Electrolux Next Gen 30, 30” GAS FREESTANDING RANGES, 36” GAS FREESTANDING RANGES Service Manual

ELECTROLUX HOME PRODUCTS NORTH AMERICA

SERVICE MANUAL

NEXT GEN

30” & 36” GAS

FREESTANDING RANGES

5995361531

White-Westinghouse

April 2001

1

1111111

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe Servicing

Practices be observed. The following are some limited examples of safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

• Remove the power cord from the electrical outlet, trip the circuit breaker to

the OFF position, or remove the fuse.

• Turn off the gas supply.

• Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN,

or GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a hazard.

6. Prior to returning the product to service, ensure that:

• All electrical connections are correct and secure

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts

• All non-insulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels

• All safety grounds (both internal and external) are correctly and securely

connected

• All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechanical training

and a level of knowledge of these subjects generally considered acceptable in the appliance

repair trade. Electrolux Home Products cannot be responsible, nor assume any liability, for

injury or damage of any kind arising from the use of this manual.

© 2001 White Consolidated Industries

2

Table of Contents

SAFE SERVICING PRACTICES 2

QUICK REFERENCE SHEET 12

MAXIMUM SURFACE TEMPERATURES 13

SECTION A - INSTALLATION INSTRUCTIONS 14 - 34

Installation instructions 30” ranges 14 - 25

Installation instructions 36” ranges 26 - 34

Safety 14

Clearances and Dimensions 14

Fuel types 14

Important notes to installer 15

Important note to consumer 15

Important safety instructions 15

Models with self-clean feature 15

Tools you will need 16

Normal installation steps 16

Anti-tip bracket installation instructions 16

Provide adequate gas supply 17

Seal the openings 17

Connect the range to the gas supply 18

Checking manifold gas pressure 18

Electrical requirements 18

Entension cord precautions 18

Grounding instructions 18

Surface burners 19

Installation of burner cap assembly 19

Electric ignition surface burners 19

Adjusting low setting of surface burner valve 19

Electric ignition burners 19

Air shutter oven burner 19

Air shutter broil burner 19

Make sure the range is level 19

Converting to LP 20 - 25

Tools Required for LP conversion 20

Converting the pressure regulator 21

Converting surface burner to LP 22

Converting the oven and broil burners 23

Reconnect gas and electric supply to range 23

Air sutter ajustment oven and broil burners 24

Installation of new LP/Propane rating/serial plate 25

Conversion to natural gas 25

Safety 26

Dimensions and clearance 26

Important notes to the installer 27

Important safety instructions 27

Provide an adequate gas supply 28

Seal the openings 28

Connecting the range to gas 28

LP gas conversion 29

Pressure regulator conversion 29

Surface burner valves conversion 30

Adjusting low surface burner setting 30

Air adjustment shutter 30

Converting oven burner orifice 31

Converting broil burner orifice 31

Electrical requirements 32

Extension cord cautions 32

3

Grounding instructions 32

Check operation 32

Check igniters 32

Non self clean models 33

Adjusting simmer setting 33

Leveling the range 33

Anti-tip bracket installation 33

SECTION B - GAS FLOW 35 - 38

Gas flow 35

Electric circuits 36

How gas flow system works 37

Troubleshooting 37

Burner flame too large 37

Burner flame too small 37

Burner flame yellow tipped 37

Top burner flame lifts off 37

Top burner spark ignition system 38

How it works 38

Troubleshooting 38

Igniters do not spark 38

Igniter system works normal for all but one valve 38

Igniter sparks at normal rate with all valves turned off 38

Igniter sparks intermittently with all valves turned off 38

SECTION C - ELECTRONIC OVEN CONTROL SYSTEMS 39 - 94

ES 100 oven control system 39 - 43

How to program the ES 100 control 39

To set the clock 39

To set the minute timer 39

To change the minute timer while in use 39

To set the control for baking 39

To change the oven temperature after baking has started 40

To set the oven control for broil 40

How the ES 100 system operates 40

Bake 40

Broil 41

Calibration 41

To change calibration 41

Troubleshooting 41

F1 code 41

F3 code 41

Control will not program 42

Blank display 42

No heat 42

Sample schematic for ES 100 control system 43

Es 200 oven control system 44 - 51

How to program the ES 200 44

Temperature conversion 44

To set the clock 44

To set the minute timer 44

To change the minute timer while in use 45

To set the control for baking 45

To change the oven temperature after baking has started 45

To set the control for continuous bake or 12 hour energy saving 45

To set the control for oven lockout feature 45

To set the control to broil 45

To set the control for a self-clean cycle 46

When the self-clean cycle is complete 46

4

Stopping or interrupting a self-cleaning cycle 46

How the ES 200 operates 46

Bake 46

Broil 47

Clean 47

Calibration 47

To change the calibration 47

Troubleshooting 48

F1 code 48

F3 code 48

F9 code 48

Control will not program 48

Blank display 48

No heat 48

Control operates normally but bake & broil burners do not heat 48

Broil burner operates but bake does not heat 49

Bake burner operates but broil does not heat 49

Self-cleaning 49

Oven door does not lock when the

oven is programmed for clean 49

Oven door locks when the oven is programmed

for clean but the oven does not heat 49

Lock motor runs continuously 49

Door latch is partly closed with the door open 49

Sample schematic for ES 200 control system 50

The ES 300 electronic oven control system 51

How to program the ES 300 system 51

For a silent control panel 51

Temperature conversion 51

To set the clock 51

To set the minute timer 51

To change the minute timer while it is in use 52

To cancel the minute timer before the set time has run out 52

To set the controls for bake 52

To change the oven temperature after baking has started 52

To set control for continuous bake or 12 hour energy saving 52

To set the control oven lockout 52

To set the timed bake feature 52

To program the oven to begin baking immediately

and shut off automatically 53

To program oven for a delay start

time and to shut-off automatically 53

When the set bake time runs out 53

To change the oven temperature or

bake time after baking has started 53

Speed bake 53

General cooking instructions 53

To set speed bake cooking system 54

To Broil 54

Self-cleaning oven 54

To start the self-clean cycle 55

When the self-clean cycle is completed 55

How the ES 300 control system works 55

Bake 55

Time bake 56

Speed bake 56

Broil 56

5

Clean 56

Calibration 57

To change the calibration 57

Troubleshooting 57

F1 code 57

F3 code 57

F9 code 57

Control will not program 57

Time bake does not operate 57

Blank display 57

No heat 58

Broil burner operates but bake burner does not 58

Bake burner operates but broil burner does not 58

Fan in oven does not run when speed bake switch is turned on 58

Self-cleaning 59

Oven door locks but oven does not heat in clean 59

Lock motor runs continuously 59

Door latch is partly closed with door open 59

Sample schematic for ES 300 control system 60

The ES 400 electronic oven control system 61

How to program the ES 400 61

Clock 61

To set the clock 61

Changing between 12 or 24 hour time of day display 61

To set the control for continuous bake or 12 hour energy saving 61

Minute timer 61

To set the minute timer 62

To change the minute timer while in use 62

To cancel the minute

timer before the set time has run out 62

Oven lockout feature 62

To active the oven lockout 62

To reactivate oven operation 62

Temperature display Fahrenheit or Celsius 62

Silent control operation 62

To change from sound to silent operation 62

Preheat 62

To change preheat temperature while oven is preheating 63

Bake 63

Time bake 63

To program the oven to begin baking

immediately and to shut off automatically 63

To program oven for a delayed start

time and to shut-off automatically 64

Broil 64

To set the oven to broil at 550 degrees F. 64

Convection bake 65

Convection roast 65

To start the self-clean cycle 65

To set the controls for the self-cleaning cycle

to start immediately and shut off automatically 65

When the self-clean cycle is completed 66

Stopping or interrupting a self-cleaning cycle 66

How the ES 400 operate 66

Preheat 66

Bake 67

Time bake 67

6

Convection bake 67

Convection roast 67

Broil 68

Clean 68

Calibration 68

To check oven calibration 68

To adjust the oven temperature higher 68

To adjust the oven temperature lower 68

Troubleshooting 68

F1 code 68

F3 code 69

F9 code 69

Control will not program 69

Time bake does not operate 69

Convection bake 69

Blank display 69

No heat 69

Bake and broil burner does not heat 70

Broil burner operates but bake burner does not heat 70

Bake burner operates but broil burner does not heat 70

Self-cleaning 70

Oven door does not lock when the

oven is programmed for clean 70

Oven door locks when the oven is

programmed for clean but oven does not heat 70

Lock motor runs continuously 70

Sample schematic for ES 400 control system 72

The ES 450 electronic oven control system 73

How to program the ES 450 73

Clock 73

Changing between 12 or 24 hour time of day display 73

Continuous bake or 12 hour energy saving 73

Minute timer 74

To change the minute timer while it is in use 74

To cancel the minute timer before the set time has run out 74

Oven lockout feature 74

To active the oven lockout 74

To reactivate oven operation 74

Temperature display Fahrenheit or Celsius 74

To change from Fahrenheit to Celsius 74

Silent control operation 74

To change from sound operation to silent operation 74

Preheat 75

Bake 75

Time bake 75

To program the oven to begin baking

immediately and to shut off automatically 75

To program oven for a delay start time

and to shut-off automatically 76

Broil 76

To set oven to broil 76

Convection bake 77

Setting food catagory feature 77

Self-clean 77

To set the control for the self-cleaning cycle to

start immediately and shut off automatically 78

When the self-clean cycle is complete 78

7

Stopping or interrupting a self-cleaning cycle 78

To set the controls for the self-cleaning cycle to start

at a delayed time and shut off automatically 78

When the self-clean cycle has completed 78

How the ES 450 operates 78

Preheat 78

Bake 79

Time bake 79

Convection bake 79

Fixed setting 80

Meats 80

Cakes 80

Breads 80

Broil 80

Clean 80

Calibration 80

To check oven calibration 80

To change calibration 80

Troubleshooting 81

F1 code 81

F3 code 81

F9 code 81

Control will not program 81

Time bake does not operate 81

Convection bake 81

Neither the fan motor or the assist element operate 81

Fan motor does not operate 81

Assist element does not operate 81

Blank display 81

No heat 82

Control operates normally but the

bake and broil burners do not heat 82

Broil burner operates but bake burner does not heat 82

Bake burner operates but broil burner does not heat 82

Self-cleaning 82

Oven door does not lock when the oven

is programmed for clean 82

Oven door locks when the oven is

programmed for clean but the oven does not heat 83

Lock motor runs continuously 83

Door latch is partly closed with door open 83

Sample schematic for ES 450 Control system 84

Electronic oven control system for 36” self-cleaning gas ranges 85

How to program the 36” gas range control 85

For a silent control panel 85

Temperature conversion Fahrenheit/Celsius 85

Lockout 85

Sabbath feature 85

To set the clock 86

To set the minute timer 86

To change the minute timer 86

To cancel the minute timer before the set time has run out 86

To set the preheat temperature 87

