Electrolux EFDE317TIW Wiring Diagram

Dryer Tech Data Sheet

1

This information is intended for Qualified Technicians Only.

TABLE OF CONTENTS

Dryer Tech Data Sheet ................................................................ 1

Diagnostic Mode Tests/Demo Mode ........................................... 2

Dryer Error Codes .......................................................................3

Notes ....................................................................................... 10

Wiring Diagrams ....................................................................... 11

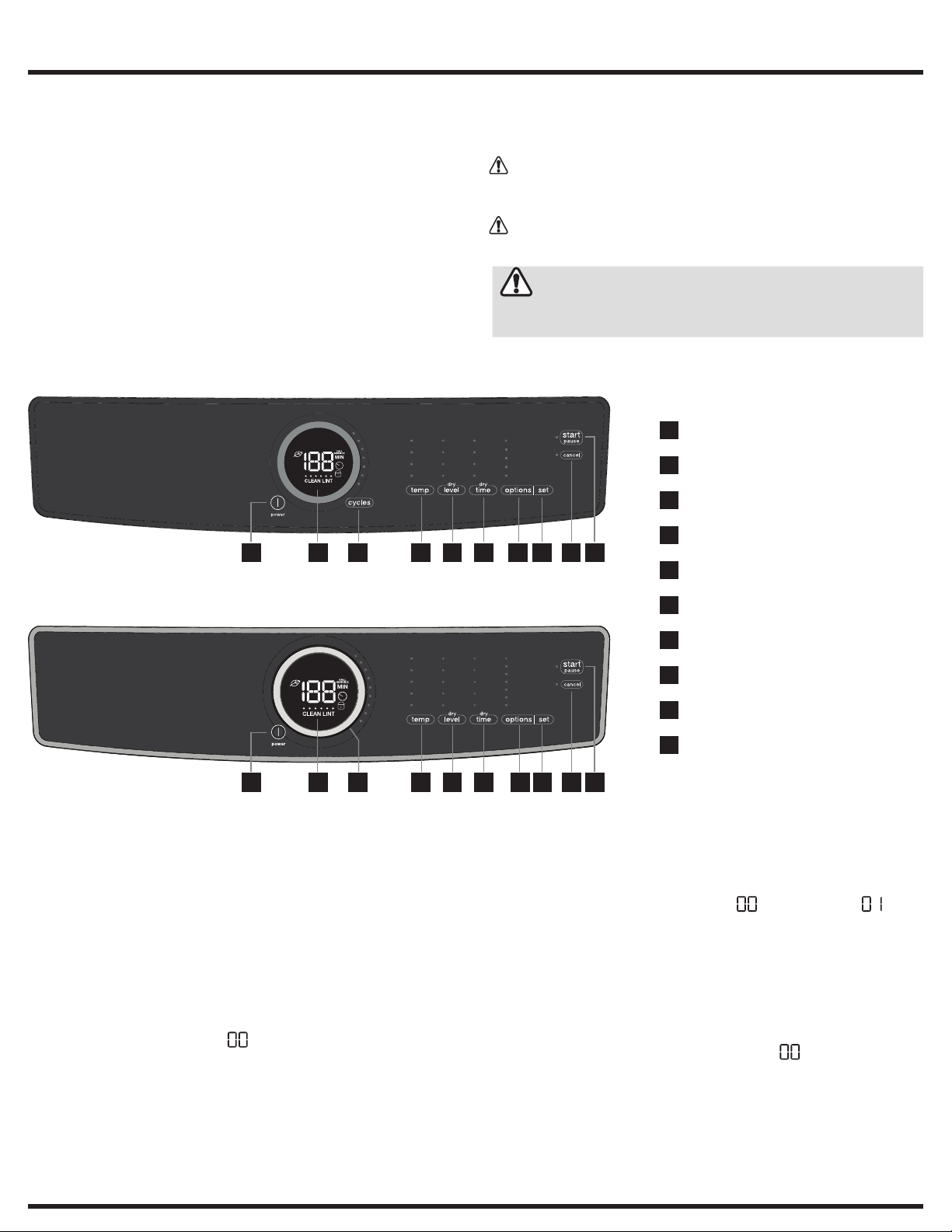

Push Button Cycle Select Dryer User Interface

2 71 63 854 9 10

Safety items throughout this manual are labeled with a WARNING or

CAUTION based on the risk type as described below:

WARNING

CAUTION

This symbol alerts you to situations that may

cause serious body harm, death or property

damage.

