Electrolux WT30H208DU (502315) Service Manual

Electrolux

EFS - Dishwashing Systems Platform

Electrolux Professional

SERVICE MANUAL

CONTENTS:

EDITION:

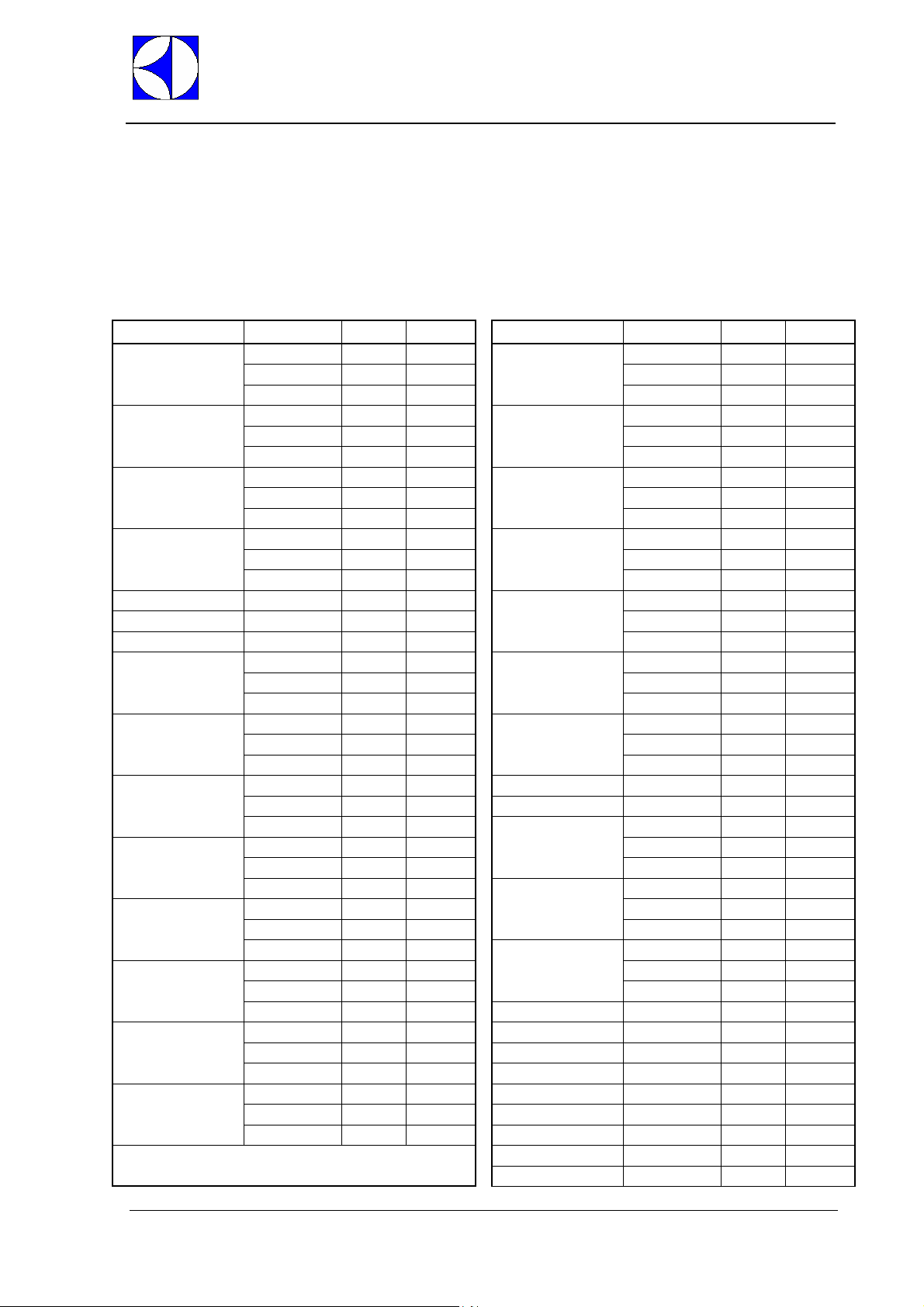

TANK

3.__

BOILER

TANK

BOILER

3.__

TANK

BOILER

3.__

This document contains the instruction to change parameter settings of electronic

board by means of user interface.

05.2008

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.1/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

INDEX

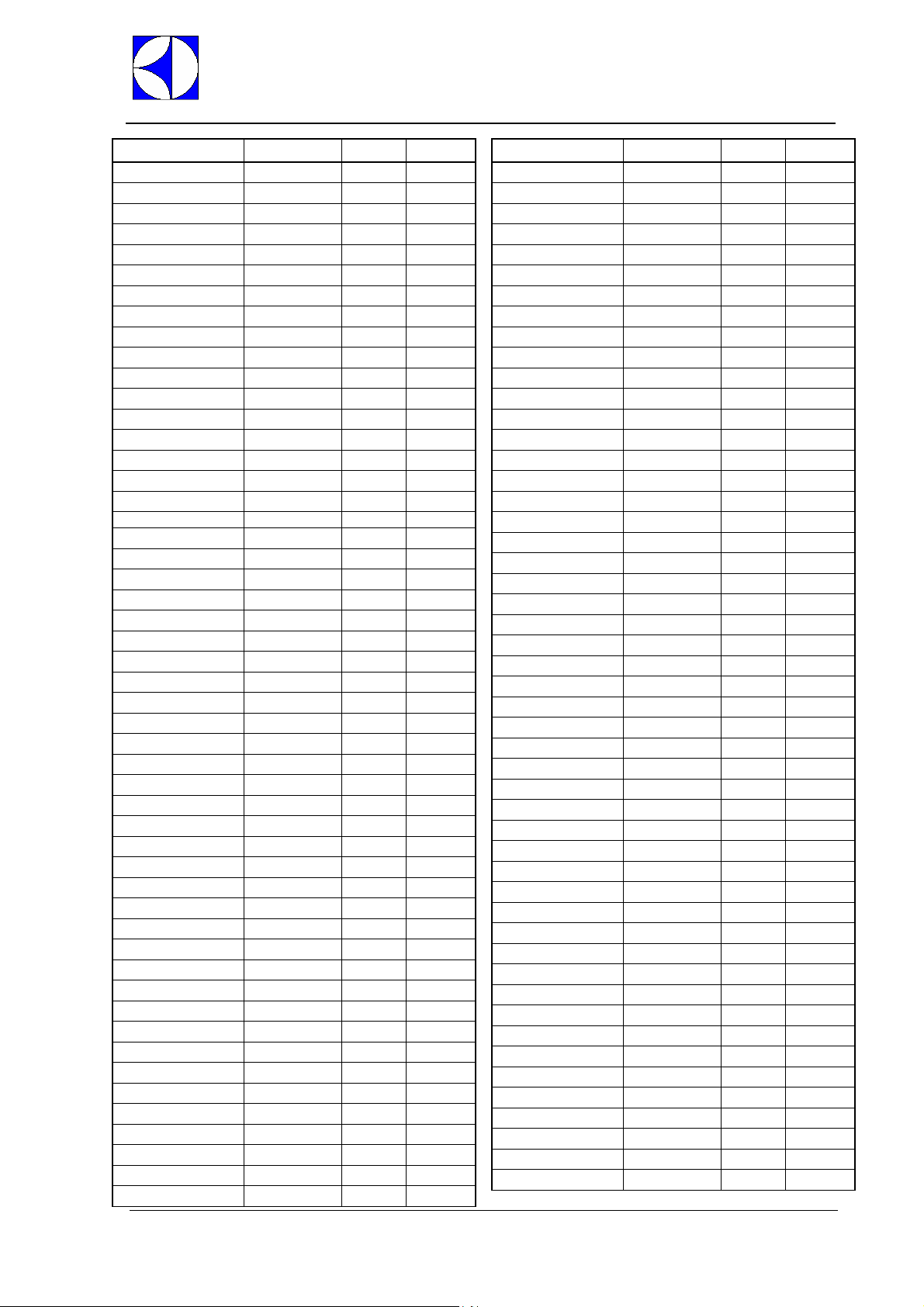

1. KEYBOARDS 3

1.1 HOODTYPE Style 3

2. MANUAL ACTIVATION OF DETERGENT AND RINSE AID DISPENSERS 5

3. RINSE PUMP MANUAL ACTIVATION 5

4. DETERGENT AND RINSE AID DOSAGE 6

1.2 UNDERCOUNTER Style 4

2.1 Detergent Dispenser Activation 5

2.2 Rinse Aid Dispenser Activation 5

GEn General Parameters 6

5. COUNTERS 8

Cnt Counters 8

6. TEMPERATURE SETTING 9

FAC Factory Parameters 8

7. CYCLE SETTING 11

CYCLE DIAGRAM

CY1 Cycle 1 Parameters 13

CY2 Cycle 2 Parameters 13

CY3 Cycle 3 Parameters 13

drn Drain/Cleaning Cycle Parameters 13

8. OTHER PARAMETERS 14

dPA Dishwashing Parameters 14

ron Read Only Parameters 14

HCP Communication and HACCP Parameters 14

CFG Configuration Parameters 15

dbG Parameters for automatic hood type dishwashers 16

9. SPECIAL FEATURES 17

9.1 RESIN REGENERATION CYCLE 17

9.2 MEDICAL LINE DISHWASHER WITH DOOR/HOOD LOCK DEVICE 17

9.3 DETERGENT AND RINSE AID LEVEL SENSORS ACTIVATION 17

9.4 dISHWASHER WITH INCORPORATED CONTINUOUS WATER SOFTENER 18

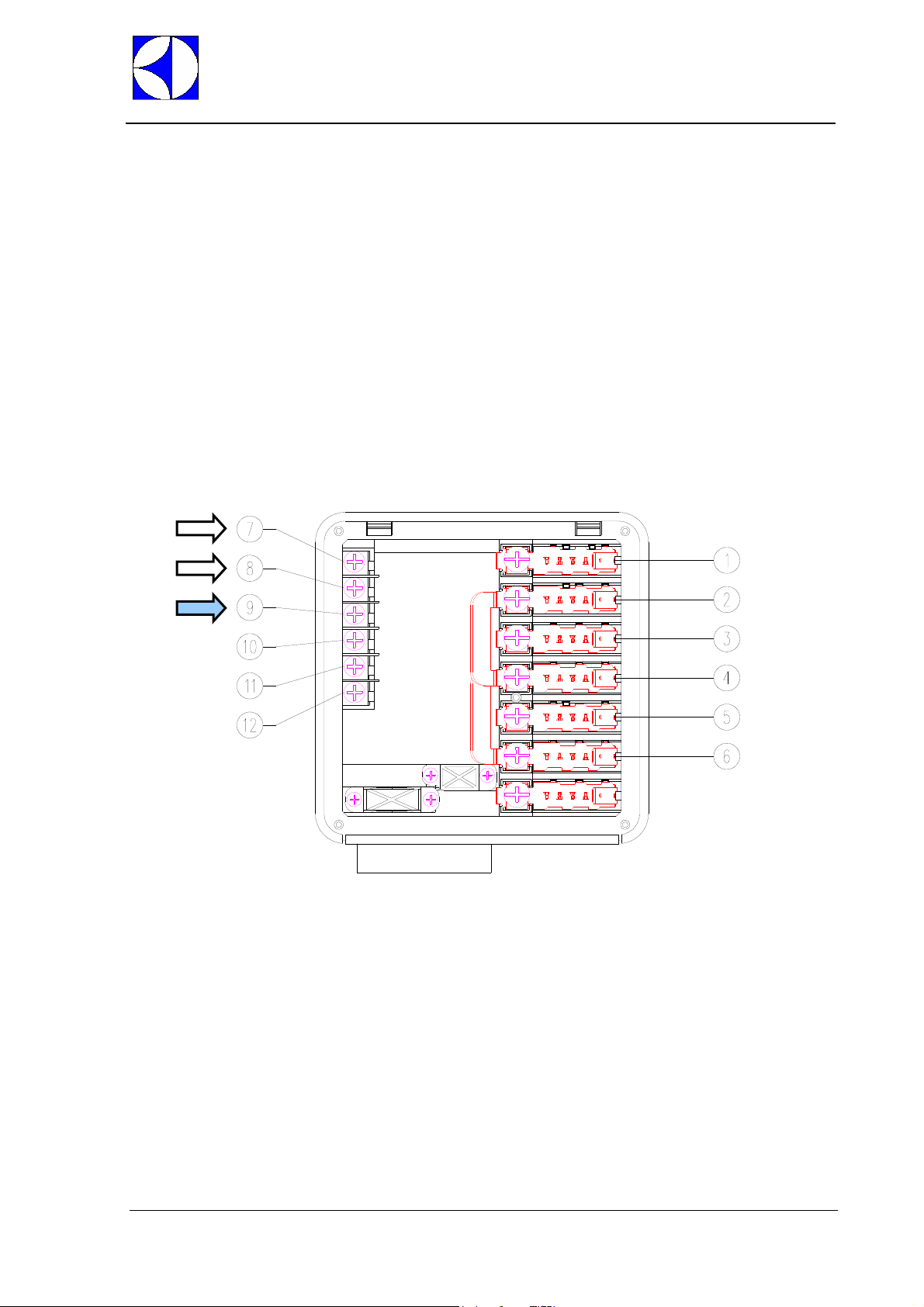

10. MAIN BOARD CONFIGURATION 19

10.1 CODEÆProg. TABLE 19

10.2 PROGRAMMING SHEETS 24

11. DEFAULT VALUES 94

12. USER INTERFACE AND MAIN BOARD CONNECTORS 97

12.1 MAIN MALFUNCTIONS NOT DUE TO THE MAIN BOARD 97

12.2 CONNECTORS LAYOUT 97

13. ALARM MESSAGES AND TROUBLESHOOTING 105

14. LIST OF PARAMETERS FOR SUBSEQUENT VERSIONS 105

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.2/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