To set the control for normal baking 87

To set or change temperature 87

To set automatic timer 87

To start heating immediately and shut-off automatically 87

8

Once the oven controls are set 87

For a delayed start time and shut-off automatically 88

To broil 88

To set the oven control for self-clean cycles 88

Calibrating oven temperature 89

How the electronic oven control system on a 36” gas range operates 89

Preheat 89

Bake 90

Broil 90

Clean 90

Calibration 91

To change calibration 91

Troubleshooting 91

F1 code 91

F3 code 91

Door code 91

Control will not program 91

Blank display 91

No heat 92

Control operates normally but the bake

and broil burners do not heat 92

Broil burner operates but the bake burner does not heat 92

Bake burner operates but the broil burner does not heat 92

Self-cleaning 92

Oven does not heat in self-clean 92

Oven heats in self-clean but the oven is not clean 92

Sample schematic for 36” gas range 93

Warmer drawer 94

To set the warmer drawer control 94

How the warmer drawer circuit works 94

Troubleshooting 94

If the element does not heat 94

If the element heats during preheat then stays off

until the temperature drops to about 130 degrees 95

Element does not cycle off 95

Warmer drawer is slow to preheat 95

Warmer drawer heats but indicator light does not glow 95

SECTION D - DISASSEMBLY AND REPLACEMENT OF PARTS 96 - 129

30” gas ranges 96 - 112

Removing backguard back panel 96

Removing infinite switches 96

Removing indicator light 97

Removing electronic oven control 97

Removing oven light switch 97

Removing the control panel 97

Removing the end cap 97

Removing the main top 98

Removing sealed burner base 99

Removing top burner igniter 99

Removing fixed top orifice sealed burner 99

Removing manifold panel sealed burners 99

Removing burner pan 100

Removing top burner igniter switches 100

Removing top burner valve 100

Removing the manifold pipe 101

Removing the latch mechanism 101

Oven door 101

9

Removing oven door seal 101

Removing oven door 101

Door hinge adjustment 102

Removing the hinge opening cover 102

Removing the door hinge 102

Removing the upper door trim 102

Removing door handle 102

Removing outer door glass trim 103

Removing center door glass 103

Removing door wool shield 103

Removing glass package and inner door liner 103

Removing oven bottom 103

Removing bake burner baffle 103

Removing bake burner igniter 104

Removing bake burner (self-clean models) 104

Removing burner heat shield (self-clean models) 104

Convection and speed bake models 105

Removing fan cover 105

Removing fan blade 105

Removing convection assist element 105

Removing broil burner and baffle (self-clean models) 106

Removing broil igniter 106

Removing oven vent (self-clean models) 106

Removing oven safety valve (self-clean models) 106

Components removed from the rear of the range 107

Removing rear manifold cover 107

Removing back cover 107

Removing heat shield 107

Removing pressure regulator 108

Removing top burner igniter spark module 108

Removing lock motor assembly 108

Removing oven sensor 109

Door switch and rod removal 109

Removing convection and speed bake motor assemblies 109

Removing bodyside panels 110

Storage drawer 111

Removing storage drawer front panel 111

Removing inside drawer panel 111

Removing drawer glides 111

Removing the warmer drawer 111

Removing the warmer drawer side rails 112

Removing warmer drawer low limit thermostat 112

Removing the warmer drawer element 112

36” gas range 113 - 129

Removing backguard glass and trim 113

Removing control buttons 113

Removing electronic oven control 113

Removing fluorescent lamp starter 113

Removing starter base 113

Removing fluorescent ballast 114

Removing oven light or fluorescent light switch 114

Removing backguard trim 114

Removing back panel of backguard 115

Removing fluorescent lamp socket 116

Removing splasher panel 116

Removing grates, griddle cover griddle fifth burner pan and main top 116

Removing pressure regulator 116

10

Removing top burners 117

Removing top burner igniters 117

Removing main top support rod 117

Removing top burner knobs 118

Removing control panel 118

Removing top burner igniter switch 118

Removing top burner valves 118

Removing manifold pipe 119

Removing the latch handle knob 119

Removing lock mechanism cover 119

Removing lock mechanism arm 119

Removing lock switch arm 120

Removing lock mechanism 120

Removing burner box side panels 120

Removing the burner box 121

Oven door 121

Removing oven door seal 121

Oven door removal 121

Removing the oven door trim 121

Removing oven door handle 122

Removing door glass 122

Removing top outer glass spacers 122

Removing center door glass 122

Removing the wool shield 122

Removing the glass package 123

Removing inner door liner 123

Removing oven door springs 123

Removing oven door hinge 123

Removing storage drawer 123

Removing storage drawer handle 123

Removing storage drawer panel 124

Removing storage drawer rollers 124

Removing storage drawer rails 124

Removing storage drawer front panel 124

Removing the oven bottom 125

Removing bake burner baffle 125

Removing bake burner igniter 125

Removing bake burner 125

Removing the bake burner pan 125

Removing oven valve cover 126

Removing oven safety valve 126

Removing broil burner 126

Removing the broil burner igniter 127

Removing broil burner baffle 127

Removing oven vent 127

Removing oven light cover 128

Removing oven light bazel 128

Removing oven light socket 128

Removing rear cover 128

Removing oven sensor 128

Removing spark module 129

Removing lock switch 129

Removing bodyside panels 129

11

QUICK REFERENCE SHEET

1. Serial number breakdown: V F 1 2 3 1 8 4 7 2

Incremented unit number

Production week

Last digit of production year

Product identification

Manufacturing Facility

RTD SCALE

Temperature °F Resistance in Ohms

32 +/- 1.9 1000 +/- 4.0

75 +/- 2.5 1091 +/- 5.3

250 +/- 4.4 1453 +/- 8.9

2. Oven sensor resistance chart:

350 +/- 5.4 1654 +/- 10.8

450 +/- 6.9 1852 +/- 13.5

550 +/- 8.2 2047 +/- 15.8

650 +/- 9.6 2237 +/- 18.5

900 +/- 13.6 2697 +/- 24.4

3. Oven igniter current spec: 3.2 to 3.6 amps

12

MAXIMUM SURFACE TEMPERATURES (allowed for gas and electric ranges)

When Electrolux tests side panels and doors for skin temperature, certain U.L. and/or A.G.A. guide

lines must be followed.

1. Product must be undamaged, correctly assembled and have the correct oven temperature.

2. All skin temperatures are based on a room temperature of 77°F (25°C) and an oven set temperature of

400°F.

3. Oven must be cycling at 400°F for one hour before test is conducted.

4. Pyrometers, (temperature testers), must be of high quality and properly adjusted.

5. An increase or decrease of 1°F in the room ambient temperature, will allow a 1°F increase or decrease

in the maximum allowable surface temperature of the range.

Side Panel, Painted 152°F

Side Panel, Porcelain 160°F

Oven Door, Glass 172°F

Oven Door, Painted 152°F

Oven Door, Porcelain 160°F

Warmer Drawer, Painted 152°F

Warmer Drawer, Porcelain 160°F

Cooktop No Temperature Limits Apply

Lower Console No Temperature Limits Apply

Oven Vent Area No Temperature Limits Apply

Knobs and Handles Skirt

Plastic* Metal Plastic* Metal

Conventional Gas & Electric 167°F 131°F 182°F 152°F

Self-Clean Gas at Clean Temperature 167°F 131°F 182°F 152°F

Self-Clean Gas at Clean Temperature 182°F 152°F 182°F 152°F

* Includes plastic with metal plating not more than 0.005" thick and metal with a plastic or vinyl covering not

less than 0.005" thick

13

SECTION A - 30" GAS RANGE INSTALLATION INSTRUCTIONS

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed

exactly, a fire or explosion may result causing property damage,

personal injury or death.

FOR YOUR SAFETY:

— Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Clearances and Dimensions

1. Location—Check location

where the range will be

installed. Check for proper

electrical and gas supply,

and the stability of the floor.

2. Dimensions that are shown

must be used. Given

dimensions provide

minimum clearance. Contact

surface must be solid and

level.

Provide Proper Fuel Type

Before Proceeding: Your range is preset to operate on natural

gas only. Some models are shipped convertible with parts and

conversion instructions supplied. Other models have a LP/Propane

Conversion Kit available through your dealer.

DO NOT attempt to convert this range to LP/Propane

settings without the proper LP/Propane conversion kit provided with

the range or obtained from your dealer. Follow all instructions

provided with the conversion kit.

14

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and

electrical supply to the range.

3. Observe all governing codes and ordinances.

Never leave children alone or

unattended in the area where an appliance is in

use. As children grow, teach them the proper, safe use

of all appliances. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

4. Be sure to leave these instructions with the

consumer.

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

future reference.

IMPORTANT SAFETY INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1—latest edition when installed

in the United States.

This range has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions

you should follow. You will find them in the Use & Care

Manual, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their

absence, with the National Electrical Code

ANSI/NFPA No .70—latest edition when

installed in the United States. See Grounding

Instructions on page 19.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/4inch thick plywood between the range and carpeting.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at

the oven vent nor around the base or beneath

the lower front panel of the range. Avoid touching

the vent openings or nearby surfaces as they may

become hot while the oven is in operation. This

range requires fresh air for proper burner

combustion.

• Do not store items of interest to children in the

cabinets above the range. Children could be

seriously burned climbing on the range.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the

burners should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating

the room. Prolonged use of the range without

adequate ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• Reset all controls to the "off" position after

using a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the

Owner's Guide.

• Unlike the standard gas range, THIS COOKTOP

IS NOT REMOVABLE. Do not attempt to remove

the cooktop.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING

AN ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat

control was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit

with a match. Hold a lighted match to the burner, then

slowly turn the knob to the LITE position. Use extreme

caution when lighting burners this way.

15

Before Starting - Tools You Will Need

For Leveling Legs and Anti-Tip Bracket:

• Adjustable wrench or channel lock pliers

• 5/16" Nutdriver or Flat Head Screw Driver

• Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry

Drill Bit if installing in concrete)

For gas supply connection:

• Pipe wrench

Important Safety Warning:

To reduce the risk of tipping of the range, the range must

be secured to the floor by a properly installed anti-tip

bracket and screws packed with the range. Failure to

install the anti-tip bracket will allow the range to tip over

if excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled

hot liquids or from the range itself.

If range is ever moved to a different location, the antitip brackets must also be moved and installed with the

range.

Instructions are provided for installation in wood or

cement fastened to either the floor or wall. When

installed to the wall, make sure that screws completely

penetrate dry wall and are secured in wood or metal.

