Page 1

SERVICE DATA SHEET

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

1453 ± 8.9

1654 ± 10.8

1852 ± 13.5

2047 ± 15.8

2237 ± 18.5

2697 ± 24.4

Open circuit/infinite resistance

RTD SCALE

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

75 ± 2.5 (24 ± 1.3)

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

650 ± 9.6 (343 ± 5.3)

900 ± 13.6 (482 ±7.5)

Probe circuit to case ground

Appliance with ES630 Electronic Oven Control

NOTICE: This service data sheet is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally considered acceptable in the

appliance repair trade. The manufacturer cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use of this data sheet.

IMPORTANT NOTE: This unit includes an EOC (electronic oven control). This board is not eld-repairable.

Safe Servicing Practices

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices be observed. The following are some, but not all, examples of safe practices.

1. Do not attempt a product repair if you have any doubts as to your ability to complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric outlet, trip circuit breaker to Off, or remove fuse.

3. Never interfere with the proper installation of any safety device.

4. Use only replacement parts specied for this appliance. Substitutions may not comply with safety standards set for home appliances.

5. Grounding: The standard color coding for safety ground wires is green or green with yellow stripes. Ground leads are not to be used as current carrying conductors. It is extremely

important that the service technician reestablish all safety grounds prior to completion of service. Failure to do so will create a potential hazard.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high-temperature components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely reassembled.

• All panels are properly and securely reassembled.

Oven Calibration

Set the electronic oven control for normal baking at 350°F. Allow oven to preheat to set temperature. Obtain an average oven temperature after a minimum of ve cycles. Press the STOP key

to end the Bake mode.

Temperature Adjustment

1. While in a non-cooking mode, press and hold the Bake key for 6 seconds.

2. The current calibration offset (temperature adjustment) should appear in the temperature display.

3. Use the number keys (0-9) to enter the desired amount of adjustments (up to 35°F).

4. Press the Self Clean key to change the sign of the adjustment to a (-), if necessary. A positive adjustment will not display a sign.

5. Once the desired adjustment (-35° to 35° F) has been entered, press the Start key to accept the change or the Cancel key to reject the change.

Note: Changing calibration affects all baking modes. The adjustments made will not change the self-cleaning temperature.

2-Speed Cooling Fan

The EOC controls the speed of the cooling fan. The cooling fan is activated at low speed during any cooking function and will remain on until the oven is cooled down. The high speed is

activated during the broil (with open door) and during clean cycles only when the temperature is above apporximately 575°F/302°C.

