Electrolux EIFLS55IIW0, EIFLS55IMB0, EIFLS55IRR0, EIFLW50LIW0, EIFLW55HIW0 Installation Guide

...Page 1

|nsta||afion |nstrucfions

Electro[u× Fro_t-Load Washer

lnstrucciones de lnsta|acion

[__avadora de carga fro_tal Electro[ux

Instructions d'insta||afion

Laveuse _ chargeme_lt fro_ta[ E[ectro[ux

Page 2

Finding Information

Please read and save this guide

Thank you for choosing Electrolux, the new premium brand in home appliances. These Installation

Instructions are part of our commitment to customer satisfaction and product quality throughout the life

of your new appliance.

We view your purchase as the beginning of a relationship. To ensure our ability to continue serving you,

please use this page to record important product information.

Keep a record for quick reference

Purchase date

Electrolux model number

Electrolux serial number

For toll-free telephone support in the U.S. and Canada: 1-877-4ELECTROLUX {1-877-435-3287)

For online support and product information visit http://www.electroluxappliances.com

Table of contents

Finding information ......................................................... 2

SAFETY .......................................................................... 3

• Pre-installation requirements ...................................... 3

Installation requirements ............................................. 4-9

Electrical system requirements ................................... 4

Grounding requirements ............................................. 4

Water supply requirements ......................................... 4

Drain system requirements ......................................... 4

Clearance requirements .............................................. 5

installed dimensions ................................................... 6

Unpacking washer ....................................................... 7-8

Removing foam packaging ......................................... 7

Removing shipping hardware ..................................... 8

Installing hole plugs .................................................... 8

Installation instructions .............................................. 9-12

Leveling your washer .................................................. 9

Connecting inlet water .............................................. 10

Connecting drain & electrical ................................... 11

Performing installation cycle .................................... 12

Reversing door ........................................................ 13-18

Options ......................................................................... 19

Accessories .............................................................. 19

Replacement parts ................................................... 19

Notes ............................................................................ 20

©2008 Electrolux Major Appliances All rights reserved.

Page 3

[mpoAant Safety Instructions

Recognize safety symbols, words and

labels

Safety items throughout this manual are labeled

with a WARNING or CAUTION based on the risk

type as described below:

Safety

WARNING situations that may cause

This symbol alerts you to

serious body harm, death

or property damage.

This symbol alerts you to

CAUTION

situations that may cause

bodily injuryor property

damage.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Clear the room, building or area of all occu-

pants.

Immediately call your gas supplier from a neigh-

bor's phone. Follow the gas supplier's instruc-

tions.

If you cannot reach your gas supplier, call the

fire department.

Preoinsta[[ation requirements

Tools and materials needed for installation:

OR OR OR

Universal wrench

supplied wkh

washer

Adjustable 3/8" or 10 mm

wrench box wrench

Ratchet and

socket set

Save these instructions

for future reference.

AND

Adjustable

plbrs

AND

Carpenter's level

Page 4

Installation Requirements

E ectrica system requirements

CIRCUIT - Individual, properly polarized and

grounded 15 amp. branch circuit fused with 15

amp. time delay fuse or circuit breaker.

POWER SUPPLY - 2 wire, with ground, 120 volt

single phase, 60 Hz, Alternating Current.

supply cord having an equipment-grounding

conductor and a grounding plug, the plug

MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and

grounded in accordance with all local codes and

ordinances or in the absence of local codes,

with the National Electrical Codes, ANSI/NFPA

70 (latest edition). If indoubt, call a licensed

electrician. DO NOT cut off or alter the grounding

prong on the power supply cord. In situations

where a two-slot receptacle is present, it is

the owner's responsibility to have a licensed

electrician replace it with a properly grounded

three prong grounding type receptacle.