This symbol alerts you to situations that may

cause bodily injury or property damage.

CAUTION

Unless otherwise directed, disconnect electrical current before

servicing.

power

1

cycle status display

2

cycle selector

3

temperature

4

dryness level

5

Rotary Dial Cycle Select Dryer User Interface

2 71 63 9854 10

Entering Diagnostic Mode:

1. Press power and look for console light up.

2. Rotate cycle selector ring (on some models) or repeatedly press

cycle button (on other models) to set cycle to normal.

3. Press the start button.

4. Power off machine by pressing the power button.

5. Power on machine by pressing the power button again.

6. Within 10 seconds, simultaneously hold temp + set buttons

together for 3 seconds.

7. Diagnostic Mode is active when LED’s start blinking in sequence.

This is the pre-test position “

8. Press the start button.

” which tests the lights and buttons.

drying time

6

options

7

set

8

cancel

9

start/pause

10

Scrolling through Diagnostic Mode tests:

Tests are selected by using the same method used to select cycles.

Models with the cycle selection button uses the cycles button to move

forward, holding a little longer for the test “

transition and press the temp key to go back to the previous test.

Models with the rotary cycle selector use the rotary selector ring to go

forward and back.

Test numbers are briefly displayed when each test is selected. The test

numbers also correspond to the selector LEDs numbered from 1 at the

top going down.

” (cycle lights) to “ ”

Exiting Diagnostic Mode:

Hold the power key for 3 seconds, when not in “ ” test step Lights/

Buttons, or unplug the unit.

USA 1-877-435-3287

www.electroluxappliances.com

A07020402 (1901)

