Electrolux Diva, Diva EDW 1500 Service Manual

SERVICE MANUAL

DISHWASHER

EDW 1500

+

© Electrolux

Muggenhofer Straße 135

D-90429 Nürnberg

Germany

Fax +49 (0)911 323 1022

Spares Operation

Ausgabe:

09.02

R.Kurzke

Publ.-Nr.:

599 515 015

EN

Dishwasher

+

EDW 1500

Index

1. Control panel ................................................................................... 3

2. Dimensions...................................................................................... 3

3. Components .................................................................................... 4

3.1 Electronic.........................................................................................4

3.2. Circulation pump .............................................................................4

3.3 Drain pump......................................................................................4

3.4 Flow heater...................................................................................... 4

3.5 Detergent dispenser ........................................................................ 5

3.6 NTC-thermal sensor ........................................................................ 6

3.7 Pressure switch ............................................................................... 6

3.8 Interference filter .............................................................................6

3.9 Spray arms ......................................................................................7

3.10 Drying fan ........................................................................................ 7

3.11 Regeneration dosing with condensor ............................................. 8

3.11.1 Water softening/regeneration .........................................................8

4. Repair informations ......................................................................... 9

4.1 Open the housing ............................................................................ 9

4.2 Position of the components ............................................................ 10 - 12

5. Water course Scheme .................................................................... 13

5.1 All-Around Water Protection ...........................................................14

5.2 Water intake .................................................................................... 15

5.2.1 Water load steps .............................................................................16 - 17

5.3 Draining ...........................................................................................18 - 19

6. Electronic......................................................................................... 20

6.1 In- and Output Elements .................................................................20

6.2 General information ........................................................................ 21

6.3 Input-philosophy: Program selection .............................................. 22

6.4 Input-philosophy: Select start time..................................................23

6.5 Input-philosophy: Program run........................................................ 24

6.6 Input-philosophy: Delete program...................................................25

6.7.1 Input-philosophy: Alter program ...................................................... 26

6.7.2 Input-philosophy: Alter program ...................................................... 27

6.8 Input-philosophy: Interrupt program................................................28

6.9 Input-philosophy: Displays ..............................................................29

6.10 Overview of service and customer support functions..................... 30

6.11 Setting of water hardness ............................................................... 31

6.12 Deactivation of rinse-aid addition....................................................32

6.13 Deactivation of signal sound ........................................................... 33

7.Service functions.............................................................................34

