ Separate hand lever with ball end

■ 9V DC battery charger 100 to 240 VDC (50 to 60Hz) with Euro/US/UK

plug adaptor

■ Operating instruction manual

■ Connection cable for RS232C (WTT-110RS model ONLY), not shown

Lever

Wire CLAMP FixtureWire TERMINAL Fixture

– 18 –

14.0 SPECIFICATIONS

Measuring Range* 0–50 Kg / 0–110 lbs / 0–500N

(units selected via keypad)

Resolution 0.01Kg / 0.1 lbs / 0.1 N

Terminal adapter

slot width (mm) 0.5, 0.8, 1.0, 1.4, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 5.0, 6.0

Accuracy ±0.5% F.S. or better

Operating Mode

Continuous Displays actual value in Kg, lbs. or N

Peak-Hold Displays peak value in Kg, lbs. or N

Wire Diameter

SAE AS7928 II AWG 8. . .30

IEC 60352-2 Cross section 0.05. . .10mm

2

Maximum 0.236" (6mm)

Overload 200% Full Scale (LCD indicator at 120%)

Display LCD, 4–1/2 digit, 12mm high

Memory Peak Value

Power Supply Internal NiCd battery, supplied with

AC adapter/charger

(100-240V/50-60 Hz)

Temp. Range

Operating 32 to104 °F (0 to 40 °C)

Storage –4 to 140 °F (–20 to 60 °C)

Weight, approx. 30.8 lbs. (14 Kg)

Dimensions 14.2" x 6.3" x 2.95" (360 x 160 x 75mm)

Material Anodized aluminum, steel and stainless steel

* Low-range model available on special order basis.

Model WTT-110RS Only

Interface

Serial 2400 KB/8/N/1/ None (selectable baud rate)

Analog 0-1VDC

– 4 –

3.0 SETUP

Place the WTT-110 Wire Terminal Tester on a level and stable work area where the

user can perform the testing in a comfortable manner. The surface should be clean and

grease-free, so that the instrument does not slip.

Make sure that there is no residue from the packaging materials stuck under and around any of the

operating components especially in the recessed

area around the rotating terminal fixture (see photo)

and under the lever arm base plate, etc.Use of

compressed air to clear any debris from these

areas is recommended.

Please note that the instrument weighs approximately 30 pounds (14 kg), so please use

necessary precautions when lifting and moving. We suggest that the location is in close

proximity to an AC-Power outlet.

Locate the lever and screw it in to the

threaded hole in the rotating wire clamp

fixture, as shown in the photo. Turn the

lever in a clockwise direction to screw-in.

Continue until it is “hand-tight.” DO NOT

OVERTIGHTEN.

4.0 C

HARGING THE BATTERY (REQUIRED BEFORE FIRST USE)

For safety reasons, the WTT-110 is supplied with the batteries fully discharged.

To obtain maximum battery life we recommend that you charge the internal NiCd

battery for approximately 18 hours before first using this instrument the first time.

Select the appropriate plug adapter for the outlet type and country of use. Plug the

charger into an AC-outlet and plug the other end into the receptacle on the left side of

the WTT-110. Charge the batteries.

Note: The BAT indicator is shown on the display when the batteries are being charged

and turns off when the batteries are fully charged. When the batteries are nearly

discharged, the "LO BAT" indicatory will blink on and off.

5.0 AC-O

PERATION

The WTT-110 can be operated using the AC-Adapter/Charger. The batteries are being

recharged while plugged into the AC power source. Total battery recharge time will be

significantly longer then if recharged while turned off.

– 17 –

13.0 TROUBLESHOOTING GUIDE

If any error codes are shown on the display, first try turning the power off and then

back on again. If the code is still on the display, refer to the chart below.

AWG Cross-Section Cable Diameter SAE AS7928 IEC 60352 Part 2 UL 486 C

30 0,06 mm_ 0,36 mm 6 N 6 N

28 0,09 mm_ 0,38 mm 11 N 11 N

26 0,14 mm_ 0,48 mm 32 N 18 N 18 N

24 0,22 mm_ 0,61 mm 45 N 28 N 28 N

22 0,34 mm_ 0,76 mm 67 N 40 N 40 N

20 0,56 mm_ 0,97 mm 85 N 60 N 45 N

18 0,93 mm_ 1,27 mm 170 N 90 N 45 N

16 1,25 mm_ 1,44 mm 223 N 135 N 68 N

14 1,93 mm_ 1,80 mm 312 N 200 N 100 N

12 3,16 mm_ 2,29 mm 490 N 275 N 138 N

10 4,65 mm_ 3,10 mm 355 N

Size of Conductor UL 486A Table 12.1 SAE AS7928 Table II

AWG (mm2) Pounds (N) Pounds (N)