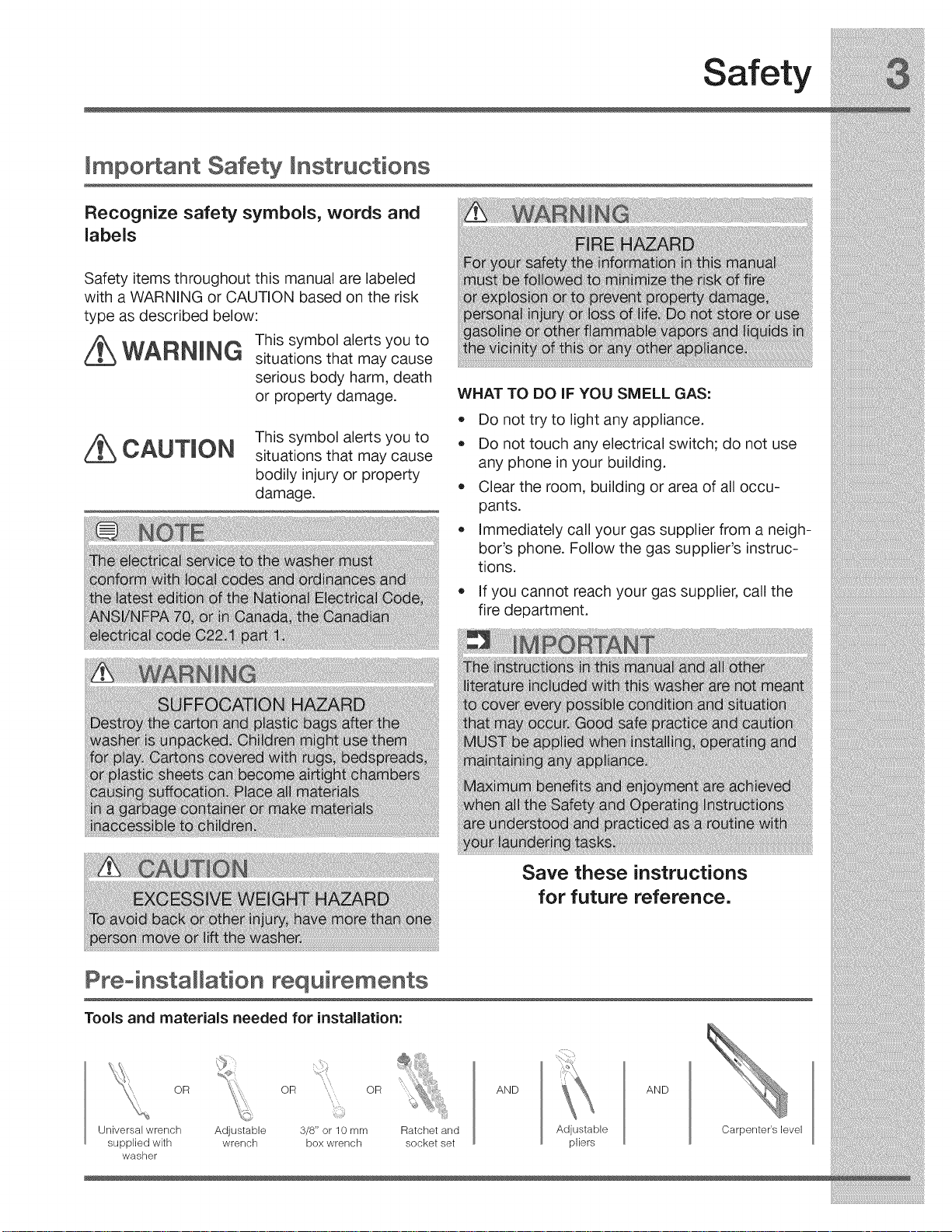

OUTLET RECEPTACLE - Properly grounded

3-prong receptacle to be located so the power

supply cord is accessible when the washer is in

an installed position.

Groul

wall

Donot, under "_

anycircumstances, |

cut, remove, /

or bypassthe |

grounding prong, j)

Powercordwith

Grounding requirements

Water supply requirements

Hot and cold water faucets MUST be installed

within 42 inches (107 cm) of your washer's water

inlet. The faucets MUST be 3/4 inch (1.9 cm) with

threading for laundry hose connection. Water pres-

sure MUST be between 30 and 120 psi. Pressure

difference between hot and cold cannot be more

than 10 psi. Your water department can advise you

of your water pressure.