When fastening to the floor or wall, be sure that screws

do not penetrate electrical wiring or plumbing.

For burner flame adjustment:

• Phillips head and

blade-type screwdrivers

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2"

Additional Materials You Will Need:

• Gas line shut-off valve

• Pipe joint sealant that resists action of LP/Propane

gas

• A new flexible metal appliance conduit (1/2" NPT

x 3/4" or 1/2" I.D.) must be design certified by CSA

International. Because solid pipe restricts moving

the range we recommend using a new flexible

conduit (4 to 5 foot length) for each new installation

and additional reinstallations.

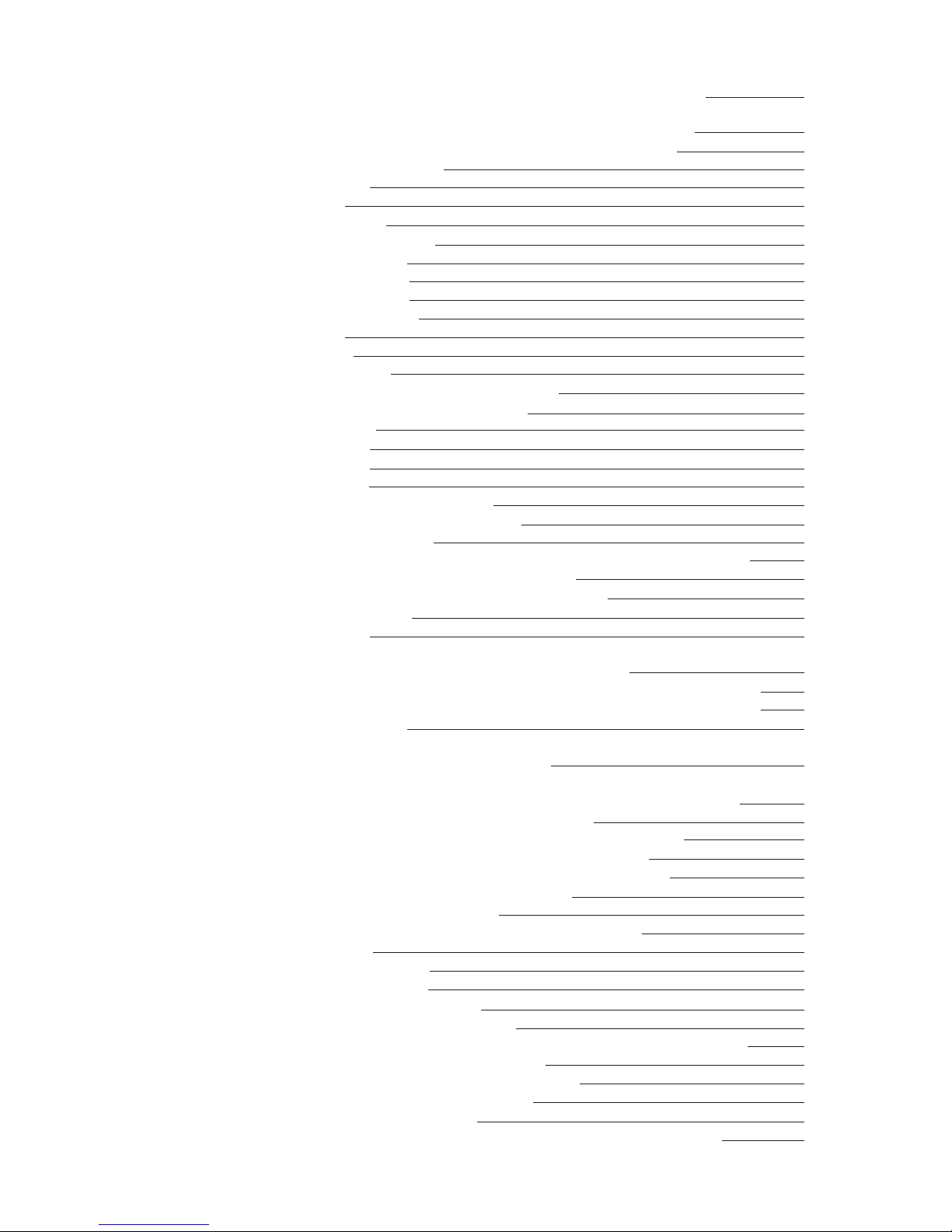

A. Locate the Bracket Using the Template - (Bracket

may be located on either the left or right side of the

range. Use the information below to locate the

bracket if template is not available). Mark the floor

or wall where left or right side of the range will be

located. If rear of range is against the wall or no

further than 1-1/4" from wall when installed, you

may use the wall or floor mount method. If molding

is installed and does not allow the bracket to fit

flush against the wall, remove molding or mount

bracket to the floor. For wall mount, locate the

bracket by placing the back edge of the template

against the rear wall and the side edge of template

on the mark made referencing the side of the

range. Place bracket on top of template and mark

location of the screw holes in wall. If rear of range

is further than 1-1/4" from the wall when installed,

attach bracket to the floor. For floor mount, locate

the bracket by placing back edge of the template

where the rear of the range will be located. Mark

the location of the screw holes, shown in template.

• Always use the (2) new flare union adapters (1/2"

NPT x 3/4" or 1/2" I.D.) supplied with the new

flexible appliance conduit for connection of the

range.

Normal Installation Steps:

1. Anti-Tip Bracket Installation Instructions

B. Drill Pilot Holes and Fasten Bracket - Drill a 1/8"

pilot hole where screws are to be located. If bracket

is to be mounted to the wall, drill pilot hole at an

approximate 20° downward angle. If bracket is to be

mounted to masonry or ceramic floors, drill a 5/32"

pilot hole 1-3/4" deep. The screws provided may be

used in wood or concrete material. Use a 5/16" nutdriver or flat head screwdriver to secure the bracket

in place.

16

pressure. A convertible pressure regulator is connected

to the manifold and MUST be connected in series with

the gas supply line. If the LP/Propane conversion kit has

been used, follow instructions provided with the kit for

converting the pressure regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14 inches of water

column pressure. The inlet pressure to the regulator

must be at least 1 inch greater than regulator manifold

pressure. Examples: If regulator is set for natural gas

4 inch manifold pressure, inlet pressure must be at

least 5 inches; if regulator has been converted for LP/

Propane gas 10 inch manifold pressure, inlet pressure

must be at least 11 inches.

Leak testing of the appliance shall be conducted

according to the instructions in step 4g.

C. Level and Position Range

Level range by adjusting the (4) leveling legs with a

wrench. Note: A minimum clearance of 1/8" is

required between the bottom of the range and the

leveling leg to allow room for the bracket. Use a spirit

level to check your adjustments. Slide range back

into position. Visually check that rear leveling leg is

inserted into and fully secured by the Anti-Tip

Bracket by removing lower panel or storage drawer.

For models with a warmer drawer or broiler

compartment, grasp the top rear edge of the range

and carefully attempt to tilt it forward.

The gas supply line should be 1/2" or 3/4" I.D.

3. Seal the openings.

Seal any openings in the wall behind the range and in the

floor under the range after gas supply line is installed.

2. Provide an adequate gas supply.

This unit is pre-set to operate on 4" natural gas manifold

17

4. Connect the range to the gas supply.

To prevent leaks, put a pipe joint sealant on all male

(outside) pipe threads. The regulator is in the location

shown below.

Do not allow regulator to turn on

pipe when tightening fittings.

f) Make sure service shut-off valve on pressure

regulator is in "ON" position.

g) Check for leaks. Turn the gas supply on to the

range and use a liquid leak detector at all joints

and conduits to check for leaks in the system.

Do not use a flame to check for gas

leaks.

Checking Manifold Gas Pressure

See page 23.

5. Read electrical connection details below and

connect electricity to range.

Before servicing, disconnect

electrical supply at circuit breaker, fuse or power

cord.

Electric Requirements:

An individual, properly grounded and polarized branch

circuit protected by a 15 amp. circuit breaker or time

delay fuse. See serial plate for proper voltage.

a) Install an external manual gas shut-off valve to

gas supply line in an easily-accessible location

outside of the range. Be sure you know how and

where to shut-off the gas supply to the range.

b) Attach appliance conduit to flare union on

regulator.

c) Attach appliance conduit to the flare union on

the regulator.

d) Install flare union adapter to external manual

shut-off valve.

e) Attach appliance conduit to flare union on shut-

off valve.

Extension Cord Precautions:

Because of potential safety hazards under certain

conditions, we strongly recommend against the use of

any extension cord. However, if you still elect to use an

extension cord, it is absolutely necessary that it be a UL

listed 3-wire grounding type appliance extension cord

and that the current carrying rating of the cord in amperes

be equivalent to or greater than the branch circuit rating.

Such extension cords are obtainable through your local

service organization.

