Page 1

RANGE

COMPOSITION

N 900: a range of over 150 models

for the professional caterer designed

to guarantee the highest level of

performance, reliability, energy

saving, safety standards and

ergonomic operation. These

concepts are reflected in the total

modularity of the range that ensures

innumerable configurations, either

free-standing, bridged or cantilever.

N 900 demonstrates how advanced

technology can satisfy the needs of

the professional caterer.

The models detailed on this sheet

are 4 gas pasta cookers: ½ and full

modules in standard versions or with

a built-in automatic pre-heating

system (Rapid System).

Model 200376

FUNCTIONAL AND

CONSTRUCTION

FEATURES

� Worktop in 20/10 stainless steel.

Front and side panels in stainless

steel with Scotch Brite finish.

� Well in 316 AISI stainless steel

thus guaranteeing high resistence

against the water and salt corrosive

action.

� Easy to use control panel

endowed with an energy regulator

and a switch regulating working

conditions: rapid filling, boiling,

boiling and refilling with pre-heated

water (only on Rapid System

models).

� The electrically-heated

pre-heating system built into the unit

(on Rapid System models,

NCPG410 and NCPG810),

guarantees very high thermal

efficiency, rapid temperature

recovery and a production rate

superior to standard models.

N 900

GAS PASTA COOKERS

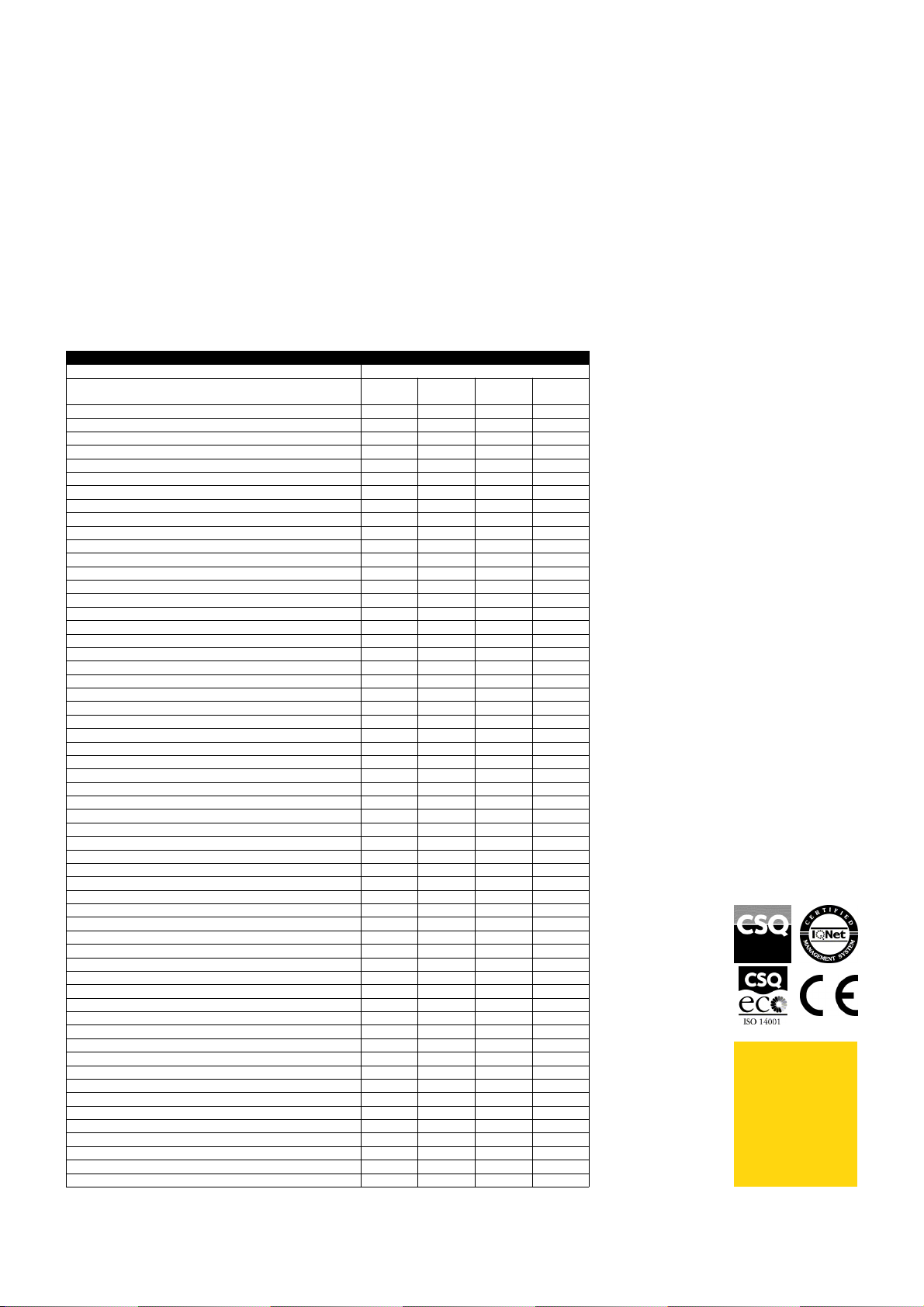

TECHNICAL DATA

CHARACTERISTICS MODELS

NCPG400

200376

Power supply Gas Gas Gas Gas

Water boiler l l

Capacity - lt. 40 40 40 40

External dimensions - mm

width 400 400 800 800

depth 900 900 900 900

height 850 850 850 850

height adjustment 50 50 50 50

N° of wells 1 1 2 2

Usable well dimensions - mm

width 300 300 300 300

depth 520 520 520 520

height 260 260 260 260

Thermocople safety valve l l l l

Temperature limiter l l l l

Maximum Well Capacity -lt 32, 40 32, 40 32, 40 32, 40

Power - kW

gas 14 14 28 28

auxiliary 0.1 3 0.2 0.2

Net weight - kg. 62 73 115 137

Supply voltage 230 V, 1N,

INCLUDED ACCESSORIES

LEFT SIDE DOOR FOR OPEN BASE

CUPBOARD

RIGHT SIDE DOOR FOR OPEN BASE

CUPBOARD

50/60

1 1 1 1

NCPG410

200377

400 V, 3N,

50/60

ZANUSSI

P R O F E S S I O N A L

NCPG800

200378

230 V, 1N,

50/60

1 1

NCPG810

200379

400 V, 3N,

50/60

Page 2

GAS PASTA COOKERS

N 900

� High-power burners (one for each well)

with optimized combustion positioned

beneath the base of the well, featuring flame

failure device and pilot light with separate

power settings for each well (standard gas

models).

� Endowed with skimming zone for

collecting and discharging, through the

overflow filter, of starches and foams.

� Safety Pressostat avoiding the machine to

work without water.

