Page 1

Identification:

Technical

Bulletin no:

Date:

Issuer:

Factory:

Subject

Model

Problem

Reason

Action in

Factory

D01-D02-D03-D04-D05-D06

CGX2006-04 (page 1 of 2), 1st ed.

28 February 2006

R. Sartor (DWS Customer Support)

DW Vallenoncello - Italy

Water Analysis Kits

Whole Dishwashing range

Stainless steel gets rusty, higher energy consumption due to scale, poor

washing/rinsing performances, etc.

The quality of water is not suitable for DW machines, i.e. the quantity of

chlorides is high (more than 20 ppm) and/or the water is hard (more than 8°dH

/ 14°fH) and/or the electrical conductivity is high (more than 400 μS/cm) etc.

There are 3 kits available for water analysis as follow:

• CHLORIDE test kit 0S0585 (approx. 200 tests);

• HARDNESS test kit 0S0586

(approx. 300 tests);

• A handy suitcase 0S0483 containing 0S0585, 0S0586, a conductivity/pH

meter 0S0481

ELECTROLUX PROFESSIONAL SPA

MAILING ADDRESS TELEPHONE WEBSITE VAT NO.

VIA SEGALUZZA, 30

33170 PORDENONE - ITALY

OFFICE ADDRESS TELEFAX E-MAIL ADDRESS

VIA SEGALUZZA, 30

33170 PORDENONE - ITALY

++39 0434 380650 www.electrolux.com 00072220932

++39 0434 380636

++39 0434 385646

riccardo.sartor@electrolux.it

Page 2

pply

Action in

Field

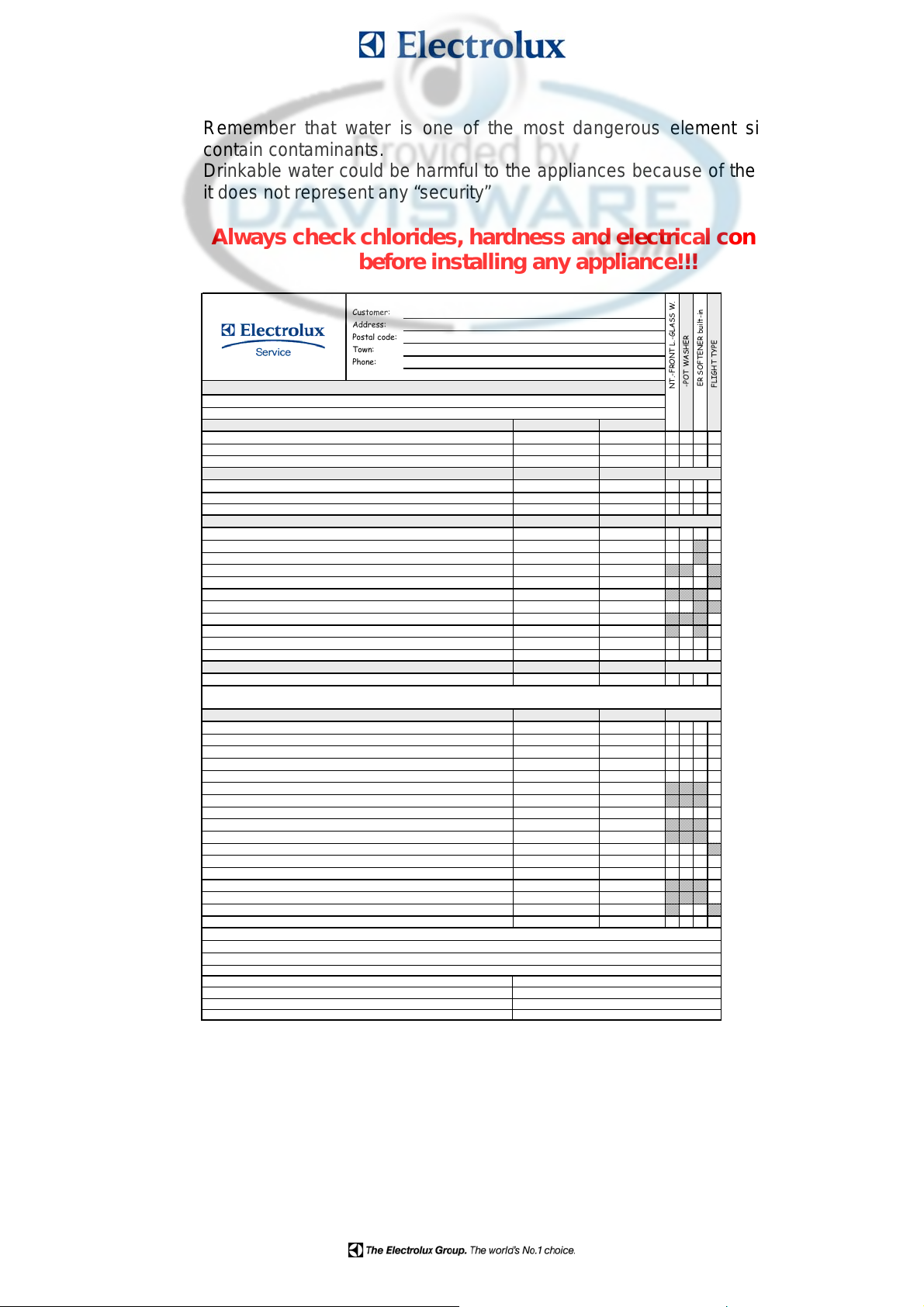

Remember that water is one of the most dangerous element since it may

contain contaminants.

Drinkable water could be harmful to the appliances because of the chloride so

it does not represent any “security”

Always check chlorides, hardness and electrical conductivity

before installing any appliance!!!

Customer:

Address:

Postal code:

Town:

Phone:

Job No: PNC: Model:

COMMISSIONING CHECK LIST:

Installation date: Serial No:

Residual current circuit breaker

Magnetic circuit breaker (automatic fuse)

Check of documentation avai lability (handbook...)

Earth continuity between main grounded terminal and panels (Ohmmeter)

voltage: □230-1N-50Hz; □400-3N-50Hz; □Other voltage _________

Su

Check equipotential bonding connection

Chlorides

Conductivity

Total hardness (for mach ines without water softener built-in)

Total hardness (for machines with water softener built-in)

Dynamic wate r pressure during filling (for a tmospheric boiler)