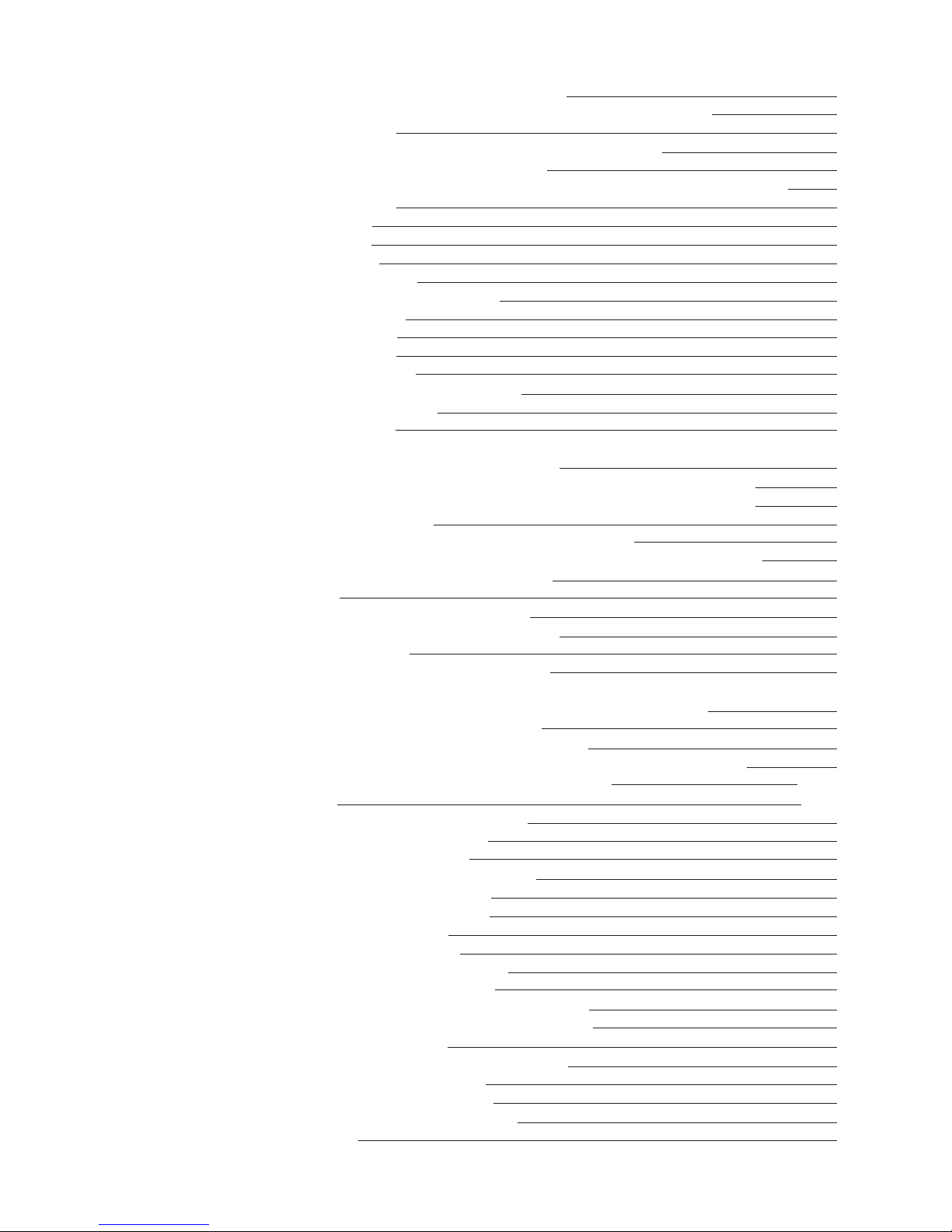

PLEASE READ CAREFULLY! For

personal safety, this product must be properly

grounded.

Grounding Instructions:

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

The customer should have the wall receptacle and

circuit checked by a qualified electrician to make sure

the receptacle is properly grounded and polarized.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

18

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD.

Surface Burners:

See Page 21.

6. Installation of Burner Cap Assembly

See Page 22.

9. Electric Ignition Burners:

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power.

The oven burner is equipped with an electric control

system as well as an electric oven burner igniter. If your

model is equipped with a waist-high broil burner, it will

also have an electric burner igniter. These control systems

require no adjustment. When the oven is set to operate,

current will flow to the igniter. It will "glow" similar to a

light bulb. When the igniter has reached a temperature

sufficient to ignite gas, the electrically controlled oven

valve will open and flame will appear at the oven burner.

There is a time lapse from 30 to 60 seconds after the

thermostat is turned ON before the flame appears at the

oven burner. When the oven reaches the dial setting, the

glowing igniter will go off. The burner flame will go "out"

in 20 to 30 seconds after the igniter goes "OFF." To

maintain any given oven temperature, this cycle will

continue as long as the dial (or display) is set to operate.

7. Electric Ignition Surface Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power.

a) To check for proper lighting, push in and turn

a surface burner knob counterclockwise to the

LITE position. You will hear the igniter sparking.

b) The surface burner should light when gas is

available to the top burner. Purge air from supply

lines by leaving knob in the LITE position until

burner ignites. Each burner should light within

four (4) seconds in normal operation after air has

been purged from supply lines.

c) Visually check that burner has lit. Once the

burner lights, the control knob should be turned

out of the LITE position.

d) There are separate electrodes (igniters) for each

burner. Try each knob separately until all burner

valves have been checked.

e) If burner goes out, reset control to OFF.

8. Adjust the "LOW" Setting of Surface Burner

Valve (Linear Flow Valves Only):

See Page 23.

Operation of Oven Burners and Oven Adjustments

After removing all packing materials and literature

from the oven:

a) Set oven to BAKE at 300ºF. See Use & Care

Manual for operating instructions.

b) Within 60 seconds the oven burner should

ignite. Check for proper flame, and allow the

burner to cycle once. Reset controls to off.

c) If your model is equipped with a waist-high

broiler, set oven to BROIL. See Use & Care

Manual for operating instructions.

d) Within 60 seconds the broil burner should ignite.

Check for proper flame. Reset controls to off.

10. Air Shutter-Oven Burner

See Page 24

11. Air Shutter-Broil Burner

See page 24

12. Make Sure Range is Level.

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs or by placing

shims under the corners of the range as needed.

13. After installation is complete, make sure all

controls are left in the OFF position.

19

Instructions for converting range to operate on Liquefied Petroleum Gas

INSTALLATION AND SERVICE MUST BE PERFORMED BY

A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

This conversion kit must be installed by a qualified service technician in accordance with

the manufacturer's instructions and all applicable codes and requirements of the authority having

jurisdiction. Failure to follow instructions may result in fire, explosion or production of carbon monoxide

causing property damage, personal injury or loss of life. The qualified service agency is responsible for

the proper installation of this kit. The installation is not proper and complete until the operation of the

converted appliance is checked as specified in the manufacturer's instructions supplied with this kit.

Before proceeding with the conversion, shut off the gas supply before disconnecting

electrical power to the range. Be sure both power supplies are off before installing the conversion kit.

Failure to do so could cause serious bodily injury.