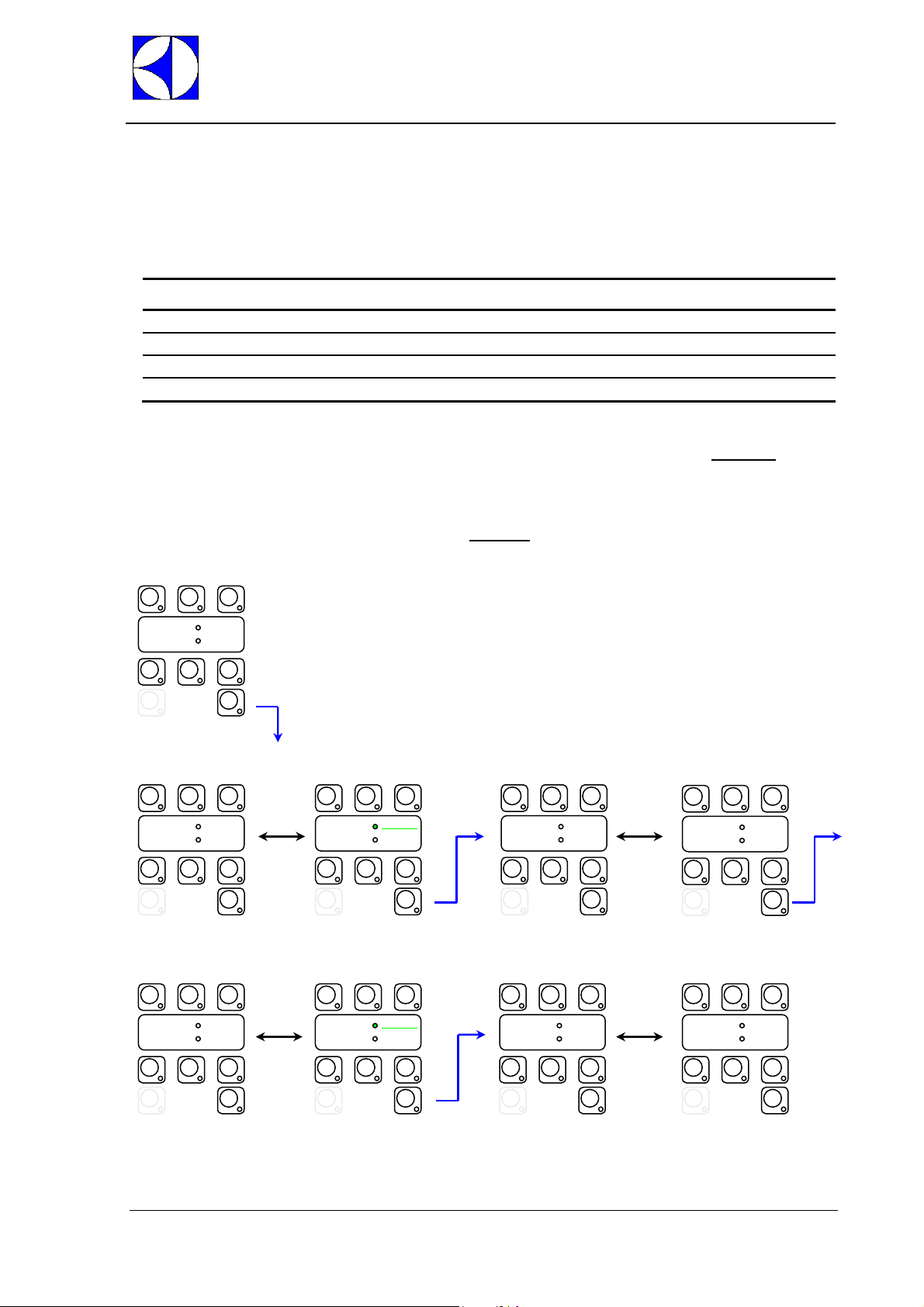

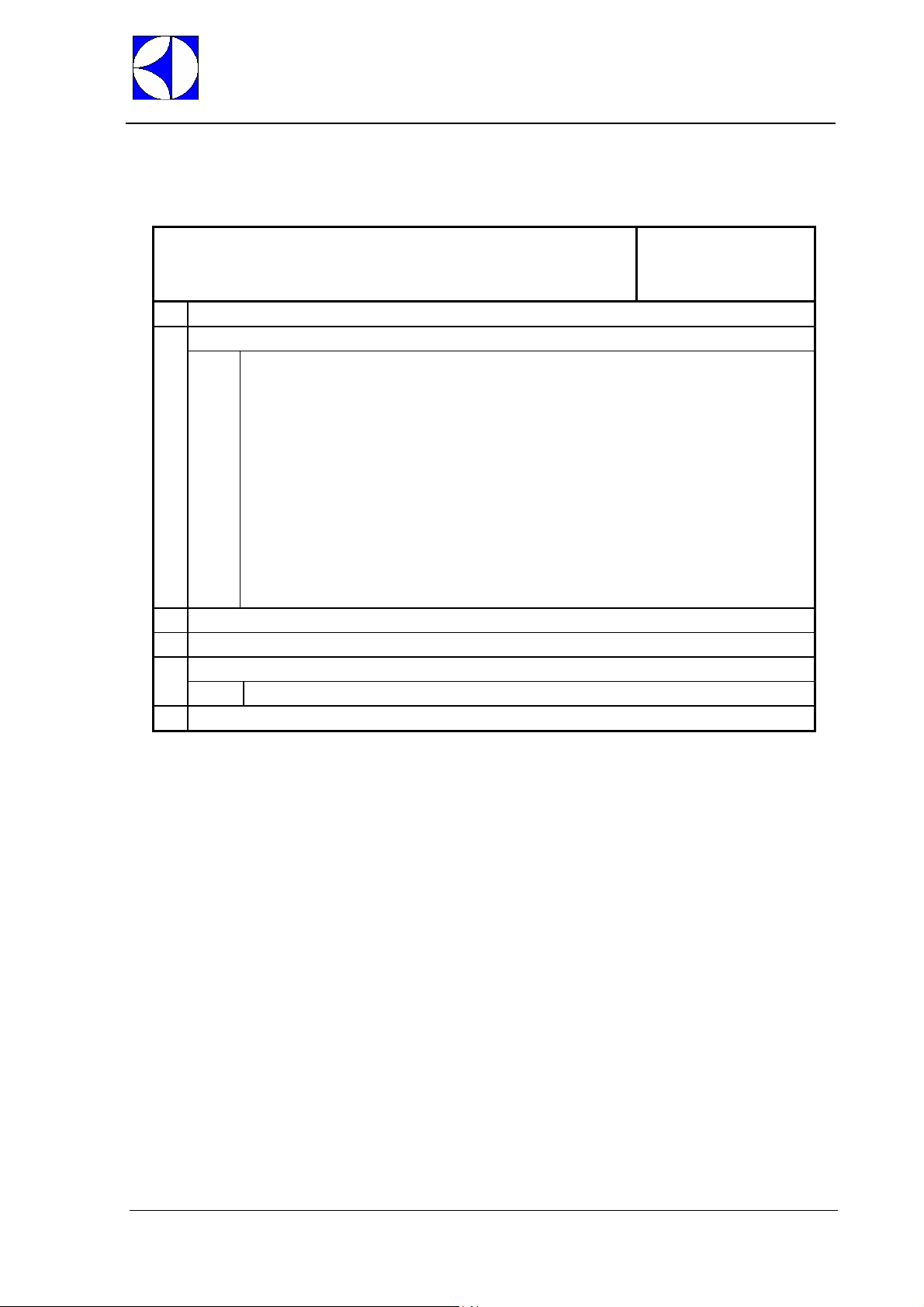

1. KEYBOARDS

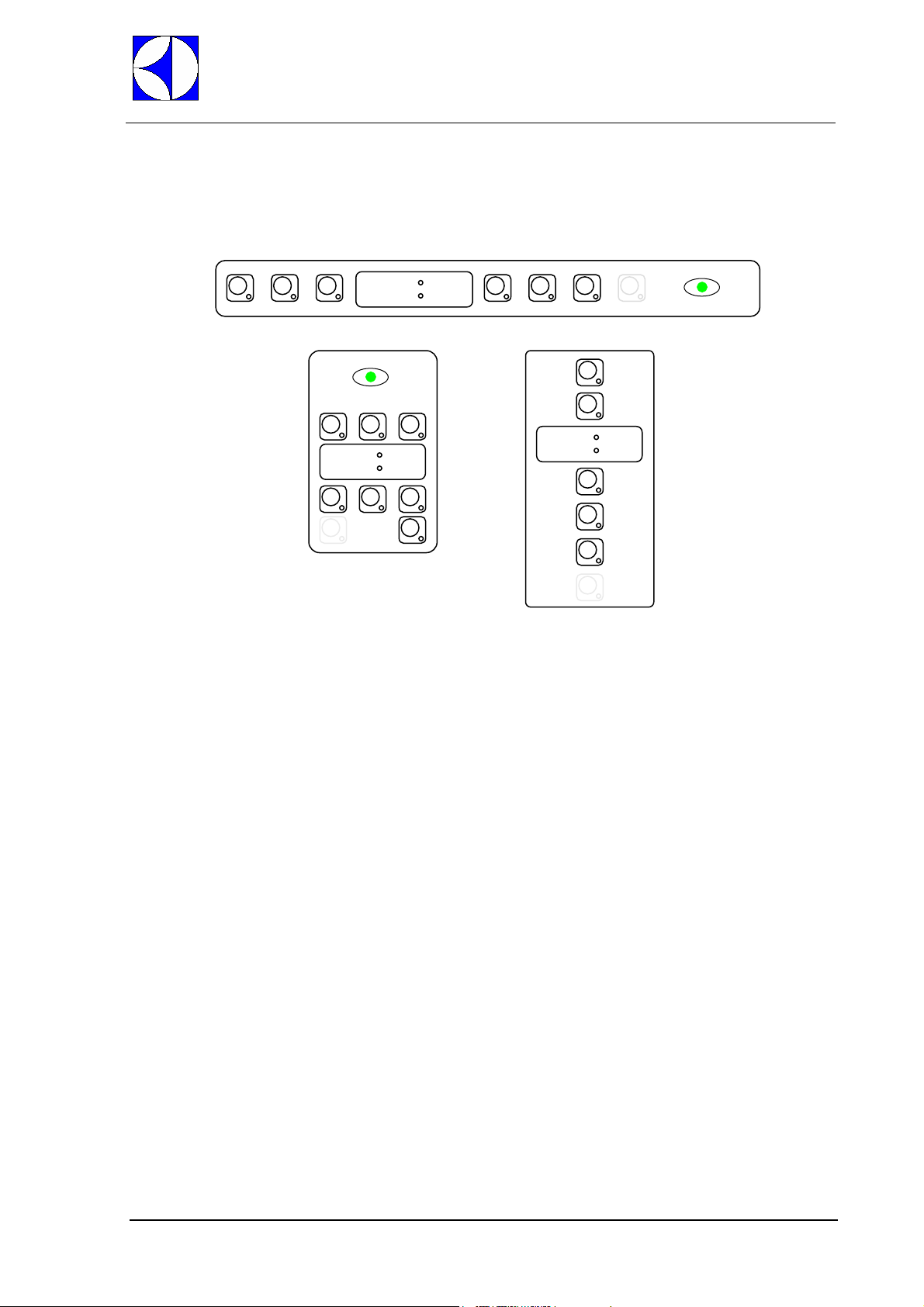

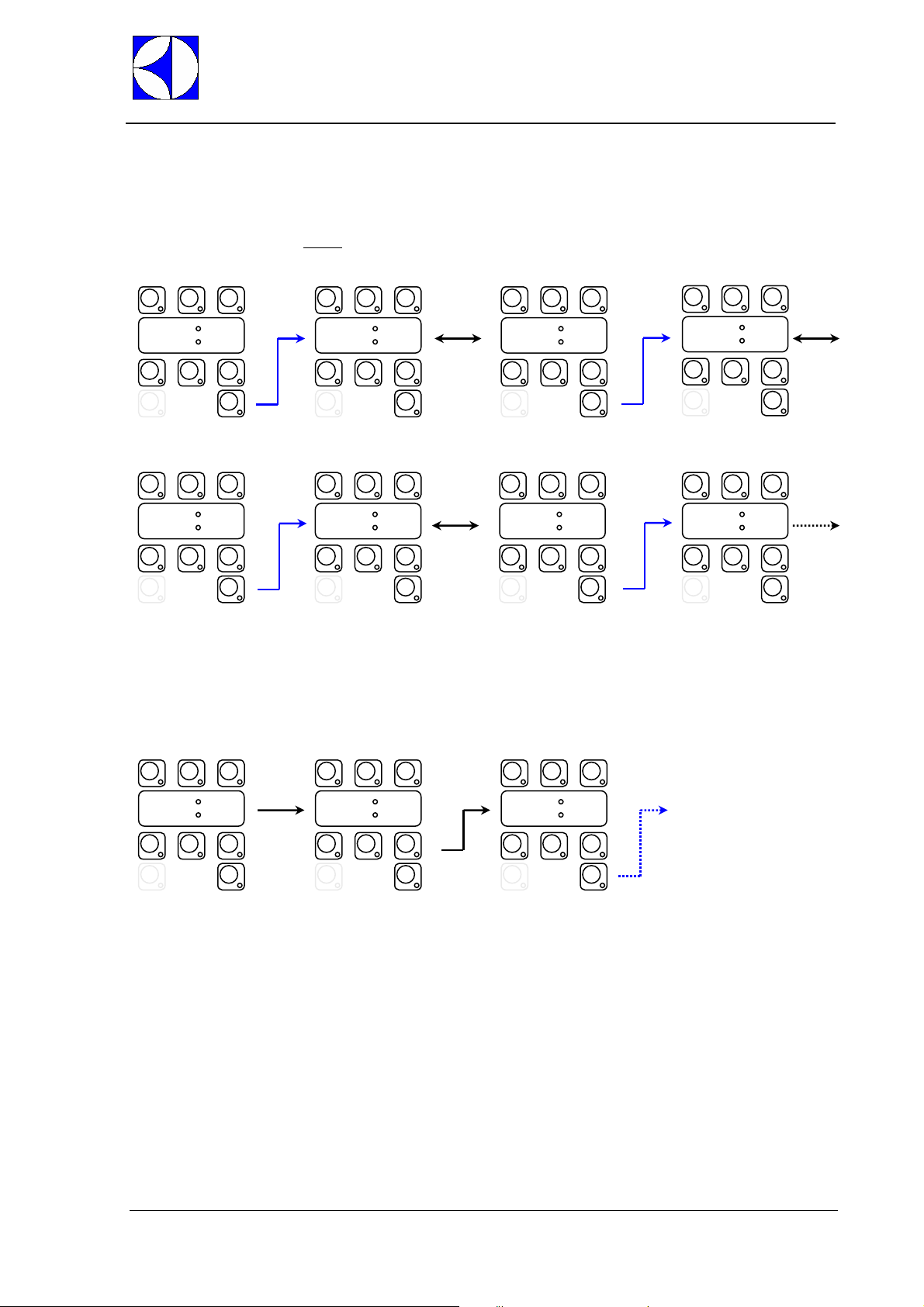

1.1. HOOD TYPE Style

dEt

Detergent dispenser

Manual Activation.

SETTING MODES:

To enter into one setting mode (Fig.1.4, Fig.1.5) the appliance should be in stand-by: switch on the

appliance, no cycles selected. Is useful keep door open to avoid start cycle in case of not

simultaneously pressure of the two keys.

Enter into General Parameters

(Hold down buttons for at least

Next Parameter Family OR

Increase Parameter Value

(In setting mode only)

Fig. 1.1

GEn

five seconds).

888

Fig. 1.6

Fig. 1.4

dEt

888

GEn

rAi

Fig. 1.2

Rinse Aid Dispenser

Manual Activation.

Enter into Factory Parameters

(Hold down buttons for at least

888

Fig. 1.7

Decrease Parameter Value

(In setting mode only)

FAC

Fig. 1.5

five seconds).

rAi

888

---

Fig. 1.3

Rinse Pump

Manual Activation

(used to EMPTY BOILER)

FAC

888

Fig. 1.8

Confirm Value and go

to next Parameter

(In setting mode only)