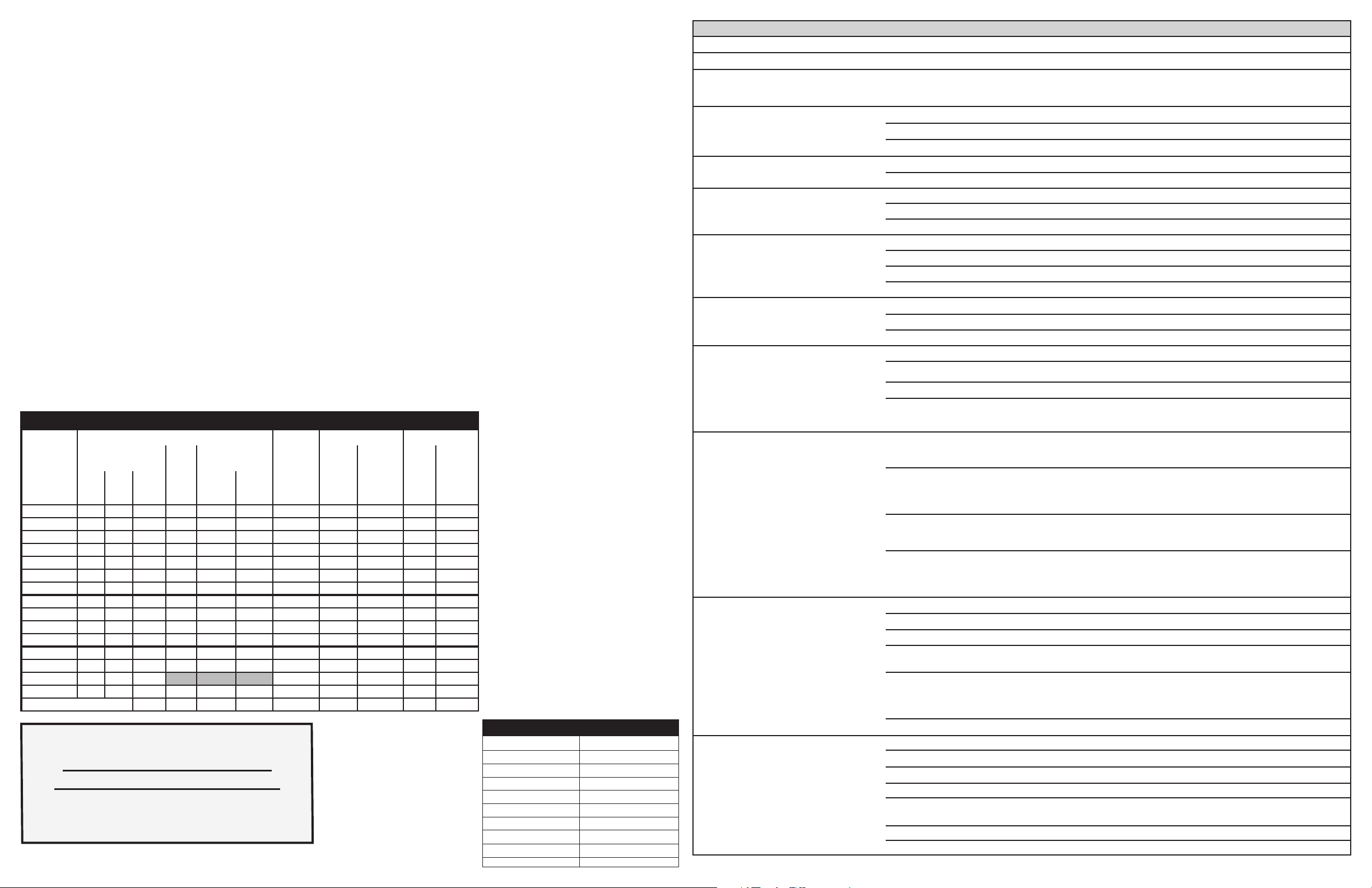

SINGLE WALL OVEN CIRCUIT ANALYSIS MATRIX

On Relay Board On Oven

Convection Fan

ELEMENTS

Door

BakeP9BroilP7Conv.

Bake X X X* X* X X

Keep Warm X X X

Broil X X X

Conv. Bake X X X X** X X X

Conv. Roast X X X X X X

Conv. Broil X X X X

Clean X X X X

Locking X

Locked

Unlocking X

Unlocked

Light X

Door Open X

Door Closed X

Bread Proof X X X X

Rack Supports not installed X

p/n 807436904 EN (Rev A 13/04)

P11

Motor

J3-5

Low

speed

J3-8

High

speed

J3-4

lights

control

board

Light

P2-1

On Display Board On Relay Board

Door

Switch

P10-3/

P10-5

Rack

Sense

Switch

P10-2/

P10-5

DLB

L2 out

P1

Cooling

Fan

J3-7

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Note: Generally speaking “F1X” implies a control failure, “F3X” an oven probe problem, and “F9X” a latch motor problem.

Failure Code/ Condition/Cause Suggested Corrective Action

F10 Control has sensed a potential runaway oven

condition. Control may have shorted relay, RTD

sensor probe may have a gone bad.

F11 Shorted Key: a key has been detected as

pressed for a long period and will be considered

a shorted key alarm and will terminate all

oven activity.

F13 Control's internal checksum may have

become corrupted.

F14 Misconnected keyboard cable Verify connection between display board and touch panel (2 ribbon cables). Make sure the cables are well connected at both ends.

F15 Controller self check failed. Verify if relay board receives 120VAC between J4 pin 1 and 3.

F23 The controller failed to communicate with the

oven lights control board.

F30 Open RTD sensor probe/ wiring problem.

Note: EOC may initially display an "F10", thinking a

runaway condition exists.

F31 Shorted RTD sensor probe / wiring problem. Let the oven cool down and restart the function.

Note: F30 or F31 is displayed when oven is in active mode or an attempt to enter an active mode is made.

F43 The cooling fan speed, as read by the

tachometer input of the EOC-display board,

is abnormally too slow.

F44 The cooling fan speed, as read by the

tachometer input of the EOC- display board,

is abnormally too fast.

F90 Door motor mechanism failure. Press any key to clear the error.

Check RTD sensor probe and replace if necessary. If oven is overheating, disconnect power. If oven continues to overheat when

power is reapplied, replace relay board and/or display board.

