Page 1

Modular Rack Type Dishwasher

Page 2

electrolux wtm2

Page 3

electrolux wtm 3

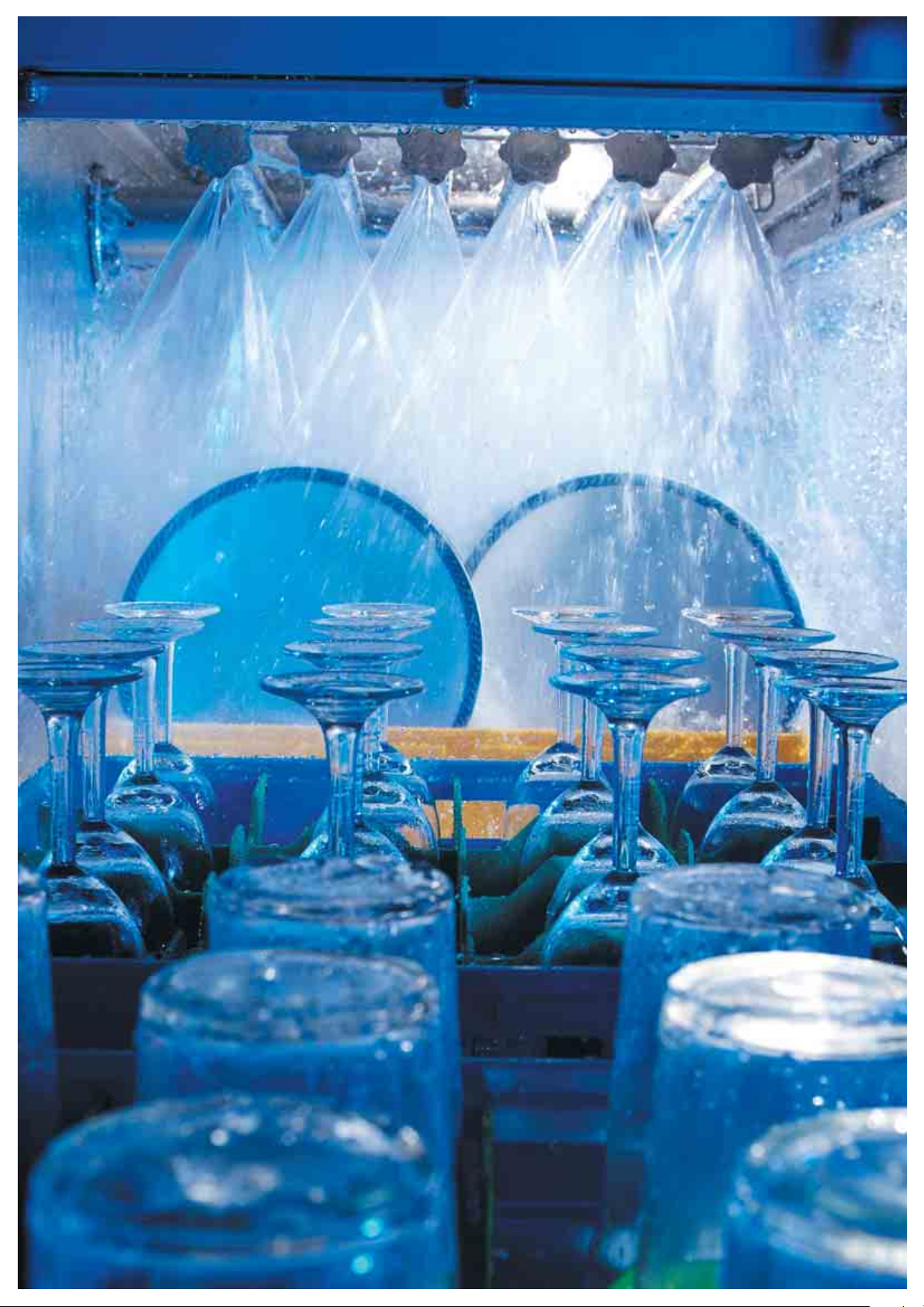

The new range of Modular Rack Type dishwashers from Electrolux

combines the highest level of washing and rinsing performance with

outstanding solidity, ideal for heavy usage installations such as hotels

restaurants, large canteens, in-flight catering and hospitals.