---

888

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.3/116

Electrolux

K

K

K

K

K

K

K

K

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

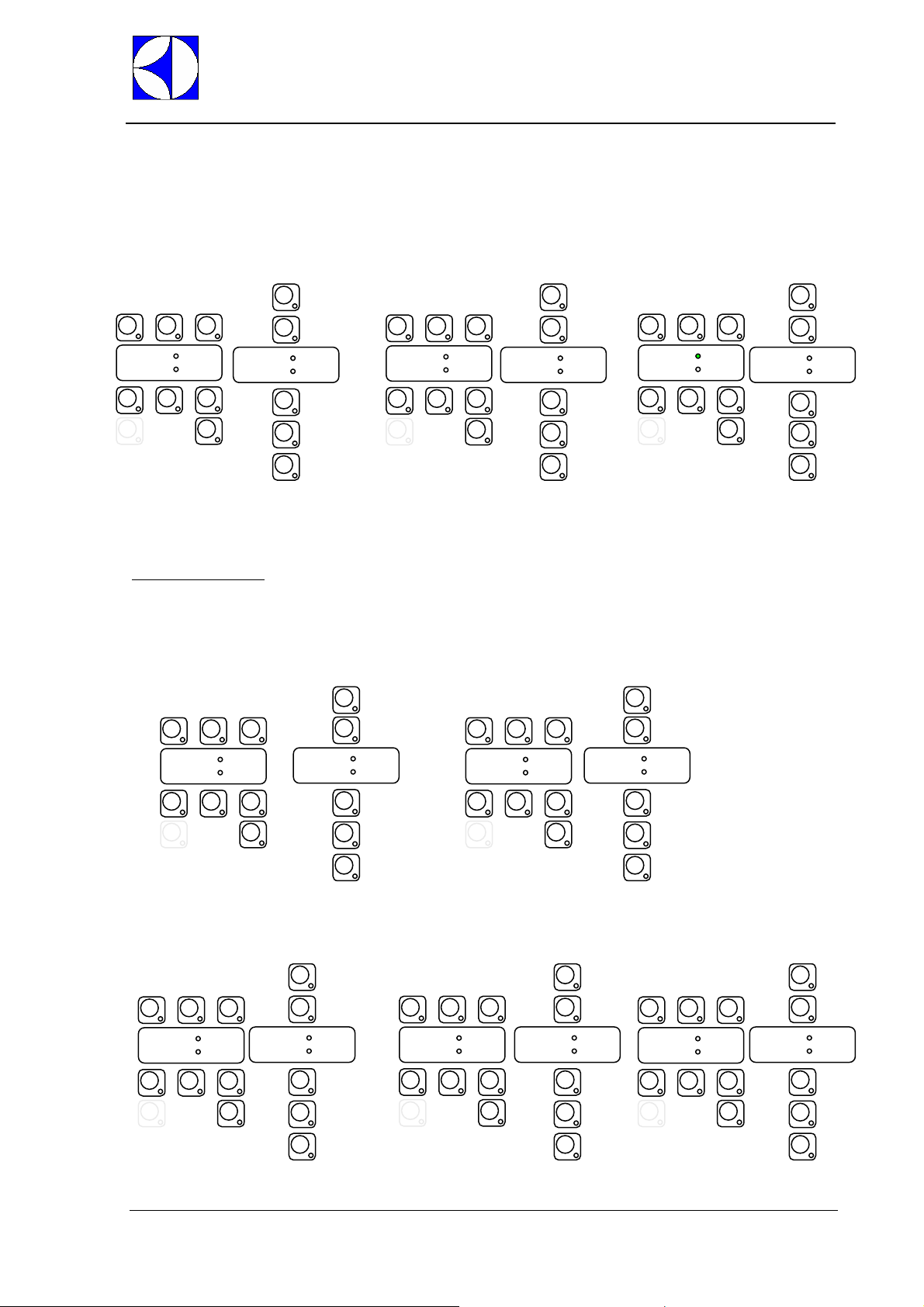

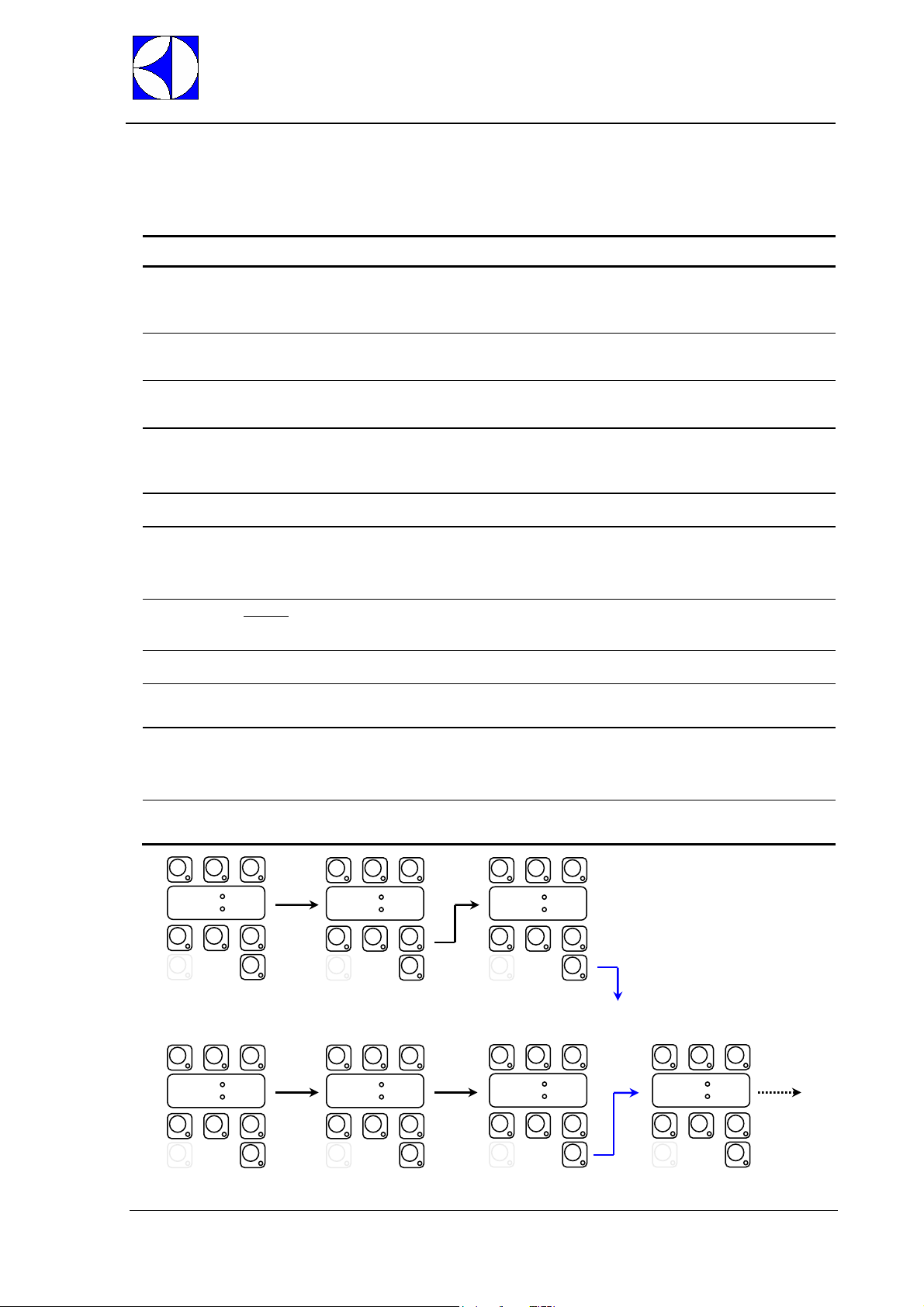

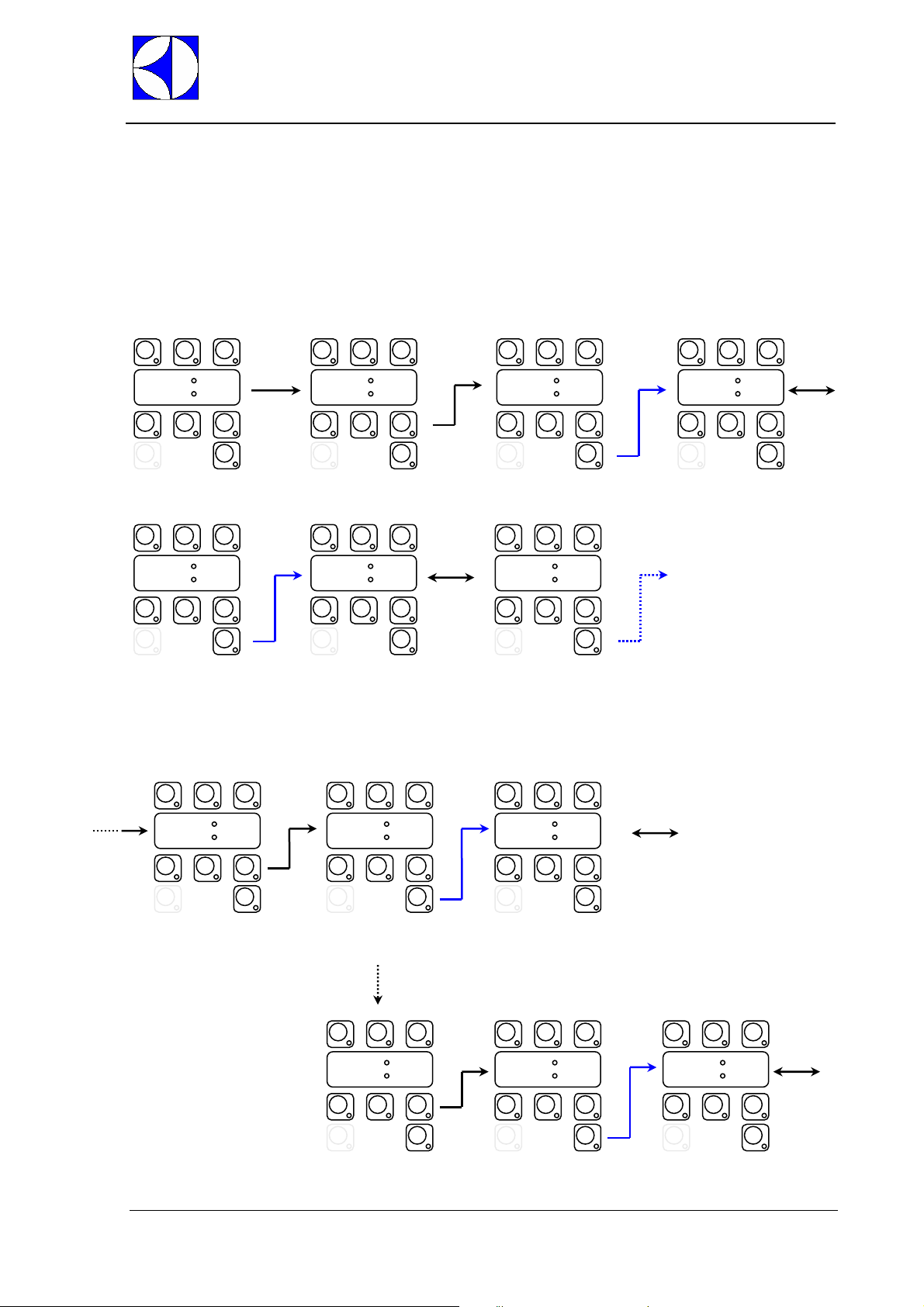

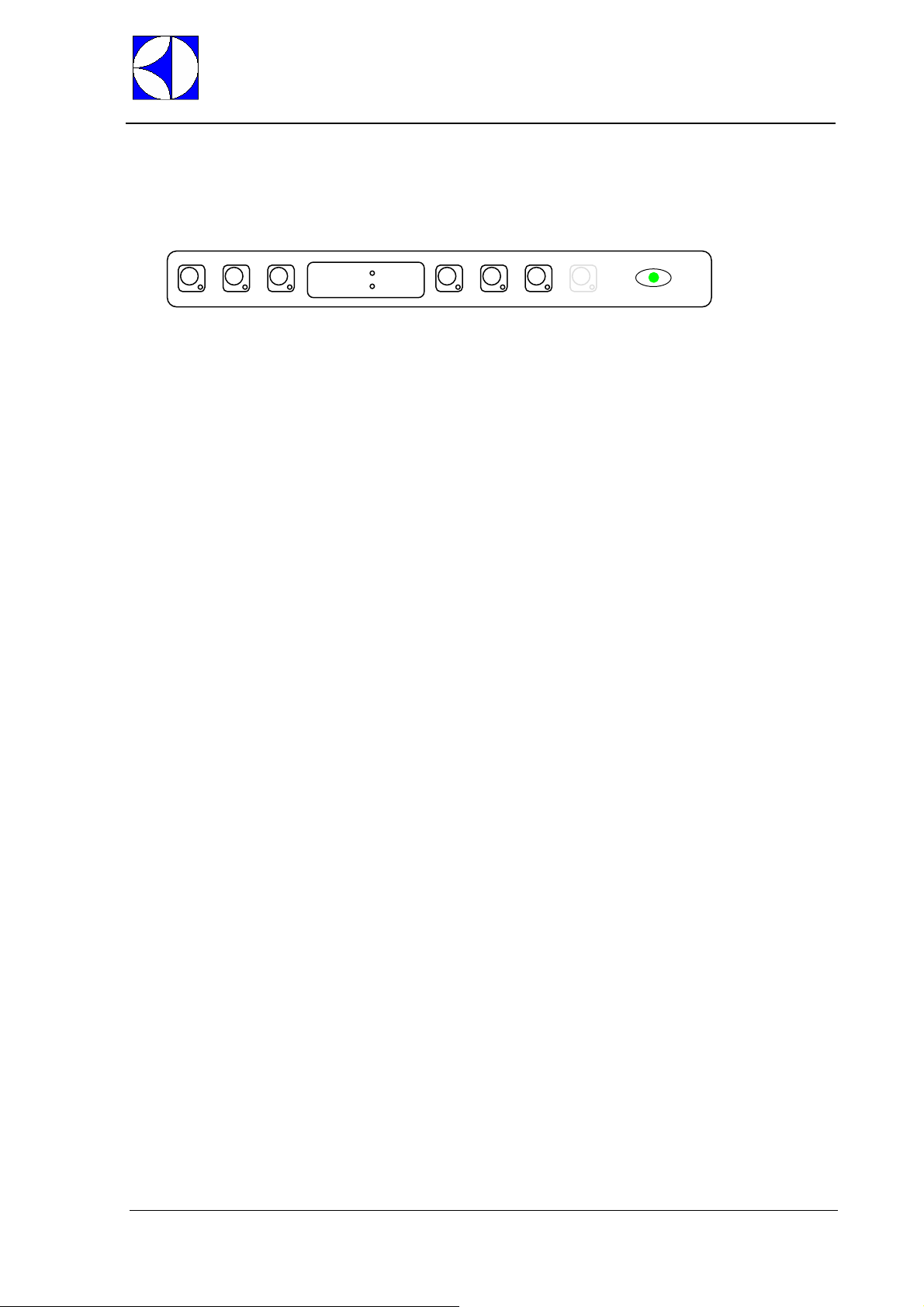

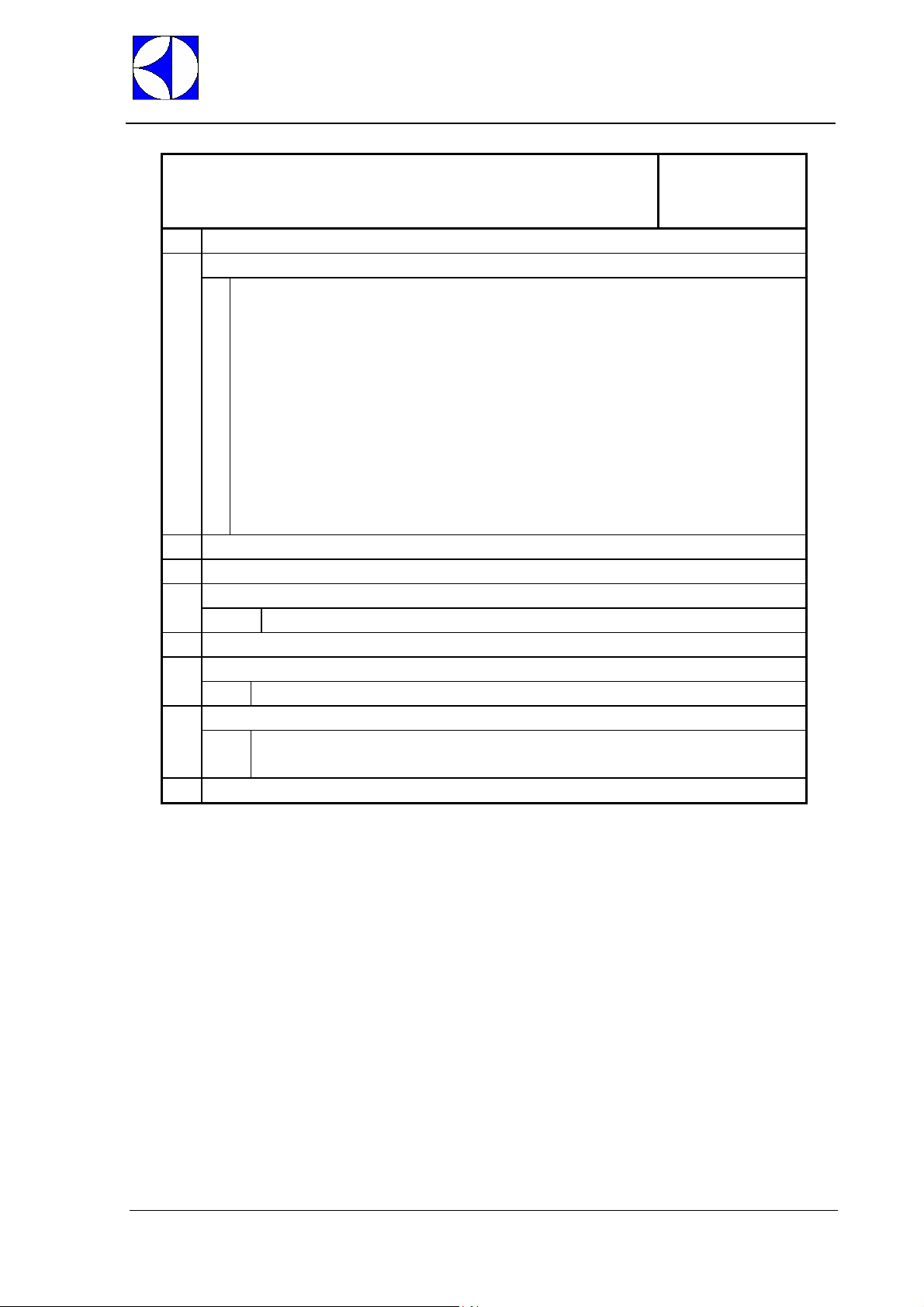

1.2. UNDERCOUNTER Style

SETTING MODES:

To enter into one setting mode (Fig.1.4, Fig.1.5) the appliance should be in stand-by: switch on the

appliance, no cycles selected. Is useful keep door open to avoid start cycle in case of not

simultaneously pressure of the two keys.

dEt

rAi

---

GEn

FAC

888

888

888

TAN

BOILER

TAN

BOILER

TAN

BOILER

TAN

BOILER

TAN

BOILER

TAN

BOILER

TAN

BOILER

TAN

BOILER

Fig.1.1

Detergent dispenser

Manual Activation

Fig.1.2

Rinse Aid Dispenser

Manual Activation

Fig.1.3

Rinse Pump

Manual Activation

(used to EMPTY BOILER)

Fig. 1.4

Enter into General Parameters

(Hold down buttons for at least five

seconds).

