Electrolux EIED200QSW00, EIED2CAQSW00 Installation Guide

Electrolux

o_o oe ooeses®s®so oo ®oese ® • s ® • • • • • • s • • s • • s • • • •

EN FRONT LOAD DRYER INSTALLATION INSTRUCTIONS

FR SECHEUSEA CHARGEMENT FRONTAL INSTRUCTIONS D'INSTALLATION

ES SECADORA DE CARGA FRONTAL INSTRUCCIONES DE INSTALACION

IMPORTANT SAFETY INSTRUCTIONS

damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent property

this or any other appliance.

I G- O FI E

Read all of the following instructions before installing and using this appliance:

* Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a garbage

container or make materials inaccessible to children.

* Clothes dryer installation and service must be performed by a qualified installer or service agency.

* Install the clothes dryer according to the manufacturer's instructions and local codes.

* The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1 part 1.

* The dryer is designed under ANSI Z 21.5.1 or ANSl/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE

only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

* Do not stack a dryer on top of washer already installed on pedestal. Do not stack dryer on top of another dryer. Do not stack

washer on top of dryer. Do not stack washer on top of another washer. Do not stack dryer on top of washer without use of

manufacturer approved and correctly installed stacking kit appropriate for your model.

* The instructions in this manual and all other literature included with this dryer are not meant to cover every possible condi-

tion and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and maintain-

ing any appliance.

To avoid back or other injury, have more than one person

movt !he ...............................................................................................................................................................

Do not install the dryer where gasoline or other flammables

are kept or stored. If the dryer is installed in a garage, it

must be a minimum of 18 inches (45.7 cm) above the floor.

Failure to do so can result in death, explosion, fireor burns.

TABLE OF CONTENTS

Important Safety Instructions .............................................. 2-3

Installation Requirements ................................................... 4-8

Installation Instructions ..................................................... 6-11

Reversing Door ............................................................... 12 -13

Accessories ......................................................................... 14

Notes ................................................................................... 18

Fran£ais ............................................................................... 16

Espafiol ................................................................................ 30

EXPLOSION HAZARD

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

IMPORTANT SAFETY INSTRUCTIONS

Unpacking

[3 Plastic film (lining drum interior) is removed and

discarded. See also image below.

Recognize safety symbols, words and labels

Safety items throughout this manual are labeled with a

WARNING or CAUTION based on the risk type as described

below:

Definitions

d_,This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation [3 Dryer plugged in

which if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which_ !! n0t avo!ded, cou!d !esu!t indeath seEi0us !nju!y:............. [3 Registration card sent in

Leveling

[3 Dryer is level, side-to-side and front-to-back

[3 Cabinet is setting solid on all corners

240v Electric Supply

[3 Approved NEMA 10-30R or 14-30R service cord with

all screws tight on terminal block

[3 Terminal access cover/strain relief installed before

initial operation

Door Reversam

[3 Follow detailed instructions in this guide

[3 Test hinge and latch for function

EmectricaN Power

[3 House power turned on

Final Checks

[3 Installation Instructions and Use and Care Guide

read thoroughly

[3 Door latches and drum tumbles when cycle starts

information which is important but not hazard-related.

Tools and materials needed for installation:

OR AND AND AND

Optional uni- Adjustable 3 or 4-wire

versal wrench pliers 240 volt

available from cord kit

dealer

Phillips screwdriver Carpenter's level

.........Installation Requirements

Electrical requirements for electric dryer

Because of potentially inconsistent voltage capabilities,

the use of this dryer with power created by gas powered

generators, solar powered generators, wind powered

generators or any other generator other than the local utility

company is not recommended. ................

CIRCUIT - Individual 30 amp. branch circuit fused with 30

amp. time delay fuses or circuit breakers. Use separately

fused circuits for washer and dryer. DO NOT operate a

washer and a dryer on the same circuit.

POWER SUPPLY - 3-wire or4-wire, 208-240 volt, single

phase, 60 Hz, Alternating Current.

This dryer is internally grounded to neutral unless it was

manufactured for sale in Canada.

Only a 4-conductor cord shall be used when the appliance

is installed in a location where grounding through the

neutral conductor is prohibited. Grounding through

the neutral link is prohibited for: (1) new branch circuit

installations, (2) mobile homes, (3) recreational vehicles,

and (4) areas where local codes do not permit grounding

through the neutral. .............

OUTLET RECEPTACLE - NEMA 10-30R or NEMA 14-30R

receptacle to be located so the power supply cord is

accessible when the dryer is in the installed position.

GROUNDING CONNECTION - See 'Grounding requirements"

in Electrical Installation section.

4-WIREPOWERSUPPLYCORDKIT (notsupplied)

4-wire receptacle

(NEMA type 14-30R)

The dryer MUST employ a 4-conductor power supply

cord NEMA 14-30type SRDT or ST (as required) rated

at 240 volt AC minimum, 30 amp,with 4 open end

spade lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. For

4-wire cord connection instructions see ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

Manufactured or mobile home installation

Installation MUST conform to current Manufactured Home

Construction & Safety Standard, Title 24 CFR, Part 32-80

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280) or Standard CAN/

CSAZ240 MH.