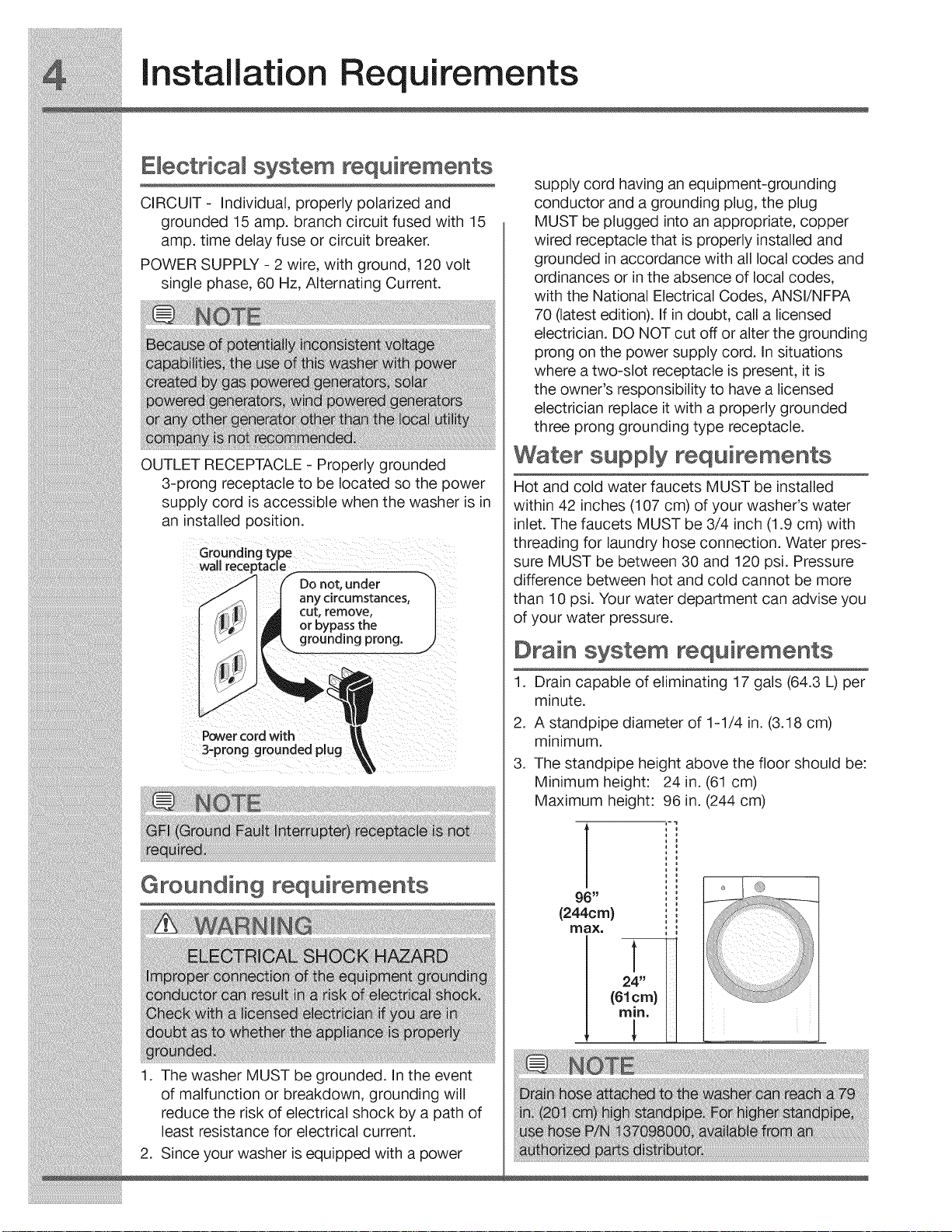

Drain system requirements

1. Drain capable of eliminating 17 gals (64.3 L) per

minute.

2. A standpipe diameter of 1-1/4 in. (3.18 cm)

minimum.

3. The standpipe height above the floor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm)

96 _

(244cm)

[lrlax.

1. The washer MUST be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electrical shock by a path of

least resistance for electrical current.