Washing Performance

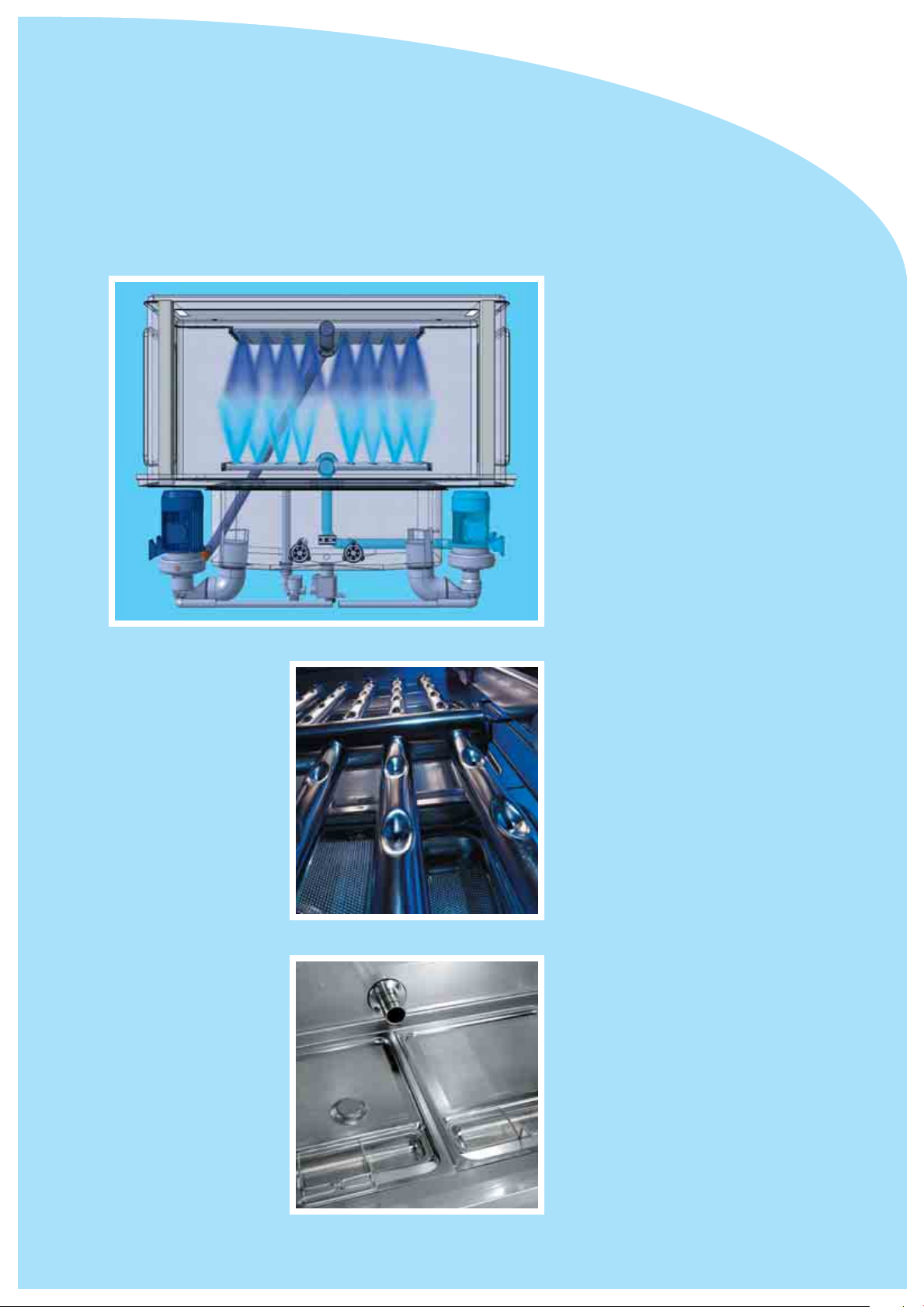

• New Ideal Wash System (IWS) to optimise results

• Duo wash configuration of wash pumps

• Maximum Water Contact (MWC) wash arms

Washware sanitisation

• Atmospheric rinse independent of incoming

water pressure

• High temperature duo rinse

Machine cleanability

• Self-draining wash pumps

• Pressed pre-wash, wash & rinse tanks

• All-round access inspection doors on every module

Sturdiness

• Solid stainless steel under-frame

• Foam injection insulated doors

• All stainless steel components

• IPX 5 water protection

Cost savings

• Continuous washing without needing to drain

detergent laden water saves 30% of water

• Duo rinse saves 50% water consumption

• Separate pre-wash zone without the need for

high volumes of cooling water

• Up to 75% detergent saving

Ergonomics

• Foam injected doors

• Low temperature drying

• Large door handles