Canada 1-800-265-8352

2

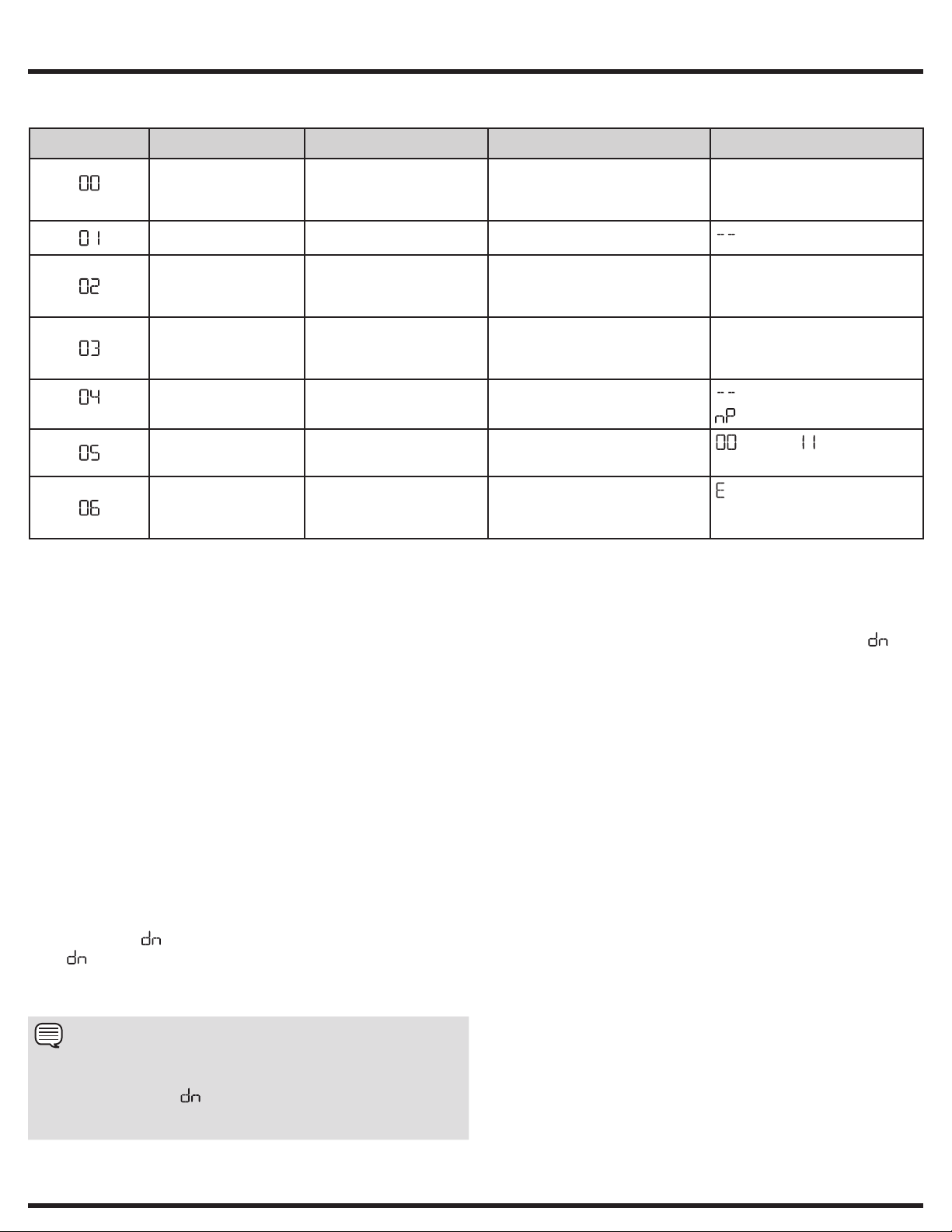

Diagnostic Mode Tests/Demo Mode

Diagnostic Mode Tests

Mode Number Test Name Components Under Test Test Conditions Displayed Feedback

Lights, Buttons LED indicators

pre-test

Motor, NO HEAT, HUM ONMotor relay

Motor, NTC1 ctrl heater,

HUM ON, NTC1 temp on

display

Motor, NTC2 ctrl heater,

HUM ON, NTC2 temp on

display

HUM ON, Mist valve ON Mist triac

(select models)

Moisture sensor circuit

open and short*

Error history The last 3 errors in memory Errors are most recent first

*The moisture sensor is to the lower left inside the door beside the lint screen. The technician may use metal to short sensor bars. The sensor is touch safe, some

materials like dry fingers or a 10k ohm resistor should have no displayed value.

LCD screen

Button response

Door switch

Motor relay

Door switch

Heater relay

NTC1

Motor relay

Door switch

Heater relay

NTC2

Valve

Moisture sensor Moisture sensor expects to read "open

Drum rotates for 10 mins

(if door closed)

Drum rotates for 10 mins

(if door closed), heater is on until NTC1

reads 44 C

Drum rotates for 10 mins

(if door closed), heater is on until NTC2

reads 120 C

Mist on for 10 mins

(if door closed)

circuit" condition and "short circuit"

condition*

(in order of history)

Note: Pressing temp + set keys

together clears error history

Number of key pressed.

Note: This number may not

necessarily correspond to key

number on table on page 1.

NTC1 reading

NTC2 reading

on units with mist valve;

on units without mist valve

(open) and (short circuit) with

nothing if sensor is between

precedes the 2 character alarm

code, alternating through the alarms

Demo Mode:

The Demo works in two ways: interactive mode and automatic loop.

The interactive mode enables the customer to use interface without

activating the appliance. The machine behavior appears similar to

operation. Start turns the drum light ON and if the door is closed the

ETR is decreased each second. The mist valve is not activated.

If no one interacts with the interface for 3 minutes, or the start button

hasn’t been pushed, the machine an automatic loop instead, simulating

the cycle execution only on display. This automatic loop cycles until

someone touches the user interface and it goes back to interactive

mode.

