Page 1

Installation, Use & Care Guide

30”(76.2 cm), 36”(91.4 cm) and 48”(121.92 cm) Hood Insert

Guide d’installation, utilisation

et d’entretien

30”(76.2 cm), 36”(91.4 cm) et 48”(121.92 cm) Doublure de Hotte

Guia de Instalación, Uso y Cuidado

Campana de línea de 30”(76.2 cm), 36”(91.4 cm) y 48”(121.92 cm)

EI30HI55KS + EI36HI55KS + EI48HI55KS

LI30FA Ed. 08/11

316902479

Page 2

2

Finding Information

Please read and save this guide

Thank you for choosing Electrolux, the new premium brand in home appliances. This Use & Care Guide is

part of our commitment to customer satisfaction and product quality throughout the service life of your new

appliance.

We view your purchase as the beginning of a relationship. To ensure our ability to continue serving you,

please use this page to record important product information.

Keep a record for quick reference

Purchase date

Model number

Serial number (see picture for location)

NOTE

Registering your product with Electrolux enhances

our ability to serve you. You can register online at

www.electroluxappliances.com by dropping your

Product Registration Card in the mail.

Questions?

For toll-free telephone support in the U.S. and Canada:

US.: 1.800.944.9044 / Canada: 1.800.265.8352

For online support and Internet product information visit http:// www.electroluxappliances.com

Table of contents

Important Safety Instructions ............................. ... 3

List of materials...................................................... ... 4

Electrical requirements ........................................ ... 5

Location requirements . .......................................... 6

Product dimensions ................................................. 6

Venting Requirements............................................... 7

Venting methods........................................................................ 7

Install Hood Insert Internal

Blower Motor.............................................................. 8

Remote Blower Motor Installation

into Hood Insert......................................................... 10

Prepare the location.................................................. 12

Install Hood Insert into Hood Cabinet.................... 13

Make Electrical Power Supply

Connection to Hood Insert....................................... 14

Complete Installation and Check Operation........ 14

Hood Insert Use......................................................... 15

Cleaning....................................................................... 15

Warranty Information................................................ 16

©2011 Electrolux Home Products, Inc. All rights reserved. Printed in Mexico

Page 3

Important Safety Instructions

Read all instructions before using this

appliance.

Save these instructions for future

references

Approved for residential appliances

For residential use only

Do not attempt to install or operate your appliance

until you have read the safety precautions in this

manual. Safety items throughout this manual are

labeled with a WARNING or CAUTION based on the

risk type.

This symbol alerts you to

situations that may cause

serious body harm, death

or property damage.

Important Safety Instructions

3

This symbol alerts you to

situations that may cause

bodily injury or property

damage.

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn off power circuit at service panel and lock out panel, before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit

Page 4

4

Important safety Instructions

READ AND SAVE THESE INSTRUCTIONS

Important safety Instructions

FOR GENERAL VENTILATING USE ONLY. DO NOT USE

TO EXHAUST HAZARDOUS OR EXPLOSIVE

MATERIALS OR VAPORS.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

Use this unit only in the manner intended by the

A.

manufacturer. If you have questions, contact the

manufacturer

Before servicing or cleaning the unit, switch power off

B.

at service panel and lock service panel disconnecting

means to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

Installation Work and Electrical Wiring Must Be Done By

C.

Qualied Person(s) In Accordance With all Aplicable

Codes & Standards, Including Fire-rated Construction.

Sufcient air is needed for proper combustion and ex

D.

hausting of gases through the ue (Chimney) of fuel

burning equipment to prevent back- drafting. Follow

the heating equipment manufacturers guideline

and safety standards such as those published by

the National Fire Protection Association (NFPA),

the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

When cutting or drilling into wall or ceiling, do not

E.

damage electrical wiring and other hidden utilities.

Ducted systems must always be vented to the

F.

outdoors.

To reduce risk of re and to properly exhaust air, be sure to

duct air outside - do not vent exhaust air into spaces within

walls, ceilings, attics, crawl spaces, or garages.

TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCT WORK.

Install this hood insert in accordance with all requirements

specied.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE.

Never leave surface units unattended at high settings.

a)

Boilovers cause smoking and greasy spillovers that

may ignite. Heat oils slowly on low or medium settings.

Always turn hood ON when cooking at high heat or

b)

when ambeing food (l.e. Crepes Suzette, Cherries

Jubilee, Peppercorn Beef Flambe’).

Clean ventilating fans frequently. Grease should not

c)

be allowed to accumulate on fan or lter.

Use proper pan size. Always use cookware appropriate

d)

for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS, IN

THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

SMOTHER FLAMES with a close - tting lid, cookie

a)

sheet, or other metal tray, then turn off the gas burner

or the electric element. BE CAREFUL TO PREVENT

BURNS. If the ames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

NEVER PICK UP A FLAMING PAN - you may be

b)

burned.

DO NOT USE WATER, including wet dishcloths or

c)

towels - a violent steam explosion will result.

Use an extinguisher ONLY if:

d)

You know you have a class ABC extinguisher,

1)

and you already know how to operate it.

The re is small and contained in the area

2)

where it started.

The re department is being called.

3)

You can ght the re with your back to an exit.

4)

OPERATION

Always leave safety grills and lters in place.Without these

components, operating blowers could catch onto hair,

ngers and loose clothing.

The manufacturer declines all responsibility in the event

of failure to observe the instructions given here for

installation,maintenance and suitable use of the product.

The manufacturer further declines all responsibility for injury

due to negligence and the warranty of the unit automatically

expires due to improper maintenance.

To Reduce The Risk Of Fire Or Electric Shock, Do Not

Use This Hood Insert With Any External Solid State Speed

Control Device.

Page 5

List of materials- Electrical & Installation

requirements

5

List of Materials

Parts included in your hood insert

Metal grease lters:

•

- Model EI30HI55KS: 2 lters

- Model EI36HI55KS: 3 lters

- Model EI48HI55KS: 4 lters

Hood insert with 4 halogen lamps installed.

•

1 - 10” (25.4 cm) square to 10” (25.4 cm) round

•

duct transition with damper.

4 - 5 x 45 mm mounting screws for cabinet

•

4 - 4.2 x 8 mm screws for 10” round ducting damper

•

2 - 18mm spacer screw (only for EI30HI55KS

•

hood insert model)

Parts Needed

Home power supply cable

•

1 - ½” (1.3 cm) UL listed or CSA approved strain relief

•

3 - UL listed wire connectors

•

1 wall or roof cap

•

Metal vent system

•

Blower motor system - internal or remote (see

•

“Blower Motor Options” section).

Tools/Materials required

Level

•

Drill

•

1¼” (3 cm) drill bit

•

11/8” (3 mm) drill bit

•

Pencil

•

Wire stripper or knife

•

Tape measure or ruler

•

Pliers

•

Blower Motor Options

(1 system is required with Vent Hood Insert)

BLOWER MOTOR SYSTEM KITS HOOD INSERT MODELS

MODEL RATING

EI06HIPIKS

(600 cfm Int. Blower Kit)

EI12HIPIKS

(1200 cfm Int.Blower Kit)

EI06HIPRKS

(600 cfm Remote Blower Kit)

EI12HIPRKS

(1200 cfm Remote Blower Kit)

You can use your range hood model with this blower motor kit.

3.7 A

7.4 A

3.7 A

7.4 A

Caulking gun and

•

weatherproof caulking

compound

Vent clamps

•

Jigsaw or keyhole saw

•

Flat-blade screwdriver

•

Metal snips

•

Phillips screwdriver

•

EI30HI55K5 EI36HI55K5 EI48HI55K5

• • •

• •

• • •

• • •

Electrical Requirements

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and

in conformance with National Electrical Code, ANSI/

NFPA 70 (latest edition), or CSA Standards C22.194, Canadian Electrical Code, Part 1 and C22.2 No.

0-M91 (latest edition) and all local codes and ordinances.

If codes permit and a separate ground wire is used, it

is recommended that a qualied electrician determine

that the ground path is adequate.

A copy of the above code standards can be obtained

from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

A 120 volt, 60 Hz., AC only, 15-amp, fused

•

electrical circuit is required.

If the house has aluminum wiring, follow the

•

procedure below:

Connect a section of solid copper wire to the

1.

pigtail leads.

Connect the aluminum wiring to the added

2.

section of copper wire using special co

nectors and/or tools designed and UL listed

for joining copper to aluminum.

Follow the electrical connector manufacturer’s recommended procedure. Aluminum/copper connection

must conform with local codes and industry accepted

wiring practices.

Wire sizes and connections must conform with

•

the rating of the appliance as specied on the

model/serial rating plate.

The model/serial plate is located behind the lter

on the rear wall of the range hood.

Wire sizes must conform to the requirements of

•

the National Electrical Code, ANSI/NFPA 70 (la

est edition), or CSA Standards C22. 1-94,

Canadian Electrical Code, Part 1 and C22.2

No. 0-M91 (latest edition) and all local codes and

ordinances.

CAUTION

To reduce the risk of re and electric shock, install

this hood insert only with internal and remote

blower models rated maximum 7.4 A

(Electrolux™).

Page 6

6

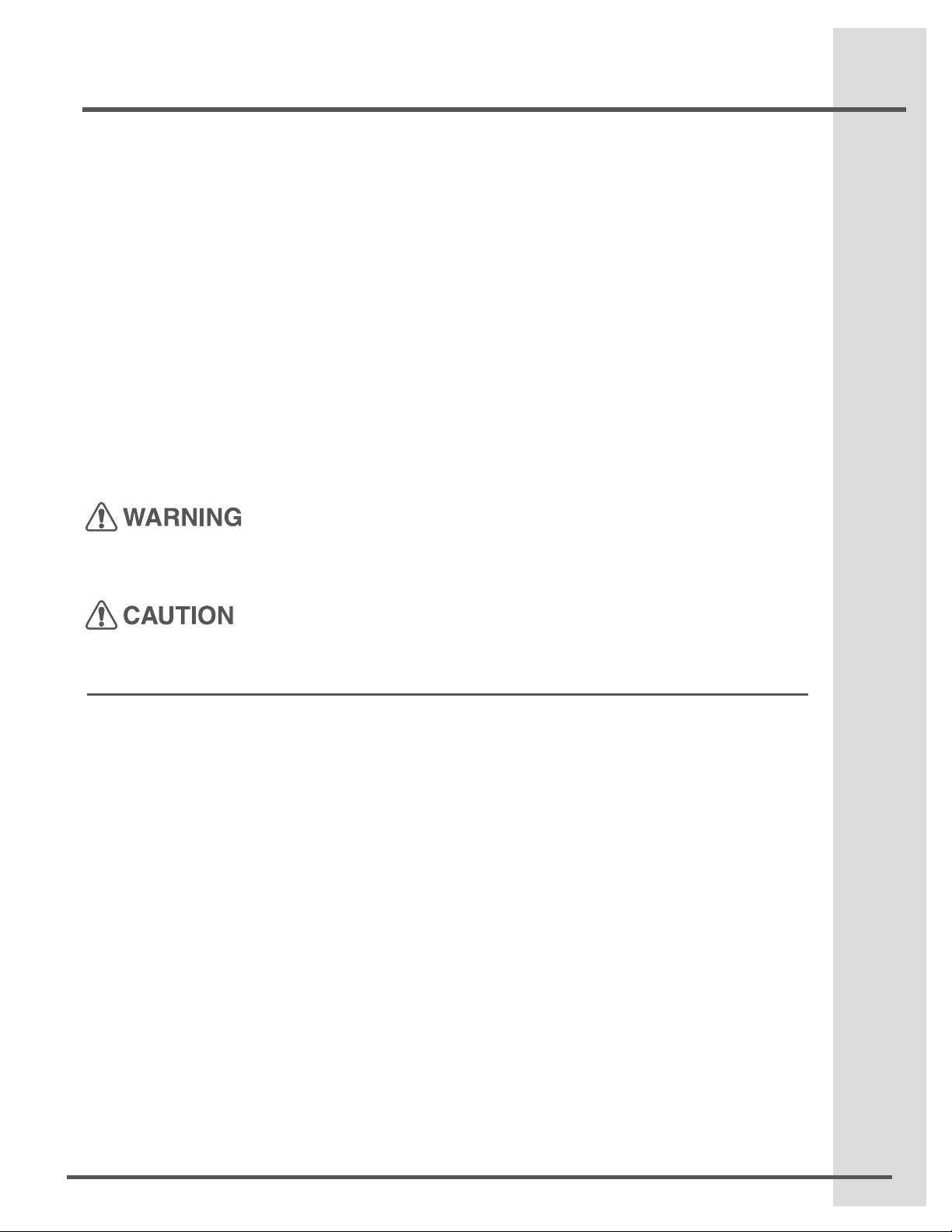

Location requirements

Location Requirements

IMPORTANT: Observe all governing codes and ordinances. Have a qualied technician install the hood

insert. It is the installer’s responsibility to comply with

installation clearances specied on the model/serial

rating plate. The model/serial rating plate is located

behind the left lter on the rear wall of the hood

insert.

