1

1.00 INTRODUCTION . . . . . . . . . . . . . . . 2

2.00 DTMB OVERVIEW . . . . . . . . . . . . . 3

3.00 DESCRIPTION OF KEYS . . . . . . . . . 4

4.00 QUICK START INSTRUCTIONS . . 5

4.10 Setup

4.20 Operation

5.00 SETUP . . . . . . . . . . . . . . . . . . . . . . 8

5.10 Installing Batteries

5.20 AC Adapter

5.30 Configuring Dip Switches

5.31 Access the DIP Switch Block

5.32 Setting the DIP Switches . . . .

5.40 Thickness Compensator

5.41 Preparing Sample .

5.42 Inserting Sample .

5.50 Gravity Correction (Zero)

6.00 BUILT-IN MEMORY SYSTEM . . . . 14

6.10 Standard Memory

6.11 Viewing Data

6.12 Clearing Data

6.20 Standard NAPO Memory

7.00 CALIBRATION . . . . . . . . . . . . . . . . 16

7.10 Checking Calibration

7.20 Field Calibration Adjustment

7.30 Special Calibraton

8.00 GENERAL NOTES . . . . . . . . . . . . . 19

8.10 Turning Power On/OFF

8.20 Display Indicators & Codes

8.21 Over Range

8.22 EPROM Error

8.23 Low Battery

8.30 Options

8.31 Ultra-High Speed Rollers

8.32 Lever

8.33 AC Adapter

8.34 Special Calibration

8.40 On-Line Mounting Holes

9.00 SPECIFICATIONS . . . . . . . . . . . . . . 22

10.00 WARRANTY . . . . . . . . . . . . . . . . . . 24

INDEX

OI810B

24

10.00 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original purchaser that this product is of merchantable quality and confirms in kind and quality with

the descriptions and specifications thereof. Product failure or malfunction arising out of

any defect in workmanship or material in the product existing at the time of delivery

thereof which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at ELECTROMATIC’s option, except

where unauthorized repair, disassembly, tampering, abuse or misapplications has taken

place, as determined by ELECTROMATIC. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by ELECTROMATIC, in advance, with all

repacking and shipping expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE OR

APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE NOR LIABLE FOR

ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR NATURE, RESULTING FROM

THE USE OF SUPPLIED EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS

DISCOVERED BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND

WHETHER OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR

SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation may not apply to you. The duration of any

implied warranty, including, without limitation, fitness for any particular purpose and

merchantability with respect to this product, is limited to the duration of the foregoing

warranty. Some states do not allow limitations on how long an implied warranty lasts

but, not withstanding, this warranty, in the absence of such limitations, shall extend for

one year from the date of invoice.

ELECTROMACTIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

2

1.00 INTRODUCTION

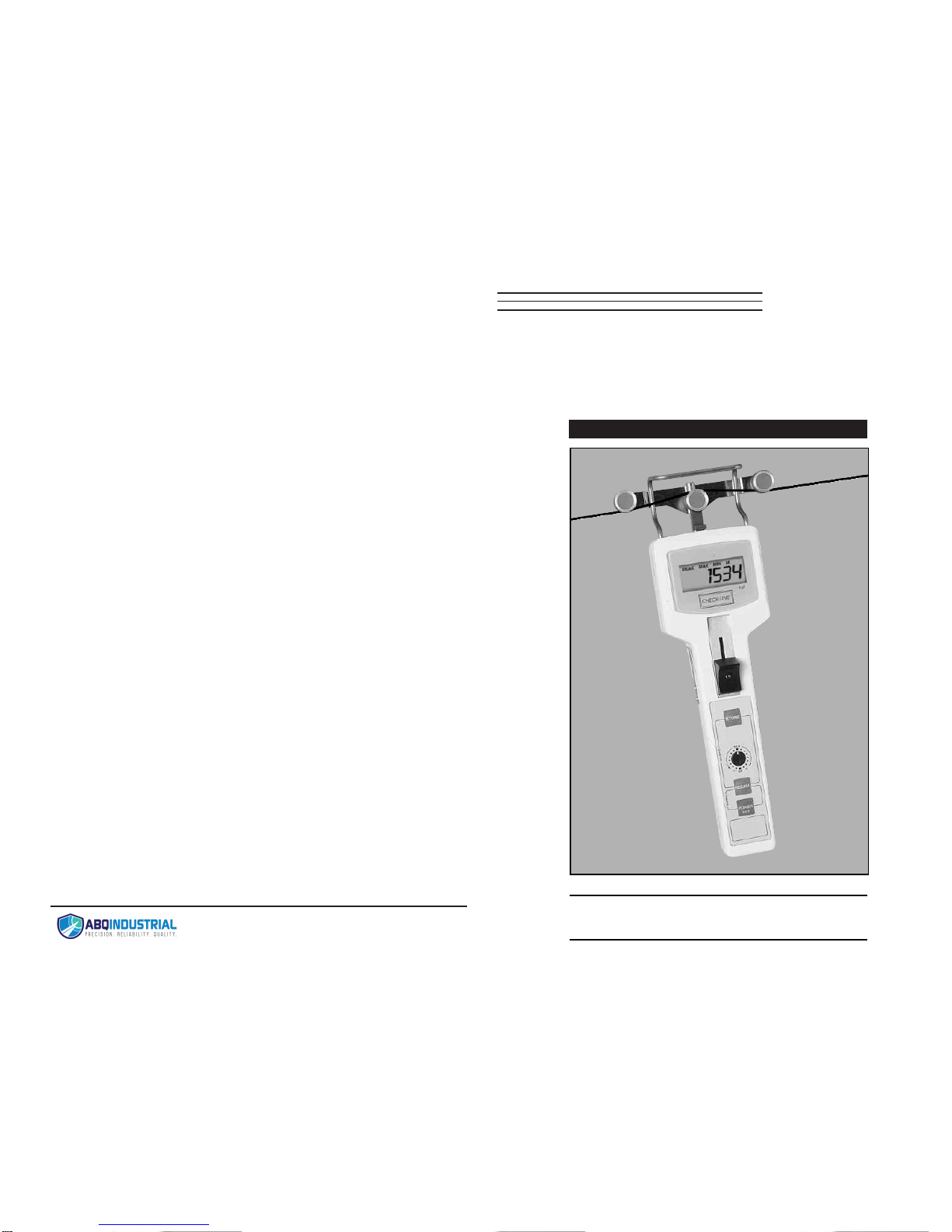

The CHECK•LINE®DTMB Digital Tension Meter is a hand-held device which

accurately measures the running as well as static tensions of a wide variety of

process materials including yarns, fibers, wires, optical fibers, etc. It employs

the "three-roller principle" of tension measurement where the outer two reference rollers are fixed to create a known angle of wrap over the middle sensing

roller. The middle roller is part of a precision strain gauge sensing system

which accurately measures the resulting force on the roller. This value is converted into a highly accurate and repeatable tension value using proprietary

computer calibration formulas which correct for different material diameters,

gravity and other critical parameters. The DTMB is powered by four AA batteries and is supplied in a rugged, die-cast aluminum housing.

The DTMB takes 62 tension measurements per second and displays the average of these measurements over a user-selected interval of 0.5, 1, 2 or 4 seconds, the Display Update Rate. This permits the user to determine the extent

of averaging (or damping) required to "stabilize" the tension readings, making

them much easier to read and eliminating the undesirable "bouncing needle"

condition found on most mechanical tension meters. To set or change the

Display Update Rate, refer to Configuring Dip Switch Settings, Section 5.30.

A built-in memory system is provided which permits storage of the maximum,

minimum and peak values occurring during a measuring interval. These values

can be recalled to the display for viewing.

23

Specifications

Measuring Principle Strain gauge

Measuring Frequency 16 msec (62.5 samples/sec)

Deflection of Sensing Roller (max.) 0.2 mm

Overload Capacity 200% of Full Scale

Temperature Coefficient Zero: less than +0.3% FS/ °C Span: less than +0.01% FS/ °C

Display 4-Digit LCD, 12 mm high

Display Update Rate 0.5, 1.0, 2.0 or 4.0 seconds, dip-switch selectable

Memory System Last, maximum, minimum and peak values

Overrange Indicator Value will blink on/off, then “FFFF”

Field Calibration Adjustment

+

7 steps, 1.5% per step

Battery Type Four (4) 1.5 V AA (included)

Battery Life 20 hours, continuous use

Auto Power Off After 2 minutes of non-use

Roller Material (standard) Hard-coated Aluminum ..

. (optional) Hardened Steel (ST), Ceramic (CE), Plastic (PL)

Maximum Speed (standard) 2000 m/ min ...

. (optional) 5000 m/ min

Housing Die-cast Aluminum

Dimensions 2.95" W x 10.83" H x 1.77" D

(75 x 275 x 45 mm)

Weight (approximate) 1.43 lbs.

