Page 1

820 41 70 0412 91110

GB

F

E

USER

USER

s MANU

s MANU

AL

AL

FCW 200

FCW 300

VACCINE/ ICEPACK CHEST FREEZER

Page 2

2

USER MANUAL

VACCINE/ ICEPACK CHEST FREEZER

* FCW 200

** FCW 300

Page 3

3

INDEX

1. GENERAL INFORMATION ..................................................................................................page 4

2. INSTALLATION ....................................................................................................................page 5-8

3. HOW TO USE.......................................................................................................................page 8-10

4. DEFROSTING & CLEANING ...............................................................................................page 10-11

5. PERIODIC OBSERVATIONS/CHECKS/ACTIONS............................................................page 12

6. TROUBLE SHOOTING ........................................................................................................page 13-14

(A) The appliance is not working

(B) Compressor is working, but cabinet temperature is higher than normal

(C) Abnormal noise in the appliance

7. SHUTTING DOWN...............................................................................................................page 14

8. STORAGE OF VACCINES AND ICEPACKS IN THE APPLIANCE ...................................page 14

Page 4

4

1. GENERAL INFORMATION

PRODUCT DESCRIPTION

The appliance is a vaccine and icepack chest freezer

designed for storage and freezing of vaccine and

icepacks for medical use mainly at high ambient

temperatures. The freezer runs by compressor

230V/50Hz electrical power with refrigerant R134a

and insulated with polyurethane foam with

cyclopentane.

The appliance is built with a compartment for vaccine

load and a smaller fast freeze compartment for

icepack freezing. The refrigerators performance and

inside temperature are controlled by a thermostat.

THERMOMETER

To enable to measure the temperature inside the

cabinet without opening the lid, a thermometer is

provided with its dial on the front side. This makes

monitoring of the vaccine temperature easy.

LOCKING SYSTEM

The appliance is equipped with a lock, operated with

a key.

POWER-SUPPLY

ARRANGEMENT

For smooth functioning of the appliance it is

advisable to connect the same to a 15 Amps power

plug socket outlet, wired from the mains with PVC

insulated cables of minimum 2.5 mm

2

section of

Aluminium (see also page 2 under `Installation').

The larger size of the plug and socket decreases

the contact resistance which in turn reduces

voltage drop and provides an easy path for the

current.

Safety of the personnel and the equipments can not

be guaranteed unless the earth wire (green/yellow)

of the cord is really earthed. It is advisable to have

the earth connections to the socket checked by a

competent electrician.

Page 5

5

2. INSTALLATION

Check the manufacturer's plate at the back of the

appliance and make sure that the appliance has

correct voltage for local supply, i.e. 230 volt (fig. 1 ).

If you have received equipments of wrong voltage

ratings, notify concerned authorities and keep the

equipments repacked.

The appliance is to be installed in a well ventilated

room, avoiding direct sunshine or any other source of

heat. Power supply socket (15 amps socket with

switch, fuse and mains indicator lamp is advisable)

should be available nearest to the place of installation

of the appliance.