The hood insert location should be away from strong

draft areas, such as windows, doors and strong heating vents.

Cabinet opening dimensions that are shown must be

used. Given dimensions provide minimum clearance.

The hood insert must be surrounded by a custom built

enclosure with hood cabinet capable of supporting 75

lb (34 kg).

Grounded electrical outlet is required. See “Electrical

Requirements” section on page 5.

All openings in ceiling and wall where canopy hood

will be installed must be sealed.

For Mobile Home Installations

The installation of this hood insert must conform to the

Manufactured Home Construction Safety Standards,

Title 24 CFR, Part 328 (formerly the Federal Standard

for Mobile Home Construction and Safety, Title 24,

HUD, Part 280) or when such standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and Setups) ANSI A225.1/NFPA 501A, or latest

edition, or with local codes.

Cabinet Dimensions

30” (76.2 cm) for 30” models

36” (91.4 cm) for 36” models

48” (121.9 cm) for 48” models

Hood insert cabinet must be

capable of supporting

75 lb (34 kg)

“X” bottom of canopy to

cooking surface

22”

(55.9 cm)

Hood insert

depth

IMPORTANT:

Minimum distance “X”: 24” (61 cm) from electric cooking surfaces.

Minimum distance “X”: 30” (76.2 cm) from gas cooking surfaces.

Suggested maximum distance “X”: 36” (91.4 cm).

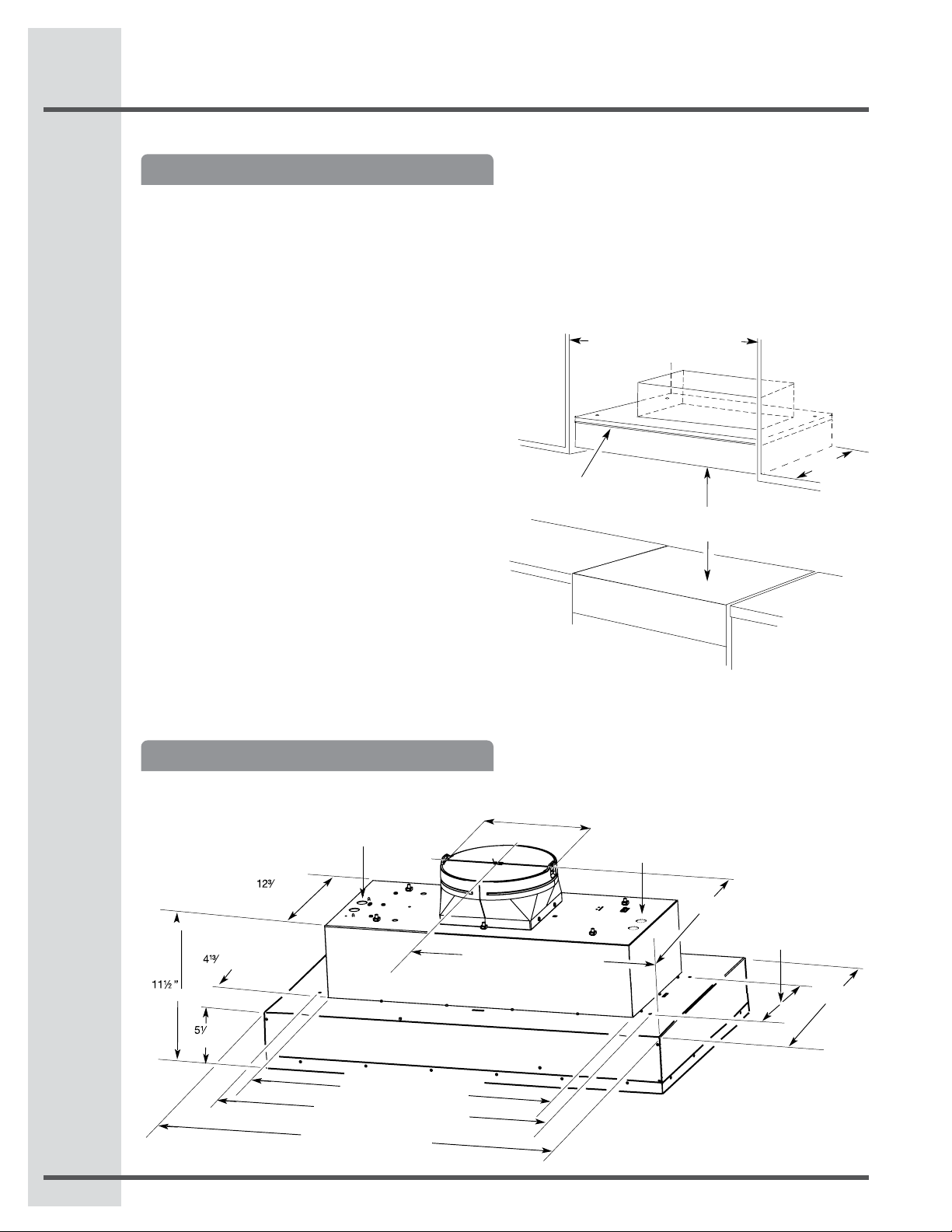

Product dimensions

36” & 48” models

wiring knockout

8

”

(31.4 cm)

16

” (12.2 cm)

(29.2 cm)

16

”

(12.8 cm)

245/16”(61.8cm) for 30” models

30” (75.8 cm) for 36 & 48” models

30” (76.2 cm) for 30” models

36” (91.4 cm) for 36” models

48” (121.4 cm) for 48” models

22” (56 cm) for 30”models

271/2”(70 cm) for 36 & 48”models

97/8” (25.11 cm)

15” (38 cm) for 30” models

18” (45.2 cm) for 36” models

24” (61 cm) for 48” models

30” model

wiring knockout

11” (28 cm)

11” (28 cm) for 30” model

10 1/8” (25.7 cm) for 36 & 48” models

22” (55.9 cm)

Page 7

Venting Requirements

Vent system must terminate to the outdoors.

•

Do not terminate the vent system in an attic or

•

other enclosed area.

Do not use 4” (10.2 cm) laundry-type wall caps.

•

Use metal vent only. Rigid metal vent is

•

recommended. Plastic or metal foil vent is not

recommended.

The length of vent system and number of elbows

•

should be kept to a minimum to provide efcient

performance.

For the most efcient and quiet operation:

Use no more than three 90° elbows.

•

Make sure there is a minimum of 24” (61.0 cm) of

•

straight vent between the elbows if more than 1

elbow is used.

Do not install 2 elbows together.

•

Use clamps to seal all joints in the vent system

•

and use furnace duct tape to fully seal joint

connection.

Use caulking to seal exterior wall or roof opening

•

around the cap.

The size of the vent should be uniform.

•

Cold weather installations

An additional back draft damper should be installed

to minimize backward cold air ow as part of the vent

system.

A thermal break should be installed to minimize conduction of outside temperatures as part of the vent

system.

The damper should be on the cold air side of the

thermal break.

The break should be as close as possible to where the

vent system enters the heated portion of the house.

Makeup air

Local building codes may require the use of makeup

air systems when using ventilation systems greater

than specied CFM of air movement. The specied

CFM varies from locale to locale.

Consult your HVAC professional for specic requirements in your area.

Venting Methods

The hood exhaust opening has a 10” diameter

•

round vent outlet.

On installations using the 600 CFM Blower Motor

•

Systems, a 6” or 8” round vent system is

recommended.

Venting Requirements

On installations using the 1200 CFM Blower Motor

•

Systems, a 10” round vent system should be

used.

You can use a smaller round vent system , but

•

there will be a louder sound level.

NOTE: Flexible vent is not recommended.

Flexible vent creates back pressure and air

turbulence that greatly reduce performance.

Vent system can terminate either through the

roof or wall. To vent through the wall, a 90° elbow

is needed.

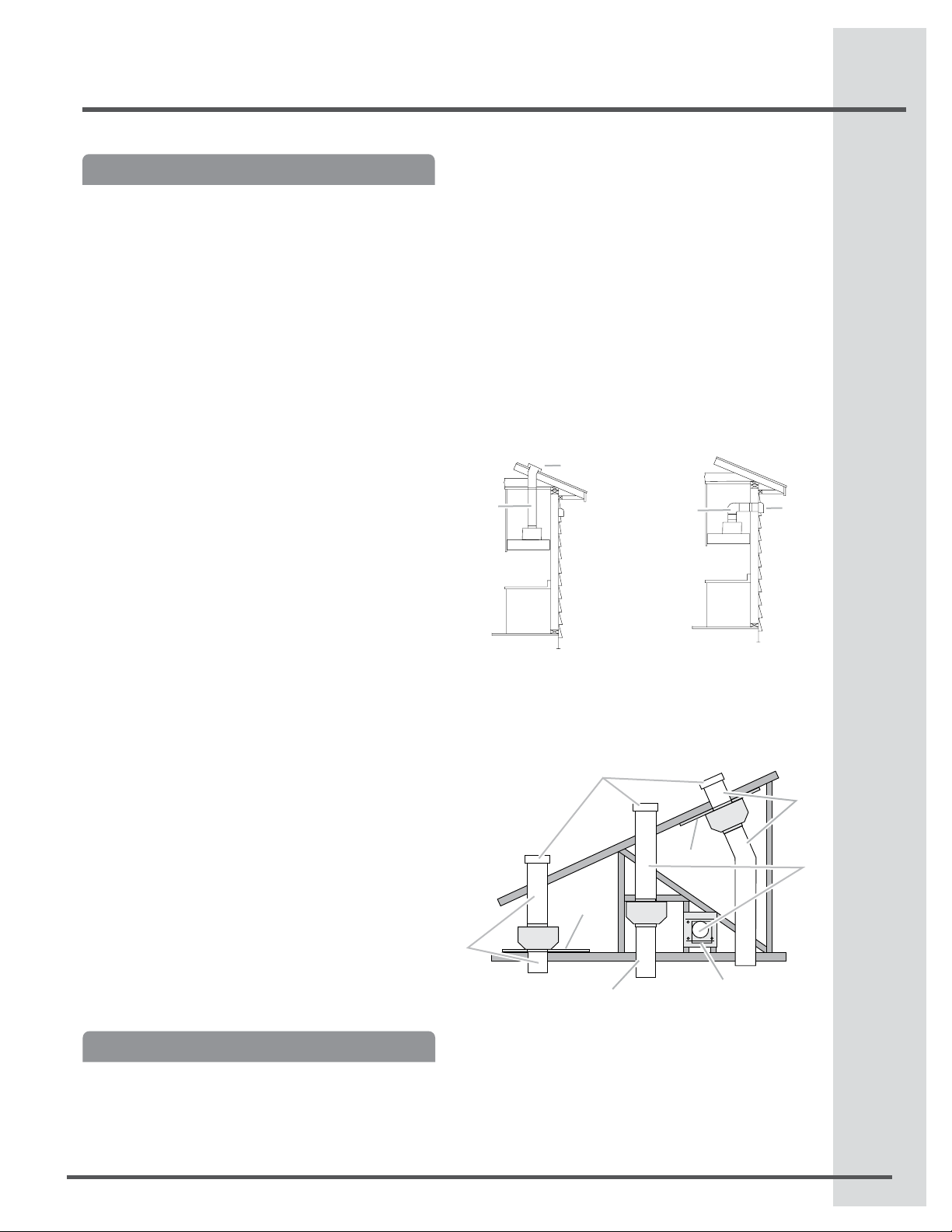

Roof venting

A

A. 10” (25.4 cm) round vent

B. Roof cap

B

Wall Venting

A

A. 10” (25.4 cm) round vent

B.Wall cap

Typical Remote Blower Motor System Venting

Installations

C

E

D

B

A

A. 10” (25.4 cm) round vent

B. Mount on top of ceiling joists.

C. Roof caps

D. Plywood (optional for some installations)

E. Mount on underside of roof rafters.

F. Mount from cross-members tied to trusses.

G. Duct horizontal; mount to cross-members tied to trusses.

H. Wall cap

D

F

G

A

H

B

A

7

A

Page 8

8

Blower Motor Systems Installation

Install Hood Insert Internal

Blower Motor

The internal blower system can be mounted for top

venting.The mounting bracket and spring clip that

comes with the blower system will mount to the top

panel of the hood insert.