30 0.050 1–1.5 6.7 N/A N/A

28 0.080 2 8.9 N/A N/A

26 0.130 3 13.4 7 3.12

24 0.200 5 22.3 10 44.5

22 0.324 8 35.6 15 66.8

20 0.519 13 57.9 19 84.6

18 0.823 20 89.0 38 169.1

16 1.310 30 133.5 50 222.5

14 2.080 50 222.5 70 311.5

12 3.310 70 311.5 110 489.5

10 5.261 80 356.0 N/A N/A

DIN 41611/3 is replaced by DIN IEC 60352 Part 2 MIL-T-7928 is replaced by SAE AS7928 Table II

BS5B178 corresponds to IEC 60352 Part 2 UL486A corresponds to IEC 60352 Part 2

Industry-Based Standards, Specifications and Recommendations

Pull Test Specifications for UL, MIL and SAE

Small Display Condition Action

Minus side overload condition

Remove excessive load. If the display does not

return to normal operation, send unit in for repair

Plus side overload condition

The load exceeds 120% Remove excessive load

of its capacity

EEPROM reading error

Turn the unit off, then turn on again.If the

display does not return to normal operation,

send the unit in for repair

EEPROM writing error

OVM

OVP

OV+

OV–

ERR

- 3 -

ERR

- 4 -

– 5 –

6.0 OVERVIEW OF KEYPAD & LCD DISPLAY

1 Low Battery Indicator. Flashes when batteries need charging, turns off when fully

charged. Remains on while charging.

2 Peak Mode Indicator. Shown on display when configured for peak mode

(stores highest peak force until it is reset by pressing zero key)

3 Units Indicator. Displays currently selected units of measure (pounds, newtons

or kilograms). Changed by pressing UNITS key.

4 F or ce Value. Displays current or peak force value in user-selected units of measure.

5 PEAK Key. Turns on Peak Force Capture Mode. When selected, the highest peak

value will be shown on the display until reset by ZERO key.

6 UNITS Key. Selects desired units of measure. Each time this key is pressed, the

units will change from one to the next.

7 ZERO Key. Performs a “tare” on the system and resets display to zero. When in

peak mode, it erases the previously stored peak value.

8 ON/OFF Key. Turns the system on and off.

LL00--BBAATT

PPEEAAKK

LLbb

ff

00..00 00

PEAK

UNITS

ZERO

ON/OFF

1

2

3

4

5

6

7

8

– 16 –

Re-Calibration Procedures

1. Turn POWER off. Make sure the weight is NOT suspended from the sample.

2. Press and hold the UNIT, PEAK and ZERO keys simultaneously.

3. Press and release the On/Off key (while continuing to press UNIT, PEAK

and ZERO) until the smaller characters at the top of the display show CAL.

4. Release the UNITS, PEAK and ZERO keys.

5. The force gauge is now in calibration mode.

6. Press the UNITS switch. The display will show ZER after blinking SCN for

10 seconds.

7. The force gauge is now ready for zero point calibration.

8. Press ZERO key to confirm the zero calibration. Wait approximately 15–20

seconds. The display will change to show PEK after blinking SCN. Do not press

any other keys or disturb the instrument or weight during calibration.

9. Hang the 50 Kg calibration weight from the sample which is hooked on to one

of the teeth of the Wire Terminal Fixture. Make sure that the material path is

unobstructed and in a straight horizontal orientation. The force gauge is now

ready for full-scale calibration.

10. Press the PEAK key to begin full scale calibration. The display will blink SCN.

Do not press any other keys or touch the weight during calibration. After approximately 15– 20 seconds the display will blink END. Then after approximately 5

seconds the display blinks OK.

11. If calibration was successful, the display will show OK momentarily (see above

illustration). Press the UNITS key, then the power will automatically switch off.

12. If calibration was unsuccessful, the display will show ERR. Remove the calibration weight, then press the UNIT key and repeat the above procedure again.

CAL

–00–

“oK”

88888

“SCN”

–00–

ZER

88888

➔

“SCN”

88888

PEK

88888

➔

“SCN”

88888

“End”

88888

➔➔

– 6 –

7.0 OVERVIEW OF OPERATING MODES

The WTT-110 can be set to operate in one of two distinct operating modes: Peak

Capture or Average. In Peak Capture Mode, the system measures the force at a frequency of 1000 Hz (1000 times per second) and displays the highest force measurement. The peak value remains on the display until a higher force value is measured or

until the user presses the ZERO key.