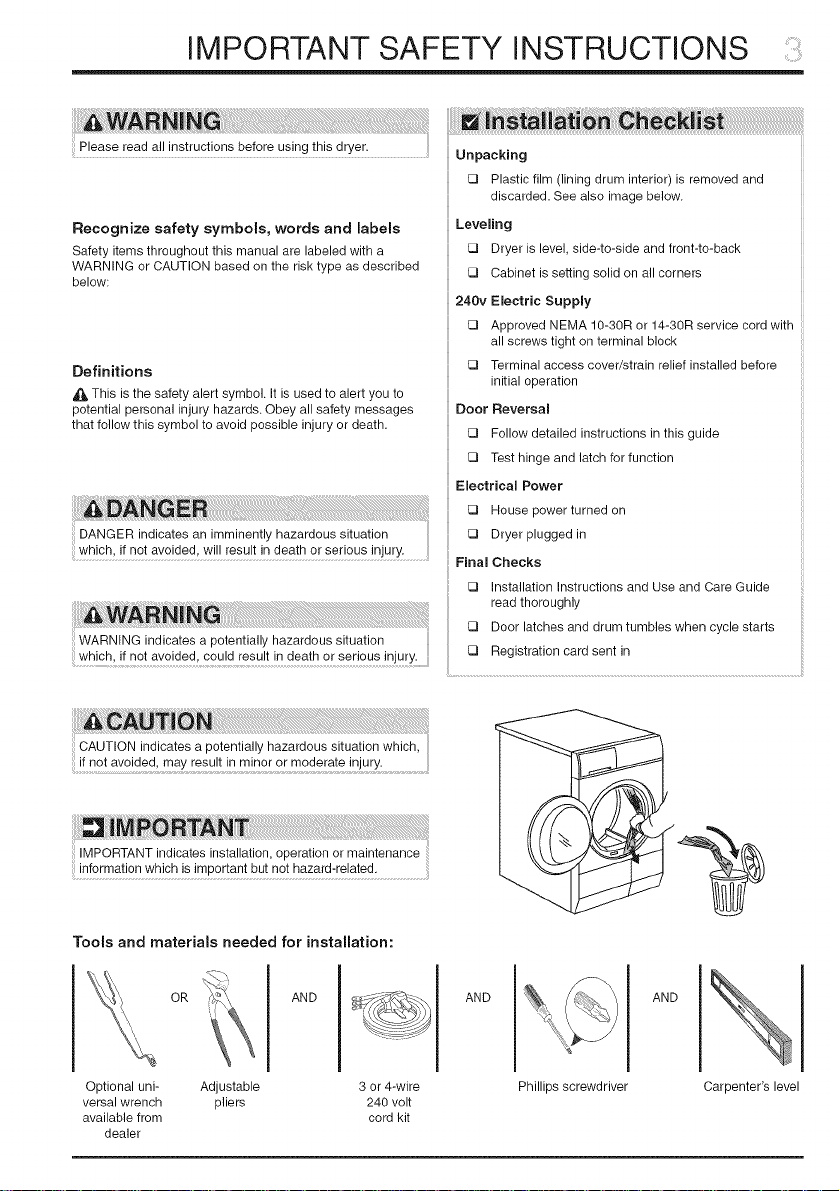

Clearance requirements

MINIMUM INSTALLATION CLEARANCES - inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 crn) 0" (0 cm)* 0" (0 crn) n/a

Under Counter 0" (0 crn) 0" (0 cm)* 0" (0 crn) n/a

(ecru} " (ocm}

Closet installation

If installing the dryer in a closet, the unit must only be

operated with the door in the open position to allow correct air

circulation. See Use and Care Guide for more information.

ZZ3_

Dryers manufactured for sale in Canada have factory-

installed, 4-wire power supply cord (NEMA 14-30R).

3-WIRE POWER SUPPLY CORD KIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3-conductor power supply cord

NEMA 10-30 type SRDT rated at 240 volt AC minimum, 30

amp, with 3 open end spade lug connectors with upturned

ends or closed loop connectors and marked for use with

clothes dryers. For 3-wire cord connection instructions see

ELECTRICAL CONNECTIONS FOR A 3-WIRE SYSTEM.

-- TZ2:Z2_

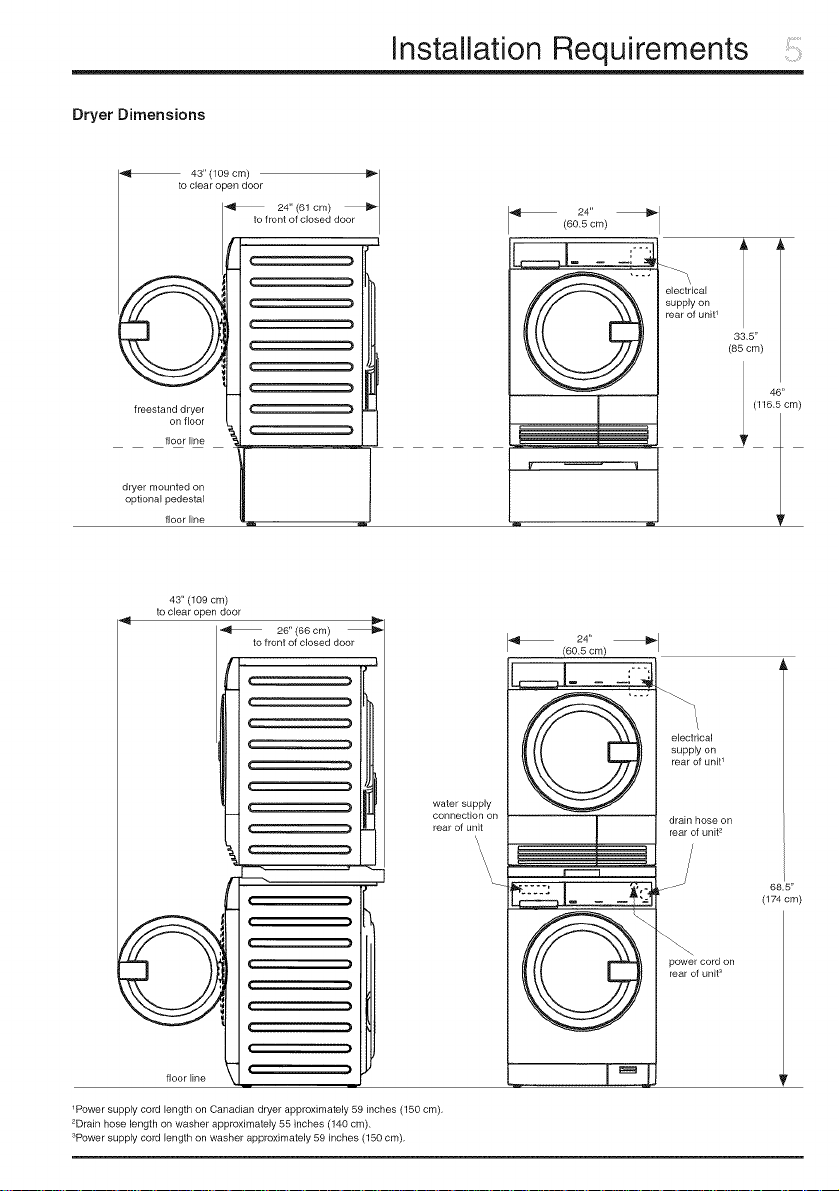

Dryer Dimensions

to clear open door

_t, 43" (109 cm) d°°_

freestand dryer

on floor

floor line

dryer mounted on

optional pedestal

floor line

43" (109 cm)

to clear open door

24" (61 cm)

to front of closed

26'* (66 cm)

to front of closed door

Installation Requirements

•_ 24" I_

.,.1

(60,5 cm)

0"

2_

2_

, = ,

...........r _

_1_ 24" I_ I

(60,5 cm)

electrical

supply on

rear of unit I

33,5"

(85 cm)

46"

(116,5 cm)

I i

I !

! f

floor line

_Power supply cord length on Canadian dryer approximataly 59 inches (150 cm).