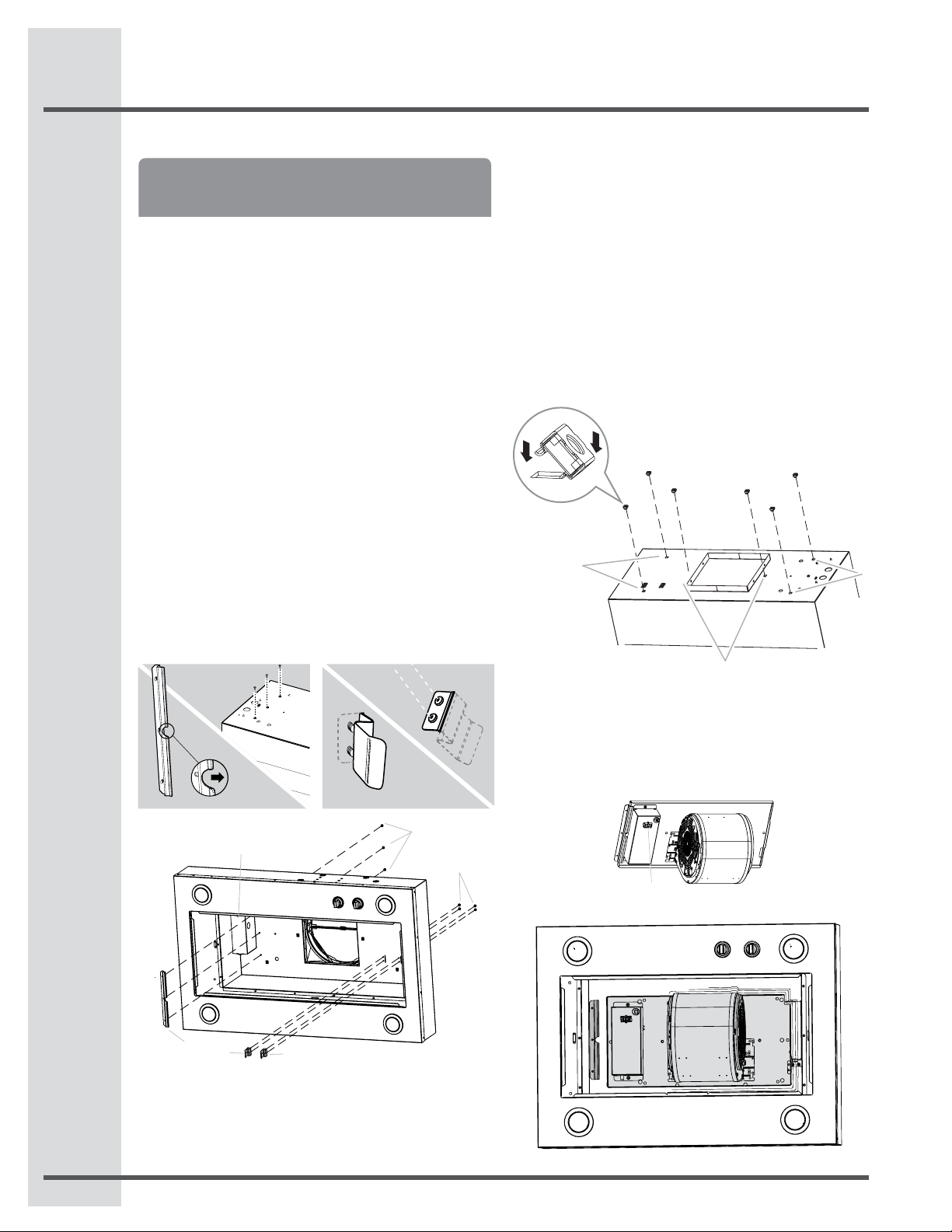

Internal Blower System Installation into Hood Insert

IMPORTANT: Perform steps 1-10 before mounting the

hood insert into the cabinet.

NOTE: Mounting hardware is included with the Blower

Motor System.

1.

Remove grease lters from hood insert. See the

“Cleaning” section in the Use and Care Guide.

2.

Install the motor support bracket using three 4.2 x

8 mm screws. Screw bracket to the inside top,

toward the left side of the hood insert (see step 2 figure).

3.

Install motor spring clip using two 4.2 x 8 mm

screws. Screw spring clip to the inside top of the

hood insert at the proper location for the selected

motor system. Slide the mounting tab of the

spring clip through the slot in the panel and secure

with the screws (see step 3 gure).

Outside the hood insert Outside the hood insert

Inside the hood insert Inside the hood insert

STEP 2 STEP 3

F*

A

C

D

A. 4.2 x 8 mm screws (3) for motor support bracket

B. 4.2 x 8 mm screws (2) for motor spring clip

C.Motor support bracket

D.Motor spring clip (single motor assembly location)

E.Motor spring clip (dual motor assembly location)

F. Terminal Box

* In model EI30HI55KS is located on the right side

E

B

Install the 6 mm clip nuts to the outside top

4.

of the hood insert at the proper location for the

selected motor system.

Two 6 mm nuts are required for 600 CFM

•

(single motor) Blower Motor Assembly.

Clip nuts into the small square notches

located at the left and right end of the

square vent opening.

Four 6 mm nuts are required for 1200 CFM

•

(dual motor) Blower Motor Assembly. Clip

nuts into the small square notches, located

at the left and right ends of the square vent

opening.

A. 6mm Clip Nut

B. Clip nut locations for single motor assembly (2)

C. Clip nut locations for dual motor assembly (4)

A

C

Install the hood insert blower motor assembly

5.

inside the hood insert canopy with the wiring

B

connection to the left for the single motor system

and to the front or top for the dual motor system

Single Blower Motor Assembly

A

A.Wiring connection

C

Page 9

Blower Motor Systems Installation

9

Dual Blower Motor Assembly

A.Wiring connection

A

To install blower motor assembly, slide the left

6.

mounting plate ange under the motor mounting

bracket.

A

Push the right end of the motor mounting plate

7.

down and snap it into the spring tab.

B

A.Motor mounting bracket

B.Mounting plate left ange

NOTE: The spring tab should be outside the slot

in the mounting plate.

A

B

A. Motor mounting plate

B. Spring clip

Align mounting holes and install 6 x 16 mm

8.

bolts and 6.4 mm lock washers.

A. Bolt with lock washer

B. Mounting hole

Attach power cord connector from the hood insert

9.

to connector on wiring box.

A. Wiring Box Connector

B. Hood Insert Connector

A

B

Install 10” round ducting damper with 4 - 4.2 x 8

10.

mm mounting screws.

Continue to Prepare the Location on page 12.

11.