In Average Measurement Mode, the system measures the force at a frequency of

1000 Hz (1000 times per second) and displays the average each time the display is

updated. The factory default display update rate is 3 times per second (1 time every

1/3 second).

Note: Refer to Advanced Setting, section 10, page 10, for additional information and

to change the update rate.

8.0 C

HANGING UNITS OF MEASUREMENT

The WTT-110 can display force measurements in any of the following theree engineering units:

■ lbf (pounds)

■ N (Newtons)

■ Kgf (kilograms)

To change the selected engineering units for display press UNITS key. Each time the

key is pressed, the units will change from one to the other as follows:

Lbf

Kgf

N

– 15 –

12.0 CALIBRATION

The WTT-110 Pull Tester has been calibrated in accordance with factory proceedures

and is certified to perform within the stated accuracy specifications shown in the

Specifications section found on page 18. Assuming the unit is handled with care

and operated as detailed in this manual it should remain accurate for an extended

time period. If however, it is subjected to forces that exceed its maximum range or

if it is not properly cared for, it might need to be recalibrated.

It is recommended that the calibration is verified at least on an annual basis and more

frequently if feasible. Normally, instruments of this type go out of tolerance from one

day to the next and rarely on a regular periodic basis.

A calibration procedure is provided in this manual, however it should only be performed by individuals properly trained for this type of service and with the appropriate

certified standards (known weights or secondary force measuring system such as a

load cell, etc.).

Re-Calibration Set-up

1. Remove the lever by unscrewing it in a

counter-clockwise direction and move

the Wire Clamp assembly out from the

path of the hanging sample.

2. Position the WTT-110 in a vertical

position so that the keypad & display

are at the top (refer to photo). Be sure

to secure it so it can not topple over

when the weight is attached.

3. Using a heavy-duty monofilament

(fishing line), wire or similar, suspend

a 50 Kg weight from one of the teeth

on the wire terminal fixture by hooking

a loop of the material over the selected

tooth.

4. Temporarily, remove the weight and

follow the Re-Calibration Procedures

shown on page 16.

■ Make sure that the

WTT-110 is well secured

in the vertical position.

Caution

■ Select a material that is strong

enough to support 50 Kg of weight.

– 7 –

9.0 GENERAL OPERATING PROCEDURES

1. Press On/Off key. During power-up, the WTT-110 performs a self-test routine.

During this procedure, the maximum capacity of the system will be temporarily

displayed in selected units of measurement. Then the unit should display zero.

Occasionally the last one or two digits might be something other then zero.

Additionally, the selected units will be shown.

2. Select the desired operation mode. To set for Peak Capture Mode, press the PEAK

key once. The peak indicator will be shown on the display when the system is set

for peak capture mode (highest value measured and stored until reset to zero). To

set for Average Mode, make sure the peak indicator is not shown. Press the PEAK

key until indicator is no longer illuminated. In this mode, the display is constantly

updated 3 times per second .

Note: The Display Update Rate can be set to update 1, 2, 3, 5, 10 or 20 times per

second (5 times per second = 0.2 seconds). Refer to Advanced Setting, section

10.4, page 11 for additional information and to change the update rate.

3. It is necessary to zero-set (“tare”) the WTT-110 before starting each force measure-

ment. Press the ZERO key for this purpose. The ZERO key is also used for clearing

the currently stored Peak value from display memory whenever desired.

4. Select the smallest suitable slot in the

Wire Terminal Fixture based on the

diameter of the wire and the physical

dimensions of the connector. Rotate

the fixture so the selected slot is in

the 3 o’clock position so it is closest

to the Wire Clamp Fixture.

5. Place the cable connection into the

fixture such that the main part of the

connector is retained on the inside of

the fixture and the sleeve and cable

will pass through the slot toward the

Wire Clamp Fixture. When pulling

on the cable, the terminal should be

well secured.

– 14 –

11.2 Analog Output

The analog output (-1...0...1 VDC) can be used for any data acquisition or data

recording device. Pull Force data will be expressed as a negative voltage. The

signal can be set to zero (reset) by performing a ZERO (tare) function. +1 VDC

and – 1VDC refers to the maximum and miniuml full scale (end of nominal

measuring range).