(650 g)

Operating Temperature 32 to 132 °F

(0 to 45 °C)

Accessories Included 4 AA batteries and operating instruction guide, all in a fitted,

hard-plastic carrying case

Warranty One year

3

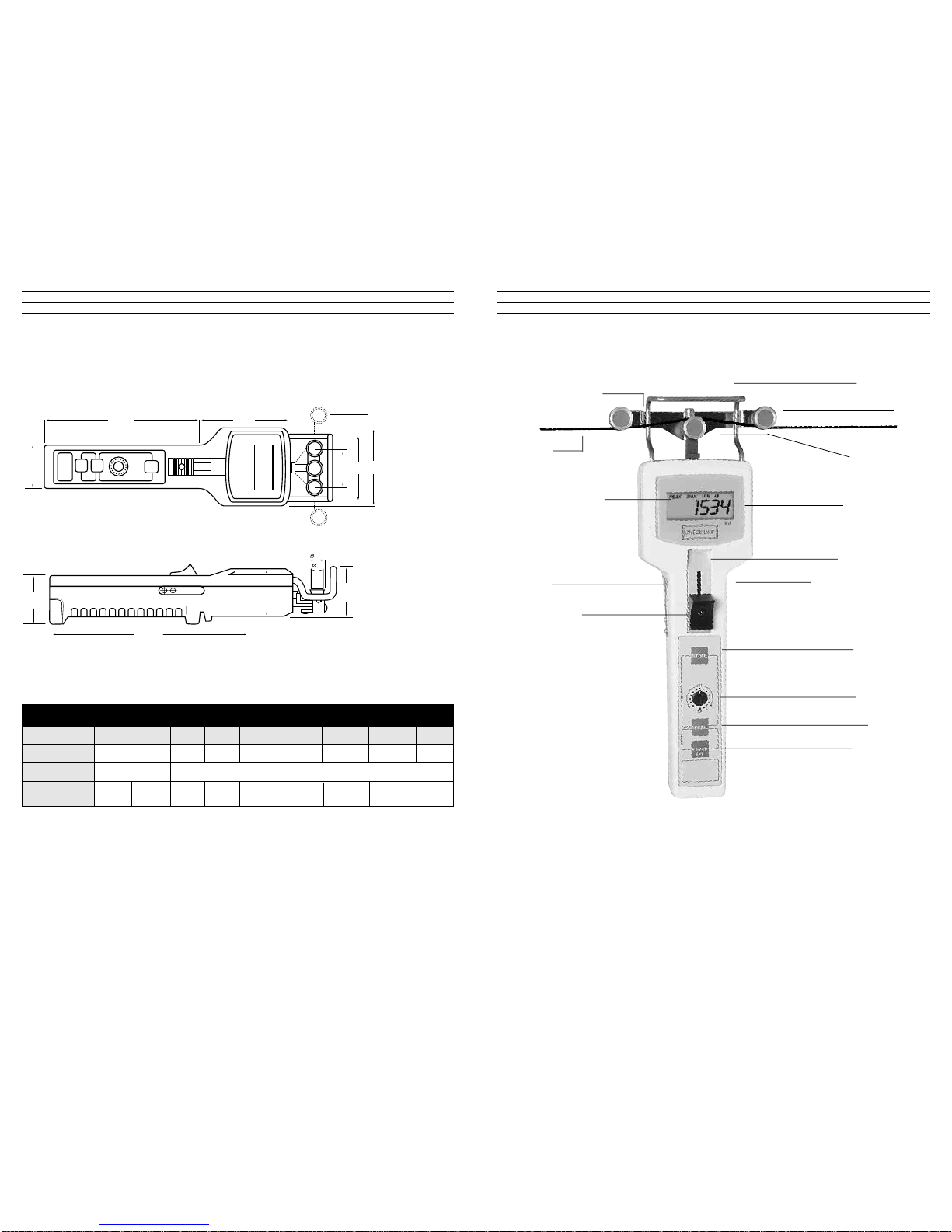

Filament Guide

Rollers

LCD Display

Slide Guide Plate

Thickness Compensator

(on back of unit)

Field Calibration

Adjustment

STORE Key

Recall Key

Power/Exit Key

Middle Sensing

Roller

Display Symbols

• MAX

• PEAK

• BATT

• MIN

Filament

Outer Roller Bracket

Sample Holding

Clips

Thumbpiece

2.00 DTMB OVERVIEW

Model DTMB-200 DTMB-500 DTMB-1K DTMB-2K DTMB- 2.5KB DTMB-5KB DTMB-10KB DTMB-20KB DTMB-20KB

Tension Range (grams) 0.1–200.0 0.1– 500.0 50 –1000 200– 2000 250 –2500 500 –5000 1.00– 10.00 Kg 2.00–20.00 Kg 50 KB

Accuracy +

1.0% or better +1.5% or better

Outer Roller Dist. (c:c) 38 mm 38 mm 38 mm 38 mm 100 mm 100 mm 100 mm 200 mm 200 mm