7.1 Fault memory / single actuator selection ........................................34

7.2 LED test ........................................................................................... 35

7.3 Manufacturing test routine ..............................................................36

7.4 Overview of error displays...............................................................37

8. Program steps ................................................................................. 38

9. Wirings ............................................................................................ 39

9.1 Circuit diagram ................................................................................ 39

9.2 Wiring diagramn .............................................................................. 40

09.2002 R.K. 599 515 015 EN

- 2 -

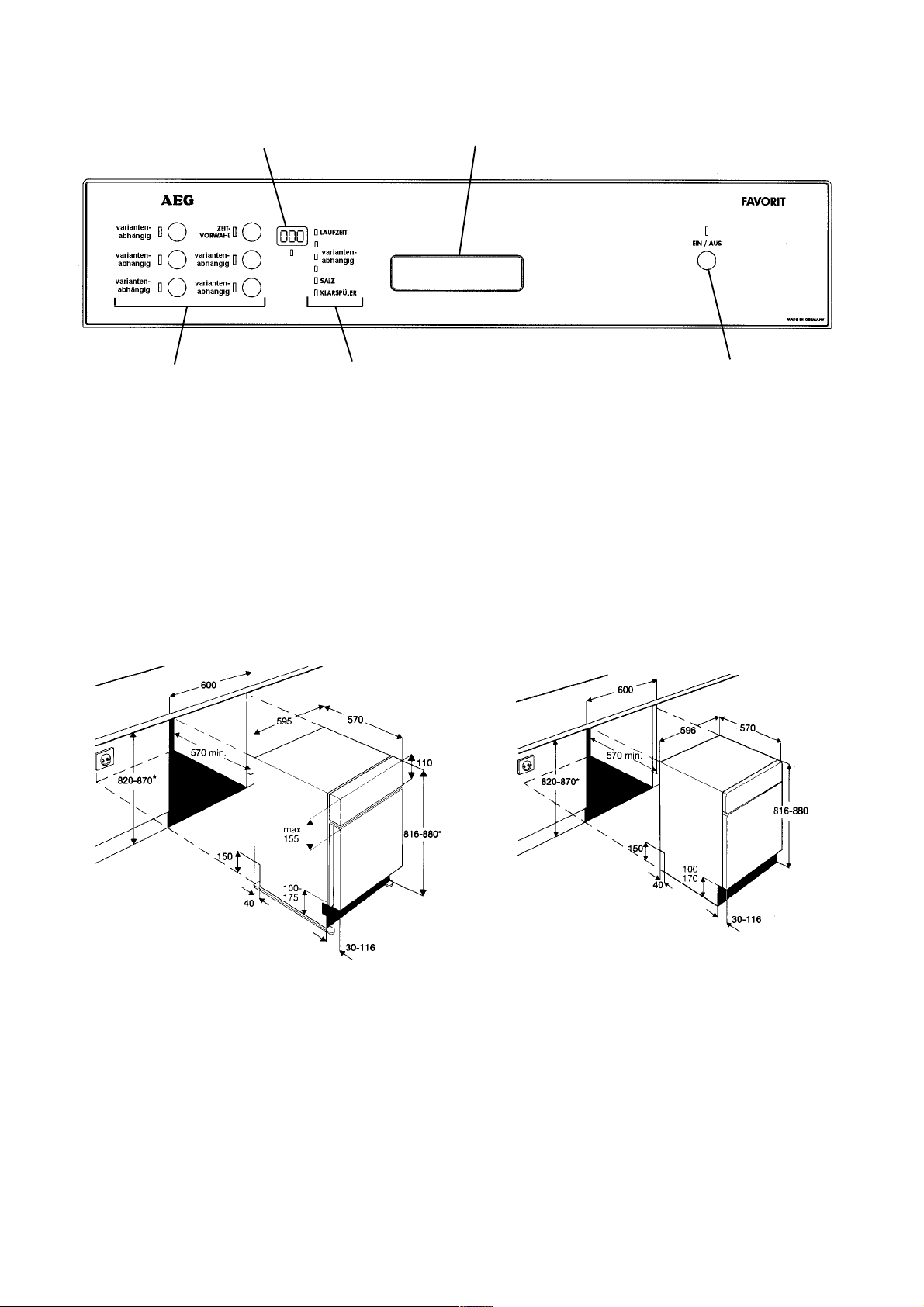

1. Control panel

Display

Control lamps

2. Dimensions

Build-in dimensions for Integrated

Dishwashers

Door handle

On/Off buttonProgamme buttons

Build-in dimensions for Built-Under

Dishwashers

ÖKO-FAVORIT

* Appliances with height-adjustable feet

Plinth height for appliances 820 mm high

100 - 175 mm

