Page 1

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

30" & 36" DUAL FUEL RANGE

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Canada

FOR YOUR SAFETY: Do not store or use gasoline or

other ammable vapors and liquids in the vicinity of this or any

other appliance.

Table of Contents

Important Safety Instructions .......................................2-4

Product Dimensions ....................................................... 5

Cabinet Dimensions ....................................................... 6

Cabinet Construction ...................................................... 7

Electrical Requirements...............................................7-8

Power Supply Cord......................................................... 8

Fuel Supply Requirements ............................................. 9

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven and the

drawer compartments before connecting the electrical

supply to the range.

3. The anti-tip bracket supplied with the appliance must

be installed.

4. Observe all governing codes and ordinances.

5. Be sure to leave these instructions with the consumer.

Connect Fuel Supply .................................................... 10

Install Oven Racks................................................... 11-12

Level the Range ........................................................... 13

Install Anti-Tip Bracket ............................................. 14-15

Install Burner Assemblies ........................................ 16-17

Check Oven Operation ................................................. 18

After Installation ............................................................ 18

Serial Plate Location (Model & Serial Number) ............ 18

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

future reference.

2. When using any appliance generating heat, there are

safety precautions you must follow. These precautions

are explained in your Use and Care manual. Read

your manual carefully.

3. Be sure your appliance is installed and grounded by a

qualied installer or service technician.

Printed in the United States

P/N 809018701 (1611) Rev.A

English – pages 1-18

Español – pages 19-36

Français – pages 37-54

1

Page 2

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

This appliance must be installed, grounded, and serviced by a qualied installer or service technician.

This manual contains important safety symbols and instructions. Please pay attention to these symbols and follow all

instructions given. Do not attempt to install or operate your appliance until you have read the safety precautions in this

manual. Safety items throughout this manual are labeled with a WARNING or CAUTION statement based on the risk type.

Warnings and important instructions appearing in this guide are not meant to cover all possible conditions and situations

that may occur. Common sense, caution, and care must be exercised with installing, maintaining, or operating your

appliance.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates a potentially hazardous situation which, if not avoided, may result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

IMPORTANT: Indicates installation, operation, maintenance, or valuable information that is not hazard related.

Tip Over Hazard

• A child or adult can tip the range

and be killed.

• Verify the anti-tip device has been

installed to floor or wall.

• Ensure the anti-tip device is re-engaged to floor or wall

when the range is moved.

• Do not operate the range without the anti-tip device in

place and engaged.

• Failure to follow these instructions can result in death or

serious burns to children and adults.

Range

leveling leg

Anti-tip

bracket

To check if the anti-tip bracket is installed properly, use both

arms to grasp the rear edge of the range back. Carefully

attempt to tilt range forward. When properly installed, the range

should not tilt forward.

Refer to the anti-tip bracket installation instructions supplied

with your range for proper installation.

If the information in this manual

is not followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

FOR YOUR SAFETY:

—Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electrical switch; do

not use any phone in your building.

•Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

•If you cannot reach your gas supplier,

call the fire department.

—Installation and service must be

performed by a qualified installer,

servicer or the gas supplier.

2

Page 3

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

• Excessive Weight Hazard--Use two or more

people to move and install range. Failure to follow

this instruction can result in back or other injury.

• Storage In or On Appliance—Flammable

materials should not be stored in an oven or

microwave, near surface burners or elements, or

in the storage or warmer drawer (if equipped). This

includes paper, plastic, and cloth items, such as

cookbooks, plastic ware, and towels, as well as

ammable liquids. Do not store explosives, such as

aerosol cans, on or near the appliance.

• Do not leave children alone - Children should

not be left alone or unattended in the area where

appliance is in use. They should never be allowed

to sit or stand on any part of the appliance,

including the storage drawer, lower broiler drawer,

warmer drawer, or lower double oven.

• Do not store items of interest to children in the

cabinets above the appliance or on the backguards

of ranges. Children climbing on or near the

appliance to reach items could be seriously injured.

• Stepping, leaning, or sitting on the door or drawers

of this appliance can result in serious injuries and

also cause damage to the appliance.

• Do not use oven or warmer drawer (if equipped) for

storage.

• Never use your appliance as a space heater to

heat or warm the room. Doing so may result in

carbon monoxide poisoning and overheating of the

appliance.

• Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

• Air curtain or other overhead range hoods which

operate by blowing a downward air ow onto a

range or cooktop, shall not be used in conjunction

with gas ranges or cooktops other than when the

range or cooktop and hood have been designed,

tested, and listed by an independent test laboratory

for use in combination with each other.

IMPORTANT INSTRUCTIONS FOR UNPACKING AND

INSTALLATION

Read and follow the below instructions and precautions

for unpacking, installing, and servicing your appliance:

• Destroy the carton and plastic bags after unpacking the

appliance. Never allow children to play with packaging

material. Do not remove the wiring label and other

literature attached to the appliance. Do not remove

model/serial number plate.

• Cold temperatures can damage the electronic control.

When using this appliance for the rst time, or when the

appliance has not been used for an extended period of

time, be sure the appliance has been in temperatures

above 32ºF (0ºC) for at least 3 hours before turning on

the power to the appliance.

• Never modify or alter the construction of the appliance

by removing the leveling legs, panels, wire covers, antitip brackets/screws, or any other part of the appliance.

• Proper Installation—Be sure your appliance is properly

installed and grounded by a qualied technician. In the

United States, install in accordance with the National

Fuel Gas Code ANSI Z223.1/NPFA No. 54, latest

edition and National Electrical Code NFPA No. 70

latest edition, and local electrical code requirements.

In Canada, install in accordance with CAN/CGA

B149.1 and CAN/CGA B149.2 and CSA Standard

C22.1, Canadian Electrical code, Part 1-latest editions

and local electrical code requirements. Install only

per installation instructions provided in the literature

package for this appliance.

• The installation of appliances designed for

manufactured (mobile) home installation must

conform with Manufactured Home Construction and

Safety Standard, title 24CFR, part 3280 [Formerly

the Federal Standard for Mobile Home Construction

and Safety, title 24, HUD (part 280)] or when

such standard is not applicable, the Standard for

Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Setups), ANSI Z225.1/

NFPA 501A-latest edition, or with local codes in United

States and with CAN/CSA-Z240 MH in Canada.

• Before installing the range in an area covered with

linoleum or any other synthetic oor covering, make

sure the oor covering can withstand heat at least

90°F (32.2°C) above room temperature without

shrinking, warping or discoloring. Do not install the

range over carpeting unless you place an insulating

pad or sheet of ¼" (0,64 cm) thick plywood between

the range and carpeting.

• Make sure the wall coverings and cabinet materials

around the range can withstand the heat generated by

the appliance.

• To eliminate the risk of burns or re by reaching over

heated surface units, cabinet storage space above the

surface unit should be avoided. If cabinet storage is to

be provided the risk can be reduce by installing a range

hood that projects horizontally a minimum of 5 inches

beyond the bottom of the cabinet.

• Do not obstruct airow at the oven vent, around

the base, or beneath the lower front panel of the

appliance. This appliance requires fresh air for proper

operation.

• Be sure to have an appropriate foam-type re

extinguisher available, visible, and easily accessible

located near the appliance.

3

Page 4

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

SPECIAL INSTRUCTIONS FOR APPLIANCES

INSTALLED IN THE STATE OF MASSACHUSETTS

This appliance can only be installed in the State of

Massachusetts by a Massachusetts licensed plumber or

gas tter. When using a exible gas connector, it must

not exceed 3 feet (36 inches) in length. A "T" handle type

manual gas valve must be installed in the gas supply line

to this appliance.

CONVERSION TO L.P. GAS

This appliance allows for conversion to Liqueed

Petroleum (L.P.) Gas.

Personal injury or death from electrical

shock may occur if the conversion to L.P. gas is not

made by a qualied installer or electrician. Any additions,

changes or conversions required in order for this

appliance to satisfactorily meet the application needs

must be made by a qualied technician.

If L.P. conversion is needed, contact your local L.P.

Gas provider for assistance. The L.P. conversion kit is

provided with this appliance and is located on the lower

REAR (back side) panel of the range. Before installing

the kit be sure to read the L.P. Installation Instructions

and follow them carefully when making the installation.

IMPORTANT INSTRUCTIONS FOR SERVICE AND

MAINTENANCE

• Do not repair or replace any part of the appliance

unless specically recommended in the manuals. All

other servicing should be done only by a qualied

technician. This reduces the risk of personal injury

and damage to the appliance.

• Always contact your dealer, distributor, service agent,

or manufacturer about problems or conditions you do

not understand.

• Ask your dealer to recommend a qualied technician

and an authorized repair service. Know how to

disconnect the power to the appliance at the circuit

breaker or fuse box in case of an emergency.

• Remove the oven door from any unused oven if it is to

be stored or discarded.

• Do not touch a hot oven light bulb with a damp cloth.

Doing so could cause the bulb to break. Handle

halogen lights (if equipped) with paper towels or soft

gloves. Disconnect the appliance or shut off the power

to the appliance before removing and replacing the

bulb.

4

Page 5

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

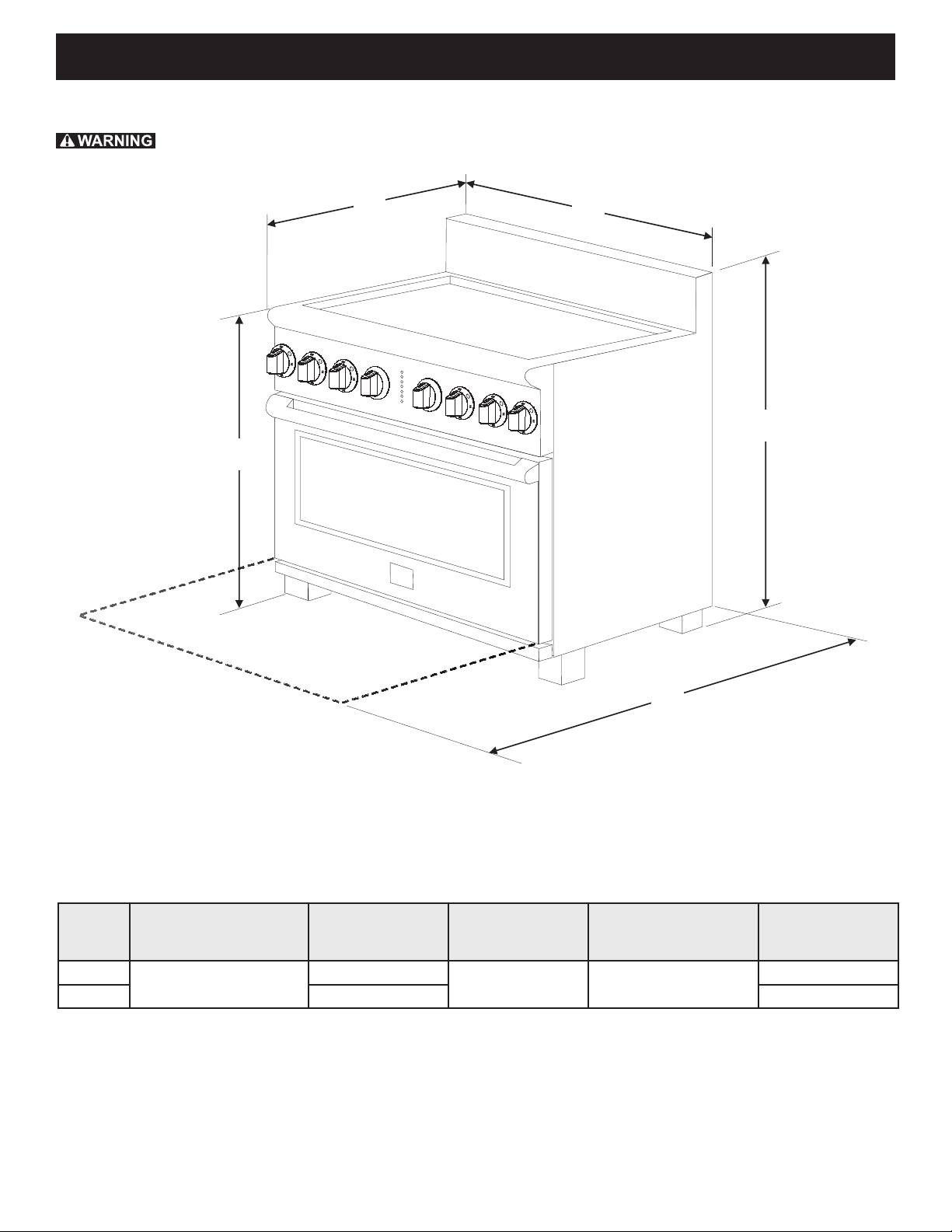

Product Dimensions

Do not install the unit in the cabinet before reading next two pages.