Entering Demo Mode:

1 Press power and look for console light up.

2 For Rotary Dial Cycle Select Dryer: Within 10 seconds select

casual and then simultaneously press and hold temp and set

buttons for 3 seconds. Skip to Step 4.

3 For Push Button Cycle Select Dryer: Within 10 seconds select

delicates and then simultaneously press and hold temp and set

buttons for 3 seconds. Continue to Step 4.

4 The message “

5 If “

” message does not appear, turn OFF machine and repeat

” will blink 3 times in the center display.

previous steps.

NOTE

Exiting Demo Mode:

1 Press power to turn the unit OFF.

2 Press power to turn the unit ON. The unit display will flash “

” 3

times on the numeric display.

3 Within 10 seconds perform steps 4 and 5.

4 Press the cycle button to scroll to the delicates position.

5 Press and hold temp and set) simultaneously for 3 seconds. The

appliance will beep once, the numeric display will cycle OFF and ON.

The appliance will then beep with the normal power on sequence.

You may also perform factory default reset. See below.

Factory Default Reset:

1 Press power and look for console light up.

2 Wait at least 10 seconds, then simultaneously press and hold dry

level and options buttons for 3 seconds.

Recalling Last Error Code:

1 Press power and look for console light up.

2 Wait at least 10 seconds, then simultaneously press and hold temp

and set buttons for 3 seconds.

3 The display will show the last error in memory.

4 Clear the display and return to normal operation by touching any

button or by pressing the power button.

Once Demo Mode is activated, every time the machine is turned on,

Demo Mode is automatically recalled; this occurrence is signaled at

the start-up by the text “

” flashing 3 times in the center display.

Unplugging the unit will not clear Demo Mode. See “Exiting Demo

Mode” for more information.

