Page 1

ELECTROLUX ZANUSSI S.p.A.

Spares Operations Italy

Corso Lino Zanussi,30

I - 33080 PORCIA /PN (ITALY)

Fax +39 0434 394096

Edition: 2007.03

Publication

number

599 38 72-30

EN

SERVICE MANUAL

DISHWASHERS

DISHWASHER

DIVA

F. S. -

B. I. F. I. -

Free-standing

Partially integrated

Fully integrated

Basic characteristics

Production: ZM Solaro_ITALY

SOI/TD - PR 1/32 599 38 72-30

Page 2

SOI/TD - PR 2/32 599 38 72-30

Page 3

TABLE OF CONTENTS

1 INTRODUCTION ........................................................................................................................................................4

1.1 PURPOSE OF THIS SERVICE MANUAL ............................................................................................................4

1.2 PRESENTATION..................................................................................................................................................5

1.3 GENERAL CHARACTERISTICS..........................................................................................................................6

1.4 FIELD OF APPLICATION.....................................................................................................................................6

1.5 ELECTRONIC MODULE ......................................................................................................................................6

1.6 DEFINITION OF STYLINGS AND FUNCTIONS ..................................................................................................7

1.7 STRUCTURAL CHARACTERISTICS.................................................................................................................11

2 STRUCTURAL CHARACTERISTICS.......................................................................................................................12

2.1 BASE ..................................................................................................................................................................12

2.2 DOOR.................................................................................................................................................................12

2.3 TUB ....................................................................................................................................................................14

2.4 HYDRAULIC SYSTEM .......................................................................................................................................15

3 HYDRAULIC AND FUNCTIONAL CHARACTERISTICS ..........................................................................................16

3.1 WATER FILL TANK ............................................................................................................................................17

3.2 WATER SOFTENING SYSTEM .........................................................................................................................17

3.3 SUMP ASSEMBLY .............................................................................................................................................18

3.4 DRYING DUCT...................................................................................................................................................18

4 ELECTRICAL COMPONENTS .................................................................................................................................19

4.1 TERMINAL BLOCK ............................................................................................................................................19

4.2 PUSHBUTTON ...................................................................................................................................................19

4.3 TIMER ................................................................................................................................................................19

4.4 LATCH ASSEMBLY............................................................................................................................................19

4.5 WASHING PUMP ...............................................................................................................................................20

4.6 CAPACITOR.......................................................................................................................................................20

4.7 DRAIN PUMP .....................................................................................................................................................20

4.8 FILL SOLENOID VALVE ....................................................................................................................................20

4.9 TUBE-ENCASED HEATING ELEMENT.............................................................................................................21

4.10 TEMPERATURE THERMOSTAT ......................................................................................................................21

4.11 TEMPERATURE SENSOR.................................................................................................................................21

4.12 TEMPERATURE SENSOR + TURBIDITY SENSOR..........................................................................................21

4.13 INTEGRATED DISPENSER...............................................................................................................................22

4.14 LEVEL & ANTI-OVERFLOW PRESSURE SWITCH...........................................................................................22

4.15 ANTI-FLOODING DEVICE .................................................................................................................................22

5 WASHING SYSTEM.................................................................................................................................................23

5.1 DEFINITION OF THE WASHING CYCLE ..........................................................................................................23

6 HYDRAULIC CIRCUIT..............................................................................................................................................24

6.1 PATH OF WATER INTAKE - "SHORT TANK"....................................................................................................24

6.2 PATH OF WATER INTAKE - "LONG TANK" ......................................................................................................25

6.3 WATER FILL SYSTEM - FUNCTIONAL DESCRIPTION ...................................................................................26

6.4 ANTI-OVERFLOW SAFETY LEVEL...................................................................................................................26

6.5 WATER SOFTENING SYSTEM .........................................................................................................................27

6.6 DEFINITION OF THE REGENERATION SYSTEM ............................................................................................29

7 DEFINITION OF THE DRYING CIRCUIT .................................................................................................................30

7.1 "NORMAL - DRY" DRYING ................................................................................................................................30

7.2 "ACTIVE - DRY" DRYING...................................................................................................................................31

7.3 "TURBO - DRY" DRYING SYSTEM ...................................................................................................................32

SOI/TD - PR 3/32 599 38 72-30

Page 4

1 INTRODUCTION

1.1 PURPOSE OF THIS SERVICE MANUAL

The purpose of this Service Manual is to provide Service Engineers, who already have the basic

knowledge necessary to repair household dishwashers, with information of a general nature regarding

the new "DIVA" range of dishwashers.

The aspects described in this document relative to the structural and hydraulic characteristics and the

basic circuits are common to all the appliances in the range, both with electromechanical and electronic

control systems.

More detailed information regarding individual models may be found in the specific information

documents for each specific functionality.