Fig. 1.5

Enter into Factory Parameters

(Hold down buttons for at least five

seconds).

Fig.1.6

Next Parameter Family

OR

Increase Parameter Value

(in setting mode only)

Fig.1.7

Decrease Parameter Value

(In setting mode only)

Fig.1.8

Confirm Value and go to next Parameter

(in setting mode only)

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.4/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

2. MANUAL ACTIVATION OF DETERGENT AND RINSE AID

DISPENSERS

When replacing detergents may be necessary activate the dispensers to fill hoses.

2.1. Detergent Dispenser Activation

dEt

Switch on the dishwasher.

Press and hold down CYCLE_2 and CYCLE INFINITE keys, after two 'beep' the detergent dispenser

starts work for 20 sec.

2.2. Rinse Aid Dispenser Activation

rAi

Switch on the dishwasher.

Press and hold down CYCLE_1 and CYCLE INFINITE keys, after two 'beep' the rinse aid dispenser

starts work for 40 sec.

3. RINSE PUMP MANUAL ACTIVATION

Use this function to empty the boiler (if the dishwasher is not to be used for a long time, for maintenance operation: ex. before replacing

main board).

---

Switch on the dishwasher.

Close the door and press and hold down DRAIN and CYCLE INFINITE keys. A buzzer signal indicates the

rinse pump activation and the display shows three blinking lines. Three beeps indicate the cycle end.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.5/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

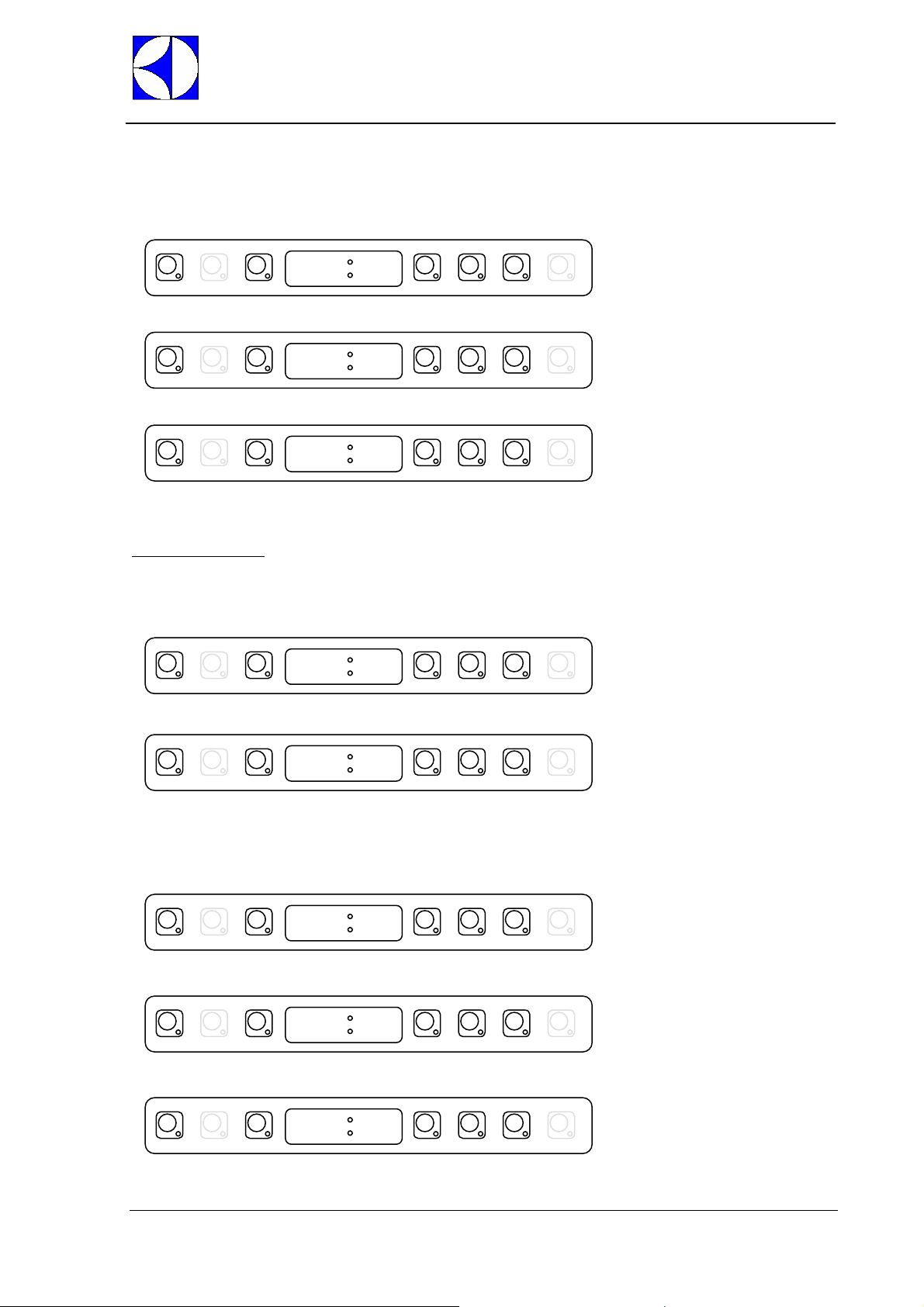

4. DETERGENT AND RINSE AID DOSAGE

In this paragraph is explained how to set the working time for the detergent and rinse aid dispensers.

For each dispenser there are two parameters: the initial time and the time during cycle execution.

GEn General Parameters

Sym. Parameter Description

dIn

rIn

dEt

rAi

How change the duration:

• Switch OFF and switch ON the dishwasher;

• Enter into the USER SETTING mode by pressing and hold down ON/OFF and CYCLE_1 keys for at least five seconds

shows

• Press CYCLE_INFINITE. The display shows alternatively the symbol

NOTE: If User Interface v.3.00 tank led is on if value correspond to factory default (Default 1, HOOD TYPE).

• Use CYCLE_1 key to decrease the duration and CYCLE_2 key to increase (Fig.3.3);

• After settled the duration press CYCLE_INFINITE key to store value

corresponding value (Fig.3.5);

• In the same way is possible to change the other duration; when finished switch OFF and switch ON.

GEn

Initial Detergent Dosage (during filling tank) [s] 0 240 90

Initial Rinse Aid Dosage (starts when tank filled) [s] 0 180 10

Detergent Dosage During Cycle Execution (during wash phase) [s] 0 182(*) 8

Rinse Aid Dosage During Cycle Execution (when refilling boiler) [s] 0 62 (*) 4

GEn (Fig.3.1);

dIn and the duration in seconds (Fig.3.2 and 3.3);

. The display shows the next parameter (Fig.3.4) and the

Unit Min Max

Factory

Default

the display

Fig. 3.1

Enter into User Mode

(press for 5 sec).

Fig. 3.2

Fig. 3.6

dIn

Initial detergent dosage

dEt

Cycle detergent dosage

DEFAULT

90

© ª

Fig. 3.3

Change duration.

(Tank LED indicates default).

DEFAULT

8

© ª

Fig. 3.7

Change time activation

(Tank LED indicates default)

rIn

Initial rinse aid dosage

rAi

Cycle rinse aid dosage

Fig. 3.4

Fig. 3.8

24

© ª

Fig. 3.5

Change duration

7

© ª

Fig. 3.9

Change time activation

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.6/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

(*) Note for external dispensers:

DEt=181 the detergent dispenser works when WASHING PUMP is being activated; at the same time voltage

• If

dEt=182 the detergent dispenser works when LOADING EV is being activated to re-fill boiler level; at the

• If

rAi= 61 the rinse aid dispenser works when LOADING EV is being activated to re-fill boiler level; at the same

• If

rAi= 62 the rinse aid dispenser works when WASHING PUMP is being activated; at the same time voltage is

• If

is supplied between connectors L1

same time voltage is supplied between connectors L1

time voltage is supplied between connectors L1

supplied between connectors L1

- For electrical connections refer to electric diagram -

–L19 (main terminal box);

7

–L19 (main terminal box);

7

–L19 (main terminal box);

8

–L19 (main terminal box);

8

Example

Suppose there is connected an external detergent dispenser with a probe into the tank. A typical setting could be:

DIn= 0 the dispenser is not activated during filling tank;

DEt=181 the dispenser is supplied during washing phase and the probe automatically dose the right detergent

amount.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.7/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

5. COUNTERS

This Parameter Family collects cycle counters and water consumption counters.

For water consumption counters a flow meter must be installed. See

PPL (calibration parameter) into dPA section (§ Other Parameters).

Cnt Counters

Sym. Parameter Description

CYC

cYc

nnc

Lit

rSt

nCY

drn

rCY

NRE

rES

USER setting mode

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.8/116

Cycles performed counter.

CYC symbol and two numbers blink consecutively. The cycle number is

obtained by joining the two numbers. Ex.

cycles executed.

Cycle counter (resettable).

This counter is similar to

below).

Water Consumption.

(only for dishwashers with incorporated continuous water softener).

Counts m3 of water consumption.

Water Consumption.

L

(only for dishwashers with incorporated continuous water softener).

litres of water consumption.

Counts

The total consumption is given by adding

Water Consumption: resettable counter. [present up to software version 3.12]

Counts the litres of water and is resettable by user (see

Reset resettable counters: cYc and Lit

To reset put 1 this parameter, switch off and then on again:

will show zero. Note that

(see next parameter,

Store thousand of cycles after that CAll message appears on display.

Ex. If this parameter is settled to 20,

reach 20.000 cycles.

Drain/Cleaning cycles performed.

Similar to

Numbers of cycles that can be made after a regeneration cycle (only for

dishwashers with non-continuous water softener) [See paragraph 9.1 resin

regeneration cycle.].

Regeneration cycle counter (only for water softener dishwasher)

[See paragraph 9.4 Dishwashers with incorporated continuous water

softener]. NrE only counts efficient regeneration cycles, i.e. those carried

out with salt in the special container (only for dishwashers with incorporated

continuous water softener)

Counter of regeneration cycles done without salt in the special container. (only

for dishwashers with incorporated continuous water softener) [See paragraph 9.4

Dishwashers with incorporated continuous water softener].

CYC but counts Cleaning Cycles.

CYC but is resettable by user (see rSt parameter

cYc is used to count cycles for CAll message

nCY).

CYC → 10 → 042 means 10042

nnc [m

CAll message appears when cYc

3

] and L [l] values.

rSt parameter below).

Fig.4.1

(press for 5s)

Fig. 4.4

CYCLES

Next Family

Fig.4.2

Fig. 4.5

Thousand.

Fig. 4.3

Counters Fam.:

Fig. 4.6

Units.

cYc and Lit

Unit Min Max

-

-

3

]

[m

[l]

[l]

-

-

-

- 20

-

-

Fig. 4.7

Next counter.

Factory

Default

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

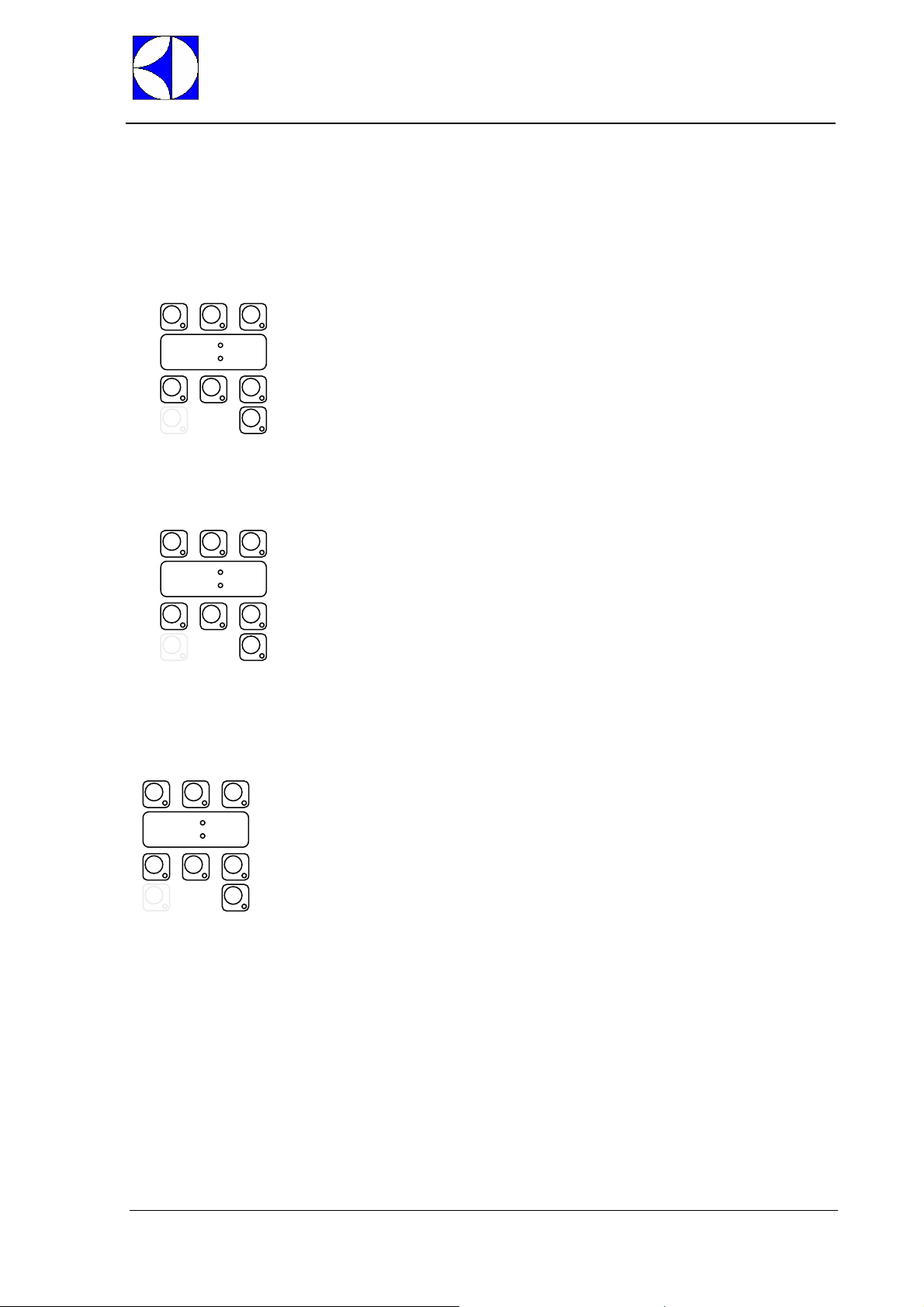

6. TEMPERATURE SETTING

In this paragraph is explained how to change temperature thresholds and all parameters related to boiler and tank.

FAC Factory Parameters

Sym. Parameter Description

bt°C

btH

bHi

bLo

Boiler Temperature: THRESHOLD.

When boiler temperature reaches this value, heaters switch off.

Boiler Temperature HISTERESIS, (represent dead band).

Heater switch on if boiler temperature is below:

Boiler Temperature: HIGH LIMIT.

When boiler temperature reaches this value

Put 0 to disable

Boiler Temperature: LOW LIMIT.

During boiler warm-up, temperature must increase at least

C 2 alarm.

E 3 warning appears.

bFL

bAJ

bP

bSt

btd

tt°C

ttH

tHi

tLo

Put 0 to disable

Boiler Filling Timeout.

If filling time is longer than

Put 0 to disable

Boiler Temperature Adjust. [°C] 0 7

Boiler Priority (enable boiler wait function)

0=disabled

1=enabled

Booster Function

Overheat gap over Boiler Temperature Threshold

Boiler temperature negative differential: when the dishwasher is in standby,

boiler threshold becomes:

(Used to save energy during machine inactivity by keeping boiler water at a

lower temperature).

