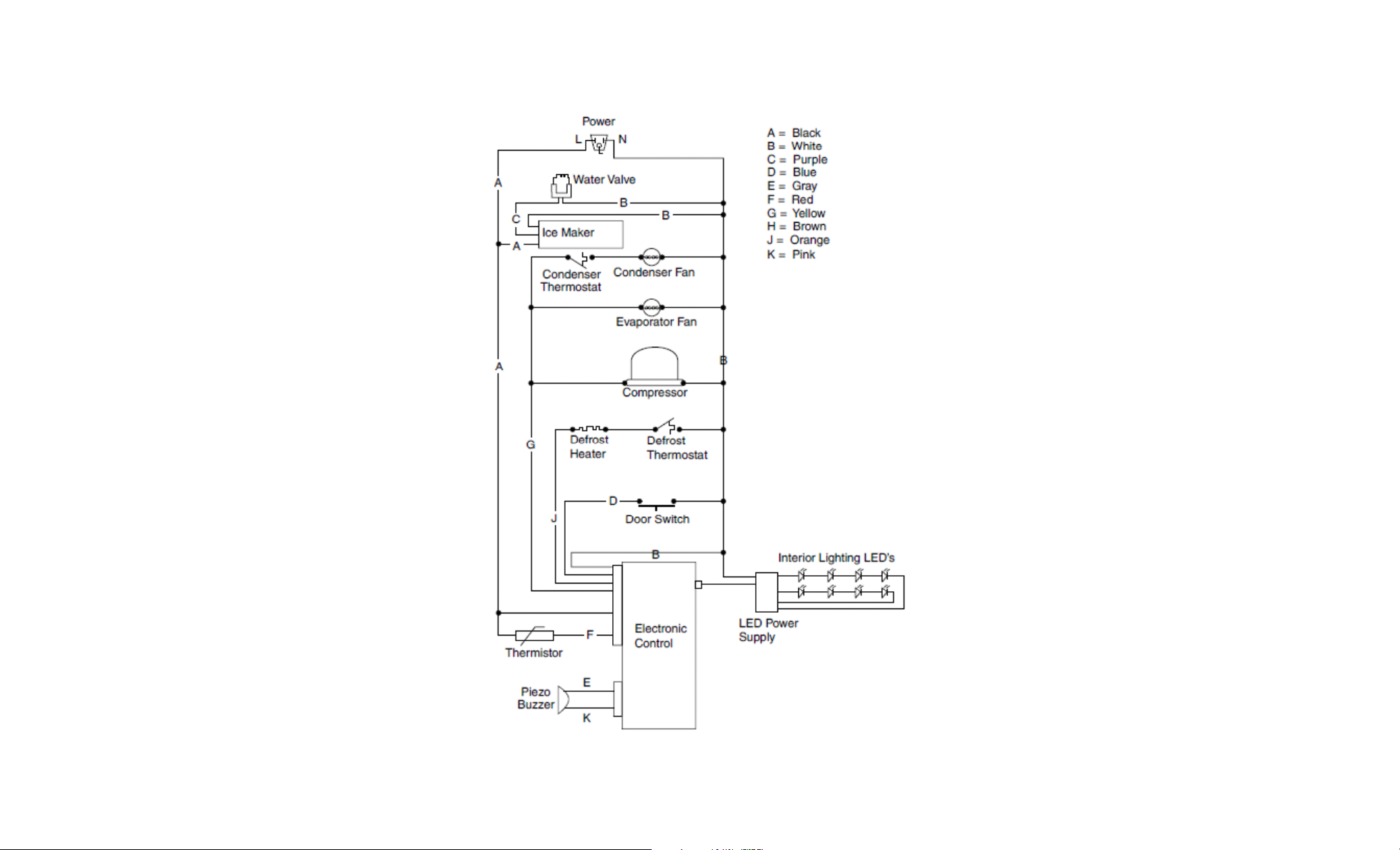

Electrolux EI32AF80QS Wiring Diagram

PERFORMANCE DATA NO LOAD & NO DOOR OPENINGS AT MID-POINT

CONTROL SETTING

T

U

R

N

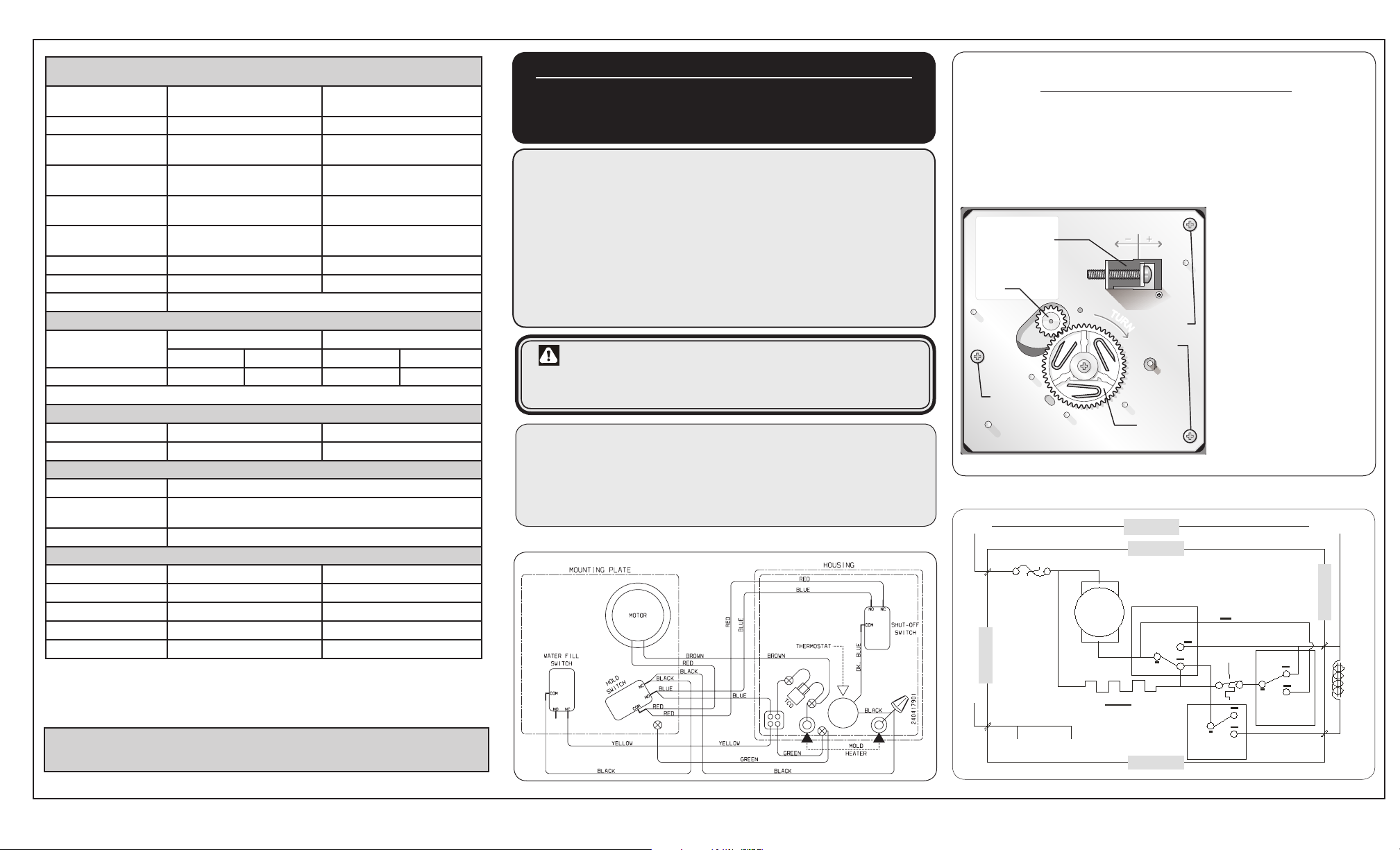

Mounting

Plate

Screws

Mounting

Plate

Screw

Motor

Gear

Timing

Gear

Water Fill

Adjustment

P O W E R

I CE MA KE R

ICE MAKER

I

CE MAKER

ICE MAKER

WATER VALVE

LINE

T HER MA L

C UT -O UT

HO LD

SW I T C H

T HER MO STAT

SH UT-OF F

SW IT CH

WA TER FI L L

S W I T C H

MOLD HEATER

MO L D

MO UN TI NG

PLATE

MOTOR

N E UT R AL

BLK

BLK

B LK

BL K

BLU

LT . B L U

LT. BLU

BRN

RED

GRN / YEL

GRN / YEL

RED

Y E L

YEL

YEL

P- 3

P- 1

P- 2

P- 4

Capacitor Run or

Induction Run

Operating Time 40 to 50% 55 to 65%

Freezer Temperature

Low Side Pressure

(cut-in)

Low Side Pressure

(cut-out)

High Side Pressure

(last 1/3 cycle)

Wattage (last 1/3 cycle) 100 to 120 110 to 130

Amps (running) .9 to 1.1 1.0 to 1.2

Base Voltage 115 vac (127 vac max)

Cabinet Size

19’ 21° F (-6° C) 42° F (6° C) 550 24

Electronic Timer - Defrost 30 minutes every 12 hours of compressor run time.

Watts RPM Amps

