Page 1

19

A.2.1 MATERIALS AND FLUIDS USED

Areas in contact with the product are manufactured in steel or

coated with non-toxic plastic material. An HFC refrigerant in

compliance with current regulations is used in the refrigerating

units. The type of refrigerant gas used is given on the data plate.

A.2.2 DIMENSIONS, PERFORMANCE AND CONSUMPTION

"V160" FREESTANDING FREEZER AND REFRIGERATED

COUNTERS

Gross capacity lt 160

External dimensions:

- width mm 595

- depth with door open mm 1167

- depth with door closed mm 620

- height: mm 855

Refrigerated cell dimensions:

- width mm 482

- depth mm 465

- height mm 728

Dimensions of freezer cell:

- width mm 429

- depth mm 396

- height mm 680

Racks provided: n° 2+1

Rack dimensions:

- rack attached to bottom - refrigerated table mm 475 x 273

- adjustable racks - refrigerated table mm 478 x 410

- rack attached to bottom - freezer table mm 415 x 250

- adjustable racks - freezer table mm 424 x 320

Refrigerated tables

Temp. range. in cell °C 0/+10

Max. ambient temperature °C +38

Consumption kwh/24h 1,73

Power supply voltage V/ph/Hz 230/1/50

Max. current A 0,5

Total power W 73

Refrigerant capacity (R134a) g. 55

Freezer tables

Temp. range. in cell °C -20/-15

Max. ambient temperature °C +38

Consumption kwh/24h 1,66

Power supply voltage V/ph/Hz 230/1/50

Max. current A 0,62

Total power W 82

Refrigerant capacity (R134a) g. 100

"V170" REFRIGERATED UNDERCOUNTERS

Gross capacity lt 170

External dimensions:

- width mm 597

- depth with door open solid door model mm 1155

- depth with door open glass door model mm 1147

- depth with door closed mm 607

- height: mm 850

Compartment dimensions solid door model:

- width mm 544

- height mm 657

Compartment dimensions glass door model:

- width mm 544

- depth mm 470

- height mm 657

Shelves supplied with all models no. 2+1

A.1.1 FOREWORD

This manual is intended to provide the necessary information for

correct installation of the appliance. Therefore the manual and all

the technical documentation enclosed with the machine must

always stay with the equipment for possible consultation by

technicians and users. It is important for the user of the appliance

to know the regulations regarding safety during and after installation.

Carefully read the instructions in this manual before carrying out

any operation as they provide important information on the

regulations regarding safe installation and use of the appliance.

Incorrect installation, adjustment, modification, assistance

or maintenance can cause damage, injury or death. The

manufacturer declines any liability for operations carried

out on the appliance without following the instructions

given in this manual. The use of non-original parts relieves

the manufacturer of any warranty and liability.

No part of this manual may be reproduced.

A.1.2 INTENDED USE AND LIMITATIONS

This appliance is designed for the refrigeration and preservation

of food. Any other use is to be considered improper. Its use is

strictly limited to adult individuals.

CAUTION:

the appliances are not suitable for installation outdoors and/or in

places exposed to atmospheric agents (rain, direct sunlight, etc.).

The manufacturer declines any liability for improper use of

the products.

A.1.3 TESTING

Our equipment has been designed and optimised with laboratory

testing in order to offer high performance and efficiency. The

product is delivered ready for use.

Passing of the tests (visual inspection - electrical test - functional

test) is guaranteed and certified by means of the specific enclosures (par. D.5).

A.1.4 GENERAL SAFETY RULES

Appliance construction complies with European Low Voltage Directives 73/23-93/68/EEC, electrical systems according to Standards EN 60-335-1, EN 60-335-2-89 and Electromagnetic Compatibility according to Standards EN 55014-1;

EN 61000-6-1; EN 61000-6-3; (89/336/EEC); EN 55014-2, EN

50366.

Validity according to the latest current regulations.

A.1.5 CUSTOMER RESPONSIBILITIES

The customer must provide an earthed electricity socket of

suitable capacity for the absorption specified on the data plate.

Between the power cord and the electrical line there must be an

omni-polar differential switch, with high sensitivity manual reset,

properly sized, realized in accordance with current standards. For

proper sizing of the switch, refer to the absorbed power as

indicted on the technical data plate of the appliance.