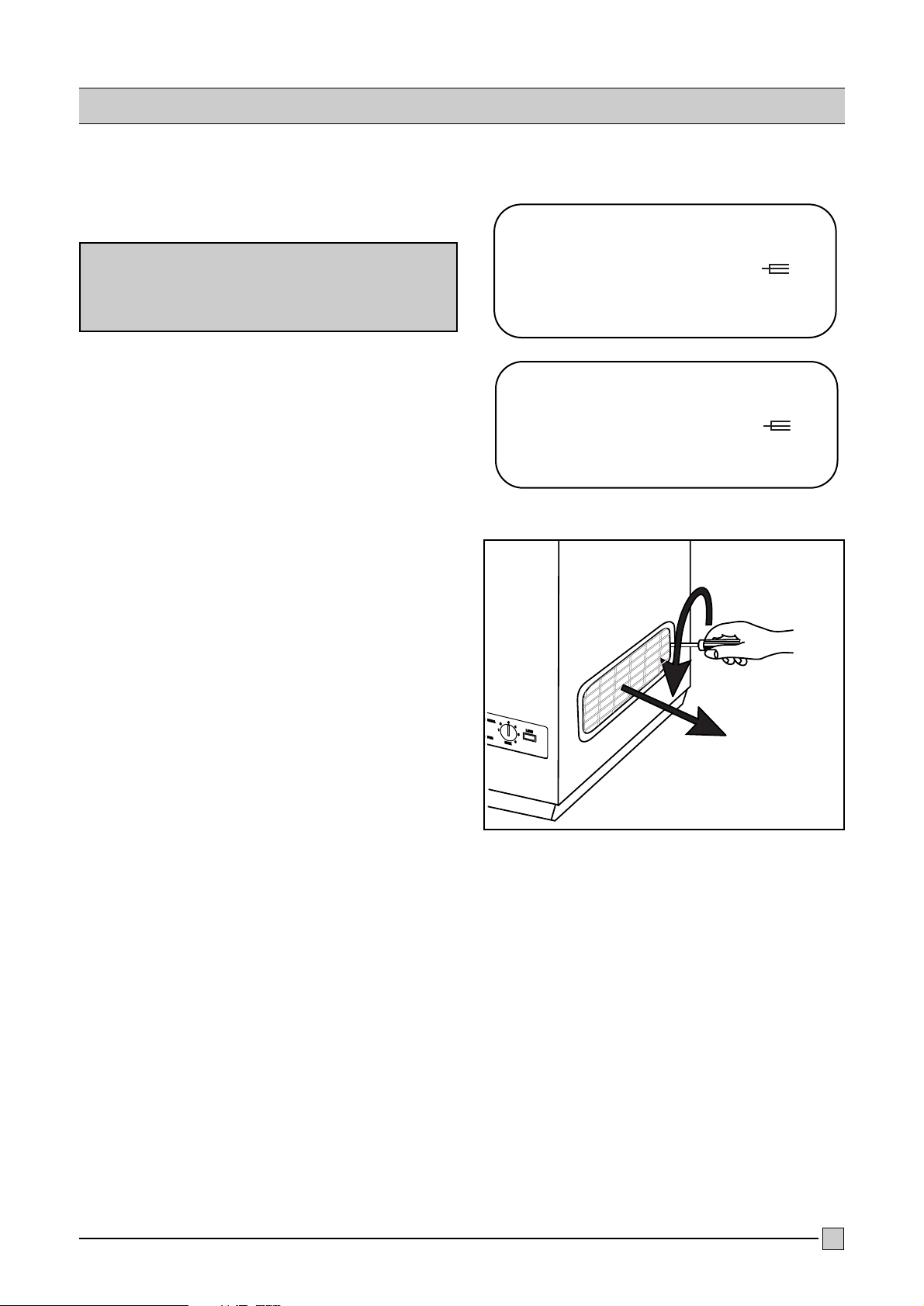

1.

Unscrew and remove the screws holding the plastic

grid of the compressor compartment on the right hand

side of the appliance and remove carefully the grid

(fig. 2)

CAUTION:

Connecting the equipment to wrong supply

voltage may damage it.

MOD. FCW 200 CLASS T

PROD. NO 9206651-01 SERIE NO 12345678

230-240 V ~50 Hz 110W 13A

VOL: GROSS 193 L

R 134a 0,120 kg

MOD. FCW 300 CLASS T

PROD. NO 9206031-01 SERIE NO 12345678

230-240 V ~50 Hz 140W 13A

VOL: GROSS 335 L

R 134a 0,156 kg

Fig 1.

Fig 2.

Page 6

6

2. INSTALLATION

2.

EXAMINE the compressor compartment (fig. 3).

Check carefully for any damage, dislocation or

looseness etc. of the components, specially at

locations A, B and C as below and rectify if necessary.

LOCATION A (fig. 4)

Check that all 4 mounting brackets of the compressor

are in place and secured.

LOCATION B (fig 5)

Check that the incoming electrical connections of the

power supply cord to the terminal strip are tight.

Fig 3.

Fig 4.

Fig 5.

Page 7

7

2. INSTALLATION

LOCATION C (fig. 6)

Check that the outgoing electrical connections from

the terminal strip are tight.

3.

Refit side cover of the compressor compartment into

position refixing the screws holding the side cover

(fig. 7)

4.