� All appliances are supplied for use with

natural gas, with LPG conversion jets

OPTIONAL ACCESSORIES

ACCESSORIES MODELS

1 ERGONOMIC BASKET FOR 40L PASTA COOKER 206237 206237 206237 206237

1 SQUARE BASKET FOR 40L PASTA COOKER 206236 206236 206236 206236

2 GN 1/2 BASKETS FOR PASTA COOKERS 927211 927211 927211 927211

2 PANELS FOR SERVICE DUCT (BACK TO BACK) 206202 206202 206202 206202

2 PANELS FOR SERVICE DUCT (SINGLE INST.) 206181 206181 206181 206181

2 SIDE COVERING PANELS FOR TOP-D=900MM 206278 206278 206278 206278

2 SIDE COVERING PANELS H=700 D=900 206134 206134 206134 206134

2 SIDE KICKING STRIPS 206180 206180 206180 206180

2 SIDE KICKING STRIPS F.CONCRETE INSTAL. 206157 206157 206157 206157

3 ERGONOMIC BASKETS FOR PASTA COOKER 206233 206233 206233 206233

3 ROUND BASKETS FOR PASTA COOKERS 927212 927212 927212 927212

3-GN 1/3 BASKETS FOR PASTA COOKERS 927210 927210 927210 927210

4 FEET FOR CONCRETE INSTALLATION 206210 206210 206210 206210

4 WHEELS (2 WITH BRAKE) 206188 206188

6 ROUND BASKETS FOR PASTA COOKERS 927213 927213 927213 927213

CHIMNEY UPSTAND 400MM 206303 206303

CHIMNEY UPSTAND 800MM 206304 206304

DRAUGHT DIVERTER WITH 120 MM DIAMETER 206126 206126

DRAUGHT DIVERTER WITH 150 MM DIAMETER 206132 206132

FALSE BOTTOM FOR 40L PASTA COOKER BASKET 206238 206238 206238 206238

FLUE CONDENSER FOR 1 MODULE DIAM.150MM 206156 206156

FLUE CONDENSER FOR 1/2 MOD. DIAM.120MM 206155 206155

FRONT.KICK.STRIP F.CONCRETE INST.1000 MM 206150 206150 206150 206150

FRONT.KICK.STRIP F.CONCRETE INST.1200 MM 206151 206151 206151 206151

FRONT.KICK.STRIP F.CONCRETE INST.1600 MM 206152 206152 206152 206152

FRONT.KICK.STRIP F.CONCRETE INST.200 MM 206146 206146 206146 206146

FRONT.KICK.STRIP F.CONCRETE INST.400 MM 206147 206147 206147 206147

FRONT.KICK.STRIP F.CONCRETE INST.800 MM 206148 206148 206148 206148

FRONTAL HANDRAIL 1200 MM 206191 206191 206191 206191

FRONTAL HANDRAIL 1600 MM 206192 206192 206192 206192

FRONTAL HANDRAIL 400 MM 206166 206166 206166 206166

FRONTAL HANDRAIL 800 MM 206167 206167 206167 206167

FRONTAL KICKING STRIP 1000 MM 206177 206177 206177 206177

FRONTAL KICKING STRIP 1200 MM 206178 206178 206178 206178

FRONTAL KICKING STRIP 1600 MM 206179 206179 206179 206179

FRONTAL KICKING STRIP 200 MM 206174 206174 206174 206174

FRONTAL KICKING STRIP 400 MM 206175 206175 206175 206175

FRONTAL KICKING STRIP 800 MM 206176 206176 206176 206176

GN 1/1 BASKET FOR PASTA COOKER 927216 927216 927216 927216

GRID SUPPORT FOR ROUND BASKETS 927219 927219 927219 927219

JUNCTION SEALING KIT 206086 206086 206086 206086

LARGE HANDRAIL(PORTIONING SHELF)400 MM 206185 206185 206185 206185

LARGE HANDRAIL(PORTIONING SHELF)800 MM 206186 206186 206186 206186

LEFT SIDE DOOR FOR OPEN BASE CUPBOARD 206195 206195 206195 206195