PROTOCOL CODE

Extern >> Average data output NA®®®®®®cr

3. digit: + /or –

4.-6. digit. Value incl. floating decimal point

Peak data output NB®®®®®®cr

3. digit: + /or –

4.-6. digit. Value incl. floating decimal point

Unit: 3 digit

0 = N

1 = kg (g)

3= lb (oz) NH®cr

Unit: 3 digit NH®cr

0 = N

1 = kg (g)

3= lb (oz)

Error OBcr Command Error

OEcr Parity Error

OFcr Format Error

OGcr Summing Error

OHcr Overflow

SPECIFICATION

Amplitude -1VDC / +1VDC

Signal generator 12-bit D/A-Converter

Signal update 100 Hz

– 8 –

6. Insert the free end of the cable using

a small amount of tension into the

Wire Clamp Fixture and rotate the

handle clockwise until the cable is

clamped between the two metal

surfaces.

You are now ready to begin the

pull test.

7. Continue to rotate the lever

clockwise. The pull force on the

terminal connection will continue to

increase as the lever is rotated.

DO NOT EXCEED THE

MAXIMUM CAPACITY OF THIS

UNIT (110 lbs/50 Kg/500N) OR

DAMAGE COULD RESULT.

8. Eventually, the cable will pull out

from the terminal connection. The

test is now complete. If set for Peak

Capture Mode (refer to Overview of

Operating Modes, page 6), the peak

force value will be stored in the

display memory. If set for Average

Mode, the display would have been

updated throughout the test cycle.

9. To perform another test, repeat the steps detailed above. If operating in Peak

Capture Mode, be sure to press the ZERO key to delete the previously stored

peak value.

– 13 –

SPECIFICATION

Baud rate 2400, 4800; 9600 or 19200 (selectable, see general settings)

Data length 8 bits

Stop bit 1

Parity None

PROTOCOL CODE

Extern >> AAcr Tare

ABcr Stop Output

ACcr Change to Peak Mode

ADcr Change to Average Mode

AEcr Reset Peak

AFcr Change Units to kg (g)

AGcr Change Units to N

AHcr Change Units to lb (oz)

BAcr Data output request (single reading)

BBcr Data output request (10/sec)

BB1cr Data output request (20/sec)

BB2cr Data output request (50/sec)

BB3cr Data output request (100/sec)

BDcr Units confirmation request

BEcr Peak data output request

BFcr Minus peak data output request

cr (carriage return)

Chart continues on next page

11.0 DATA TRANSFER (MODEL WTT-110RS ONLY)

Model WTT-110RS testers can transfer measuring data by means of an RS-232C interface. A 9-pin D-Sub connector is provided for this purpose, which can be found at the

left side of the instrument. A connector cable for the serial port is included. If a custom

serial cable must be used or if the user wishes to access the analog output, the pin

designations are as follows:

11.1 RS-232C Interface

The RS-232C interface can be used for the direct communication between an

appropriate serial I/O-card of a computer and the instrument. The minimum

requirement for the data transfer up to 19200 baud is the connection of the

RXD, TXD and GND communication terminal.

SPECIFICATION

Baud rate 2400, 4800; 9600 or 19200 (selectable, see general settings)

Data length 8 bits

Stop bit 1

Parity None

PROTOCOL CODE

Extern >> AAcr Tare

ABcr Stop Output

ACcr Change to Peak Mode

ADcr Change to Average Mode

AEcr Reset Peak

AFcr Change Units to kg (g)

AGcr Change Units to N

AHcr Change Units to lb (oz)

BAcr Data output request (single reading)

BBcr Data output request (10/sec)

BB1cr Data output request (20/sec)

BB2cr Data output request (50/sec)

BB3cr Data output request (100/sec)

BDcr Units confirmation request

BEcr Peak data output request

BFcr Minus peak data output request

cr (carriage return)

Pin Description

1 Analog signal +

2 Serial : TXD

3 Serial : RXD

5 Serial : GND

9 Analog: Signal Gnd

– 9 –

9.10 Additional Operating Information

Low Battery

When battery charge is low, the LO BAT indicator will blink on and off in the

LCD Display indicating that the batteries need to be charged. Charging time

of fully depleted batteries is approximately 18 hours when the unit is off. The

adapter/charger automatically shuts off when the battery is at full charge to

protect the battery. The adapter/charger can be used to power the unit during

battery charging, but this will lengthen the charging time. Refer to Charging

the Battery, section 4, page 4, for additional information.

Auto Power Off

If the gauge is on and there is no activity for 10 minutes, the unit will automatically power off to conserve battery charge. PWR appears above the display digits

to notify that there is 1 minute before power off. If the adapter/charger is powering the gauge, auto power off function becomes inactive.