2. Since your washer is equipped with a power

(61 C/r I)

mln" m

Page 5

Installation Requirements

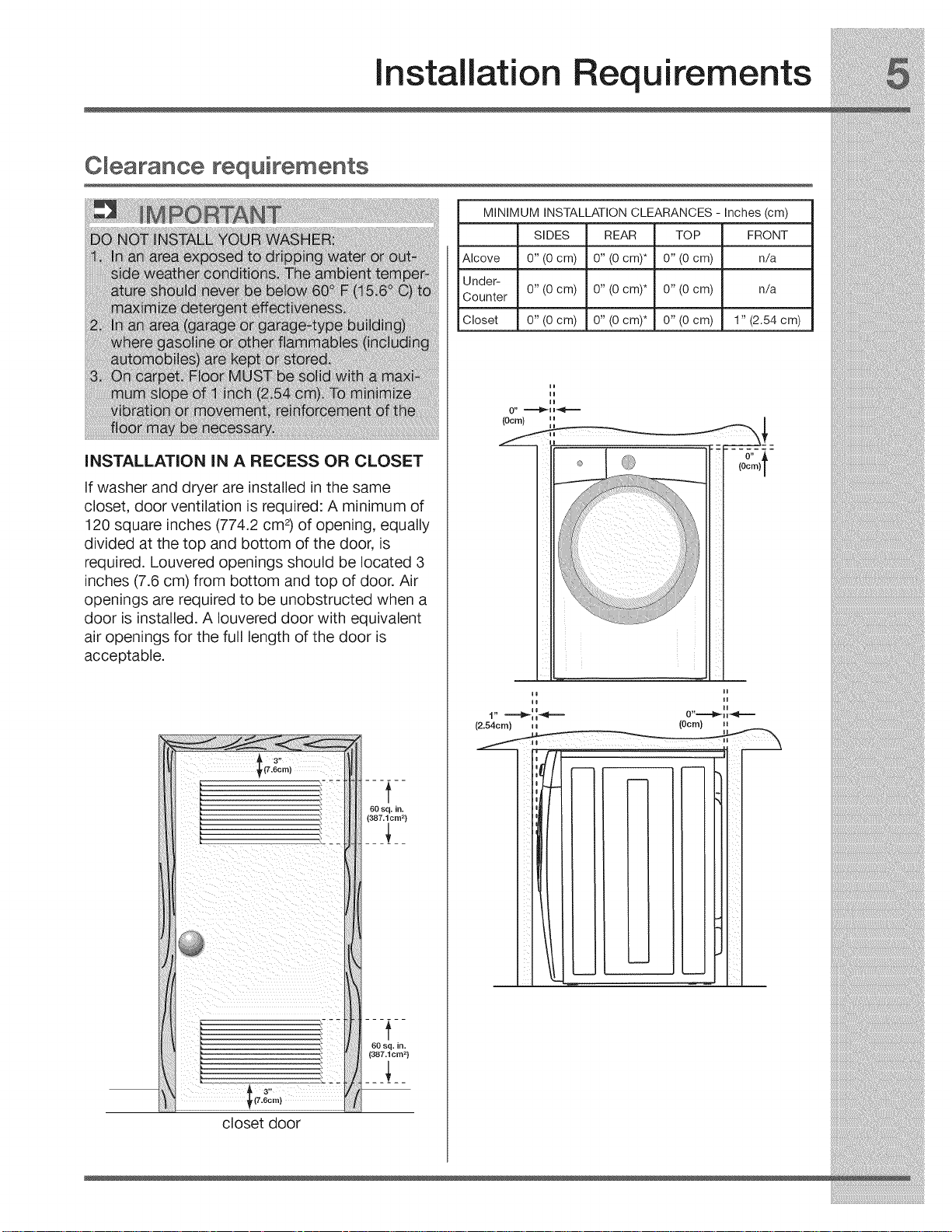

Clearance requirements

iNSTALLATiON iN A RECESS OR CLOSET

If washer and dryer are installed in the same

closet, door ventilation is required: A minimum of

120 square inches (774.2 cm 2)of opening, equally

divided at the top and bottom of the door, is

required. Louvered openings should be located 3

inches (7.6 cm) from bottom and top of door. Air

openings are required to be unobstructed when a

door is installed. A Iouvered door with equivalent

air openings for the full length of the door is

acceptable.