INSTALL firmly the appliance on a level floor,

preferably on wooden blocks or on a wooden platform

to protect it from damp and dirt. (fig. 8)

Leave sufficient space on all sides

of the appliance, keep it away from

the walls for good circulation of air

around it, see below:

Back and left side should be

minimum 3 cm away from the walls

(fig. 8a)

Hinges can be pushed against the

wall.

Right side should be minimum 10

cm away from the wall (fig. 8b)

5.

The appliance has 4 supporting

legs. If the appliance is not in a

level and stable position, adjust this

by adding wooden blocks or similar

under the legs.

Fig 6.

Fig 7.

Fig 8.

Fig 8b.

Fig 8a.

Page 8

8

2. INSTALLATION

6.

Connect the leads of the power supply cord to a

suitable 3-pin plug as shown below (fig. 9)

Lead of cord Pin of plug

Green/yellow Earth

Blue Neutral

Brown Phase

NOW THE APPLIANCE IS READY TO START

1.

Install and prepare the appliance as detailed under

`Installation' in the previous chapter.

2.TEMPERATURE CONTROL

The thermostat ensures that the required temperature

is maintained in the freezer. Adjust the temperature by

turning the button with a coin that fits the groove.

Turning the thermostat button towards no. 7 makes

the temperature in the freezer colder, and turning the

button towards no. 1 makes the temperature

warmer. The inner temperature must not be lower than

-15 °C.

3. HOW TO USE

Fig 9.

Fig 10.

Page 9

9

3. HOW TO USE

3. CONTROL PANEL

The green light is illuminated as long as the freezer is

connected.

The yellow light is illuminated when the Super button

is depressed.

The red light is illuminated when the temperature in

the freezer is higher than the thermostat setting.

The red alarm light can be due to:

Insertion of a large amount of vaccine/icepack. The

red alarm light will go out after a while.

Opening the lid too long. The red alarm light will go out

after a while.

A defect in the system. See under TROUBLE

SHOOTING

4. OPENING/CLOSING THE LID

The lid is fitted with a tightly closing sealing strip to

prevent moisture getting inside the freezer and

increasing the amount of frost formed. When the lid is

opened the air inside the freezer becomes slightly

warmer and expands. As soon as the lid is closed

again the air is cooled immediately. This may lead to

the creation of a vacuum which makes it hard to open

the lid immediately after it has been closed. This is

quite normal. Wait a few minutes until the vacuum has

disappeared, then open the lid by pulling gently.

Never pull the handle violently.

5.

Allow the appliance to run. The temperature inside the

cabinet will be indicated on the thermometer on the

front side. Observe the temperature from time to time

(fig.12)

6.

Initially the temperature inside the appliance will be

similar to, or slightly below, the room temperature. It

should decrease slowly and should remain steady

within a small range, after 1-3 days, depending upon

different conditions.

Green light

SUPER button

Yellow light

Thermostat button

Red alarm light

Fig 11.

Fig 12.

Page 10

10

3. HOW TO USE

7.

If the cabinet temperature does not reach the required

low level of 2-3 days, the freezer-thermostat setting

can be increased to a higher setting by turning its

knob clockwise.

8.

After storing the vaccines, keep the lid properly closed

and locked (fig. 13).

DEFROSTING & CLEANING

The moisture in the air, which enters the appliance

due to lid opening (and also may be due to defective

lid-gasket or door alignment) is attracted by the cold

surfaces inside the appliance. So, formation of frost

and ice occurs on the walls. When the frost layer is 1

/4" to 1 /2" (6-12 mm) thick, it is time for `defrosting'

the appliance.

MOST IMPORTANT:

Before defrosting the appliance, the vaccines

preserved in it will have to be removed and stored

temporarily in other working freezer.

If a second appliance is not available, the vaccines will

have to be preserved in Cold-Box or Vaccine carrier,

properly lining the same with frozen ice packs, such

that the vaccine temperature remains within the

recommended storage temperature during the

defrosting of the appliance.

DEFROSTING & CLEANING

PROCEDURE

1.

Switch OFF the power supply to the appliance and

remove the plug of its power supply cord from the wall

socket.

2.

Prepare the temporary storage and transfer the

vaccines and preserve them properly with care.