This information covers:

Technical characteristics

Circuit diagrams

Exploded diagrams and Lists of spare parts

may be found in the Service Notes and Service Manuals issued separately for each specific model

SOI/TD - PR 4/32 599 38 72-30

Page 5

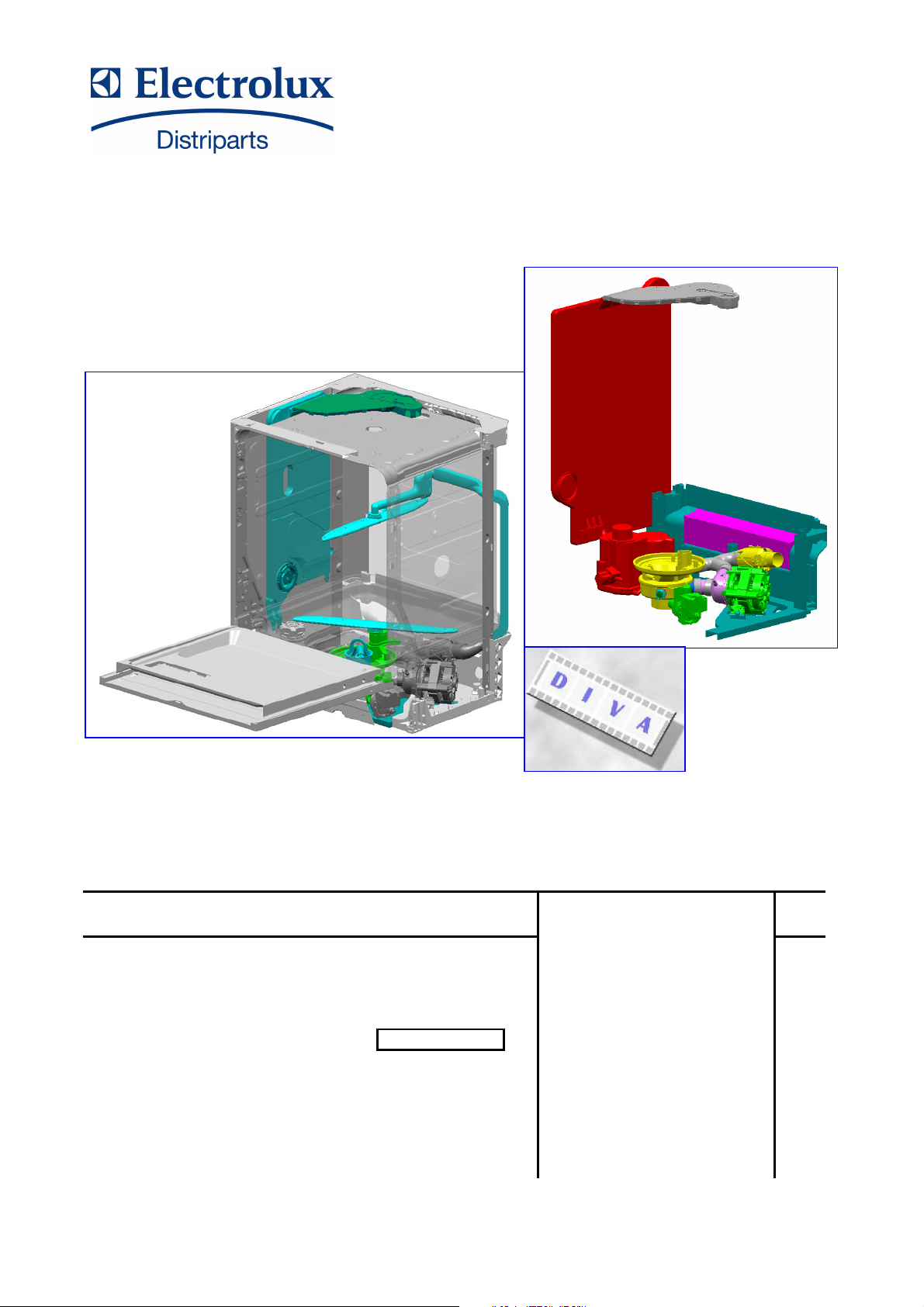

1.2 PRESENTATION

NEW TECHNOLOGY: DISHWASHERS CREATED WITH COMPUTER-AIDED DESIGN SYSTEMS

AND BUILT USING MODERN INDUSTRIAL TECHNOLOGY.

RESULT:

Drawing on our vast experience and resources, combined with the latest technical and structural

techniques, we have produced this range of innovative appliances to meet the demands of a market

that is constantly evolving.

1.2.1 MAIN CHARACTERISTICS

1.2.1.1 STRUCTURAL CHARACTERISTICS:

- Modular and convertible, in three versions: Free-standing, Partially built-in, Fully built-in

- Monobloc load-bearing base in sound-absorbing plastic material.

- Two removable side panels.

- Styling variable to meet the various configurations requested.

- Simplification of free-standing and built-in installation.

- On built-in models, the rear foot can be adjusted from the front of the appliance.

1.2.1.2 HYDRAULIC CHARACTERISTICS:

- Newly-designed integrated hydraulic circuit.

- New integrated sump.

- New water softening system (if featured).

- Softening of regeneration water up to 90°F - 50°D (if featured).

- Optimization of the regeneration system with 5 to 10 levels of regeneration (if featured).

- Manual regulation of the regeneration level, if featured, on electromechanical models, software

regulation for electronic models.

1.2.1.3 ELECTRICAL CHARACTERISTICS:

- New washing pump motor.

- New drain pump motor.

- New types of timer.

- New types of electronic boards (PCB).

1.2.1.4 CONTROL AND SAFETY SYSTEMS:

- Measurement of water temperature by means of thermostats or temperature sensors for electronic

models.

- Measurement of water fill level by means of a pressure switch.

- Anti-overflow safety system using a pressure switch.

- Anti-leakage safety system using an anti-flooding device.

- Protection against overheating using a safety thermostat (software for electronic models).

- Electrical door aperture safety system.

- Functional protection with constant monitoring (with software control for electronic models).

1.2.1.5 SOUND-PROOFING:

- Improved silence thanks to the use of new materials and new construction technologies.