2Drain hose length on washer approximately 55 inches (140 cm),

_Power supply cord length on washer approximataly 59 inches (150 cm).

water supply

connection on

rear of unit

\

electrical

supply on

rear of unit I

drain hose on

rear of unit 2

\

\

\

power cord on

rear of uniP

68,5"

(174 cm)

..........Installation Instructions

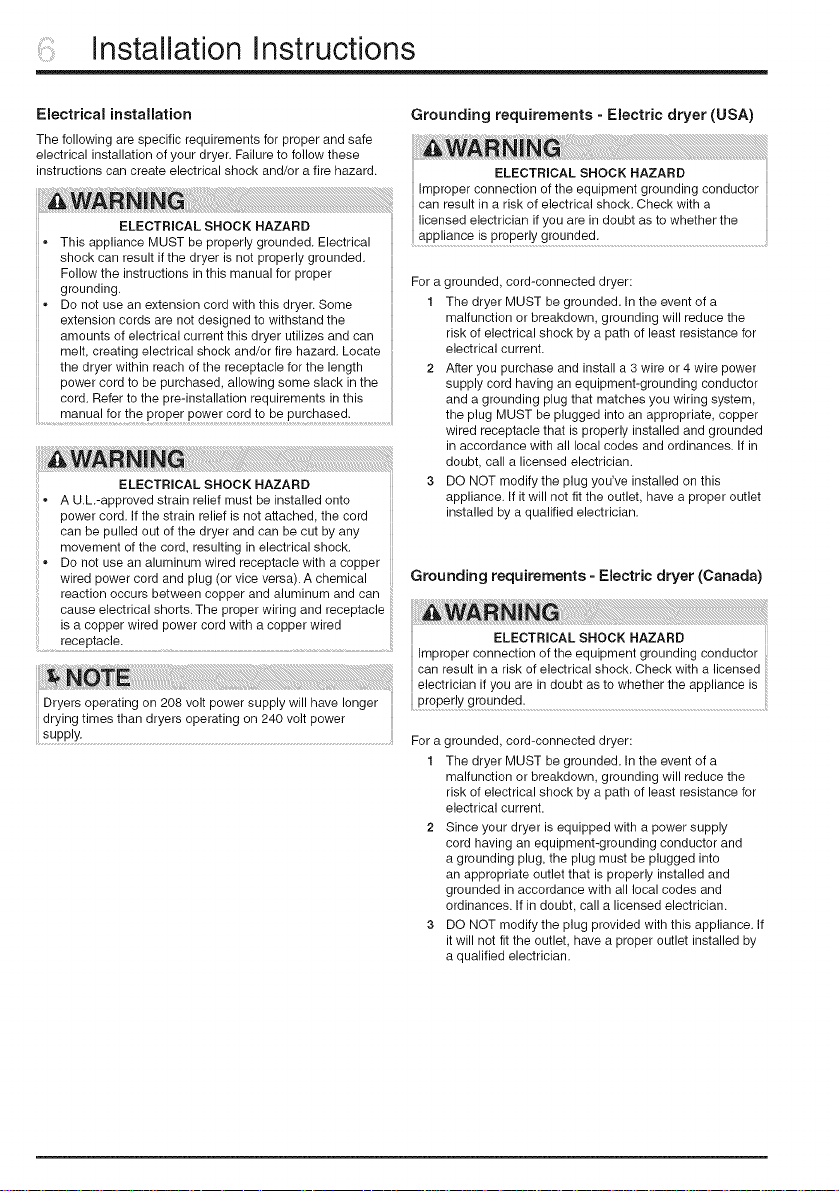

Electrical installation

The following are specific requirements for proper and safe

electrical installation of your dryer. Failure to follow these

instructions can create electrical shock and/or a fire hazard.

........................................................ can result in a risk of electrical shock. Check with a

• This appliance MUST be properly grounded. Electrical

• Do not use an extension cord with this dryer. Some

ELEcTRiCAL SHOCK HAZARD licensed electrician if you are in doubt as to whether the

shock can result ifthe dryer is not properly grounded.

Follow the instructions in this manual for proper

grounding.

extension cords are not designed to withstand the

amounts of electrical current this dryer utilizes and can

melt, creating electrical shock and/or fire hazard. Locate

the dryer within reach of the receptacle for the length

power cord to be purchased, allowing some slack in the

cord. Refer to the pre-installation requirements in this

..................manua !o !h p!op_powe co b pu!chased.............................

• A U.h-approved strain relief must be installed onto

• Do not use an aluminum wired receptacle with a copper

............!eceptac!e: .............................................................................................

ELECTRICAL SHOCK HAZARD

power cord. If the strain relief is not attached, the cord

can be pulled out of the dryer and can be cut by any

movement of the cord, resulting in electrical shock.

wired power cord and plug (or vice versa). A chemical

reaction occurs between copper and aluminum and can

cause electrical shorts. The proper wiring and receptacle

is a copper wired power cord with a copper wired

Grounding requirements - Electric dryer (USA)

Improper connection of the equipment grounding conductor

appliance is properly grounded.

For a grounded, cord-connected dryer:

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2 After you purchase and install a 3 wire or 4 wire power

supply cord having an equipment-grounding conductor

and a grounding plug that matches you wiring system,

the plug MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

3 DO NOT modify the plug you've installed on this

appliance. If it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

Grounding requirements - Electric dryer (Canada)

Improper connection of the equipment grounding conductor

ELECTRICAL SHOCK HAZARD

Dryers operating on 208 volt power supply will have longer properly grounded.

drying times than dryers operating on 240 volt power .....

supply.

.... For a grounded, cord-connected dryer:

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2 Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. If in doubt, call a licensed electrician.

3 DO NOT modify the plug provided with this appliance. If

it will not fit the outlet, have a proper outlet installed by

a qualified electrician.