New Ideal Wash Pressed tank

Pressed ceiling Duo rinse system

Ergonomics

Page 4

electrolux wtm4

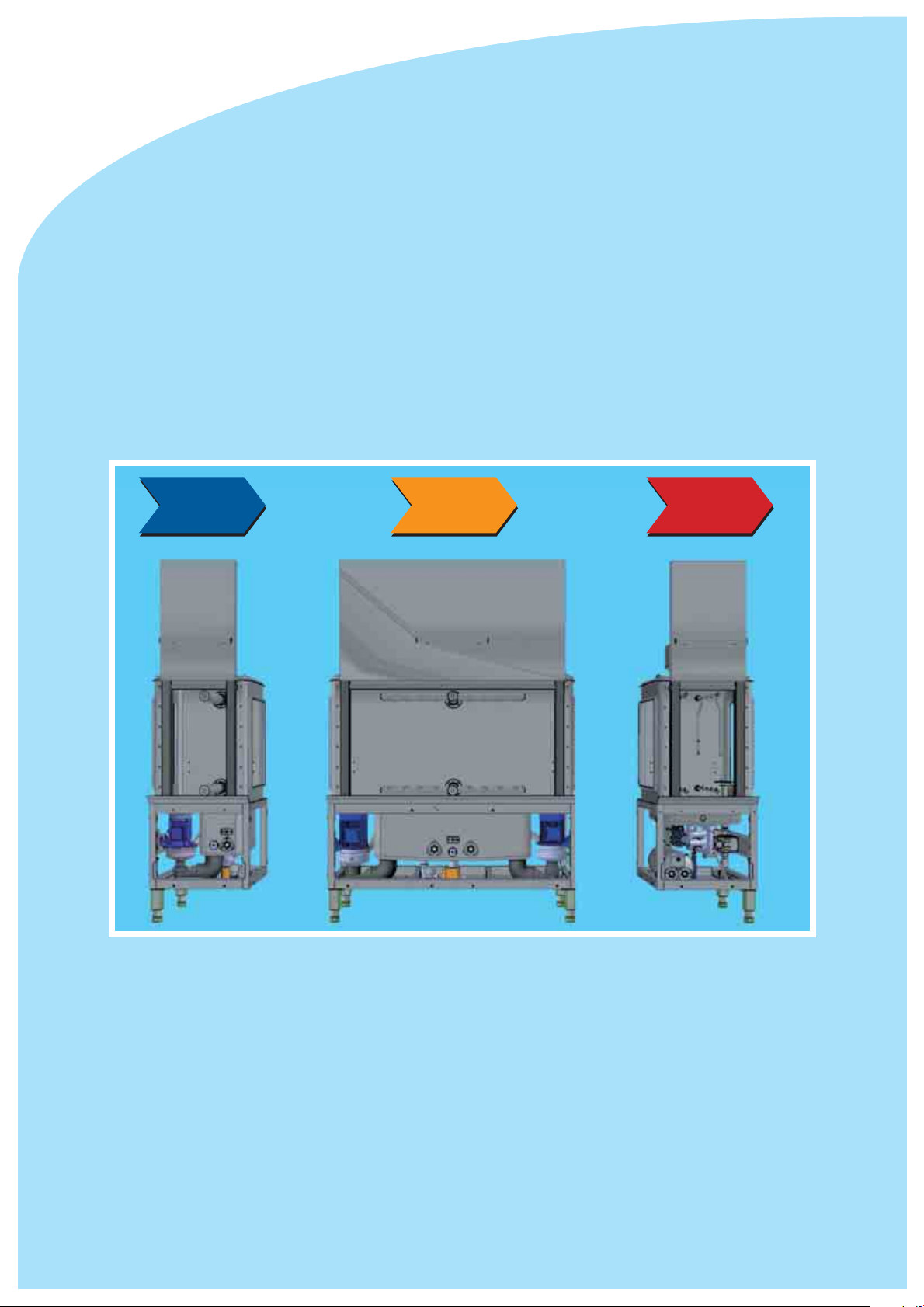

PRE-WASH

WASH

RINSE

Washing performance

The Ideal Wash System (IWS) is designed to wash every item perfectly the first time - 24 hours per day, 7 days a week.

The pre-wash zone typically contains the dirtiest water in the dishwasher and provides the base for perfect washing.

Unlike traditional systems, the Electrolux pre-wash is completely detached from the detergent laden heated wash

zone water and uses only fresh cold water to prevent protein based food stuffs sticking to the plates.

The wash zone is also physically separated from the rinse zone, (that in a traditional system is carried over from rinse area)

so the wash tank is free of rinse aid that typically weakens the washing power of the detergent; resulting in excessive

detergent consumption.