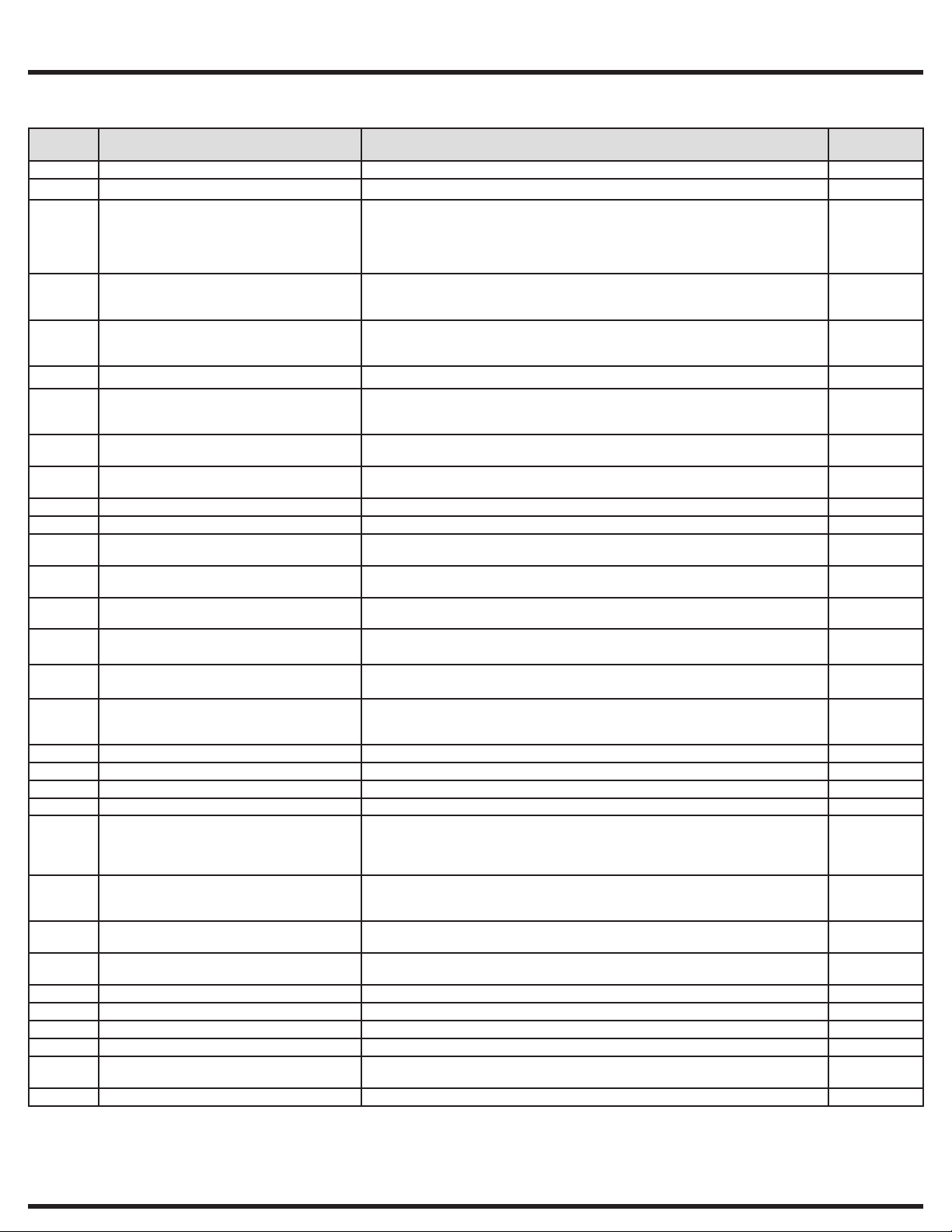

Dryer Error Codes

3

Error

Error Description Possible Causes Display

Code

41 Door opened at cycle start Door open Yes

42 Door closed sensing error Door switch or wiring or sensing circuit on main board failure No

51 Drum motor relay error With line safe relay closed, motor sensing detects voltage on motor

52 Drum motor start sensing error Motor relay driven but start sensing not congruent

53 Drum motor centrifugal switch error Motor driven but sensing not congruent

54 Drum motor sensing error Drum motor relay sensing circuit failure (main board failure) No

61 Heater relay error 1. Heater disconnected (wiring or connector failure)

63 Heater short error 1. Heater sensing circuit failure (main board failure)

64 Heater open error 1. Heater sensing circuit failure (main board failure)

65 Thermostat open Heater thermostat trip No

67 Heater sensing error Heater sensing circuit failure (main board failure) No

71 NTC1 (OPEN) error 1. NTC open/disconnected

72 NTC1 (SHORTED) error 1. NTC short

73 NTC2 (OPEN) error 1. NTC open/disconnected

74 NTC2 (SHORTED) error 1. NTC short

91 User Interface protocol incongruence error The User Interface mounted is not compatible with the main board connected No

1. Motor short circuit to ground (motor or wiring)

2. Electrical noise

3. Line safe relay problem (main board failure)

4. Motor relay open or short

1. Motor fault

2. Main board fault

1. Motor fault

2. Main board fault

2. Heater failure

3. Heater relay failure (open circuit)

2. Heater failure

2. Heater failure

2. Main board fault

2. Main board fault

2. Main board fault

2. Main board fault

Notification

No

No

No

No

No

No

No

No

No

No

92 User Interface UI/mainboard comunication error 1. Wiring failure

93 MCF checksum error Wrong machine configuration file in main board Yes

94 CCF checksum error Wrong cycle configuration file in main board Yes

97 Missing program on CTF error Software problem in main board Yes

9C User Interface configuration checksum error Software problem between main board and User Interface board Yes

9E User Interface touch sensor not working One or more touch buttons have calibration problems.