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Under-

Counter 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Closet 0" (0 cm) 0" (0 cm)* 0" (0 cm) 1" (2.54 cm)

r(7.6crn]

closet door

lo O0

io II

H H

1" ""='€_ i i_ _=''= 0" -...........'li_i i_II,._

(2.54cm) i i (Ocrn} i i

i

Page 6

installation Requirements

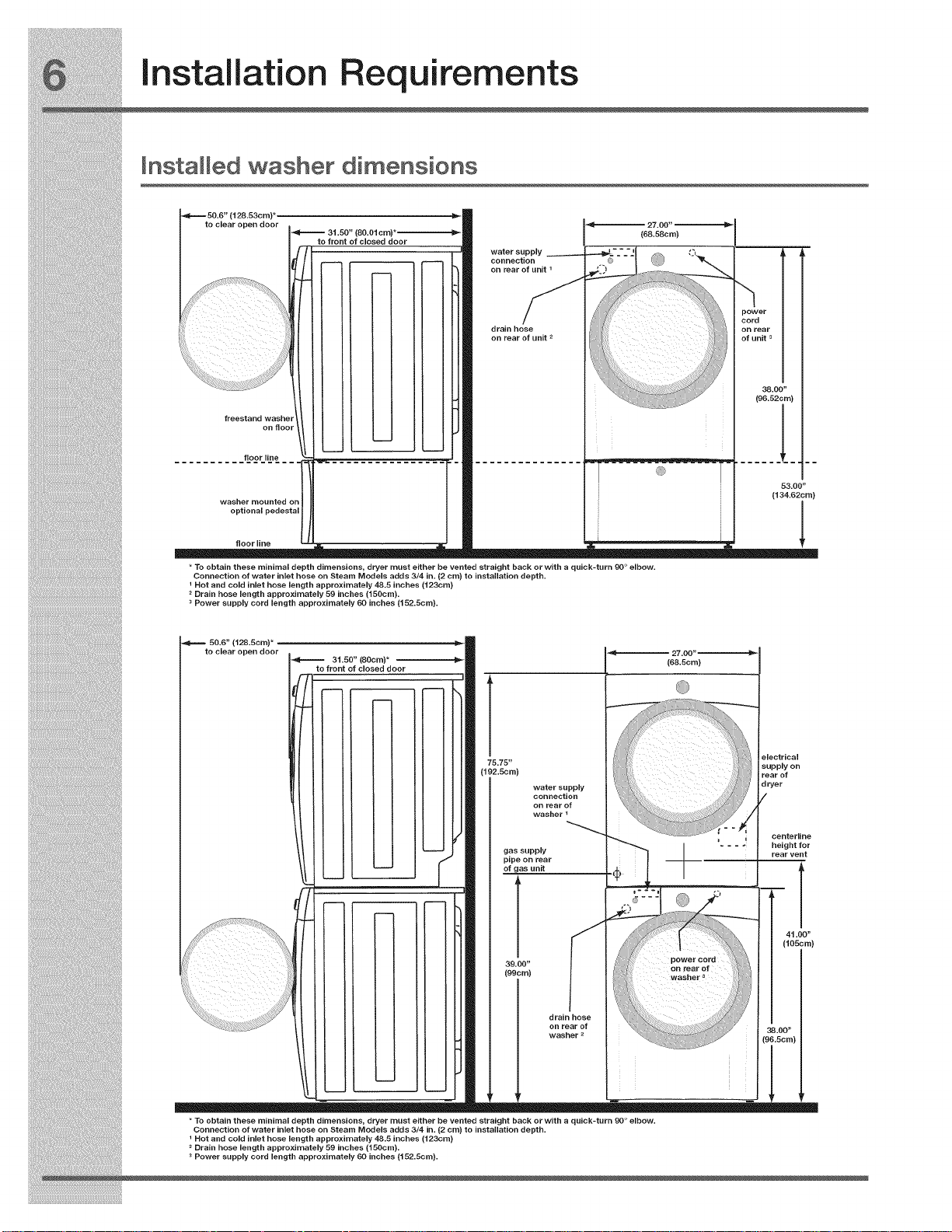

Installed washer dimensions

(128.53cm)*

to clear open door

freestand washer

floor line

washer mounted on

optional pedestal

on floor

(80.01cm)

to front of closed door

water supply

connection

on rear of unit 1

drain hose

on rear of unit 2

(68.58cm)

power

cord

on rear

of unit 3

(96.52cm)

38.00"

(134.62cm)

!