Installation Instructions

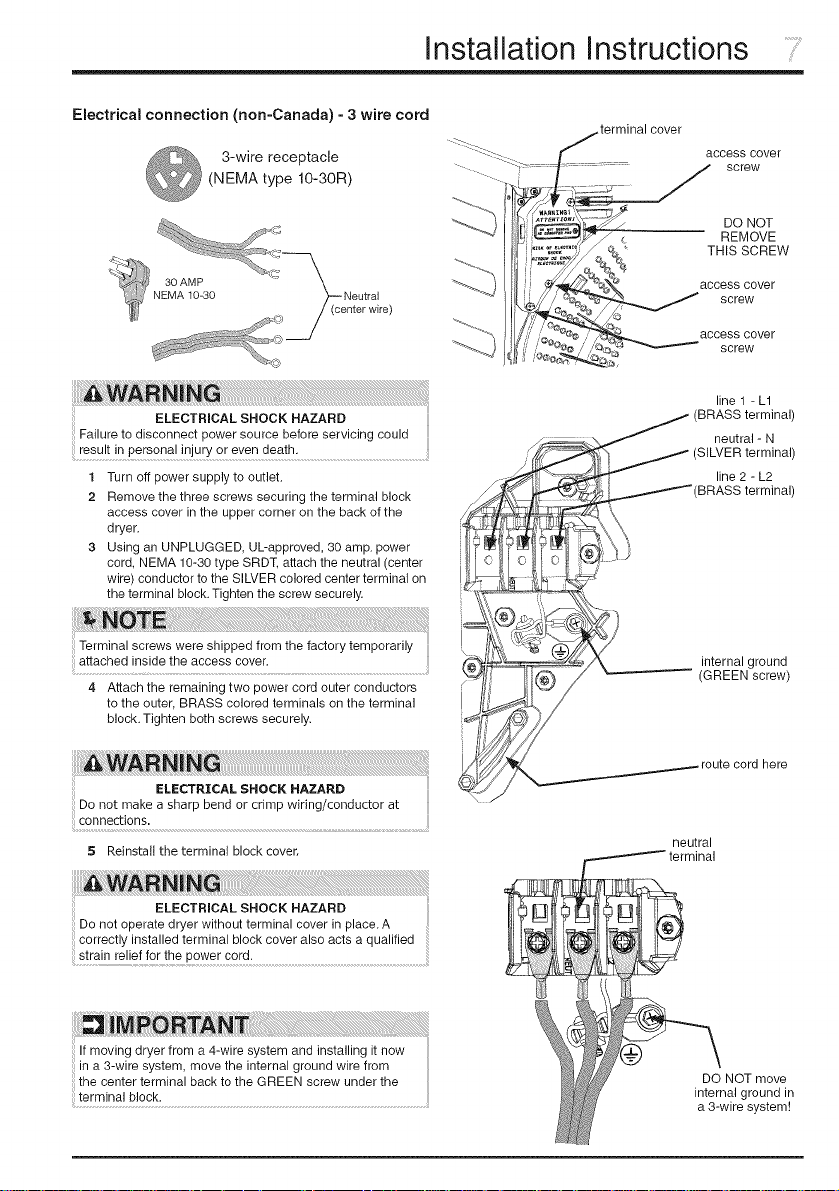

Electrical connection (non=Canada) =3 wire cord

3-wire receptacle

(NEMA type 10-30R)

Failure to disconnect power source before servicing could

result in personal injury or even death.

1 Turn off power supply to outlet.

2 Remove the three screws securing the terminal block

access cover in the upper corner on the back of the

dryer.

3 Using an UNPLUGGED, UL-approved, 30 amp. power

cord, NEMA 10-30 type SRDT, attach the neutral (center

wire) conductor to the SILVER colored center terminal on

the terminal block. Tighten the screw securely.

Terminal screws were shipped from the factory temporarily

attached inside the access cover.

4 Attach the remaining two power cord outer conductors

to the outer, BRASS colored terminals on the terminal

block. Tighten both screws securely.

" ---......

terminal cover

DO NOT

REMOVE

THIS SCREW

line 1 - L1

BRASS terminal)

neutral - N

terminal)

line 2 - L2

BRASS terminal)

internal ground

(GREEN screw)

Do not make a sharp bend or crimp wiring/conductor at

connections.

5 Reinstall the terminal block cover.

Do not operate dryer without terminal cover in place. A

correctly installed terminal block cover also acts a qualified

strain relief for the power cord.

If moving dryer from a 4-wire system and installing it now

in a 3-wire system, move the internal ground wire from

the center terminal back to the GREEN screw under the

terminal block.

ELECTRICAL SHOCK HAZARD

- route cord here

neutral

Installation Instructions

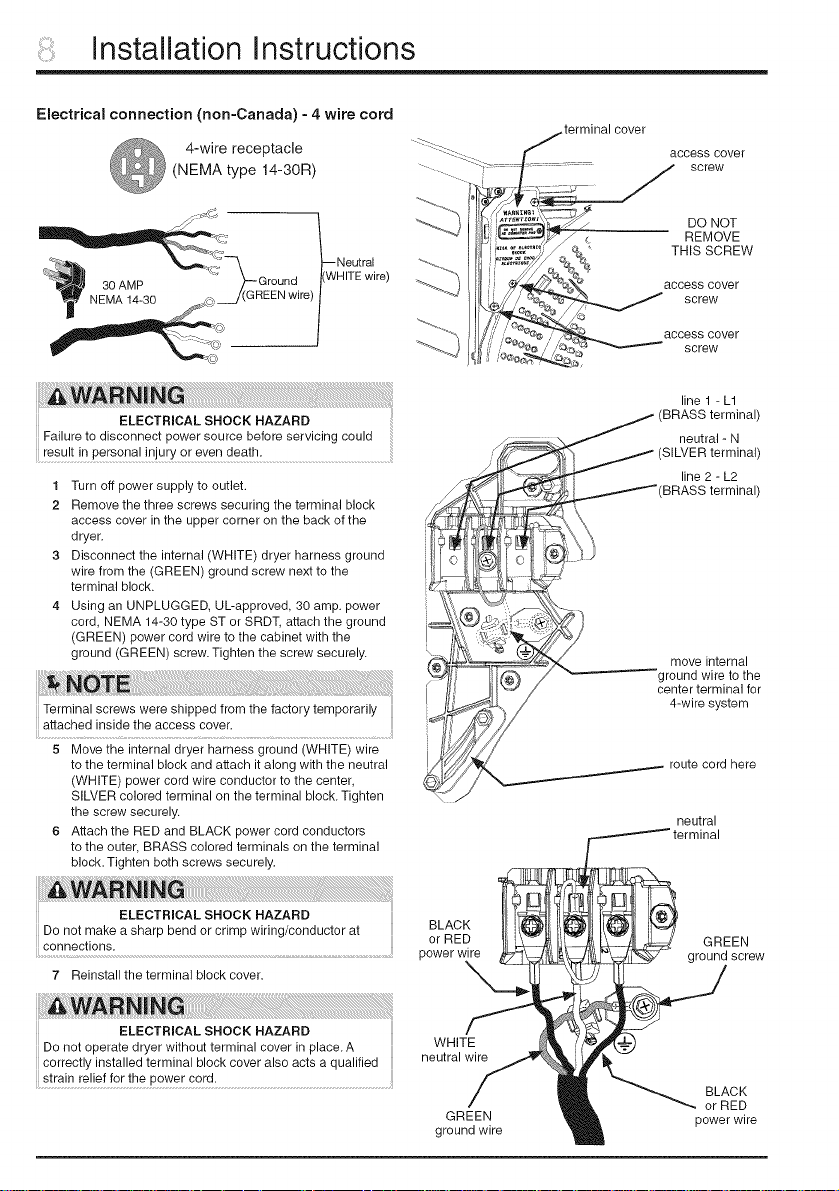

Electrical connection (non=Canada) - 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

_._

.............. ., --_ Neutral

T NEMA14-30 _©_J(GREEN wire)

H_J 30AMP _G .... d. i(WHITEwire)

Failure to disconnect power source before servicing could

result in personal injury or even death.