D

C

B

A

E

Figure 1: Product Dimensions

C. DEPTH TO

MODEL A. HEIGHT B. WIDTH

30"

36" 35 7/8" (91.1 cm) 48 3/8" (122.9 cm)

41 5/8" (105.7 cm) Min.

42 5/8" (108.3 cm) Max.

29 7/8" (75.9 cm)

FRONT OF

RANGE

27 1/2" (69.9cm)

D. HEIGHT OF

COOKTOP

35 3/4" (90.8 cm) Min.

36 3/4" (93.3 cm) Max.

E. DEPTH WITH

DOOR OPEN

46 1/4" (117.5 cm)

5

Page 6

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

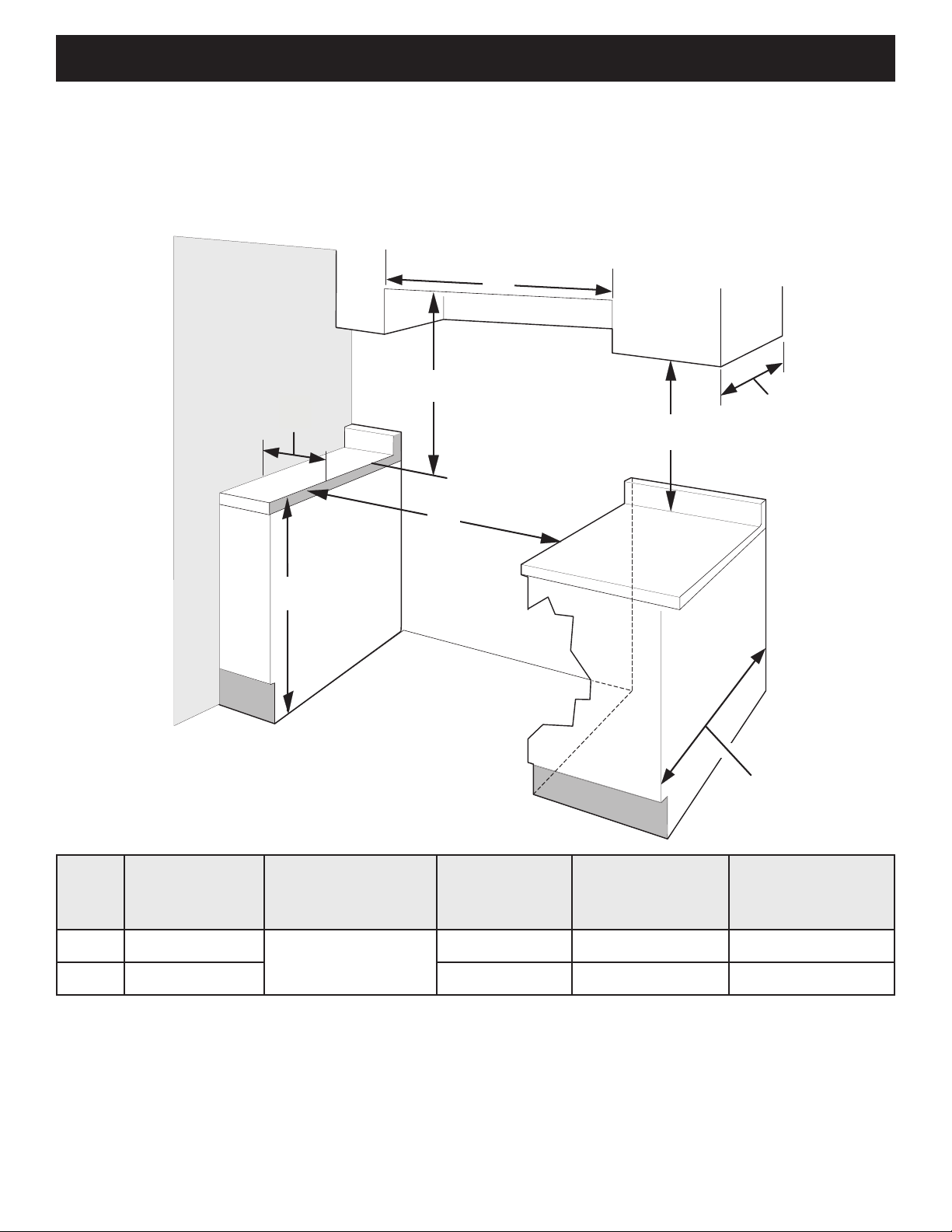

Cabinet Dimensions

Clearances and Dimensions

• Provide adequate clearances between the appliance and adjacent combustible surfaces.

• Location - Check location where the appliance will be installed. Check for proper electrical supply and oor

stability.

• Dimensions shown must be used. Given dimensions provide minimum clearance. Contact surface must be

solid and level.

J

H

G

I

F

Figure 2: Cabinet Dimensions

13" Max.

(33 cm Max.)

18" Min.

(45.7 cm Min.)

24" Min.

(61 cm Min.)

24½" max.

(62.2 cm Max.)

MODEL

30" 30 1/16" (76.4 cm)

36" 36 1/16" (91.6 cm) 7" (17.8 cm) Min. 36" (91.4 cm) Min. 36" (91.4 cm) Min.

NOTES:

1. Do not seal the range to the side cabinets.

2. Clearance from adjacent walls or other vertical surfaces or structures such as cabinets.

3. Measurements listed are minimum clearances between the cooktop and the bottom of the cabinet.

4. 0" clearance between range and cabinets or vertical surfaces that are below the cooktop height.

5. 0" clearance between range back and rear wall or cabinet.

F. MINIMUM

CUTOUT WIDTH

G. HEIGHT OF

COUNTERTOP

36" (91.4 cm) Standard

35 3/4" (90.8 cm) Min.

H. CLEARANCE

FROM SIDE

WALLS

5" (12.7 cm) Min. 30" (76.2 cm) Min. 30" (76.2 cm) Min.

6

2

I. CLEARNACE

FROM COOKTOP

AND CABINET

BOTTOM

3

J. CLEARANCE

WIDTH OF

OVERHEAD

CABINETS

Page 7

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Follow instructions for

the type of installation you have

Center

Line of

Range

1

Cabinet Construction

To eliminate the risk of burns or re by

reaching over heated surface units, do not have cabinet

storage space above the range. If there is cabinet storage

space above range, reduce risk by installing a range

hood that projects horizontally a minimum of 5" (12.7 cm)

beyond the bottom of the cabinet.

Figure 3: Cabinet construction

1.1

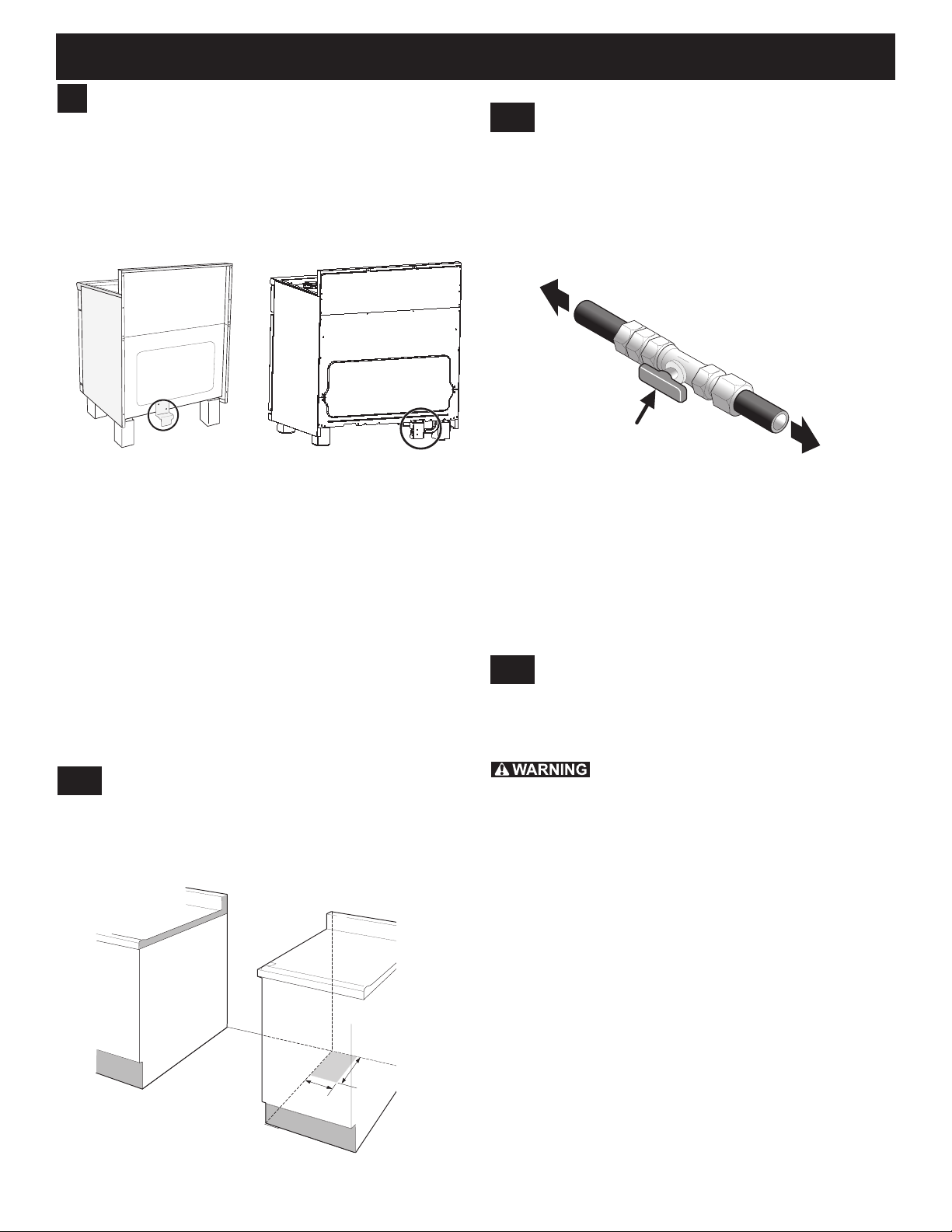

Installation: Cabinet on Both Sides

1. If range will be installed with a cabinet on both sides,

Draw a center line on the oor between the cabinets

(Figure 5).

2. If back of range will not be ush with the wall (the

location of the outlet may not allow the range to be

positioned against the wall), draw a line on the oor

where the back edge of the range will be.

3. Install anti-tip brackets (see "Anti-Tip Bracket

Installation").

2

Electrical Requirements

Electrical Shock Hazard –Electrical ground is

required on this appliance. Use only the power cord

supplied with the appliance. Improper connections and

grounding may result in electric shock, damage to the

appliance, personal injury, re or death.

Grounding Requirements

This appliance must be installed and grounded by a

qualied technician.

In the United States, install in accordance with the National

Fuel Gas Code ANSI Z223.1/NPFA No. 54, latest edition

and National Electrical Code NFPA No. 70 latest edition,

and local electrical code requirements. In Canada, install in

accordance with CAN/CGA B149.1 and CAN/CGA B149.2

and CSA Standard C22.1, Canadian Electrical code, Part

1-latest editions and local electrical code requirements.

For personal safety, this appliance must be properly

grounded. For maximum safety, the power cord must

be plugged into an electrical outlet that is the correct

voltage, is correctly polarized and properly grounded

in accordance with local codes. It is the personal

responsibility of the consumer to have the appropriate

outlet with the correct, properly grounded wall receptacle

installed by a qualied electrician.

This appliance is intended to be plugged into a 14-50R

standard wall receptacle.

