Electrolux Thermetic Operation Manual

Thermetic

TILTING PRESSURE BRAISING PANS, ELECTRIC

(GX........)

US OPERATING AND SAFETY INSTRUCTIONS

Doc. 62.9696.01

Edition 1

03.2005

CONTENTS

I GENERAL INFORMATION .........................................................................3

1. INSTRUCTIONS FOR SAFETY AND USE ......................................................................... 3

2. TECHNICAL DATA ............................................................................................................. 4

3. PACKAGING ....................................................................................................................... 4

4. TESTS / CERTIFICATES .................................................................................................... 4

5. SPECIFICATION PLATE .................................................................................................... 4

6. SERIAL NUMBER YWWXXXXX ......................................................................................... 4

7. FURTHER DOCUMENTS ................................................................................................... 4

II OPERATING INSTRUCTIONS ....................................................................5

1. DESCRIPTION/ CONSTRUCTION ..................................................................................... 5

2. INITIAL OPERATION .......................................................................................................... 5

3. STANDBY ........................................................................................................................... 5

4. AUTOMATIC CONTROL .................................................................................................... 6

5. LID LOCK ............................................................................................................................ 8

6. ADDITIONAL EQUIPMENT .............................................................................................. 10

7. WORKING RULES ............................................................................................................ 10

8. CLEANING ........................................................................................................................ 13

9. TROUBLESHOOTING ...................................................................................................... 13

10. TREATMENT OF COMMERCIAL KITCHEN APPLIANCES ............................................ 13

GENERAL INFORMATION

I . GENERAL INFORMATION

1. INSTRUCTIONS FOR SAFETY AND USE

1.1 INSTALLATION AND INITIAL OPERATION

S The installation, adjustment and initial opera-

tion of the appliance must be carried out

according to the manufacturer's instructions

and only by an authorised specialist.

S Installations for the supply of electricity and

gas must be carried out by approved specialists in compliance with specific national and

local regulations. They bear the responsibility.

S The appliance must not be placed in opera-

tion until the user has become familiar with its

operation. The operating instructions and the

related safety precautions must be followed

precisely. Follow strictly the attention and

warning label indications on the appliances.

1.2 OWNER'S OBLIGATIONS

S The manager is responsible for ensuring that

all components relevant for safety are in perfect working order at all times. The operating

condition of these components must be examined by an authorized technician at least once

a year and any defects remedied if required.

1.3 USE AS PRESCRIBED

S The appliance must only be used for cooking

food in commercial kitchens. The appliance

has only been approved for supervised operation by trained persons.

S Closed containers (jars, cans, bottles, tubes,

etc.) must not be heated owing to the danger

of bursting and injuries.

S During pressureless cooking the filling of the

appliance must never rise above 1.6“ (4 cm)

below the boiler rim. Depending on the type

of food to be cooked, filling must be less so

as to prevent bubbling over.

S During pressure cooking the pan must be

only half or less filled.

S This appliance must not be used for deep fat

frying purposes. Do not use large cuantities

of oil. The appliance must not be operated

close to materials and vapours which constitute a fire hazard.

S During operation, no objects are to be placed

on the lid

1.4 SAFETY-CONSCIOUS WORKING

S Overheated oil can self-ignite. Never leave

braising oil unattended.

S Never quench burning oil with water, but

smother the flames with the cover or a wet

cloth.

S Devices on wheels set up in block configura-

tion must be checked before each start-up

whether the potential equalization is connected with the neighbour equipment. The

connection may be done only by authorized

technical personnel.

S Spraying the appliance or parts of it with a

high-pressure cleaning device may cause

malfunctions and is not to be done.

S To avoid damage to the appliance, do not let

water flow from the mixer tap onto the cooking plates.

S When putting oil, fat, water or ingredients in

the preheated hot boiler, they may splash danger of burning!

S Always use the handle to open the cover.

Note that while doing so, hot air or steam

may flow out or hot fat may spit out - danger

of burning!