Page 5

electrolux wtm 5

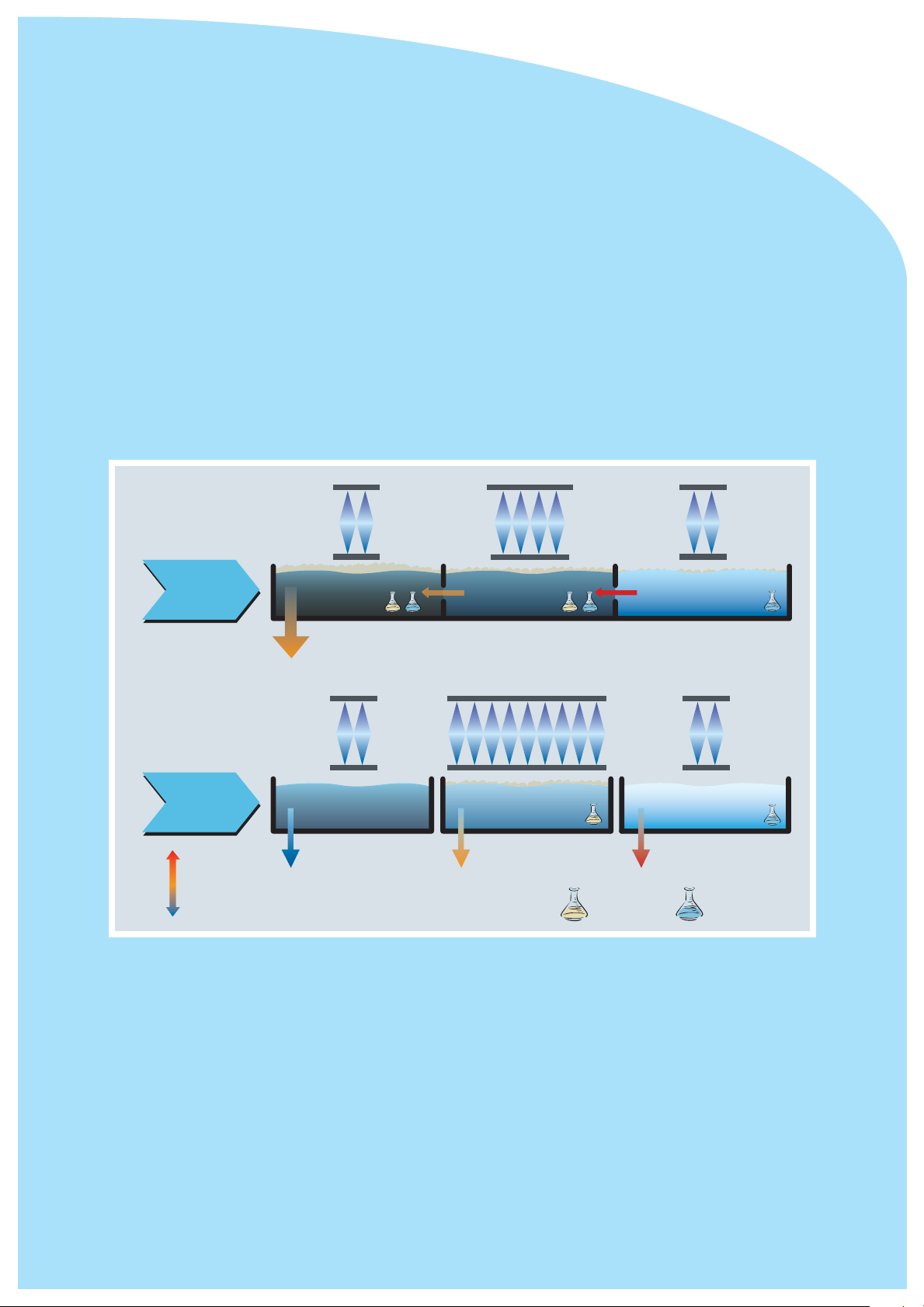

TRADITIONAL

PROCESS

Pre-wash

ELECTROLUX

IDEAL WASH

SYSTEM

Pre-wash

85°C

50°C

10°C

Wash Rinse

Wash Rinse

Detergent Rinse aid

Even during long washing periods lasting several hours, where traditional dishwashers need to be completely drained

and re-filled at some stage, the IWS continues washing with only a minimal quantity of water being consumed.

Each machine has two pre-set speeds - slow for more baked on dirt, fast for lighter soiling; both speeds

can be fine tuned on-site via the electronic control panel to suit customer needs.

When the pre-wash or wash water becomes too dirty to wash effectively, a part of the dirty wash water is automatically

drained and replenished without stopping the dishwasher enabling continuous-all day washing. Drainage quantities and

frequencies are all variable via the electronic control panel in order to maximize washing performance with minimum water

consumption.