1.2.1.6 SERVICE:

- Easier access to components thanks to careful positioning, from the two removable side panels

and from the frontal plinth.

Electronic models:

- Facilitation of repairs using diagnostics tests and trouble-shooting procedures.

- The washing parameters can be modified to improve washing performance.

SOI/TD - PR 5/32 599 38 72-30

Page 6

1.3 GENERAL CHARACTERISTICS

Power supply ⇒ 230 V / 50 Hz (limits 187−254 V)

Total power absorption ⇒ 2300 W (with 2100 W heating element)

Water supply ⇒ Min. / Max. Pressures: 5 − 80 N/cm2

Load capacity ⇒ 9 place settings for 45cm and 12 place settings for 60cm

Noise level ⇒ db 50 / 56 (A) sound pressure (electromechanical)

⇒ db 46 / 50 (A) sound pressure (electronic)

Class ⇒ [AAA] - [AAB] (electronic models)

* Declared consumption [BIO AAB programmes]

- Water - Energy - Duration of cycle ⇒ 14Lt. - 1,10 KWh - 150 Min

* Example of programme declared to the various consumer institutes (electronic models).

1.4 FIELD OF APPLICATION

Washing system ⇒ CONTINUOUS (electromechanical)

⇒ CONTINUOUS /IMPULSE OPERATION (electronic)

Control system ⇒ TIMER (electromechanical)

⇒ CONTROL BOARD (electronic)

Water fill level ⇒ PRESSURE SWITCH CONTROL (electromechanical)

⇒ PRESSURE SWITCH+SOFTWARE CONTROL (electronic)

Water heating ⇒ HEATING ELEMENT IN PROTECTIVE TUBE

Temperature control ⇒ THERMOSTATS (electromechanical)

⇒ NTC TEMPERATURE SENSOR (electronic)

Drying system ⇒ NORMAL DRY (electromechanical)

⇒ ACTIVE DRY (electronic)

⇒ TURBO DRY (electronic)

Safety systems ⇒ HYDRAULIC/ELECTRICAL SYSTEMS (electromechanical)

⇒ TOTAL PROTECTION: HYDRAULIC/ELECTRICAL +

SOFTWARE (electronic)

Alarms ⇒ SOFTWARE SYSTEM WITH VISUAL DISPLAY (electronic)

1.5 ELECTRONIC MODULE

Power board ⇒ MAIN OPERATIONAL CONTROL (built-in microprocessor)