Press any key to clear the error.

If fault returns, replace the keyboard (touch panel).

If the problem persists, replace the display board.

Press any key to clear the error.

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, replace display board.

If the cables are good, replace the touch panel.

If the problem persists, replace the display board.

Verify the wiring between J2 on the relay board and P16 on the display board.

If wiring and 120VAC supply is good replace the display board.

If problem persists replace the relay board.

Verify wiring between P2 on the display board and P2 on the oven lights control board.

If wiring is good, replace oven lights board.

If the problem persists, replace the display board.

Check wiring in probe circuit for possible open condition.

Check RTD resistance at room temperature (compare to probe resistance chart). If resistance does not match the chart, replace the RTD sensor probe.

If the problem persists, replace the display board.

Determine rst if the problem appears to be caused by a cooling fan not turning or turning slowly or by a problem with the sensing of

the fan speed. Start a Bake and check during the rst 15 seconds if the fan is turning (should feel air owing through the vent above

the upper oven door).

If the fan does not appear to be turning or turn slowly check the 120VAC at the fan. If 120VAC is present at the fan motor but the fan

does not turn replace the fan motor. If 120VAC is not present at the fan motor when a Bake is started check the connection to the

relay board (J3 pin 7) and Neutral: is there 120VAC on J3 pin 7? Does it reach the fan motor? Is the other terminal of the fan motor

connected to Neutral? If the harness or relay board are faulty replace them.

If the fan appears to be normally turning but an F43 error code is generated, it means there is a problem with the reading of the fan

speed sensor. Make sure the connection of the fan speed sensor is properly made (refer to wiring diagram), between the sensor on

the fan and the EOC- display board.

For trouble-shooting purposes, it is possible to enter a test mode that will indicate on the display the reading of the fan speed in RPM:

to enter the test mode, power-up the unit and within 30 seconds press and hold the upper oven Bake and Broil keys for 3 seconds

(until you see all segments in the screen illuminated). Once in the test mode, pressing the upper oven Light key once will display the

fan speed in RPM. In normal client mode the F43 error is generated for a fan speed below approximately 700 RPM.

Inspect the cooling fan. Does it appear to be turning normally (air ow, noise)? Verify the fan blade is well assembled.

Verify there is nothing blocking the air ow of the fan (that could make the fan turn faster).

Check the 120VAC voltage on the fan. A voltage higher than 120VAC + 10% could make it go too fast.

Make sure the connection of the fan speed sensor is properly made (refer to wiring diagram), between the sensor on the fan and the

EOC- display board.

For trouble-shooting purposes, it is possible to enter a test mode that will indicate on the display the reading of the fan speed in RPM: to enter

the test mode, power-up the unit and within 30 seconds press and hold the upper oven Bake and Broil keys for 3 seconds (until you see all

segments in the screen illuminated). Once in the test mode, pressing the upper oven Light key once will display the fan speed in RPM. In normal

client mode the F44 error is generated for a fan speed above approximately 2500 RPM.

If problem persists replace both the fan+sensor assembly and the EOC- display board.

I

f it does not eliminate the problem, turn off power for 30 seconds, then turn on power.

Check wiring of Lock Motor, Lock Switch and Door Switch circuits.

Unplug the lock motor from the board and apply power (L1) directly to the Lock Motor. If the motor does not rotate, replace Lock Motor Assembly.

Check Lock Switch for proper operation (do they open and close, check with ohmmeter). The Lock Motor may be powered as in above

step to open and close Lock Switch. If the Lock Switch is defective, replace Motor Lock Assembly.

If all above steps fail to correct situation, replace the display board and/or the relay board in the event of a motor that does not rotate.

If all the above steps fail to correct the situation, replace the display board in the event of a motor that rotates endlessly.