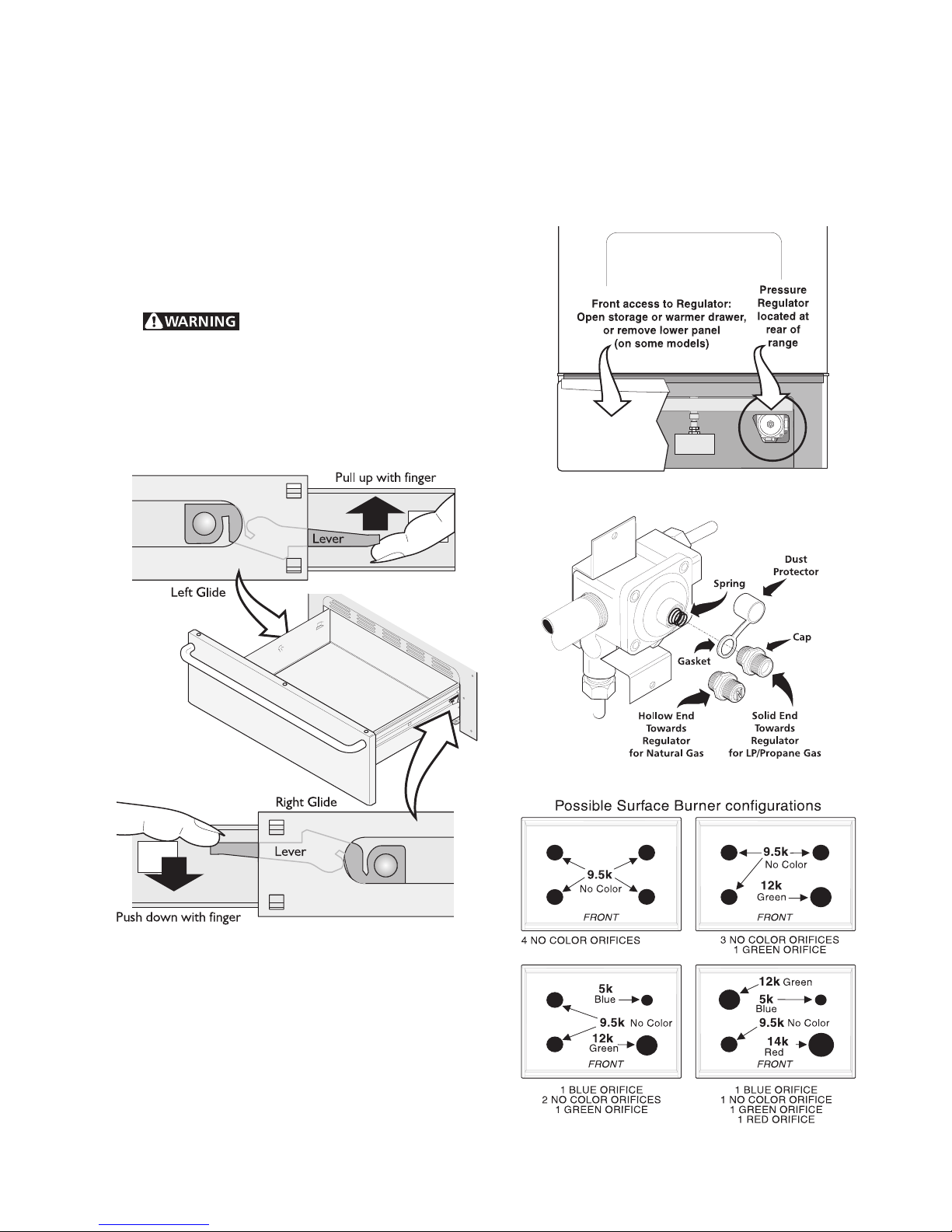

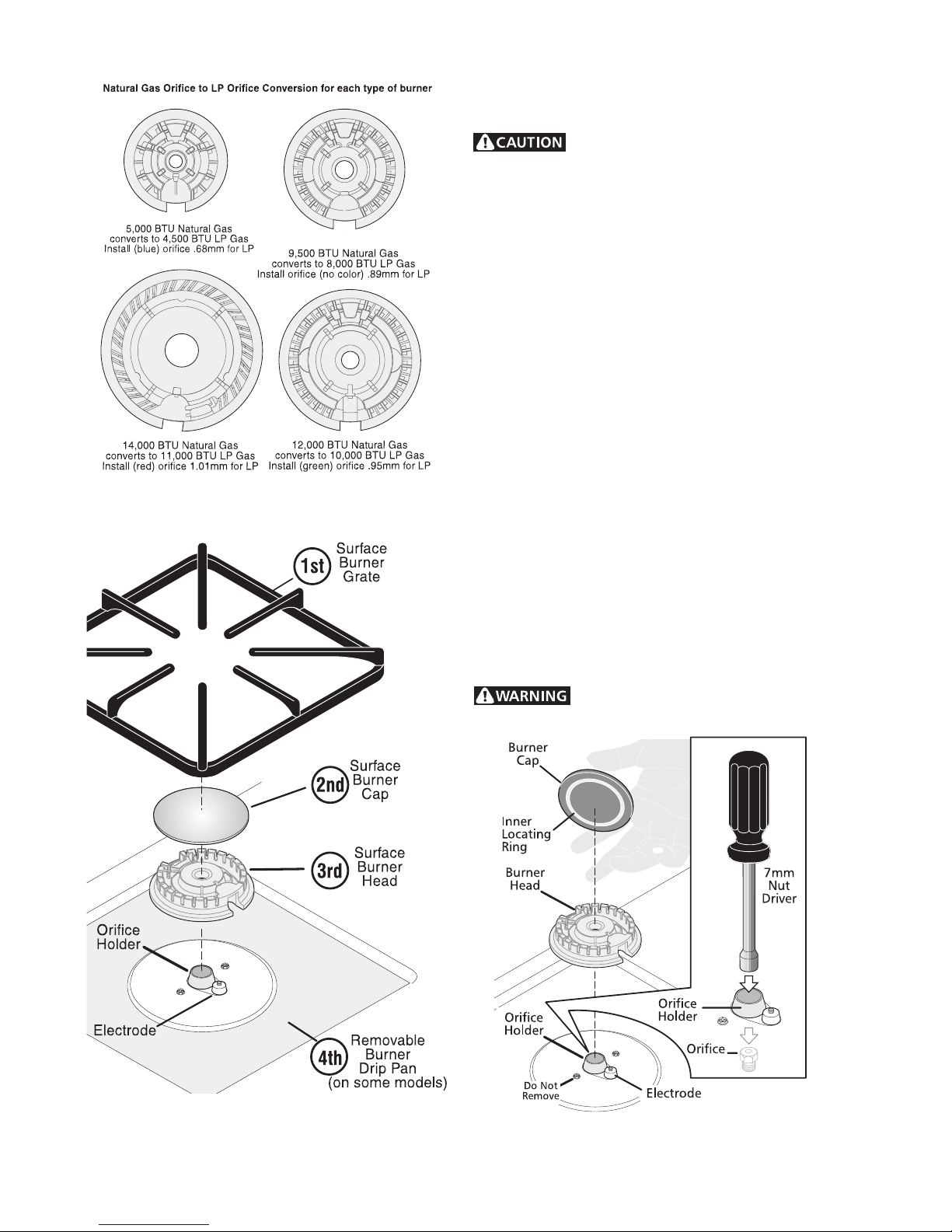

Determine the combination of top burners that are featured on your range. Then identify the parts you

need from this kit to completethe LP conversion. When burners are converted from Natural to LP the BTU

rating is as follows:

5,000 BTU* Natural Gas to 4,500 BTU* LP Gas 9,500 BTU* Natural Gas to 8,000 BTU* LP Gas

12,000 BTU* Natural Gas to 10,000 BTU* LP Gas 14,000 BTU* Natural Gas to 11,000 BTU* LP Gas

Quantity Part Number Part Description Notes

1 316037526 L.P. Conversion Kit Label English & French

1 316248105 Instructions for converting range to LP Gas English, French & Spanish

1 316005215 Rating Plate - English 4 - 8K

1 316005216 Rating Plate - English 3 + 1

1 316005217 Rating Plate - English 2 + 1 + 1

1 316005218 Rating Plate - English 1 + 1 + 1 + 1

1 316005219 Rating Plate - French 4 - 8K

1 316005220 Rating Plate - French 3 + 1

1 316005221 Rating Plate - French 2 + 1 + 1

1 316005222 Rating Plate - French 1 + 1 + 1 + 1

1 316241200 L.P. Conversion Label English, French & Spanish

1 316237904 Orifice - 11,000 BTU* RED

1 316237905 Orifice - 10,000 BTU* GREEN

1 316237906 Orifice - 8,000 BTU* NO COLOR

1 316237907 Orifice - 4,500 BTU* BLUE

*Note: For operation at elevations above 2000 ft., appliance rating shall be reduced at the rate of 4 percent

for each 1000 ft. above sea level.

IMPORTANT: After replacing the natural gas to LP orifices, be sure to keep the original factory installed

natural gas orifices for future range conversion back to natural gas. The factory orifices are marked with

101 for 5,000 BTU; 154 for 9,500 BTU; 175 for 12,000 BTU and 193 for 14,000 BTU.

Tools Required for L.P. Conversion:

3/8", 1/2" and 5/8" Open End Wrench

1/8" Wide Flat Blade Screwdriver

7mm Nutdriver

20

How to Convert the Range for use with LP/Propane

Gas

1. Convert the Pressure Regulator

To access the gas regulator, remove the storage drawer

or warmer drawer. If equipped with a storage drawer,

open and remove the drawer completely. For models

equipped with a storage drawer or front panel, remove the

storage or front panel and skip steps a & b below. For

models equipped with warmer drawer, follow all the

instructions below to remove the warmer drawer.

a. Electrical Shock Hazard can occur

and result in serious injury or death. Disconnect

electrical power to the range before removing the

warmer drawer for servicing.

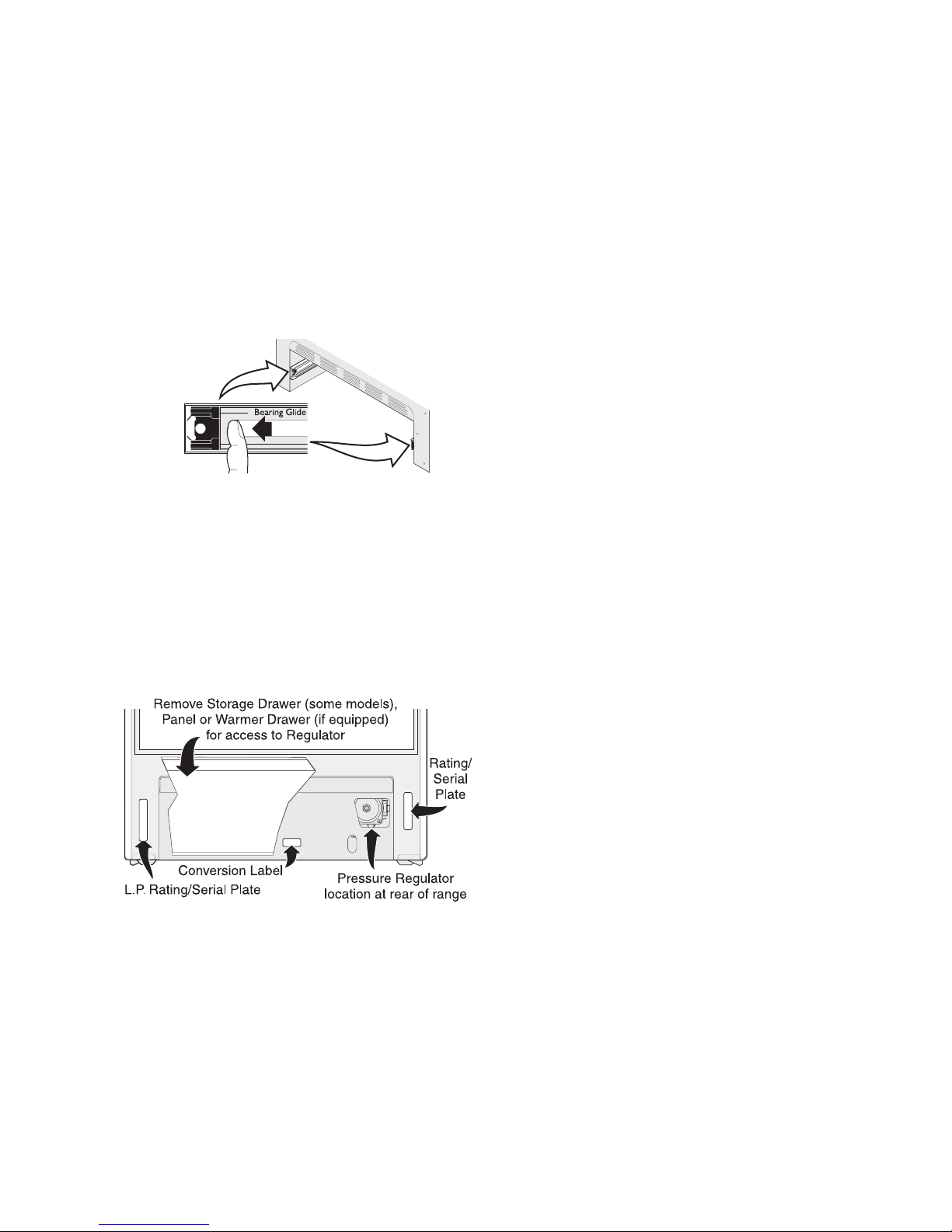

b. Locate glide lever on each side of drawer, pull up on

the left glide lever and push down on the right glide

lever (See Figure 1).

f. Turn the cap over so the hollow end faces outward.

Place the solid end of the cap into the loop end of the

dust protector (See Figure 3).

g. Replace the cap on the regulator. The letters LP

should be visible on the exposed end of the cap.

Snap the dust protector over the regulator cap.

Figure 2

Figure 1

c. Pull the drawer away from the range (See Figure 2).

d. Remove the regulator access cover if equipped. Do

not remove the Pressure Regulator or allow it to

turn.

e. Remove the dust protector from the cap. Using a 5/

8" wrench, unscrew the cap from the pressure

regulator. Do not remove the spring from the

regulator.