A. 10” round ducting damper

B. Installation screws

A

B

A

BB

Page 10

10

Blower Motor Systems Installation

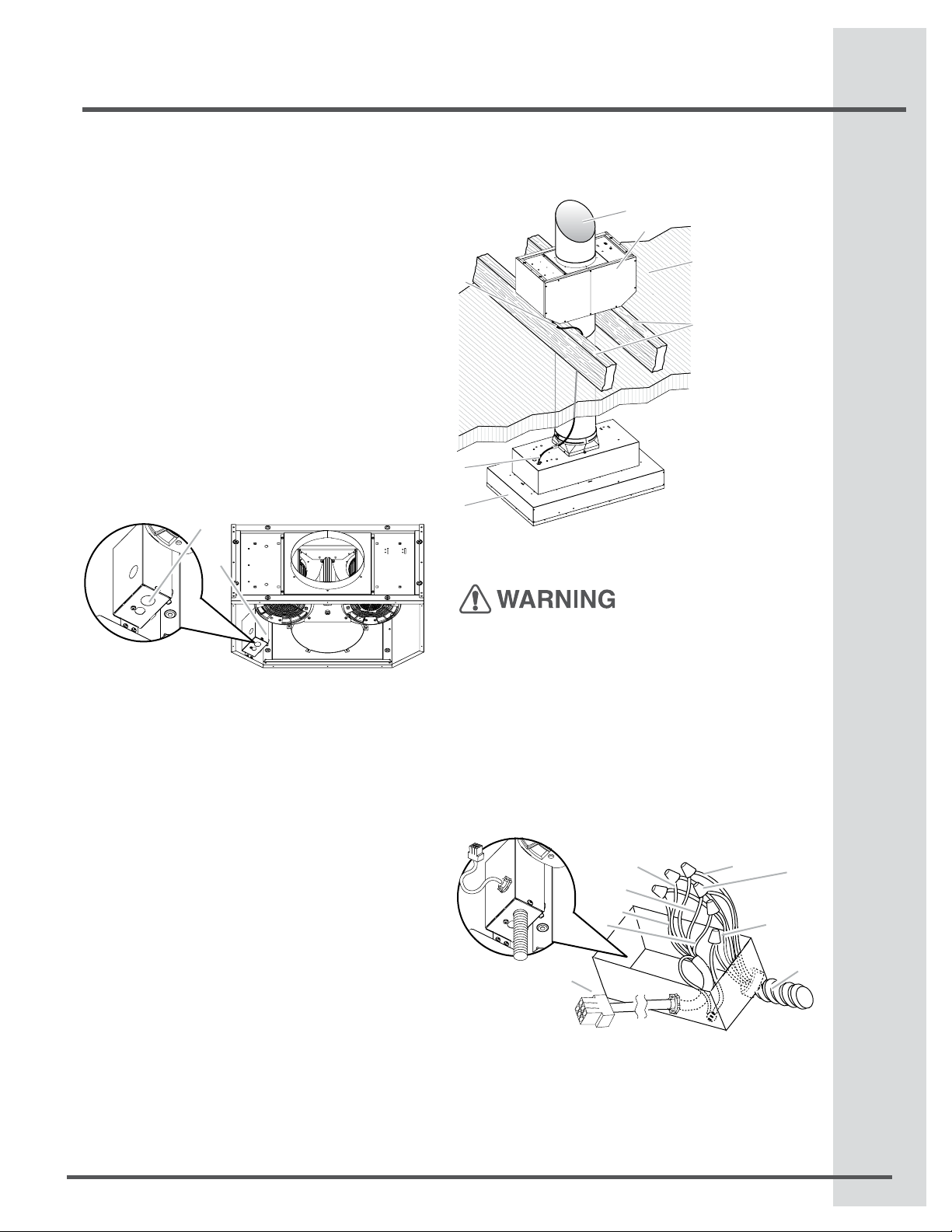

Remote Blower Motor

Installation into Hood Insert

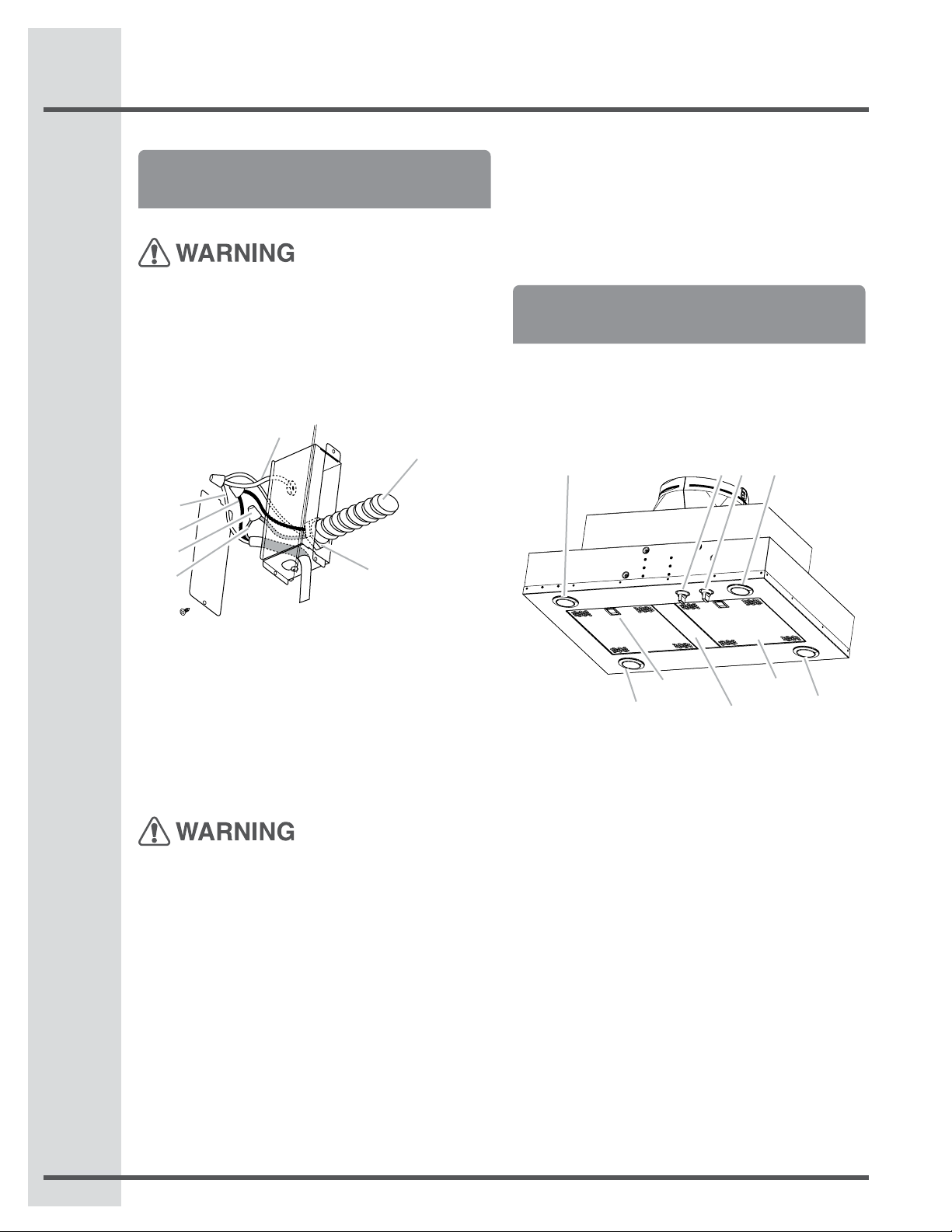

Prepare for Mounting the Remote Blower System

The remote blower system must be fastened to a secure structure of the roof, ceiling, wall, oor, or new or

existing frame construction. The 4 holes on either the

inlet (bottom) side or the outlet (top) side of the blower

must be used to mount the remote blower system to

the structure.

NOTE: The mounting hole locations must span the

studs. Additional stud framing may be required.

Plywood may be used to span open areas between

ceiling joists or roof rafters to aid installation. This

structure must be strong enough to support the weight

of the remote blower system (50 lb [22.6 kg] min).

Prepare the Remote Blower System

Excessive Weight Hazard

Use two or more people to move and install

Remote blower motor system.

Failure to do so can result in back or other injury.

A. Front cover

B. Blower mounting bolts (4)

C. Spring clip

A

D. Motor electrical plug

B

C

D

Install Remote Blower Motor System

NOTE: The blower motor housing can be mounted

using 4 holes from either the inlet side or the outlet side

of the blower.

A

A

Inlet Side

Using two or more people, move the remote

1.

blower motor system to the mounting location.

Remove the 10 screws from the front cover of the

2.

remote blower motor housing and set them aside.

Remove the front cover of the remote blower

3.

motor housing and set it aside.

NOTE: To make the blower motor housing easier to

mount, the blower motor assembly can be removed. If

you do not want to remove the blower motor assembly, proceed to “Install Remote Blower System” in this

section.

To Remove Blower Motor

Disconnect the motor electrical plug from the

1.

blower motor assembly.

Remove the screws that secure the blower motor

2.

assembly to the remote blower housing and set

them aside.

Pull the spring clip to release the blower motor

3.

assembly. Remove the blower motor assembly

from the housing and place it on a covered

surface.

A. Mounting holes

A

A

Outlet Side

Position the remote blower motor housing in its

1.

mounting location and mark the 4 mounting hole

locations.

Drill 4 mounting pilot holes using a ³⁄16” (5 mm) drill bit.

2.

Attach the remote blower motor housing to the

3.

mounting location with four 6 x 80 mm mounting

screws and washers.

If Blower Motor is removed, reinstall the blower

4.

motor assembly and secure it with the screws

A

A

Page 11

Blower Motor Systems Installation

11

previously removed. If it is removed, reattach the

motor electrical plug to the connector on the

blower motor assembly.

Complete Preparation

Determine and make all necessary cuts for the

1.

vent system.

IMPORTANT: When cutting or drilling into the ceiling

or wall, do not damage electrical wiring or other hidden utilities.

Determine the location where the ½” (1.3 cm)

2.

wiring conduit will be routed through the ceiling or

wall between the remote blower and the hood insert.

Drill a 1¹⁄4” (3.2 cm) hole at this location.

3.

Locate the electrical terminal boxes in the remote

4.

blower housing and hood insert (see “Complete

Preparation” in the “Prepare Location” section).

Remove the terminal box covers and set the

covers and screws aside.

B

A

A. Electrical terminal box

B. Electrical knockout

Remove the electrical knockout from the remote

5.

blower housing and hood insert (see “Preparation”

in the “Prepare Location” section) to prepare for

the installation of the UL listed or CSA approved

½” (1.3 cm) wiring conduit and conduit connector.

NOTE: Strain relief conduit are supplied with

remote blower hardware.

With the hood insert mounted (see the “Install Hood

6.

Insert” section), run the ½” (1.3 cm) wiring conduit

between the remote blower motor housing and the

hood insert. Pull enough ½” (1.3 cm) wiring conduit

to allow for easy connection to the terminal boxes

in the remote blower housing and hood insert.

Run the six 18 AWG wires through the 1⁄2” (1.3

7.

cm) wiring conduit and conduit connectors and

into the terminal boxes on the remote blower

housing and hood insert. Leave enough wire length

in each terminal box to make the wiring connections.

Install the conduit connectors and conduit to the

8.

remote blower housing and hood insert electrical

terminal boxes.

NOTE: Strain relief conduit are supplied with

remote blower hardware.

Connect the vent system to the hood insert and

9.

remote blower motor system. Use clamps at all

joints. Use furnace duct tape to seal all joints

tightly.

E

A

B

C

D

F

G

A. Vent System

B. Remote Blower Motor

C. Ceiling

D. Roof rafters / Plywood

E. Remote Blower Wiring

Conduit

F. Hood Insert Wiring

Conduit

G. Hood Insert

Make Electrical Connections for Remote Blower

Motor System

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical

shock.

Electrical Connection Inside Remote Blower System

Disconnect power.

1.

Connect the wires from the wiring conduit to the

2.

wires from the motor electrical plug cable inside

the remote blower housing terminal box.

C

E

F

G

I

A.UL listed or CSA approved

1

⁄2” (1.3 cm) wiring conduit

B.UL listed wire connectors

C.Black wires

D.White wires

E. Red wires

F. Blue wires

G. Gray wires

H. Green (or yellow/green) and

green/yellow wires

I.Motor electrical plug cable

D

B

H

A

Page 12

12

Make Electrical Connections

Use UL listed wire connectors and connect the

3.

black wires (C) together.

Use UL listed wire connectors and connect the

4.

white wires (D) together.

Use UL listed wire connectors and connect the

5.

red wires (E) together.

Use UL listed wire connectors and connect the

6.

blue wires (F) together.

Use UL listed wire connectors and connect the

7.

gray wires (G) together.

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground

wire in terminal box.

Failure to do so can result in death or electrical shock.

Connect the green (or yellow/green) ground wire

8.

to the green/yellow ground wire (H) in the terminal

box using UL listed wire connectors.

Reinstall the remote blower terminal box cover

9.

and screw.

Reinstall the front cover of the remote blower

10.

housing and secure it with 10 mounting screws.

Make Electrical Connection for Inside Hood Insert

Between Remote Blower Motor System and Hood

Insert

With the hood insert mounted (see the “Install

1.

Hood Insert” section), locate the wiring cable

connector inside the hood insert.

Connect the 6-wire connector assembly supplied

2.

with the remote blower motor system to the

mating cable connector from the hood insert.

Locate the terminal box inside the hood insert and

3.

install a ½” (1.3 cm) UL listed or CSA approved

strain relief.

Run the wire ends from the 6-wire connector a

4.

sembly through the ½” (1.3 cm) strain relief,

leaving enough wire length to make the wiring

conections. Tighten the strain relief screws.

Connect the wires from the 6-wire connector

5.

asembly to the wires from the remote blower

system wiring conduit inside the hood insert

terminal box.

Connect the same color wires to each other (black

6.

to black, white to white, etc.) using UL listed wire

connectors.

NOTE: Connect the green (or green/yellow) ground

wire from the Remote Blower Motor wiring conduit to

the green (or bare) ground wire from the home power

supply using UL listed wire connectors (refer to “Make

Electrical Power Supply Connection to Hood Insert”

section).

J K

B

A. UL listed or CSA approved

1

⁄2” (1.3 cm) wiring conduit

B. UL listed wire connectors

C. Black wires

D.White wires

E. Red wires

A

F. Blue wires

G.Gray wires

H. Green (or green/yellow) wire

I. 6-wire connector assembly

J. Home power supply knockout

K. Remote Blower Motor knockout

I

Ground Wiring

Connections

Home

Power Supply

Blower Motor

Go to the “Make Electrical Power Supply

7.

Wire

Conector

Remote

Connection to Hood Insert” section.

Prepare the Location

Disconnect power.

1.

Determine which venting method to use: roof or

2.

wall exhaust.

Select a at surface for assembling the hood

3.

insert. Place covering over that surface.

It is recommended that the vent system be

•

installed before hood is installed.

Before making cutouts, make sure there is proper

•

clearance within the ceiling or wall for exhaust vent.

Hood insert should be installed a minimum 24”

•

(61 cm) above an electric cooktop surface and 30”

(76.2 cm) above a gas cook top surface.

The maximum recommended height over both

cook tops is 36” (91.44 cm).

C

D

E

F

G

H

Hood

Insert

Page 13

Make Electrical Connections

13

Check that all installation parts have been

•

removed from the shipping carton.

Using 2 or more people, lift hood insert onto

4.

covered surface.

Remove the lters. See the “Cleaning”

5.

section on page 15.

Install Hood insert into

Hood Cabinet

The hood insert attaches to the hood cabinet using

four mounting screws and washers.

NOTE: Hood cabinet must be capable of supporting

75 lb (34 kg).