Comandi / Visualizzazione ⇒ USER-MACHINE INTERFACE

SOI/TD - PR 6/32 599 38 72-30

Page 7

1.6 DEFINITION OF STYLINGS AND FUNCTIONS

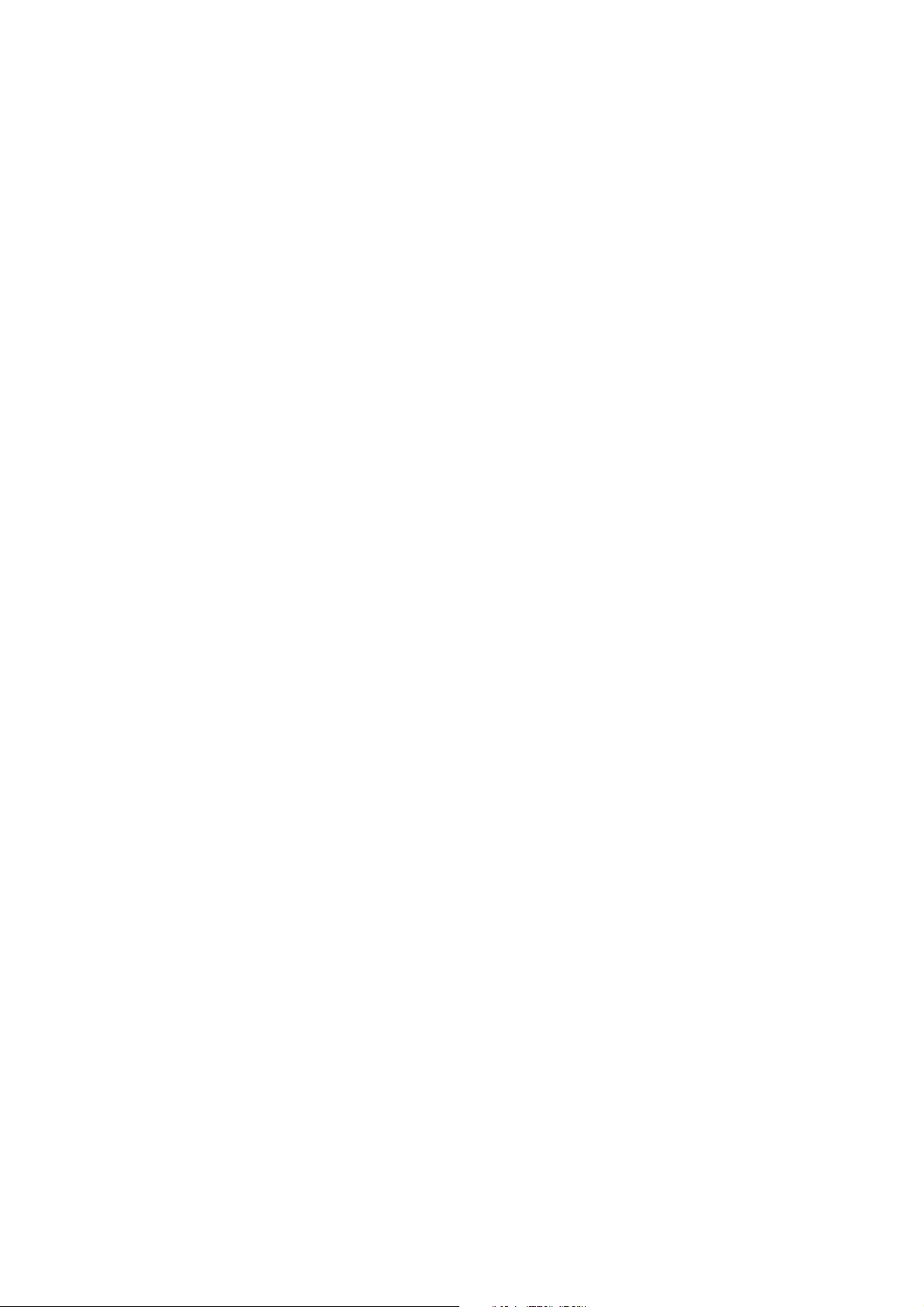

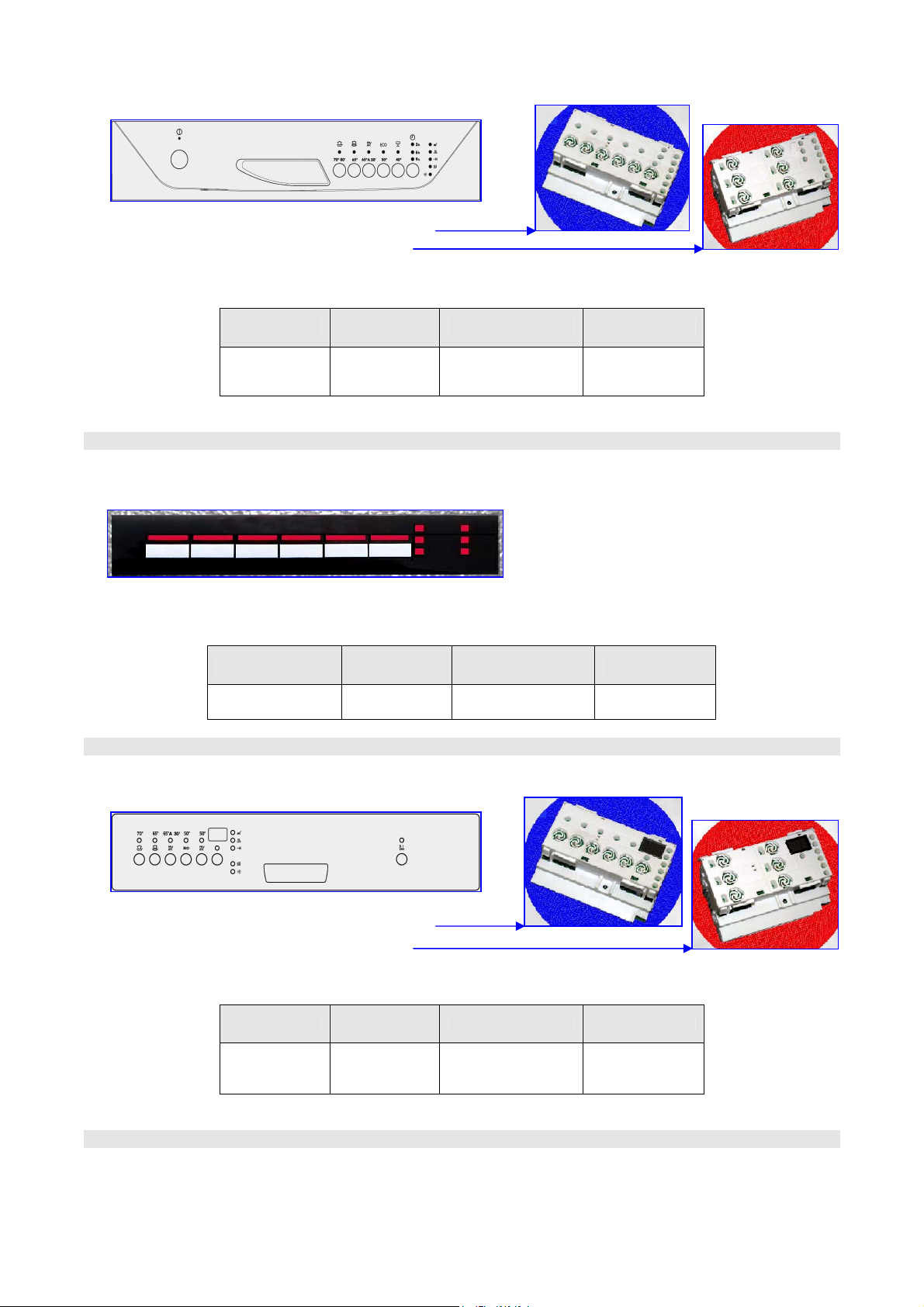

1.6.1 Control panel: - DIVA_ ELM

Option key Salt level indicator Programme selector knob

On/Off key

••••

DEFINITION OF FUNCTIONS

DIVA_ ELM [electromechanical]