Page 2

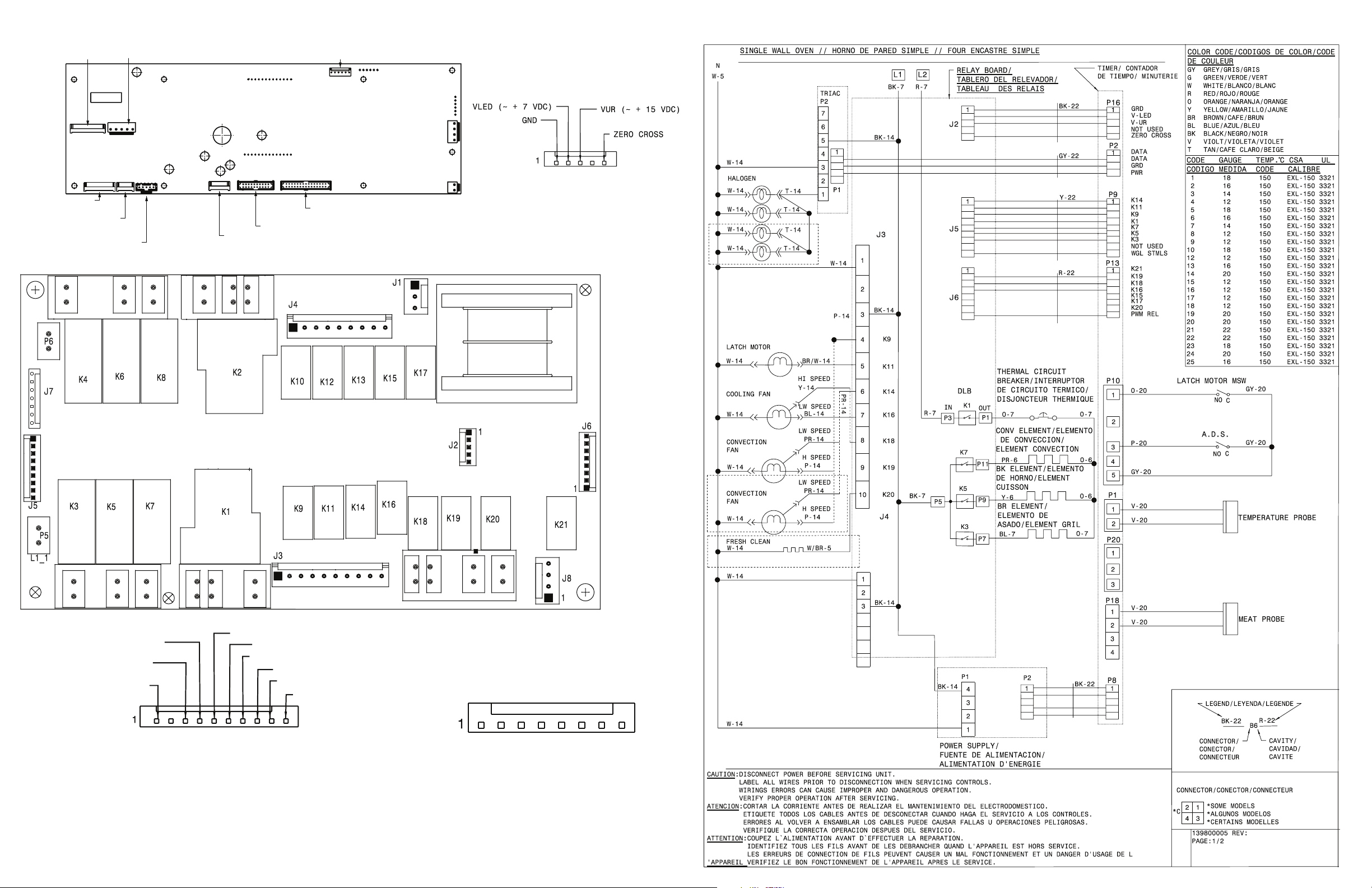

RELAY BOARD

P9 OUT

CONNECTS TO POWER SUPPLY

USER INTERFACE BOARD

J2 DC POWER TO UIB PCB

CONVECTION F

MDL

AN - HIGH SPEED

J3 OUTPUTS

F

T

CONNECTS TO UIB/PCB P13

CONNECTS TO J5

P13 AUX OUT

CONNECTS TO J6

P2 LIN COMM 1

CONNECTS TO TRIAC

P8 BACKLIGHT POWER

P10 SWITCH 1 OUT

P6 PROGRAMMING

HEADER

P7 EXT LEDS/KEY, RING LIGHTS,

PANEL BACKLIGHT CONTROL/POWER

P16 POWER IN CONNECTS TO J2

P3 TOUCH KEY INPUTS

GENERAL TROUBLESHOOTING SCHEMATIC

P18 MEAT PROBE

P1 TEMP PROBE

P8 P10P12 P2 P4

1

1

P7

BROIL

BAKE

CONV

P18

1

P3P11P9

L2 OUT

P1P17

1

L2 IN

1

P13

CLEAN CATALYST

P19

P15

L1 IN

P16

AN - HIGH

L1

NEUTRAL

CONVECTION FAN - LOW

COOLING FAN - LOW SPEED

COOLING F

SELF CLEAN CATALYST

J6 CONTROLS

AN, NIGHT LIGHT, AUX OUTU

Page 3

FEUILLET DE DONNÉES TECHNIQUES

IMPORTANT

N’ENLEVEZ P

AS CE SAC OU NE

DÉTR

UISEZ P

AS SON CONTENU

CONTIENT LES SCHÉMAS DE CÂBLAGE ET

LES INFORMATIONS DE RÉPARATION

REMETTRE LE CONTENU

DANS LE SAC

Résistance (ohms)

1 000 ± 4,0

1 091 ± 5,3

1 453 ± 8,9

1 654 ± 10,8

1 852 ± 13,5

2 047 ± 15,8

2 237 ± 18,5

2 697 ± 24,4

Circuit ouvert/résistance infinie

ÉCHELLE DU DÉTECTEUR DE TEMPÉRATURE

À RÉSISTANCE

Température °F (°C)

32 ± 1,9 (0 ± 1,0)

75 ± 2,5 (24 ± 1,3)

250 ± 4,4 (121 ± 2,4)

350 ± 5,4 (177 ± 3,0)

450 ± 6,9 (232 ± 3,8)

550 ± 8,2 (288 ± 4,5)

650 ± 9,6 (343 ± 5,3)

900 ± 13,6 (482 ±7,5)

Circuit de la sonde mise à la

terre à la caisse

Électroménager avec commande de four électronique

AVIS: Cette feuille de données d’entretien est destinée aux personnes ayant reçu une formation en électricité et en mécanique, et qui possèdent un niveau de connaissance jugé acceptable

dans l’industrie de réparation des appareils électroménagers. Le fabricant ne peut être tenu responsable, ni assumer aucune responsabilité, pour toute blessure ou dommage de quelque

nature que ce soit pouvant résulter de l’utilisation de cette feuille de données.

NOTEs IMPORTANTES: Cet appareil inclut un contrôleur de four électronique. Le tableau de contrôle n’est pas réparable sur place.

Pratiques d’entretien Sécuritaires