Plinth height for appliances 870 mm high

150 - 230 mm

ÖKO-FAVORIT

* Appliances with

height

adjustable feet

Dimensions for Freestanding Dishwasher

Height 85 cm

Width 60 cm

Depth 60 cm

Height with worktop removed 82 cm

Feet adjustment 1 cm

09.2002 R.K. 599 515 015 EN

- 3 -

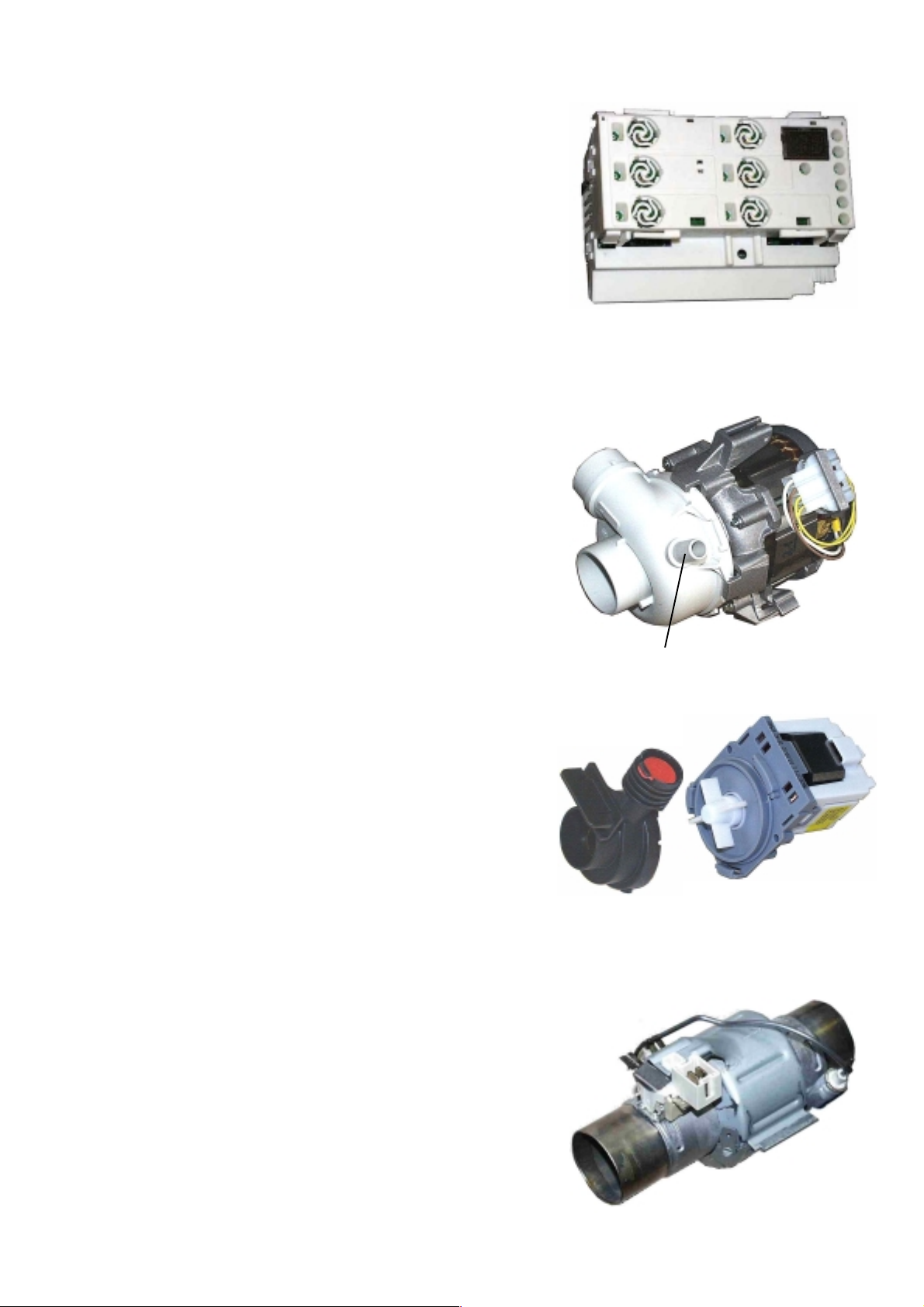

3. Components

3.1 Electronic

On electronic models, a micro processor controls all

components, this is done using triacs. The electronic also

memorizes all programme data.

The heating is switched by a relay on the electronic board.

3.2 Circulation Pump

The circulation pump is driven by an asynchronous motor with

an auxiliary winding. The auxiliary winding ist in circuit with a 3

mF capacitor. A tacho generator is used for speed control.

There are three speeds for rinsing.

2800 1/min, 2200 1/min, 1900 1/min, 1700 1/min, 1600 1/min,

Power output50 W.

Only for models with ceiling Sprayarm

3.3 Drain Pump

The drain pump is driven by a synchronous motor.

Power output 26 W.

Pump rate 15 l/min.

3.4 Flow Heater

The flow heater heats the water to the required temperature.

During the wash cycle, water is contantly passing through the

flow heater.