Figure 3

Figure 4

21

Figure 5

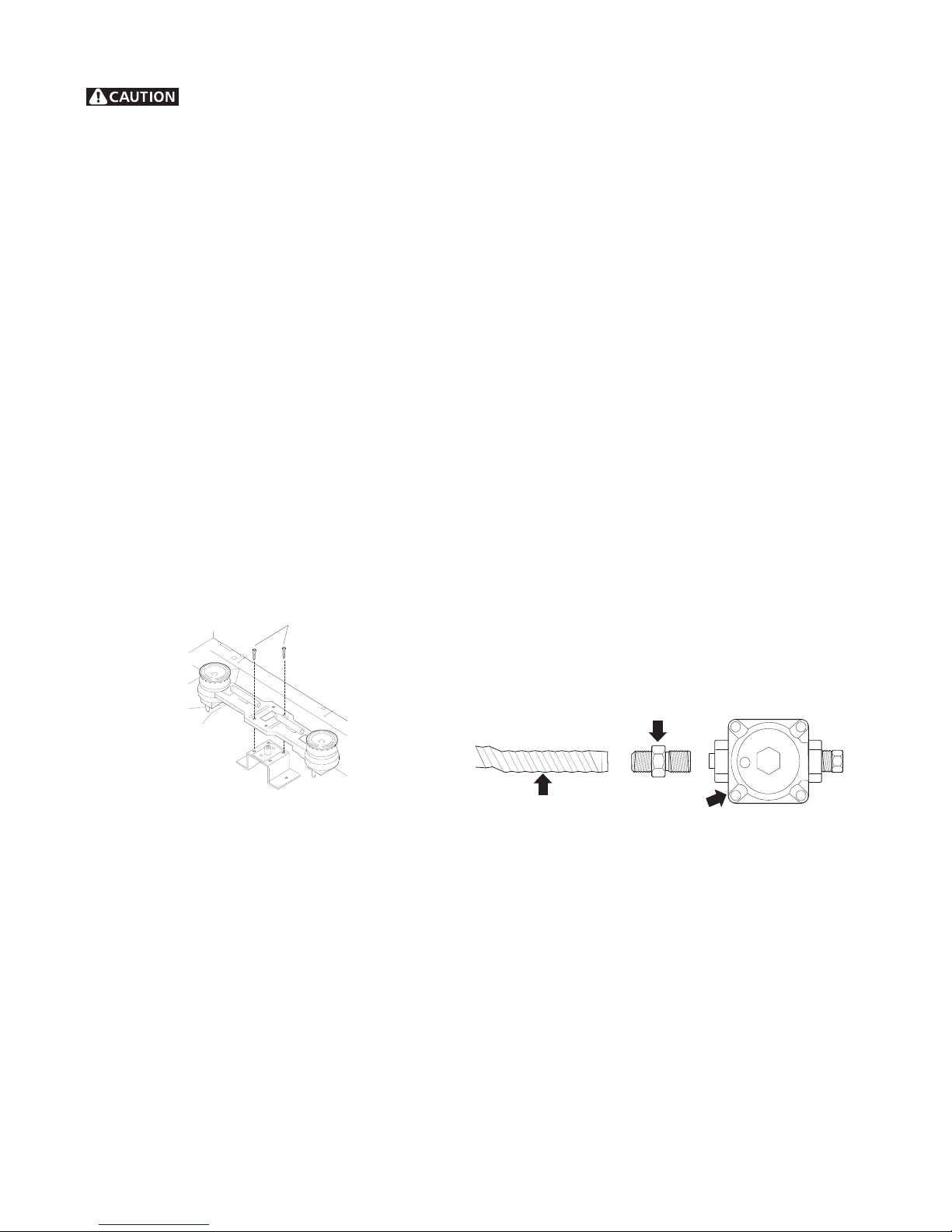

2. Convert Surface Burners for use with LP/

Propane Gas

Unlike the standard gas range, THIS

COOKTOP IS NOT REMOVABLE. Do not attempt to

remove this cooktop. Save the natural gas orifices

removed from the appliance for possible future conversions

to natural gas.

For all burner locations:

a. Remove the top grate and burner cap (See Figure 6).

b. Use your hand to remove the burner head.

c. Remove the four factory installed natural gas orifices

from the center of the orifice holders using a 7

mm nutdriver (See Figure 7). Remember to keep the

original Natural Gas Orifices for later conversion to

Natural Gas. Refer to page 1 under "IMPORTANT" to

identify their markings.

d. Replace the orifice in each of the four orifice holders

with the correct LP/Propane gas orifice (refer to the

LP Kit chart listed on page 1; also refer to Figures

4 and 5 for the correct LP orifice installation at

each of the four surface burner locations). Tighten

each orifice until snug. Use caution not to overtighten.

e. Replace the four burner heads (be sure burner head

mates correctly with each surface igniter) then replace

the burner caps and grates.

Use caution when replacing each burner

cap so the electrode is not damaged.

Figure 6

Figure 7

22

3. Convert Oven Burner Orifice for LP/Propane

Gas (16,000 BTU*)

a. Locate the oven burner spud (See Figure 8).

b. Using a 1/2" wrench, turn down the adjustable spud,

which injects gas into the oven burner, until snug

against the LP/Propane metering pin (approximately

2-1/2 turns). Do not over tighten.

4. Convert Waist-High Broiler Burner Orifice Flame

for LP/Propane Gas (13,500 BTU*) —Self-Cleaning

Models Only

a. Open the oven door.

b. Locate the broiler burner spud and turn down until

snug against the LP/Propane metering pin

(approximately 2-1/2 turns). Do not over tighten

(See Figure 8).

14" water column. When properly adjusted the manifold

water column pressure is 10" for LP/Propane gas or 4"

for Natural gas.

Do not use a flame to check for gas

leaks.

a. Disconnect the range and its individual shut-off valve

from the gas supply piping system during any

pressure testing of that system at test pressures

greater than 14" of water column pressure

(approximately 1/2" psig).

b. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-

off valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 14" of water column pressure (approximately

1/2" psig).

5. Reconnect Gas and Electrical Supply to

Range.

Leak testing of the appliance shall be conducted according

to the Installation Instructions provided with the Range.

Figure 8

Checking Manifold Gas Pressure

To

Surface

Burner

Figure 9

Figure 10

Test to verify if “LOW” setting should be adjusted:

a. Push in and turn control to LITE until burner ignites.

b. Push in and quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

If it should be necessary to check the manifold gas

pressure, remove the burner cap and connect a

manometer (water gauge) or other pressure device to the

top right front burner orifice. Using a rubber hose with

inside diameter of approximately 1/4," hold tubing down

tight over orifice. Turn burner valve on. For an accurate

pressure check, have at least two (2) other surface

burners burning. Be sure the gas supply (inlet) pressure

is at least one inch above specified range manifold

pressure. The gas supply pressure should never be over

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame

size can be increased or decreased with the turn of

the screw. Turn counterclockwise to increase flame

size. Turn clockwise to decrease flame size. (See

Figures 9 and 10).

Adjust flame until you can quickly turn knob from LITE to

LOWEST POSITION without extinguishing the flame.

Flame should be as small as possible without going out.

23

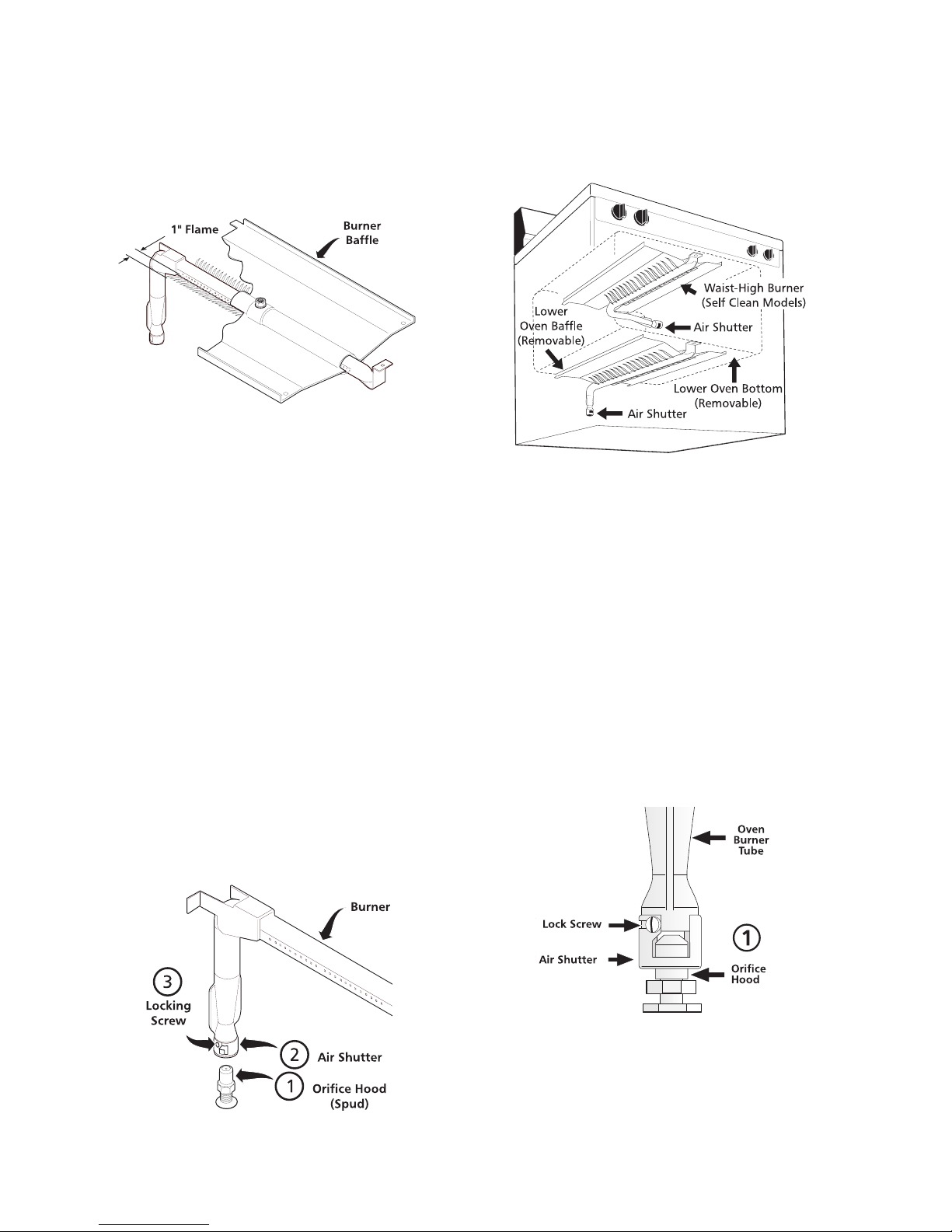

7. Air Shutter-Oven Burner

The air shutter for the oven burner may need adjustment,

especially if the unit has been converted for use with LP/

Propane gas. The approximate flame length of the oven

burner is 1 inch (distinct inner, blue flame) (See Figure

11).

Figure 11

To determine if the oven burner flame is proper:

a. To access the air shutter you must remove the

warmer drawer.

Retest the burner by repeating step “d” above. When the

burner flame is a distinct blue color burning steady, the

air shutter is adjusted correctly.

f. Replace burner baffle and oven bottom.

Figure 13

8. Air Shutter-Broil Burner

b. Remove the oven bottom by removing the screws at

rear of oven bottom. Lift up the rear of oven bottom

and slide toward back of range to disengage from

front of oven front frame.

c. Remove burner baffle by removing nut located on top

of baffle and two screws from front edge of oven front

frame. Lift baffle straight up and out of the oven.

d. Set the oven to bake at 350°F and observe the flame.

If the flame is yellow in color, increase air shutter

opening size. If the flame is a distinct blue color, but

lifting away from the burner; reduce the air shutter

opening size.

e. Turn off oven and allow to cool before adjusting air

shutter. To adjust loosen lock-screw (See Figure

12), reposition air shutter, and tighten lock-screw.

a. Observe the flame to determine if the broiler burner

flame is properly adjusted. It should be steady with

approximately 1" blue cones and no yellow or orange

flame tips (See Figure 13).

b. If adjustment to the air shutter is necessary, locate

the broiler burner air shutter (See figure 14), loosen

shutter lock screw, and adjust to obtain optimum

flame. This will normally be completely open for LP/

Propane gas. If the flame is yellow in color, increase

the air shutter opening size. If the flame is a distinct

blue, but lifting away from the burner, reduce the air

shutter opening size. Tighten the shutter set screw.