Electrical Wall Receptacle

1.2

Installation: Cabinet on One Side Only

1. If range will be installed with a cabinet on one side

only, move the range into nal position.

2. Draw a line on the oor along the side of the range

that is not against the cabinet. If back of range will

not be ush with the wall (the location of the outlet

may not allow the range to be positioned against the

wall), draw a line on the oor where the back edge of

the range will be.

3. Install anti-tip brackets (see "Anti-Tip Bracket

Installation").

1.3

Installation: Without Cabinet

1. If range will not be installed against a cabinet, move

range into nal position.

2. Mark on the oor along both sides of the range.

If back of range will not be ush with the wall (the

location of the outlet may not allow the range to be

positioned against the wall), draw a line on the oor

where the back edge of the range will be.

3. Install anti-tip brackets (see "Anti-Tip Bracket

Installation").

Required for all installations

4-Wire receptacle (14-50R)

When only 4-wire, single phase, 240 volt, 60 Hz, AConly electrical supply is available, this appliance requires

minimum 40 amp circuit protection fused on both sides of

the line.

A time-delay circuit breaker or fuse is recommended.

Be sure the wall receptacle is within reach of the

appliance's nal installed location.

Do not pinch the power supply cord between the range

and the wall.

7

Page 8

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

12”

(30.5 cm)

8”

(20.3 cm)

Recommended Wall Outlet Installation

Locations

Suggested location of the wall outlet is shown in Figure 4

for 30" models and in Figure 5 for 36" models. The

outlet may also be located in the lower left corner of the

adjacent right cabinet, as shown in Figure 6

Center

Line of

Range

10"

(25.4 cm)

7" Max.

(17.8 cm Max.)

Locate Electrical Hook-up

Inside Shaded Area

Figure 4: 30" Models Outlet Location

WALL

FLOOR

Center

Line of

Range

Power Supply Cord

3

Electrical Shock Hazard –Do not attempt to install

the appliance directly to a junction box, modify the

factory-installed cord, or connect a different power

cord to the appliance. If the wall outlet is not sufcient

to support the requirements of this appliance, it is the

responsibility of the consumer to have the appropriate

outlet installed by an electrician. Improper installation

and electrical connections can result in electric shock,

damage to the appliance, personal injury, re, or death.

This appliance is equipped with a factory-connected,

4-wire power supply cord (Figure 7). This cord is rated

at 240 volts, 40 amps, and temperature rated at 194°F

(90°C). This cord is UL/CSA listed and has been tested

and approved for use with this appliance.

Center

Line of

Range

14"

(35.6 cm)

(1 cm Max.)2.7

5" Max.

WALL

Locate Electrical Hook-up

FLOOR

Inside Shaded Area

Center

Line of

Range

Figure 5: 36" Models Outlet Location

Figure 7: Factory connected power supply cord

Appliance Rating* Power Supply

Rating

120/240 Volts 120/208 Volts Amps

1-10 kW 0-7.6 kW 30

8.8-16.5 kW 7.8-12.5 kW 40 or 50

16.6-22.5 kW 12.6-18.5 kW 50

* The NEC calculated load is less than the total connec-

ted load listed on the serial plate.

Figure 6: Adjacent Cabinet Outlet Location

8

Page 9

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Shutoff Valve -

Open position

to appliance

to gas supply line

12”

(30.5 cm)

8“

(20.3 cm)

Fuel Supply Requirements

4

This unit is designed to operate on 4"(10.16 cm) water

column (1.0 kPa) natural gas manifold pressure.

A convertible pressure regulator is connected to the

range manifold and MUST be connected in series with

the gas supply line. The regulator is located as shown on

Figure 8 and it is accessible from front of the range.

30" Models 36" Models

Figure 8: Regulator locations

4.2

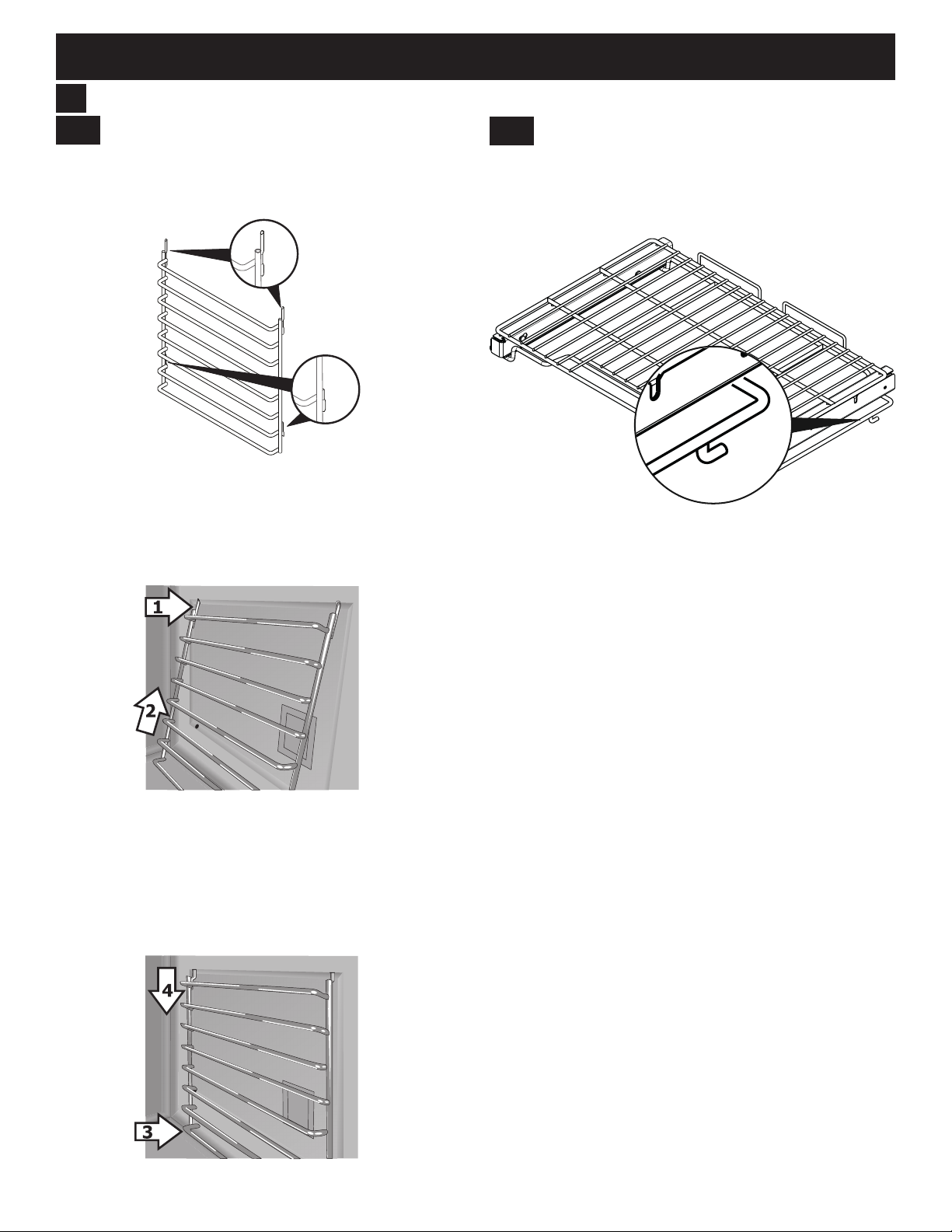

Shutoff Valve

The supply line should be equipped with an approved

shutoff valve as shown in Figure 10. This valve should

be located in the same room as the range and should

be in a location that allows ease of opening and closing.

Do not block access to the shutoff valve. The valve is for

turning on or shutting off gas to the appliance.

Figure 10: Shutoff valve

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14" (35.56 cm) of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least

1" (0.25 kPa) greater than the regulator manifold

pressure setting. The regulator is set for 4" (10.16 cm)

water column (1.0 kPa) Natural gas manifold pressure;

the inlet pressure must be at least 5" (12.60 cm) water

column (1.25 kPa) Natural gas.

For operation at 2000 ft. above sea level, appliance rating

is reduced by 4 percent for each additional 1000 ft.

4.1

The gas supply piping can be through the side wall of the

right cabinet. The right side cabinet is an ideal location

for the main shutoff valve, if the range is installed within

cabinet storage space.

Gas Supply Location

The gas supply between the shutoff valve and the

regulator may be connected by rigid piping or by A.G.A./

C.G.A.- approved exible metallic union-connected

piping where local codes permit use.

The user must know the location of the main shutoff

valve and have easy access to it.

4.3

Conversion to Liqueed Petroleum

(L.P.) Gas

This appliance allows for conversion to Liqueed

Petroleum (L.P.) Gas.

Personal injury or death from electrical

shock may occur if the conversion to L.P. gas is not

made by a qualied installer or electrician. Any additions,

changes or conversions required in order for this

appliance to satisfactorily meet the application needs

must be made by a qualied technician.

If L.P. conversion is needed, contact your local L.P.

Gas provider for assistance. The L.P. conversion kit is

provided with this appliance and is located on the lower

REAR (back side) panel of the range. Before installing

the kit be sure to read the L.P. Installation Instructions

and follow them carefully when making the installation.

For LP/Propane gas, the regulator must be set for

10"(25.4 cm) water column (2.5 kPa) manifold pressure;

the inlet pressure must be at least 11"(27.9 cm) water

column (2.75 kPa).

Figure 9: Recommended gas supply location

9

Page 10

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Flare

Union

Flare

Union

GAS FLOW

Manual

Shutoff

Valve

Pressure

Regulator

On

Off

Flexible

Connector

Access

Cap

Nipple Nipple

Connect Fuel Supply

5

5.1

Fuel Supply Connection

This appliance must be installed,

grounded, and serviced by a qualied installer or service

technician.

Do not make connections too tight. The

regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible re or

explosion.

This appliance includes a regulator. The gas supply line

requires the following parts which are not supplied with

the appliance:

• Manual shutoff valve

• 1/2" nipples (2)

• 1/2" are union adapter (2)

• Flexible connector

The gas supply line to the shutoff valve should be

1/2"(1.27 cm) or 3/4"(1.9 cm) solid pipe.

Install the gas supply pipe to the pressure regulator in

the order shown in Figure 11. All connections should be

tightened with a wrench.

5.2

Check For Leaks

Do not use a ame to check for leaks from

gas connections. Checking for leaks with a ame may

result in a re or explosion.

After connecting the range to the gas supply, check the

system for leaks with a manometer. If a manometer is not

available, turn on the gas supply and use a liquid leak

detector (or soap and water) at all joints and connections

to check for leaks. Leaks will be indicated by bubbles

appearing at the connections or joints.

All openings in the wall or oor where the range is to be

installed must be sealed.

1. Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

2. Disconnect this range and its individual shutoff valve

from the gas supply piping system during any pressure

testing of the system at test pressures greater than

1/2 psig (3.5 kPa or 14"(35.56 cm) water column).

3. Isolate the range from the gas supply piping system by

closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig (3.5 kPa

or 14"(35.56 cm) water column).

Figure 11: Fuel supply connection ow

When using exible gas conduit on the range, allow

sufcient slack to pull the range outside the cutout for

cleaning or servicing.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If exible

connectors are used, be certain connectors are not

kinked.

Do not allow the exible conduit to get pinched between

the wall and the range.