DIVA_ ELMDIVA_ ELM

Structure Function Type of control Programmes

FreeStanding /

Built- in

Electromechanical

On/Off key

1

>

3_keys

+ knob

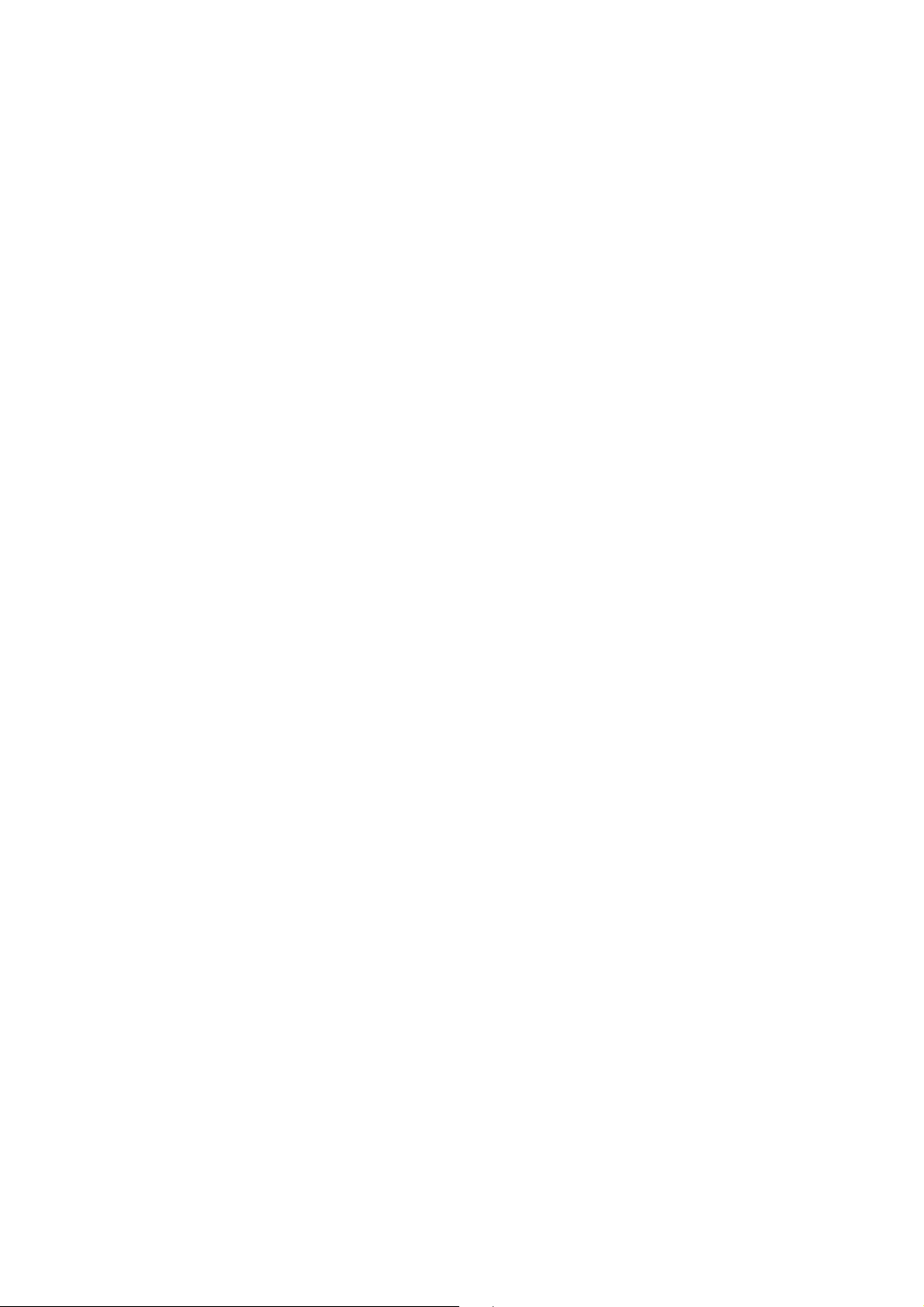

1.6.2 Control panel: - DIVA_ E

DIVA_ EDW500

DIVA_ EDIVA_ E

DW500

DW500DW500

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

1

>

Free- Standing

/ Built- in

EDW_500

2_keys

+ knob also as

ON/OFF

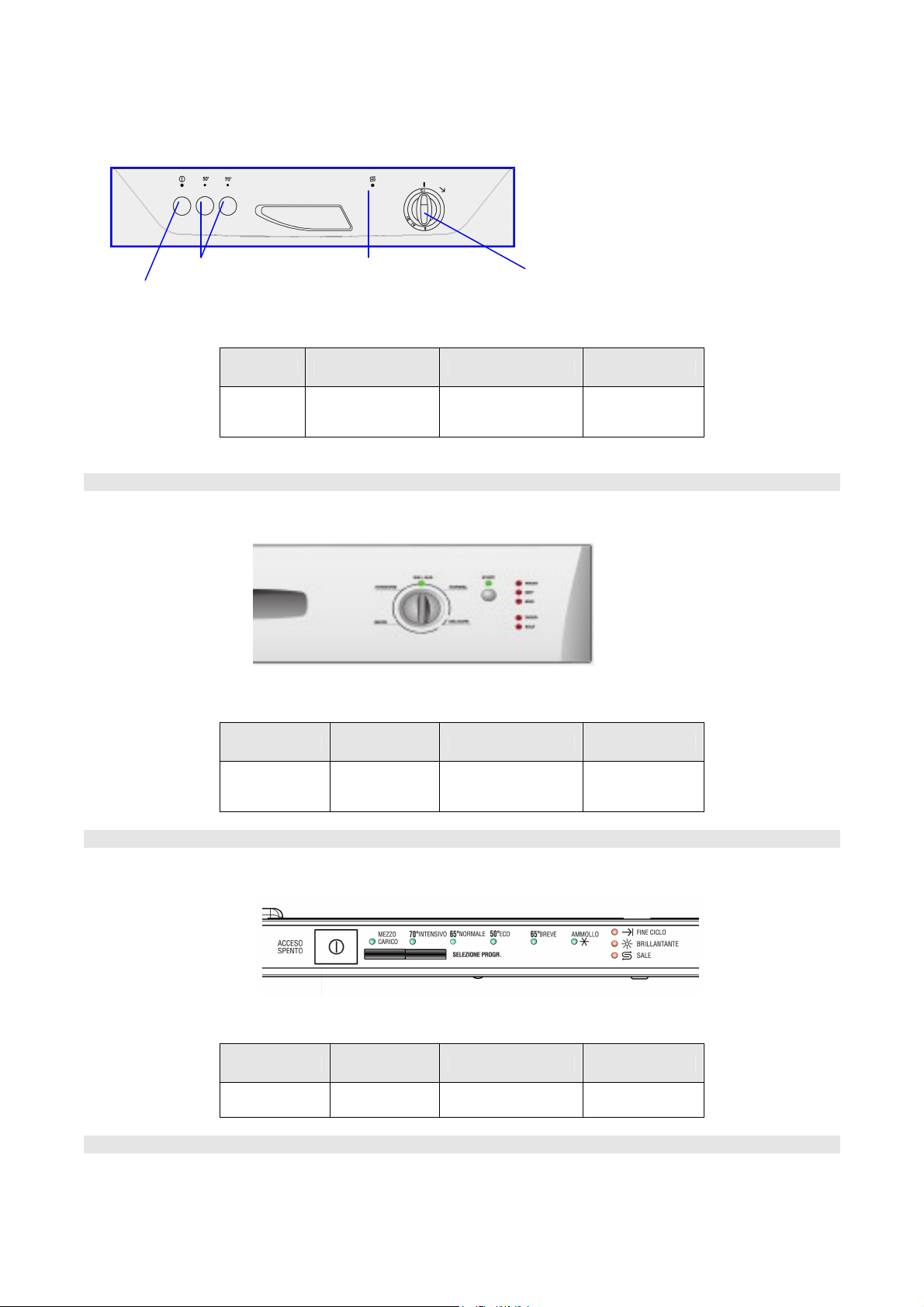