22

10.00 SPECIFICATIONS

37

153 60

38 65 76

Outer roller spacing c:c

2.5KB–10 KB 100 mm

20KB– 50 KB 200 mm

40

192

45

48

15

12

All dimensions in mm

Model Data

4

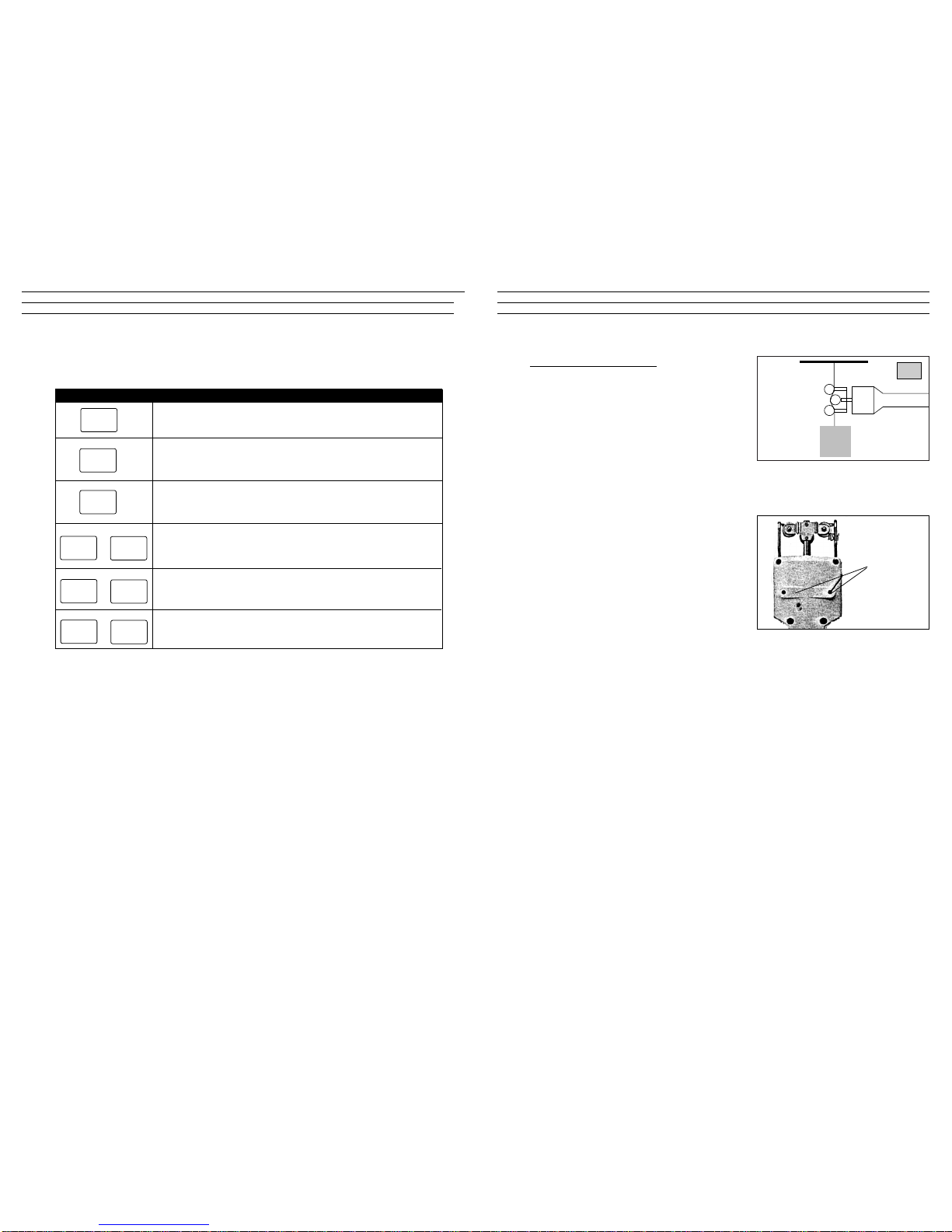

• Starts/Stops scanning for Max/Min/Peak values. (Standard Memory)

• Starts/Stops automatic recording of values into memory (Continuous Data Logging Model).

• Loads displayed value into memory (On-Demand Data Logging Model).

• Enters Recall Mode to review statistics and recorded Data.

• In recall mode, changes display from LAST ➔ MAX ➔ MIN ➔ PEAK ➔ LAST ➔ MAX etc.

• When in Data Logging Mode: changes display from LAST ➔ MAX ➔ MIN ➔ PEAK.

➔ AVERAGE ➔ STANDARD DEVIATION➔ D ATA # 1➔ D ATA #2 ➔ DATA #3 etc.

• Turns power on.

• Turns power off if pressed and held for 5 or more seconds.

• Exits from Recall Mode when reviewing data.

• Clears all data in Basic Memory (“CCCC” momentarily shown on display).

• Zeros gauge (“Tare”) for use in any orientation (“Gravity Correction”).

Key Description of Functions

3.00 DESCRIPTION OF MEMBRANE KEY FUNCTIONS

STORE

RECALL

POWER

EXIT

RECALL

STORE

+

POWER

EXIT

RECALL

+

* When the units of measure are changed to grams, the “gf” indicator will

momentarily flash on and then turn off. Otherwise the “lb.” or “oz” indicators

will be shown.