Page 6

Page 7

electrolux wtm 7

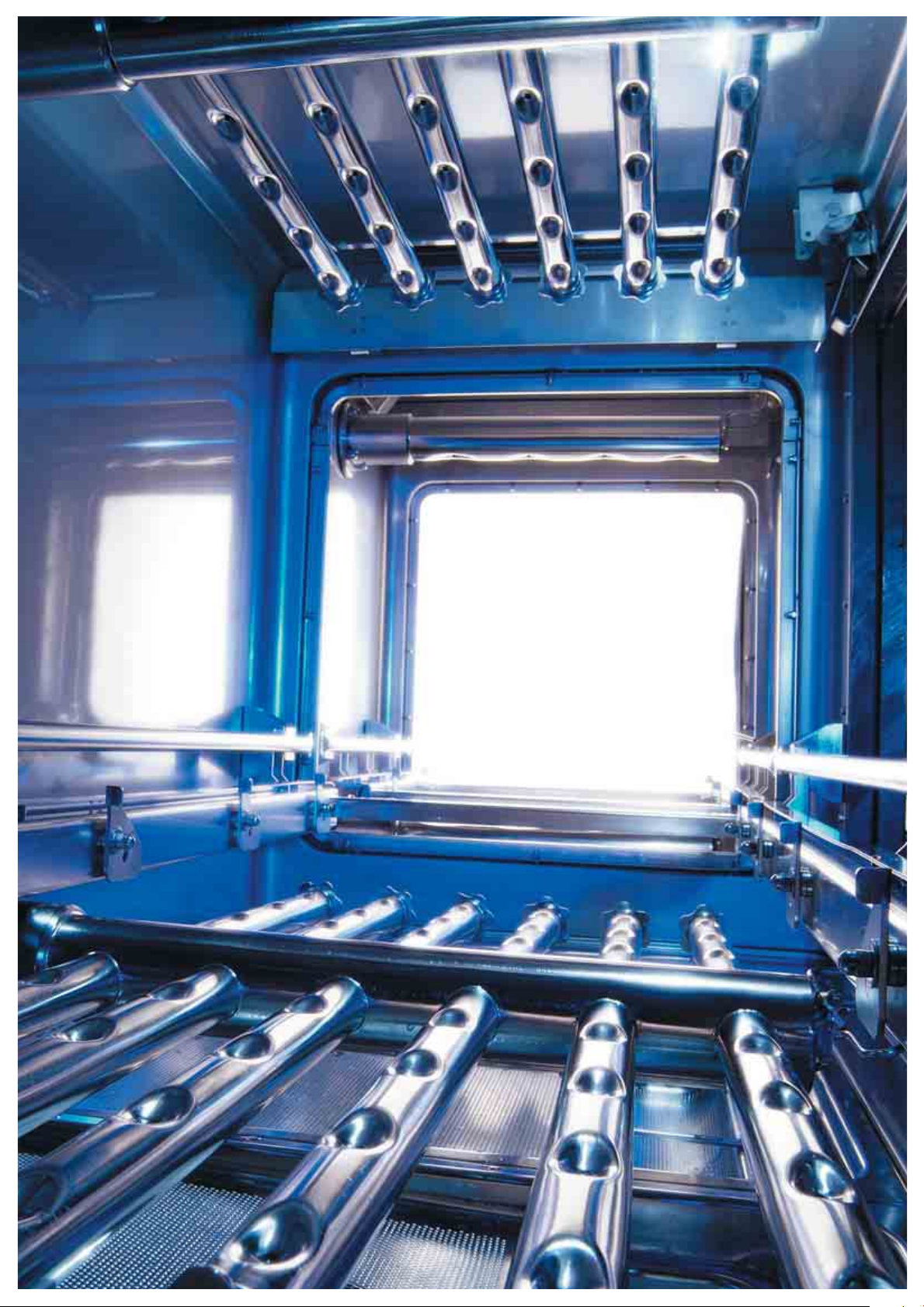

On 150 litre modules, the duo wash pump

configuration features one 2,2kW pump

supplying the upper wash arms, another

1,1kW pump supplying the lower wash

arms, concentrating as much high powered

wash water as possible - ideal for dried on

foods or where large number of containers

or utensils are washed.

In order to wash in the shortest possible

space, the Maximum Water Contact (MWC)

wash arms are positioned along the full

length of the wash tank. Thus doubling the

amount of wash water contact time in

comparison to traditional wash arm

configurations. Just because a basket is in

the wash zone for 2 minutes, it doesn’t

mean it is being washed in water

for 2 minutes.

Duo filter system minimises food debris

entering the wash water system, reducing

the need to regenerate water. The curtain

system prevents water splash over from

tank to tank.

Page 8

Page 9

Washware sanitisation

The atmospheric duo rinse system with built-in air gap

70°C 85°C

is the benchmark for rinsing. Hot water at a constant

temperature in any conditions provides the peace

of mind that every washed item will be detergent free

and sanitised.

electrolux wtm 9

Duo Rinse Pump Boiler

Duo Rinse system

Air Gap

(Type AB)

The tried and tested two stage rinse system,

the duo rinse, ensures complete detergent removal with

minimum water consumption - hot rinse even from the

nd

2

in the duo rinse tank.

The Energy Saving Device is able to pre-heat incoming

cold water, saving up to 12kW in energy as well as

condensing the steam in the kitchen.

Dry air

steam

Energy Saving Device

rinse created by additional 3kW electrical elements

50°C

70°C 85°C

Rinse Pump

Cold Water (15°C)

Atmopheric Duo Rinse shown with Energy Saving Device

Duo Rinse Pump

Boiler

Page 10

electrolux wtm10

Sturdiness

The Electrolux RT dishwasher is

designed to be the work-horse of the

kitchen, able to work continuously under

heavy conditions.