Check the flatness of the appliance support surface.

A.1.6 DATA PLATE POSITION

The data plate that includes all data for the appliance is located

on the right-hand side where there is the unit compartment, when

looking at the appliance from the rear.

In "V160" freestanding counters the plate giving the appliance

PNC code and serial number is located below the logo.

In "V170" undercounters the plate giving the appliance PNC

code and serial number is located above the thermostat inside,

whereas the plate giving the appliance technical data is located

on the right side of the unit compartment.

A.1 GENERAL INFORMATION

GB

A.2 TECHNICAL DATA

Page 2

20

- Solid door models - exterior covering in steel

Shelf dimensions:

- shelf fixed to bottom - refrigerated counter mm 475x175 (1)

- adjustable shelves - refrigerated counter mm 527x410 (2)

- Solid door models - exterior covering prepainted white

- Glass door models - exterior covering prepainted white

Shelf dimensions:

- shelf fixed to bottom - refrigerated counter mm 496x162 (1)

- adjustable shelves - refrigerated counter mm 528x335 (2)

Solid door models - exterior covering in steel

Temp. range in compartment °C 0/+10

Max. ambient temp. °C +38

Consumption kwh/24h 1.73

Power supply voltage V/ph/Hz 230/1/50

Peak current A 0.7

Total power W 107

Refrigerant qty (R134a) g 55

Solid door models - exterior covering prepainted white

Temp. range in compartment °C 0/+10

Max. ambient temp. °C +38

Consumption kwh/24h 1.73

Power supply voltage V/ph/Hz 230/1/50

Peak current A 0.7

Total power W 107

Refrigerant qty (R134a) g 55

Glass door models - exterior covering prepainted white

Temp. range in compartment °C 0/+10

Max. ambient temp. °C +32

Consumption kwh/24h 2.249

Power supply voltage V/ph/Hz 230/1/50

Peak current A 0.7

Total power W 107

Refrigerant qty (R134a) g 55

A.2.3 MECHANICAL SAFETY CHARACTERISTICS, HAZARDS

The appliance has no sharp or protruding parts.

The guards for moving or live parts are screwed to the cabinet to

prevent accidental.

