Page 1

PROFESSIONAL LAUNDRY

Industrial ironers

IC44819FFS, IC44825FFS, IC44832FFS

Features and benefits

• One-person operation from feeding wet items to piles of folded sheets – The optimum in ironing

• 4815mm x 1820mm / 189 9/16 x 71 5/8 inch overall dimensions (IC44832FFS). The most compact of its kind on the

market

• One station automatic feeding with electro-mechanical clamps and standard vacuum table for a smooth and

efficient quality feeding

• Standard touch screen control with text free operating mode for optimum user friendliness

TM

• Standard multi-layer thermal oil Dubixium

electric and gas heated versions. This allows up to 20% increase in production compared to traditional cylinders

• Standard automatic ironing speed control system DIAMMS

operator. This unique feature guarantees you with a perfectly dry linen regardless of operators skill

• Maintenance free ceramic gas burner increases reliability while minimizing production disruption and gas

consumption (up to 20%). Unique and patented feature

• Standard stand-by and sleeping modes for optimum energy savings

• Spring loaded pressure roll ensuring outstanding ironing quality

®

• Durable ironing belts in Nomex

• Finger guard protection provides optimum safety for operators

• Versatile stacker for delivery of linen stacks to the front or the rear of the machine

withstanding temperatures above 200˚C / 392˚F for optimum quality and safety

cylinder guarantees zero overheating of cylinder sides on

TM

allows optimum productivity by any

Main options

• Fully integrated air compressor for autonomous operations and faster installation

• Cancellation of stacker for delivery of folded linen onto a conveyor

• CMIS connection for traceability according to European Standard EN14065 on RABC quality approach