1 Turn off power supply to outlet.

2 Remove the three screws securing the terminal block

access cover in the upper corner on the back of the

dryer.

3 Disconnect the internal (WHITE) dryer harness ground

wire from the (GREEN) ground screw next to the

terminal block.

4 Using an UNPLUGGED, UL-approved, 30 amp. power

cord, NEMA 14-30 type ST or SRDT, attach the ground

(GREEN) power cord wire to the cabinet with the

ground (GREEN) screw. Tighten the screw securely.

Terminal screws were shipped from the factory temporarily

attached inside the access cover.

5 Move the internal dryer harness ground (WHITE) wire

to the terminal block and attach it along with the neutral

(WHITE) power cord wire conductor to the center,

SILVER colored terminal on the terminal block. Tighten

the screw securely.

6 Attach the RED and BLACK power cord conductors

to the outer, BRASS colored terminals on the terminal

block. Tighten both screws securely.

terminal cover

-- .. ":,_ ........... _:' screw

"" _-::::_.__ccess cover

"_ ) i__ _ DONOT

_/ II/,i' " _#_ '' ,(_<_-_'_'_ screw

TTE .to \\--, _ /

_' / c REMOVE

Iq __'_s#,'_'_J/ %_ THIS SCREW

access cover

" __ _ screw

-----, accesscover

line 1 - L1

neutral - N

SILVER terminal)

line 2 - L2

'BRASS terminal)

move internal

ground wire to the

center terminal for

4-wire system

._ route cord here

neutral

)

Do not make a sharp bend or crimp wiring/conductor at BLACK

connections, or RED

7 Reinstall the terminal block cover.

Do not operate dryer without terminal cover in place. A

correctly installed terminal block cover also acts a qualified

strain relief for the power cord.

ELECTRICAL SHOCK HAZARD

power wire

WHITE

neutral wire

GREEN

ground wire

GREEN

ground screw

BLACK

or RED

power wire

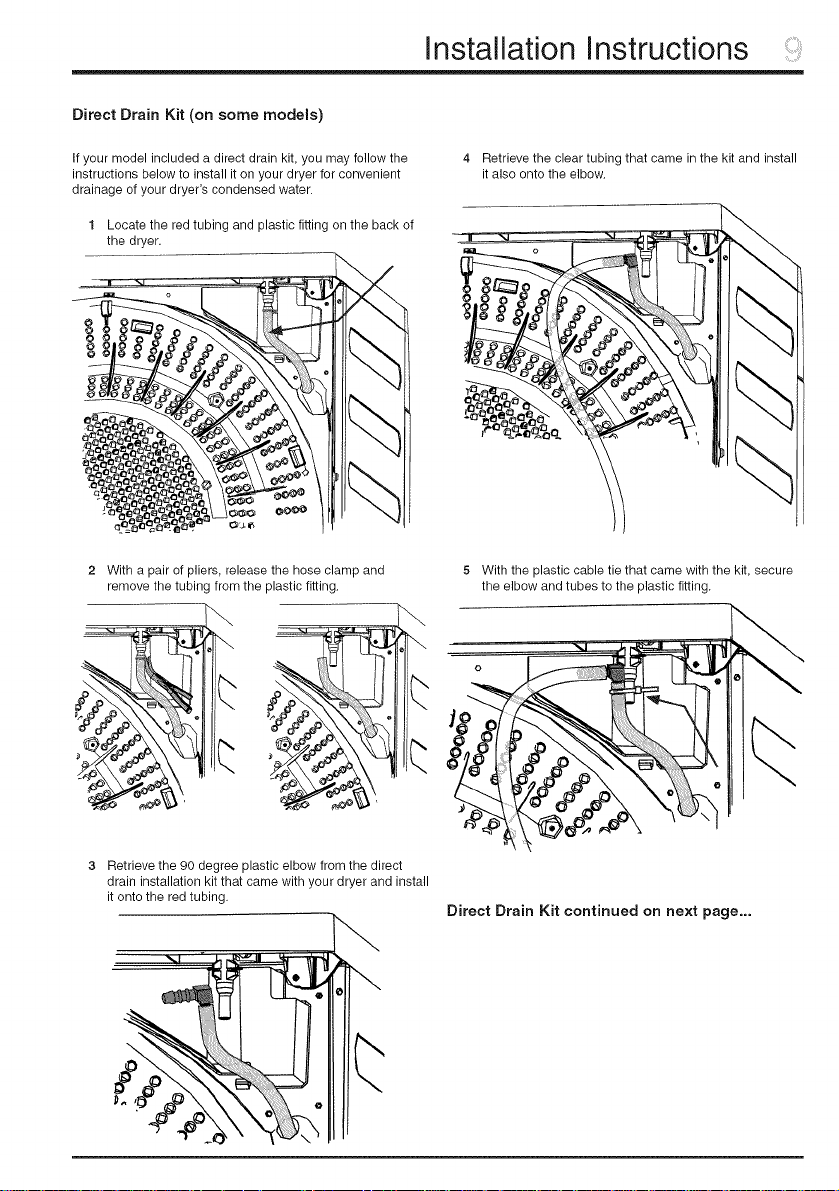

Direct Drain Kit (on some models)

Installation Instructions

If your model included a direct drain kit, you may follow the

instructions below to install it on your dryer for convenient

drainage of your dryer's condensed water.

1 Locate the redtubing and plastic fitting on the back of

the dryer.

With a pair of pliers, release the hose clamp and 5 With the plastic cable tie that came with the kit, secure

remove the tubing from the plastic fitting, the elbow and tubes to the plastic fitting.

4 Retrieve the clear tubing that came in the kit and install

it also onto the elbow.

Retrieve the 90 degree plastic elbow from the direct

drain installation kit that came with your dryer and install

itonto the redtubing.

\

\

\

Direct Drain Kit continued on next page...