53.00"

floor line

* To obtain these minimal depth dimensions, dryer must either be vented straight back or with a quick-turn 90 ° elbow.

Connection of water inlet hose on Steam Models adds 3/4 in. (2 cm) to installation depth.

I Hot and cold inlet hose length approximately 48.5 inches (123cm)

2 Drain hose length approximately 59 inches (150cm).

3 Power supply cord length approximately 60 inches (152.5cm).

50.6" (128.5cm) _

to clear open door

31.50" (80cm)* --

to front of closed door

75.75"

(192.5cm)

water supply

connection

on rear of

washer 1

gas supply

pipe on rear

of gas unit

39.00"

(99cm)

!

drain hose

on rear of

washer 2

27.00

(68.5cm)

power cord

on rear of

electrical

supply on

rear of

dryer

centerline

height for

rear vent

(105cm)

41.00"

* To obtain these minimal depth dimensions, dryer must either be vented straight back or with a quick-turn 90 ° elbow.

Connection of water inlet hose on Steam Models adds 3/4 in. (2 cm) to installation depth.

I Hot and cold inlet hose length approximately 48.5 inches (123cm)

2 Drain hose length approximately 59 inches (150cm).

3 Power supply cord length approximately 50 inches (152.5cm).

Page 7

Removing foam packaging

1. Temporarily remove door tape.

2. Open washer door and remove everything from

the drum.

3. Close door and reapply door tape.

4. Using a rug, blanket or piece of cardboard to

protect the floor, carefully lay the washer on it's

back.

Unpackin

!

Washer

5. Remove styrofoam base and shipping plug and

set them aside.

6. Carefully return the washer to an upright posi-

tion.

7. Carefully move the washer to within 4 feet (1 m)

of its final location.

Page 8

Unpacking Washer

Removing shipping hardware

1 SHIPPING FORK

Remove all of the following:

1 SHIPPING FORK ® 5 SPACERS

[]5PCLAMPS 05BOLTS

Installing hole pmugs

[] 5 P CLAMPS ® 5 SPACER

sX

• BOLTS

UNWERSAI " ®_

WRENCH

(SUPPLIED) _/_

Locate 7 hole plugs in the small bag supplied

with washer instruction guides. Insert them in

the holes in washer back panel.

/

A 7 HOLE PLUGS

(IN BAG)

Page 9

Installation instructions

Leveling your washer

Excessive noise and vibration can be prevented by

properly leveling the washer.

1. For free standing installation and with the

washer within 4 feet (1 m) of its final location,

place a level on top of the washer.

2. Use the universal wrench to adjust the level-

ing legs so the washer is level front-to-rear and

side-to-side, and stable corner-to-corner.

3. Press down on alternate corners and sides and

feel for the slightest movement. Adjust the

appropriate leg(s) so the washer sits solidly on

the floor on ALL four legs. Keep the leveling leg

extension at a minimum for best performance

of the washer.

Page 10

installation instructions

Connecting inlet water

1. Run some water from the hot and cold faucets

to flush the water lines and remove particles

that might clog the water valve screens and to

determine which faucet is hot and which is cold

supply.

2. Look in the end of each water supply inlet hose

and verify that the rubber washers are in place.

RUBBER WASHERS

MUST BE PRESENT

3. Connect the HOT inlet hose to the HOT water

supply and the COLD inlet hose to the COLD

water supply. Tighten by hand until snug.

4. Tighten each supply connection another 2/3

turn with pliers.

5. Turn on the water and check for leaks.

Page 11

Installation Instructions

Connecting drain

1.

Snap one end of the drain hose hanger

(shipped in washer drum) onto the drain hose.

Continue wrapping it around the hanger and

snap it in place.

.

Place the hook end of the drain hose in the drain

opening. Secure the drain hose with the cable tie

(provided in the enclosure package) to the stand-

pipe, inlet hose, laundry tub, etc. so the hose

does not pull out from the force of the water.

3. Plug the power cord into a grounded outlet.

¸wall

and electrical

CABLE T[E

I

I

Page 12

Installation Instructions

Pe#ormin9 Installation Cycle

If your washer has this console: | I "_

! :. li i io°

ooo o

L

1.Empty washer's drum and close door.

2.After you plug inthe washer the first time: wake up the washer by pressing any button, rotate cycle

knob to hand wash cycle, press the start button and then the cancel button.