H1/B1 Power supply frequency out of range 1. Power supply problems

H2/B2 Power supply amplitude out of range (too

HIGH)

H3/B3 Power supply amplitude out of range (too

LOW)

H4/B4 Line wiring error Wrong line wiring/connection Yes

HA/BD Line safe relay short circuit error Line safe relay problem (main board failure) No

HE/BE Line safe error Line safe relay problem (main board failure) No

HF/BF Line safe sensing error Line safe sensing circuit failure (main board failure) No

F1 Ventilation blocked error Air flow duct clogged or blocked, remove debris and clean and check one

F6 Safety reset error Main board fault No

2. User Interface board failure

3. Main board failure

1. Electrical noise

2. Humidity/water on UI board

3. UI board defective

2. Wrong MCF

3. Main board failure

1. Power supply problems - too HIGH VOLTAGE

2. Main board failure

1. Power supply problems - too LOW VOLTAGE

2. Main board failure

way vent operation

No

No

Yes

Yes

Yes

Yes

4

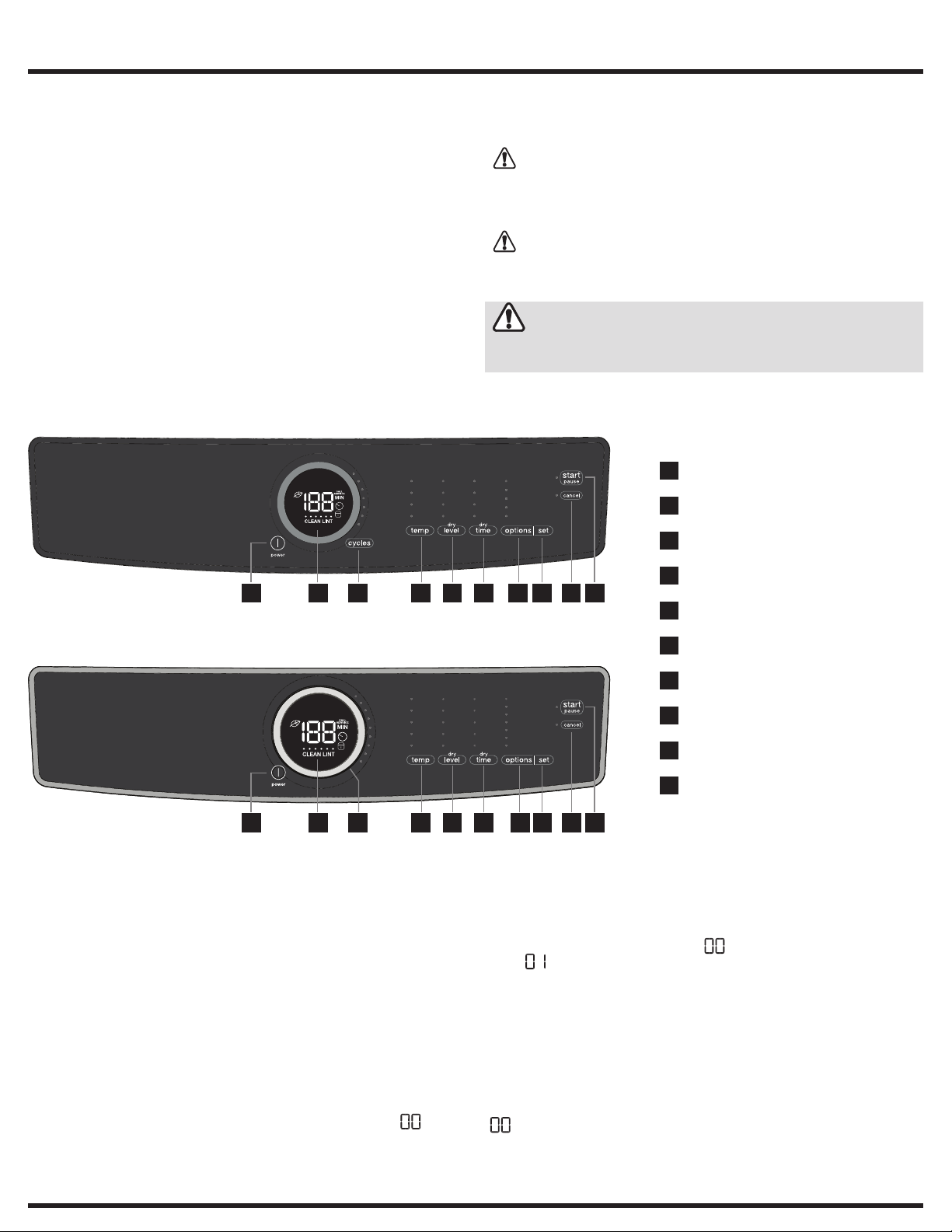

Fiche de Données Techniques de la Sécheuse

Ces renseignements sont destinés exclusivement aux techniciens quali-

fiés.

Les mesures de sécurité présentées dans ce guide sont identifiées

par le mot AVERTISSEMENT ou ATTENTION selon le type de risque

présenté.

TABLE DES MATIÈRES

AVERTISSEMENT

Fiche de Données Techniques de la Sécheuse ...........................4

Essais du Mode Diagnostic/Mode Démo .................................... 5

Codes d’Erreur de la Sécheuse .................................................. 6

ATTENTION

Remarques ............................................................................... 10

Schémas de câblage ................................................................ 11

ATTENTION

Sauf indication contraire, débranchez le courant électrique avant tout

entretien.

Modèle de Sélecteur de Programme à Bouton-Poussoir de l’interface Utilisateur

Ce symbole vous avertit à propos

des situations pouvant causer

des dommages matériels, des

blessures graves ou même la

mort.

Ce symbole vous avertit à propos

des situations pouvant causer

des dommages matériels ou des

blessures.

bouton d’alimentation