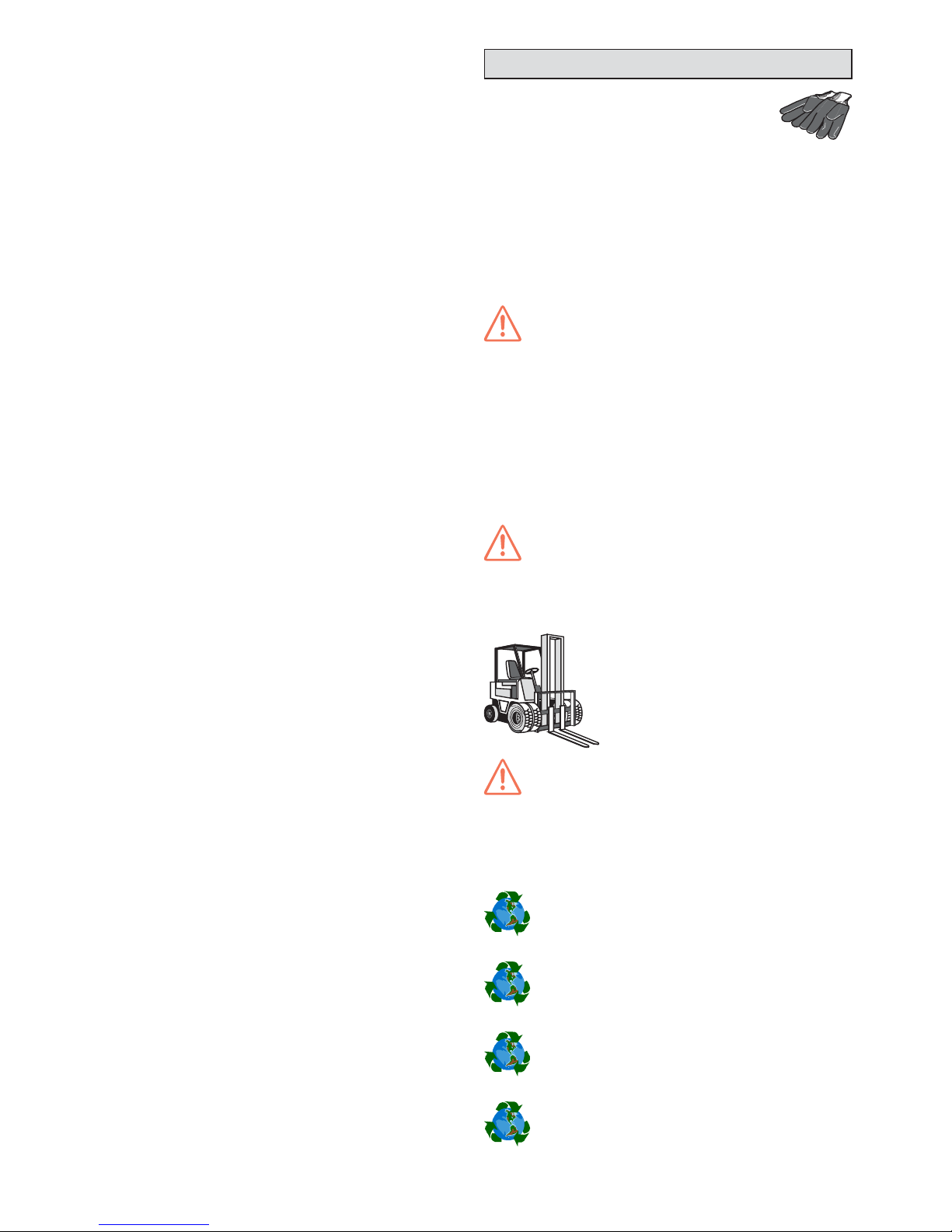

ATTENTION: BEFORE STARTING INSTALLATION OPERATIONS, WEAR SUITABLE PROTECTION EQUIPMENT (PROTECTIVE GLOVES).

To ensure correct operation of the appliance and for maintaining

safe conditions during use, carefully follow the instructions given

below in this section.

B.1.1CHECKS ON RECEIVING THE APPLIANCE

The equipment is delivered in protective packing; check the state

of the packing and any protection materials before unpacking.

Any damage must be promptly reported to the carrier. Under no

circumstances should a damaged appliance be returned to the

manufacturer without prior notice and written permission.

CAUTION:

the operations described below must be carried out in compliance with current safety regulations, regarding the equipment used and the operating procedures.

IMPORTANT: before moving the appliance, make sure that

the load-bearing capacity of the lifting equipment to be used

is suitable for its weight .

B.1.2 UNPACKING

B.1.2.1 Unpacking and handling

Wear protective gloves before carrying out unpacking operations.

CAUTION:

the packaging materials may constitute a hazard due to risk

of suffocation. They should therefore be kept out of the reach

of children!

Remove the protective film, taking care not to scratch the surface

if scissors or blades are used. Then remove

the polystyrene padding.

On the stainless steel parts, peel off the

protective film very slowly, without tearing it,

to avoid leaving glue stuck to the surface.

Lift the appliance with a fork-lift truck inserting the forks under the pallet, and carry it to

the place of installation, making sure the

load is balanced.

CAUTION:

Do not push or pull the appliance to move it, as it may tip over.

B.1.2.2 Packing disposal

Packing materials must be disposed of in compliance with current

laws in the country where the appliance is used.

Recyclable plastic parts are marked as follows:

polyethylene: outer wrapping, instruction booklet bag

PE

polypropylene: straps

PP

polystyrene foam: corner protectors

PS

pressboard: corner protectors

B.1 INSTALLATION

Page 3

21

The symbol L shown on the product means that it must not be

considered as domestic refuse, but rather must be disposed of

properly, in order to prevent any negative consequence for

individuals or the environment.

For further information concerning the recycling of this product,

contact the product’s local retailer agent, after sales technical

service or the local authority for waste disposal.

B.1.3 POSITIONING

B.1.3.1 General instructions

Install the equipment, taking all the safety precautions required for this type of operation, also respecting the relative

fire-prevention instructions.