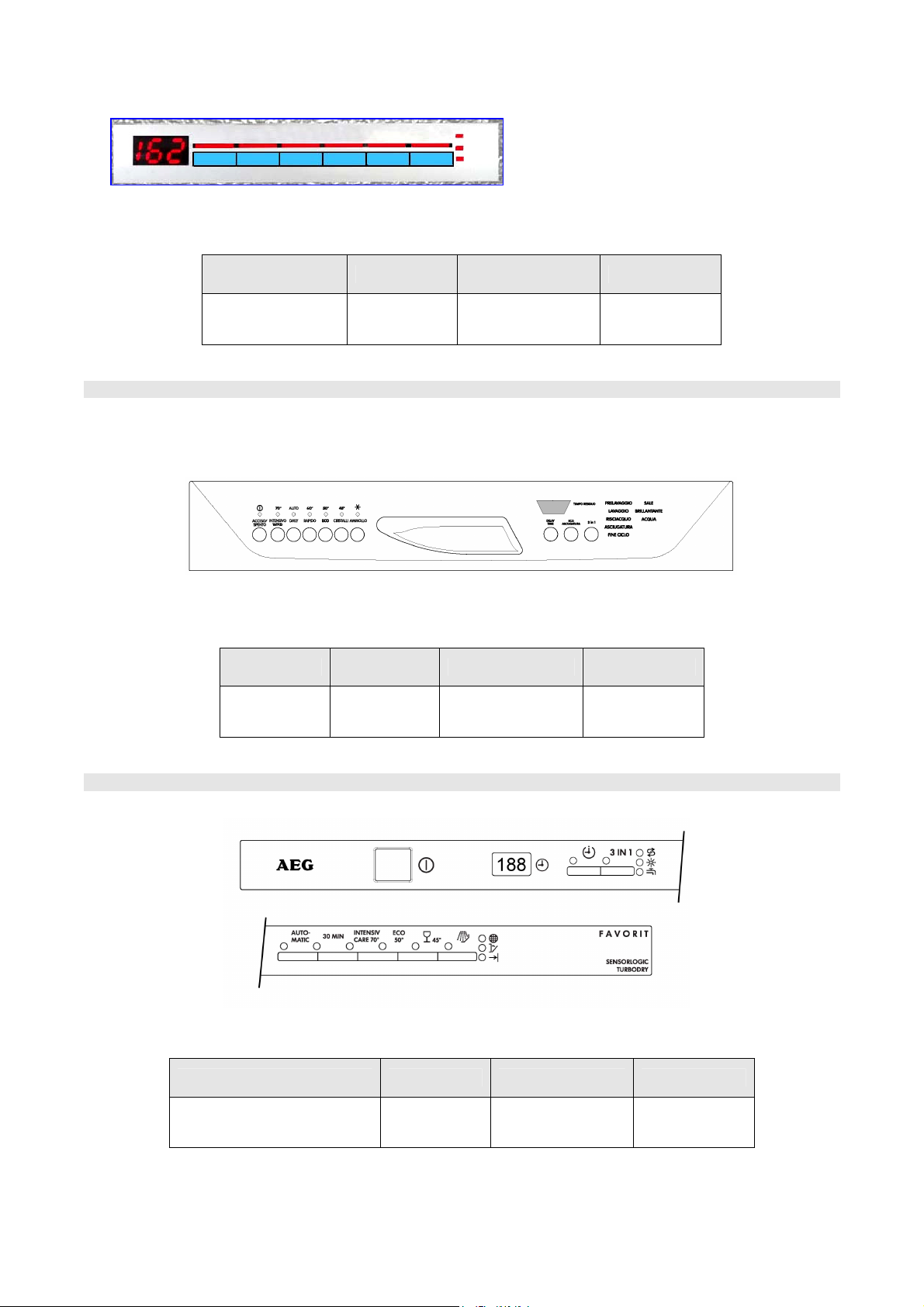

1.6.3 Control panel: - DIVA_ E

DIVA_ EDW503

DIVA_ EDIVA_ E

DW503

DW503DW503

••••

DEFINITION OF FUNCTIONS

3

>

3

>

6_progr.

5_progr.

Structure Function Type of control Programmes

Free- Standing

/ Built- in

EDW_503

On/Off key

1

>

2_keys

3

>

5_progr.

SOI/TD - PR 7/32 599 38 72-30

Page 8

1.6.4 Control panel: - DIVA_ EDW1001

DIVA_ EDW1001----EDW1100

DIVA_ EDW1001DIVA_ EDW1001