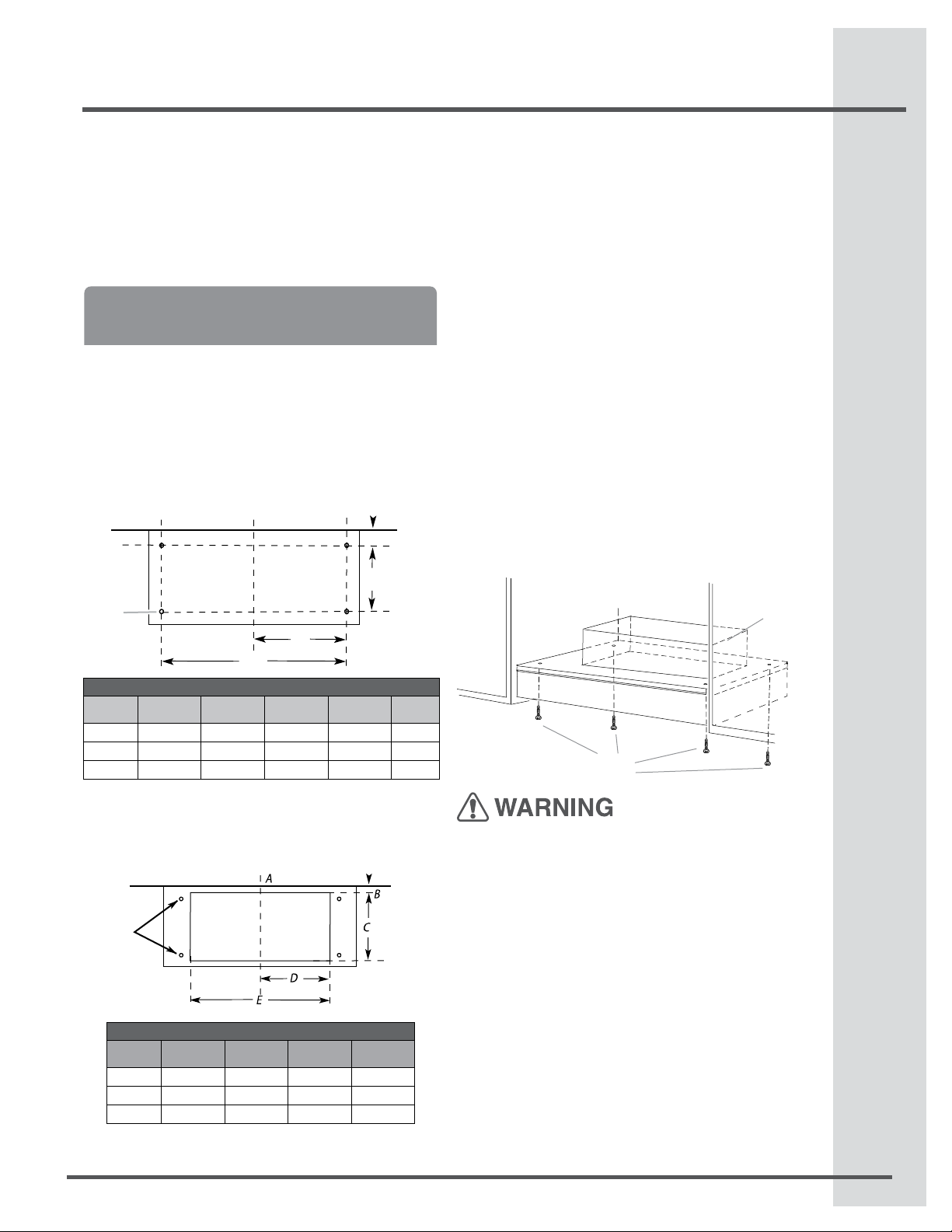

Prepare Hood Insert for mounting into cabinet

Mark the locations for the four mounting screws

1.

on the hood cabinet as shown below.

Using a ¹⁄8” (3 mm) drill bit, drill the 4 holes.

2.

F

A. Centerline

Hood

Insert

EI30HI55KS

EI36HI55KS

EI48HI55KS

3.

DIM B DIM C DIM D DIM E DIM F

51⁄2” (13.9 cm) 11” (28 cm) 125⁄32” (30.9 cm) 245⁄16” (61.8 cm) 1/8” (3mm)

6” (15.1 cm) 101⁄8” (25.7 cm) 1415⁄16” (38 cm) 2913⁄16” (75.8 cm) 1/8” (3mm)

6” (15.1 cm) 101⁄8” (25.7 cm) 1415⁄16” (38 cm) 2913⁄16” (75.8 cm) 1/8” (3mm)

Mark the cutout for the rectangular clearance hole

for the upper hood insert motor housing as shown.

Using a jigsaw or keyhole saw, cut out the rectan-

4.

gular clearance hole for the upper hood insert housing.

Mounting

holes

A. Centerline

A

D

E

MOUNTING HOLE DIMENSIONS

B

C

Complete Installation

Determine and make all necessary cuts in the

1.

wall or roof for the vent system. Install the vent

system before installing the cabinet hood insert.

See the “Venting Requirements” section.

Determine the location where the power supply

2.

cable will be run through the wall.

Drill a 1¹⁄4” (3.2 cm) hole at this location.

3.

Pull enough power supply cable through the wall

4.

to allow for easy connection to the terminal box.

Remove terminal box cover and set aside.

5.

Remove knockout from the top of the vent hood

6.

and install a UL listed or CSA approved ½”

(1.3 cm) strain relief.

Place the hood insert near its mounting position

7.

and run the power supply cable through the strain

relief into terminal box (enough to make connection).

Tighten the strain relief screws.

8.

Using 2 or more people, lift the hood insert into

9.

hood cabinet.

Fasten the hood insert using four 5 x 45 mm

10.

screws to the hood cabinet and tighten securely.

Insert Motor Housings

4 mounting

screws

EXCESSIVE WEIGHT HAZARD

USE TWO OR MORE PEOPLE TO MOVE AND

INSTALL HOOD INSERT.

FAILURE TO DO SO CAN RESULT IN BACK OR

OTHER INJURY.

Upper Hood

Hood

Insert

EI30HI55KS

EI36HI55KS

EI48HI55KS

UPPERHOOD MOTOR HOUSINgS DIMENSIONS

DIM B DIM C DIM D DIM E

413⁄32” (11.2 cm) 133⁄16” (33.5 cm) 1113⁄32” (29 cm) 2213⁄16” (58 cm)

413⁄32” (11.2 cm) 133⁄16” (33.5 cm) 143⁄16” (36 cm) 283⁄8” (72 cm)

413⁄32” (11.2 cm) 133⁄16” (33.5 cm) 143⁄16” (36 cm) 283⁄8” (72 cm)

Page 14

14

Make Electrical Connections

Make Electrical Power Supply

Connection to Hood Insert

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical

shock.

Disconnect power.

1.

Locate terminal box inside of the hood insert.

2.

A

B

C

D

A.White wires

B. Black wires

C. UL listed wire connectors

D. Green, bare or yellow/green wires

E.Home power supply

F. UL listed or CSA approved ¹⁄2” (1.3 cm) strain relief

G. Ground Wire tab

Use UL listed wire connectors and connect black

3.

wires (B) together.

Use UL listed wire connectors and connect white

4.

wires (A) together.

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground

wire in terminal box.

Failure to do so can result in death or electrical

shock.

NOTE: When using an Remote blower motor system,

the green (or green/yellow) ground wire in the conduit

from the Remote blower motor system is to be

connected with the green (or bare) wire of the home

power supply cable and with the green/yellow wire (D)

in the terminal box.

G

E

F

Connect green (or bare) ground wire from home

5.

power supply to the green/yellow ground wire (D)

in terminal box using UL listed wire connectors.

Install terminal box cover.

6.

Check that all light bulbs are secure in their

7.

sockets.

Reconnect power.

8.

Complete Installation and Check

Operation

Install grease lters. See the “Cleaning”

1.

section. See page 15.

Check operation of the Hood Insert blower and

2.

lights. See the “Hood Insert Use” section.

See page 15.

3.

whether a circuit breaker has tripped or a hous

hold fuse has blown.

4.

wiring is correct.

NOTE: To get the most efcient use from your new

hood insert, read the “Hood Insert Use” section.

A AB C

If the hood insert does not operate, check to see

Disconnect power supply and check that the

D E

A

A. Halogen lights

B. Halogen light switch

C. Blower control switche

D. Grease lter handle

E. Grease lter

F. Filter Spacer (Only for EI30HI55KS model)

F

A

Page 15

Hood Insert Use

15

Hood Insert Use

The hood insert is designed to remove smoke, cooking vapors and odors from the cooktop area. For best

results, start the hood before cooking and allow it to

operate several minutes after the cooking is complete

to clear all smoke and odors from the kitchen.

The hood controls are located on the underside of the

hood insert.

Light control Fan control

Operating the light

Turn the light switch (A) to the left 1 position for HIGH.

Turn the light switch (A) to the left 2 postions for LOW.

To turn the lights OFF, rotate the light switch (A) to the

right to the OFF position.

Operating the fan

The fan has 4 speeds. Rotate the fan switch (B) to

the left to turn the fan to the ON position. Continue to

rotate the switch to the desired fan speed.

To turn the fan OFF, rotate the fan speed (B) switch to

the right to the OFF position.

WARNING: The internal blower motor of the hood is

thermally protected against high temperatures.

If the hood insert is not turned on during the cooking

process, high temperatures could be present inside

the hood and the motor could not work until the temperature is safe. The hood insert should be

turned on during cooking operations.

Cleaning

IMPORTANT: Clean the hood insert and grease lters

frequently according to the following instructions. Replace grease lters before operating hood insert.

Exterior Surfaces:

To avoid damage to the exterior surface, do not use

steel wool or soap-lled scouring pads.

Always wipe dry to avoid water marks.

Cleaning Method:

Liquid detergent soap and water, or all-purpose

•

cleaner.

Wipe with damp soft cloth or nonabrasive sponge,

•

then rinse with clean water and wipe dry.

Metal Grease Filter:

Remove each lter by pulling the spring release

1.

handle and then pulling down the lter.

Wash metal lters as needed in dishwasher or hot

2.

detergent solution.

Reinstall the lter by making sure the spring

3.

release handles are toward the front. Insert

aluminum lter into upper track.

Push in spring release handle.

4.

Push up on metal lter and release handle to latch

5.

into place.

Repeat steps 1-5 for the other lter.

6.