Place the appliance in a well-ventilated place, away from heat

sources such as radiators or air-conditioning systems, in order to

allow correct cooling of the refrigerating unit components. Insufficient ventilation will in fact damage the appliance and prevent it

from working properly. Also, if the temperature is very high, the

compressor will activate more frequently and for longer periods

of time, resulting in higher consumption of electrical energy.

Keep the ventilation openings free of any sort of obstruction.

Never cover the condenser, even temporarily, as this may compromise its proper operation and therefore that of the appliance.

If the appliance is installed in rooms where there are corrosive

substances (chlorine, etc.), it is advisable to go over all the

stainless steel surfaces with a cloth soaked in paraffin oil to create

a protective film.

The equipment’s performance is guaranteed at an ambient

temperature of +38°C. In any case, the max. ambient temperature at which the equipment can operate is +38°C.

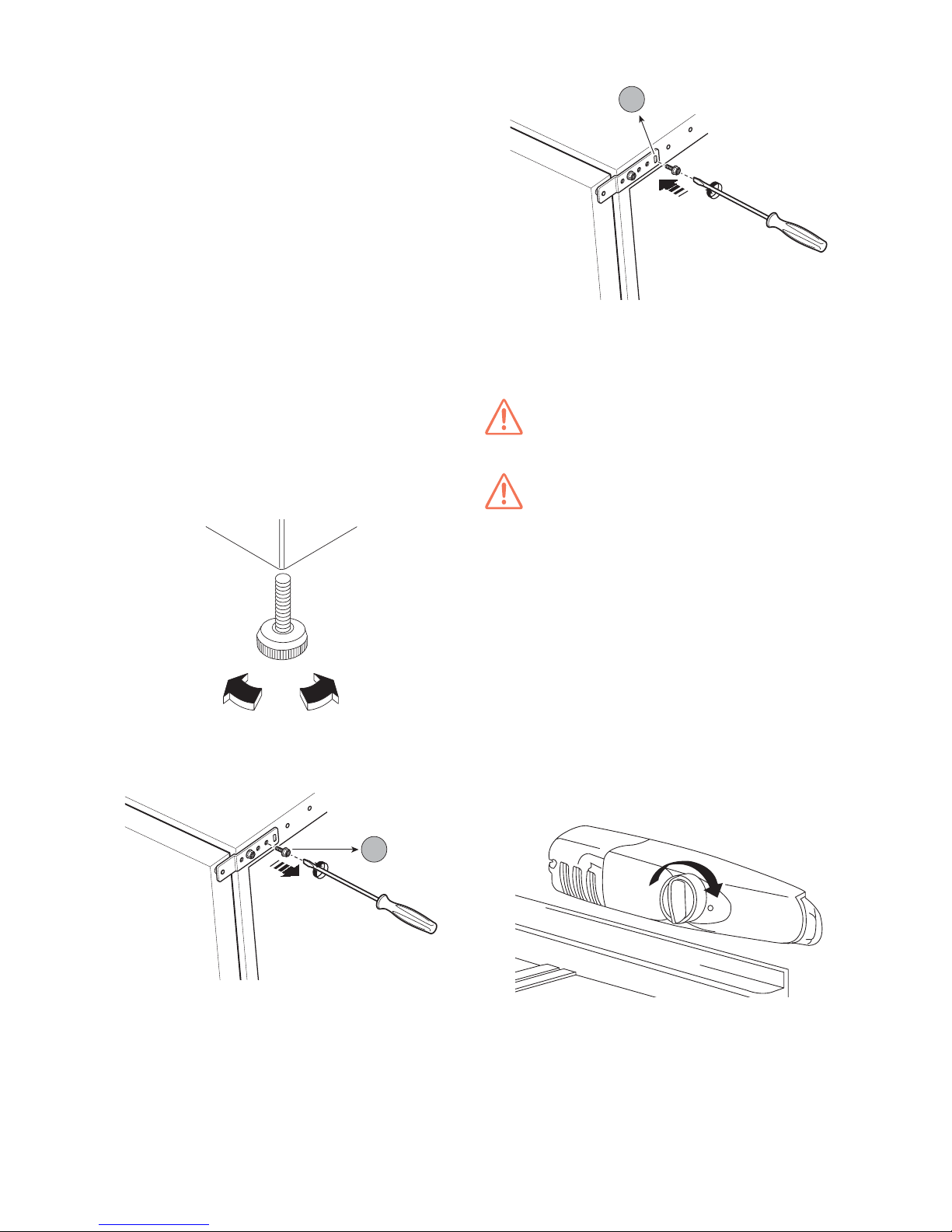

Adjust height and levelling by means of the levelling feet,

while at the same time checking the doors for proper closure.