LID AND LID HOLDER FOR PASTA COOKERS 206190 206190 206190 206190

MATCHING RING FOR FLUE CONDENSER 150DIAM 206133 206133

PAIR OF COVERING STRIPS FOR END ELEMENTS 206234 206234 206234 206234

PRESSURE REGULATOR FOR GAS UNITS 927225 927225 927225 927225

REAR FLUE UPSTAND FOR LARGE CHIMNEY 206160 206160

RIGHT SIDE DOOR FOR OPEN BASE CUPBOARD 206194 206194 206194 206194

SIDE HANDRAIL-RIGHT/LEFT HAND 206165 206165 206165 206165

SUPPORT FOR "BRIDGE" SYSTEM 1000 MM 206138 206138 206138 206138

SUPPORT FOR "BRIDGE" SYSTEM 1200 MM 206139 206139 206139 206139

SUPPORT FOR "BRIDGE" SYSTEM 1400 MM 206140 206140 206140 206140

SUPPORT FOR "BRIDGE" SYSTEM 1600 MM 206141 206141 206141 206141

SUPPORT FOR "BRIDGE" SYSTEM 400 MM 206154 206154 206154 206154

SUPPORT FOR "BRIDGE" SYSTEM 800 MM 206137 206137 206137 206137

SUPPORT FRAME TO HOLD 6 ROUND BASKETS 960644 960644 960644 960644

BACS1 2009-07-03 The Company reserves the right to alter technical specifications without prior notice.

supplied as standard.

� Ease of maintenance guaranteed by

frontal access to all working components.

� All models have right-angled side edges to

allow flush fitting joins between units,

eliminating gaps and possible dirt traps.

� Feet in stainless steel 50 mm adjustables

in height.

� All models can be installed on cantilever

system.

� The special design of the control knob

system guarantees against water infiltration.

� Main connections can be via the base of

NCPG400

200376

NCPG410

200377

NCPG800

200378

NCPG810

200379

the unit.

� All models provided with service duct to

facilitate installation.

� IPX5 water protection.

Productivity (rapid system models)

� Spaghetti 25 kg/h

� Bavette 20 kg/h

� Penne 20kg/h

� Fusilli 15 kg/h

� Tortiglioni 15 kg/h

* In accordance withH regulations for gas models

belonging to class B11 (power over 14kW), it is

necessary to install a chimney (if installed under a

hood) or chimney and draft diverter if the waste gases

are vented directly outside.

ZANUSSI

P R O F E S S I O N A L

www.zanussiprofessional.com

Page 3

GAS PASTA COOKERS

N 900

200376, 200379, 200378, 200377

I

710

50

674

400

0

+0.2

90 400

50 300 400 50

630

B

710

0

800

+0.2

450

C

C B

50

300

B

69

593

900

B

H

124 674 100

900

I

50

H

I

90 400

H

LEGEND

NCPG400

200376

NCPG410

200377

NCPG800

200378

NCPG810

200379

B - Cold water inlet 3/4" 3/4" 3/4" 3/4"

C - Water drain 1" 1" 1" 1"

H - Gas connection 3/4" 3/4" 3/4" 3/4"

I - Electrical connection 230 V, 1N, 50/60 400 V, 3N, 50/60 230 V, 1N, 50/60 400 V, 3N, 50/60

BACS1 2009-07-03 The Company reserves the right to alter technical specifications without prior notice.

ZANUSSI

P R O F E S S I O N A L

www.zanussiprofessional.com

Loading...

Loading...