3.Wake up the washer again by pressing any button, then immediately and simultaneously press and

hold both the eco friendly and my favorite buttons for 5 seconds, or until the LCD display changes.

4.The LCD window will display INSTAL EMCLE and show estimated time of cycle completion. Press the

start button. The Installation Cycle will automatically test for if water has been turned on. At cycle

completion, the LCD window may display INSTAL PASS!, meaning your new washer is properly installed

and ready for use. If it prompts an action such as no WATER, EHECHHOSES or

CALL SERUICE 8-?7 H35 328-?, review the installation steps and make the necessary corrections be-

fore you attempt to use the washer.

5.Your washer will exit the Installation Cycle and return to normal operation the next time you wake it up.

6.Please read the Use & Care Guide and enjoy your new premium washer!

If your washer has this console: { f

L_ _@ =,=_=,=o Oo

1.After you plug inthe washer the first time: wake up the washer by pressing any button and then follow

the prompts on the LCD User Interface, including language selection.

2.The Installation Cycle will automatically test for, and if water has been turned on. At cycle completion,

the LCD window may display INSTAL PASS!, meaning your new washer is properly installed and ready

for use. If it prompts an action such as [10 WATER, CHECHHOSESor

CALL 5ERUICE 8-?-?H3S 328-?, review the installation steps and make the necessary corrections be-

fore you attempt to use the washer.

3.Your washer will exit the Installation Cycle and return to normal operation the next time you wake it up.

4.Please read the Use & Care Guide and enjoy your new premium washer!

Page 13

Preparing to reverse door swing

Reversing Door

1 Be sure you have adequate swing area before reversing door.

2 You will need a screw driver with a #2 square bit.

3 Protect flat work surface, such as top of washer or floor near

washer, with a soft cloth or towel.

4 Be sure washer is unplugged from power source!

Removing door and hardware

A) Removing Trim Ring

1 Open the door to a 90 degree angle.

2 Remove and save the trim plug and long,

course-thread, panhead screw.

B) Removing Door from Hinge

1 Reopen door to 90 degree angle.

2 Remove 4 long, course-thread, counter-sunk

Tools needed:

%

Screwdrivers with

#2 square &

straight bit

hinge screws from door.

34Close the door.

Rotate the door trim approximately 3/4"

counter-clockwise and pull it away from the

front of the door.

3

While supporting the weight of the door

with both hands, separate the door from the

hinge.

/

/

!

/

t

4 Gently place the door face down on a flat,

covered work surface.

Page 14

Reversing Door

C) Removing Hinge from Front Panel

1 With the hinge in open position, remove 2

short, course-thread, panhead screws on

hinge plate.

2 Remove 3 short, fine-thread, counter-sunk

screws in hinge side.

D) Removing Door Lock from Front Panel

1 Remove 2 short, course-thread, panhead

screws from the door lock.

Slide the lock toward the outer edge of the

front panel. Pivot the lock slightly outward

while slowly pulling it through opening to

expose the attached harness.

3 Slide the hinge toward the center of the front

panel, and then pivot the hinge inward while

slowly pulling it away from the front panel to

expose the attached harness.

4 Lift up on the tab and the release harness

from the retainer, allowing the harness to lay

outside the front panel.

Release the harness from the terminal

with the small lever on back of the lock.

S0eparate the harness from the lock,

allowing the harness to lay outside the front

panel.

Page 15

Reversing door and hardware

Reversing Door

E) Reattaching Door Lock to Front Panel

1 Rotate the door lock and move it to the

opposite opening.

2 Connect the harness to the door lock by

inserting it in the terminal and firmly pushing

it in place.

3

Insert the harness connection through the

front panel first, and then pivot the lock until

it is flush. Slide the lock toward the center of

the front panel until the screw holes line up.

F) Reattaching Hinge to Front Panel

1 Rotate the hinge and move it to the opposite

opening.

2 Connect the harness to the hinge retainer

by inserting it in the retention terminal and

gently pushing until you hear the fastening

tab click.

3

Gently pull on the harness to be sure it is

secure.

4

Use the side locating pins to align the hinge

and install 1 short, fine-thread, counter-sunk

screw in the center hole of hinge side.