4. DEFROSTING & CLEANING

Fig 13.

Page 11

11

4. DEFROSTING & CLEANING

3.

Open the drainage plug at the bottom, inside the

cabinet.

Keep a suitable container under the drain hose to

collect the defrost water (fig. 14).

4.

Keep the lid open and allow the frost to melt

completely.

Never use any heat source other than hot water to

speed up defrosting.

Never use any sharp-edged instrument for removing

frost or for cleaning the liner etc.

5.

Clean the appliance carefully as below,

a) Wash all parts inside the cabinet with warm water

and mild detergent.

b) Clean the lid and the lid seal (gasket) similarly. After

the rubber seal (gasket) is wiped and dried, it

should be rubbed with unscented talcum powder

(or French chalk) specially on the hinge side.

c) Clean the outside of the appliance, also with warm

water and mild detergent.

6.

Allow the cleaned parts to dry completely.

7.

Reset the drain plug at its position at the bottom.

8.

Close the lid. Connect the power supply plug to the

wall socket.

9.

Allow the appliance to run and observe the cabinet

temperature on the thermometer.

10.

Put back the vaccines into the appliance from the

temporary storage, only when the appliance has

attained safe recommended temperature range for

storage of the vaccines.

Fig 14.

Page 12

DAILY

1. Take temperature readings from the thermometers

and note down the temperature and the time of

reading.

Keep the temperature records systematically. It is

suggested that minimum 2 readings should be

taken (in the morning and afternoon) preferably at

the same hours of each day.

If the temperature is observed to be below or

above the required range, adjust the thermostat

(see Action 2 on page 8) by steps, allow the

appliance to run for about one hour under

observation. If required, adjust the thermostat

further until the required temperature range is

obtained.

To make the inside colder, the thermostat knob is

to be turned clockwise to a higher setting.

To make the inside warmer, the thermostat knob is

to be turned anti-clockwise to a lower setting.

2. Clean the exterior of the appliance with a clean dry

cloth.

WEEKLY

1. Examine the inner compartment and see if frost

formation is more than 1 /4" (6 mm). If so,

DEFROST the appliance as described earlier (see

page 10).

If it is observed that Defrosting is required to be

done each week:

a) Examine the rubber seal on the lid, if it sits

properly. Any gap between the cabinet and seal

can be checked by placing a visiting card between

them. The card should resist being pulled out

freely. If the card can be pulled out freely, there

exists a gap. Such gap will allow outside air to go

in and form frost early. In such cases the lid should

be adjusted or the seal should be changed.

b) Restrict and reduce frequency of opening the

appliance. Open only when absolutely necessary.

MONTHLY

1. Clean the compressor compartment:

a) Put off the switch, if any, and take out the plug from

the wall socket.

b) Take out the plastic grid of the compressor

compartment (see page 5, actions 1 ). Clean the

interior of the compressor compartment with a

soft brush.

c) Check the mounting brackets of compressor, if

they are tight. If not, rectify.

d) Fit back the plastic grid (see page 7, actions 3)

2. Clean the lid seal (see page 11, action 5b).

3. If possible, put a standard mercury thermometer

inside the cabinet and compare the readings

with those of the dial thermometers and see if

they are correct.

Dial thermometers with incorrect readings may have

to be re-adjusted or replaced, as incorrect readings

may lead to wrong storage temperature and loss of

the potency of the vaccines preserved.

5. PERIODIC OBSERVATIONS / CHECKS / ACTIONS

12

Page 13

13

IMPORTANT:

When an appliance is found to be not working at all or

not working properly, see that the vaccine

temperature is within the recommended limits.

Do not open the lid unless very essential.

Observe temperature from time to time and if you feel

that temperature may exceed the higher limit before

the appliance is repaired - transfer the vaccines to

other working appliance/refrigerator or cold-box.

For any abnormal sound, smoke, smell etc. in the

appliance disconnect the plug from the wall socket

and notify refrigerator technician.

A) THE APPLIANCE IS NOT

WORKING

1. Observe the green mains-on indicator light on

right on the front panel.

IF NOT GLOWING

I) Check if wall socket switch is OFF

II) Check if power supply is available at the wall

socket. This can be tested by connecting an

electric lamp or other appliances to the socket.