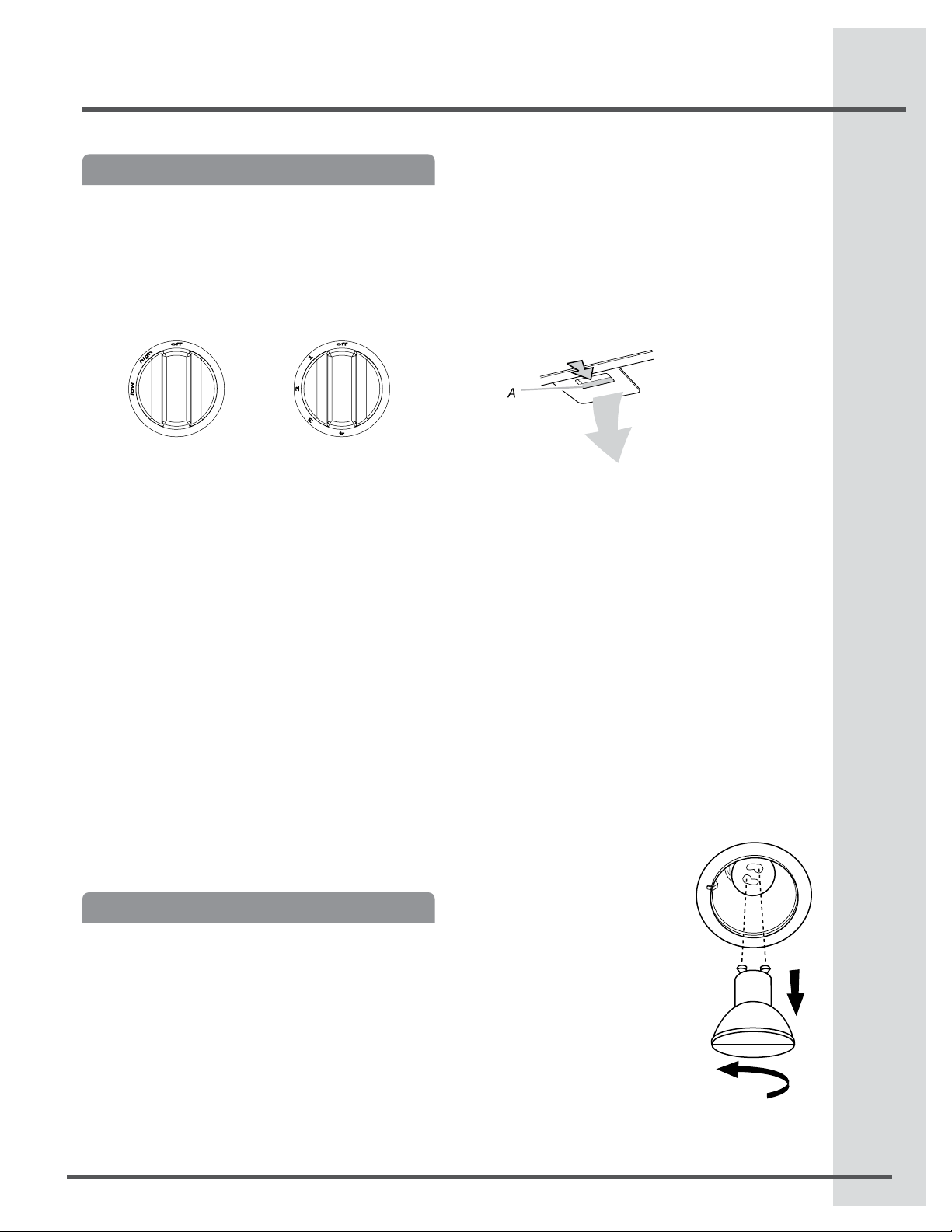

Replacing the Halogen Lamps

Turn off the hood insert and allow the halogen lamp

to cool. To avoid damage or decreasing the life of the

new bulb, do not touch bulb with bare ngers. Replace bulb, using tissue or wearing cotton gloves to

handle bulb.

If new lamps do not operate, make sure the lamps are

inserted correctly before calling service.

Disconnect power.

1.

Push up on the lens and turn

2.

it counterclockwise.

Remove the bulb and replace

3.

it with a 120-volt, 50-watt

maximum halogen bulb with a

GU10 base. Turn it clockwise

to lock it into place.

Repeat steps 2-3 for the other

4.

bulb if needed.

Reconnect power.

5.

A.Spring release handle

Page 16

16

Warranty Information

Your appliance is covered by a one year limited warranty. For one year from your original date of purchase, Electrolux will pay

all costs for repairing or replacing any parts of this appliance that prove to be defective in materials or workmanship when

such appliance is installed, used and maintained in accordance with the provided instructions.

Exclusions This warranty does not cover the following:

1. Products with original serial numbers that have been removed, altered or cannot be readily determined.

2. Product that has been transferred from its original owner to another party or removed outside the USA

or Canada.

3. Rust on the interior or exterior of the unit.

4. Products purchased “as-is” are not covered by this warranty.

5. Food loss due to any refrigerator or freezer failures.

6. Products used in a commercial setting.

7. Service calls which do not involve malfunction or defects in materials or workmanship, or for appliances

not in ordinary household use or used other than in accordance with the provided instructions.

8. Service calls to correct the installation of your appliance or to instruct you how to use your appliance.

9. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards,

shelves, etc., which are not a part of the appliance when it is shipped from the factory.

10. Service calls to repair or replace appliance light bulbs, air lters, water lters, other consumables, or

knobs, handles, or other cosmetic parts.

11. Surcharges including, but not limited to, any after hour, weekend, or holiday service calls, tolls, ferry trip

charges, or mileage expense for service calls to remote areas, including the state of Alaska.

12. Damages to the nish of appliance or home incurred during installation, including but not limited to

doors, cabinets, walls, etc.

13. Damages caused by: services performed by unauthorized service companies; use of parts other than

genuine Electrolux parts or parts obtained from persons other than authorized service companies; or

external causes such as abuse, misuse, inadequate power supply, accidents, res, or acts of God.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES CUSTOMER’S SOLE AND

EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR OR

REPLACEMENT AS PROVIDED HEREIN. CLAIMS BASED ON IMPLIED WARRANTIES, INCLUDING

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO

ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW, BUT NOT LESS THAN ONE YEAR.

ELECTROLUX SHALL NOT BE LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES SUCH AS

PROPERTY DAMAGE AND INCIDENTAL EXPENSES RESULTING FROM ANY BREACH OF THIS

WRITTEN LIMITED WARRANTY OR ANY IMPLIED WARRANTY. SOME STATES AND PROVINCES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR

LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES, SO THESE LIMITATIONS OR

EXCLUSIONS MAY NOT APPLY TO YOU. THIS WRITTEN WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

If You Need Keep your receipt, delivery slip, or some other appropriate payment record to establish the warranty period

Service should service be required. If service is performed, it is in your best interest to obtain and keep all receipts.

Service under this warranty must be obtained by contacting Electrolux at the addresses or phone numbers

below.

This warranty only applies in the USA and Canada. In the USA, your appliance is warranted by Electrolux Major Appliances

North America, a division of Electrolux Home Products, Inc. In Canada, your appliance is warranted by Electrolux Canada

Corp.

Electrolux authorizes no person to change or add to any obligations under this warranty. Obligations for service and parts

under this warranty must be performed by Electrolux or an authorized service company. Product features or specications

as described or illustrated are subject to change without notice.

USA

1.282.622.373

Electrolux Major Appliances

North America

10200 David Taylor Drive

Charlotte, NC 28262

Canada

1.800.265.8352

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

L5V 3E4

Page 17

Trouver l’information

Lisez ces instructions et conservez-les

Merci d’avoir choisi Electrolux, le nouveau premier brand pour les appareils domestiques. Ce Guide

d’Utilisation et d’Entretien fait partie de notre engagement pour la satisfaction du client et la qualité du produit

à travers un service d’assistance pour votre nouvel appareil.

Votre achat est le début de notre relation. Pour nous assurer de continuer à bien vous servir, utiliser cette

page pour enregistrer des informations produit importantes.

Garder une trace pour trouver rapidement une référence.

17

Date d’achat

Numéro modèle Electrolux

Numéro de série Electrolux

Enregistrer votre produit avec Electrolux nous permet

de mieux vous servir. Vous pouvez vous enregistrer

sur www.electroluxappliances.com ou en envoyant

votre Carte d’Enregistrement Produit par courrier.

REMARQUE

Des Questions?

Pour assistance téléphonique aux U.S. et Canada:

US.: 1.800.944.9044 / Canada: 1.800.265.8352

Pour support online et information produit sur Internet, visiter http:// www.electroluxappliances.com

Table des matières

Avis de sécurité important................................... 18

Outils et pièces...................................................... 21

Spécifications électriques.................................... 21

Exigences d’emplacement................................... 22

Dimensions du produit ......................................... 22

Exigences concernant l’évacuation................... 23

Méthodes d’évacuation................................................. 23

Installation du moteur interne

a la hotte intégrée.................................................. 24

Installation du moteur remote

a la hotte intégrée.................................................. 26

Réalisation des connexions électriques

du Motor Remote Systeme.................................. 27

Préparation de l’emplacement............................ 29

Réalisation des connexions de l’alimentation

électrique à la caisse de la hotte......................... 30

Achever l’installation et vérier

le fonctionnement.................................................. 31

Utilisation de la hotte.............................................31

Nettoyage................................................................ 32

Informations sur la garantie................................. 33

Page 18

18

Avis de sécurité important

Avis de sécurité important

Lire toutes les instructions avant

d’utiliser l’appareil.

Conserver ces instructions pour une

future consultation.

Approuvé comme appareil domestique.

Pour usage résidentiel uniquement.

Ne pas essayer d’installer ou d’utiliser votre appareil

si vous n’avez pas lu les instructions de sécurité de

ce manuel. Les particularités de sécurité de ce

manuel sont marqués d’ un AVERTISSEMENT ou

ATTENTION selon le type de risque.

Ce symbole vous avertit de situations pouvant

causer de graves lésions corporelles, la mort ou

un dommage matériel.

Ce symbole vous avertit de situations pouvant

causer des blessures corporelles ou des dégâts

matériels.

VEUILLEZ LIRE CES INSTRUCTIONS AU COMPLET AVANT DE COMMENCER.

L’INSTALLATION DE L’APPAREIL DOIT RESPECTER TOUS LES CODES EN VIGUEUR.

IMPORTANT : Conservez ces instructions an de pouvoir les remettre à l’inspecteur-électricien de votre

région.

INSTALLATEUR : Veuillez laisser ces instructions avec l’appareil pour le propriétaire.

PROPRIÉTAIRE : Veuillez conserver ces instructions pour pouvoir vous y référer plus tard.

Avertissement de sécurité : Coupez l’alimentation du circuit dans le panneau électrique et verrouillez le

panneau avant de raccorder les ls de cet appareil.

Exigence : 120 V c.a., 60 Hz circuit de dérivation de 15 V c.a., 20 Hz, de 15 ou 20 A.

Page 19

Avis de sécurité important

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

Avis de sécurité important

19

UTILISER CET APPAREIL À DES FINS DE VENTILATION

GÉNÉRALE SEULEMENT. NE PAS UTILISER CET

APPAREIL POUR ÉVACUER DES MATÉRIAUX OU DES

VAPEURS DANGEREUX OU EXPLOSIFS.

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE

CHOC ÉLECTRIQUE ET DE BLESSURE,

RESPECTER LES DIRECTIVES SUIVANTES:

Utiliser cet appareil uniquement aux ns prévues

A.

par le fabricant. Si vous avez des questions à propos

de l’appareil, communiquez avec le fabricant.

Avant de faire l’entretien de l’appareil ou de le nettoyer,

B.

coupez l’alimentation dans le panneau électrique et

verrouillez le panneau en bloquant le dispositif

permettant d’empêcher d’activer l’alimentation

accidentellement. S’il n’est pas possible de verrouiller

l’accès au panneau, xez une étiquette très voyante au

panneau électrique.

Une personne qualiée doit effectuer l’installation

C.

et le câblage des ls électriques en conformité

avec tous les codes et toutes les normes, y compris la

cote de résistance au feu.

Il est important de prévoir sufsamment d’air pour

D.

assurer une bonne combustion de l’équipement

de chauffe et l’évacuation adéquates des gaz par

le conduit de cheminé an de prévenir les refoulements

d’air. Respectez les directives et les normes de sécurité

des fabricants de l’équipement de chauffage, comme

celles publiées par la National Fire Protection

Association (NFPA), la American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

et le code des autorités de votre région.

Au moment de couper ou de percer un mur ou

E.

un plafond, assurez-vous de ne pas endommager

la lerie électrique ou tout autre accès à un

service publique.

Il faut toujours évacuer à l’extérieur les systèmes

F.

à conduit.

Pour réduire les risques d’incendie et évacuer l’air

correctement, assurez-vous que le conduit mène à

l’extérieur; il ne faut pas évacuer l’air dans l’espace entre

les murs, dans les plafonds, dans les greniers, les vides

sanitaires ou les garages.

POUR RÉDUIRE DES RISQUES D’INCENDIE, UTILISEZ

UNIQUEMENT DES CONDUITS EN MÉTAL.

Installez cette hotte en respectant toutes les exigences

mentionnées.

Pour réduire les risques d’incendie et de choc électrique,

n’utilisez pas cette hotte avec un contrôleur de vitesse à

semi-conducteurs.