Power output 2000 W

Resistor 25 W

Protector 98 °C ± 5 K

Thermal fuse 260 °C

05.2002 R.K. 599 514 DE

- 4 -

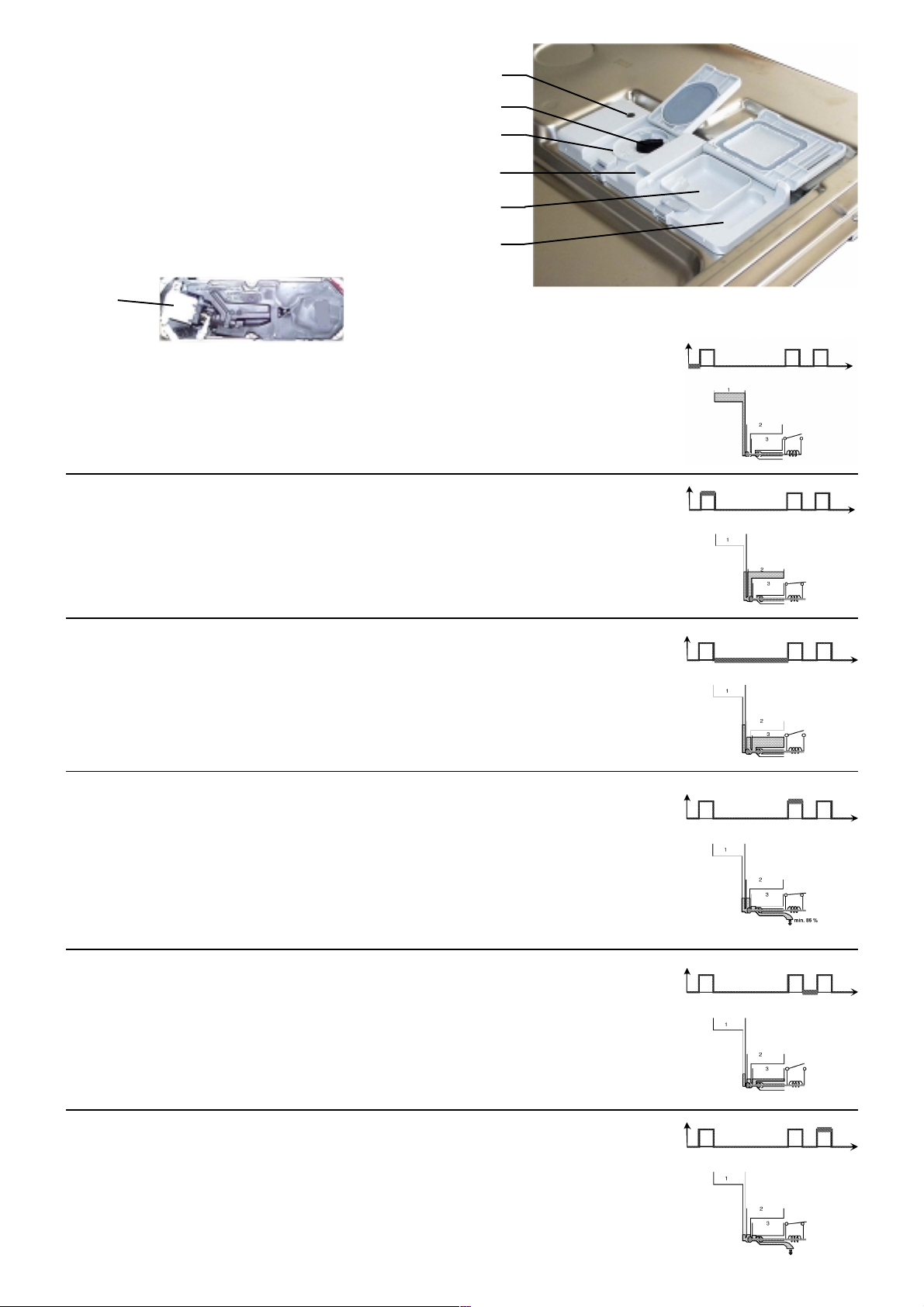

3.5 Detergent dispenser

display lack of rinse aid

Dosing of detergent

prewash 10 ml

wash 20 - 30 ml

Dosing of rinse aid

position 1 - 6 2 ml - 7 ml

Capacity

140 ml

coil

The detergent compartment 1 is filling corresponding to the set dosing

quantity when the door is open. Possibly existing rinse-aid in compartments

2 and 3 flows back into the storage tank of the rinse-aid. The detergent

trays are filled up. The door will be closed and the detergent for prewash

will be rinsed out through the slots in the detergent dispenser cover.

During the washing cycle the coil is switched on and the detergent

compartment cover releases the detergent. The rinse-aid flows from

compartment 1 into compartment 2.

dosing of rinse-aid

maximum filling level

outlet of rinse-aid

detergent tray

detergent tray for pre wash

Spule

EIN

AUS

EIN

AUS

Zeit

Zeit

After switching off the coil, the rinse-aid flows from compartment 2 into

compartment 3.

During the rinse cycle, the coil will be switched on when the rinse is warmed

and the rinse-aid runs from compartment 3 into the rinse tank. At the same

time, the remaining rinse-aid (15 %) runs from compartment 1 into

compartment 2.

With the coil switched off, the rinse-aid flows from compartment 2 into

compartment 3.

EIN

AUS

Zeit

EIN

AUS

Zeit

EIN

AUS

Zeit

EIN

During the rinse cycle, the coil is always switched on twice. When it is

AUS

Zeit

switched on the second time, the remaining rinse-aid flows into the rinse

tank.