4 Secure the lock with 2 short, course-thread,

panhead screws.

5 Install the other 2 short, fine-thread, counter-

sunk screws in the upper and lower holes of

hinge side.

6 Install 2 short, course-thread, panhead

screws through hinge plate.

Page 16

Reversing Door

G) Removing Striker Plate

1 Remove 2 long, course-thread, counter-sunk

screws and striker plate.

2 Set the striker plate to the side for later.

H) Removing Latch Indicator

I) Removing Hole Plug

iI_I_I i iii_ii_

1 Insert flat blade screwdriver into open slot of

hole plug.

2 Gently pry upward to release tab.

1 Insert flat blade screwdriver into open slot of

latch indicator.

2 Gently pry upward to release tab.

3 Pull the indicator out and set it aside.

3 Pull the hole plug out and set it aside.

Page 17

Reversing Door

J) Reinserting Latch Indicator

1 Rotate the latch indicator and move it to the

opposite hole in the door.

insert indicator

2

Firmly insert the two small tabs on either

side of the latch indicator into the two slots

on either side of the hole in the door.

_slot

K) Reattaching Striker Plate

1 Rotate the striker plate and move it to the

opposite side of door above the indicator.

2 Reattach with 2 long, course-thread,

counter-sunk screws.

7

L) Reinserting Hole Plug

1 Rotate the hole plug and move it to the

opposite hole in the door.

2 Firmly insert the two small tabs on either

side of the hole plug into the two slots on

either side of the hole in the door.

\

insert tab

3

Firmly press downward on the indicator until

the tab snaps _nplace.

L

pressdown

and snap

insert tab

3

Firmly press downward on the hole plug until

the tab snaps _n 31ace.

Page 18

Reversing Door

Reattaching door and hardware

M) Reattaching Door Assembly

1 Open the hinge to a 90 degree angle.

2 Install the door onto the hinge locating pins.

\

\

3 Secure the door with 4 long, course-thread.

counter-sun k screws.

O) Reinstalling Trim Ring

1 CIosethe door.

2 Orient the trim so 12 position is

approximately 3/4"to the left of top center.

The opening in the trim ring should be on the

hinge side.

3 Insert the trim ring in the slots and rotate it

clockwise approximately 3A".

P) Reinstalling Trim Plug

1 Open the door to a 90 degree angle.

2 Install the trim plug with 1 long, course-

thread, panhead screw.

4 Close the door and test the operation of the

latch.

N) Reversing Trim Ring

1 Trim ring orientation is marked on the back.

2 Remove the trim nng cover plate. To remove

the cover plate from the right, pivot point is

up. To remove the cover plate from the left,

pivot point is down.

3 Rotate the trim ring cover plate and move

it to the opposite opening in the trim and

reinsert.

Q) Plug in washer and continue operation.

Page 19

MATCHING STORAGE PEDESTAL

Island White Pedestal - P/N EPWD15iW

Mediterranean Blue - P/N EPWD15MB

Silver Sands Pedestal- P/N EPWD15SS

Turquoise Sky Pedestal - P/N EPWD15TS

A storage pedestal accessory, specifically

designed for this washer may be used to elevate

the dryer for ease of use. This pedestal will add

about 15" (38.1cm) to the height of your unit for a

total height of 53" (134.62 cm).

DRYER STACKING KiT

P/N 134700400

A kit for stacking the matching dryer on top of

this washer is available with the purchase of the

matching dryer.

DRAIN HOSE EXTENSION KIT

P/N 137098000

in order to reach standpipe heights or distances

beyond the reach of the drain hose supplied, order

the DRAIN HOSE EXTENSION KIT.

Options

0

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installation in a mobile home requires the use of a

MOBILE HOME INSTALLATION KIT.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

Your washer was supplied with a UNIVERSAL

APPLIANCE WRENCH. If you desire another

wrench, you may order one.

Repmacement paAs: 1-877-4ELECTROLUX (1-877-435-3287}

If replacements parts are needed for your washer,

contact the source where you purchased your

washer, call 1-877-4ELECTROLUX (1-877-435-

3287), or visit our website,

www.electroluxappliances.com, for the Electrolux

Authorized Parts Distributor nearest you.

Page 20

Notes

Loading...

Loading...