POUR RÉDUIRE LES RISQUES D’INCENDIE DE GRAISSE

SUR LES CUISINIÈRES.

Ne laissez jamais la cuisinière sans surveillance

a)

lorsqu’elle est réglée à une haute température.

Les débordements par bouillonnement causent de la

fumée et des débordements de gras qui peuvent

s’enammer. Faites chauffer l’huile lentement, à une

température basse ou moyenne.

Faites toujours fonctionner la hotte lorsque vous

b)

utilisez la cuisinière à une haute température ou que

vous faites amber des aliments (P. ex.: crêpes Suzette,

cerises jubilées, boeuf au poivre ambé).

Nettoyez les hélices de ventilation fréquemment. Il ne

c)

faut pas que la graisse s’accumule sur les lres ou les

hélices.

Utilisez le bon format de casserole. Utilisez toujours un

d)

chaudron de taille approprié à l’élément de la cuisinière.

Page 20

20

Avis de sécurité important

POUR ÉVITER DE BLESSER QUELQU’UN LORS

D’UN INCENDIE DE GRAISSE SUR LA CUISINIÈRE,

SUIVRE LES CONSEILS SUIVANTS :

ÉTOUFFER LES FLAMMES avec un couvercle aux

a)

dimensions de la taque de cuisson, une tôle à biscuit ou

tout autre plateau métallique, puis couper le gaz ou

l’alimentation électrique de la cuisinière. FAIRE

ATTENTION A NE PAS SE BRÛLER. Si les ammes ne

s’éteignent pas immédiatement, QUITTER LA PIÈCE ET

APPELER LES POMPIERS.

NE JAMAIS PRENDRE EN MAIN UNE CASSEROLE

b)

EN FEU, vous pourriez vous blesser.

NE PAS UTILISER D’EAU, y compris les essuies

c)

de vaisselle ou les serviettes humides – une violente

explosion due à la vapeur formée pourrait survenir.

Utiliser un extincteur SEULEMENT si :

d)

Vous êtes sûr d’avoir un extincteur de classe

1)

ABC que vous savez utiliser.

Le feu est petit et conné à la zone où il s’est

2)

formé.

Les pompiers ont été appelés.

3)

Vous pouvez lutter contre le feu avec une

4)

sortie derrière vous.

MODE OPÉRATOIRE

Toujours laisser les grilles de sécurité et les ltres à leur

place. Sans la présence de ces derniers, les parties aspirantes pourraient attirer les cheveux, les doigts ou les vêtements.

Le fabricant décline toute responsabilité si les informations

détaillées dans ce manuel pour l’installation, l’entretien et

l’utilisation adéquate du produit ne sont pas observées.

Le fabriquant décline en outre toute responsabilité pour

d’éventuelles blessures dues à des négligences; en outre,

la garantie de l’appareil sera annulée suite à des conditions

d’entretien inappropriées. Cet appareil est fabriqué pour un

usage interne. Ne pas utiliser cet appareil à l’extérieur.

Page 21

Outils et pièces- Spécications électriques

21

Outils et Pièces

Pièces fournies

Filtres à graisse métalliques:

•

- Modèle EI30HI55KS: 2 ltres

- Modèle EI36HI55KS: 3 ltres

- Modèle EI48HI55KS: 4 ltres

Caisse de la hotte avec lampes à halogène installées.

•

1 - raccord de conduit carré de 10” (25,4 cm) à

•

rond de 10” (25,4 cm) avec clapet anti-retour.

4 - vis de montage de 5 x 45 mm

•

4 - vis de montage de 4.2 x 8 mm

•

2 - 18 mm entretoise vis (uniquement pour

•

EI30HI55KS modèle).

Pièces nécessaires

Câble d’alimentation électrique du domicile

•

1 serre-câble de ½” (1,3 cm) (homologation UL ou CSA)

•

3 connecteurs de ls homologués UL

•

1 bouche de décharge (décharge à travers le mur

•

ou à travers le toit)

Circuit d’évacuation métallique

•

Système du moteur du ventilateur — interne ou

•

remote (voir “Options du système moteur ”).

Outils nécessaires

Niveau

•

Perceuse

•

Foret de 1¼” (3 cm)

•

Foret de 1/8” (3 mm)

•

Crayon

•

Pince à dénuder ou

•

couteau utilitaire

Mètre-ruban ou règle

•

Pince

•

Options du système moteur

(1 système est nécessaire pour la hotte)

Options du systeme moteur HOTTE DE LA CUISINIERE MODELES

MODELES RATING

EI06HIPIKS

(600 cfm Int. Moteur Kit)

EI12HIPIKS

(1200 cfm Int. Moteur Kit)

EI06HIPRKS

(600 cfm Remote Moteur Kit)

EI12HIPRKS

(1200 cfm Remote Moteur Kit)

Vous pouvez utiliser le modèle de votre hotte de cuisinière avec ce kit

moteur du ventilateur.

3.7 A

7.4 A

3.7 A

7.4 A

Pistolet à calfeutrage

•

et composé de

calfeutrage résistant

aux intempéries

Brides de conduit

•

Scie sauteuse ou scie

•

à guichet

Tournevis à lame plate

•

Cisaille de ferblantier

•

Tournevis Phillips

•

EI30HI55K5 EI36HI55K5 EI48HI55K5

• • •

• •

• • •

• • •

Spécications électriques

Observer les dispositions de tous les codes et

règlements en vigueur.

Vérier que l’installation électrique a été correctement

effectuée et qu’elle est conforme aux spécications

de la plus récente édition des normes National Electrical Code, ANSI/NFPA 70, ou de la norme CSA C22.194, Code canadien de l’électricité, partie 1 et C22.2 N°

0-M91 (dernière édition) et de tous les codes et

règlements en vigueur locaux.

Si les codes le permettent et si on utilise un conducteur

distinct de liaison à la terre, il est recommandé qu’un

électricien qualié vérie la qualité de la liaison à la terre.

Pour obtenir un exemplaire de la norme des codes

ci-dessus, contacter:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

L’appareil doit être alimenté par un circuit de 120

•

V, CA seulement, 60 Hz, 15 A, protégé par fusible.

Si le domicile est équipé d’un câblage en

•

aluminium, suivre les instructions suivantes :

Connecter une section de câble en cuivre

1.

massif aux conducteurs en queue de cochon.

Connecter le câblage en aluminium à la

2.

section ajoutée de câblage en cuivre en

utilisant des connecteurs et/ou des outils

spécialement conçus et homologués UL pour

xer le cuivre à l’aluminium.

Appliquer la procédure recommandée par le fabricant

des connecteurs. La connexion aluminium/cuivre doit

être conforme aux codes locaux et aux pratiques de

câblage acceptées par l’industrie.

Le calibre des conducteurs et les connexions

•

doivent être compatibles avec la demande de

courant de l’appareil spéciée sur la plaque

signalétique. La plaque signalétique de l’appareil

est située derrière le filtre, sur la paroi arrière de la hotte.

Le calibre des conducteurs doit satisfaire aux

•

exigences de la plus récente édition de la norme

National Electrical Code, ANSI/NFPA 70, ou de la

norme CSA C22.1-94, Code canadien de

l’électricité, partie 1 et C22.2 n° 0-M91 (dernière

édition) et de tous les codes et règlements en vigueur.

ATENTTION

Pour réduire le risque d’incendie ou de choc électrique, installez cette hotte uniquement avec les

modèles de moteurs internes et remote avec une

capacité de 7.4 A (Electrolux™).

Page 22

22

Exigences d’emplacement

Exigences d’emplacement

IMPORTANT: Observer les dispositions de tous les

codes et règlements en vigueur.

Demander à un technicien qualié d’installer la caisse

de la hotte. C’est à l’installateur qu’incombe la responsabilité de respecter les distances de séparation

spéciées sur la plaque signalétique de l’appareil. La

plaque signalétique de l’appareil est située derrière le

ltre de gauche, sur la paroi arrière de caisse de hotte.

La caisse de la hotte doit être installée à l’écart de

houte zone exposée à des courants d’air, comme des

fenêtres, des portes et bouches de chauffage à fort

débit.

Respecter les dimensions indiquées pour les ouvertures à découper dans les placards. Ces dimensions

tiennent compte des valeurs minimales des dégagements de séparation.

La caisse de la hotte doit se trouver dans un enceinte

construite sur mesure avec un support de hotte capable de soutenir une charge de 75 lb (34 kg).

On doit disposer d’une prise de courant électrique

reliée à la terre. Voir la section “Spécications électriques”.

On doit assurer l’étanchéité au niveau de chaque

ouverture découpée dans le plafond ou un mur

traversé par l’équipement de la hotte.

Installation dans une résidence mobile

L’installation de cette hotte doit satisfaire aux exigences de la norme Manufactured Home Construction

Safety Standards, Titre 24 CFR, partie 328 (anci-

ennement Federal Standard for Mobile Home Construction and Safety, titre 24, HUD, partie 280); lorsque

cette norme n’est pas applicable, l’installation doit

satisfaire aux critères de la plus récente édition de la

norme Manufactured Home Installation 1982 (Manufactured Home Sites, Communities and Setups) ANSI

A225.1/NFPA 501A, ou des codes locaux.

Dimensions du placard

30” (76.2 cm) Modèle 30”

36” (91.4 cm) Modèle 36”

48” (121.9 cm) Modèle 48”

Le support de la hotte

doit être capable de soutenir

une charge de 75 lb (34 kg)

Distance “X” entre le bas

du auvent et la surface de cuisson

Profondeur

de la caisse

de hotte

22” (55.9 cm)

IMPORTANT:

Valeur minimale de la distance “X” : 24” (61 cm) à partir des

surfaces de cuisson électriques.

Valeur minimale de la distance “X” : 30” (76,2 cm) à partir des

surfaces de cuisson au gaz.

Valeur maximale suggérée pour la distance “X” : 36” (91,4 cm)

Dimensions du produit

modèles de 36” et 48”

sortie de câblage

8”

(31.4 cm)

16

” (12.2 cm)

(29.2 cm)

16”

(12.8 cm)

271/2”(70 cm) modèles 36 et 48”

245/16 (61.8cm) Modèles 30”

30” (75.8 cm)

30” (76.2 cm) Modèle 30”

36” (91.4 cm) Modèle 36”

48” (121.4 cm) Modèle 48”

22” (56 cm)modèle 30”

Modèles 36 et 48”

97/8” (25.11 cm)

15” (38 cm) Modèle 30”

18” (45.2 cm) Modèle 36”

24” (61 cm) Modèle 48”

modèle de 30”

sortie de câblage

11” (28 cm)

10 1/8” (

11” (28 cm) pour le modèle 30”

25.7 cm) pour les modèles 36 & 48”

22” (55.9 cm)

Page 23

Exigences concernant l’évacuation

Le système doit décharger l’air à l’extérieur.

•

Ne pas terminer le circuit d’évacuation dans un

•

grenier ou dans un autre espace clos.

Ne pas utiliser une bouche de décharge murale de

•

4” (10,2 cm) normalement utilisée pour un

équipement de buanderie.

Utiliser un conduit métallique uniquement. Un

•

conduit en métal rigide est recommandé. Ne pas

utiliser de conduit de plastique ou en aluminium.

La longueur du système d’évacuation et le

•

nombre de coudes doit être réduit au minimum

pour des performances optimales.

Pour un fonctionnement efcace et silencieux:

Ne pas utiliser plus de trois coudes à 90°.

•

Veiller à ce qu’il y ait une section droite de

•

conduit d’un minimum de 24” (61 cm) entre les

raccords coudés, si on doit en utiliser plus d’un.

Ne pas installer 2 coudes successifs.

•

Au niveau de chaque jointure du circuit

•

d’évacuation, assurer l’étanchéité avec les brides

de serrage, et utiliser du ruban adhésif pour sceller

complètement les connexions.