S Keep your distance from the lid closing area

when closing the lid - danger of injury!

S To avoid damage to the appliance the mixer

tap outlet must be to the front before the lid is

opened or closed.

S Tilting is only to be carried out slowly to avoid

the contents spilling over the rim.

S Hot steam can be expelled on opening the

lid. Staff must take appropriate measures

(stand well back) to avoid injuries.

S The area around the tilting boiling pan must

be kept free. Tilting is only to take place with

the lid fully open - danger of burning!

S If the operator observes the change in the

lock, the lid must not be closed and the appliance must not be used for pressure cooking.

The Customer Service must be contacted

immediately.

S Devices on wheels set up in block configura-

tion must be checked before each start-up

whether the potential equalization is connected with the neighbour equipment. The

connection may be done only by authorized

technical personnel.

S Appliances on wheels must be fastened with

the wall.

1.5 AFTER-SALES SERVICE AND REPAIR

S In the event of a permanent fault which inter-

feres with operation, the appliance must be

switched off and disconnected from the

power supply.

S Repair, maintenance work and other adjust-

ments are only to be carried out by an authorized specialist. The valid local and national

regulations must be observed. This applies

especially to burners, ignition, safety and control elements. Parts requiring replacement are

only to be replaced by original spare parts.

Periodic tests for gas leaks must be carried

out. A service contract is recommended.

S Cleaning and maintenance must be done only

when the heating surfaces are cold. Do not

use inflammable liquids to clean the appliance.

S An obligatory service check is required

annually.