The lamp should glow or the appliances should

work, if supply is available at the socket.

If not available:

There may be some defect in the power supply circuit

(viz: blow-off fuse, loose connections, faulty switch or

socket, single phasing etc.) which should be rectified

through competent Electrical Maintenance

Technicians.

If power is available at the socket:

III) Check that the plug is inserted properly into the

socket.

IV) Check the plug for loose connection or

dislocation of power supply cable connections -

rectify if required.

V) Remove the plug from socket. Check the

incoming and outgoing cable connections on

the terminal strip in the compressor

compartment (see page 6, actions 2B and 2C)

VI) Even after actions as above, the green lamp is

not glowing - Notify Refrigerator Technician.

B) COMPRESSOR IS WORKING,

BUT CABINET TEMPERATURE

IS HIGHER THAN NORMAL

NOTE:

The cabinet temperature may go little higher than

normal, but should come down after some time

when:

New vaccines are stored

The lid is opened frequently or kept open for

longer duration

Unfrozen ice packs are put in for freezing.

1.

Check if recommended space is left on back and

sides of the appliance for air circulation (see page

7, action 4).

2.

Check if there is too much frost formation in the

liner chamber on the inside walls. If so, defrost (see

page 10 for Defrosting and Cleaning)

3.

Check if the compressor is cut off by the

thermostat before required temperature is attained.

If so, adjust thermostat setting (see page 8, action

2).

4.

If the compressor is observed to be running

continuously but no cooling is attained - this may be

due to leakage of refrigerant gas from the system or

defect in the unit, - Notify Refrigerator Technician.

5.

Check if the compressor tries to start but trips-off

early by the over-load protector. This may be either

due to too low supply voltage or defect in the

compressor or starting relay - put `off' the

appliance till return of normal voltage and try to run

once again. If the defect prevails, - Notify

Refrigerator Technician.

6. TROUBLE SHOOTING

Page 14

C) ABNORMAL NOISE IN THE

APPLIANCE

In case of any abnormal noise coming out from the

appliance, try to locate the source of the noise.

Generally it may come from the compressor

compartment. In such cases,

1. Take out the plug of the appliance from socket and

open the plastic grid of the compressor

compartment (see page 5, actions 1 )

2. Examine if the mounting brackets of the

compressor are in place and secure, and if the

mounting bolts for the fan are tight. If required

replace broken or lost brackets and tighten loose

bolts (see page 6 & 7, fig. 4 & 6)

IF THE APPLIANCE IS TO BE

SHUT DOWN FOR

TRANSPORTATION ETC.

Disconnect the power-supply plug from socket

Defrost and clean the interior

Leave the lid open till the appliance is absolutely dry

Roll the power supply cord into a coil and bind and

place it carefully to avoid damage

3. Check if any pipe or component has come out of

its position and also touching others. !f so,

rectify carefully.

4. Check if the appliance is level and firm on its

base. If not, rectify.

5. Even after actions as above if it is observed that

the noise is still present or it is coming from the

inside of the compressor - Notify Refrigerator

Technician.

FOR STORING VACCINES

1. Keep the packets containing the vaccines in neat

rows,

2. Different vaccines should be kept separately to

facilitate easy identification.

3. Keep about 2 cm space between rows for

circulation of air.

4. Keep a separate thermometer among the vaccines

to ascertain the actual vaccine temperature.

6. TROUBLE SHOOTING

7. SHUTTING DOWN

8. STORAGE OF VACCINE AND ICEPACKS IN APPLIANCE

14

Page 15

FCW 200 VACCINE LOADING

Vaccine storage capacity 144 litre

Vaccine storage capacity 264 litre

FCW 200 ICEPACK LOADING

FCW 300 ICEPACK LOADING

Maximum icepack freezing with vaccine

7,2 kg/24hour

Maximum icepack freezing with vaccine

7,2 kg/24hour

Maximum icepack freezing without vaccine

22,8 kg/24hour

Maximum icepack freezing without vaccine

13,2 kg/24hour

FCW 300 VACCINE LOADING

15

Page 16

Printed by Xerox Hungary Ltd. 2003. 02. 12<None>.

Loading...

Loading...