Electromatic Equipment Co., Inc.

-12-

NOTES

Electromatic Equipment Co., Inc.

-1-

TABLE OF CONTENTS

1.0 Introduction ………………………………………………………..… 2

2.0 Calibration curves ……………….………………………………..… 4

3.0 Design of the device ……………………………………………….. 5

3.1 Menu

3.2 Keypad symbols

4.0 Most common reasons for miss readings ……….……………..… 8

5.0 Device maintenance instructions ………………………………..… 8

6.0 Changing batteries ………………………………………………..… 9

7.0 Determination of the material moisture …………………………… 9

8.0 Technical data …………………………………………………….… 10

10.0 Warranty ……………………………………………………………… 11

Electromatic Equipment Co., Inc.

-2-

1.0 INTRODUCTION

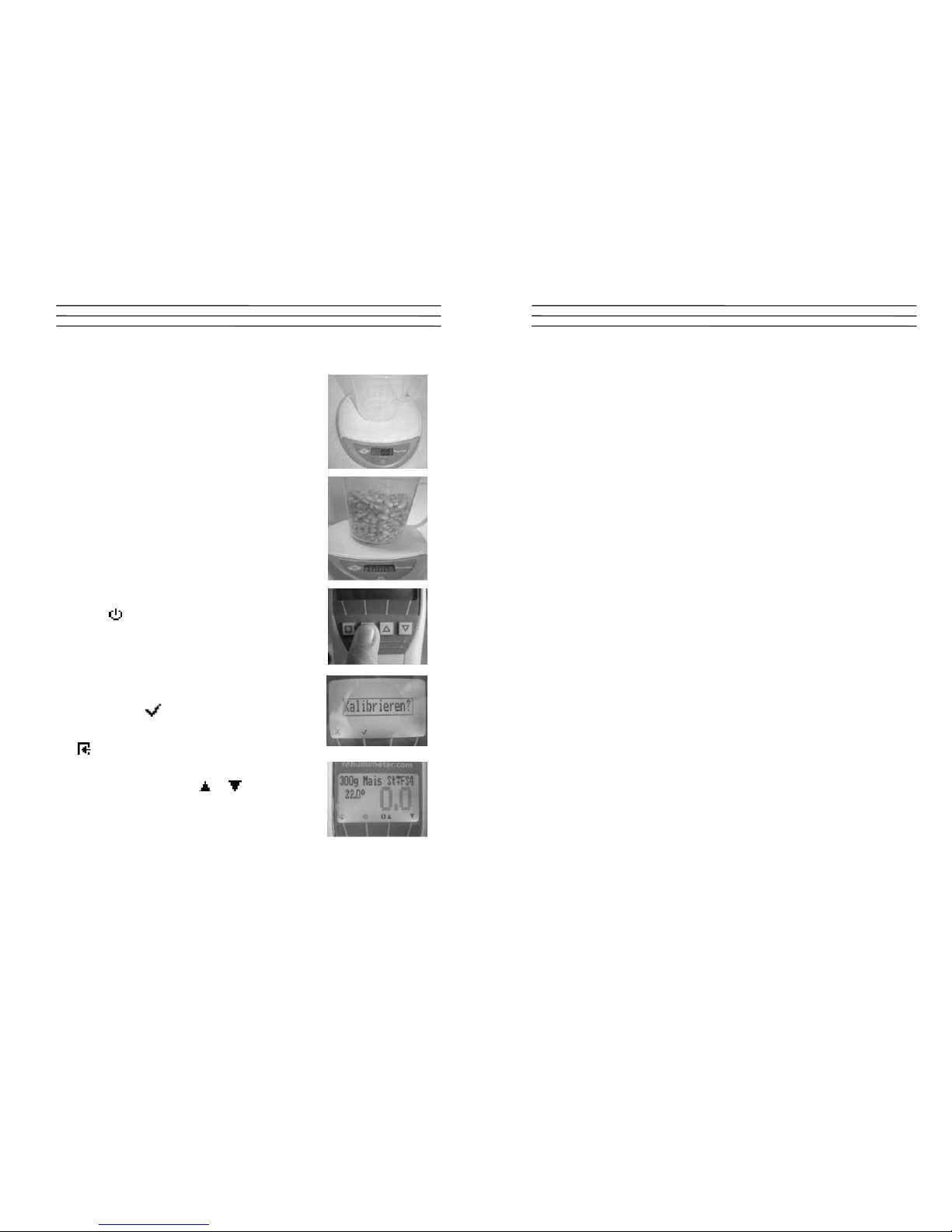

1. Place the empty provided cup (0.5 litre) on the scale

and turn the scale on. It shows 0.0 gram.

2. Fill up the cup with the sample material (+/- 1.0g). The

fill quantity is shown on the upper left corner on the

display of the humimeter FS2.

3. Make sure that the measuring chamber is completely

empty. It is important that no material is left in the

measuring chamber when you turn on the device.

4. Switch on the humimeter FS2 by pressing the power

button (

) for 3 sec.

5. As the next step, please do the self calibration. The

word “calibrate” will show up on your display. Accept

by pressing the

button.

6. In case a menu point is shown, press the left button

( ) until you reach the measuring window.

7. Select the right calibration curve for your material

under test using the buttons

or .

Electromatic Equipment Co., Inc.

-11-

9.0 WARRANTY

Electromatic Equipment Co., Inc. (Electromatic) warrants to the original purchaser

that this product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out of