Tub Temperature: THRESHOLD

When tank temperature reaches this value, heater switch off.

Tub Temperature: HISTERESIS, (represent dead band).

Heater switch on if tank temperature is below:

Tank Temperature: HIGH LIMIT.

When tank temperature reaches this value

Put 0 to disable

Tank Temperature: LOW LIMIT.

During tank warm-up, temperature must increase at least

E 3 warning.

A 1 alarm.

C 3 alarm.

E 2 warning appears.

E 2 warning.

A 1 alarm.

tFL

Put 0 to disable

Tank Filling Timeout.

If filling time is longer than

Put 0 to disable

bt°C - btH

C 2 alarm appears.

bLo °C otherwise

bFL, A 1 alarm appears.

bt°C - btd

tt°C - ttH

C 3 alarm appears.

bLo °C otherwise

tFL, A 1 alarm appears.

Unit Min Max

[° C]

[° C]

[° C]

[° C]

[min] 0 42

- 0 1

[°C] 0 15

[°C] 0 20

[° C]

[° C]

[° C]

[° C]

[min] 0 42

45 95

2 10

0 98

0 10

40 85

2 30

0 95

0 10

Factory

Default

78

2

96

1

5

4

1

2

0

63

5

75

1

20

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.9/116

©ª

©ª

btH

Fig. 5.4

bLo

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

To modify thresholds do the following:

• Switch OFF and switch ON the dishwasher;

• Enter into the FACTORY SETTING mode by pressing and hold down ON/OFF and CYCLE_2 keys for at least five seconds (Fig.5.1);

• Press CYCLE INFINITE. The display shows alternatively the symbol

• Use CYCLE_1 key to decrease the value and CYCLE_2 key to increase (Fig.4.3);

• Press CYCLE INFITE key to confirm

• In the same way is possible to change the other parameters; when finished switch OFF and switch ON.

FAC

Factory setting mode

Change value & Store

At the end the display will show again ‘FAC’ and by pressing CYCLE_2 key (Fig.4.9) is possible to change cycle duration (see next

paragraph).

FAC

Factory setting mode

Fig. 5.1

2

© ª

Fig. 5.5

Fig. 5.9

. The display shows the next parameter (Fig.4.4) and the corresponding value (Fig.4.5);

bt°C

Boiler temp. threshold

bHi

Tank temp. High limit.

FAC

Fig. 5.2

Fig. 5.6

Fig. 5.10

Next Family

Electronic Dishwasher

SERVICE MANUAL

bt°C (Fig.5.2) and the corresponding value 76 (Fig.5.3);

76

Change value & Store

96

Change value & Store

CY1

Cycle 1 Family: ENTER

Fig. 5.3

Boiler Temp Hysteresis

Fig. 5.7

Fig. 5.11

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.10/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

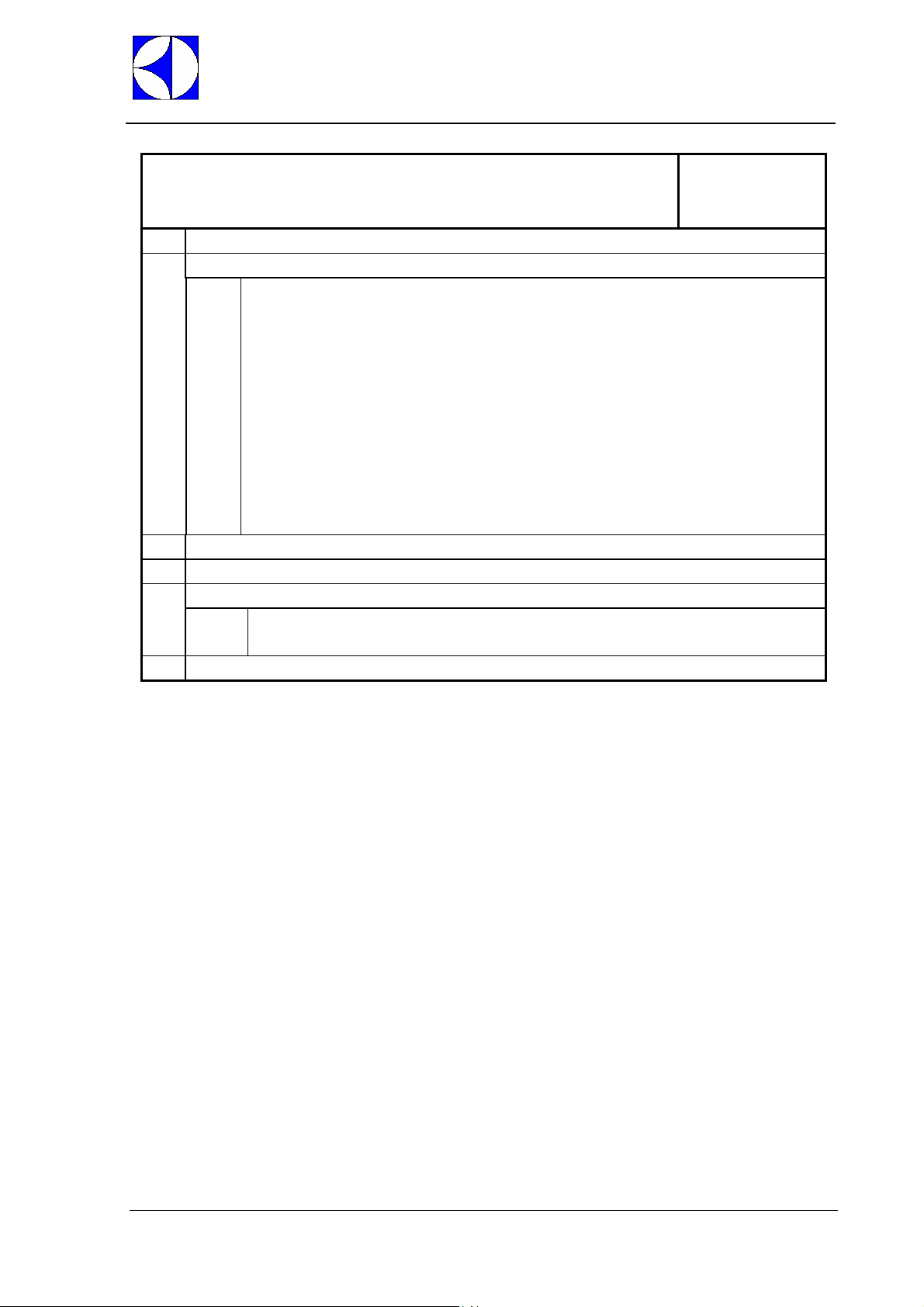

7. CYCLE SETTING

In this paragraph is explained how to change cycle phases duration (see Tab.1 next page).

• Switch on the dishwasher;

• Enter into the FACTORY SETTING mode: press and hold down ON/OFF and CYCLE_2 keys for at least 5 seconds (Fig.5.1);

• Press CYCLE_2 key to select CYCLE_1 parameters.

• Press CYCLE_INFINITE. The display shows alternatively the symbol (Fig.5.2) and the corresponding value (Fig.5.3);

• Use CYCLE_1 key to increase the value and CYCLE_2 key to decrease (Fig.5.3);

• Press CYCLE_INFINITE key to confirm. The display shows the next parameter (Fig.5.4) and the corresponding value (Fig.5.5);

• In the same way is possible to change the other parameters;

FAC

Fig. 6.1

Factory setting mode.

0

© ª

Fig. 6.5

Change value & Store.

After settled all parameters referring Cycle 1, by pressing CYCLE_2 key is possible to change the Cycle 2 parameters (Fig.5.8, 5.9) and so

on.

CY1

Cycle 1 Parameters.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.11/116

Fig. 6.8

FAC

Fig. 6.2

Select next class.

Fig. 6.6

CY2

Sh1

Wash duration [sec].

Cycle 2 Parameters: ENTER

Fig. 6.9

CY2

Cycle 2 Parameters:

next Family

Fig. 6.11

CY1

Fig. 6.3

Cycle 1 Family: ENTER

35

©ª

Fig. 6.7

Change value & Store.

Ln2

Fig. 6.10

Wash duration [min].

Cy3

Cycle 3 Parameters:

Fig. 6.12

ENTER

Ln1

Fig. 6.4

Wash duration [min].

…

Ln3

Wash duration [min].

© ª

Fig. 6.13

…

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

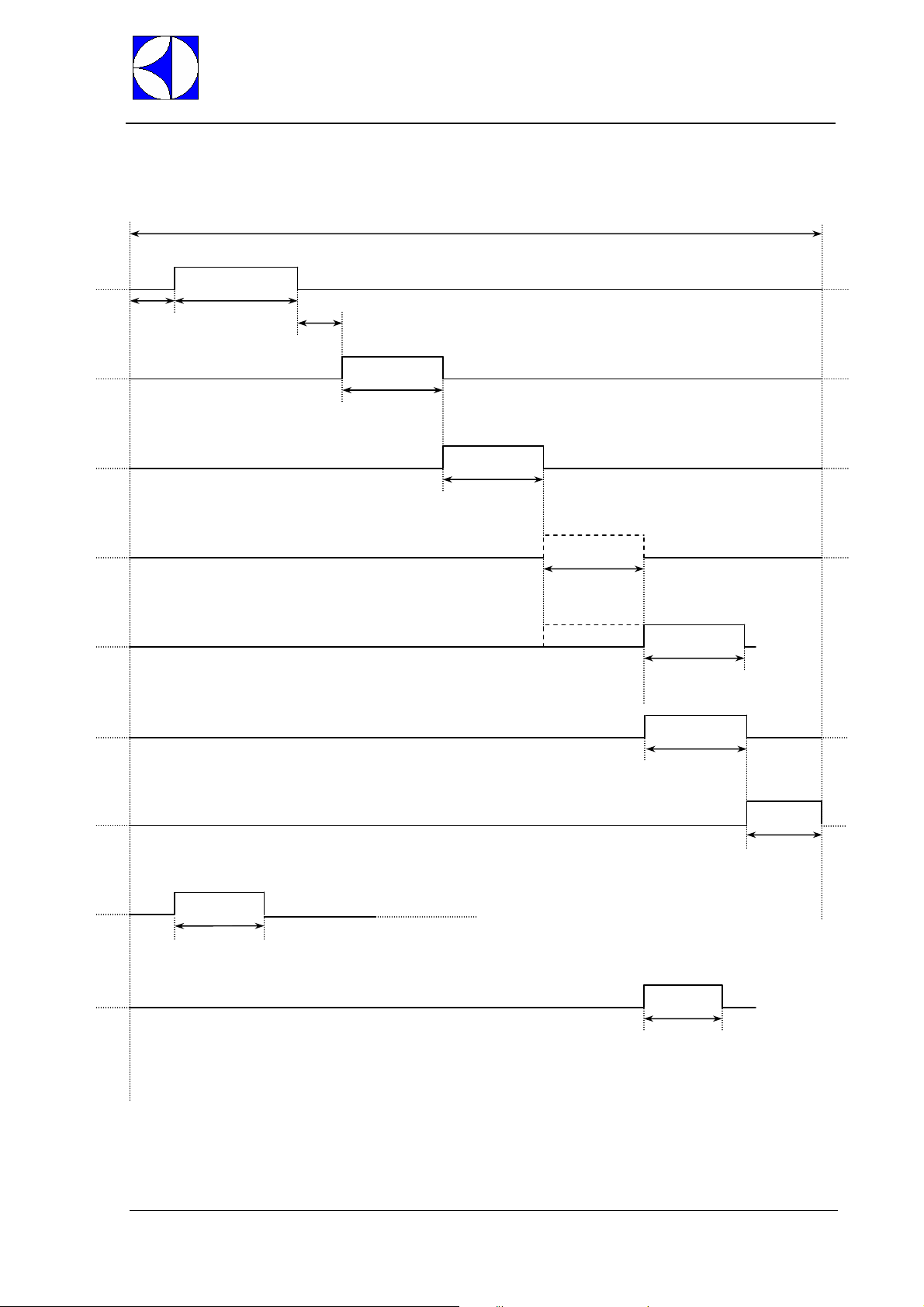

CYCLE DIAGRAM

WASH

Electronic Dishwasher

CYCLE TYME

SERVICE MANUAL

IPA

Ln Sh

PA

PRE RINSE

Pr

RINSE

ri

COLD RINSE

cr

DRAIN

dr

rPA

FINAL

PAUSE

FP

DETERGENT

DEt

RINSE AID

RAi

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.12/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

CY1 Cycle 1 Parameters

Sym. Parameter Description

Ln1

Sh1

PA1

Pr1

ri1

cr1

dr1

FP1

CY2 Cycle 2 Parameters

Sym. Parameter Description

Ln2

Sh2

PA2

Pr2

ri2

cr2

dr2

FP2

Wash Phase Long [min] 0 20

Wash Phase Short [s] 1 60

Pause [s] 0 20

Pre-rinse Duration [s] 0 30

Rinse Phase Duration [s] 10 45

Cold Rinse Phase Duration [s] 0 50

Drain [s] 0 40

Final Pause at End of Cycle [s] 0 60

Wash Phase Long [min] 0 20

Wash Phase Short [s] 1 60

Pause [s] 0 20

Pre-rinse Duration [s] 0 30

Rinse Phase Duration [s] 10 45

Cold Rinse Phase Duration [s] 0 50

Drain [s] 0 40

Final Pause at End of Cycle [s] 0 60

Electronic Dishwasher

SERVICE MANUAL

Unit Min Max

Unit Min Max

Factory

Default

0

35

4

0

16

0

16

0

Factory

Default

0

45

4

0

16

0

16

0

CY3 Cycle 3 Parameters

Sym. Parameter Description

Ln3

Sh3

PA3

Pr3

ri3

cr3

dr3

FP3

bt3

Wash Phase Long [min] 0 20

Wash Phase Short [s] 1 60

Pause [s] 0 20

Pre-rinse Duration [s] 0 30

Rinse Phase Duration [s] 10 45

Cold Rinse Phase Duration [s] 0 50

Drain [s] 0 40

Final Pause at End of Cycle [s] 0 60

Boiler Temperature Threshold: only for Cycle 3.

This parameter allows having a different rinsing temperature for the

third cycle. Only values above 45°C are allowed.

Unit Min Max

[°C] 0 95

Factory

Default

1

40

4

0

16

0

16

0

0

drn Drain/Cleaning Cycle Parameters

Sym. Parameter Description

Idr

Fdr

drt

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.13/116

Initial Drain Phase Duration [s] 0 240

Final Drain Phase Duration [s] 0 240

Drain without cleaning cycle - 0 1

Unit Min Max

Factory

Default

40

60

0

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

8. OTHER PARAMETERS

Dishwashing Parameters

dPA

Sym. Parameter Description

IPA

dLY

Pdr

RPA

C F

rit

PPL

CdE

1LE

1HS

2LE

2Hs

Note:

1LE, 1HS, 2LE, 2HS

physical quantity.

Initial Pause before start washing (for ALL cycles) [s] 0 10

Delay for the 2nd wash pump (PW only) [s] 0 10

Active a drain phase at the end of washing phase. [s] 0 40

Duration of pause after rinse cycle (valid for dishwashers with door/hood

lock device) [See par. 9.2 Medical line dishwasher with door/hood lock

device].

Celsius/Fahrenheit selection

0 = Celsius

1 = Fahrenheit

Rinse Temperature Display.

Enable rinse temperature probe (if installed).

0 = during rinse phase the display shows boiler temperature;

1 = during rinse phase the display shows rinse temperature;

Pulse Per Litre.

This parameter must be settled in according to flow meter installed

[present up to software version 3.12].

Number of wash cycles performable without detergent (only for

dishwashers with external detergent level sensor – par. 9.2.1 Detergent

and rinse aid level sensors activation) [LES=1]

Pressure sensor threshold 1 [present up to software version 2.11]. - 0 255

Pressure sensor histeresis 1 [present up to software version 2.11]. - 0 255

Pressure sensor threshold 2 [present up to software version 2.11]. - 0 255

Pressure sensor histeresis 2 [present up to software version 2.11]. - 0 255

parameters emulates a two levels pressure switch, keep in mind that value doesn’t correspond to a

Electronic Dishwasher

SERVICE MANUAL

Unit Min Max

[s] 0 60

- 0 1

- 0 1

[p/l] 0 255

- 0 5

Factory

Default

0

3

0

0

0

0

0

5

140

50

140

50

ron Read Only Parameters

Sym. Parameter Description

rEL

rLs

ACC

CAll

C 8

F21

Main Board Firmware Release - - - -

Water softener board software version. (only for dishwashers with

incorporated continuous water softener).