• Changes units of measure from grams (or Kg) to pounds (or ounces) and back again

each time this key combination is pressed.

STORE

POWER

EXIT

+

*

21

8.34 Special Calibration

If the standard Factory Calibration and

the Field Calibration Adjustment does not

provide the desired accuracy, a Special

Calibration can be ordered. A l0' sample

of the process material must be provided

for calibration purposes.

8.40 On-Line Mounting Holes

The DTMB is supplied with two threaded

holes for on-line mounting in a fixed position when performing measurements over

an extended period.

Thread Size M5 (metric)

Thread Depth 7.5 mm (max.)

W

Mounting

holes

SP

5

4.00 QUICK START INSTRUCTIONS

4.10 Setup

1. Insert a sample of the process material into the Thickness Compensator and

secure the ends of the sample under the Sample Holding Clips on each side

of the unit.

Note: Thickness Compensator is not used on the DTMB-200 Model.

2. Set the Field Calibration Adjustment to "STD”

4.20 Operation

1. Turn the unit on by pressing the

key. Display should show zero

when unit is in measuring position. If

the gauge displays zero go to Step 3,

otherwise perform a Gravity Correction

Procedure (Step 2).

2. Position the DTMB into the measuring

position and perform a Gravity

Correction procedure (Zero):

Press the and keys

simultaneously, and hold until the

display shows “0” or “0.0”.

POWER

EXIT

POWER

EXIT

RECALL

20

8.23 Low Battery

When the BATT indicator appears on the

display, the batteries are low. Data will be

lost when the batteries are removed.

8.30 Options

8.31 Ultra-High Speed Roller Assemblies

For line speeds up to 5,000 m/min., specify

“U” roller guides.

8.32 Lever

For high tension ranges, specify an “L”

Lever attachment to make it easier to push

the outer rollers forward for material

acquisition.

8.33 AC Adapter.

Use this adapter during long-term, on-line

measurements to save battery power.

Connects to 115 VAC power sources.

BATTindicator appears on

display.

U

L

AC

6

3. Open the 3-roller system by pushing the

Thumbpiece forward until the outer rollers

extend beyond the Filament Guide.

Position the DTMB so that the process

material contacts the Filament Guide and

passes between the outer rollers and the

middle sensing roller.

4. Release the Thumbpiece SLOWLY until

it returns to its original position. Do

not let it snap back as this could

effect the calibration and damage

the instrument. The display will begin

to show tension readings.

5. Press the key to start and stop

the Measuring Interval.

The M indicator will blink on and off

indicating that the memory is active.

Refer to Built-In Memory, Section 6.00.

STORE

Filament

Filament guide

Thumbpiece

19

8.00 GENERAL NOTES

8.10 Turning Power On/Off

Turn Power On: Press key

T

urn Power Off: Press and the key

for five (5) seconds

Note: DTMB will power off automatically

after 90 seconds of inactivity, except for the

following instances:

• Memory Mode configured for Standard - NAPO (No Auto Power Off)

• When AC Adapter is used

8.20 LCD Display Indications and Codes

.