05.2002 R.K. 599 514 DE

- 5 -

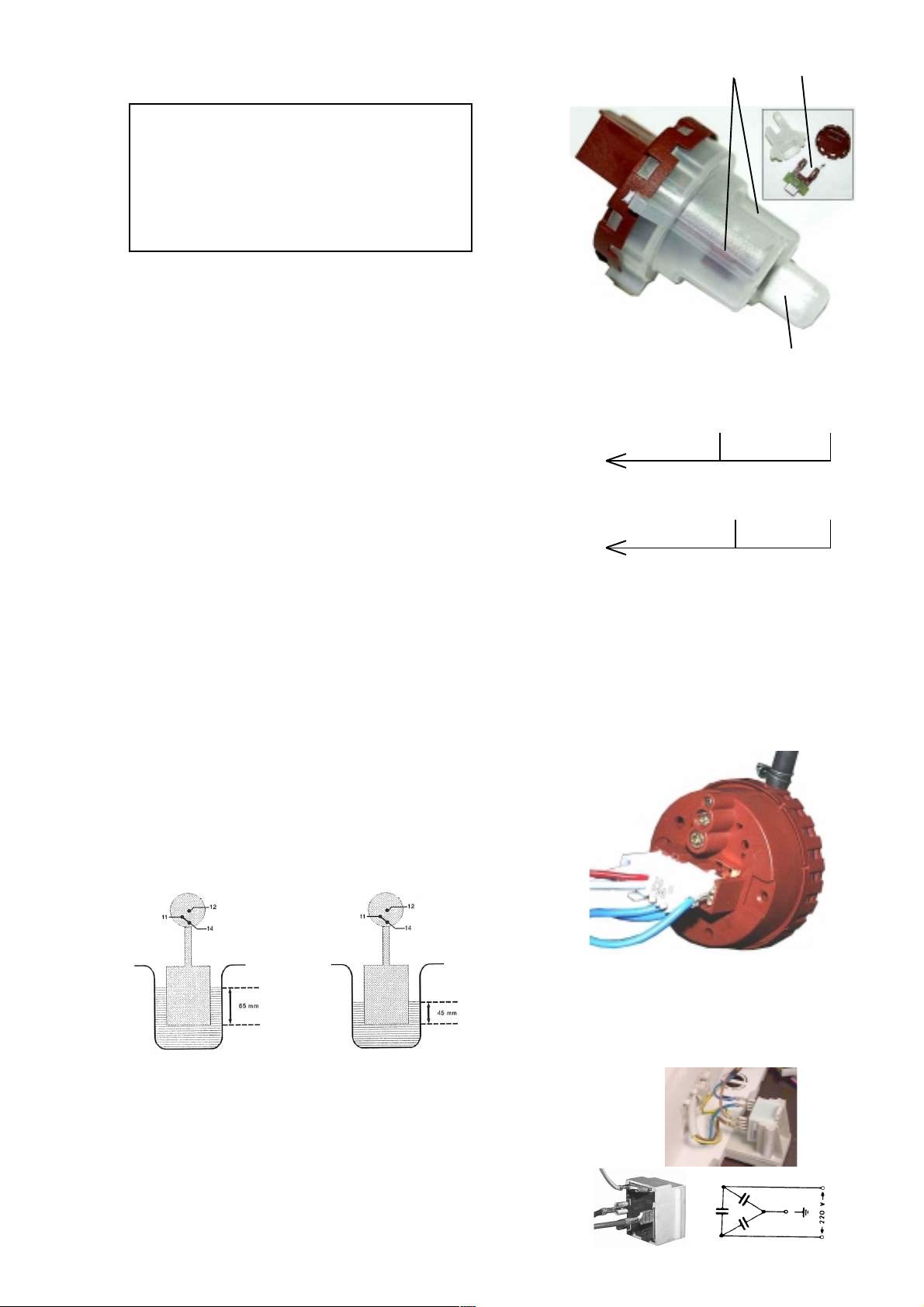

3.6 NTC-Temperature sensor with

integrated turbidity sensor

Turbidity sensor

NTC

Temp. Widerstand

10°C 9653 Ohm

25°C 4843 Ohm

60°C 1204 Ohm

90°C 445 Ohm

The turbidity sensor function is only activated in cycles AUTO

Function:

The input voltage with the turbidity sensor may be between 6 V

and 11.4 V. (The measurements are described in detail in the

chapter Measuring Points at the Electronic Control (in the base)).

For a clear water the output voltage must always be 4.3 V. If that

value differs due to soiling of the turbidity sensor after a longer

operational period, the Easytronic plus recontrols the input voltage

with the turbidity sensor automatically until the output voltage is

4.3 V. This happens during the final rinse cycle.

If the 4.3 V is not achieved within 8 seconds, the fault C5 is

stored in the fault memory. If the output voltage falls below 3 V in

the prewash cycle and below 3.8 V in the intermediate rinsing

cycle, turbid water will be detected. With the service test routine

the turbidity sensor will be calibrated to 3.5 V not with water but

with air.

That corresponds to 4.3 V with water.

NTC

output voltage prewash

turbit water clear water

output voltage intermediate

turbit water clear water

3,8V

4,3V3V

4,3V

3.7 Pressure Switch

The pressure switch controls the water level.

Without water, contact 11 - 12 is closed.

fN Switch point with level 65 mm Ws

Reset point with level 45 mm Ws

The pressure switch is not adjustable.

3.8 Interference Filter

The interference filter is connected in the terminal board parallel to the mains feed.