Active column: indicates through which of the two continuous water

softener columns boiler filling is being carried out: 0 = column A and 1 =

column B (only for dishwashers with incorporated continuous water

softener).

When CAll message appears, the parameter value becomes 3.

After maintenance, to clear

When C 8 alarm appears, the machine is frozen and this parameter is 3.

After maintenance (see alarm codes document), insert 0 to enable the

machine.

This alarm appears in case of malfunctioning in the continuous water

softener. To facilitate fault-finding, see par. E "Alarm codes that stop the

machine for models with incorporated continuous water softener".

CAll message, insert 0.

Unit Min Max

- - - -

- - - -

- - - -

- - - -

- - - -

Factory

Default

HCP Communication and HACCP Parameters

Sym. Parameter Description

SEr

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.14/116

Serial Device

0 = 8N1

1 = PC connection (DAAS 8E1)

7 = HACCP network (ECAP 8E1+LK485)

(LK485 board is necessary)

9 = Dishwashers with incorporated continuous

water softener

11 = Machines with incorporated continuous water

Unit Min Max

- 0 63

Factory

Default

1

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

Adr

Prn

bt

bH

tt

tH

softener that communicate with LK485 board

16 = HACCP printer (8N1)

32 = MODEM GSM (DAAS 8N1)

33 = MODEM GSM (DAAS 8E1)

48 = Hyper Terminal (8N1)

Address.

This parameter specifies the address of the appliance into the

‘HACCP_network’.

Works only if ‘HACCP network’ is selected (see above parameter).

Print parameter table. - 0 1

HACCP ‘Basic’ (printer)

Boiler temperature: high limit.

HACCP ‘Basic’ (printer)

Boiler temperature: gap below high limit.

HACCP ‘Basic’ (printer)

Tank temperature: high limit.

HACCP ‘Basic’ (printer)

Tank temperature: gap below high limit.

- 0 255

[°C] 45 95

[°C] 0 20

[°C] 35 75

[°C] 0 20

1

1

90

10

68

10

CFG Configuration Parameters

Sym. Parameter Description

tYP

boi

doo

dFL

trc

b_t

btF

LES

UI

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.15/116

Dishwasher Model:

0 = HOOD TYPE & UNDERCOUNTER

1 = POT WASHER

2 = AUTOMATIC POT WASHER

3 = MEDICAL LINE DISHWASHER WITH LOCK DOOR/HOOD

DEVICE

Boiler type:

0 = ATMOSPHERIC BOILER

1 = PRESSURE BOILER

2 = EXTERNAL BOILER

Door type:

0 = AUTOMATIC HOOD

1 = MANUAL HOOD

2 = FRONT LOADING

3 = POT WASHER

Default model (see Default tables):

1 = HOOD TYPE

2 = POT WASHER

3 = UNDERCOUNTER

Solid State Relay (TRIAC).

0 = not enabled;

1 = SOFT START enabled;

3 = SLOW SOFT START enabled

(works only on boards with Solid State Relay).

Boiler/Tank heating swap:

0 = boiler heaters and tank heater can work simultaneously;

1 = swap enabled: tank heating starts only boiler temperature is

reached;

(Note: disabling this function changes the global electrical power of

appliance; before enabling this function check available power, supply cable

section, fuses in according to User Manual).

Tank Filling Mode

Enable filling tank by means of rinsing cycles.

Ex:

btF = 75 means that boiler water is heated at 75°C, then follows a

rinse phase and so on until tank is full.

btF = 0 the tank is filled by solenoid valve in the traditional way (On

If

machines with incorporated continuous water softener, even if btF is set to

0, filling occurs through subsequent rinses).

Detergent Level Switches

0 = level switches not enabled;

1 = enable detergent level switches;

USER INTERFACE MODEL

8 = ACTIVE function disabled

42100099] set to 0)

9 = hood type, under counter (up to version 3.11 [up to serial nr.

42100099] set to 1)

13 = LS5 with atmospheric boiler(up to version 3.11 [up to serial nr.

42100099] set to 5)

15 = LS5 with pressure boiler (user interface without display); (up to

version 3.11 [up to serial nr. 42100099] set to 7)

(up to version 3.11 [up to serial nr.

Unit Min Max

- 0 3

- 0 2

0 3

- 0 3

- 0 3

- 0 1

[°C] 0 85

- 0 1

- 0 15

Factory

Default

0

0

1

-

0

1

75

0

9

rE

ALr

AAG

FrG

SrU

BPo

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

24 = LS5 with atmospheric boiler (From Ser. Nr.: 821).

See parameter

installed in the board.

Enable “regeneration cycle” key (only for dishwashers with non-continuous

water softener) [See paragraph 9.1 resin regeneration cycle].

ALARMS ENABLE

0 = alarms disabled (to disable also warnings see

1 = alarms enabled;

If this function is disabled, faults can be detected so display do not shows

any alarm code.

Air gap with float level sensor normally closed (the level sensor is closed

when the boiler is empty). E.g. the boiler level sensor for machines with

incorporated continuous water softener.

Forced start of a resin regeneration cycle (only for dishwashers with

incorporated continuous water softener). [See paragraph 9.4 Dishwashers

with incorporated continuous water softener].

Max. rinse water hardness (only for dishwashers with incorporated

continuous water softener). After modifying, disconnect and reconnect the

machine's main power supply by means of the main switch. [See paragraph

9.4 Dishwashers with incorporated continuous water softener].

Boiler heating control.

Defines the max. permissible temperature difference during boiler heating in

a time interval of 2 minutes and 30 seconds.

rEL(family ron) to check the software version

Electronic Dishwasher

SERVICE MANUAL

bLo and tLo);

- 0 1

- 0 1

- 0 1

- 0 2

°fH 4 14

°C 25 80

0

1

0

0

10

50

Parameters for automatic hood type dishwashers

dbG

Sym. Parameter Description

t 1

t 2

t 3

t 4

t 5

t 6

AL_

Ith

Ith

DELAY_K1

Time (during hood lifting) within which S3” must return to the rest position.

HOOD_TOUT

TIMEOUT – max. time allowed for complete hood opening/closing.

DELAY_K1_S3

During hood lowering, firstly S3” must cut in and then after a time

t3 .the bottom limit switch S3.

DELAY_K

Time within which K and K’ must be both closed or both open.

DELAY_S3

Time during hood lifting within which the bottom limit switch must return

to the rest position..

DELAY_S5

Time during hood lowering within which the top limit switch must return to

the rest position.

Displays the last alarm code relative to automatic hood type dishwashers. - - -

Parameter only valid for hood type models.

Hood lifting motor absorption threshold.

(50 units correspond to a current of approx. 1 ampere).

Parametro valido solo per cappottine.

Soglia limite di assorbimento del motore di sollevamento della cappotta

(50 Unità corrispondono ad una corrente di circa un ampere).

Unit Min Max

0.1 s 0.0 s. 20.0 s

0.1 s 0.0 s. 20.0 s

0.1 s 0.0 s. 20.0 s

0.1 s 0.0 s. 20.0 s

0.1 s 0.0 s. 20.0 s

0.1 s 0.0 s. 20.0 s

- 0 250

- 0 250

Factory

Default

15

200

15

10

20

20

-

100

100

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.16/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

9. SPECIAL FEATURES

9.1 RESIN REGENERATION CYCLE

The regeneration cycle is activated by pressing the button shown in the figure, for at least 5 seconds.

For this key to be enabled parameter

At this point you can enter the number of wash cycles that can be performed after each regeneration: parameter rCY in the

counters family

message

operation of the appliance, so you can continue to use the dishwasher). The message is cleared when the regeneration cycle is

terminated.

The number of regeneration cycles performed can be checked by consulting the parameter

counters.

When there are just 15 cycles remaining before the next regeneration cycle, at the end of the wash cycle the display shows the

message

display informs the user of the number of wash cycles still available before resin regeneration is required.

Before starting the regeneration cycle remove the siphon spillway.

CAUTION: if the regeneration cycle is accidentally started, it can be switched off by pressing the button shown in the figure, for

at least 5 seconds.

The hardness of the water exiting the softener can vary between 3°fH - 10 °fH / 1.7 °dH - 5.6 °dH / 2.1 °cH - 7 °cH.

Cnt. If rCY is set to zero the counter is disabled, otherwise after the preset number of cycles the

rEG is displayed to confirm that regeneration is possible (this is an information-only message with no effect on

End followed by 15, at the end of the next wash cycle the display shows End and 14, and so forth, i.e. the

TANK

BOILER

rE (in family CFG) must be set to 1.

nrE in the Cnt family of

9.2 MEDICAL LINE DISHWASHER WITH DOOR/HOOD LOCK DEVICE

The medical line dishwasher with door/hood lock device has a device that prevents door/hood opening for the entire duration of

the work cycle.

For the door/hood lock to be active, the parameter

The dishwasher door/hood is locked at the start of a wash cycle and is released at the end of the final pause after rinse. The

wash compartment can be accessed by stopping the work cycle in progress, as the locking device is thus disabled.

A pause at the end of rinse can be set by means of the parameter

3 wash cycles. The rinse water temperature is displayed during this pause. Another final pause in the cycle can be set by setting

the parameters

The door/hood lock device will be deactivated at the end of the final pause (

For correct performance of the wash cycle the pause at the end of rinse and the final pause must assume the default values

(see Prog 032 – 034 - 035).

FP1, FP2, FP3. During the final pause the display shows the time remaining for completion of the cycle.

tYP (in the CFG family) must be set to 3.

rPA (in thedPA family). This parameter is common to all

FP1, FP2, FP3).

9.3 DETERGENT AND RINSE AID LEVEL SENSORS ACTIVATION

By setting the parameter

detergent and rinse aid tanks is enabled. During the rinse phase, when the rinse aid inside the tank has finished, the message

LES (in the CFG family) to 1, management of the level sensors located inside the external

rAi 0 appears on the display.

When the detergent inside the tank is finished, the message

to

CdE (in the dPA family) the dishwasher inhibits the activation of other wash cycles. Therefore the detergent level in the

tank must be restored.

dEt 0 is displayed and after a number of wash cycles equal

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.17/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

9.4 DISHWASHER WITH INCORPORATED CONTINUOUS WATER SOFTENER

Dishwashers with incorporated continuous water softener have a continuous softener in the water circuit. By means of special

resins, this device removes the calcareous substances from the feed water, supplying decalcified water for washing.

To activate the continuous water softener, set the parameter

water softener board is connected to the LK485 board.

For the continuous softener to work properly the resins must be regenerated periodically with a frequency depending on the

hardness of the inlet water, the number of wash cycles carried out and the max. hardness set with the parameter

SER (in the HCP family) to the value 9 or the value 11 if the

SrU (in the

CFG family).

Unlike conventional water softeners, this continuous softener does not require machine stops for regenerating the resins.

To regenerate the resins it is necessary to put coarse salt in the special container located in the dishwasher.

In particular, the salt container must be filled when the dishwasher is used for the first time and whenever the messages

SAL 0 or SAL END are displayed at the start or end of a wash cycle. The salt container holds up to 1.5 kg of salt.

CAUTION: use only coarse salt with a NaCl purity grade of 99.8 %. The use of salt with a lower purity grade may cause

the sale container filter to clog and the water softener to malfunction.

IMPORTANT: The messages

salt, as the salt must circulate in the entire system. Correct operation of the dishwasher is not, however, affected.

The number of regeneration cycles performed can be checked by consulting the parameter

counters.

nrE only counts regeneration cycles carried out with the salt container adequately filled; there is another counter, rES (in the

Cnt family) that indicates the number of regeneration cycles done without salt.

If the parameter

vary between 3°fH - 10 °fH/ 1.7 °dH - 5.6 °dH / 2.1 °cH - 7 ° cH.

AUTONOMY OF A COLUMN OF RESINS ACCORDING TO THE CHANGE IN INLET WATER HARDNESS, WITH OUTLET

WATER HARDNESS OF 10 °fH / 5.6 °dH /7 °cH (

Maximum outlet water hardness can be modified by setting the SrU value. The outlet water hardness can be modified from the

value of 4° fH to 14° fH.

NB: To save the new water hardness value, in addition to the normal parameter modification and saving operations it is necessary to

disconnect and reconnect the machine's main power supply by means of the main switch on the external board.

Water softener operation can be checked by forcing the regeneration of resins, without waiting for the outlet water hardness to

reach the set max. value (

To do this, wait for the water softener to finish previous resin washing or regeneration operations and set the parameter FrG

(CFG family) to 1 for regenerating column A or to 2 for regenerating column B.

Switch the machine off and on again so that it carries out complete regeneration of the set column. If previous resin washing or

regeneration operations were not completed, the manual request for regeneration is not carried out.

It is possible to check which column is being used for boiler filling by querying the parameter AAC (ron family): if AAC = 0

column “A” is used, if AAC =1 column “B” is used.

The number of litres used by the machine can be checked by querying the parameters nnc (m3 ) and L (litres). To calculate the

total number of litres used by the machine, add the nnc and L values.

NB: In machines with incorporated continuous water softener, tank filling cannot be carried out through overflowing (btF=0) but

only by means of successive rinse cycles (btF=75). Therefore the btF parameter must be set to 75.

SrU is set to the value10, according to the factory setting, the water softener outlet water hardness can

SAL 0 or SAL End may appear for several wash cycles even after topping-up the

nrE in the Cnt family of

SrU =10 according to the factory setting).

°fH °dH °cH Number of cycles

15 8,4 10,5 14

20 11,2 14 10

25 14 17,5 7

30 16,8 21,1 6

35 19,6 24,6 5

40 22,4 28,1 4

SrU ).

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.18/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

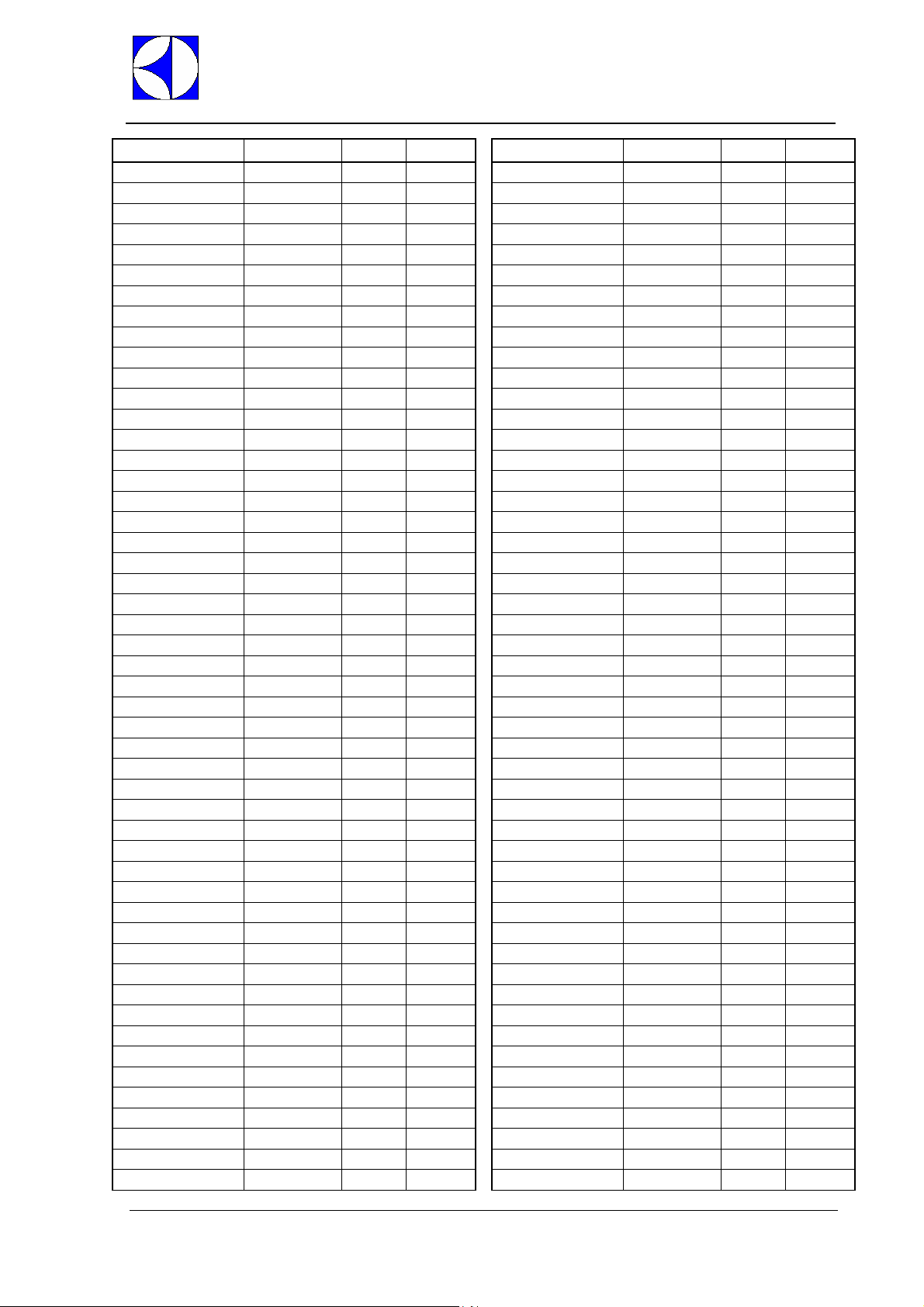

10. MAIN BOARD CONFIGURATION

When receiving an electronic board (spare part) may be necessary to configure it in according to the machine where has to be replaced.