Align the door with the side, adjusting the hinge on the bottom of

the appliance: remove screw "a" from its seat

b

a

and screw it in slot "b" provided on the edge as shown in the figure

b

b

Now, with the hinge loosened, the door can be aligned.

After completing the operation, tighten the screw.

Make sure the floor on which the appliance stands is perfectly

level, in order to ensure its optimal operation.

CAUTION:

the appliance must be level, otherwise its operation could be

compromised.

CAUTION:

wait at least 2 hours before starting the appliance to allow the oil

to flow back into the compressor.

B.1.3.2 Instructions for "V170" undercounters

For positioning "V170" undercounters under a worktop, proceed

as follows:

• undo the screws fixing the top to the appliance, located at the

back;

• slide the top outwards a little to release it from the stops and

remove it from its seat;

• undo the screws fixing the rear feet to the appliance;

• remove the 3 mm spacer from the feet and reposition them in

their seats;

• lastly, fit the front feet and adjust them until the appliance is at

the required height.

- ADJUSTMENT OF TEMPERATURE IN REFRIGERATED

APPLIANCES:

Turn the knob of the thermostat to “6”, “1” or any position in

between.

0

6

The thermostat knob is located at the upper right and is used to

set the temperature at which you wish the appliance to work. The

most suitable operating temperature needs to be selected in light

of the following factors:

• the ambient temperature in which the appliance operates;

• how often the door is opened;

• the amount of food stored;

• the position of the appliance with respect to the setting where

it is installed.

Page 4

22

"V160" freestanding counters and "V170" undercounters are

normally provided with the door hinges on the right-hand side. To

change to hinges on the left-hand side, proceed as follows:

• disassemble the lower hinge;

• disassemble the door;

• remove the door;

• unscrew the pin of the upper hinge and re-install it on the

opposite side of the cabinet;

• unscrew the foot and re-install it on the other side of the cabinet;

• re-install the door and the hinge on the opposite side of the

cabinet;

• unscrew the handle and re-install it on the opposite side after

having perforate the plugs with an auger.

NOTE:

when the door has been reversed, make sure that the magnetic seal adheres perfectly to the appliance. If the ambient

temperature is low, the seal may not adhere perfectly to the

cabinet. If this happens, wait for the seal to return to normal

on its own, or you can speed up this process by heating the

involved part with a hair dryer.

D.1.1INSTRUMENT (refer to figure 2)

A - Digital thermostat display

D.1.2 DIGITAL THERMOSTAT DISPLAY

The digital thermostat has a 3-digit electronic display for showing

the temperature measured by the sensor, and three LEDs (refer

to paragraph D.1.5).

D.1.3 KEYS

The digital thermostat comprises 4 keys for control and programming the instrument.

- Multifunction “UP” key

for increasing the values and

activating manual defrost.

- "DOWN" key for decreasing the values.

- “fnc” key

fnc

with ESC (quit) function.

- “SET” key

set

for accessing the Set point.

When switched on, the instrument carries out a Lamp Test, i.e. for

a few seconds the display and LEDs flash, verifying that it is

working properly.

D.1.4SWITCHING ON AND TEMPERATURE ADJUSTMENT

To start the appliance, you need only to plug it in.

To SET the compartment temperature, follow these steps:

- Press and release key

set

the message “SEt” appears.

- Press the key

set

again and the SET POINT value appears

on the display.

- Change the SET value by pressing the increase value "UP" key

or the decrease value “DOWN” key .

If no button is pressed for 15 seconds (“TIME OUT”) or by

pressing the “fnc” key once, the digital thermostat memorizes the

last set value and the normal display is restored.

The temperature is automatically controlled, but it can be increased or decreased as follows:

• Position “1” = internal temperature warmer

• Position “6” = internal temperature colder

• Position “0” = cooling deactivated / OFF

For especially harsh operating environments, with ambient tem-

peratures higher than 32°C and high humidity, it is advisable to

set the thermostat between 1 and 4.