Pour éviter tout risque de blessure et/ou dommage matériel, il est important que des pratiques d’entretien sécuritaires soient suivies. Voici quelques exemples de pratiques sécuritaires.

1. N’essayez jamais de réparer un appareil si vous ne croyez pas avoir les compétences nécessaires pour le faire de manière satisfaisante et sécuritaire.

2. Avant de procéder au service d’entretien ou de déplacer tout appareil ménager, débranchez le cordon d’alimentation de la prise électrique, réglez le disjoncteur de circuit à OFF, ou

enlevez le fusible et fermez le robinet d’alimentation en gaz.

3. N’entravez jamais l’installation adéquate de tout dispositif de sécurité.

4. Utilisez que les pièces de remplacement énumérées dans le catalogue pour cet appareil. La moindre substitution risque de ne pas être conforme aux normes de sécurité établies pour

les appareils électroménagers.

5. Mise à la Terre: La couleur de codage standard des conducteurs de mise à la terre de sécurité est verte ou verte à barres jaunes. Les conducteurs de mise à la terre ne doivent pas

être utilisés comme conducteurs de courant. Il est d’une importance capitale que le technicien d’entretien complète toutes les mises à la terre de sécurité avant de terminer le service.

Si cette recommandation n’est pas suivie à la lettre, il en résultera des risques pour les personnes et les biens.

6. Avant de retourner le produit au service de réparation ou d’entretien, assurez-vous que:

• Toutes les connexions électriques sont correctes et sécuritaires.

• Tous les conducteurs électriques sont correctement préparés et à l’abri des bords tranchants, des composants à température élevée, et des parties mobiles.

• Toutes les bornes électriques, connecteurs, réchauffeurs, etc. dénudés sont espacés convenablement loin de toute pièce en métal et des panneaux.

• Toutes les mises à la terre de sécurité (interne et externe) sont correctement ré-assemblées de façon sécuritaire.

• Tous les panneaux sont correctement et fermement remontés.

Étalonnage du Four

Réglez le régulateur électronique de four pour une cuisson normale à 350 ºF (177 ºC). Comptez-vous de four préchauffer choisir températures. Vous devez obtenir une température moyenne

de four après 5 cycles. Appuyez sur la touche Stop (arrêt) pour mettre n au mode de cuisson.