2.3 1100 CW Opposite Shaft 0.13 Running

Electrical 115 vac (127 vac max) 60 Hertz

Thermostat

Heater Wattage 165

ICE MAKER CONNECTOR PLUG CONNECTIONS

Wire Number Wire Color Connects to:

1 Green/Yellow Ground

IMPORTANT: PLEASE RETURN THIS SHEET TO IT’S

ORIGINAL LOCATION

2 Yellow Water Valve

3 Black Line

4 Light Blue Neutral

70°F (21°C) Ambient 90°F (32°C) Ambient

-3° to 3° F

-19° to -16° C

6 to 12 psig

41 to 83 kPa

-1 to 3 psig

-4 to 21 kPa

85 to 100 psig

575 to 670 kPa

DEFROST SPECIFICATIONS

Thermostat Heater

Cut-in Cut-out Watts Ohms

CONDENSER FAN MOTOR

ICE MAKER SPECIFICATIONS

Opens at 48° F ( 9° C), Closes at 15° F ( -9° C)

Models with orange wire close at 8.96° F (-12.8° C)

-19° to -16° C

41 to 83 kPa

120 to 135 psig

810 to 910 kPa

-3° to 3° F

6 to 12 psig

-1 to 3 psig

-4 to 21 kPa

SERVICE DATA SHEET - 297299800

STANDARD - AUTOMATIC DEFROST FREEZER

MODELS (R134a)

IMPORTANT SAFETY NOTICE

The information provided herein is designed to assist qualified

repair personnel only. Untrained persons should not attempt to

make repairs due to the possibility of electrical shock. Disconnect

power cord before servicing.

IMPORTANT

If any green grounding wires are moved during servicing,

they must be returned to their original position and properly

secured.

CAUTION: All electrical parts and wiring must be

shielded from torch flame. Do not allow torch to contact

insulation; it will char at 200°F.

NOTE: Products come equipped with an Electronic Defrost

Control. To initiate defrost, press and hold air filter and alarm

reset key simultainiously for three seconds. To terminate defrost,

press and hold air filter and alarm reset key simultainiously for

three seconds

ICE MAKER INFORMATION

Test Cycling

Remove cover by inserting screwdriver in notch at bottom and

prying cover from housing. Use screwdriver to rotate motor gear

counterclockwise until holding switch circuit is completed. All

components of ice maker should function to complete the cycle.

Water Fill Volume

The water fill adjustment

screw will change the

fill time. One full turn is

equal to 20cc (.68 oz.).

The correct fill is 95 to

105cc (3.2 to 3.6 oz.).

When a water valve is

replaced, the fill volume

must be checked.

Loading...

Loading...