In general, it is advisable to set the knob to the intermediate

position.

- ADJUSTMENT OF TEMPERATURE IN FREEZERS:

Refer to paragraph D.1.

B.1.5 ELECTRICAL CONNECTION

Before undertaking any procedure involving electrical connec-

tion, we recommend cleaning the cell with lukewarm water and

neutral soap, or with products that are 90% bio-degradable (to

reduce the emission of pollutants into the environment ), then

rinse and dry carefully.

Plug in the appliance.

N.B.: The plug must be accessible even after positioning the

appliance in the place of installation. Also make sure the plug

is not crushed by the appliance. If the power cord is damaged it may overheat and catch fire or cause a short circuit.

When making the electrical connection, make sure to respect that

given on the data plate.

The appliance works on a single-phase 230V 50Hz power supply

Connection to the electrical power supply must be done in

accordance with current regulations.

To connect to the power supply, insert the power plug in the

corresponding power socket, firstly making sure that:

- The plug has an efficient earth connection and the mains

voltage and frequency correspond to that given on the data

plate. In case of any doubts regarding the efficiency of the earth

connection have the circuit checked by a qualified technician.

- In order to protect the appliance from possible dispersion,

overloads or short-circuits, a suitable differential thermal

magnetic circuit-breaker realized in compliance with current

standards. For proper sizing of the switch, refer to the absorbed

power as indicted on the technical data plate of the appliance.

- After making the connection, with the appliance operating

check that the rated voltage level does not fluctuate by ± 10%.

Note: If the power cable is damaged it must be replaced by

the technical assistance service or in any case by qualified

personnel, in order prevent any risk.

The connection must be made with cable of suitable section.

Insert and secure the cables with the special cable clamp.

Correctly connect each wire to the corresponding terminal.

The manufacturer declines any liability for damage or injury

resulting from breach of the above rules or the current

electrical safety standards in the country where the appliance is used.

C.1 DOOR REVERSIBILITY

D.1 USE OF DIGITAL THERMOSTAT ON

"V160" FREESTANDING FREEZER

COUNTERS

Page 5

23

The temperature range is set from a minimum to a maximum,

according to the following values:

Position Minimum = -15°C

Position Maximum = -22°C

D.1.5 DIGITAL THERMOSTAT INDICATOR LED

The digital thermostat has 3 LEDs indicating:

- LED

on indicates activation of the compressor, LED

flashing indicates compressor delay.

- LED

on indicates manual defrost in progress; when

flashing it indicates manual activation.

- LED

on indicates an alarm has triggered during

appliance operation.

D.1.6 ALARMS AND SIGNALLING

D.1.6.1 Alarms and signalling

The alarm is signalled by an LED

coming on at the alarm

icon.

The alarm signal due to a faulty cell sensor (referred to sensor 1)

appears directly on the instrument’s display with the indication

“E1”.

The alarm signal due to a faulty evaporator sensor (sensor 2)

appears directly on the instrument’s display with the indication

“E2”.

The maximum and minimum temperature alarms, referred to the

thermostat sensor, are defined by the parameters “HAL” (maximum temperature alarm) and “LAL” (minimum temperature alarm).

The latter are not shown on the display, but they can be viewed

by entering the folder “AL”.

Faulty cell sensor alarm

DISPLAY ALARM

High cell temperature sensor alarm

E1

Low cell temperature sensor alarm

AH1

AL1

E2 Faulty evaporator sensor alarm

D.1.7 DEFROSTING

- Automatic defrost

The appliance is equipped with an automatic defrost function.

This function is signalled by lighting up of the DEFROST LED

.

The defrost water is run into a bowl and automatically evaporated.

- Manual activation of defrost

Keep the “UP” button pressed for at least 5 seconds to

start a manual defrost cycle. This function is signalled by lighting

up of the DEFROST LED .

If defrost conditions do not exist, the display flashes three times

to signal that the operation will not be carried out.

Defrosting cannot be started during the programming phase.

CAUTION:

Do not use spray defrost products on the freezers. They can be

harmful to the health and/or they may damage the materials of

which the appliance is made.