1

affichage des données du programme

2

sélecteur de programme

3

2 71 63 854 9 10

Modèle de Sélecteur de Programme à Anneau Rotatif de l’interface Utilisateur

2 71 63 9854 10

Passage au mode Diagnostic :

1 Appuyez sur power (marche/arrêt) pour mettre la machine en

marche.

2 Faites tourner l’anneau de sélection du cycle (sur certains modèles)

ou appuyez sur le bouton de cycle à plusieurs reprises (sur d’autres

modèles) pour régler le cycle à normal.

3 Appuyez sur le bouton start (démarrer).

4 Éteignez la machine en appuyant sur le bouton power (marche/

arrêt).

5 Allumez la machine en appuyant sur le bouton power (marche/arrêt)

une autre fois.

6 Dans un délai de 10 secondes, appuyez simultanément sur les

boutons temp (température) et set (Réglage) pendant 3 secondes.

7 Le mode Diagnostic est actif lorsque les DEL commencent à clignot-

er en séquence. Ceci est la position de essai préliminaire “

essai les Lumières et Boutons.

8 Appuyez sur le bouton start (démarrer).

”, qui

Défilement des essais du mode Diagnostic :

Les essais sont sélectionnés à l’aide de la même méthode qui est utilisée

pour sélectionner les cycles. Pour les modèles disposant du bouton de

sélection du cycle, utilisez le bouton cycles pour aller de l’avant, appuyez

un peu plus longtemps pour l’essai

sition

“ ”

précédent. Pour les modèles munis d’un sélecteur de cycle rotatif, utilisez l’anneau de sélection rotatif pour aller de l’avant et revenir en arrière.

Les numéros d’essai sont affichés brièvement lorsque chaque essai est

sélectionné. Les numéros d’essai correspondent également aux DEL du

sélecteur numérotés à partir de 1 en haut en descendant.

et appuyez sur la touche température pour revenir à l’essai

Sortie du mode Diagnostic :

Appuyez sur la touche power (marche/arrêt) pendant 3 secondes,

lorsque les lumières/boutons d’étape d’essai ne sont pas en position

“

”, ou débranchez l’appareil.

température

4

niveau de séchage

5

durée de séchage

6

options

7

choisir

8

annuler

9

démarrer/pause

10

“ ”

(lumières du cycle) à la tran-

USA 1-877-435-3287 www.electroluxappliances.com

Canada 1-800-265-8352

Loading...

Loading...