05.2002 R.K. 599 514 DE

- 6 -

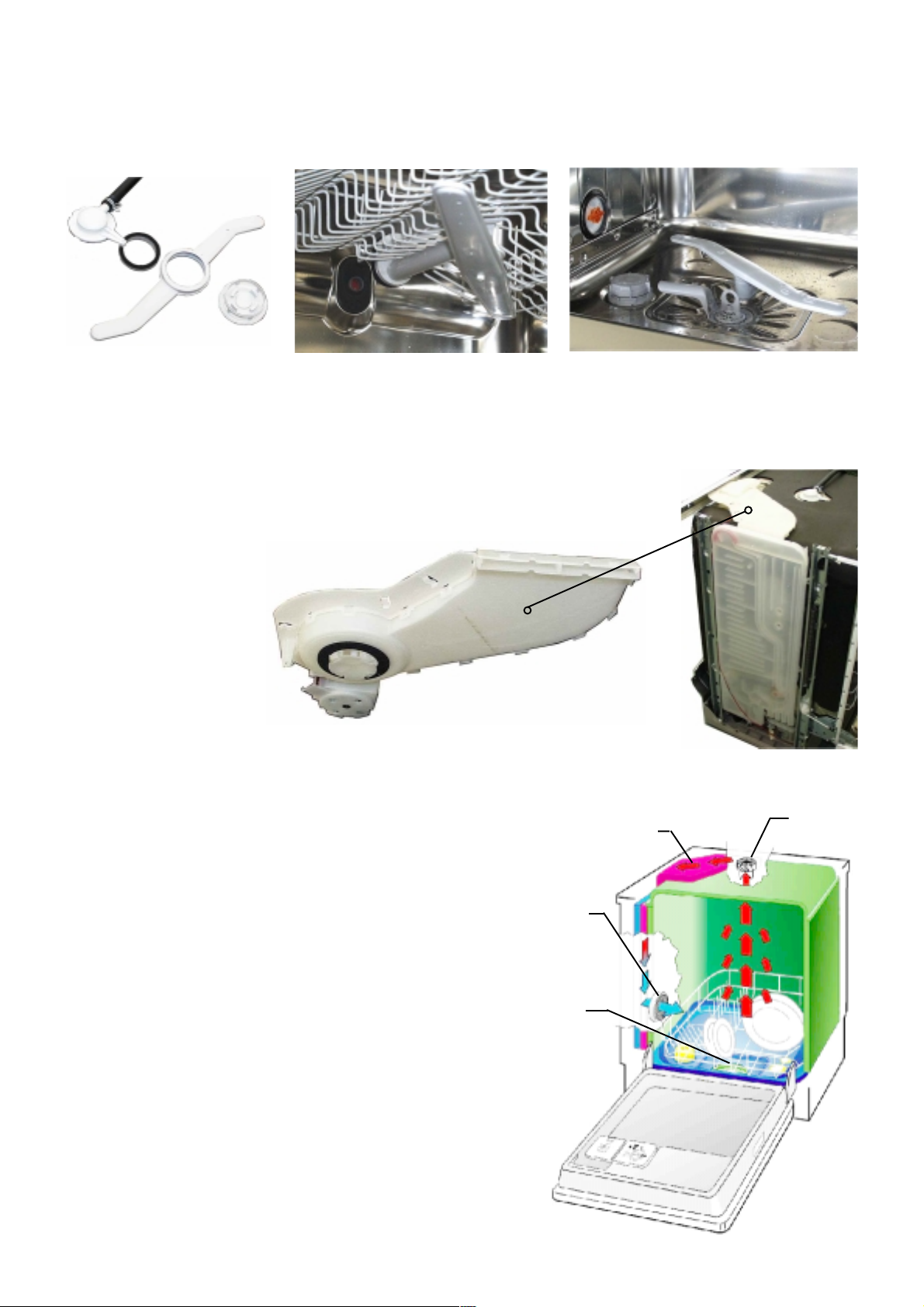

3.9 Spray arms

The new cutlery basket is placed at the upper diswasher basket. The celling sprayarm sprays the water

directly onto the cutlery basket and tguarantees an excellent washing result with the cutlery placed in

that basket.

Celling spray arm

upper spray arm lower spray arm

3.10 Drying fan

The new drying fan is located at the top on the rinse tank.

Function mode of the condensing drying

Rinse tank, fan and regenerating dosing with

condenser form a closed circuit. The humid air is

sucked from the top of the rinse tank and blown

through an air guide between rinse tank and

regenerating dosing. Thereby the air gets dry and

the condensate is guided to the drain tub.

The dry air gets through the rinse tank ventilation

into the rinse tank. During the drying phase, the

condenser is additionally cooled with 1 liter of

water.