62.9696.01 Page 3

GENERAL INFORMATION

2. TECHNICAL DATA

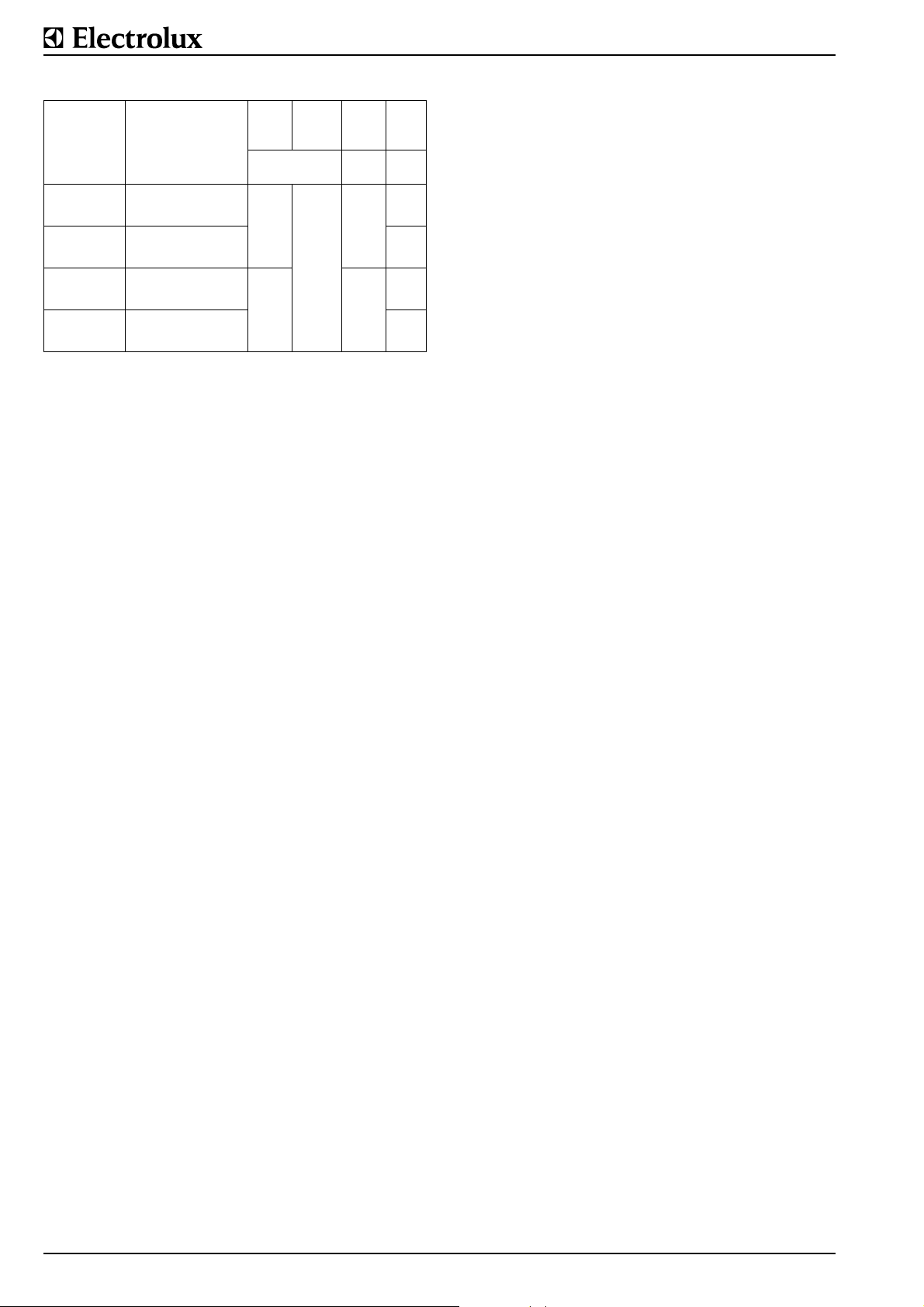

Electr.

PNC

Appliances

9CHG583299

9CHG583300

9CHG583301

9CHG583302

9CHG583303

9CHG583304

9CHG583305

9CHG583306

9CHG583307

9CHG583308

9CHG583309

9CHG583310

Appliance type Width

Depth

Height

GXWBOEOOOO

GXXBOEOOOO

GXYBOEOOOO

GXWDOEOOOO

GXXDOEOOOO

GXYDOEOOOO

GXWEOEOOOO

GXXEOEOOOO

GXYEOEOOOO

GXWHOEOOOO

GXXHOEOOOO

GXYHOEOOOO

47.2

35.4

27.6

(1200

900

700)

63

35.4

27.6

(1600

900

700)

inch

(mm)

Feet,

Wheel

Height

7.9

(200)

Power

kW lt

12.2

18.2

Boiler

size

(gal)

60

(15.9)

90

(23.8)

100

(26.4)

150

(39.6)

3. PACKAGING

All the packaging materials used are environmentally friendly.

They may burnt at an incineration plant or sent for recycling.

4. TESTS / CERTIFICATES

All electrical appliances are UL 197 and NSF/ANSI 4-2002 and

NSF/ANSI 8-2002 tested.

The appliance noise level is negligible. The statutory guidelines

are fulfilled; the sound pressure level is less than 70 dB (A).

5. SPECIFICATION PLATE

The specification plate (E) is located in each case inside and

outside on the right of the control panel (C).

6. SERIAL NUMBER YWWXXXXX

The serial number of the appliance is marked on the type

plate. The 8 digits give following information:

Y last digit of the year of production

WW week of production

XXXXX running number

7. FURTHER DOCUMENTS

• Installation instruction

• Service manual

• Wiring diagram

• Spare parts list

Page 4 62.9696.01

II . OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

1. DESCRIPTION/ CONSTRUCTION

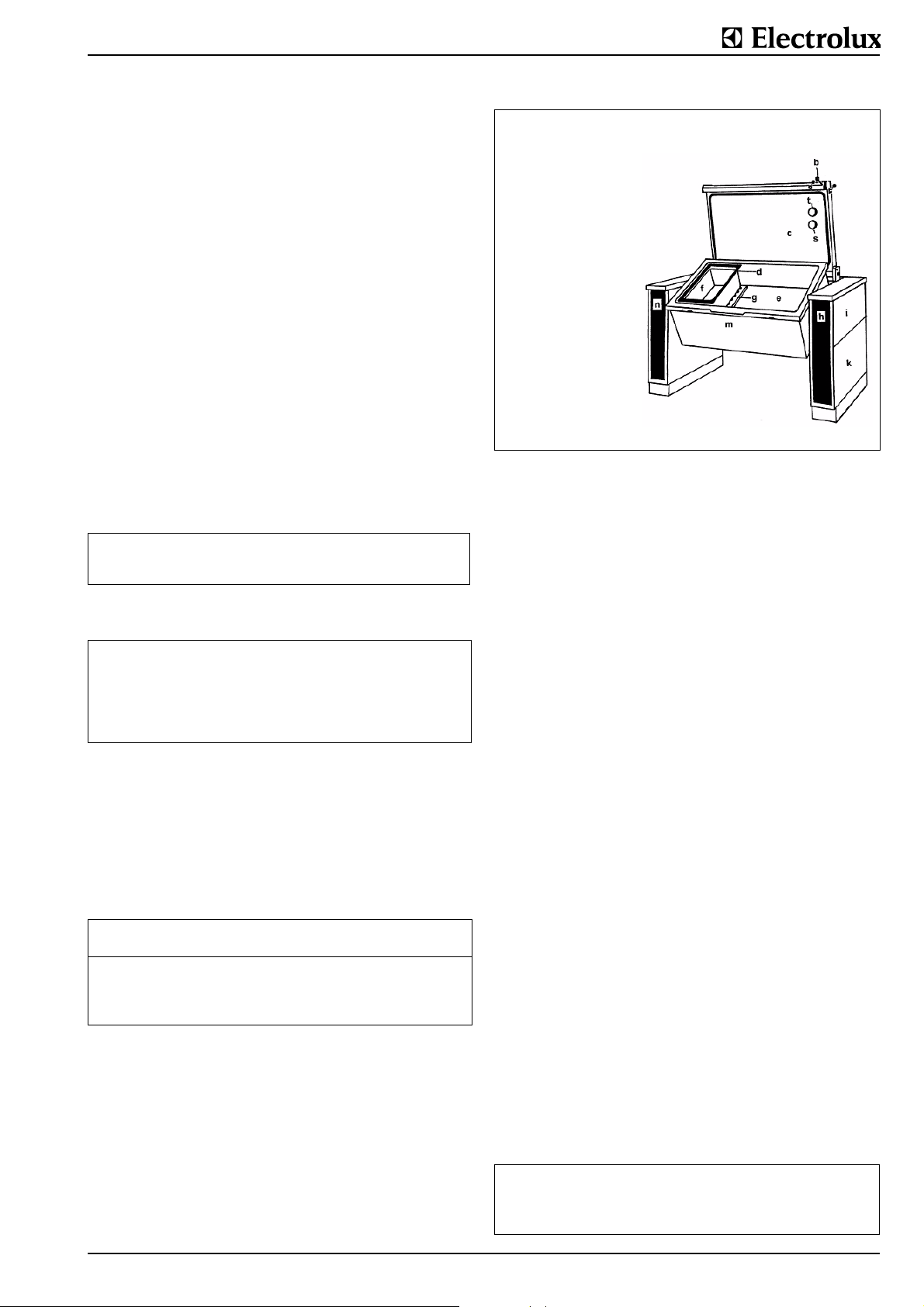

The tilting pressure braising pan with polished chromium nickel

steel plated bottom essentially serves three purposes, which

can also be combined with one another:

• Roasting, Browning, Stewing, Preparation of sauces

• Cooking, Pressure cooking, Sauteing, Steaming, Boiling

• Pressureless steaming, Pressure steaming, Braising

TILTING PRESSURE BRAISING PAN

The appliance is totally constructed externally and internally of

corrosion-resistant chrome nickel steel. The appliance is floor

mounted on the two consoles. The pan is supported on bearings which allow it to tilt. Precise amounts of food can be

poured out of the pan by turning the knob of the appliance

which features motorized tilting. A precise, state-of-the-art

electronic microprocessor control system with digital preselection of temperature, cooking time, starting time and steam condensation ensures perfect adherence to the pre-programmed

cooking functions. The methods used for roasting and cooking

are the same as those in normal roasting pans or cooking

appliances. The steaming procedure refers to gentle, rapid

and uniform cooking alternatively without pressure in the temperature range up to 212°F (100°C) or under saturated steam

pressure of 0,4 bar (228°F, 109°C) positive pressure. The

cooking time decrease sharply with increasing cooking temperature:

Temperature 212°F (100°C) 228°F(109°C)

Pressure 0 5.8 psi (0,4 bar)

Cooking time % 100 54

The pan can be loaded with the following Gastro-Norm containers of size GN1/1:

Type Number GN 1/1 max.depht of the

containers mm

60 LT 2 150

90 LT 2 250

100 LT 3 150

150 LT 3 250

Depending on the type of food, perforate or imperforate containers are used. The former are most frequently used for

steaming. Perforated containers are used for food from which

the water is to be removed (e.g. vegetables). Imperforate containers are for food which is to remain moist in the water. The

containers are either placed directly on the inserted perforated

base or are hung in the frames provided. The appliance must

not be used for deep fat frying.

Technical data:

Type El. power rating Cooking area Capacity

kW mm lt gal

60 LT 12,2 620 x 490 x 220 67 17.7

90 LT 12,2 620 x 490 x 290 94 24.8

100 LT 18,2 990 x 490 x 220 104 27.5

150 LT 18,2 990 x 490 x 290 145 38.3

bLid knob

c Pressure lid

d Suspension

frame

ePan

f GN 1/1 con-

tainer

g Bottom grid

h Control ele-

ments

iConsole

k Support

m Spout

n Tilting devices

s Steam baffle of

lid regulation

and safety valve

t Steam baffle of

steam release

valve

Fig. 1 Construction

2. INITIAL OPERATION

Thoroughly wash the entire pan with hot soapy water, rinse it

with clean water and allow it to dry. The new pan should then

be heated up at a temperature of 320°F (160°C) for about 30

minutes.

Tilting pans with polished steel bottoms should additionally be

treated as follows: load the cold pan with good quality roasting

fat (lard, butter) and about 2“ thick raw potato slices. Then

lightly roast the potato slices for about 60 minutes, turning

them several times. As a result of this treatment, the bottom

loses its metallic flavour. Empty the pan and rub it thoroughly

with a dry cloth or absorptive paper.

Do not use oil or vegetable fat for the above procedure.

3. STANDBY

Check each time before use:

D The lid regulation and safety valve must be built in cor-

rectly.

D Operating elements must not be damaged.

D The correct function of the lid lock elements must be

checked.

Filling

Fill with water via mixer unit or hose. Maximum fillings see

chapter „Filling“. Salt is only to be added in dissolved form. It

must not be added to an empty pan. Use only a wood or plastic

spatula for stirring.

Heating up time

After filling with liquid produce, the appliance can be switched

on. The lid should be kept closed during heating to reduce

energy losses and heating time. At full power, the maximum

heating-up times from 68°F (20°) to 194°F (90°C) for pans full

of water correspond to the values listed below. Heating-up

times are reduced when pans are only partially filled. Whilst full

power is required for initial heating, this is not the case for further cooking. The power requirements for cooking with lid open

is many times that with the lid closed. The lid should therefore

always remain closed during cooking.

The heating-up time in (minutes) for an empty pan from 68°F

(20°) to 446°F (230°C) is approx.:

Type Pan empty Water 100% Water 50%

60 LT 14 30 17

90 LT 14 45 24

100 LT 15 34 20

62.9696.01 Page 5