Note: defrosting takes place automatically also in refrigerated appliances. Defrost water is collected in a container in

the rear section, and from there it evaporates. Clean the drain

hole with the pipe-cleaner provided for this purpose. This

pipe-cleaner must be removed if the cavity is clogged (see

following figure).

D.1.8 PRODUCT LOADING (for all models)

Distribute the product evenly inside the compartment (away from

the door and back) in order to ensure good air circulation. The

racks can be placed in various positions thanks to the guides on

the walls of the cell.

Cover or wrap food before placing it in the refrigerator and avoid

putting very hot foods or steaming liquids inside. Do not leave the

door open any longer than necessary when placing food in the

refrigerator.

We suggest keeping the keys in a place which is accessible only

by authorized personnel. To prevent use of the appliance by

unauthorized personnel, it is advisable to lock it at all times.

For the maximum loads for each shelf, adhere to the following

table:

SHELF MAX. LOAD

"V 160“ FREESTANDING

COUNTER

"V170“ UNDERCOUNTER

10 kg

10 kg

SUGGESTIONS FOR REFRIGERATED MODELS:

• Meat (all types): should be placed in plastic bags and

preferably set on the lowest shelf. In this position it can be

conserved for a maximum of one or two days.

Page 6

24

• Cooked foods, cold plates, etc.: these must be well-covered

and can be set on any shelf.

• Butter and cheese: these should be wrapped in plastic

wrapper or aluminium to prevent contact with the air and they

can be set on any shelf.

• Bananas, potatoes, onions and garlic, if not packaged,

should not be stored in the refrigerator.

NOTES FOR FREEZER MODELS:

never insert carbonated beverages as they may explode.

Frozen products placed on top of the unit may cause con-

densation to form due to the cold. This compartment contains the electronic components. Should water reach these

components, the appliance may be damaged by a short

circuit. Therefore, do not place frozen foods on top of the

appliance.

To defrost frozen foods, place them in the refrigerator, so

that the cold from the frozen foods is used to cool the

refrigerator itself.

D.2.1 PRECAUTIONS FOR MAINTENANCE

Routine maintenance tasks can be performed by non-specialized

personnel provided the instructions given below are carefully

followed. The manufacturer shall not be held responsible for

any operations carried out on the machine if these instructions are not complied with.

ATTENTION:

Do not touch the equipment with wet hands or feet or when

barefoot. Before carrying out any cleaning or maintenance,

disconnect the appliance from the electrical mains and

carefully pull the plug to disconnect the machine. Do not

remove the safety devices for carrying out routine maintenance. Use suitable protection equipment (protective gloves).

D.2.2 CLEANING THE CABINET AND ACCESSORIES

Clean stainless steel parts every day using lukewarm water and neutral soap or products that are

over 90% biodegradable (in order to reduce the

emission of pollutants into the environment), then

rinse and dry thoroughly. Do not use

solvent-based detergents (e.g. trichloro-ethylene) or abrasive powders for cleaning. Do

not use spray defrost products on the freezers.

They can be harmful to the health and/or they may

damage the materials of which the appliance is

made. It is advisable to go over the stainless steel

surfaces with a cloth moistened with paraffin oil in

order to create a protective film.

Frequently check the power cable and replace it if

it shows signs of wear.

Have the equipment periodically checked (at least once a year).

D.2.3 CELL CLEANING

To clean the cell properly, all of the racks must be removed. They

must therefore be removed from the cell before you start cleaning. To extract them, just pull them towards you (you can put them

back in afterwards by proceeding in the reverse manner). Clean

the cells with products that are more than 90% bio-degradable,

then rinse and dry thoroughly.

D.2.4 PERIODICAL CLEANING OF THE CONDENSER

WATCH OUT FOR THE ELECTRICAL CABLES!

The condenser can be cleaned with a brush, provided the bristles

are not in steel or a material that can compromise good operation,

or with a simple paintbrush to get rid of dust.

D.2 ORDINARY MAINTENANCE

Special maintenance must be carried out by specialized

personnel, who may request the service manual from the

manufacturer.

BEFORE CARRYING OUT ANY SPECIAL MAINTENANCE, MAKE SURE YOU ARE WEARING

PROTECTIVE GLOVES AND A MASK.

ATTENTION:

Do not touch the equipment with wet hands or feet or when

barefoot. Unplug the appliance before carrying out any

cleaning or maintenance. Pull the plug out carefully to disconnect the machine. Do not remove the safety guards. Use

suitable protection equipment (protective gloves).