any defect in workmanship or material in the product existing at the time of delivery

thereof which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at Electromatic’s option, except

where unauthorized repair, disassembly, tampering, abuse or misapplication has

taken place, as determined by Electromatic. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by Electromatic, in advance, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER W ARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to the

duration of the foregoing warranty. Some states do not allow limitations on how long

an implied warranty lasts but, not withstanding, this warranty, in the absence of such

limitations, shall extend for one year from the date of invoice.

Electromatic Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516 - USA

Tel: 1-800-645-7330 / Tel: 516-295-4300 / Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein

are used for identification purposes only, and are trademarks or registered trademarks of their

respective holders.

Electromatic Equipment Co., Inc.

-10-

8.0 TECHNICAL DATA

Resolution of the display 0,1% water content

0,5°C temperature

Measuring range 5 up to 50 % depending on the material

Operation temperature 0°C up to 40°C

Storage temperature -20°C up to 60°C

Temperature compensation Automatically

Power supply 4 pcs. 1.5 Volt AA Alkaline batteries

(1800 measurements)

Auto Switch OFF After app. 6 minutes

Current consumption 55 mA (with light)

Display 128 x 64 matrix display (lighted)

Dimensions 260 x 70 x 250 mm

Weight app. 1.3 kg (with batteries)

Degree of protection IP 40

Scope of supply Plastic case

Digital scale 1000g

Measuring cup 0.5 litre

4 x 1.5Volt AA Alkaline Batteries

Electromatic Equipment Co., Inc.