Figure 12

Figure 14

9. Replace Storage Drawer or Warmer Drawer

(instructions for warmer drawer if equipped):

24

a. Pull the bearing glides to the front of the chassis

glide (See Figure 15).

b. Align the glide on each side of the drawer with the

glide slots on the range.

c. Push the drawer into the range until levers “click”

(approximately 2”). Pull the drawer open again to

seat bearing glides into position. If you do not hear

the levers “click” or the bearing glides do not

feel seated remove the drawer and repeat

steps "a" through "c". This will minimize possible

damage to the bearing glides.

Figure 15

10. Installation of New LP/Propane Rating/Serial

Plate

c. Remove the four LP orifices using 7mm nutdriver and

replace with the four original factory installed natural

gas orifices at their original locations (See figure 4 for

locations).

d. Convert Oven Burner Orifice for Natural Gas by

loosening spud counter-clockwise (approximately

2-1/2 turns; See step 3).

e. Convert Waist-High Broiler Burner Orifice (Self-

Cleaning Models Only) for Natural Gas by loosening

spud counter-clockwise (approximately 2-1/2 turns).

(See step 4.)

f. Readjust “LOW” Setting for Surface Burner Valves

following instructions. (See step 6.)

g. Readjust Oven & Broil Burner Air Shutters. (See

steps 7 & 8.)

Record the model and serial number on the LP/Propane

Rating/Serial plate provided in this kit. The information

can be obtained from the existing Rating/Serial plate.

Place new plate as close as possible to the existing

Rating/Serial plate on range (See the recommended

locations shown in Figure 16).

Figure 16

CONVERSION TO NATURAL GAS

If it becomes necessary to convert the range back to

natural gas:

a. Disconnect gas and electrical supply from range.

b. Convert pressure regulator (See step 1), turn cap

over so the solid end of cap faces outward. Place the

hollow end of the cap into the loop end of the dust

protector.

25

36" GAS RANGE INSTALLATION INSTRUCTIONS

INSTALLATION AND SERVICE MUST BE PERFORMED

BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

FOR YOUR SAFETY:

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appli-

ance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service agency or the gas supplier.

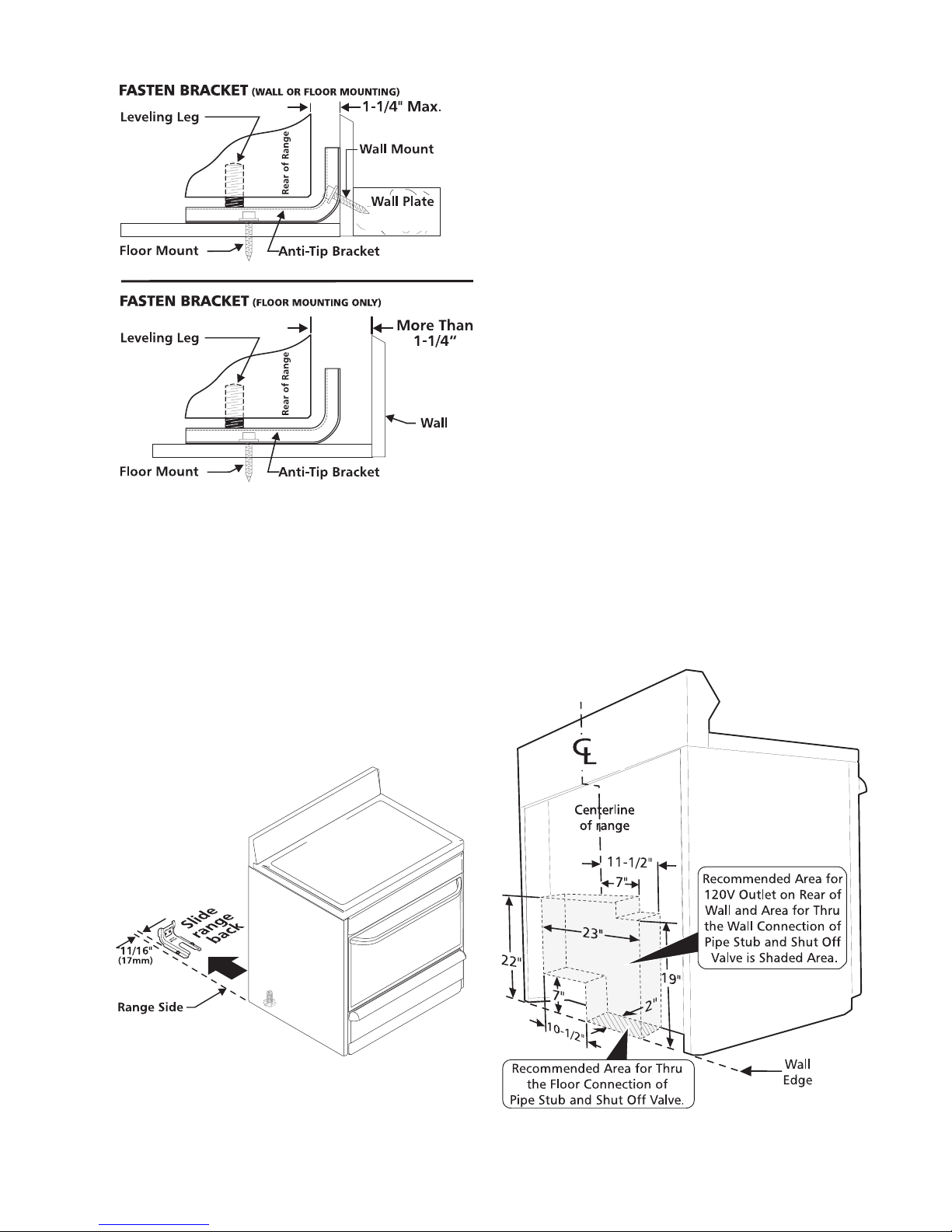

Dimensions and Clearance

Provide adequate clearance between range

and adjacent combustible surfaces.

TYPICAL CONTROL PANEL X. HEIGHT

HI Profile Control Panel 45 5/8" min.

LO Profile Control Panel 40 7/8" Min.

35 15/16”

X

45 3/8”

25 1/8”

36” +/- 1/8”

36”

Door open

Minimum to

wall on either

side of range

above 36”

height

36”

30” Minimum

2”

36 1/4”

Between Cabinets

Minimum to cabinets

on either side of

18”

range

0” Clearance at rear of

range below cooktop

Figure 1

26

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing the range.

2. Remove all packing material before connecting the

electrical supply to the appliance.

Standard, title 24CFR, part 3280 [Formerly the

Federal Standard for Mobile Home Construction

and Safety, title 24, HUD (part 280)] or when such

standard is not applicable, the Standard for Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Set ups), ANSI

Z225.1

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your Use and Care Guide

for future reference.

IMPORTANT SAFETY INSTRUCTIONS

Installation of this range must conform with local

codes, or in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1—latest edition.

This range has been design certified by American

Gas Association (A.G.A.). As with any appliance

using gas and generating heat, there are certain

safety precautions you should follow. You will find

them in the Use and Care Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes, or in their absence, with the National Electrical Code ANSI/

NFPA No. 70—latest edition.

• The installation of appliances designed for manu-

factured (mobile) home installation must conform

with Manufactured Home Construction and Safety

• Before installing the range in area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over

carpeting unless you place an insulating pad

or sheet of ¼” thick plywood between the

range and carpeting.

• Make sure the wall coverings around the

range can withstand the heat generated by

the range.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching

the vent openings or nearby surfaces as they

may become hot. This range requires fresh air

for proper burner combustion.

• Do not store items of interest to children in the

cabinets above the range. Children could be

seriously burned climbing on the range to reach

items.

• To eliminate the need to reach over the sur-

face burners, cabinet storage space above the

burners should be avoided.

• Adjust surface burner flame size so it does

not extend beyond the edge of the cooking

utensil. Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• All ranges

can tip.

• Injury to

persons

could result.

• Install antitip device

packed with

range.

To reduce the risk of

tipping of the range, the

range must be secured

by properly installed antitip bracket (s) provided

with the range. To check

if the bracket(s) is

installed properly, grasp

the top rear edge of the

range and carefully tilt it

forward to make sure the

range is anchored.

• Never use your range for warming or heating

the room. Prolonged use of the range without

adequate ventilation can be hazardous.

• Do not store or use gasoline or other flam-

mable vapors and liquids near this or any

other appliance. Explosions or fires could result.

• Remove broiler pan and other utensils and wipe

up excess spillage before self-cleaning the oven

(if equipped).

27

Do not make any attempt to oper-

ate the electric ignition oven during an electrical power failure. Resumption of electric power

when OVEN TEMP and OVEN SET controls are in

any position other than OFF will result in automatic

ignition of the oven or broiler burner.

For checking the regulator, the inlet pressure must

be at least 1" water column pressure greater than the

regulator manifold outlet setting. If the regulator is

set for 4" of manifold pressure, the inlet pressure

must be at least 5". If the regulator is set for 10", the

inlet pressure must be at least 11".

In case of a power outage, you can light the surface burners on your range with a match. Hold a

lighted match to the burner, then slowly turn the

knob to the LITE position. Use extreme caution

when lighting burners this way.

Surface burner in use when electrical power failure

occurs will continue to operate normally.

The oven burner and broil burner on your range

are lighted by electrical ignition. The oven and

broiler cannot be operated in the event of a

power failure.

1. Before Installing the Range

Remove shipping material

Remove all tape, shipping and packaging materials

and the oven rack packaging. Lift up cooktop and

remove the two shipping screws from the cooktop

burners (see figure 2).

Screws

The gas supply line into the range should be ½” or

¾” I.D. flexible metal appliance connector five feet

in length.

3. Seal the Openings

Seal any openings in the wall behind the range and

in the floor under the range when hookups are completed.