Réglage de la Température

1. Assurez-vous de ne sélectionner aucun mode de cuisson, puis appuyez sur la touche Bake (cuisson au four) et maintenez-la enfoncée pendant 6 secondes.

2. L’afcheur de température indique l’écart actuel de calibration (ajustement de température).

3. Utilisez les touches numériques (0 à 9) pour entrer l’ajustement désiré (jusqu’à 35 ºF/19 ºC).

4. Appuyez sur la touche Self Clean (autonettoyage) pour ajouter le symbole à (-) à l’ajustement, si nécessaire. Aucun signe n’apparaît si l’ajustement est positif.

5. Lorsque vous avez fait le réglage désiré (-35 à 35 ºF / -18 à 18 ºC), appuyez sur la touche Start (mise en marche) pour conrmer le choix ou Cancel (annuler)

6. pour l’annuler.

Remarque: La modication de la calibration affecte tous les modes de cuisson. Les ajustements n’inuent pas sur la température du cycle d’autonettoyage.

2-Vitesse Ventilateur rafraîchissant

Les contrôleurs de four électronique dirige vitesse de

le ventilateur rafraîchissant. Le ventilateur rafraîchissant activer à basse vitesse vitesse pendant une

cuisson fonction, et il reste allumé jusqu’à ce que du

four refroidir. Le haut débit activer pendant grillage

(avec la porte ouverte) et pendant clean cycles seul

quand la température est plus que approximativement 575ºF/302ºC.

Sur le Panneau Relais

ÉLÉMENTS Moteur

Cuis.P9GrilP7Conv.

Cuisson X X X* X* X X

Garder chaud

Gril X X X

Cuisson conv. X X X X** X X X

Rôtissage conv. X X X X X X

Gril conv. X X X X

Nettoyage X X X X

Verrouillage X

Verrouillé

Déverrouillage X

Déverrouillé

Lumière X

Porte ouverte X

Porte fermée X

Pâte à pain X X X X

Support grille pas installé X

X X X

P11

MATRICE D'ANALYSE DU CIRCUIT

Ventilateur convection

porte

J3-5

Basse

vitesse

J3-8

Haute

vitesse

J3-4

Sur le

Panneau de

lumières

Lumière

P2-1

Sur panneau

d'afchage

Interr.

porte

P10-3 /

P10-5

Interr.

grilles

P10-2/

P10-5

Sur Panneau

Relais

DLB

Vent.

L2

refroid.

sortie

P1

J3-7

DESCRIPTION DES CODES D'ERREUR DE LA COMMANDE DE FOUR

Note : De façon générale “F1X” indique des erreurs internes de la commande du four, “F3X” un problème avec la sonde du four et “F9X” un problème avec le moteur verrou.

Code d'erreur/Condition/Cause Actions correctives suggérées

F10

La commande de four a décelé une condition

d'emballement possible. La commande présente un

relais en court-circuit, (RTD) mauvais fonctionnement

de la sonde.

F11 Touches en court-circuit: si une touche a été détectée

comme enfoncée durant une longue période de temps

on la considère comme court-circuitée et une alarme

termine toute activité.

F13 La mémoire interne du contrôle est corrompue. 1) Appuyez sur une touche pour effacer le code d'erreur. 2) Débranchez l'appareil, attendez 30 secondes et re-branchez

F14 Câble du clavier mal connecté. 1) Vériez les connections entre le panneau d'afchage et le clavier (2 câbles ruban). Assurez-vous que les câbles sont bien

F15 Problème avec l'auto-vérication du contrôleur.

F23 Le contrôleur a manqué sa communication avec le

panneau de contrôle des lumières.

F30 Problème avec le lage de sonde/lage ouvert (F30)

ou Note: La commande de four afchera initialement le

code "F10", cela signie qu'il décèle l'existence d'une

condition d'emballement.

F31

Court-circuit (F31) RTD problème sonde/lage.

Note: Si F30 ou F31 s'afche lorsque le four est actif ou lorsqu'il est en train d'entrer dans un mode actif.

F43 La vitesse du ventilateur de refroidissement, tel

que lu par le tachymètre au panneau d'afchage du

contrôleur, est anormalement lente.