-3-

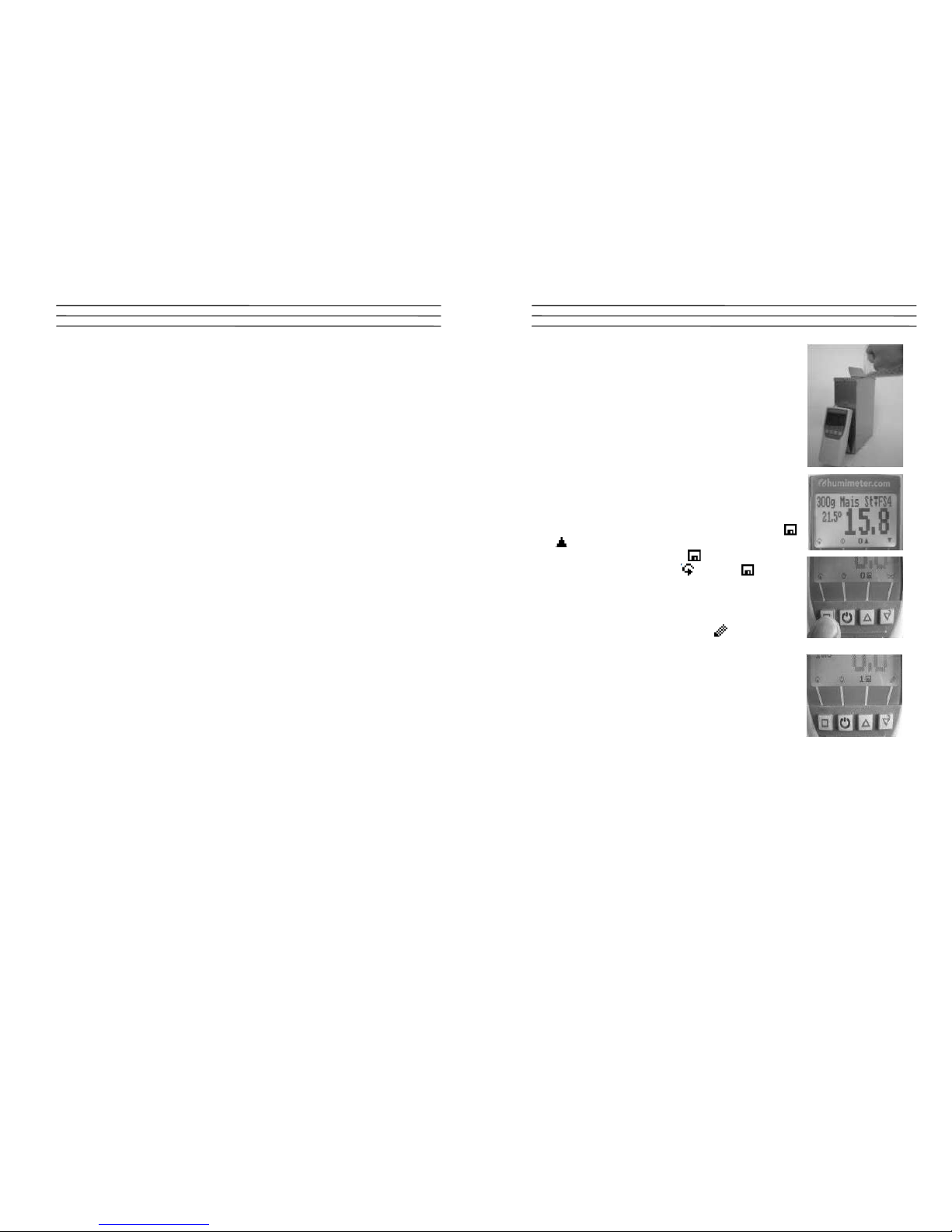

8. Fill up the measuring device with the sample material.

The filling needs to be done slowly and constantly to

ensure reproducible results.

9. The display shows the measuring result.

10. To save the results in the stor menu press the

( button). The storage was successful when the

number in front of the symbol

increased. To reach

the store menu please press (

) until the appears.

11. To name the saved results press the

button.

12. Empty the humimeter and ensure that no grain rests

are accumulated in the measuring chamber.

Electromatic Equipment Co., Inc.

-4-

2.0 CALIBRATION CURVES

Name of Calibration

curve

Material

under test

Fill quantity

300g corn stand. corn standard 300g

300g corn hand corn hand reaped 300g

300g rye rye 300g

300g triticale triticales 300g

300g whea/spe.pe wheat / spelt peeled 300g

300g barley barley 300g

190g oats oats 190g

300g rape rape 300g

230g pumpkin pumpkin seed 230g

310g peas peas 310g

300g soybean soybean 300g

277g beetle beans beetle bean 277g

295g horse bean horse bean 295g

180g sunflower sunflower seed 180g

reference -------- --------

Reference: To test the humimeter FS2. Do not use for measuring the moisture!