rinse tank

ventilation

drain tub

air guide for

condenser

fan

05.2002 R.K. 599 514 DE

- 7 -

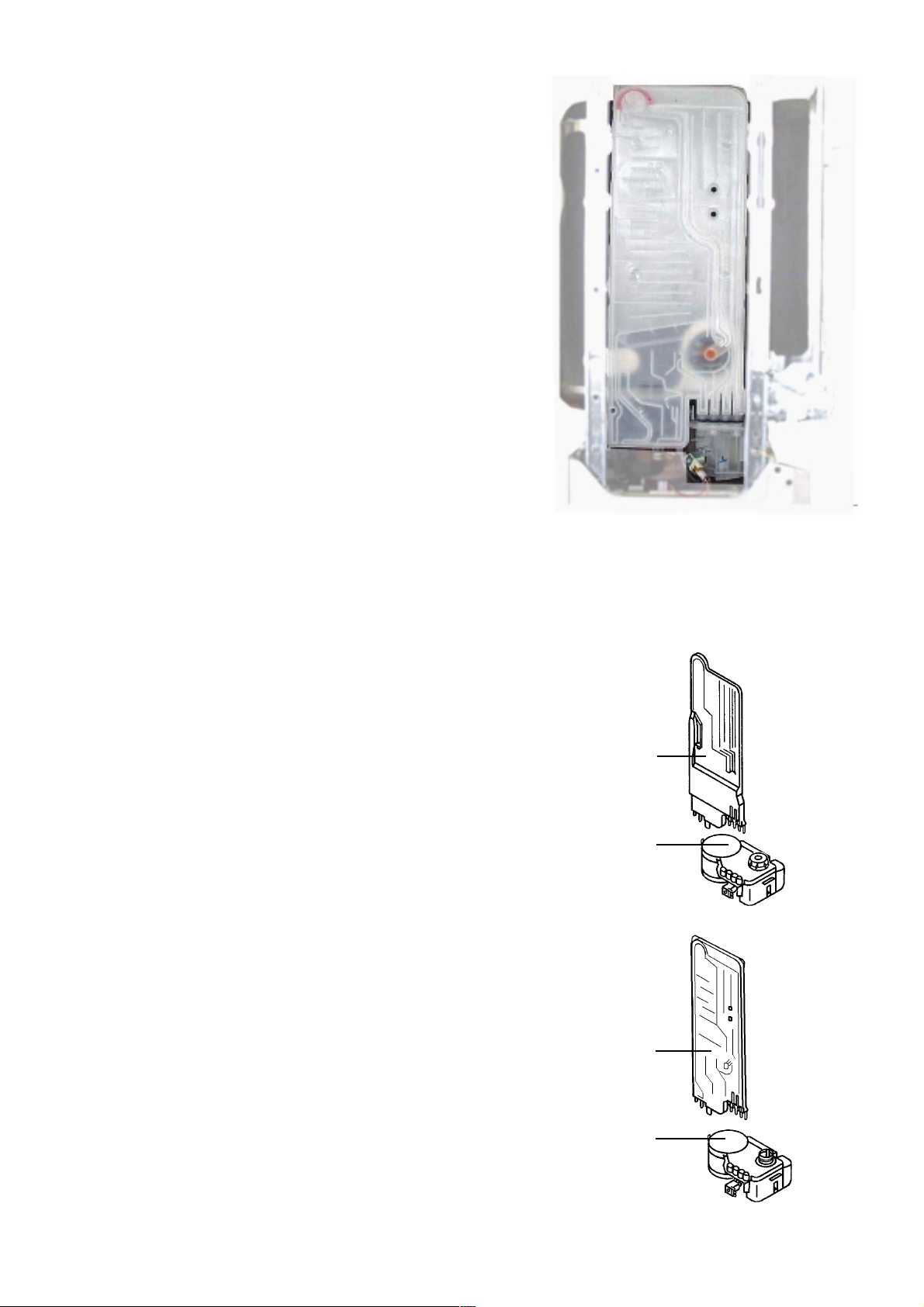

3.11 Regenerating dosing

with condenser

With every filling step, the condenser

cools down due to the cold incoming

water. Therefore another 1 liter of water

is required during the drying cycle.

1. softener unit

3.11.1 Water softening/regeneration

The water softening can be adjusted in 10 levels. The incoming

water flows until positon 5 to 85 % through the softener which

works according to the ion exchange principle. The ion exchanger

is filled with small epoxy resin balls. The resins exchange the

hardness constituents (calcium and magnesium), for sodium

ions.

When all the sodium ions are used up, it is necessary to

regenerate the softener. This is done by flushing a brine solution

through the softener.

Afterwards the softener is washed out with fresh water and is now

fully effective.

Depending on the water hardness, regeneration is only necessary

after several wash cycles.

The remaining 15 % of water flow through the rinse tank ventilation

directly into the appliance.

2. regeneration dosage

chamber

2

1

From setting of level 6, the whole water flows through the

softener. For this purpose you also have to set mechanically from

0 to 1 with the regenerating dosing.

With the setting of level 9, it is additionally regenerated after the

washing in a rinse cycle. With the settings 1 to 8, it is regenerated

after the final rinse depending on need. The softening system is

designed for a water hardness of up to 70 °dH.

05.2002 R.K. 599 514 DE

- 8 -

2

1

4. Service tips

4.1 Open the housing

Remove the screws (Abb.1) of the

upper plate on the left and right side.

Push the upper plate in front direction

to remove the plate (Abb.2).

To remove side panel remove fixing screws, pull

the panel away from the rear, and gently out of

the front trim. (pic.1).

1

1

You need

Torx epuipment

Remove the screws (1) to pull the

outer door away.

2

Removing the

cover plates of the

base area, remove

these screwst

(Abb1+2).

To remove the panel, remove the

fixing screws (2) .

2

1

2

3

05.2002 R.K. 599 514 DE

- 9 -

4.2 Position of Components

Detergent dispenser (1)

Spray arms (2)

Roof-mounted shower (3)

Salt container (4)

Filter (5)

3

5

4

2

Type plate (6)

On/Off-Switch (1)

Electronic (2)

Electronic

Panel (1)

Detergent dispenser (2)

1

6

1

2

1

2

Thermal sensor (3)

Drain pump (4)

Pressure switch (5)

3

05.2002 R.K. 599 514 DE

- 10 -

4

5

Back side view

- Flow heater (1)

- Terminal box (2)

- Inlet hose (3)

- Drain hose (4)

5

- Water inlet for above spray arm (5)

Removing the detergent dosage chamber:

- disengage locking tabs (1), disconnect hoses (2)

- holding the top of the chamber, pull upwards

disengaging it from the softener.