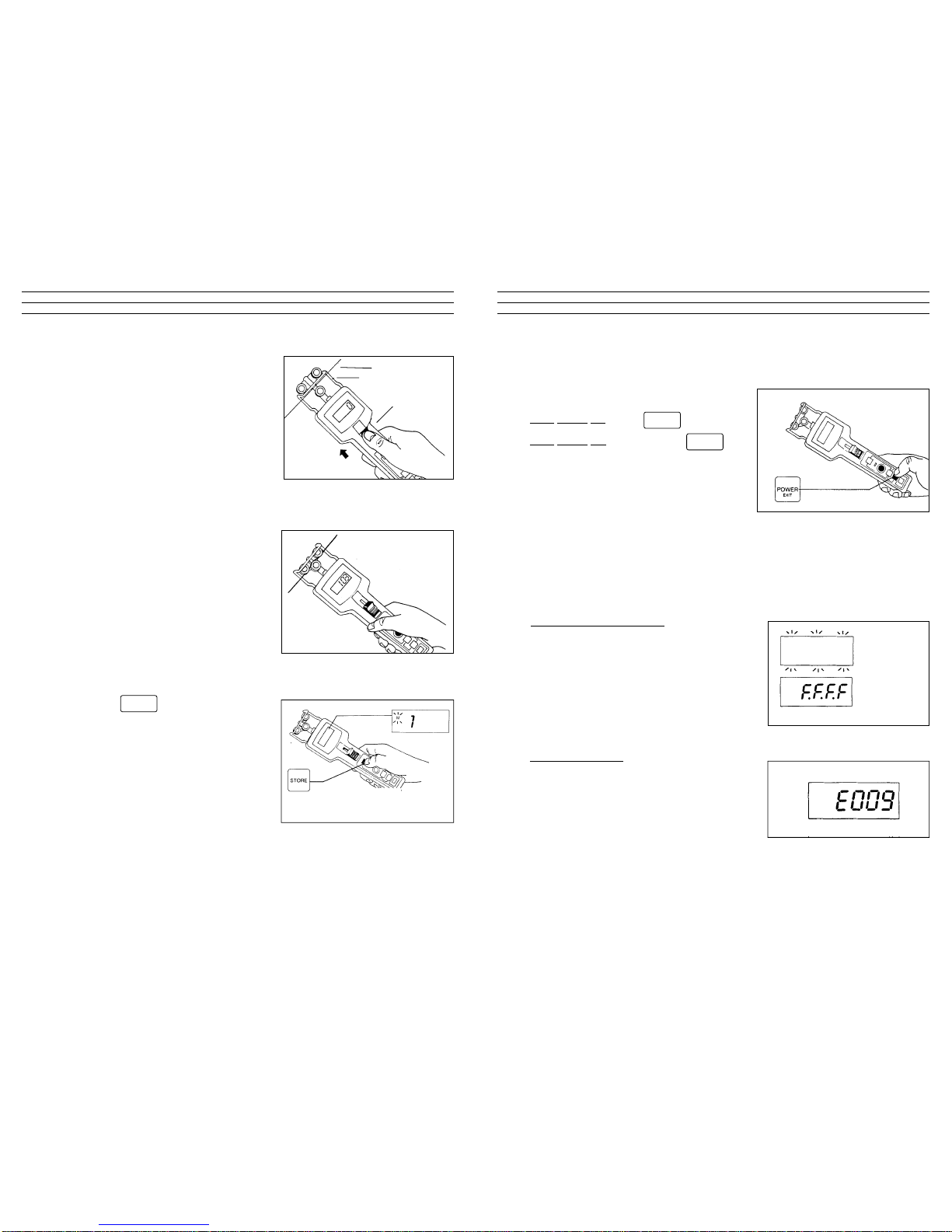

. 8.21 Over Range Display

When a displayed value is flashing on & off,

this indicates that this reading is higher than

the maximum range of the unit. The accuracy

of the flashing value is not guaranteed. When

all F’s are displayed, this indicates that the

current value greatly exceeds the maximum

range of the unit.

8.22 EProm Error

When this code is displayed, the EProm is

not responding properly. Try turning the

power off and then on again. Try this a few

times. If code will not clear, contact factory.

POWER

EXIT

POWER

EXIT

Flashing

display

values

All “F’s” in

display

“E0009” in display

7

6. Press the key repeatedly to

review the data stored in memory.

Press the key at any time to exit Recall Mode.

The DTMB will automatically power off after 90 seconds of inactivity.

To manually turn off the power, press and hold the key for

5 seconds.

RECALL

MAX

MIN

PEAK

Maximum Value

Last Reading

Minimum Value Peak Value

POWER

EXIT

POWER

EXIT

18

7.20 Field Calibration Adjustment

The Field Calibration Adjustment permits

the end user to "shift" the calibration curve

to provide better accuracy when the Factory

Standard Calibration is not suitable. Each

step on the Field Calibration Adjustment

will increase (clockwise) or decrease

(counterclockwise) the displayed value

by 1.5%.

Increase: [7 steps] x [1 .5% per step] = +10.5%

Decrease: [7 steps] x [1.5% per step] = –10.5%

If a Field Adjustment Calibration is not adequate, the accuracy of the DTMB

can be increased further by ordering a Special Calibration using a calibration

sample supplied by the user. Refer to Special Calibration, Section 7.30.

7.20 LCD Display Indications and Error Codes

7.21 Over Range Display

When a displayed value is flashing on & off, this

indicates that this reading is higher than the

maximum range of the unit. The accuracy of the

flashing value is not guaranteed. When all F’s are

displayed, this indicates that the current value

greatly exceeds the maximum range of the unit.

7.22 Error Codes

If the Error Code “E009” is displayed, try turning

the power on and off a few times to clear it. If it

does not clear, contact the factory. If the Error

Code “E001” is displayed, the user is attempting

to store date with units (g or lb.) different than

those values already stored in memory. Clear the

data stored in memory and start again.

Decrease

1.5%

per step

Increase

1.5%

per step

Factory Calibration

Special Calibration

8

5.00 SETUP

5.10 Installing/Replacing Batteries

1. Using a slotted screwdriver or coin,

loosen the battery cover screw located

at the end of the unit by turning the

screw counterclockwise.

2. Insert four (4) AA , 1.5 volt akaline

batteries into the battery sleeve.

Insert them in the direction indicated

on the top of the sleeve. Use of NiCad

rechargeable batteries is not

recommended.

3. Replace battery cover by first inserting

the tab of the cover into the slot of the

housing and pressing the cover into

place. Tighten the screw by turning it

clockwise.