Electromatic Equipment Co., Inc.

-9-

6.0 CHANGING BATTERIES

Your new device is provided with batteries.

Change the batteries:

1. Press with your finger onto the arrow of the battery

cap and pull it back.

2. Remove the empty batteries.

3. Put four new batteries in the device. Make sure the

position of the battery poles is correct.

4. Press down the batteries and close the cap.

7.0 DETERMINATION OF THE MATERIAL MOISTURE

The principle is a comparison measurement with the drying out method according to

DIN 10350: 1967 09. Take the measured sample and weigh it. Dry it out in an oven

and weigh it again. Following formula can be taken to determine the absolute

moisture:

Note: The dried material may not be used any more for measuring purposes!

Mn : Mass with average moisture content

M

t

: Mass of the dried sample

%F : Calculated absolute moisture

Exemption from liability

For miss-readings and wrong measurements and of this resulting damage we refuse

any liability. This is a device for quick determination of moisture. The moisture

depends on multiple conditions and multiple materials. Therefore we recommend a

plausibility check of the measuring results. Each device includes a serial number

and the guarantee stamp. If those are broken, no claims for guarantee can be

made. In case of a faulty device, please contact Electromatic.

%F = x 100

Mn - M

t

Mn

Electromatic Equipment Co., Inc.

-8-

4.0 MOST COMMON REASONS FOR MISS READINGS

• Product temperature out of application range

Material below 0°C resp. above 40°C (32 to 104 °F) may cause faulty

measurements. The storage of cold material in a warm storage area usually

creates condensed water which may lead to major measuring errors.

• Not adjusted material

Let your humimeter FS2 adjust to the surrounding temperature of the material for

approximately half an hour.

A very high temperature difference has a negative effect on the stability of the

measurement result.

• Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

• Wrong fill quantity

Fill exactly the right weight (± 1.0 g) in the measuring chamber.

• Wet or mouldy material

• Frozen measuring material.

5.0 DEVICE MAINTENANCE INSTRUCTIONS

To provide a long lives of your device please do not expose it to strong mechanical

loads or heat e.g. dropping it or direct sunlight exposure.

Clean your device using a dry cloth. The measuring chamber needs to be cleaned

with a dry and soft brush.

Any kind of wet cleaning damages the device. The instrument is not rainproof. Keep

it in dry areas.

We recommend an interval ISO-conforming device check with the drying method.

Electromatic will also provide for a fee a test with a calibration certificate.

Electromatic Equipment Co., Inc.

-5-

3.0 DESIGN OF THE DEVICE

Batteries slot

(flipside)

Measuring

chamber

Filler assistance

Name of

calibration

Moisture content

POWER button

Electromatic Equipment Co., Inc.

-6-

3.1 Menu

There are 3 menu levels.

The symbols show the key functions in the different menus.

1. Type Selection :

2. Store Menu :

3. Main menu:

Edit Logs

Manual Logs

Clear Logs

Print Logs

Last Log

All Logs

Clear

Send Logs

Manual Logs

Clear Logs

Options

Date / Time

Language

Unlock

°C / °F

Password

Reset

Materialcalib.

Status

Electromatic Equipment Co., Inc.

-7-

3.2 Keypad symbols

Measuring window:

: Rolling Menu

: Power ON / OFF

: Switch upper

: Switch lower

: Save

: Hold

: Watch the measuring rows

: Suppliers data can be added

Menu:

: Enter

: Switch upper

: Switch lower

: Exit

: Enter numbers

: Enter letters

: Next or right

: Left

: Yes

: No

: Shift

: OK

FS2

GRAIN MOISTURE METER

OPERATING INSTRUCTIONS

Distributed by:

ABQ Industrial LP USA

Tel: +1 (281) 516-9292 / (888) 275-5772 eFax: +1 (866) 234-0451

Web: https

://www.abqindustrial.net E-mail: info@abqindustrial.net

Loading...

Loading...