Foam insulated counter-balanced

doors add strength in arduous

conditions.

The solid 3mm thick stainless steel box

sub-frame provides long term sturdiness

with bolt-together construction that can be

split on-site for increased site accessibility.

Page 11

electrolux wtm 11

All main components made in heavy duty

anti-corrosive 304 AISI stainless steel:

all tanks, panels, wash & rinse arms

and end caps, doors, front, rear and

side-panels, feeding system fingers, basket

runners and rear tubing.

Stainless steel wash pumps ideal for

heavy duty usage installations or where

water supply is not constant.

Brass inlet valves are standard for extra

reliability at high incoming water

temperatures. IPX5 water protection for

easy hosing down of the machine exterior.

All elements in Incoloy 800, protected

against all detergents.

Page 12

electrolux wtm1212

Machine cleanability

The Electrolux Modular Rack Type

dishwashers have been engineered

to be fully and quickly cleaned both

internally and externally.

Self-draining wash pumps provide

maximum hygiene with no smells.

Hinged flap, for easy access to the energy

saving condenser unit, housed on

extractable runners to aid cleaning.

Page 13

electrolux wtm 13

Large balanced inspection doors for easy access to

wash and rinse area.

Removable washing arms and end-caps in stainless

steel.

Pressed tanks in the pre-wash, wash and rinse zones,

sloped towards drain to prevent dirt build up.

Washing chamber without internal pipes.

Page 14

Page 15

Ergonomics

electrolux wtm 15

Foam injection insulated doors to

reduce noise and cool uncomfortably hot

surfaces (less than 60°C.) Counter balanced

door with springs open with minimum

operator effort and incorporate a safety

device to block the door during cleaning.

Door handles designed to be accessed

from any position.

Quick pull-out stainless steel filters.

Easily removable “click-in / click-out” wash

arms.

The drying zone removes every trace

of water from the crockery via a high

powered fan, that sucks dry air from outside

with minimum temperature loss and

steam escape.

Page 16

Page 17

electrolux wtm 1717

Electronic control panel

Touch button electronics provide notable benefits, whether for the operator, the owner or the engineer and also the user:

in order to avoid time-loss for the operator, the electronic control audibly and visually signals on the display, messages such as:

Door open - close the door / Warm up / Clean - cleaning cycle being performed / Drain / Wash /

Time-to-heat-up message from start up.

Pre-arranged for HACCP monitoring

equipment such as computers, printers and

modem for remote control.

Optional measuring of water, detergent and

energy consumption.

The following information can be selected

and displayed in the window:

Stand by mode

Actual and set temperature values

Flow limit settings

Todays washing statistics

Todays washing alarms

Time left to service

HACCP function

Washing mode

Washing efficiency

Current alarms

Actual & set temperature values

Flow/speed/electrical actual power

values (if meters are installed)

Todays washing statistics

Todays washing current alarms

Setup mode

The following fields can be set:

For the user

Date and time

Language

For the technician

Model and serial number,

electricity supply, maximum absorbed

power and production year

Temperatures

Service timer

HACCP protocols

Water flows (option)

Page 18

Page 19

Cost savings

Water consumption

electrolux wtm 19

The unique wash and rinse system minimises water,

energy and chemical usage to reduce overall running

costs.

Traditional System

Detergent consumption

up to 30% saving

Electrolux System

The IWS avoids the need to completely drain all the

wash tanks when the water becomes too dirty to wash.

A part of the dirty water, typically 15 litres/hr, is drained

away and topped up with clean water on a predefined

basis (variable onsite) so the dishwasher can operate

all day. Water saving is up to 30%.

The separate pre-wash zone does not use heated water

and therefore requires no additional water for cooling.

Autostart ensures no water and energy consumption

during periods when dishwasher is on stand-by.

The boiler is insulated to avoid further heat loss.