F44 La vitesse du ventilateur de refroidissement, tel que lu

par le tachymètre au panneau d'afchage du contrôleur,

est anormalement trop rapide

1) Vériez la sonde RTD et remplacez-la si nécessaire. Si le four surchauffe, coupez le courant. S'il continue de surchauffer

une fois que le courant est rétabli, remplacez le panneau de relais et/ou le panneau d'afchage.

1) Appuyez sur une touche pour effacer le code d'erreur. 2) Si le code réapparaît, remplacez le panneau de commande

(clavier). 3) Si le problème persiste, remplacez le panneau d'afchage.

l'appareil. Si le problème réapparaît lors du branchement, changez le panneau d'afchage.

connectés à chaque extrémité. 2) Si les câbles sont intactes, remplacez le clavier. 3) Si le problème persiste, remplacez le

panneau d'afchage.

1) Vériez si le panneau de relais reçoit 120VAC entre J4 pin 1 et pin 3. 2) Vériez le lage entre J2 sur le panneau de relais

et P16 sur le panneau d'afchage. 3)Si le lage et l'entrée 120VAC sont corrects, remplacez le panneau d'afchage. 4) Si le

problème persiste, remplacez le panneau de relais.

1) Vériez le lage entre P2 sur le panneau d'afchage et P2 sur le panneau de contrôle des lumières. 2) Si les ls sont bons,

remplacez le panneau du ventilateur. 3) Si le problème persiste, remplacez le panneau d'afchage.

1) Vériez le lage du circuit de la sonde, il est peut-être ouvert ou coupé. 2) Vériez la résistance RTD à la température de

la pièce (comparez les données au tableau). Si celle-ci ne concorde pas, remplacez sonde (RTD). 3) Laissez refroidir le four

et redémarrez la fonction. 4) Si le problème persiste, remplacez le panneau d'afchage.

1) Premièrement déterminez si le problème apparaît à cause que le ventilateur de refroidissement ne fonctionne pas, tourne

lentement ou à cause d'un problème avec le senseur de vitesse. Débutez un mode de cuisson et vériez, au cours des 15

premières secondes, si le ventilateur tourne (vous devriez sentir un courant d'air provenant de l'évent situé au dessus de

la porte).2) Si le ventilateur ne semble pas tourner ou tourne lentement vérier le 120VAC au ventilateur. Si le 120VAC est

présent au moteur du ventilateur mais que le ventilateur ne fonctionne pas, remplacer le moteur. Si le 120VAC n'est pas

présent au moteur du ventilateur lorsqu'un mode de cuisson est démarré vériez la connexion du panneau de relais (J3 tige

7) et du neutre: Y a-t-il 120VAC à la borne J3 tige 7? Rejoint-il le moteur du ventilateur? Y a-t-il d'autre terminal branché au

neutre? Si le lage ou le panneau de relais est défectueux, remplacez-les.3) Si le ventilateur semble tourner normalement

mais que le code d'erreur 43 est généré, cela signie qu'il y a un problème avec le senseur de vitesse du ventilateur. Assurez-

vous que la connexion du senseur de vitesse du ventilateur est adéquat (voir le schéma de câblage) entre le senseur sur le

ventilateur et le EOC- Panneau d'afchage. 4) Pour le dépannage, il est possible d'entrer en mode test, lequel indiquera à

l'écran la lecture de la vitesse du ventilateur en RPM. Pour entrer en mode test, mettez l'appareil sous-tension et dans les

30 secondes, appuyez et maintenez les touches Cuire et Griller du four supérieur pendant 3 secondes (jusqu'à ce que tous

les segments s'allument). Une fois en mode test, appuyez sur la touche lampe du four supérieur une fois, l'écran afche la

vitesse du ventilateur en RPM. En mode normal, un code d'erreur F43 est généré lorsque la lecture est en bas de 700RPM.

5) Si la connexion du senseur est bonne et que le code d'erreur F43 est toujours généré, le problème peut être causé par

l'assemblage ventilateur+senseur ou par le EOC- Panneau d'afchage. Vériez si le senseur du ventilateur (situé près de l'arbre

du ventilateur, à côté du connecteur) est endommagé. Si le problème persiste, remplacez l'assemblage ventilateur+senseur

et le EOC- Panneau d'afchage.

1) Inspectez le ventilateur de refroidissement. Est-ce que le ventilateur semble fonctionner normalement (courant d'air, bruit?).