1

4

2

3

1

Removing the softener unit :

- remove the securing nut located under the salt cap.

- press softener (1) down and remove it through the front

from the base area

- CAUTION if accessible release reed switch.

2

1

05.2002 R.K. 599 514 DE

- 11 -

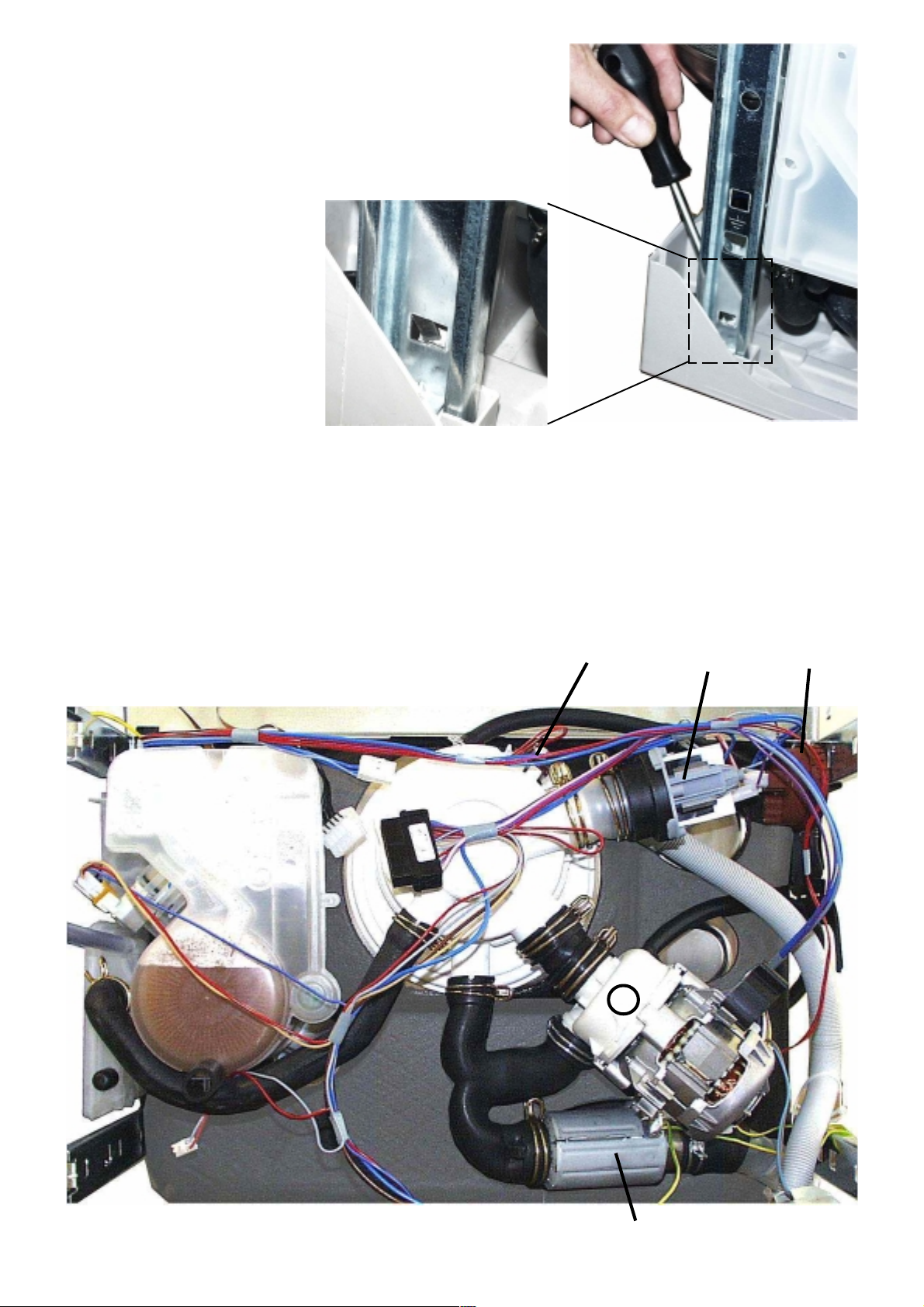

Removing the base :

- remove side panels, rear panel and plinth panel

- gently release base fixing clips with a screwdriver (figure)

- take off base carefully and release circulation pump,

electronic and heater relay

- disconnect the float switch

With base removed, following components are accessible:

- Drain pump (1)

- Circulation pump (2)

- Flow heater (3)

- Temperature sensor / Turbidity sensor (4)

- Pressure switch (5)

4

1

5

2

3

05.2002 R.K. 599 514 DE

- 12 -

Loading...

Loading...