Installation Instructions

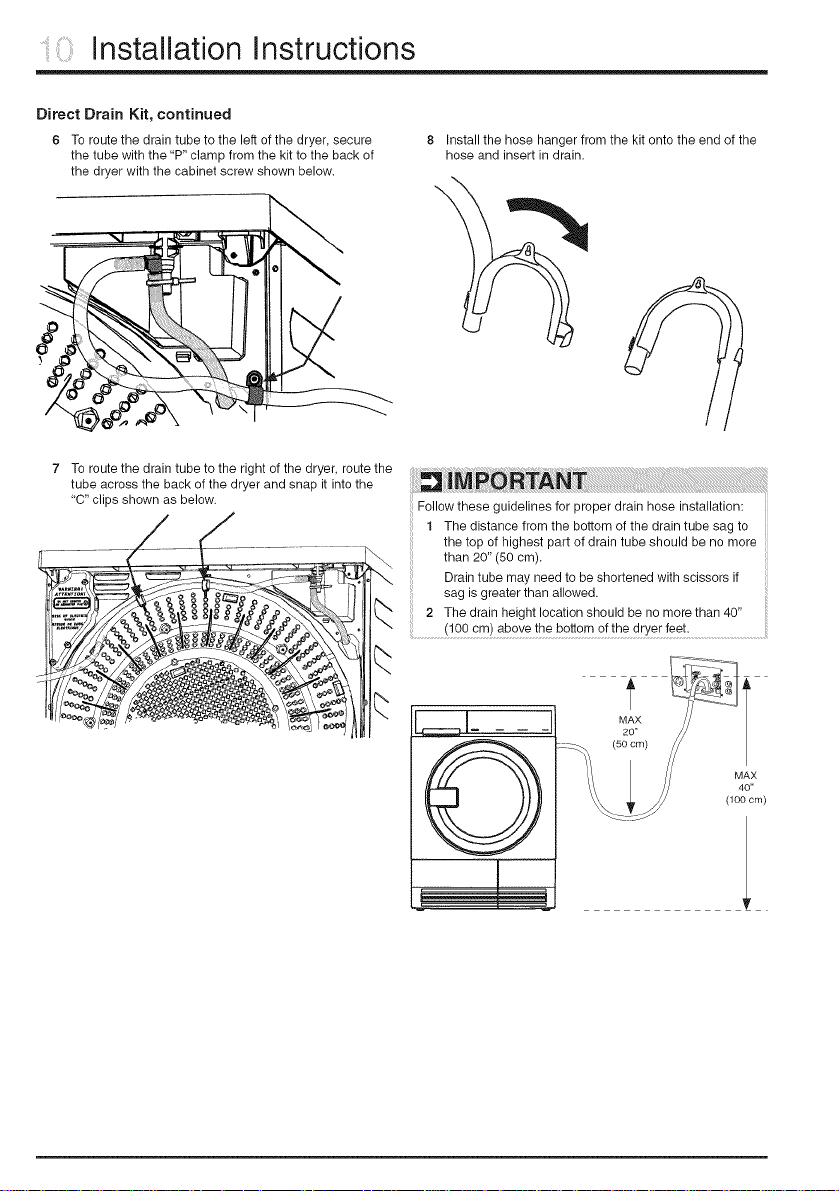

Direct Drain Kit, continued

6 To route the drain tube to the left of the dryer, secure

the tube with the =P"clamp from the kit to the back of

the dryer with the cabinet screw shown below.

7 To route the drain tube to the right of the dryer, route the

tube across the back of the dryer and snap it into the

'C" clips shown as below.

8 Install the hose hanger from the kit onto the end of the

hose and insert in drain.

Follow these guidelines for proper drain hose installation:

1 The distance from the bottom of the drain tube sag to

the top of highest part of drain tube should be no more

than 20" (50 cm).

Drain tube may need to be shortened with scissors if

sag is greater than allowed.

2 The drain height location should be no more than 40"

(100 cm) above the bottom of the dryer feet.

40"

(100crn)

O (50 cm) MAX

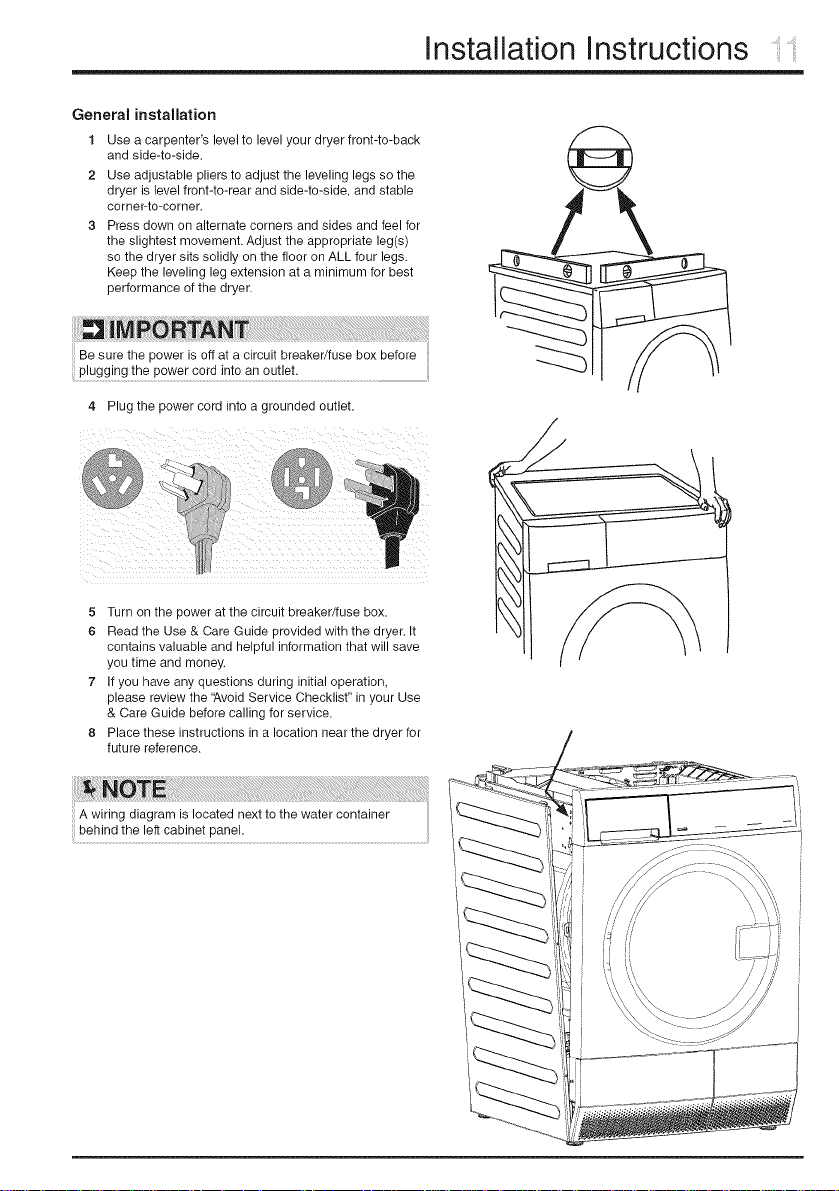

General installation

1 Use a carpenter's level to level your dryer front-to-back

and side-to-side.