Vériez si les pales du ventilateur sont installées correctement. 2) Vériez s'il y a quelque chose qui bloque la sortie de l'air

(ceci peut faire tourner le ventilateur plus rapidement). 3) Vériez le voltage (120VAC) au ventilateur. Un voltage supérieur

à 10VAC + 10% peut faire tourner le ventilateur plus rapidement. 4) Assurez-vous que la connexion du senseur de vitesse

du ventilateur est adéquate (voir le schéma de câblage) entre le senseur du ventilateur et le EOC- Panneau d'afchage. 5)

Pour le dépannage, il est possible d'entrer en mode lequel indiquera à l'écran la lecture de la vitesse du ventilateur faite en

RPM. Pour entrer en mode test, mettez l'appareil sous-tension et dans les 30 secondes, appuyez et maintenez les touches

Cuire et Griller du four supérieur pendant 3 secondes (jusqu'à ce que tous les segments s'allument). Une fois en mode test,

appuyez sur la touche lampe du four supérieur une fois, l'écran afchera la vitesse du ventilateur en RPM. En mode normal,

un code d'erreur F44 est généré lorsque la lecture est en bas de 2500RPM. 6) Si le problème persiste remplacez l'assemblage

ventilateur+senseur et le EOC- Panneau d'afchage.

p/n 807436904 FR (Rev A 1404)

F90 Système de verrouillage de porte défectueux. 1) Appuyez sur une touche pour effacer le code d'erreur. 2) Si cette étape n'élimine pas le problème, coupez le courant

pendant 30 secondes et redémarrez l'appareil. 3) Vériez le lage du moteur verrou, de l'interrupteur verrou et le circuit de

l'interrupteur de la porte. 4) Débranchez le moteur verrou, appliquez du courant (L1) directement au moteur verrou, si le moteur

ne fonctionne pas, remplacez l'assemblage. 5) Vériez si l'interrupteur verrou A fonctionne correctement (Est-ce qu'il permet

d'ouvrir et de fermer, vériez avec un ohm mètre). Le moteur verrou doit être réactivé tel qu'indiqué à l'étape précédente an

que l'interrupteur s'ouvre et se ferme. Si l'interrupteur verrou est défectueux, remplacez-le. 6) Si toutes les étapes mentionnées

ci-haut échouaient, remplacez le panneau de relais ou le panneau électronique analogique dans le cas où le moteur verrou

ne tourne pas. 7) Si toutes les étapes mentionnées ci-haut échouent, remplacez le panneau électronique analogique dans

le cas où le moteur verrou tourne trop faiblement.

Page 4

SCHÉMA DE DÉPANNAGE GÉNÉRAL

CARTE RELAIS

PLAQUETTE D'INTERFACE DE UTILISATEUR

PLAQUETTE D'INTERFACE DE UTILISATEUR PCB

VENTILA

- HAUTE VITESSE

MOTEUR VERROU DE LA PORTE

- HAUTE VITESSE

J3 SORTIES

J6 CONTRÔLES

VENTILATEUR, LUMIÈRE DE NUIT, SORTIE AUXILIAIRE

SE CONNECTE À UIB/PCB P13

P9 POUR RACCORDER J5 P12 COMMUTATEUR 1 SORTIE

P13 AUX SORTIE

CONNECTE SUR J6

P2 LIN COMM 1

CONNECTE SUR TRIAC

P8 ECLAIRAGE ALIMENTATION

PERMET DE CONNECTER

ALIMENTATION

P8 P10P12 P2 P4

L1 INFÉRIEUR

1

P6 PROGRAMMATION TÊTE

P7 EXT LEDS/CLÉ, ANNEAU LUMIÈRE,

PANNEAU ECLAIRAGE DE L'ALIMENTATION

P3 TOUCHER INTRANTS CLÉS

P16 ALIMENTATION ENTRÉE

CONNECTE SUR J2

P18

1

P18 SONDE THERMIQUE

P1 SONDE DE TEMPÉRATURE

1

J2 DC ALIMENTATION DE LA

1

P7

GRIL

CUISSON

P11

P9

CONVECT

TUER DE CONVECTION

NEUTRE

P3

L2 SORTIE

L1

P13

P1P17

1

L2 ENTRÉE

VENTILATUER DE CONVECTION - BASSE VITESSE

VENTILATEUR DE REFROIDISSEMENT - BASSE VITESSE

VENTILATEUR DE REFROIDISSEMENT

AUTO-NETTOYAGE CATALYSEUR

AUTO-NET SUP

P19

P16

P15

AUX

L1 ENTRÉE

Loading...

Loading...