10

Page 11

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Install the Oven Racks

6

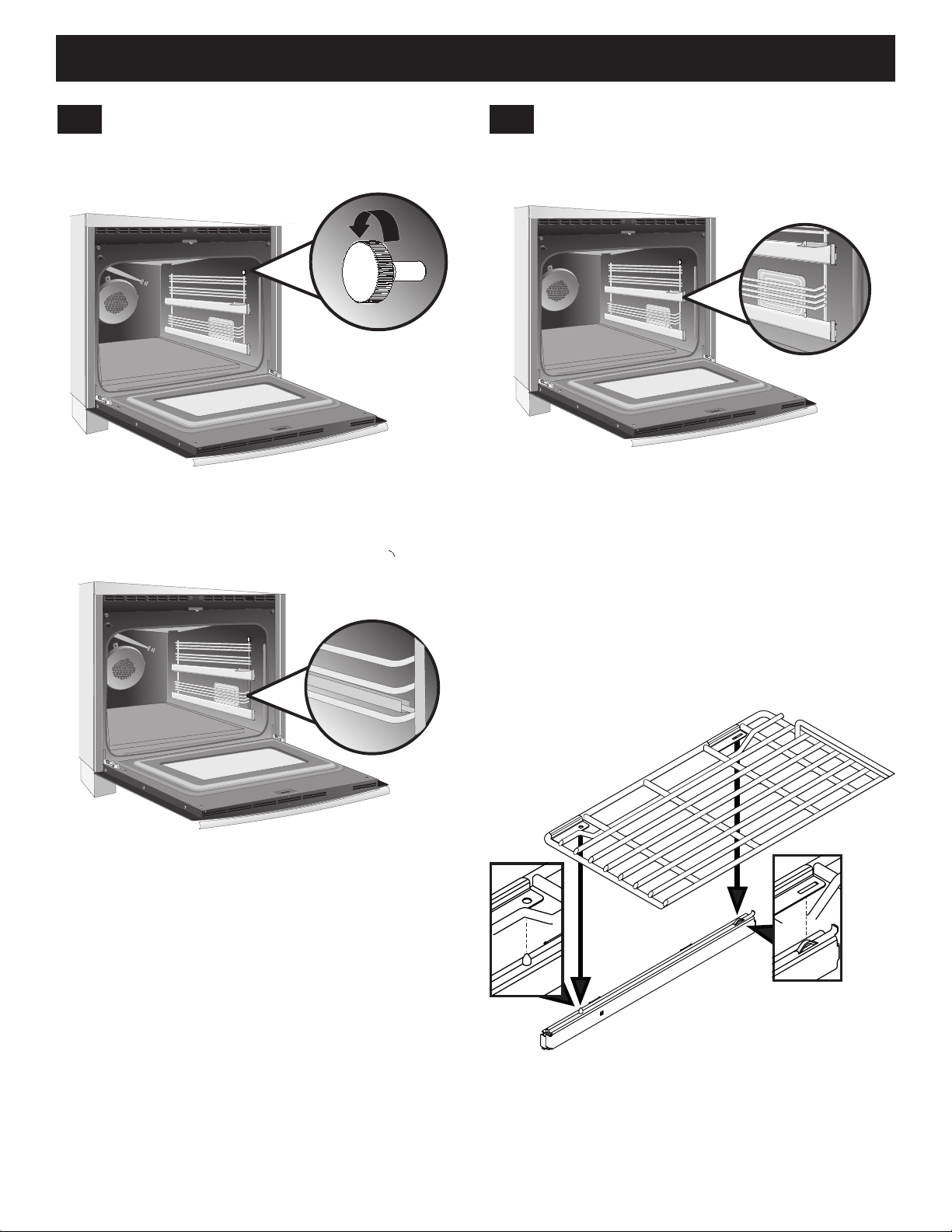

6.1

30" Models - Ladder Rack Supports

To aid installation of the porcelain oven rack supports,

apply a thin layer of cooking oil to all the prongs of the

supports as shown in Figure 12.

Figure 12: Ladder rack supports - oil areas

1. Hold the oven rack support at a slight angle and insert

prongs into the holes at the top of the oven cavity

(Figure 13).

2. Lift the rack into the top holes, aligning the bottom

prongs with the bottom holes (Figure 13).

6.2

30" Models - Glide Racks

The glide racks install like other oven racks.

The glide rack stop (Figure 15) must be inside the ladder

support for the rack to slide in and out properly.

Figure 15: Glide rack stop

Place the oven rack on the rack supports. Tilt the back of

the rack upward slighly to get the stop into place inside the

ladder rack. Slide the oven rack back into place

Be sure to slide the rack all the way in so that the back of

the rack stops by meeting the vertical support of the ladder

rack.

To prevent possible damage to the oven, do not attempt to

close the oven door until all oven racks are fully positioned

inside the oven cavity.

Figure 13: Ladder rack supports - top prongs

3. Once the upper prongs are in place, hold the oven

rack support ush with the oven side and insert the

bottom prongs into the bottom holes (Figure 14).

4. Slide the bottom prongs down into the lower holes.

Some force may be required to set the rack into place

(Figure 14).

Figure 14: Ladder rack supports - bottom prongs

11

Page 12

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

6.3

36" Models - Ladder Rack Supports

1. Remove the thumb screws located on each side of the

oven cavity (see Figure 16).

Figure 16: Ladder rack thumb screw

2. Place the ladder racks into the support brackets located on the oven sides (see Figure 17).

6.4

36" Models - Glide Racks

On 36" models, the glide tracks for the gliding oven racks

come pre-installed on the ladder rack supports (see

Figure 18).

Figure 18: Ladder rack glides

The glide racks appear slightly different than the at

racks (see Figre 19). Only the glide racks can be

installed onto the glide tracks.

1. Extend the two bottom glides fully out of the oven.

2. Place the glide rack on top of the glides.

3. Near the back of the rack, t the rack slot onto the

track tabs. Near the front of the rack, t the track pin

into the hole on the rack (see Figure 19).

4. Once the rack is installed, it can be pulled in and out

of the oven cavity on the glide tracks. Repeat for the

top set of glides.

Figure 17: Ladder rack supports

3. Replace the screws removed in Step 1.

Figure 19: Installing glide racks

The glide racks can only be used in these positions. The

racks may be removed from the tracks and used like a

regular at rack on all the other rack positions.

Insert regular at oven racks in any desired position.

12

Page 13

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

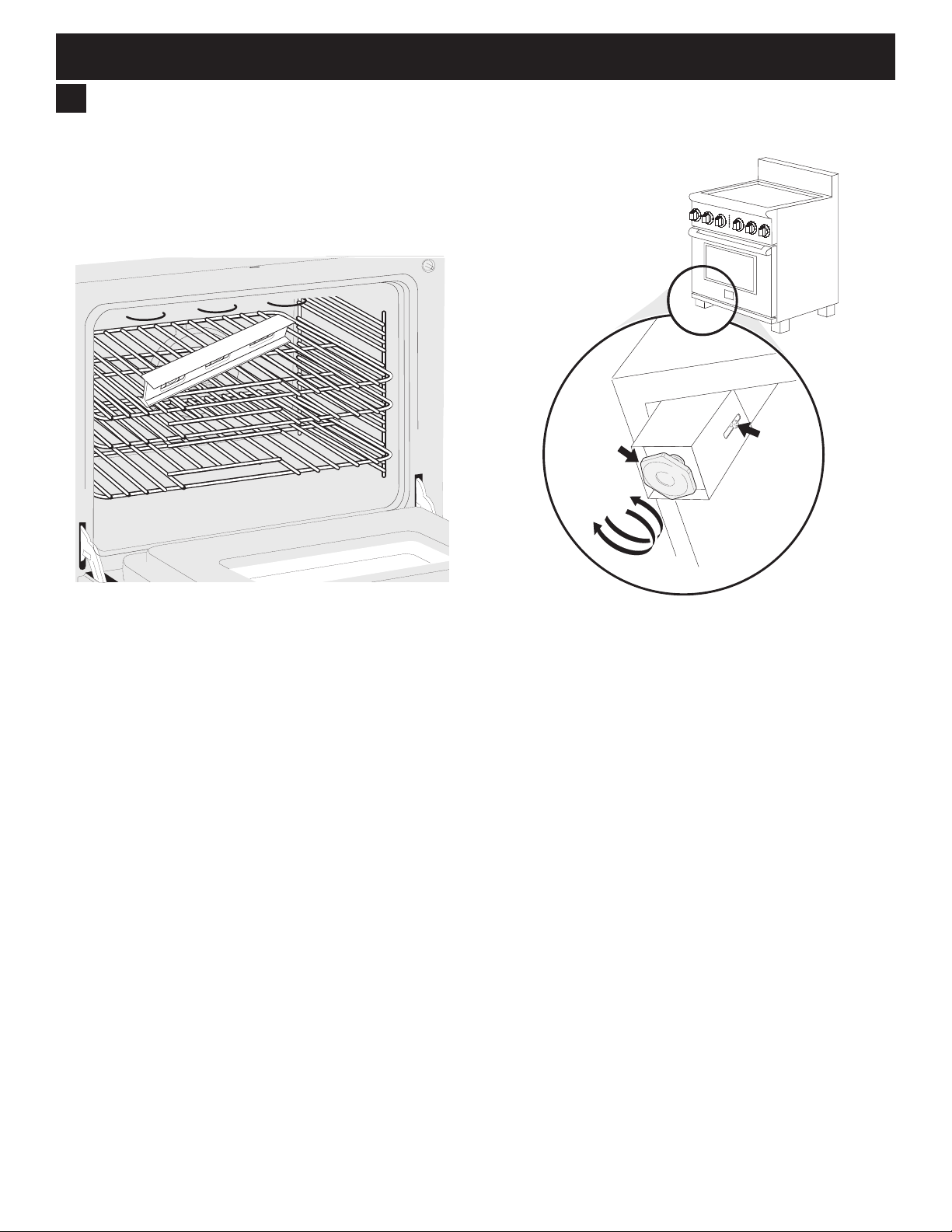

7

Level the Range

Level the range and set cooktop height before

installation in the cut-out opening (if applicable).

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (Figure 20). Take 2

readings with the level placed diagonally in one

direction and then the other.

3. Level the range, if necessary, by adjusting the 4 leg

levelers with a wrench (Figure 21).

Base of Range

Figure 20: Use the oven racks to level appliance

Leveling leg

Raise

Lower

Figure 21: Adjusting appliance height

4. Slide range into cut-out opening and double check

for levelness. If the range is not level, pull unit out

and readjust leveling legs, or make sure oor is level.

Decorative

Leg Screw

13

Page 14

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

8

Install Anti-Tip Bracket

To reduce the risk of tipping the appliance,

the appliance must be secured to the oor by the properly

installed anti-tip bracket and screws packed with the

range. These parts are located in the oven. Failure to

install the anti-tip bracket will allow the range to tip over if

excessive weight is placed on an open door or if a child

climbs on it. Serious injury might result from spilled hot

liquids or from the range itself.

If range is ever moved to a different location, the antitip brackets must also be moved and installed with the

range.

Tools Required:

• Adjustable Wrench

• Ratchet

• Drill & 1/8" (0.32 cm) bit

• 5/16" (0.8 cm) Nut driver

• Level

Tip Over Hazard

• A child or adult can tip the range

and be killed.

• Verify the anti-tip device has been

installed to floor or wall.

• Ensure the anti-tip device is re-engaged to floor or wall

when the range is moved.

• Do not operate the range without the anti-tip device in

place and engaged.

• Failure to follow these instructions can result in death or

serious burns to children and adults.