D.3.1 REPLACING THE POWER CABLE

To replace the power cable, proceed as follows:

• disconnect the power supply;

• open the compressor box on the back of the appliance;

• replace the power cable;

• close the compressor box again;

• switch the power on.

CAUTION:

Do not clean the appliance with jets of water.

D.3.2 PRECAUTIONS IN CASE OF PROLONGED DISUSE

If the appliance is not going to be used for a long period, take the

following precautions:

• disconnect the plug from the power socket;

• remove all food from the compartment and clean the inside and

the accessories;

• leave the door ajar so that air can circulate inside, preventing

the formation of unpleasant odours.

• Air the room regularly.

D.3.3 LAMP REPLACEMENT (only for "V160" freestanding

refrigerated counters and "V170" undercounters)

To replace the internal lamp, proceed as follows:

• disconnect the power supply;

• unscrew the fastening screw from the light fixture;

• disconnect the removable part by pressing on it as shown in

the figure

• replace the lamp with one of the same power;

• put the removable part back in place;

• screw the fastening screw of the light fixture back in;

• switch the power on.

D.3 SPECIAL MAINTENANCE

Page 7

25

D.3.4 REPLACING COMPRESSOR COMPONENTS

Whenever any of the compressor components has to be replaced, the electrical box protection must be removed as follows:

b

1

b

3

b

2

Using a flat blade screwdriver, press on the plastic retainer inside

the box (phases 1 and 2). Now the box is released and can be

removed from its seat (phase 3).

D.4.1 WASTE STORAGE

At the end of the product’s life-cycle, make sure it is not dispersed

in the environment. The door must be disposed of before disposing of the rest of the appliance.

Special waste materials can be stored temporarily awaiting

disposal by means of treatment and/or permanent storage. The

current environmental protection laws in the user’s country must

be observed.

D.4.2 PROCEDURE FOR PRELIMINARY DISMANTLING OF

THE APPLIANCE

Different regulations are in force in the various countries, therefore the provisions laid down by the laws and the competent

authorities in the countries where disposal takes place must be

observed.

In general terms, the refrigerator must be taken to a specialized

collection/demolition centre. Dismantle the components and group

them together according to their chemical characteristics, remembering that the compressor contains lubricant oil and coolant,

which can be recycled, and that the refrigerator components are

classed as special waste which can be disposed of with urban

waste.

Make the appliance unusable by removing the power cable and

any compartment locking mechanisms, in order to avoid the risk

of someone becoming closed inside.

DISMANTLING OPERATIONS MUST BE CARRIED OUT BY

QUALIFIED PERSONNEL.

• Quality control testing receipt

• Wiring diagram

• Installation diagram

D.5 ENCLOSED DOCUMENTATION

D.4 WASTE DISPOSAL AND

DE-COMMISSIONING

Page 8

26

D.6.1 QUICK TROUBLESHOOTING GUIDE

In some cases, faults can be remedied easily and quickly; the following is a list of some faults and relative remedies:

THE INSIDE TEMPERATURE IS

TOO HIGH:

THE APPLIANCE IS

EXCESSIVELY NOISY

1. Make sure the applianc e is level. Of f balance positioning

may c ause v ibr ation.

or part s which may star t r esonat ing.

2. Make sure the applianc e is not t ouc hing other appliances

2. Make sure there is no heat source near t he applia nce.

3. Make sure the door c loses properly.

1. Make sure the plug is properly inserted in t he power socket .

2. Chec k t hat the socket is powered.

1. Chec k t he thermostat setting;

THE APPLIANCE DOES NOT

SWITCH ON:

If the fault persists after having carried out the above checks, contact Technical Assistance, remembering to give the following details:

• the nature of the fault;

• the appliance PNC (production code);

• the Ser. No. (appliance serial number).

N.B.: the code and serial number are essential for identifying the type of appliance and date of manufacture.

E.g: PNC 726479 00 - Ser.No. 54000010

726479:refrigerated table

54000010: manufactured in 2005, week 40, 10th piece.

D.6 TROUBLESHOOTING

PNC 726479

Ser.No. 54000010

Loading...

Loading...