1. With the machine CODE enter into the following table and read the corresponding Prog. number;

2. Follow the instructions reported into the corresponding Prog.XXX sheet (next pages).

3. With the machine CODE find the Layout number in Par. 12.2 – Connectors layout.

10.1. CODEÆProg. TABLE

MODEL CODE Prog. Layout

400007

WT4

WT4B

WT4D

WT4DB

WT46 400016 020 16

WT4G 400017 022 8

WT4DG 400018 022 8

WT4WS1

WT4BWS

WT4DWS1

WT4BDWS

WT4D60

WT4DDG

LS5/1

LS5/1 DP

Up to Ser.: 806 021 11

From Ser.: 807 065 11

400008

Up to Ser.: 806 020 16

From Ser.: 807 064 16

400009

Up to Ser.: 806 021 11

From Ser.: 807 065 11

400015

Up to Ser.: 806 020 16

From Ser.: 807 064 16

400019

Up to Ser.: 806 024 21

From Ser.: 807 066 21

400027

Up to Ser.: 806 012 17

From Ser.: 807 063 17

400028

Up to Ser.: 806 024 21

From Ser.: 807 066 21

400029

Up to Ser.: 806 012 17

From Ser.: 807 063 17

400042

Up to Ser.: 806 021 11

From Ser.: 807 065 11

400043

Up to Ser.: 806 036 11

From Ser.: 807 067 11

400100

Up to Ser.: 806 021 11

From Ser.: 807 065 11

400102

Up to Ser.: 806 021 11

From Ser.: 807 065 11

MODEL CODE Prog. Layout

400103

LS5/1WS

LS5/1WSDP

LS5/3

LS5/3 DP

LS5/3WS

LS5/3WSDP

LS5/3WSDPD

LB5G 400118 022 8

LB5GDP 400119 022 8

LS5/1DP60

LS5/1DPAUS

LS5/1DPCS

LS6EP 502003 013 16

LS6EP/DD 502004 013 16

LS6EA/DD 502005 011 8

LS6EA/DD/DP 502006 011 8

WT38TDE 502007 032 10

WT38/M50 502008 015 9

LS6EADPWS 502014 044 8

LS6EADPWSG 502015 044 8

WT38WS 502016 044 8

Up to Ser.: 806 024 21

From Ser.: 807 066 21

400110

Up to Ser.: 806 024 21

From Ser.: 807 066 21

400112

Up to Ser.: 806 020 16

From Ser.: 807 064 16

400113

Up to Ser.: 806 020 16

From Ser.: 807 064 16

400114

Up to Ser.: 806 012 17

From Ser.: 807 063 17

400115

Up to Ser.: 806 012 17

From Ser.: 807 063 17

400117

Up to Ser.: 806 012 17

From Ser.: 807 063 17

400124

Up to Ser.: 806 021 11

From Ser.: 807 065 11

400125

Up to Ser.: 806 036 11

From Ser.: 807 067 11

400126

Up to Ser.: 806 036 11

From Ser.: 807 067 11

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.19/116

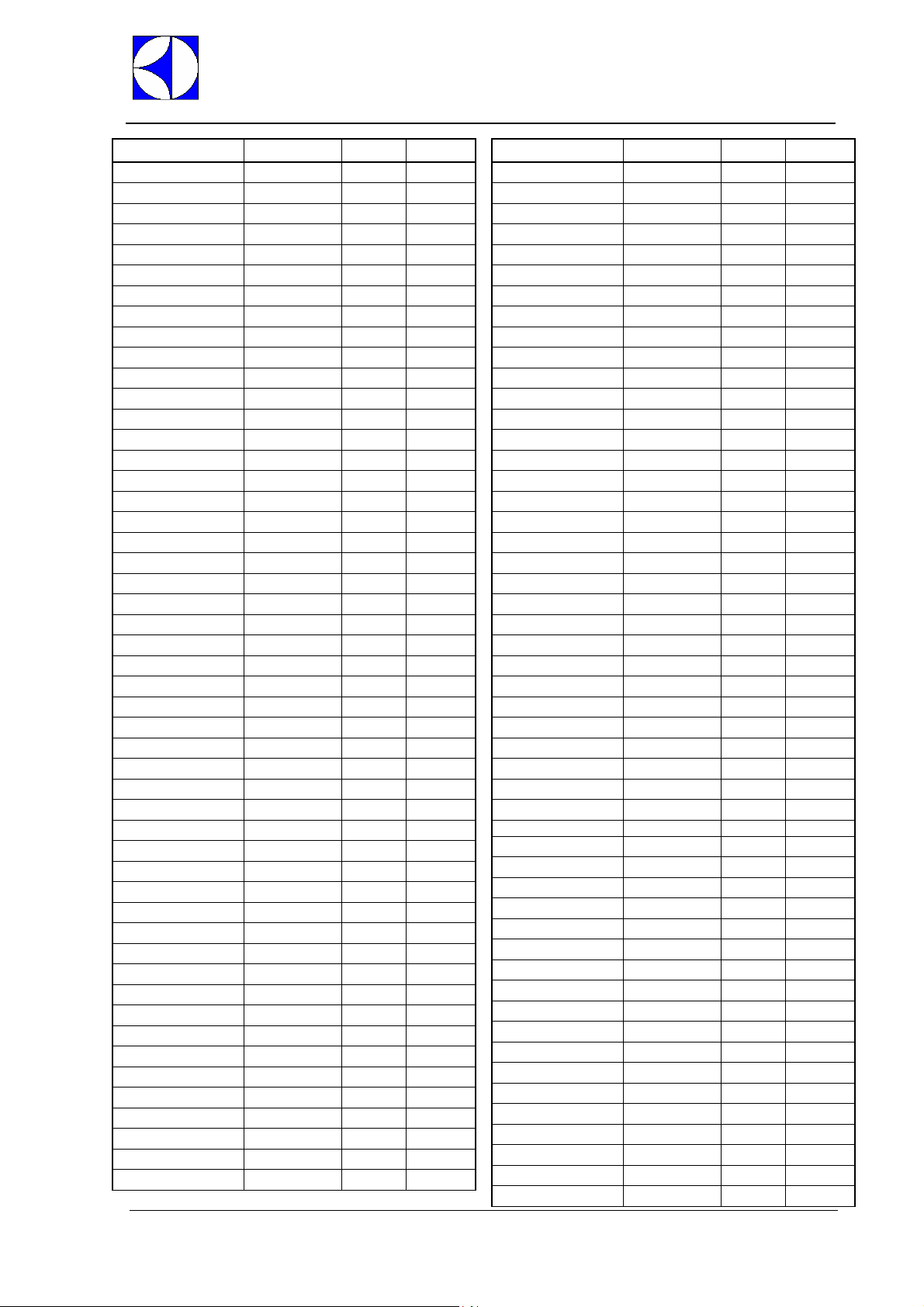

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

MODEL CODE Prog. Layout

WT38WSG 502017 044 8

WT38MEDWS 502018 045 8

WT38PM50 502019 039 19

WT37LEV/9 502020 051 18

LS6EADPDWS 502022 044 8

WT38DWS 502023 044 8

LS6SANA 502024 053 10

WT38M50/4 502029 015 9

LS6EA/UK 502030 011 8

LS6EA/UKDP 502031 011 8

LS6EA/60 502041 011 8

WT 38DD 502110 011 8

WT 37 502111

WT 38 502112

WT 37/4.5 502117

WT 38/4.5 502118

WT 37/UK 502122

WT38C 502125 033 18

WT38C60 502126 033 18

WT38CUK 502127 033 18

WT38/4.5NW 502129 011 8

WT 38/UK 502217

WT37J60 502218

WT37J50 502219

LS6AH240U 502312 027 9

WT30H208U 502313 031 9

WT30H240U 502314 031 9

WT30H208DU 502315 027 9

WT30H240DU 502316 027 9

WT30H208RU 502317 031 9

WT30H240RU 502318 031 9

LS6H208DU 502319 027 9

LS6AH208U 502320 027 9

WT 38/60 502321 011 8

WT 38/M60 502322 015 9

WT 38MED 502323 014 8

LS6H240DU 502325 027 9

LS6H208RU 502326 027 9

LS6H240RU 502327 027 9

WT30M208U 502328 034 10

WT30M240U 502329 034 10

WT30M208DU 502339 034 10

WT30M240DU 502341 034 10

WT30M208RU 502342 034 10

WT30M240RU 502343 034 10

WT30C208DU 502344 038 9

WT30C240DU 502345 038 9

WT38PM60 502346 039 19

WT38M60/4 502347 015 9

WT30H208WS 502348 056 9

011

011

011

011

046

011

046

046

Electronic Dishwasher

8

8

8

8

8

8

8

8

SERVICE MANUAL

MODEL CODE Prog. Layout

WT30H240WS 502349 056 9

WT30H208DN 502352 068

WT30H240DN 502353 068

WT38WL 502514 055 8

LS6EA 502520 011 8

LS6EA/DP 502521 011 8

LS6EAH 502523 011 8

LS6MCD 502524 033 18

LU7PDP 503020 040 24

LU7ADP 503021 041 22

LU7ADPWS 503022 061 22

WTU40PDP 503023 040 24

WTU40ADP 503024 047 22

WTU40ADPWS 503025 062 22

WTU40ADPD 503026 047 22

LS 10 504100 002 1

LS14EA 504101 001 4

LS 10 UK DP 504102 002 1

ET12E 504104 003 1

LS 10/60Hz 504105 002 1

LS 10 CW 504107 002 1

LS 10 INS 504108 002 1

HT 1200 ins DEK 504109 001 1

LS14EA/INS 504110 001 4

LS 10 N 504111 002 1

LS 10 DP 504114 002 1

LS 10 HD 504115 008 1

LS14EA/AU 504116 004 15

LS14EA/60 504117 001 4

LS 10 UK1 504118 002 1

LS 10 UK3 504119 002 1

LS 12 INS 504120 001 1

LS 12 504121 001 1

LS 12 DP 504122 001 1

LS 12 60Hz 504125 001 1

LS 12 CW 504128 001 1

HT 1200 DEK 504129 001 1

LS14EA/ASIA 504131 009 4

LS14EA/G 504133 001 4

WT 60 DP 504134 001 1

WT 60 504135 001 1

WT 60 CW 504136 001 1

WT 60 UK DP CW INS 504137 001 1

WT 60 INS 504138 001 1

WT 60 CW INS 504139 001 1

WT 60 AU CW 504140 004 14

WT 60 AU N 504141 004 14

LS10EA 504142 002 4

WT 60/60HZ 504145 001 1

WT 60/60HZ CW 504146 001 1

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.20/116

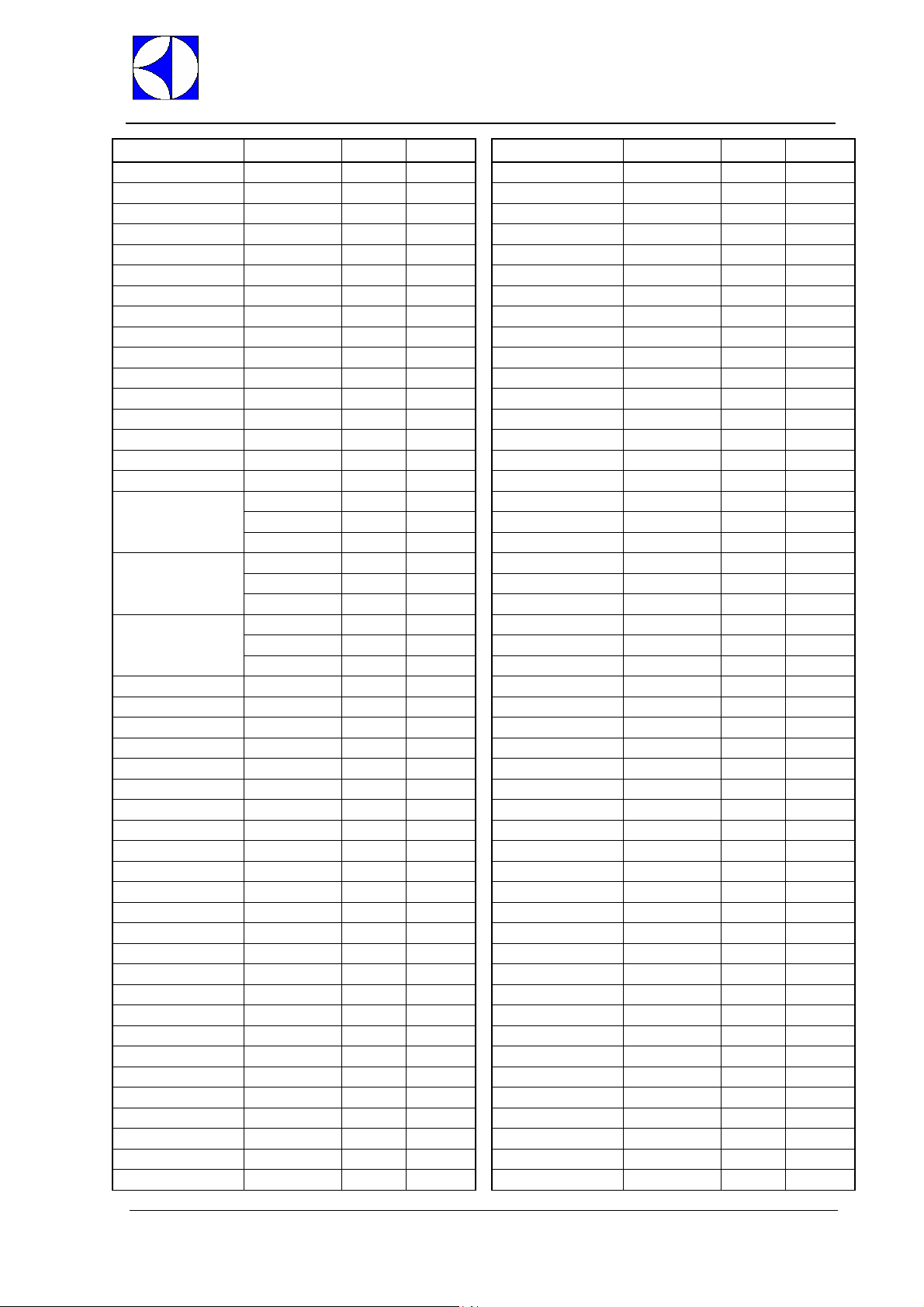

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

MODEL CODE Prog. Layout

WT 60 N 504151 001 1

WT 60 N INS 504152 001 1

LS 12 HD 504153 007 1

LS14EA/DD 504155 001 4

WT65E 504156 001 1

WT65EB 504157 001 4

WT65EI 504158 001 1

WT 60 AU DP 504159 004 14

LS 12 UK/3 CW 504161 001 1

WT 60 UK CW 504162 001

LS 12 AU 504163 004 14

LS 12 UK DP CW 504164 001 1

ECOTEMP 12 SW 504165 001 1

WT65EBI 504166 001 4

WT65EBIA 504167 004 15

WT65EIA 504168 004 15

WT65E60 504169 001 1

WT65EB60 504170 001 4

WT 60 U/400 504171 006

WT 60 U/440 504172 006

WT65EBIDG 504173 001 4

WT65EBASIA 504174 009 4

WT65EIM50 504175 006 2

WT65EIM60 504176 006 2

WT 60 MX 220/60 504177 001 1

LS 12 CW INS 504178 001 1

LS14ADP/G 504179 001 4

WT65MED 504180 010 4

WT65EJ50 504183 001 1

WT65EJ60 504186 001 1

LS14AH240U 504187 028 3

WT65H208U 504188 028 3

WT65H240U 504189 028 3

LS 12 ASIACW 504190 009 1

WT 60 ASIACW 504191 009 1

LS 12 ASIANB 504192 009

WT60ASIANB 504193 009

LS14H208DU 504194 028 3

LS14AH208U 504195 028 3

LS14H240DU 504196 028 3

LS14H208RU 504197 028 3

LS14H240RU 504198 028 3

WT65H208DU 504199 028 3

WT65H240DU 504200 028 3

WT65H208RU 504201 028 3

WT65H240RU 504202 028 3

WT65M208U 504203 035 12

WT65M240U 504204 035 12

WT65M208DU 504205 035 12

WT65M240DU 504206 035 12

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.21/116

Electronic Dishwasher

SERVICE MANUAL

MODEL CODE Prog. Layout

WT65M208RU 504207 035 12

WT65M240RU 504208 035 12

LS14EAWS 504209 042 4

LS14ADPWSG 504210 042 4

LS14EAIWS 504211 042 4

WT65EBWS 504212 042 4

WT65BIDWSG 504213 042 4

WT65EBIWS 504214 042 4

WT65MEDWS 504215 043 4

WT65H208WS 504216 057 3

WT65H240WS 504217 057 3

ET12EWS 504218 058 4

WT65ROW 504219 052 6

LS14ROW 504220 052 6

LS14SANA 504221 054 12

WT65EID 504222 001 4

WT65EBIWSD 504223 042 4

LS14ROW60 504224 052 6

WT65ROW60 504225 052 6

LS9P 505022 019 13

LS9P DD 505033 019 13

LS9A UK 505034 018 20

LS9P60 505035 019 13

WT55P 505038 019 13

WT55P6 505039 019 13

LS9ADG1 505041 018 23

WT55ADG1 505042 018 23

LS9PAUS 505043 019 13

WT55PM50 505044 019 13

WT55PM60 505045 019 13

PPW1 M 506010 005 3

PPW1 M UK 506011 005 3

PPW1 60 Hz 506012 005 7

PPW1 MH 506013 005 3

PPW2 M 506014 005 3

PPW2 M UK 506015 005 3

PPW2 60 Hz 506016 005 7

PPW2 V 506017 005

WT830 M 506018 005 3

WT830 M UK 506019 005 3

WT830 60 Hz 506020 005 3

WT850 M 506022 005 3

WT850 M UK 506023 005 3

WT850 60 Hz 506024 005 3

WT850 V 506025 005

WT830 MH 506026 005 3

WT830M208U 506029 037 3

WT830M240U 506030 037 3

WT830H208U 506031 037 3

WT830H240U 506032 037 3

WT850M208U 506033 037 3

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

MODEL CODE Prog. Layout

WT850M240U 506034 037 3

PW1M208U 506035 037 3

PW1M240U 506036 037 3

PW1MH208U 506037 037 3

PW1MH240U 506038 037 3

PW2M208U 506039 037 3

PW2M240U 506042 037 3

ET830M 506045 005 3

ET830MH 506046 005 3

ET850M 506047 005 3

WT830EA 506215 017 5

WT850EA 506216 017 5

WT830EAG 506217 017 5

WT850EAG 506218 017 5

FL5 690004 020 16

FL5DP 690005 020 16

690006

LV5

LV5DP

LV5/3WSDP

FL5/3WSDP 690009 012 17

UC5/1DP 690010 021 11

UC5/1WSDP 690011 024 21

LD5DP 690013 020 16

LD5 690014 020 16

UC5/1DITO 690017 021 11

UC5/1DPDITO 690018 021 11

FL5DDG 690027 067 11

FL 620EP 698003 013 16

ET5EDG 698004 023 8

LV6EP 698006 013 16

H3300 698007 029 8

H2500 698008 019 13

H3500 698009 001 4

ET5EDCW 698010 016 8

LV6EADPWS 698011 048 8

HT1200WS

HT1200IWS

FL620ADPWS 698014 048 8

H1310SANA 698016 030 8

H1510SANA 698017 010 4

LV1200IWS

ET7ADP

HT900P 698022 019 13

LV900P 698023 019 13

Up to Ser.: 806 020 16

From Ser.: 807 064 16

690007

Up to Ser.: 806 020 16

From Ser.: 807 064 16

690008

Up to Ser.: 806 012 17

From Ser.: 807 063 17

698012

698013

698018

698019

042 4

042 4

042 4

047 22

Electronic Dishwasher

SERVICE MANUAL

MODEL CODE Prog. Layout

LD900 698024 019 13

FL620EAG 698026 011 8

FL620DPWSG 698027 044 8

HT900ADG1 698028 018 23

HT1200BIDG 698029 001 4

LU700PDP 698033 040 24

LU700ADP 698034 047 22

LU700ADPWS 698037 062 22

HT1200BIDWG 698038 042 4

PW100MG 698039 005 3

PW100 M 698040 005 3

PW200 M 698041 005 3

PW200 V 698042 005 3

PW100 MH 698043 005 3

LV100M 698044 005 3

LV200M 698045 005 3

PW200MG 698046 005 3

HT 1200 698050 001 4

HT 1000 698051 002 4

HT 1000 INS 698052 002 1

HT 1200 INS 698053 001 4

HT 1200 DP 698055 001 1

ET12EIG 698056 026 3

ET12EI 698057 025 4

LV1000 698059 002 4

LV1200INS 698060 001 4

ET12EICWG 698061 001 3

ET12EICW 698062 025 3

ET12EIWS 698063 059 4

ET12EIF 698065 050 4

FL 620EA 698070 046 8

FL 620EADP 698071 046 8

ET5E 698076 016 8

ET5ED 698077 016 8

FL 620EP/DD 698078 013 16