Range

leveling leg

Anti-tip

bracket

8.1

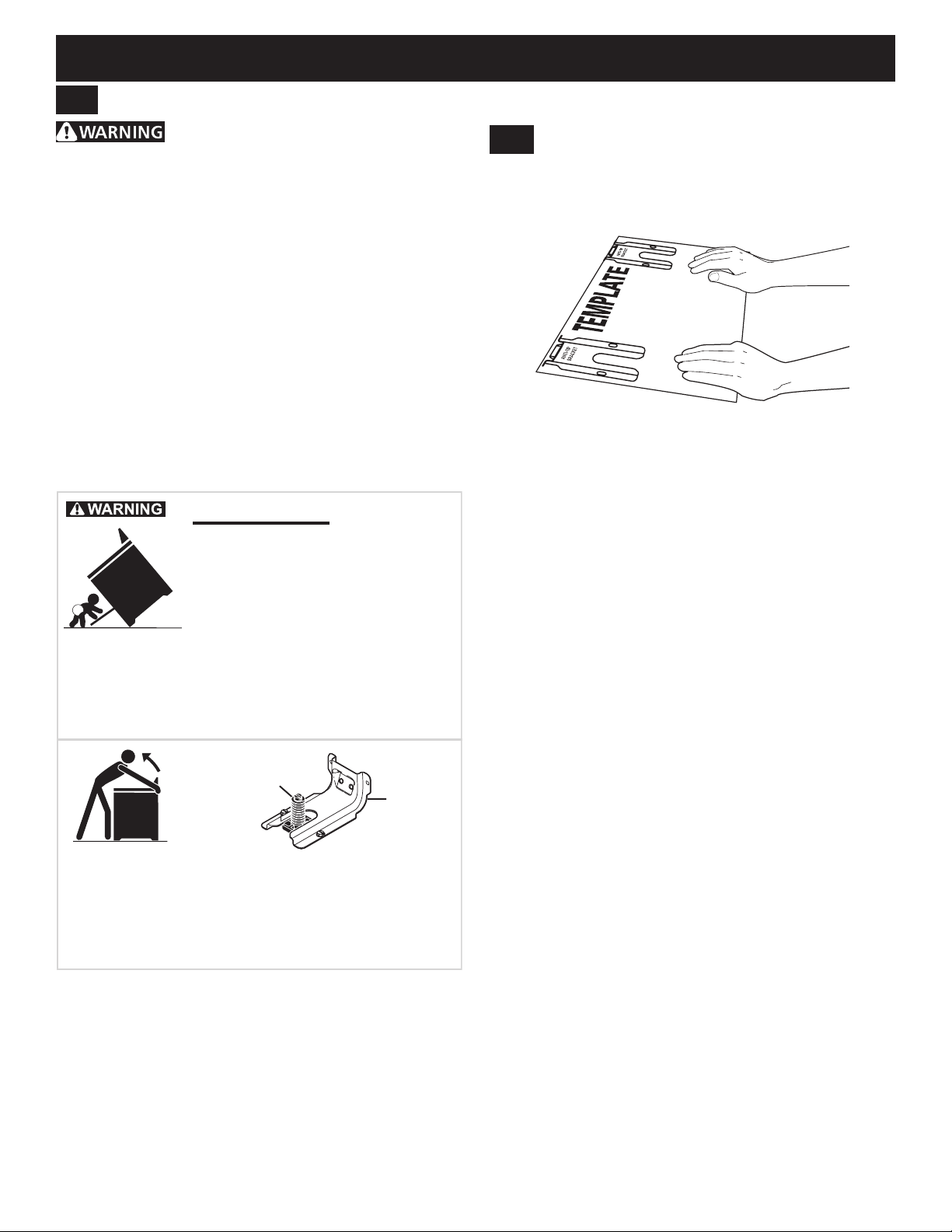

Locate the Bracket Using the Template

Bracket may be located on either the left or right side of

the range. Mark the oor or wall where left or right side of

the range will be located.

Figure 22: Bracket template

If rear of range is against the wall or no further than 1/2”

(1.3 cm) from wall when installed, you may use the wall

or oor mount method. If moulding is installed and does

not allow the bracket to t ush against the wall, remove

moulding or mount bracket to the oor.

For wall mount, locate the bracket by placing the back

edge of the template against the rear wall and the side

edge of template on the mark made referencing the side

of the range. Place bracket on top of template and mark

location of the screw holes in wall.

If rear of range is further than 1/2” (1.3 cm) from the wall

when installed, attach bracket to the oor. For oor mount,

locate the bracket by placing back edge of the template

where the rear of the range will be located.

Mark the location of the screw holes shown in template.

To check if the anti-tip bracket is installed properly, use both

arms to grasp the rear edge of the range back. Carefully

attempt to tilt range forward. When properly installed, the range

should not tilt forward.

Refer to the anti-tip bracket installation instructions supplied

with your range for proper installation.

14

Page 15

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Leveling Leg

Anti-Tip Bracket

Floor Mount

8.2

Drill Pilot Holes and Fasten Bracket

Drill a 1/8” pilot hole where screws are to be located.

If bracket is to be mounted to the wall, drill pilot hole at

an approximate 20° downward angle. If bracket is to

be mounted to masonry or ceramic oors, drill a 3/16”

(4.8 mm) pilot hole 1-3/4” deep.

Figure 23: Drill pilot holes

The screws provided may be used in wood or concrete

material. Use a 5/16” nut-driver or at head screwdriver to

secure the bracket in place.

8.3

Check Level and Position the Range

Check the level of the nal installation. Note: A minimum

clearance of 1/8” is required between the bottom of the

range and the levelling leg to allow room for the bracket.

Use a spirit level to check your adjustments.

1/8" Minimum

Figure 24: Fastening the bracket

Wall Mount

Figure 25: Use the oven racks to level appliance

Slide range into position.

Wall Plate

Figure 26: Slide appliance into bracket

To check if the anti-tip bracket is installed properly,

use both arms and grasp the rear edge of range back.

Carefully attempt to tilt range forward. When properly

installed, the range should not tilt forward.

If range is moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

15

Page 16

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

9

Install Burner Assemblies

To prevent are-ups use the cooktop with all burner caps properly installed.

9.1

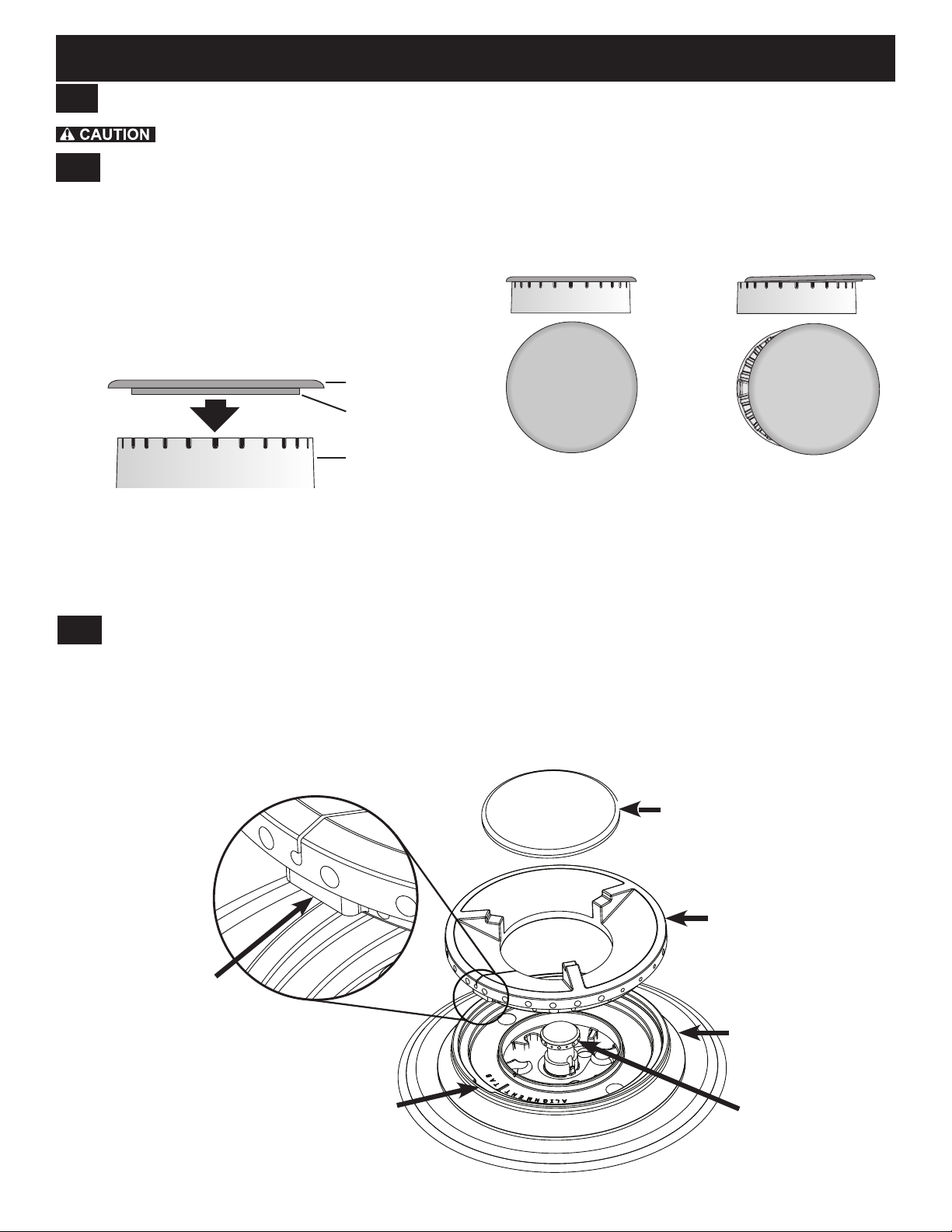

Standard Sealed Burners

Place a burner cap on each burner head, matching the cap size to the head size.

The cap for each burner has an inner locating ring which centers the cap correctly on the burner head. Make sure

each burner cap is properly aligned and level. Burners may not light or burn evenly if the burner caps are not correctly

place on the head.

Burner cap

Locating ring

Burner head

Figure 27: Burner cap assembly

9.2

Specialty Burners

Install the specialty burners as shown in Figure 29.

When the burner ring is properly seated, it will click into place. When the burner cap is properly set in place it should not

move out of the recessed area of the burner head.

To ignite properly, burner ring alignment tab must be tted into the burner base alignment tab slot. Make sure burner cap

and ring are secure before attempting to light the burner.

Correct cap placement Incorrect cap placement

Figure 28: Burner cap placement

Burner cap

Burner ring

alignment tab

Burner alignment

tab slot

Figure 29: Specialty burner assembly

Burner ring

Burner base

Simmer head

16

Page 17

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

9.3

Check Ignition on Surface

Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

1. Push in and turn a surface burner knob to the

sparking position. All electronic surface ignitors will

spark at the same time. Only the burner you are

turning on will ignite.

2. The surface burner should light once the ow of gas

reached the surface burner. Each burner should light

within four (4) seconds in normal operation after air

has been purged from supply lines. Visually check

that burner has lit.

3. Once the burner lights, the control knob should be

rotated out of the LITE position.

Turn on each of the surface burners and check to see

that they light properly and that the ames are even.

Adjust settings if necessary.

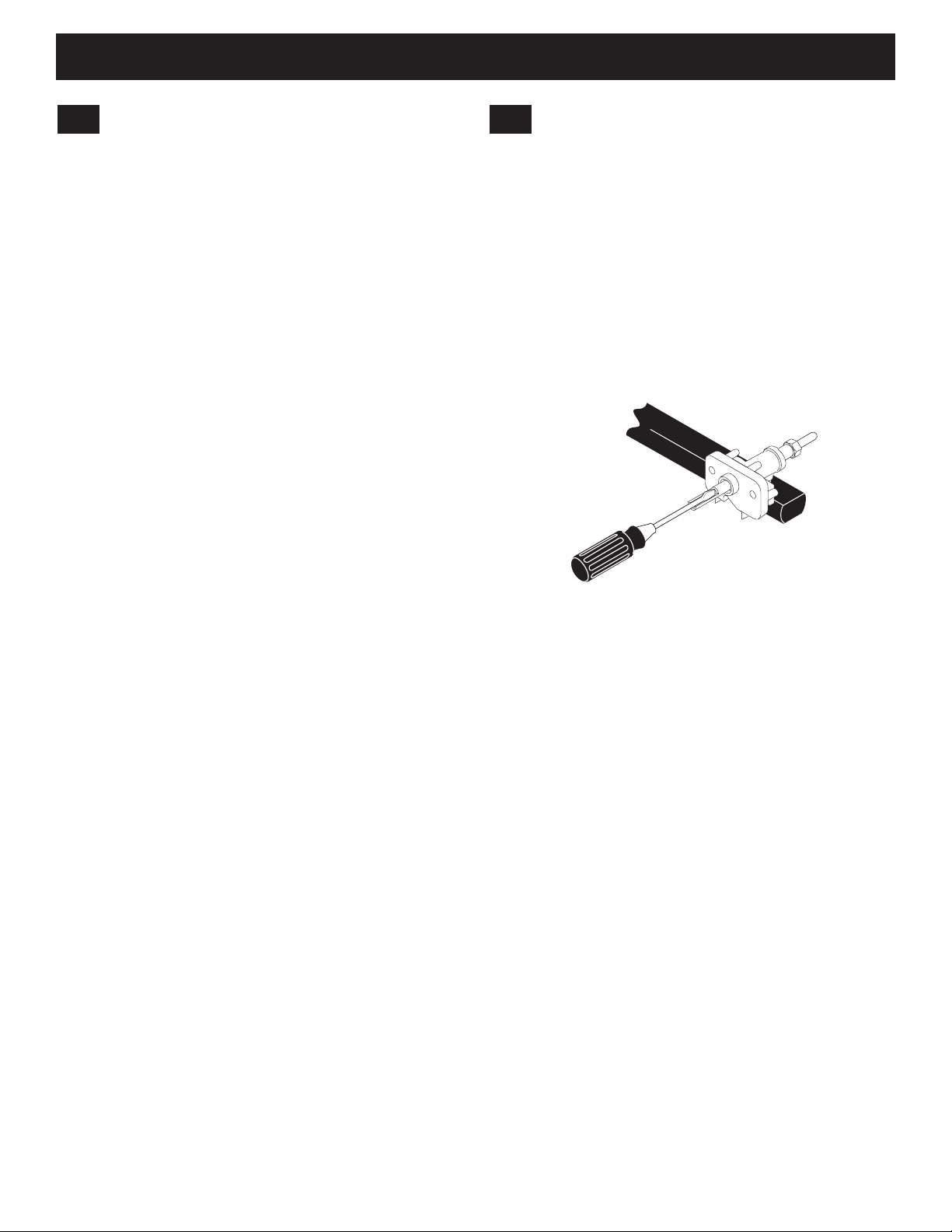

9.4

Adjust Low Settings on Surface

Burners

To adjust the low setting of surface burners:

1. Push in and turn control to LITE until burner ignites.

2. Quickly turn knob to LOWEST POSITION.

3. If burner goes out, reset control to OFF.

4. Remove the surface burner control knob and

decorative ring.

5. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased by turning the screw.

Figure 30: Turn to adjust surface ame

6. Adjust ame until you can quickly turn knob from the

sparking position to the lowest ame position without

extinguishing the ame. Flame should be as small as

possible without going out.

Notes:

• Air mixture adjustment is not required on surface

burners.

• Some models have two ames on each burner. The

center ame on these burners is not adjustable.

17

Page 18

30" & 36" DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Check Oven Operation

10

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Remove all packaging from the oven before testing.

The oven is equipped with an electronic oven control.

Each of the functions has been factory checked before

shipping. However, it is suggested that you verify the

operation of the electronic oven controls once more.

Refer to the Owner's Guide for operation. Follow the

instructions for the Clock, Timer, Bake, Broil, Convection,

and Clean functions.

Bake–After setting the oven to 350°F (177°C) for baking,

the oor of the oven cavity should become warm.

Broil–When the oven is set to BROIL, the upper element

in the oven should become red.

Clean–When the oven is set for a self-cleaning cycle,

the upper element should become red during the preheat

portion of the cycle. After reaching the self-cleaning

temperature, the oor of the oven cavity should become

hot.

Convection–When the oven is set to CONV. BAKE/

ROAST at 350°F (177°C), both elements cycle on and

off alternately and the convection fan will turn. The

convection fan will stop turning when the oven door is

opened during convection baking or roasting.

After Installation

11

When All Hookups are Complete

Make sure all controls are left in the OFF position.

Model and Serial Number Location

The serial plate is located on top of the range's lower

front panel, and can be clearly viewed when the door is

open. When ordering parts for or making inquiries about

your range, have the model and serial numbers ready.

(Figure 31).

Figure 31: Model, serial number location

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Owner's Guide. It may save you time

and expense. The list includes common occurrences that

are not the result of defective workmanship or materials

in this appliance.

Refer to the warranty and service information in your

Owner's Guide for our phone number and address.

Please call or write if you have inquiries about your

range product and/or need to order parts.

18

Page 19

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

INSTRUCCIONES DE INSTALACIÓN

DUAL DE 30" Y 36"

ESTUFA DE COMBUSTIBLE DUAL DE 30" Y 36"

LA INSTALACIÓN Y SERVICIO DEBERÁN SER REALIZADOS POR UN INSTALADOR

CUALIFICADO.

IMPORTANTE: GUARDE ESTE DOCUMENTO PARA USO DEL INSPECTOR ELÉCTRICO.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA FUTURAS CONSULTAS.

Canadá

POR SU SEGURIDAD: No guarde ni use gasolina

ni otros vapores o líquidos inamables cerca de éste o de

cualquier otro aparato.

Contenido

Instrucciones importantes para la seguridad ...........20-22

Dimensiones del producto ............................................ 23

Dimensiones del armario .............................................. 24

Construcción del armario.............................................. 25

Requisitos eléctricos..................................................... 25

Cable de la fuente de alimentación .............................. 26

Requisitos del suministro de combustible .................... 27

Conecte el suministro de combustible .......................... 28

Instale las rejillas de horno ...................................... 29-30

Nivele la estufa ............................................................. 31

Instale el soporte antivuelco .................................... 32-33

Instale los conjuntos de quemador ..........................34-35

Compruebe el funcionamiento del horno...................... 36

Después de la instalación............................................. 36

Ubicación de la placa de serie

(número de modelo y de serie)..................................... 36

Notas importantes para el instalador

1. Lea todas las instrucciones contenidas en estas

instrucciones de instalación antes de instalar la estufa.

2. Retire todos los materiales de embalaje del horno

y de los compartimentos de cajón antes de conectar

el suministro eléctrico a la estufa.

3. Deberá instalarse el soporte antivuelco suministrado

con el aparato.

4. Observe toda la normativa vigente.

5. Asegúrese de entregar estas instrucciones

al consumidor.

Impreso en Estados Unidos

Nota importante para el consumidor

1. Conserve estas instrucciones con la guía del

propietario para futuras consultas.

2. Al utilizar cualquier aparato que genere calor hay

algunas precauciones que deberá seguir. Estas

precauciones se detallan en su manual de uso

y cuidados. Lea atentamente su manual.

3. Asegúrese de que su dispositivo sea instalado

yconectadoatierraporuninstaladorcualicado

o técnico de servicio.

P/N 809018701 (1611) Rev.A

English – pages 1-18

Español – pages 19-36

Français – pages 37-55

19

Page 20

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

ADVERTENCIA

ATENCIÓN

DUAL DE 30" Y 36"

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Este dispositivo deberá ser instalado, conectado a tierra y sujeto a tareas de servicio por un instalador

o técnico de servicio cualicado.

Este manual contiene instrucciones y símbolos importantes para su seguridad. Por lo que se recomienda prestar atención

a los símbolos y seguir todas las instrucciones indicadas en el mismo. No trate de instalar ni hacer funcionar su producto

antes de leer las precauciones de seguridad de este manual. Las indicaciones de seguridad en este manual llevan un

símbolo de ADVERTENCIA o PRECAUCIÓN en función del tipo de riesgo.

Las advertencias e instrucciones importantes que aparecen en esta guía no pretenden cubrir todas las situaciones posibles

que pueden producirse. Utilice el sentido común, la precaución y el cuidado al instalar, mantener o hacer funcionar su producto.

Este es el símbolo de alerta de seguridad. Se usa para alertar sobre peligros potenciales de lesiones personales.

Obedezca todos los mensajes de seguridad que tengan este símbolo para evitar posibles lesiones o la muerte.

Indica una situación potencialmente peligrosa que, si no se evita, podría causar lesiones graves

o la muerte.

Indica una situación potencialmente peligrosa que, si no se evita, podría causar lesiones personales

leves o moderadas.

IMPORTANTE: Indica información importante, de instalación, de funcionamiento o de mantenimiento que no está

relacionada con situaciones de peligro.

WARNING:

Riesgo de volcamiento

• Un niño o adulto puede volcar la estufa y

acabar muerto.

• Verifique que se haya instalado el

dispositivo antivuelco en el piso o en la

pared.

• Asegúrese de que el dispositivo antivuelco se haya reacoplado

cuando mueva la estufa sobre el piso o a la pared.

• No utilice la estufa sin el dispositivo antivuelco instalado y

acoplado.

• Si no se siguen estas instrucciones, se puede provocar la muerte

o quemaduras graves en niños y adultos.

Tornillo

nivelador de

la estufa

Para verificar si el soporte antivuelco está instalado

correctamente, sostenga el borde trasero de la parte

trasera de la estufa usando ambos brazos. Intente inclinar

la estufa hacia adelante con cuidado. Si está instalada

correctamente, la estufa no debería inclinarse hacia

adelante.

Consulte las instrucciones de instalación del soporte

antivuelco proporcionadas con la estufa para instalarlo

adecuadamente.

Soporte

antivuelco

ADVERTENCIA

Si no se sigue exactamente

la información contenida en este manual

podría ocurrir un incendio o explosión

causando daños materiales, lesiones o muerte.

POR SU SEGURIDAD:

—No almacene ni utilice gasolina ni

otros vapores o líquidos inflamables

cerca de este o algún otro electrodoméstico.

—QUÉ HACER SI HUELE A GAS:

• No encienda ningún electrodoméstico.

• No toque ningún interruptor eléctrico;

no utilice ningún teléfono de la casa.

• Llame inmediatamente a la empresa

de suministro de gas desde el teléfono

de un vecino. Siga las instrucciones de

la empresa de suministro.

• Si no puede ponerse en contacto con

la empresa de suministro de gas, llame

a los bomberos.

—Las operaciones de instalación y servicio

técnico debe realizarlas un instalador

o proveedor de servicios cualificado

o la empresa suministradora de gas.

20

Page 21

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

DUAL DE 30" Y 36"

• Las temperaturas bajas pueden dañar el control

electrónico. Cuando use el electrodoméstico por primera

• Peligro de peso excesivo: Son necesarias dos

o más personas para mover e instalar la estufa.

No seguir esta instrucción puede provocar lesiones

de espalda o de otro tipo.

• Almacenamiento dentro o sobre el

electrodoméstico: No deben almacenarse

materialesinamablesenelinteriordeunhorno

o microonda, cerca de los elementos o resistencias

delasupercienienelcajóndealmacenamiento

o del calentador (en su caso). Esto incluye artículos

de papel, plástico y tela, tales como libros de cocina,

objetos de plástico y toallas, así como líquidos

inamables.Noguardeexplosivos,comolatasde

productos en aerosol, sobre o cerca del aparato.

• No deje a los niños solos y desatendidos:

Los niños deben estar siempre acompañados

y atendidos por un adulto cuando haya un

electrodoméstico en uso. Nunca permita que los

niños se sienten o se paren sobre ninguna pieza

del electrodoméstico, incluyendo el cajón de

almacenamiento, el cajón asador inferior, el cajón

calentador o el horno doble inferior.

• No guarde artículos que les interesen a los niños en los

armarios situados sobre el aparato ni en el protector

trasero. Si los niños se suben al aparato para alcanzar

dichos artículos podrían sufrir lesiones graves.

• Pararse, apoyarse o sentarse en la puerta o los

cajones de este aparato puede causar lesiones

graves y además dañar el electrodoméstico.

• No utilice el horno ni el cajón calentador

(en su caso) para guardar objetos.

• No utilice nunca este dispositivo como calentador

ambiental para calentar la sala. Esto podría tener

comoconsecuenciaenvenenamientopormonóxido

de carbono y sobrecalentamiento del aparato.

• No guarde ni use gasolina ni otros vapores o líquidos

inamablescercadeésteodecualquierotroaparato.

• No se utilizarán usar cortinas de aire ni cualquier otra

campana de ventilación superior que sople aire hacia

abajo sobre la estufa o cubierta en conjunción con

cubiertas o estufas de gas a menos que la campana

de ventilación, la estufa y la cubierta hayan sido

diseñadas,probadasycerticadasporunlaboratorio

de pruebas independiente para usarse de forma

combinada.

INSTRUCCIONES IMPORTANTES PARA

DESEMPACADO E INSTALACIÓN

Lea y siga las siguientes instrucciones y precauciones

a la hora de desempacar, instalar y realizar el

mantenimiento del electrodoméstico:

• Destruya la caja de cartón y las bolsas de plástico

después de desempacar el producto. Nunca deje que

los niños jueguen con el material de empaque. No quite

la etiqueta de cableado ni otra información adherida al

dispositivo. No quite la placa de número de modelo/serie.

21

vez, o cuando este no se haya usado por un período

largo de tiempo, asegúrese de que la unidad esté en

temperaturas superiores a los 32 °F (0 °C) durante al

menos 3 horas antes de encenderla.