EDW1100----EDW1110

EDW1100EDW1100

Control panel versions HORIZONTAL

VERTICAL

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

Free- Standing

/ Built- in

EDW_1001

EDW_1100

EDW_1110

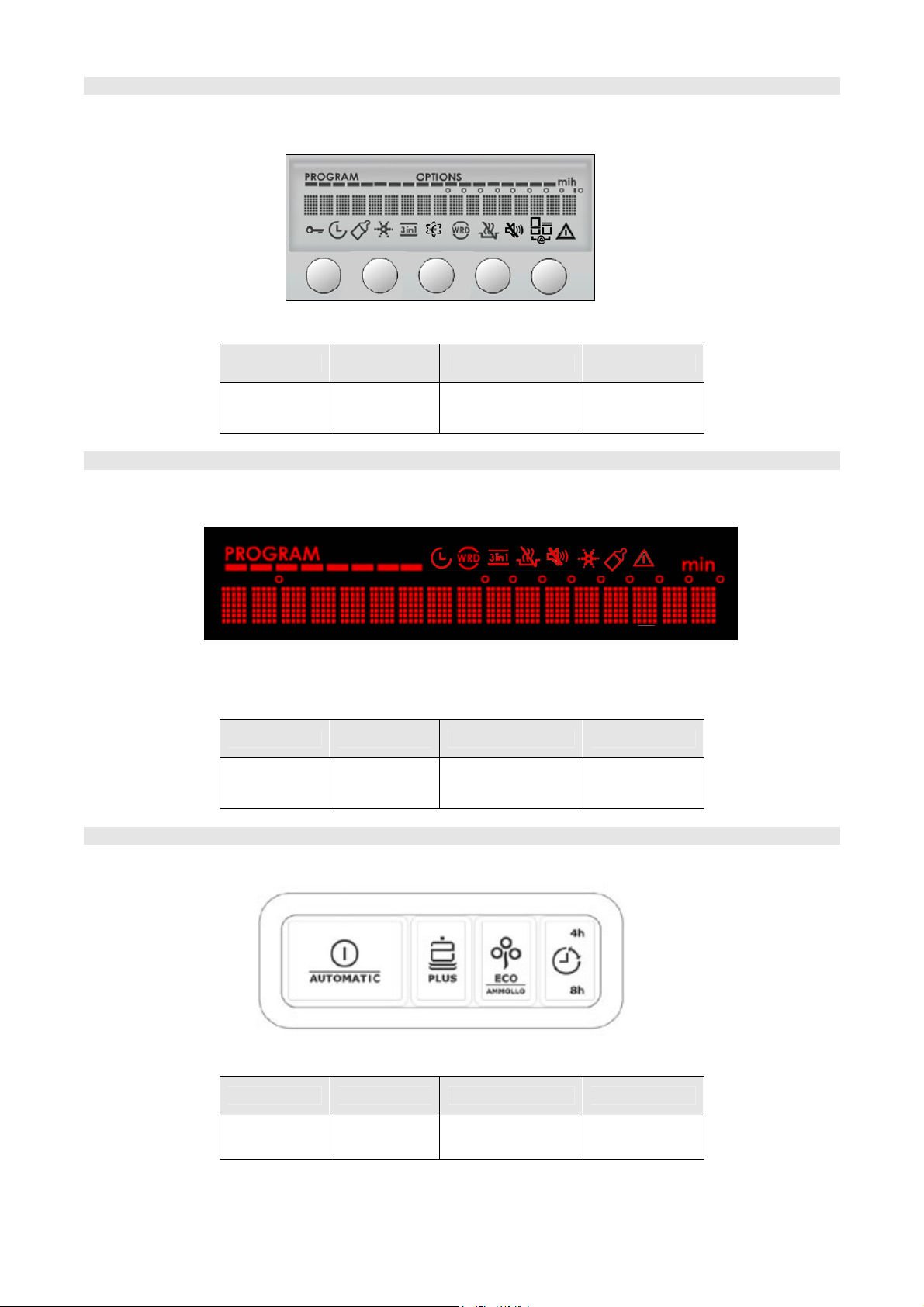

1.6.5 Control panel: - DIVA_ EDW1003

DIVA_ EDW1003

DIVA_ EDW1003DIVA_ EDW1003

••••

DEFINITION OF FUNCTIONS

EDW1110

EDW1110EDW1110

On/Off key

3

>

6_keys / leds

3

>

6_ progr.