FL 620EA/DD 698079 046 8

FL 620EADP/DD 698080 046 8

LV6EA 698081 046 8

LV6EADP 698082 046 8

ET5EDWS 698084 060 8

ET5EDF 698090 049 8

LS10 INS DP S36220 002

LS 10 INS S37858 002

LS 10 S39968 002

LS 10/fiera S42549 002

LS 10 INS S43062 002

LS 10 S43327 002

HT 1000 S475CH 002

LS 10 CW S47APN 002

LS 10 CW S47CF5 002

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.22/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

MODEL CODE Prog. Layout

LS 10 CW S47DU4 002

LS 10 CW S47DU7 002

LS 10 CW S47DUA 002

LS 10 CW S47DUF 002

LS 10 CW S47E17 002

LS 10 CW S47E2C 002

LS 10 CW S47E2H 002

LS 10 CW S47E2M 002

LS 10 CW S47E2R 002

LS 10 UK1 S47E50 002

LS 10 CW S47E6M 002

HT1200 S46002 001

WT 60 CW INS S46880 001

HT 1000 S4734M 002

WT 60/9 S47539 001

WT 60/9 S4756O 001

WT 60/9 S4756P 001

WT60 INS S475GJ 001

WT60 INS S475GY 001

WT 60 CW S476HA 001

LS 12 HD S4775E 007

HT1200 S4777U 001

LS 12 CW INS S477BM 001

WT 60 AU CW S477JR 004

WT 60 INS S477M1 001

WT 60 INS S477M1 001

WT 60 N INS S477MB 001

WT 60/60HZ DP S477QB 001

LS 12 CW INS S477V7 001

WT 60 DP S47811 001

WT 60/9 S4781D 001

WT 60/60HZ DP S4781I 001

WT 60/9 INS S4786P 001

WT 60 U/230 S478KF 006

LS 12 CW INS S478LV 001

WT 60 CW INS S478SP 001

LS 12 CW INS S479VE 001

WT 60 S479Z3 001

WT 60 S479Z9 001

WT 60 AU CW S47AP80 004

LS 12 CW S47APP 001

HT 1200 S47B9I 001

LS 12 UK/3 CW S47BJI 001

LS 12 CW S47C1Z 001

WT 60 CW S47C6B 001

LS 12 CW S47CCS 001

WT 60 S47CCY 001

WT 60 CW S47CEA 001

WT 60/9 S47CEH 001

WT 60/9 S47CEI 001

WT 60 S47CKD 001

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.23/116

Electronic Dishwasher

SERVICE MANUAL

MODEL CODE Prog. Layout

LS 12 CW D04713 001

LS 12 CW S34369 001

WT 60 giappone S34377 001

WT 60 giappone S34378 001

WT 60 giappone S35178 001

WT 60 giappone S35179 001

LS 12 CW S35246 001

HT1200 S35330 001

WT 60 giappone S36384 001

WT 60 giappone S36385 001

LS 12 CW S36846 001

LS 12 CW S36847 001

HT1200 S39964 001

HT1200 S40472 001

ECOTEMP 12 S40785 003

WT 60/9 INS S41170 001

HT1200 S41185 001

LS 12 INS S42032 001

WT 60/60HZ S42170 001

LS 12/fiera S42550 001

WT 60/60HZ S42617 001

WT 60 N S43119 001

LS12 CW S43488 001

LS 12 INS S43563 001

LS 12 DP CW S43734 001

LS 12 CW S43806 001

LS 12 CW S43830 001

WT 60 CW INS S44421 001

LS6EA S477BL 011

WT 37 S4784U 011

LS6EA S4787B 011

FL 620EA S478BN 011

WT830 MH S46881 005

PPW1 M S4758V 005

WT830 MH S476YZ 005

PPW1 MH S477IT 005

WT830 M S479QS 005

PPW1 M UK S47BKQ 005

WT 60 CW INS S47CPB 001

WT 60 CW INS S47CQS 001

ECOTEMP 12 SW S47CVG 001

ECOTEMP 12 SW S47CVH 001

WT 60 CW INS S47D9Y 001

WT 60 S47DCA 001

LS 12 CW S47DE0 001

LS 12 CW S47DMM 001

WT 60 S47DSK 001

WT 60 S47DWC 001

WT 60 S47DWD 001

PPW1 MH S47C37 005

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

10.2. PROGRAMMING SHEETS

LS12 – LS14 / WT60 - 65 Prog. 001

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify Factory parameters:

FAC

5. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters.

tYP 0

boi 0

doo 1

dFL 1

trc 0

b_t 1

btF 75

LES 0

Hood Type like working cycles.

Atmospheric boiler.

Manual Hood.

Default values for Hood Type models.

(for this appliance SOFT START is NOT possible).

Tank heater works only if boiler temperature reached.

Enable filling tank by means of rinsing cycles.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Factory parameters family

bt°C 78

Regeneration cycle disabled.

Alarms enabled.

Boiler Temperature Threshold.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.24/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

LS10 Prog. 002

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify Factory parameters:

FAC

5. Modify Cycle parameters:

CY1

CY2

6. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters:

tYP 0

boi 0

doo 1

dFL 1

trc 0

b_t 1

btF 75

LES 0

Hood Type like working cycles.

Atmospheric boiler.

Manual Hood.

Default values for Hood Type models.

(for this appliance SOFT START is NOT possible).

Tank heater works only if boiler temperature reached.

Enable filling tank by means of rinsing cycles.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Factory parameters family

bt°C 78

Cycle 1

Sh1 45

Cycle 2

Ln2 1

Sh2 40

Regeneration cycle disabled.

Alarms enabled.

Boiler Temperature Threshold.

Short Wash Phase [s]

Long Wash Phase [min]

Short Wash Phase [s]

Electronic Dishwasher

SERVICE MANUAL

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.25/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

ECOTEMP12 Prog. 003

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify Factory parameters:

FAC

5. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters:

tYP 0

boi 0

doo 1

dFL 1

trc 0

b_t 0

btF 75

LES 0

Hood Type like working cycles.

Atmospheric boiler.

Manual Hood.

Default values for Hood Type models.

(for this appliance SOFT START is NOT possible).

Boiler heaters and tank heater work simultaneously. .

Enable filling tank by means of rinsing cycles.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Factory parameters family

bt°C 65

bAJ 2

Regeneration cycle disabled.

Alarms enabled.

Boiler Temperature Threshold.

Boiler Temperature Adjust.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.26/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

LS12 AU / WT60 - 65 AU Prog. 004

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify Factory parameters:

FAC

5. Modify the other parameters:

CY1

CY2

CY3

dPA

6. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters:

tYP 0

boi 0

doo 0

dFL 1

trc 0

b_t 1

btF 75

LES 0

Hood Type like working cycles.

Atmospheric boiler.

Automatic Hood.

Default values for Hood Type models.

(for this appliance SOFT START is NOT possible).

Tank heater works only if boiler temperature reached.

Enable filling tank by means of rinsing cycles.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Factory parameters family

bt°C 78

Cycle 1

FP1 2

Cycle 2

FP2 2

Cycle 3

FP3 2

Dishwashing parameters family.

IPA 2

Regeneration cycle disabled.

Alarms enabled.

Boiler Temperature Threshold.

Final Pause [s]

Final Pause [s]

Final Pause [s]

Initial Pause

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.27/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

PW 1 - 2 / WT830 - 850 Prog. 005

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify Factory parameters:

FAC

5. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters:

tYP 1

boi 0

doo 2

dFL 2

trc 0

b_t 1

btF 0

LES 0

Pot Washer.

Atmospheric boiler.

Front loading function.

Default values for Pot Washer models.

(for this appliance SOFT START is NOT possible).

Tank heater works only if boiler temperature reached.

The tank is filled into the traditional way.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Factory parameters family

bt°C 78

Regeneration cycle disabled.

Alarms enabled.

Boiler Temperature Threshold.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.28/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

WT60 - 65 USPH Prog. 006

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify Factory parameters:

FAC

5. Modify the cycle parameters:

CY1

CY2

CY3

6. Select Fahrenheit :

dPA

6. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters:

tYP 0

boi 0

doo 1

dFL 1

trc 0

b_t 1

btF 75

LES 0

Hood Type like working cycles.

Atmospheric boiler.

Manual Hood.

Default values for Hood Type models.

(for this appliance SOFT START is NOT possible).

Tank heater works only if boiler temperature reached.

Enable filling tank by means of rinsing cycles.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Factory parameters family

bt°C 78

Enter into Cycle 1 parameters family.

ri1 25

dr1 25

Enter into Cycle 2 parameters family.

ri2 25

dr2 25

Enter into Cycle 3 parameters family.

ri3 25

dr3 25

Enter into Dishwashing parameter family.

C F 1

Regeneration cycle disabled.

Alarms enabled.

Boiler Temperature Threshold.

Rinse Phase Duration [s]

Drain [s]

Rinse Phase Duration [s]

Drain [s]

Rinse Phase Duration [s]

Drain [s]

Select Fahrenheit degrees.

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.29/116

Electrolux

EFS – Dishwashing Systems Platform

Electrolux Professional

Electronic Dishwasher

SERVICE MANUAL

LS12HD Prog. 007

1. Switch OFF and then switch ON the machine.

2.

CFG

3. Switch OFF and then switch ON the machine.

4. Modify the cycle parameters:

CY1

CY2

CY3

5. Switch OFF and then switch ON the machine.

Enter into CFG parameter family and set the following parameters:

tYP 0

boi 0

doo 1

dFL 1

trc 0

b_t 1

btF 75

LES 0

Hood Type like working cycles.

Atmospheric boiler.

Manual Hood.

Default values for Hood Type models.

(for this appliance SOFT START is NOT possible).

Tank heater works only if boiler temperature reached.

Enable filling tank by means of rinsing cycles.

Detergent level switches not enabled.

UI 9 Select user interface hood type model (up to version 3.11 set to 1).

rE 0

ALr 1

Enter into Cycle 1 parameters family.

Pr1 20

dr1 36

Enter into Cycle 2 parameters family.

Pr2 20

dr2 36

Enter into Cycle 3 parameters family.

Pr3 20

dr3 36

Regeneration cycle disabled.

Alarms enabled.

Pre-rinse Duration [s]

Drain [s]

Pre-rinse Duration [s]

Drain [s]

Pre-rinse Duration [s]

Drain [s]

DOC. NO. 5956.446.06 ©Copyright 2005 by Electrolux Professional P.30/116

Loading...

Loading...