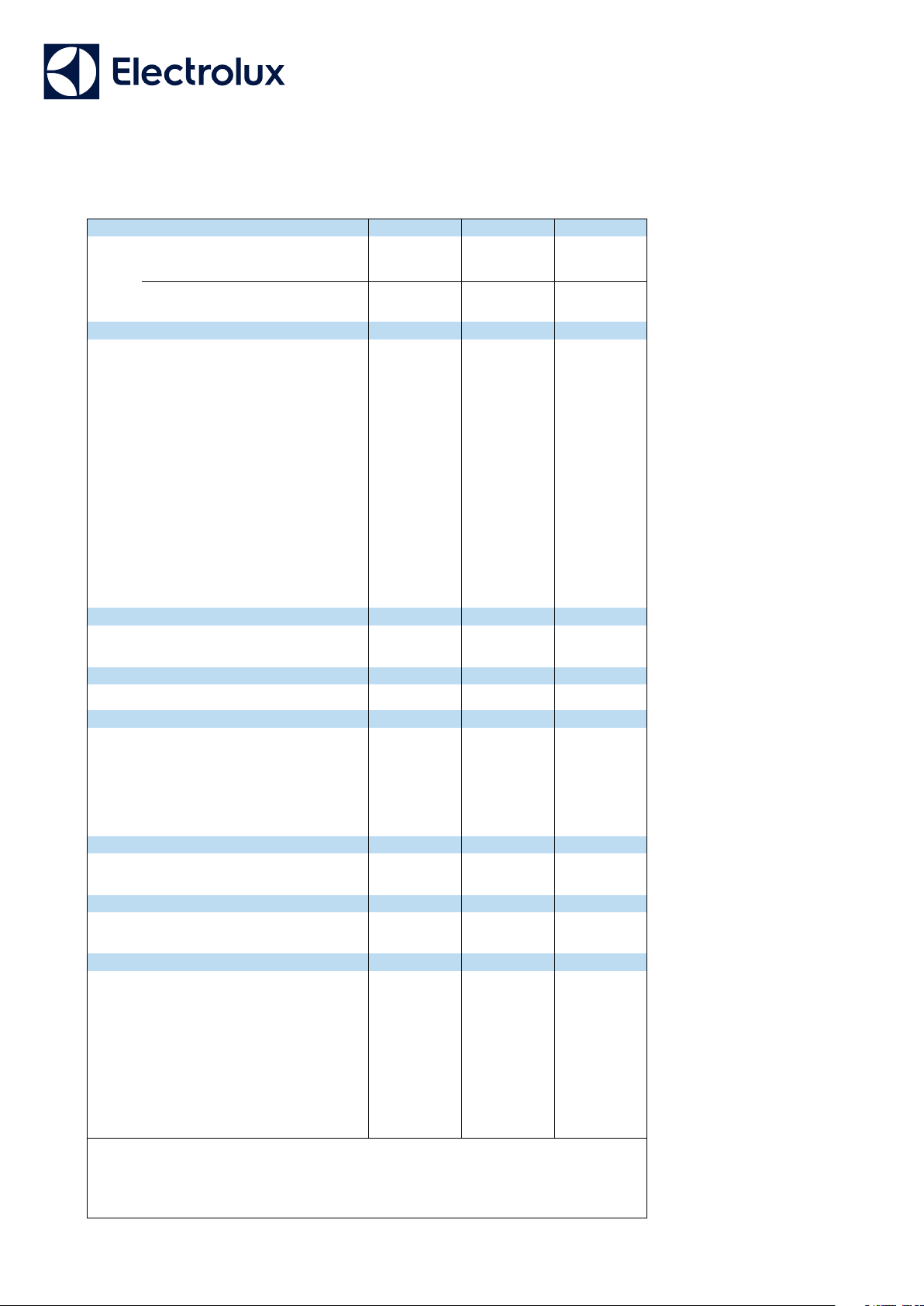

Main specifications

Capacity*, max. water evaporation** l/h

gallon/h

Cylinder, diameter (electricity, gas/steam) mm

inch

length mm/inch

Ironing speed ft/min

Heating, electricity kW

steam (130 psi) lb/h

gas Btu/h (kW)

* 50% residual moisture content cotton 6.35 oz/ft2 and 100% roller utilization (ISO 9398-1).

** El/steam/gas.

IC44819FFS IC44825FFS IC44832FFS

38/57/35 48/75/46 59/93/59

10/15/9.2 12.7/19.9/12.2 15.6/24.6/15.6

479/457 479/457 479/457

18 7/8 / 18 18 7/8 / 18 18 7/8 / 18

1910 / 75 3/16 2540 / 100 3170 / 124 13/16

4.9-36 4.9-36 4.9-36

33 44 54

183 243 311

133100 (39) 177400 (52) 221800 (65)

Page 2

Electrical connections

IC44819FFS IC44825FFS IC44832FFS

Heating Voltage

El 208-240V 3AC 60 Hz kW(A)

Gas,

steam 208-240V 3AC 60 Hz kW(A)

35.7 (63) 46 (80) 56.8 (100)

2.9 (15) 2.9 (15) 3.2 (15)

Steam, gas and air connections

Steam inch

Rec. steam pressure psi

Condensate inch

Gas inch

Gas pressure,

natural gas (G20/G25) psi

kPa/WC inch

propane (G31) psi

kPa/WC inch

Air outlet ø mm/inch

Evacuated air

gas ft

el, steam ft

Pressure drop max. psi/WC

Compressed air mm

inch

Rec. air pressure psi

3/4 3/4 3/4

130 130 130

3/8 3/8 3/8

3/4 3 /4 3/4

0.29/0.36 0.29/0.36 0.29/0.36

2/8 2/8 2/8

0.54/0.73 0.54/0.73 0.54/0.73

3.7/14.9 3.7/14.9 3.7/14.9

160 / 6 5/16 160 / 6 5/16 160 / 6 5/16

3

28252 33549 35668

/h

3

26133 31077 33902

/h

0.03/0.830404 0.03/0.830404 0.03/0.830404

6/8 6/8 6/8

1/4 / 5/16 1/4 / 5/16 1/4 / 5/16

80-100 80-100 80-100

Sound levels

Airborne sound level

dB(A)

65 65 65

Heat emission

% of installed power, max.