2 Use adjustable pliers to adjust the leveling legs so the

dryer is level front-to-rear and side-to-side, and stable

corner-to-corner.

3 Press down on alternate corners and sides and feel for

the slightest movement. Adjust the appropriate leg(s)

so the dryer sits solidly on the floor on ALL four legs.

Keep the leveling leg extension at a minimum for best

performance of the dryer.

Be sure the power is off at a circuit breaker/fuse box before

plugging the power cord into an outlet.

4 Plug the power cord into a grounded outlet.

5 Turn on the power at the circuit breaker/fuse box.

6 Read the Use & Care Guide provided with the dryer. It

contains valuable and helpful information that will save

you time and money.

7 If you have any questions during initial operation,

please review the Avoid Service Checklist" in your Use

& Care Guide before calling for service.

8 Place these instructions in a location near the dryer for

future reference.

Installation Instructions

A wiring diagram is located next to the water container

behind the left cabinet panel.

I

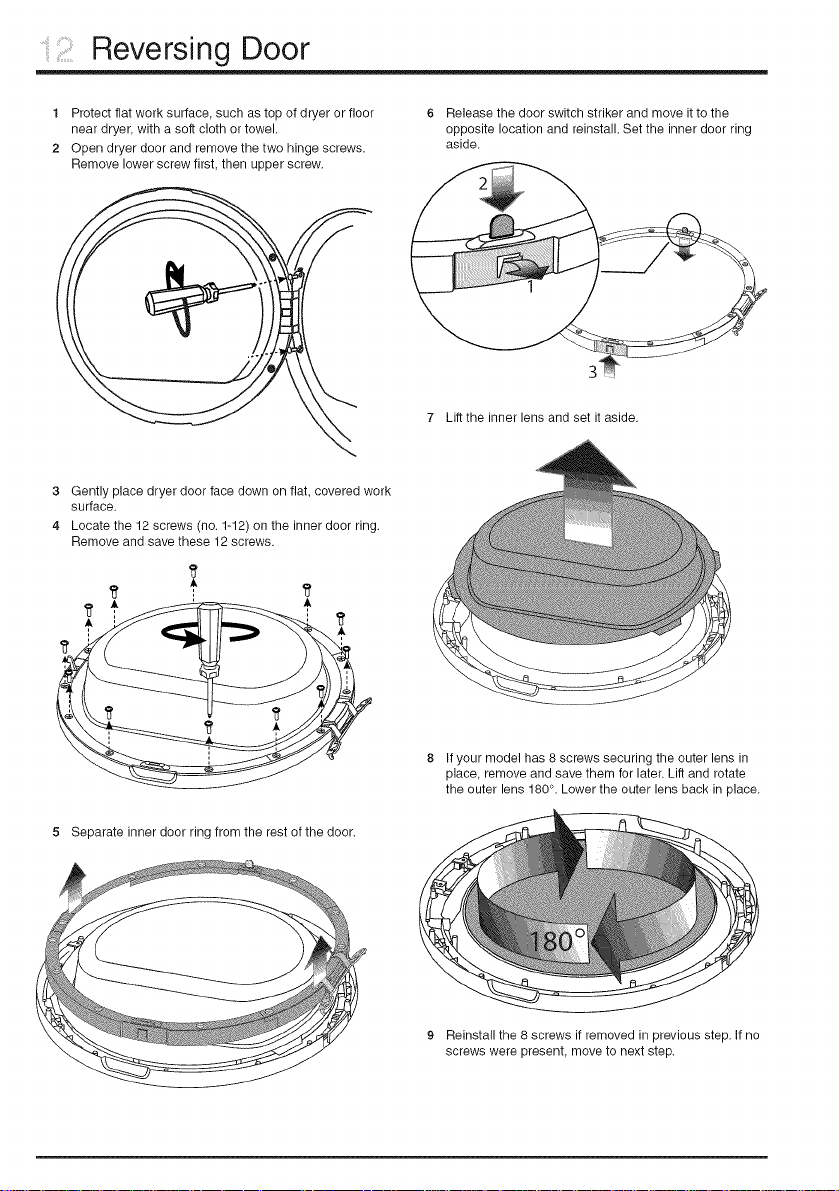

:::::Reversing Door

1 Protect flat work surface, such as top of dryer or floor

near dryer, with a soft cloth or towel.

2 Open dryer door and remove the two hinge screws.

Remove lower screw first, then upper screw.

3 Gently place dryer door face down on flat, covered work

surface.

4 Locate the 12 screws (no. 1-12) on the inner door ring.

Remove and save these 12 screws.

I' ,k 1'

A i i I_

6 Release the door switch striker and move it to the

opposite location and reinstall. Set the inner door ring

aside.

7 Lift the inner lens and set it aside.

i

5 Separate inner door ring from the rest of the door.

8 If your model has 8 screws securing the outer lens in

place, remove and save them for later. Lift and rotate

the outer lens 180 ° . Lower the outer lens back in place.

9 Reinstall the 8 screws if removed in previous step. If no

screws were present, move to next step.