• Nuncamodiqueoalterelaconstruccióndeldispositivo

retirando patas de nivelación, paneles, cubiertas de

cables y abrazaderas antivuelco/tornillos u otras partes

del dispositivo.

• Instalación correcta—Asegúrese de que su dispositivo

sea instalado y conectado a tierra por un técnico

cualicado.EnEstadosUnidos,instaleelproducto

de conformidad con el National Fuel Gas Code ANSI

Z223.1/NPFA No. 54, última edición y el National

Electrical Code NFPA No. 70 última edición y cumpla

todos los códigos eléctricos locales. En Canadá, este

artefacto debe instalarse según CAN/CGA B149.1

y CAN/CGA B149.2 y la norma CSA Standard C22.1,

Código Canadiense de Electricidad (Canadian

Electrical Code), Parte 1, y los códigos eléctricos

locales.Instaleelartefactosiguiendoexclusivamente

las instrucciones de instalación proporcionadas en la

documentación de este dispositivo.

• La instalación de dispositivos diseñados para

su instalación en hogares prefabricados (móviles)

debe ser conforme a la norma Manufactured Home

Construction and Safety Standard, título 24CFR,

parte 3280 [antes Federal Standard for Mobile Home

Construction and Safety, título 24, HUD (parte 280)] o,

si dicha norma no es aplicable, la norma Standard for

Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Setups), ANSI Z225.1/

NFPA 501A-última versión, o los códigos locales en

Estados Unidos y CAN/CSA-Z240 MH en Canadá.

• Antes de instalar la estufa en un área con suelo

de linóleo u otro recubrimiento sintético, asegúrese

de que el recubrimiento del suelo pueda soportar

temperaturas de al menos 90°F (32,2°C) por encima

de la temperatura ambiente sin encoger, deformarse

o decolorarse. No instale la estufa sobre moqueta sin

colocar una lámina de madera contrachapada de ¼"

(0,64 cm) de grosor entre la estufa y la moqueta.

• Asegúrese de que el recubrimiento de las paredes y los

materiales de los armarios que rodean la estufa puedan

soportar el calor generado por el aparato.

• Para eliminar riesgo de quemaduras o incendio por

contactoconlasunidadesdelasuperciecaliente,deberá

evitarse el espacio de almacenamiento en armarios sobre

lasupercie.Siesnecesariodisponerdealmacenamiento

en armarios, es posible reducir el riesgo instalando una

campana de estufa que que se proyecte horizontalmente

al menos 5 pulgadas más allá de la parte inferior del armario.

• No obstruya la circulación de aire en el respiradero

del horno, alrededor de la base o bajo el panel frontal

inferior del aparato. Este dispositivo necesita aire

fresco para funcionar correctamente.

• Asegúresedequehayaunextintordeespuma

adecuado disponible, ubicado de manera visible

y fácilmente accesible cerca del electrodoméstico.

Page 22

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

DUAL DE 30" Y 36"

INSTRUCCIONES ESPECIALES PARA

ELECTRODOMÉSTICOS INSTALADOS

EN EL ESTADO DE MASSACHUSETTS

Este electrodoméstico solo puede ser instalado en el

Estado de Massachusetts por un fontanero o instalador

de gas con licencia de Massachusetts. Al utilizar un

conectordegasexible,nodeberásuperarlos3pies

(36 pulgadas) de longitud. Deberá instalarse una

válvula manual de gas con manija tipo "T" en la línea

de suministro de gas al dispositivo.

CONVERSIÓN A GAS LP

Este electrodoméstico permite la conversión a gas de

petróleo licuado (LP).

Si la conversión a gas licuado

no es realizada por un instalador o un electricista

calicadoexistenriesgosdelesionespersonales

o la muerte por choque eléctrico. Las adiciones, cambios

o conversiones necesarios para que esta estufa cumpla

satisfactoriamente con sus requisitos de funcionamiento

deben ser realizados por un técnico de servicio.

INSTRUCCIONES IMPORTANTES PARA SERVICIO

Y MANTENIMIENTO

• No repare ni cambie ninguna pieza del aparato que

noestéespecícamenteindicadaenlosmanuales.

Todas las restantes tareas de servicio deberán ser

realizadasexclusivamenteporuntécnicocualicado.

Esto reduce el riesgo de lesiones personales y daños

en el aparato.

• Póngase siempre en contacto con su distribuidor,

concesionario, agente de servicio o fabricante en

relación con cualquier problema o circunstancia que

no comprenda.

• Pida a su distribuidor que le recomiende un técnico

cualicadoyunserviciodereparaciónautorizado.

Aprenda a desconectar la corriente del aparato y el

disyuntor o caja de fusibles en caso de emergencia.

• Retire la puerta del horno no utilizado que vaya a tirar

o guardar.

• No toque la bombilla de luz del horno caliente con

un paño húmedo. Esto podría provocar la rotura

de la bombilla. Manipule las bombillas halógenas

(en su caso) con un paño de papel o guantes suaves.

Desconecte el aparato o apague la alimentación del

aparato antes de quitar y cambiar la bombilla.

Si necesita realizar una conversión a gas LP,

llame a su distribuidor local de gas LP para obtener

asistencia. El kit de conversión a gas LP se incluye con

este electrodoméstico y se encuentra en el panel inferior

trasero (parte trasera) de la estufa. Antes de instalar el

kit, asegúrese de leer atentamente las instrucciones de

instalación de LP y seguirlas cuidadosamente al realizar

la instalación.

22

Page 23

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

DUAL DE 30" Y 36"

Dimensiones del producto

No instale la unidad en el armario antes de leer las dos páginas siguientes.

D

C

B

A

E

Figura 1: Dimensiones del producto

C. FONDO EN EL

MODELO A. ALTO B. ANCHO

30"

36" 35 7/8" (91,1 cm) 48 3/8" (122,9 cm)

41 5/8" (105,7 cm) Mín.

425/8"(108,3cm)Máx.

29 7/8" (75,9 cm)

FRONTAL DE LA

ESTUFA

27 1/2" (69,9cm)

D. ALTURA DE LA

CUBIERTA

35 3/4" (90,8 cm) MÍn.

363/4"(93,3cm)Máx.

E. FONDO CON

LA PUERTA

ABIERTA

46 1/4" (117,5 cm)

23

Page 24

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

DUAL DE 30" Y 36"

Dimensiones del armario

Separaciones y dimensiones

• Dejeunaseparaciónadecuadaentreelelectrodomésticoylassuperciescombustiblesadyacentes.

• Ubicación: compruebe la ubicación en la que se instalará el electrodoméstico. Compruebe que la

alimentación eléctrica y la estabilidad del suelo sean adecuadas.

• Deberán utilizarse las dimensiones indicadas. Las dimensiones indicadas ofrecen una separación mínima.

Lasuperciedecontactodeberásersólidaynivelada.

J

H

G

I

F

Figura 2: Dimensiones del armario

13"Máx.

(33cmMáx.)

18" Mín.

(45,7 cm Mín.)

24" Mín.

(61 cm Mín.)

24½"Máx.

(62,2cmMáx.)

F. ANCHO

MODELO

30"

36"

NOTAS:

1. No selle la estufa a los armarios laterales.

2. Separacióndelasparedesadyacentesuotrassuperciesoestructurasverticales,comoarmarios.

3. Las mediciones indicadas son la separación mínima entre la cubierta y la parte inferior del armario.

4. 0"deseparaciónentrelaestufaylosarmariososuperciesverticalespordebajodelaalturadelacubierta.

5. 0" de separación entre la parte posterior de la estufa y la pared o armario.

MÍNIMO DEL

RECORTE

30 1/16"

(76,4 cm)

36 1/16"

(91,6 cm)

G. ALTURA DEL

MOSTRADOR

36" (91,4 cm) Estándar

35 3/4" (90,8 cm) Mín.

H. SEPARACIÓN

DESDE LAS

PAREDES

LATERALES

5" (12,7 cm) Mín. 30" (76,2 cm) Mín. 30" (76,2 cm) Mín.

7" (17,8 cm) Mín. 36" (91,4 cm) Mín. 36" (91,4 cm) Mín.

24

2

I. SEPARACIÓN

DESDE LA

CUBIERTA Y LA

PARTE INFERIOR

DEL ARMARIO

J. ANCHO DE

SEPARACIÓN DE

LOS ARMARIOS

3

SUPERIORES

Page 25

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

ATENCIÓN

correspondientes a su tipo de instalación

DUAL DE 30" Y 36"

1

Construcción del armario

Para eliminar riesgo de quemaduras

o incendio por contacto con las unidades de la

superciecaliente,nodejeespaciodealmacenamiento

en armarios sobre la estufa. Si hay espacio de

almacenamiento en armarios sobre la estufa, reduzca

el riesgo instalando una campana de estufa que que se

proyecte horizontalmente al menos 5 pulgadas /12,7 cm)

más allá de la parte inferior del armario.

Línea central

de la estufa

Siga las instrucciones

Figura 3: Construcción del armario

1.1

Instalación: Armario a ambos lados

1. Si la estufa va a instalarse con armario a ambos

lados, dibuje una linea central en el suelo entre los

armarios (Figura 5).

2. Si la parte posterior de la estufa no queda al nivel de

la pared (la ubicación de la toma de corriente puede

no permitir que la estufa se coloque contra la pared),

dibuje una línea en el suelo donde estará el borde

posterior de la estufa.

3. Instale soportes antivuelco (ver "Instalación del

soporte antivuelco").

1.2

Instalación: Armario solo a un lado

1. Si va a instalar la estufa con armario solo a un lado,

muevalaestufaasuposiciónnal.

2. Dibuje una línea en el suelo por el lateral de la estufa

que no queda junto al armario. Si la parte posterior

de la estufa no queda al nivel de la pared (la ubicación

de la toma de corriente puede no permitir que la estufa

se coloque contra la pared), dibuje una línea en el

suelo donde estará el borde posterior de la estufa.

3. Instale soportes antivuelco (ver "Instalación del

soporte antivuelco").

1.3

Instalación: Sin armario

1. Si la estufa no va a instalarse junto a un armario,

muevalaestufaasuposiciónnal.

2. Haga una marca en el suelo a ambos lados de la

estufa. Si la parte posterior de la estufa no queda

al nivel de la pared (la ubicación de la toma de

corriente puede no permitir que la estufa se coloque

25

contra la pared), dibuje una línea en el suelo donde

estará el borde posterior de la estufa.

3. Instale soportes antivuelco (ver "Instalación del

soporte antivuelco").

2

Requisitos eléctricos

Peligro de descarga eléctrica –Este aparato precisa

conexiónatierra.Utilicesoloelcabledealimentación

suministradoconelelectrodoméstico.Unaconexión

o toma de tierra inadecuada puede provocar descargas

eléctricas, daños en el electrodoméstico, lesiones

personales, fuego o la muerte.

Requisitos de puesta a tierra

Este dispositivo deberá ser instalado y conectado a tierra

poruntécnicodeserviciocualicado.

En Estados Unidos, instale el producto de conformidad

con el National Fuel Gas Code ANSI Z223.1/NPFA No. 54,

última edición y el National Electrical Code NFPA No. 70

última edición y cumpla todos los códigos eléctricos locales.

En Canadá, este artefacto debe instalarse según CAN/

CGA B149.1 y CAN/CGA B149.2 y la norma CSA Standard

C22.1, Código Canadiense de Electricidad (Canadian

Electrical Code), Parte 1, y los códigos eléctricos locales.

Para su seguridad personal, este electrodoméstico debe

estardebidamentepuestoatierra.Paraunamáxima

seguridad, el cable de alimentación debe estar enchufado

a un tomacorriente del voltaje adecuado, que esté

correctamente polarizado y debidamente puesto a tierra

de acuerdo con los códigos locales. Es responsabilidad

personal del consumidor hacer que un electricista

calicadoinstaleuntomacorrienteadecuadoconun

receptáculo de pared debidamente puesto a tierra.

Este dispositivo está previsto para conectarse a un

tomacorriente estándar 14-50R.

