Page 1

PROFESSIONAL LAUNDRY

Industrial Ironers

IC44819, IC44821, IC44825, IC44828, IC44832 /F-R/FLF

Features and benefits

• Fully electric feeder requiring no compressed air –

regular, silent and smooth work

• Electro-mechanical clamps, automatic linen detection, smooth closing and holding of the linen, smooth

opening and feeding of item

(compensation of the elasticity of the fibres)

• Easy-to-use electronic control panel, RABC

(Risk Analysis and Biocontamination Control –

EN 14065) compatible

• DIAMMS (Direct Ironer Advanced Moisture Management System); Automatic speed adjustment with

moisture sensors to ensure a perfect result

• Spring loaded pressure roll ensures outstanding

ironing quality

• Durable ironing belts made of Nomex

withstand temperatures above 430°F

• Fully encased machine for maximum workplace

safety and energy saving

• Finger guard protection provides additional security

for operators

®

which can

Main specifications

Capacity*, max. water evaporation** gallon/h

Cylinder, diameter (gas/steam) mm

inch

length mm

inch

Ironing speed ft/min

Heating, steam (900 kPa) lb/h

gas Btu/h (kW)

* 50% residual moisture content cotton 6.35 oz/ft2 and 100% cylinder use

(ISO 9398-1).

** El/steam/gas.

Certified in accordance with UL/ETL standards.

• Nickel-plated cylinder prevents rust and improves

lifetime

• Maintenance free ceramic gas burner minimizes

downtimes. 20% more efficient than regular blue

flame burners. A unique and patented burner by

Electrolux

• Return feed, can be installed close to a wall for

maximum space utilisation

• Labour saving automatic Feeding and Length-Folding device (FLF model)

• Automatic Feeding and Rear delivery (F-R model)

• Easy access to all parts for easy maintenance

Main options

• Multi-layer cylinder DubixiumTM for increased

production on gas heated machines

• CMIS (Certus Management Information System)

connection for traceability according to

European Standard EN14065

IC44819 IC44821 IC44825 IC44828 IC44832

15 / 9.3 16.6 / 9.8 19.8 / 12.2 21.4 / 13.5 24.6 / 15.6

479/457 47 9/4 57 479/457 479/4 57 479/45 7

29.5/18 29.5/18 29.5/18 29.5/18 29.5/18

1910 2120 2540 2750 3170

75 3/16 83 7/16 100 108 1/4 124 13/16

4.9-29.5 4.9-29.5 4.9-29.5 4.9-29.5 4.9-29.5

183 203 243 271 311

133100(39) 150100(44) 177400(52) 191100(56) 221800(65)