Dynamic water pressure during filling (for atmospheric boiler in Rack Type / Flight Type)

Dynamic water p ressure during filling (for pre ssurized boiler)

Dynamic wate r pressure during filling (for pressurized boile r in Rack Type / Flight Type)

Dynamic steam pressure during heating

Cold water temperature

Hot water temperature

□

Reversal osmosys; □Nanofilter; □Softener; □No treatment

Proceed with c ommissioning if installation is satisfactory. If no t, report the problem to servic e manager and inform customer. If in doubt, refer to manufacturer instructions. In

the event of unsafe appliance or at risk situation, stop the appliance and inform immediately your service manager and issue a warning note.

Appliance levelling

Smooth movement of doors/hood

Rinse aid/detergent adjustment and connections

Pumps/motors/fans rotation (see printed arrow sense)

Check working temperature range on boiler (see service or instruction manual if out of range)

Check working temperature range on prewash tank

Check working temperature range on prewash tank (compact & modular Rack Type only)

Check working temperature range on wash tank

Check working temperature range on pre-rinse tank

Check temperature range on hot air blower/drying tunnel

Check discharge height of drain hose from machine base (if drain pump fitted)

Start and check a complete wash program

Check water leakage

Check end limit switch on unloading table

Check emergency stop switch

Hood safety-microswitches work properly (automatic hood)

Training to end user

Comments (Non conformity/Suggestions):

PRELIMINARY CHECK LIST

CONNECTIONS

WATER CHECKING (from appliance inlet)

WATER TREATMENT INSTALLED

TESTING

DISHWASHING

RANGE/UNIT READING

max 400 μS/cm

max 14°fH / 8°dH / 10°cH

max 40°fH / 22°dH / 28° cH

See Tech. Bulletin PD15-00

30 mA

see handbook

<0,1 Ohm

max 20 ppm

0,8÷7 bar

1,5÷7 bar

2÷3 bar

3÷7 bar

0,5÷3 bar

10÷15°C

max 50°C

see handbook

83÷90°C

35÷50°C

10÷35°C

55÷65°C

65÷75°C

50÷80°C

700÷1000 mm

RACK TYPE-FLIGHT TYPE

UC-HT WATER SOFTENER built-in

UNDERCOUNT.-FRONT L. -GLASS W.

HOOD TYPE-POT WASHER

Service Partner: Customer print name:

Tech. print name: Tech.No: Customer signature:

Tech. signature: Position:

Travel time: Labour time: Date:

2

Loading...

Loading...