À l’aide d’un produit de calfeutrage, assurer

•

l’étanchéité autour de la bouche de décharge à

l’extérieur (à travers le mur ou le toit).

La taille du conduit doit être uniforme.

•

Installations pour régions à climat froid

On doit installer un clapet anti-retour supplémentaire

à l’arrière pour minimiser le reux d’air froid dans le

cadre du système de ventilation.

Incorporer un élément d’isolation thermique pour

minimiser la conduction de chaleur par l’intermédiaire

du conduit d’évacuation, de l’intérieur de la maison à

l’extérieur dans le cadre du système de ventilation.

Le clapet anti-retour doit être placé du côté air froid de

la résistance thermique.

L’élément d’isolation thermique doit être aussi proche

que possible de l’endroit où le circuit d’évacuation

s’introduit dans la partie chauffée de la maison.

Air d’appoint

Les codes locaux en bâtiment peuvent imposer

l’emploi d’un circuit de renouvellement de l’air/introduction d’air d’appoint, lors de l’utilisation d’un circuit

d’aspiration de débit supérieur à une valeur spéciée

en pieds cubes par minute. Le débit spécié en pieds

cubes par minute varie d’une juridiction à l’autre.

Consulter un professionnel des installations de

chauffage ventilation/climatisation au sujet des

Exigences de Ventilation

exigences spéciques applicables dans la juridiction

locale.

Méthodes d’évacuation

L’ouverture de sortie de la hotte a un diamètre de 10 “.

•

Dans les installations utilisant le Système moteurs

•

600 CFM est recommandé d’utiliser un système

de ventilation de 6” ou 8”.

Dans les installations utilisant le Système moteur

•

de 600 CFM doit utiliser un système de ventilation

de 10”.

Vous pouvez utiliser un plus petit système de

•

refroidissement, mais va générer un niveau de bruit.

REMARQUE: évent exible n’est pas recommandée.

Évent exible crée une contre-pression et l’air

turbulences qui réduisent considérablement les

performances. Système de ventilation peut résilier

ce soit à travers la toit ou le mur. Pour ventilation

dans le mur, un coude à 90 ° est nécessaire.

Décharge à travers le toit

B

A

A. Conduit circulaire de 10” (25,4 cm)

B. Bouche de décharge sur toit

Typique Installations du système de ventilation

par moteur externe

B

A

A. Conduit circulaire de 10” (25,4 cm)

B. Montage au-dessus des solives.

D. Contreplaqué (facultatif pour certaines installations)

G. Conduit horizontal, montage sur traverses de ferme.

C. Bouches de décharge sur toit

F. Montage sur traverses de ferme.

H. Bouche de décharge murale

C

D

A

E.Montage sous les chevrons.

Évacuation par le mur

A

A. Conduit circulaire de 10” (25,4 cm)

B. Bouche de décharge murale

D

A

E

F

G

H

23

B

A

Page 24

24

Installation des Systèmes Moteurs

Installation du moteur interne a

la hotte intégrée

Le système de ventilation interne peut être monté pour

une évacuation par le dessus. Pour la ventilation par

le dessus, le support de montage et l’attache à ressort

fournis avec le système de ventilation seront montées

sur le panneau supérieur de la caisse de la hotte.

Installation du moteur interne a la hotte intégrée

IMPORTANT: Exécuter les étapes 1 à 10 avant de

monter la caisse de la hotte de cuisinière.

REMARQUE: Le matériel de montage est inclus avec

le système moteur.

1.

Retirer les ltres à graisse de la caisse de la

hotte. Voir la section “Nettoyage” du guide

d’utilisation et d’entretien.

2.

Monter le support du moteur à l’aide des trois vis

de 4,2 x 8 mm. Visser le support à l’intérieur au

sommet, du côté gauche de la caisse de la hotte

(voir la gure à l’étape 2).

3.

Installer la languette à ressort du moteur à l’aide

des deux vis de 4,2 x 8 mm. Visser la languette

à ressort à l’intérieur au sommet de la caisse de la

hotte, à l’endroit correct selon le système de mo teur sélectionné. Glisser la patte de montage de la

languette à ressort par la fente dans le panneau et

la xer à l’aide des vis. (voir la gure à l’étape 3).

Sur le hotte Sur le hotte

Dans la hotte Dans la hotte

ÉTAPE 2 ÉTAPE 3

F*

A

A. 3 vis de 4,2 x 8 mm pour le

support du moteur

B. 2 vis de 4,2 x 8 mm pour la

languette à ressort du moteur

C. Support de montage du

moteur

C

D

E

D. Languette à ressort du moteur

(emplacement pour système à un seul

ventilateur)

E. Languette à ressort du moteur

(emplacement pour système à deux

ventilateurs)

B

Fixer les écrous de 6 mm à l’extérieur de la hotte,

4.

en haut ou à l’arrière (autre emplacement sur certains

modèles) de la caisse de la hotte, à l’endroit correct

selon le système de ventilation sélectionné.

Deux écrous de 6 mm sont nécessaires pour

•

le système à un seul ventilateur de 600 CFM.

Emboîter les écrous dans les petites encoches

carrées situées à droite et à gauche de l’ouverture

d’évacuation carrée.

Quatre écrous de 6 mm sont nécessaires

•

pour le système à deux ventilateurs de 1200 CFM.

Emboîter les écrous dans les petites encoches

carrées, l’une située à l’avant de l’ouverture

d’évacuation carrée et les quatre autres à gauche

et à droite de l’ouverture d’évacuation carrée.

A. 6mm écrous

B.Emplacement des écrous à emboîter pour le

système à un seul ventilateur (quantité 2)

C. Emplacement des écrous à emboîter pour le

système à deux ventilateurs (quantité 4)

A

C

Installer le moteur du ventilateur de la caisse de la

5.

hotte à l’intérieur de l’auvent de la caisse,

B

connexion du câblage à gauche pour le système

à ventilateur unique et à l’avant ou au-dessus pour

le système à deux ventilateurs.

Assemblage du moteur simple

A

A.connexion des câbles

C

Page 25

Assemblage du moteur dual

A.connexion des câbles

A

Pour installer le système moteur, glisser le rebord

6.

gauche de la plaque de montage sous le support

de montage du moteur.

A

Pousser l’extrémité de droite de la plaque de

7.

montage du moteur et l’enclencher dans la

languette à ressort.

B

A. Support de montage du moteur

B. Rebord gauche de la plaque de montage

REMARQUE : La languette à ressort doit être à

l’extérieur de la fente de la plaque de montage.

A

B

A. Plaque de montage du moteur

B. Languette à ressort

Installation des Systèmes Moteurs

Faire correspondre les trous de la plaque de

8.

montage du moteur avec les écrous à emboîter

servant à xer le moteur et installer les vis de

6 x 16 mm et les rondelles-freins de 6,4 mm

A

A. Bolt with lock washer

B. Mounting hole

B

Relier le connecteur du cordon d’alimentation de

9.

la hotte au connecteur du boîtier de connexion..

A. Connecteur du boîtier

de connexion

B. Connecteur du cordon

d’alimentation de la hotte

Instalez raccord de conduit rond de 10” avec 4 à

10.

A

B

4,2 x 8 mm vis de montage.

A

BB

Continuer à préparer l’emplacement à la page 29.

11.

A.Raccord de conduit rond de 10”

(25,4 cm) avec clapet anti-retour.

B. Vis de montage

25

Page 26

26

Installation des Systèmes Moteurs

Installation du moteur remote

a la hotte intégrée

Preparation du montage du systeme de ventilation

à distance

Le systeme de ventilation à distance doit etre xe a

une structure securisee de la toiture, du plafond, mur,

sol, ou une nouvelle charpente ou une charpente

preexistante. Les 4 trous sur l’entree (bas) ou la sortie

(haut) du ventilateur doivent etre utilises pour monter le

systeme de ventilation à distance a la structure.

REMARQUE: Les emplacements des trous de montage doivent traverser les poteaux de colombage.

Des pans a colombage supplementaires pourraient

s’averer necessaires. Il est possible d’utiliser du contre-plaque pour couvrir les zones qui se trouvent entre

les solives de plafond ou les chevrons du toit an de

faciliter l’installation. Cette structure doit etre sufsamment solide pour supporter le poids du systeme de

ventilation à distance (50 lb [22,6 kg] min).

Preparation du systeme de ventilation à distance

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer

et installer la hotte de la cuisinière.

Le non-respect de cette instruction peut causer

une blessure au dos ou d’autre blessure.

Tirer sur la languette a resort pour degager

3.

l’ensemble moteur-ventilateur. Retirer l’ensemble

moteur-ventilateur du carter et le placer sur une

surface couverte.

A. Couvercle avant

B. Vis de montage du

ventilateur

C. Languette à ressort

A

D. Trous de montage du carter

inférieur

E. Fiche électrique du moteur

B

C

D

Installation du moteur remote

REMARQUE: Le boîtier moteur du ventilateur peut être

monté l’aide de 4 trous soit du côté de l’entrée ou la

sortie de la souferie

A

A

Côté entrée

A l’aide d’au moins 2 personnes, deplacer le

1.

systeme du moteur du ventilateur à distance

jusqu’a l’emplacement de montage.

Enlever les 10 vis du couvercle avant du carter du

2.

moteur du ventilateur à distance et les mettre de

cote.

Enlever le couvercle avant du carter du moteur du

3.

ventilateur à distance et le mettre de cote.

REMARQUE: L’ensemble moteur-ventilateur peut etre

retire pour faciliter le montage du carter du moteur du

ventilateur. Si l’on ne souhaite pas retirer l’ensemble

moteur-ventilateur, passer a “Installation du systeme

de ventilation à distance” dans cette section.

Pour déconnecter le système moteur

Debrancher la prise electrique du moteur de

1.

l’ensemble moteur-ventilateur.

Enlever les vis qui xent l’ensemble moteur-

2.

ventilateur au carter du ventilateur à distance et

découpage nécessaires pour le passage du circuit

d’évacuation les mettre de cote.

A. Trous de montage

A

A

Côté de la sortie

Positionner le carter du moteur du ventilateur dans

1.

son emplacement de montage et marquer les

emplacements des 4 trous de montage.

A

A

Page 27

Percer 4 avant-trous a l’aide d’un foret de 3” (5mm).

2.

Fixer le carter du moteur du ventilateur à distance à

3.

l’emplacement de montage avec quatre vis de

montage et rondelles 6 x 80 mm.

Réinstaller l’ensemble moteur-ventilateur s’il a été

4.

enlevé et le xer avec les vis enlevées

précédemment.

Achever la préparation

Déterminer et marquer toutes les lignes de

1.

découpage nécessaires pour le passage du circuit

d’évacuation.

IMPORTANT: Lors des opérations de découpage et

de perçage dans un mur ou un plafond, veiller à ne

pas endommager les câblages électriques ou canalisations qui peuvent s’y trouver.

Déterminer l’emplacement de passage du conduit

2.

de câblage de ¹⁄

le mur entre le ventilateur à distance et la caisse

2” (1,3 cm) à travers le plafond ou

de la hotte.

Percer un trou de 1¹⁄4” (3,2 cm) à cet endroit.

3.

Localiser les boîtiers de connexion dans le carter

4.

du ventilateur à distance et la caisse de la hotte.

Retirer les couvercles du boîtier de connexion et

les mettre de côté avec les vis.

B

A

A. Boîtier de connexion

B.Opercule arrachable

Retirer l’opercule arrachable du carter du

5.

ventilateur à distance et de la caisse de hotte an

de préparer l’installation du conduit de câblage de

¹⁄

2” (1,3 cm) et de son connecteur (homologation

UL ou CSA).

REMARQUE: Le serre-câble sont fournies avec le

matériel du remote moteur.

Une fois la caisse de hotte montée, (voir la section

6.

“Installation de la caisse de la hotte”), acheminer

le conduit de câblage de ¹⁄

2” (1,3 cm) entre le

carter du moteur du ventilateur à distance et la

caisse de la hotte. Tirer sufsamment de conduit

de câblage de ¹⁄