NOTES:

1. If battery cover will not close, confirm that the batteries are inserted in the

proper orientation. Refer to step 2 above.

2. After replacing the battery, make sure the proper units of measure are

selected.

Battery cover screw

Battery cover

Battery sleeve

Battery

cover

tab

17

7.10 Checking Calibration

It is important to check the calibration of the DTMB

frequently to insure that the gauge continues to

perform within factory specifications. Implementing

a periodic calibration check will help identify when

(and if) the gauge goes out of calibration due to

unreported damage, overload, or other unknown

reason.

To check the calibration:

1. Suspend a known weight “W” from the

process material in either a vertical or

horizontal direction, best simulating the

orientation that will be used during

actual measurement. Fix the process

material at one end.When fixing the

process material horizontally, use a

roller (or other free-rotating guide) prior to fixing the known weight. Refer to

sketches. Select a weight within the expected operating tension range of the

the application

2. Setup DTMB by inserting sample into Thickness Compensator and

performing a Gravity Correction (Zero) if using a horizontal material path.

Refer to QuickStart Instructions, Section 4.0.

3. The DTMB should display a value equal to (or within quoted accuracy

specification) of the known Weight “W”. If not, refer to Field Calibration

Adjustment, Section 7.20.

W

Horizontal Material Path

W

Vertical

Material

Path

Roller

Roller

9

5.20 Using AC-Adapter

The optional AC-DTMX AC Adapter can be

used as an alternative to batteries. Plug one

end of the adapter into an appropriate AC

outlet and the other end into the receptacle

located on the side of the DTMB.

NOTES:

1. When using the AC Adapter, do not remove the batteries as they are used

to save the data in memory when the power is turned off.

2. If the units of measure were changed while the AC Adapter was in use, the

units of measure will revert back to the one’s selected prior to the change.

AC Adaptor receptacle

16

7.00 CALIBRATION

The DTMB is factory calibrated by taking a series of measurements with

known weight standards suspended from Factory Calibration Standard

Materials. The built-in microprocessor uses this calibration data with a complex

formula to calculate a calibration curve which takes into account the material

thickness and orientation of use. The factory calibration works well in most

cases. However, if the process material to be measured differs significantly

from the Factory Calibration Standard Materials (see table below) or if the

application requires the highest accuracy possible, perform a Field Calibration

Adjustment (refer to Section 7.20) or return the gauge to the factory for an

optional Special Calibration.

Note: When ordering a Special Calibration, please supply a 10' sample of the

process material for calibration purposes.

Model Monofilament (mm)

DTMB-200 0.10

DTMB-500 0.10 and 0.20

DTMB-1K 0.20 and 0.40

DTMB-2KB 0.40 and 0.70

DTMB-2.5K 0.40 and 0.70

DTMB-5KB 0.60 and 1.20

DTMB-10KB 0.80 and 1.40

DTMB-20 KB Customer supplied sample

DTMB-50 KB Customer supplied sample

10

5.30 Configuring Dip Switches

The DTMB is supplied with six (6) dip switches permitting the user to select

desired Display Update Rate and Memory Mode as detailed below.

To access the dip switches, the Thumbpiece and Slide Guide Plate must be

removed. Refer to access instructions below.

5.31 Accessing The Dip Switch Block

1. Turn the DTMB power off by pressing and holding the key

for five (5) or more seconds. The display will go blank.

2. Using a small Phillips screwdriver, remove

the screw in the center of the Thumbpiece.

Remove the Thumbpiece and screw. The

Slide Guide Plate and screw will be visible.

3. Using a small Phillips screwdriver, remove

the screw at the bottom of the Slide Guide

Plate and remove plate.

Display Update Rate

Memory Mode

0.5 sec. 1 sec. 2 sec. 4 sec.

Standard Standard-NAPO

= Denotes Factory Setting Standard N A P O = Standard Memory with No Auto Power Off

POWER

EXIT

Slide Guide

Plate

Thumbpiece

15

6.11 Viewing Data in Standard Memory

To view data stored in Standard Memory, press the key.

The following will be displayed when the key is pressed repeatedly.

Each time the key is pressed the displayed value will change.

Press the key at any time to exit the Recall Mode.

6.12 To Clear All Data Stored in the Standard Memory

Press the key and the key simultaneously

6.20 Standard Memory with No Auto Power Off (Standard - NAPO)

This memory mode is identical to the Standard Memory Mode detailed above,

except that when configured in this mode the power will not turn off

automatically after 90 seconds of inactivity.

MAX

MIN

PEAK

Maximum Value

Last Reading

Minimum Value Peak Value

Action Display Will Show LCD Indicator

Press R

ECALL key Maximum Value MAX

Press R

ECALL key Minimum Value MIN

Press R

ECALL key Peak Value PEAK

Press R

ECALL key Last Reading none

RECALL

RECALL

POWER

EXIT

STORE

RECALL

11

4. The Dip Switch Block will be located

at the top of the opening after

removing the Slide Guide Plate.