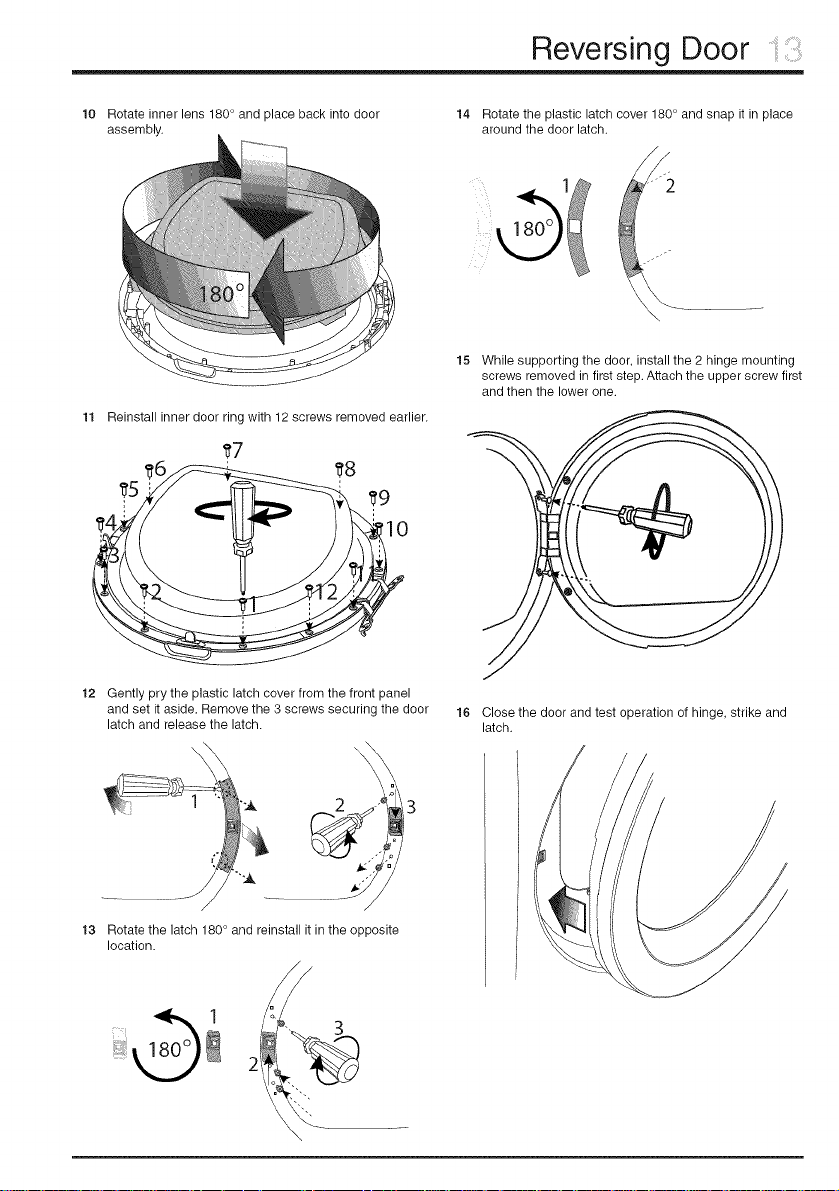

Reversing Door

10 Rotate inner lens 180 ° and place back into door

assembly.

11 Reinstall inner door ring with 12 screws removed earlier.

_7

0

12

Gently pry the plastic latch cover from the front panel

and set it aside. Remove the 3 screws securing the door

latch and release the latch.

14 Rotate the plastic latch cover 180° and snap it in place

around the door latch.

15 While supporting the door, install the 2 hinge mounting

screws removed in first step. Attach the upper screw first

and then the lower one.

18 Close the door and test operation of hinge, strike and

latch.

13

Rotate the latch 180 ° and reinstall it in the opposite

location.

:: Accessories

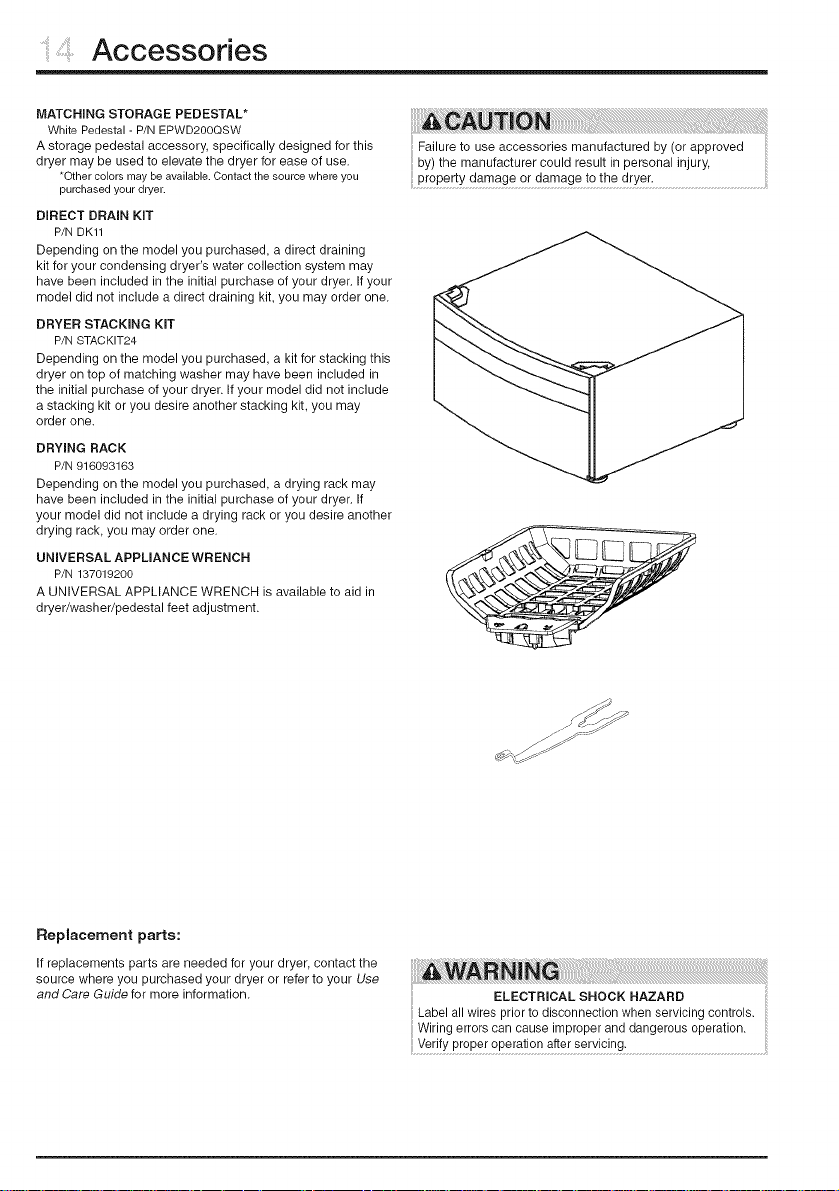

MATCHING STORAGE PEDESTAL*

White Pedestal - P/N EPWD200QSW

A storage pedestal accessory, specifically designed for this

dryer may be used to elevate the dryer for ease of use.

*Other colors may be available. Contact the source where you

purchased your dryer.

DIRECT DRAIN KiT

P/N DK11

Depending on the model you purchased, a direct draining

kit for your condensing dryer's water collection system may

have been included in the initial purchase of your dryer. If your

model did not include a direct draining kit, you may order one.

DRYER STACKING KiT

P/N STAC KIT24

Depending on the model you purchased, a kit for stacking this

dryer on top of matching washer may have been included in

the initial purchase of your dryer. If your model did not include

a stacking kit or you desire another stacking kit, you may

order one.

DRYING RACK

P/N 916093163

Depending on the model you purchased, a drying rack may

have been included in the initial purchase of your dryer. If

your model did not include a drying rack or you desire another

drying rack, you may order one.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is available to aid in

dryer/washer/pedestal feet adjustment.

Failure to use accessories manufactured by or approved

by the manufacturer could result in personal in ury,

property damage or damage to the dryer.

Replacement parts:

If replacements parts are needed for your dryer, contact the

source where you purchased your dryer or refer to your Use

and Care Guide for more information.

Wiring errors can cause improper and dangerous operation.

Label all wires prior to disconnection when servicing controls.

Verify proper operation after servicing.

Loading...

Loading...