Page 2

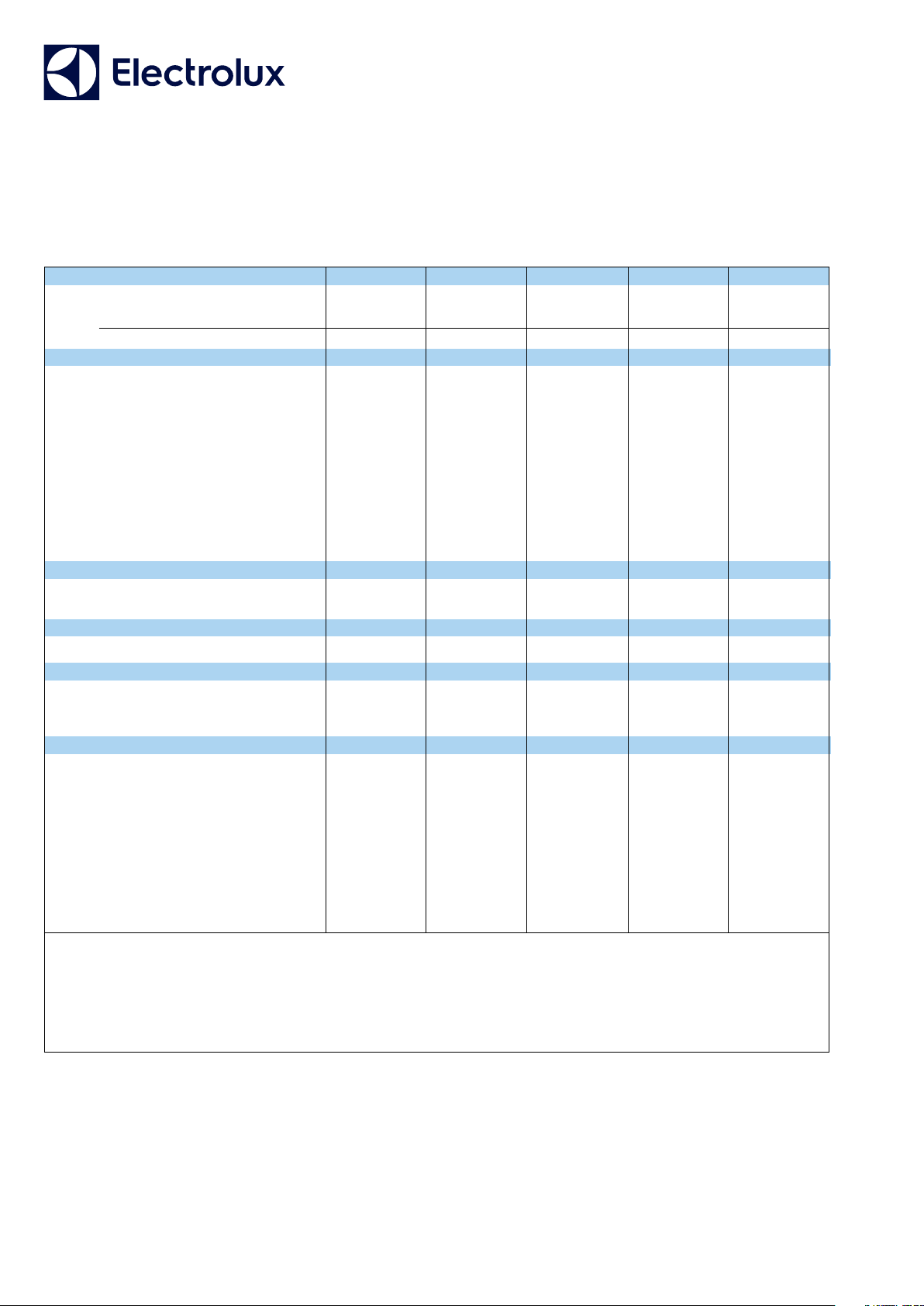

Electrical connections*

IC44819 IC44821 IC44825 IC44828 IC44832

Heating Voltage

Gas, 208-240V 3AC 60 Hz kW(A)

steam 400-415V 3AC 50/60 Hz kW(A)

2 (15) 2 (15) 2 (15) 2 (15) 2 (15)

2 (15) 2 (15) 2 (15) 2 (15) 2 (15)

Steam, gas and air connections

Steam inch

Rec. steam pressure psi

Condensate inch

Gas inch

Gas pressure,

natural gas (G20/G25) psi

propane (G31) psi

Air outlet ø mm/inch

Evacuated air

gas ft

el, steam ft

Pressure drop max. psi

Sound levels

Airborne sound level

dB(A)

3/4 3/4 3/4 3/4 3/4

130 130 130 130 130

3/8 3/8 3/8 3/8 3/8

3/4 3/4 3/4 3/4 3/4

0.29 / 0.36 0.29 / 0.36 0.29 / 0.36 0.29 / 0.36 0.29 / 0.36

0.54 / 0.73 0.54 / 0.73 0.54 / 0.73 0.54 / 0.73 0.54 / 0.73

160 / 6 5/16 160 / 6 5/16 160 / 6 5/16 160 / 6 5/16 160 / 6 5/16

3

/h

28252 29311 33549 34608 35668

3

/h

26133 26133 31077 32489 33902

0.03 0.03 0.03 0.03 0.03

73 73 73 73 73

Heat emission

% of installed power, max.

Shipping data, (F-R model)**

net, kg/lbs

Shipping volume, F-R model m

Dimensions in mm / inch

A Width

B Depth

C Height

D

E F-R model only

F F-R model only

G F-R model only

H

I

K

L

3 3 3 3 3

1170 / 2579 1250 / 2755 1330 / 2931 1395 / 3075 1465 / 3229

3

3

/ft

5.8 / 205 6.2 / 219 7 / 248 7.4 / 261 8.2 / 290

2575 / 101 3/8 2785 / 109 5/8 3205 / 126 3/16 3415 / 134 7/16 3835 / 151

1280 / 50 3/8 1280 / 50 3/8 1280 / 50 3/8 1280 / 50 3/8 1280 / 50 3/8

1460 / 57 1/2 1460 / 57 1/2 1460 / 57 1/2 1460 / 57 1/2 1460 / 57 1/2

1160 / 45 11/16 1160 / 45 11/16 1160 / 45 11/16 1160 / 45 11/16 1160 / 45 11/16

670 / 26 3/8 670 / 26 3/8 670 / 26 3/8 670 / 26 3/8 670 / 26 3/8

800 / 31 1/2 800 / 31 1/2 800 / 31 1/2 800 / 31 1/2 800 / 31 1/2

840 / 33 1/16 840 / 33 1/16 840 / 33 1/16 840 / 33 1/16 840 / 33 1/16

1050 / 41 5/16 1050 / 41 5/16 1050 / 41 5/16 1050 / 41 5/16 1050 / 41 5/16

1910 / 75 3/16 2120 / 83 7/16 2540 / 100 2750 / 108 1/4 3170 / 124 13/16

355 / 14 355 / 14 355 / 14 355 / 14 355 / 14

190 / 7 1/2 190 / 7 1/2 190 / 7 1/2 190 / 7 1/2 190 / 7 1/2

1 Control panel

2 Exhaust connection

3 Steam connection

4 Condensate connection

5 Electrical connection

6 Gas connection

7 Feeder control panel

* Other voltages available, see installation manual.

** Average data. Crated weight/shipping volume depends on configuration.

Please contact logistics for exact measures.

Page 3

W00001

A

17

5

2

H

C

K

6

3, 4

5

17

2

I

L

W00003

B

DE F

G

2

W00002

Front view Right view

Top view

Multi-layer thermal oil DubixiumTM cylinder guarantees smooth operation at all times thanks to zero

overheating of sides.

Maintenance free ceramic gas burner

minimizes downtimes. 20% more efficient than regular

blue flame burners. A unique and patented burner by

Electrolux

Automatic ironing speed adjustment systems DIAMMSTM is

based on real moisture of the items.

Unique and patented.

Page 4

www.electroluxusa.com/professional

Share more of our thinking at www.electrolux.com

Art. No. 438918728/2015.01.14

We reserve the right to alter specifications without notice.

Loading...

Loading...