Shipping data**

Ironer mass net, kg/lbs

crated, kg/lbs

Shipping volume, ironer m

Stacker mass net, kg/lbs

crated, kg/lbs

Shipping volume, stacker m

3 3 3

1405/3097 1545/3406 1715/3781

1700/3748 1890/4167 2075/4575

3

3

7.6/268.4 9.2/325 10.7/378

/ft

175/386 175/386 175/386

345/761 345/761 345/761

3

3

2.9/102.4 2.9/102.4 2.9/102.4

/ft

Dimensions for automatic feeding

Minimum mm/inch

Maximum mm/inch

1100 / 43 5/16 1100 / 43 5/16 1100 / 43 5/16

1910 / 75 3/16 2540 / 100

Dimensions for automatic folding

Minimum mm/inch

Maximum* mm/inch

Dimensions in mm/inch

A Width

B Depth

C Height

D

E

F

G

H

J

K

900 / 35 7/16 900 / 35 7/16 900 / 35 7/16

3500 / 137 13/16 3500 / 137 13/16 3500 / 137 13/16

3555 / 139 15/16 4185 / 164 3/4 4815 / 189 9/16

1820 / 71 5/8 1820 / 71 5/8 1820 / 71 5/8

1590 / 62 5/8 1590 / 62 5/8 1590 / 62 5/8

2575 / 101 3/8 3205 / 126 3/16 3835 / 151

980 / 38 9/16 980 / 38 9/16 980 / 38 9/16

1090 / 42 15/16 1090 / 42 15/16 1090 / 42 15/16

1030 / 40 9/16 1030 / 40 9/16 1030 / 40 9/16

675 / 26 9/16 675 / 26 9/16 675 / 26 9/16

90 / 3 9/16 90 / 3 9/16 90 / 3 9/16

500 / 19 11/16 500 / 19 11/16 500 / 19 11/16

1 Control panel

2 Exhaust connection

3 Steam connection

5 Electrical connection

6 Compressed air connection

7 Gas connection

4 Condensate connection

* Recommended for most textiles. May vary depending on textile thickness and nature.

** Average data. Crated weight/shipping volume depends on configuration.

Please contact logistics for exact measures.

3170 / 124 13/16

Page 3

Right side view

Front view

Top view

Production in items per hour Textile quality RM*

Electric/Gas

50/50 polyester-cotton sheet,

3000 x 1800 mm / 118 1/8 x 70 7/8 inch 140 gr/m

50/50 polyester-cotton sheet,

2900 x 2400 mm / 114 3/16 x 94 1/2 inch 140 gr/m

100% cotton sheet,

3000 x 2800 mm / 118 1/8 x 110 1/4 inch 160 gr/m

100% cotton table cloth,

2000 x 1500 mm / 78 3/4 x 59 1/16 inch 260 gr/m

Production in items per hour Textile quality RM*

Steam (9 bar)

50/50 polyester-cotton sheet,

3000 x 1800 mm / 118 1/8 x 70 7/8 inch 140 gr/m

50/50 polyester-cotton sheet,

2900 x 2400 mm / 114 3/16 x 94 1/2 inch 140 gr/m

100% cotton sheet,

3000 x 2800 mm / 118 1/8 x 110 1/4 inch 160 gr/m

100% cotton table cloth,

2000 x 1500 mm / 78 3/4 x 59 1/16 inch 260 gr/m

* RM: Residual Moisture before ironing

Above production figures correspond to the machine capacity.

They can vary with the efficiency of the operator and are achieved with 300 mm / 11 13/16 inch between items at feeding.

IC44819FFS IC44825FFS IC44832FFS

2

110 110 160

35%

2

- 115 135

35%

2

- - 80

50%

2

62 80 80

55%

IC44819FFS IC44825FFS IC44832FFS

2

110 110 200

35%

2

- 115 155

35%

2

- - 95

50%

2

75 95 95

55%

Page 4

Multi-layer thermal oil DubixiumTM cylinder guarantees smooth operation at all times thanks to zero

overheating of sides.

Automatic ironing speed adjustment systems DIAMMSTM is

based on real moisture of the items.

Unique and patented.

www.electroluxusa.com/professional

Share more of our thinking at www.electrolux.com

Art. No. 438903518/2015.01.14

We reserve the right to alter specifications without notice.

Loading...

Loading...