5.32 Setting Dip Switches

Using a small slotted screwdriver or other pointed tool, slide each of the five (5)

Dip Switches into the ON (up) or OFF (down) position as indicated in the illustration below for the desired setting. Dip Switch #6 is not used.

Memory Mode DIP-5 Data Stored in Memory

Standard Memory OFF MIN, MAX, PEAK

Standard Memory

Without Auto– ON MIN, MAX, PEAK

Power Off

Display Update Rate DIP-1 DIP-2 DIP-3 DIP-4

0.5 sec ON OFF OFF OFF

1.0 sec OFF ON OFF OFF

2.0 sec OFF OFF ON OFF

4.0 sec OFF OFF OFF ON

123456

ON

DIP Switch #6

(Not Used)

Factory switch:

DO NOT

TOUCH

DIP switches

14

6.00 BUILT-IN MEMORY SYSTEM

The DTMB Built-In Memory System can be configured to operate in one of two

modes: Standard Memory or Standard Memory With No Auto Power Off. The

data stored in the Standard Memory can be recalled to the display for viewing.

6.10 Standard Memory Mode

The DTMB takes 62 tension measurements per second and displays the average of these measurements over a user-selected Display Update Rate of 0.5, 1, 2

or 4 seconds. The Standard Memory system checks each displayed value and

retains the Maximum, Minimum and Peak tension values which occurred during the Measuring Interval. The Measuring Interval is started and stopped by

pressing the key.

Maximum V

alue: highest

displayed value during

measuring interval

Minimum

Value: lowest

displayed value during

measuring interval

Peak V

alue: highest transient

valu of all of the measurements used to calculate each displayed value

Note: The “M” indicator on the LCD display will flash on and off, indicating

that the Standard Memory system is activated.

To Start/Stop measuring interval for Standard Memory, press key.

STORE

STORE

1312

5.42 Inserting Sample Into Thickness Compensator

Push the Thumbpiece forward to separate the two

anvils. Insert the sample into the slot and slowly

release the Thumbpiece back to its resting position.

The material sample should be secured between

the two anvils. Place the ends of the sample under

the Sample Holding Clips located on each side of

the unit. If the ends stick up bend them back so they will not present a safety

hazard.

NOTE: In lieu of a sample, an equivalent shim can be inserted into the

Thickness Compensator as long as its compressed thickness is the same as the

process material. The shim should be secured using a spray adhesive on one

side, so it will not fall out each time the Thumbpiece is pushed forward.

5.50 Gravity Correction Procedure (ZERO)

The DTMB is factory calibrated for use in

the right-handed, horizontal position

(vertical material path) with the rollers

aligned vertically. When using the DTMB

in any other orientation, a Gravity

Correction Procedure (Zero) should be

performed.

Hold the instrument in the measuring

position and press the and

keys simultaneously. The display will show zero.

The DTMB is now ready for use.

POWER

EXIT

RECALL

Sample Holding Clip

5.40 Thickness Compensator

When using the "three-roller” principle of tension measurement, an increase in

material diameter will result in an increased tension reading even when the line

tensions are unchanged. The DTMB is supplied with a proprietary Thickness

Compensation system which automatically shifts the outer rollers to compensate

for this effect. Additionally, the Thickness Compensator measures the material

diameter with an accuracy of 0.01 mm (0.0004 ") for use as a factor in the computer calibration formula.

The Thickness Compensator is located on the back of the instrument. When the

Thumbpiece is pushed forward, two metal plates (anvils) will separate creating a

slot for insertion of the material sample.

NOTES:

1. Some monofilaments, wires and other difficultto-bend samples will need special preparation

prior to insertion into the Thickness

Compensator. See Preparing Sample for

Thickness Compensator.

2. It is unnecessary to use the Thickness

Compensator on the DTMB-200 because the

range of material diameters used with this

model is inconsequential.

5.41 Preparing Sample For Thickness Compensator

When using monofilament, wire or other difficultto-bend materials, the sample must be prepared

properly before inserting into the Thickness

Compensator. Using the pliers supplied, bend the

sample as noted in the sketch. For monofilaments,

maintain arc “A” as shown, so sample bends into

anvils.

Thickness Compensator

anvils

1-1/4"

1-1/4"

1-1/2"

arc A

OPERATING MANUAL

Digital

TENSION METER

CHECK•LINE

®

BY ELECTROMATIC

Model DTMB

Distributed by: ABQ Industrial LP USA

Tel: +1 (281) 516-9292 / (888) 275-5772 eFax: +1 (866) 234-0451

Web: https://www.abqindustrial.net E-mail: info@abqindustrial.net

Loading...

Loading...