Tomacorriente eléctrico

Se requiere para todas las

instalaciones

Tomacorriente de cuatro

cables (14-50R)

Si solo se dispone de corriente eléctrica CA de 4 cables

monofásica de 240 voltios y 60 Hz, este dispositivo

necesitará protección de circuitos con fusibles de un

mínimo de 40 amperios en ambos lados del cable.

Se recomienda un disyuntor o fusible de retardo.

Asegúrese de que el tomacorriente esté al alcance de la

ubicaciónnaldelaparato.

No pellizque el cable de alimentación eléctrica entre

la estufa y la pared.

Page 26

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

12”

(30,5 cm)

8”

(20,3 cm)

ADVERTENCIA

dentro de la zona sombreada

de la estufa

de la estufa

DUAL DE 30" Y 36"

Cable de la fuente de alimentación

3

Ubicaciones recomendadas para

la instalación de tomacorrientes

La ubicación sugerida para la tomacorriente se muestra

en la Figura 4 para modelos de 30" y en la Figura 5

para modelos de 36". La toma también puede estar en

la esquina inferior izquierda del armario adyacente a la

derecha, según se muestra en la Figura 6

Línea

central

de la estufa

10"

(25,4 cm)

PARED

7" Máx.

(17,8 cm Máx.)

Busque el conector eléctrico

en la zona sombreada

Figura 4: Ubicación de la toma en modelos de 30"

SUELO

Línea

central

Peligro de descarga eléctrica –No trate de instalar

el dispositivo directamente a una caja de empalme,

modicarelcableinstaladodefábricaniconectar

al aparato un cable de alimentación distinto. Si la

tomadecorrientenoessucienteparasoportarlos

requisitos de este electrodoméstico, es responsabilidad

del consumidor solicitar la instalación de una toma

adecuada por un electricista. Una instalación

oconexióneléctricainadecuadapuedeprovocar

descargas eléctricas, daños en el electrodoméstico,

lesiones personales, fuego o la muerte.

Este dispositivo está equipado con un cable de fuente

de alimentación de cuatro hilos conectado de fábrica

(Figura 7). Este cable tiene una capacidad nominal de

240 voltios, 40 amperios y una temperatura nominal de

194°F (90°C). Este cable está homologado por UL/CSA

y ha sido comprobado y autorizado para su uso con este

dispositivo.

Línea

central de

la estufa

14"

(35,6 cm)

(1 cm Máx.)2.7

5" Máx.

PARED

SUELO

Busque el conector eléctrico

Línea

central

Figura 5: Ubicación de la toma en modelos de 36"

Figura 7: Cable de alimentación eléctrica conectado

de fábrica

Potencia nominal del

electrodoméstico*

120/240

Voltios

120/208

Voltios

Potencia nominal de la

fuente de alimentación

Amperios

1-10 kW 0-7.6 kW 30

8,8-16,5 kW 7,8-12,5 kW 40 o 50

16,6-22,5 kW 12,6-18,5 kW 50

* La carga NEC calculada es inferior a la carga

conectada total indicada en la placa del número de serie.

Figura 6: Ubicación de la toma en el armario adyacente

26

Page 27

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

al dispositiv

s

Posición abierta

)

DUAL DE 30" Y 36"

Requisitos del suministro

4

de combustible

Esta unidad está diseñada para operar con columna

de agua de 4"(10,16 cm) con presión de colector de gas

natural de (1,0 kPa).

Un regulador de presión convertible se conecta al

colector de la estufa y DEBERÁ estar conectado en

serie con la línea de suministro de gas. El regulador está

ubicado según se muestra en la Figura 8 y es accesible

desde la parte inferior de la estufa.

del lado derecho es la ubicación ideal para la válvula

principal de cierre, si la estufa se instaló dentro del

espacio de almacenamiento del armario.

4.2

Válvula de cierre

La línea de suministro deberá estar equipada con una

válvula de cierre homologada según se muestra en

la Figura 10. Esta válvula deberá estar ubicada en la

misma habitación que la estufa y deberá estar en una

ubicación que facilite su apertura y cierre. No bloquee el

acceso a la válvula de cierre. La válvula sirve para abrir

o cerrar el gas que llega al aparato.

o

a la tubería de

suministro de ga

Paraunadecuadofuncionamiento,lapresiónmáxima

de entrada al regulador deberá ser no superior a 14"

(35,56 cm) de columna de presión de agua (3,5 kPa).

La presión de entrada del regulador deberá ser al menos

1" (0,25 kPa) mayor que el ajuste de presión del colector

regulador. El regulador está ajustado para columna de

agua de 4" (10,16 cm) de presión de colector de gas

natural (1,0 kPa); la presión de entrada deberá ser al

menos de columna de agua de 5" (12,60 cm) de gas

natural (1,25 kPa).

Para funcionar a 2000 pies sobre el nivel del mar, el ajuste

nominal del aparato se reduce en un 4 por ciento cada

1000 pies adicionales.

4.1

Los tubos de suministro de gas se encuentran en

la pared lateral del armario de la derecha. El armario

Figura 9: Ubicación recomendada del suministro de gas

Modelos de 30"

Figura 8: Ubicaciones del regulador

Modelos de 36"

Ubicación del suministro de gas

8”

(20,3 cm

12”

(30,5 cm)

Válvula de cierre

Figura 10: Válvula de cierre

El suministro de gas entre la válvula de cierre y el

regulador puede estar conectado mediante tubo rígido

omediantetuberíametálicaexibleconectadamediante

uniones con homologación A.G.A./C.G.A. cuando los

códigos locales permitan su uso.

El usuario deberá conocer la ubicación de la válvula

principal de cierre y tener fácil acceso a ella.

4.3

Conversión a gas de petróleo licuado

(L.P.) Gas.

Este electrodoméstico permite la conversión a petróleo

licuado (LP). Gas.

Si la conversión a gas licuado

no es realizada por un instalador o un electricista

calicadoexistenriesgosdelesionespersonalesola

muerte por choque eléctrico. Las adiciones, cambios

o conversiones necesarios para que esta estufa cumpla

satisfactoriamente con sus requisitos de funcionamiento

deben ser realizados por un técnico de servicio.

Si necesita realizar una conversión a gas LP, llame

a su distribuidor local de gas L.P. para obtener

asistencia. El kit de conversión a gas LP se incluye con

este electrodoméstico y se encuentra en el panel inferior

trasero (parte trasera) de la estufa. Antes de instalar el

kit, asegúrese de leer atentamente las instrucciones de

instalación de L.P. y seguirlas cuidadosamente al realizar

la instalación.

Para LP/gas propano, el regulador deberá estar ajustado

para columna de agua de 10" (25,4 cm) de presión de

colector (2,5 kPa); la presión de entrada deberá ser al

menos de columna de agua de 11" (27,9 cm) (2,75 kPa).

27

Page 28

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

ADVERTENCIA

ATENCIÓN

Válvula de

cierre

manual

Unión

abocinada

Unión

abocinada

FLUJO DEL

GAS

Regulador

de presión

Apagado

Racor

Racor

Conector

flexible

Acceso

Tapa

Encendido

ADVERTENCIA

DUAL DE 30" Y 36"

Conecte el suministro

5

de combustible

5.1

Conexión del suministro de combustible

Este dispositivo deberá ser instalado,

conectado a tierra y sujeto a tareas de servicio por un

instaladorotécnicodeserviciocualicado.

Noaprietedemasiadolasconexiones.

Elreguladoresdevaciado.Apretarexcesivamentepuede

crear grietas en el regulador, lo que puede suponer

pérdidadegasypotencialmentefuegooexplosión.

Este aparato incluye un regulador. La línea de suministro

de gas precisa las siguientes piezas que no se

suministran con el aparato:

• Válvula de cierre manual

• Racores de 1/2" (2)

• Adaptador de unión abocinada de 1/2" (2)

• Conectorexible

La línea de suministro de gas a la válvula de cierre deberá

ser de tubo sólido de 1/2" (1,27 cm) o 3/4" (1,9 cm).

Instale el tubo de suministro de gas al regulador de

presión en el orden indicado en la Figura 11. Todas las

conexionesdeberánapretarseconllaveinglesa.

5.2

Comprobar si hay pérdidas

No utilice llama para comprobar

sihaypérdidasenlasconexionesdegas.Comprobar

laexistenciadepérdidasconllamapuedeprovocar

fuegooexplosión.

Después de conectar la estufa al suministro de gas,

compruebe si hay pérdidas en el sistema con un

manómetro. Si no dispone de manómetro, abra el

suministro de gas y utilice un detector de pérdidas de

líquidos(oaguayjabón)entodaslasjuntasyconexiones

para comprobar si hay pérdidas. Las pérdidas se indicarán

mediantelaaparicióndeburbujasenlasconexiones

o juntas.

Deberán sellarse todas las aperturas en la pared o suelo

donde esté instalada la estufa.

1. Aprietetodaslasconexionessiesnecesariopara

evitar la pérdida de gas en la estufa o línea de

suministro.

2. Desconecte esta estufa y su válvula de cierre

individual del sistema de tuberías de suministro de

gas durante las pruebas de comprobación del sistema

a presiones de prueba superiores a 1/2 psig (columna

de agua de 3,5 kPa o 14" (35,56 cm)).

3. Aísle la estufa del sistema de tuberías de suministro

de gas cerrando la válvula manual de cierre individual

durante las pruebas del sistema de tuberías de suministro

de gas a presiones iguales o inferiores a 1/2 psig

(columna de agua de 3,5 kPa o 14" (35,56 cm)).

Alutilizarconductodegasexibleenlaestufa,déjelo

losucientementeojocomoparasacarlaestufafuera

del recorte para tareas de limpieza o servicio.

Utilice un compuesto para juntas de tubería para uso

con gas natural y LP/propano para sellar todas las

conexionesdegas.Siseutilizanconectoresexibles,

asegúrese de que los conectores no dañados.

Nopermitaqueelconductoexiblequedepinzadoentre

la pared y la estufa.

Figura 11: Flujo de conexión del suministro

de combustible

28

Page 29

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

DUAL DE 30" Y 36"

Instale las rejillas de horno

6

6.1

Modelos de 30" - Soportes de rejilla

en escalera

Para ayudar en la instalación de los soportes de rejillas

de horno de porcelana, aplique una ligera capa de aceite

decocinaratodoslosextremosdelossoportessegúnse

muestra en la Figura 12.

Figura 14: Soportes de rejilla de escalera - extremos

inferiores

6.2

Modelos de 30" - Rejillas deslizantes

Las rejillas deslizantes se instalan como otras rejillas

del horno.

El tope de la rejilla deslizante (Figura 15) deberá estar

dentro del soporte de escalera para que la rejilla se deslice

Figura 12: Soportes de rejilla de escalera - áreas con

aceite

adecuadamente.

1. Mantenga el soporte de rejillas de horno con un

pequeñoánguloeinsertelosextremosenlosoricios

de la parte superior de la cavidad del horno (Figura 13).

2. Introduzcalarejillaenlosoriciossuperiores,

alineandolosextremosinferioresconlosoricios

de la parte de abajo (Figura 13).

Figura 13: Soportes de rejilla de escalera - extremos

superiores

3. Unavezcolocadoslosextremossuperiores,

mantenga el soporte de rejillas al nivel del lateral del

hornoeinsertelosextremosinferioresenlosoricios

de la parte de abajo (Figura 14).

4. Deslicelosextremosinferioresenlosoriciosdela

parte de abajo. Es posible que precise hacer algo

de fuerza para ajustar la rejilla en su sitio (Figura 14).

Figura 15: Tope de rejilla deslizante

Coloque la rejilla en los soportes de las rejillas. Incline

la parte posterior de la rejilla ligeramente hacia arriba

para que el tope quede colocado en el interior de la rejilla

de escalera. Vuelva a colocar la rejilla del horno en su

posición

Asegúrese de deslizar por completo la rejilla de modo que

la parte posterior se detenga al encontrarse con el soporte

vertical de la rejilla de escalera.

Para evitar posibles daños en el horno, no intente cerrar

la puerta del horno hasta que todas las rejillas están

completamente posicionadas dentro de la cavidad del horno.

29

Page 30

INSTRUCCIONES DE INSTALACIÓN DE ESTUFA DE COMBUSTIBLE

DUAL DE 30" Y 36"