Temperature Compensation

The WTT-110 utilizes a built-in temperature compensation system to provide

optimum accuracy and to prevent signal drift. If the user would like to disable

this feature, please refer to the Advanced Settings section on page 10.

– 12 –

OFF

ZERO

Press and hold ZERO button. Press and release POWER button.

F01

0001

F01

— 0001

F01

0001

F02

3

F03

10

F04

2400

Plus or minus sign

PEAK

UNIT

Data was memorized

UNIT UNIT

Plus

Minus

PEAK

PEAK

PEAK

Plus or minus sign

Display Update

Auto power off

Baud rate of

RS232C

F02

5

F02

10

UNIT

UNIT

F02

20

UNIT

F02

1

UNIT

F02

2

UNIT

F02

3

UNIT UNIT

F03

OFF

F03

10

UNIT

UNIT UNIT

UNIT

F04

4800

F04

9600

UNIT

F04

19200

UNIT

F04

2400

UNIT UNIT

1. Press and hold the ZERO button.

2. Press and release the POWER button.

3. Each time the PEAK button is pressed, the FGE/V-X will scroll through each of the functions.

4. Press the ZERO button to exit,

NOTE: In function 2, the numbers signify as follows:

1- 1 time/sec 2- 2 times/s 3- 3 times/sec 5- 5 times/sec 10- 10 times/sec 20- 20 times/sec

10.5 Flow Chart Illustrating the Steps Required To Change Advanced

Settings

– 10 –

10.0 A

DJUSTING ADVANCED SETTINGS

There are several adjustable settings that can be changed from the factory defaults to

customize the WTT-110 to meet the exact requirements of the user. These settings are

saved in the microprocessor and are recalled each time the system is powered up.

10.1 Temperature Compensation (Default: SET=on)

In general, it is recommended to have the this function turned on as long as it

does not effect your measuring results. Only when measuring very minute

forces over a longer period of time at a slow rate and under stable environmental

conditions might it be useful to switch this off.

■ Switch off the instrument.

■ Press and hold PEAK- and MODE-buttons.

■ Press ON/OFF-button.

■ Wait until TRK oFF is displayed.

■ Release PEAK- and MODE-buttons.

10.2 Selecting the baud rate of the RS232C interface (Default: 2400)

On the WT-110RS model ONLY, the speed of the data transfer for the RS232C

interface can be adjusted as follows:

■ Switch off the instrument.

■ Press and hold RESET-button.

■ Press ON/OFF-button.

■ Wait until f01 is displayed, then release RESET-button.

■ Select function f04 by repeating to press the PEAK-button until f04 is shown

on the display.

■ Select appropriate baud rate (2400/4800/9600/19200) by repeating to press

the MODE-button.

■ Press RESET-button to save your settings.

10.3 Switching off Auto Power-Off function (Default: 10 min)

While operating under battery power the instrument will be automatically

switched off after approx. 10 minutes on inactivity. This Auto Power-Off function can be deactivated, which may become necessary when monitoring the

fluctuation of applied forces for a longer period of time. This function is

disabled when the instrument is powered by the AC-adaptor.

■ Switch off the instrument.

■ Press and hold RESET-button.

■ Press ON/OFF-button.

■ Wait until f01 is displayed, then release RESET-button.

■ Select function f03 by repeating to press the PEAK-button until f03 is shown

on the display.

■ Select setting (10/OFF) by repeating to press the MODE-button.

■ Press RESET-button to save your settings.

TRK

oFF

– 11 –

10.4 Change the refresh rate of the display (Default: 3/sec)

The force applied to the load cell of the instrument is internally processed at a

rate of 1000 Hz, which allows the precise capturing of the peak values. The readings on the display, however, are refreshed 3 times/sec only for the convenience

of the human eyes. You may increase or decrease the factory settings for them to

match your personal demands.

■ Switch off the instrument.

■ Press and hold RESET-button.

■ Press ON/OFF-button.

■ Wait until f01 is displayed, then release RESET-button.

■ Select function f02 by repeating to press the PEAK-button until f02 is shown

on the display.

■ Select refresh-time (1/2/3/5/10/20 times/sec) by repeating to press the

MODE-button.

■ Press RESET-button to save your settings.

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300

• FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

WTT-110 & WTT-110RS

W

IRE TERMINAL PULL TESTER

Operating Instructions

CHECK•LINE

®

BY ELECTROMATIC

OI311

Loading...

Loading...