The Energy Saving Device incorporates a large

condenser unit able to pre-heat incoming cold water to

50°C, saving up to 12kW as well as avoiding the need

for a dedicated ventilation hood.

Traditional System

up to 75% saving

Electrolux System

Page 20

electrolux wtm2020

Handling systems

The Electrolux Modular Rack type dishwasher is the centre of a fully

integrated rack loading system aimed at maximising efficiency in terms

of capacity as well as minimising crockery breakage.

Strength guaranteed by all stainless steel construction, ease of cleaning

by rounded corner construction, comfortable ergonomic operation by

correctly dimensioned functions, the system is ideal for installations up

to 3,000 plates per hour.

Page 21

electrolux wtm 2121

Full system shown with automatic stacking table, 180° curve and roller conveyor.

Cord conveyor for maximum hygiene. 180° curve-rounded corners and all working

components hidden underneath to aid cleaning.

Page 22

electrolux wtm2222

Product Range

WTM Rack Type Product Range

Model Type Total length Capacity

WTM140 100litre wash & rinse 1773mm from 80 to 140

Baskets/hour

WTM165 150litre wash & rinse 2100mm from 90 to 165

WTM180 50litre pre-wash & 2573 mm from 110 to 180

100litre wash & rinse

WTM200 50litre pre-wash & 2900mm from 130 to 200

150litre wash & rinse

WTM250 100litre pre-wash & 3270mm from 160 to 250

150litre wash & rinse

WTM300 150litre pre-wash & 3600mm from 180 to 300

150litre wash & rinse

All versions available either with or without energy saving device, electric or steam heated.

Page 23

electrolux wtm 2323

Technical Data WTM140 WTM165 WTM180 WTM200 WTM250 WTM300

Slow speed (can be increased on-site) baskets/hr 80 90 110 130 160 180

2ndSpeed (can be decreased on-site) baskets/hr 140 165 180 200 250 300

Length of machine (without drying) mm 1773 2100 2573 2900 3270 3600

Length of machine (with straight drying) mm 2673 3000 3473 3800 4170 4500

Pre-wash

Power

upper kW 0,23 0,23 2,2 2,2

lower kW 1,1

Circulation

upper l/min 150 150 600 500

lower l/min 350

tank capacity l 45 45 100 150

Wash

Power

upper kW 2,2 2,2 2,2 2,2 2,2 2,2

lower kW 1,1 1,1 1,1 1,1

Circulation

upper l/min 600 500 600 500 500 500

lower l/min 350 350 350 350

tank capacity l 100 150 100 150 150 150

Rinse

duo-rinse kW 0,35 0,35 0,35 0,35 0,35 0,35

duo-rinse l/min 15 15 15 15 15 15

duo-rinse l 23 23 23 23 23 23

boiler l 12 12 12 12 12 12

Final Rinse consumption l/hr 240 300 300 300 300 300

Electrical loading

wash tank elements kW 12 21 12 21 21 21

duo rinse tank elements kW 33333 3

boiler elements kW 12 16,5 16,5 16,5 16,5 16,5

Drying Heating elements kW 8,25 8,25 8,25 8,25 8,25 8,25

Drying Fan kW 1,1 1,1 1,1 1,1 1,1 1,1

Drying m3/h 1000 1000 1000 1000 1000 1000

Drying Temperature °C 50-60 50-60 50-60 50-60 50-60 50-60

Transport motor kW 0,25 0,25 0,25 0,25 0,25 0,25

ESD fan kW 0,13 0,13 0,13 0,13 0,13 0,13

Total power (with power reducer without drying) kW 27,4 31,5 31,8 31,8 44,2 45,3

Total power (with power reducer with drying) kW 36,7 40,8 41 41,0 53,5 54,6

Hot water connection °C 50 50 50 50 50 50

Cold water connection °C 15 15 15 15 15 15

Noise Level dBA <70 <70 <70 <70 <70 <70

Page 24

www.electrolux-professional.com

The Company reserves the right to change specifications without notice.

9JEB7U

Loading...

Loading...