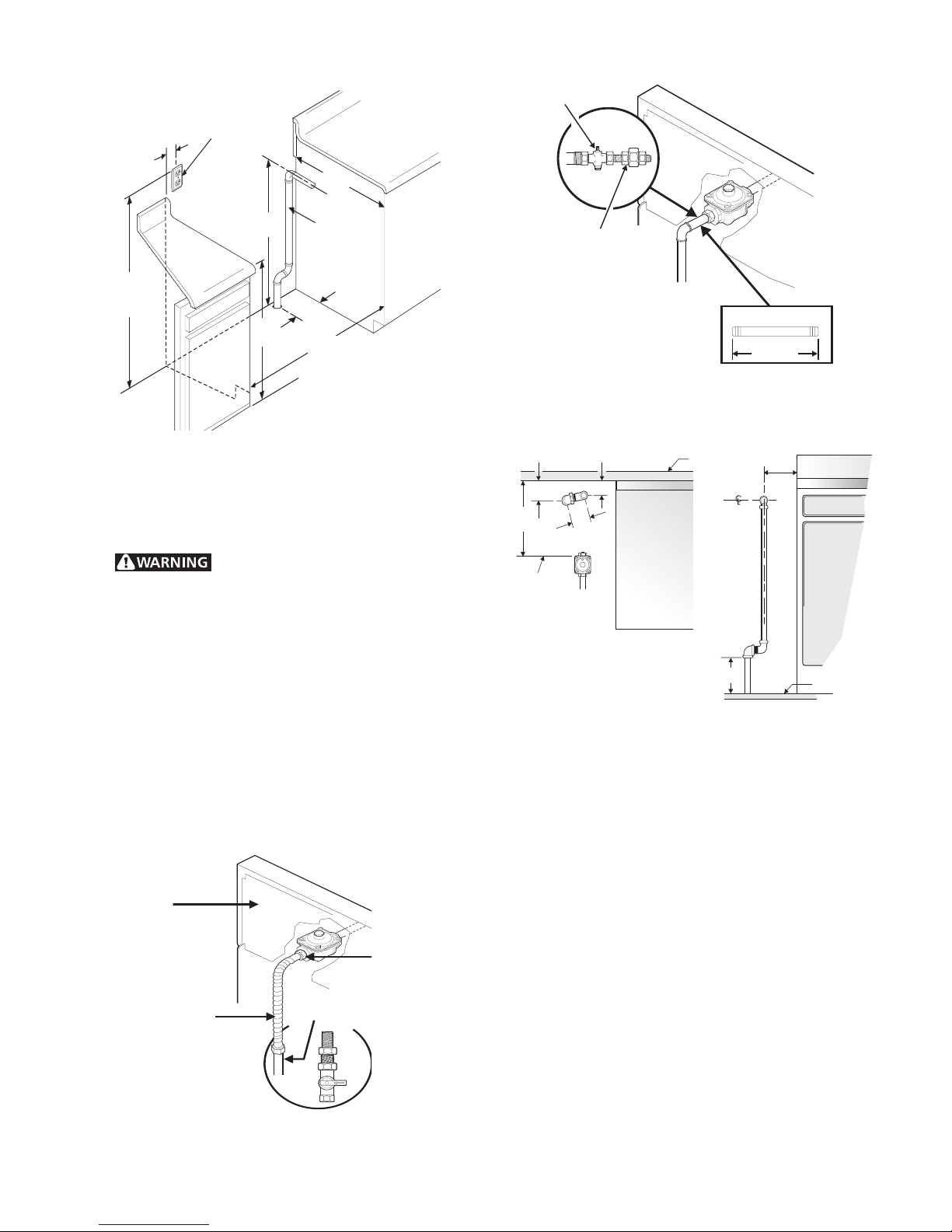

4. Connect the Range to Gas

Refer to Figures 4 to 7 for recommended connections.

A. Install a manual shut-off valve in the gas line in

an easily accessible location outside of the range.

Be sure you know how and where to shut-off the

gas supply to the range.

B.Install ½” flare union adaptor supplied with the

connector, to the ½” NPT internal thread on pressure regulator.

Gas Connection for Electric Ignition Models

Figure 2

2. Provide an Adequate Gas Supply

This range is designed to operate on natural gas at

4" of manifold pressure or on LP gas at 10" of

manifold pressure. It is shipped from the factory

set for natural gas. If it is to be used with LP gas,

adjustments must be made.

A convertible pressure regulator is connected in series with the manifold of the range and must remain

in series with the supply line regardless of whether

natural or LP gas is being used.

For proper operation, the maximum inlet pressure to the regulator must be no more than 14" of

water column (W.C.) pressure.

Flare Union Adaptor

Flexible Appliance

Connector

Pressure

Regulator

Figure 3

C.Because solid pipe restricts moving the range we

recommended use of A.G.A. design certified flexible metal appliance connector. Connect flexible

appliance to flare union.

D.Move range into approximate position and con-

nect flexible appliance connector to gas supply

line with proper flare union adaptor. The adaptor

supplied with the flexible connector must be used.

E. Check for leaks. Turn the gas supply on the

range and use a liquid leak detector at all joints

and connections to check for leaks in the system.

28

3"

3-Wire Polarized

120V. Outlet

32 7/8" ± ¼"

Gas Supply

Pipe

25"

Shut-Off Fitting

Union

Back of

Range

20"

or Lower

36"

Figure 4

Recommended locations for installing the electrical

outlet and pipe opening may be adjusted to meet

specific requirements.

Do not use a flame to check for

leaks from gas connections. Checking for leaks with

a flame may result in a fire or explosion.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of that system at test pressures

greater than 14" of water column pressure (approx.

½” psig).

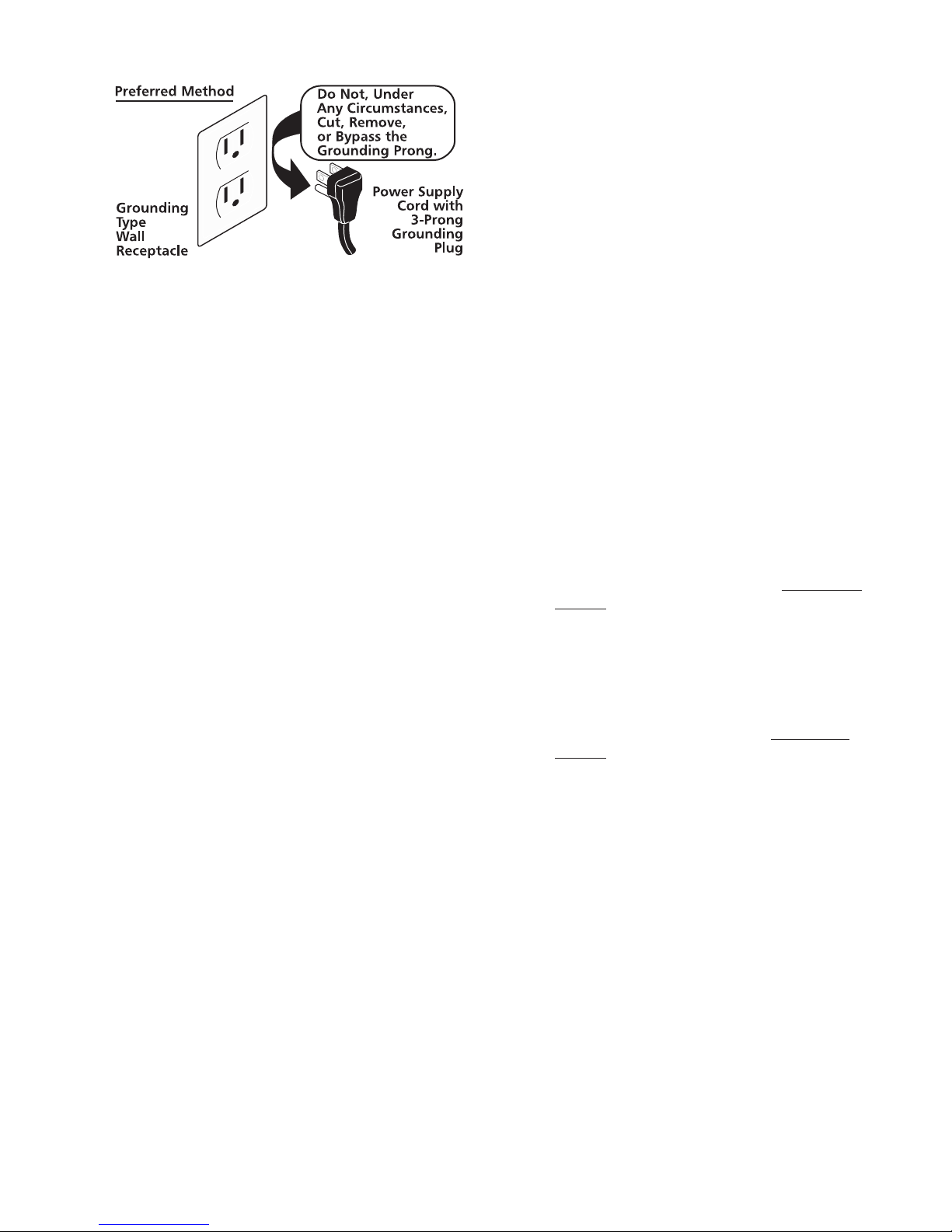

6 ¾"

36 ¼"

1 7/16"

11 ½ "

End of

Pressure

Regulator

Solid Pipe Hookup

¾

"

3 ¾"

TOP VIEW

Figure 6

Wall

Counter

To p

½" Nipple

Manifold

6"

FRONT VIEW

6 3/8"

2 5/8"

±¼"

Floor

Isolate the range from the gas supply piping

system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

14" of water column (approx. ½” psig).

Back of

Range

½" Close Nipple

Flexible

Connector

Flexible Connector Hookup

Recommended Shut-Off

Location

Figure 5

29

Solid Pipe Hookup Detail

Figure 7

5. LP/Propane Gas Conversion

A. Pressure Regulator Conversion

Do Not Remove the Pressure Regulator

Remove cap-screw and snap out the nylon gas

indicator by pushing it sideways. Turn the nylon

gas indicator for type gas (Natural or LP) and

snap it back in the cap-screw. Put cap-screw

back on gas regulator.

3.Lower main top and apply gas to check for proper flame

size. Flame should be steady with approximately ½”

blue inner cones and no yellow or orange tips.

L.P.

Figure 8

B. Surface Burner Valves Conversion

Air Shutter

Hood

NAT.

Cap Screw

Nat.

L.P.

Pin

Inner Cone Flame Length

½"

Figure 11

Proper Air Adjustment

If air shutter is adjusted so that too much air flows

into the burner, the flame will appear unsteady,

possibly not burning all the way around and will be

noisy (like a blow torch).

C. Readjust the “LOW” Setting Surface Burner

Valve

1. Turn control to LITE until burner ignites.

2. Quickly turn knob down to LOWEST SETTING.

Top Burner Adjustment

Figure 9

1. Lift cooktop to gain access to the surface

burner spuds.

2. With ½” wrench, turn spud down or clockwise

until snug (approximately 2 ½ turns). This restricts the flow of gas through spud to that allowed only by the hollow LP metering pin. Do

not overtighten.

Pin

Spud

Natural Gas

Increase Gas

Increase Flame

Size

(Pre-Set at Factory

for Natural Gas)

L.P. Gas

Decrease Gas

Decrease Flame

Size

Figure 10

3. If burner goes out, readjust valve as described

in “Adjust the LOW Setting Surface Burner

Valve” from Page .

D. Air Adjustment Shutter

Apply gas to the burner and adjust air shutter on

burner venturi tube to proper flame. For LP gas,

the air shutter is generally left completely open.

Air adjustment shutter

Figure 12

The air adjustment for each burner is located at

the open end of the venturi tube and sits on the

hood of the valve. The shutter is held in place by

friction fit.

30

Loading...

Loading...