Structure Function Type of control Programmes

Fully integrated EDW_1003

1.6.6 Control panel: - DIVA_ EDW1500

DIVA_ EDW1500----EDW1510

DIVA_ EDW1500DIVA_ EDW1500

EDW1510

EDW1510EDW1510

Control panel versions HORIZONTAL

VERTICAL

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

Free- Standing

/ Built- in

EDW_1500

EDW_1510

3

>

On/Off key

3 >

6_ keys /

+ display

On/Off key

6_keys / leds

leds

3 > 6_ progr.

3

>

6_ progr.

SOI/TD - PR 8/32 599 38 72-30

Page 9

1.6.7 Control panel: - DIVA_ EDW1503

DIVA_ EDW1503

DIVA_ EDW1503DIVA_ EDW1503

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

Fully integrated EDW_1503

1.6.8 Control panel: - DIVA_ EDW2000

DIVA_ EDW2000

DIVA_ EDW2000DIVA_ EDW2000

••••

DEFINITION OF FUNCTIONS

On/Off key

3 >

6_ keys /

+ display

leds

3

>

6_ progr.

Structure Function Type of control Programmes

Free- Standing

/ Built- in

1.6.9 Control panel: - DIVA_ EDW2

DIVA_ EDW2003

DIVA_ EDW2DIVA_ EDW2

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

Free- Standing / Built- in EDW_2003

EDW_2000

003

003003

On/Off key

9_ keys /

+ display

leds

On/Off key

7_ keys /

+ display

leds

6_ progr.

6_ progr.

SOI/TD - PR 9/32 599 38 72-30

Page 10

1.6.10 Control panel: - DIVA_ EDW2

DIVA_ EDW2555500

DIVA_ EDW2DIVA_ EDW2

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

00

0000

Free- Standing

/ Built- in

EDW_2500

1.6.11 Control panel: - DIVA_ EDW2

DIVA_ EDW2555500003333

DIVA_ EDW2DIVA_ EDW2

••••

DEFINITION OF FUNCTIONS

Structure Function Type of control Programmes

Free- Standing

/ Built- in

EDW_2503

1.6.12 Control panel: - DIVA_ EDW2000

DIVA_ EDW2000 VISI

DIVA_ EDW2000DIVA_ EDW2000

••••

DEFINITION OF FUNCTIONS

VISI

VISI VISI

On/Off key

11_ keys /

+ LCD

On/Off key

4_ keys /

+ LCD

leds

leds

6_ progr.

6_ progr.

Structure Function Type of control Programmes

Free- Standing

/ Built- in

EDW_2000

VISI

On/Off key

3_ keys / leds

4_ progr.

SOI/TD - PR 10/32 599 38 72-30

Page 11

1.7 STRUCTURAL CHARACTERISTICS

This convertible modular dishwasher is designed for maximum flexibility, and can be installed in the

FREE-STANDING or BUILT-IN versions.

Structure Version Version

MODULAR FREE-STANDING BUILT-IN

1.7.1 INTERNAL CHARACTERISTICS

1. Upper basket guide

2. Water softening level selector (if featured)

3. Salt container cap (if featured)

4. Detergent/rinse-aid dispenser

5. Control panel

6. Serial number plate

7. Central filter (drain)

8. Main filter (washing)

9. Lower spray arm

10. Upper spray arm

11. Upper basket

12. Work-top (free-standing versions only)

SOI/TD - PR 11/32 599 38 72-30

By removing the work top, the dishwasher

can be inserted beneath a sink or a preexisting work-top in marble or wood, on

condition that the dimensions of the

compartment are as shown in the figure.

This type of dishwasher is designed for installation

beneath a sink or a pre-existing work-top in marble or

wood, on condition that the dimensions of the

compartment are as shown in the figure. The feet can

be adjusted to a maximum of 80 mm. The rear foot is

adjusted from the front of the appliance.

Page 12

2 STRUCTURAL CHARACTERISTICS

The appliance consists of four main assemblies:

2.1 BASE

2.2 DOOR

2.2.1 CONTROL PANEL

2.2.2 INNER DOOR

2.2.3 DOOR

- BASE - DOOR - TUB - HYDRAULIC SYSTEM

These four assemblies are enclosed in a cabinet designed with the following removable parts:

- Front panel (secured by two screws)

- Two side panels (secured by six screws)

- A work-top (free-standing versions only) secured to the

structure by two screws at the rear.

The specially-shaped base is moulded in sound-absorbing plastic material.

- The base, which supports the body of the appliance, is fixed structurally to the tub.

The following components are located in the base

- The fill valve

- The integrated terminal block, power cable and anti-interference capacitor

- The washing pump capacitor

- The anti-flooding device, if featured

- The support system (rubber support blocks) for the washing pump

- The counterweight (free-standing versions only, if featured)

The door consists of the following sub-assemblies:

The control panel is in moulded plastic, and is secured to the inner door by six self-tapping screws.

The control panel may be customized for the various stylings, with different colours and silk-screened

markings, or by the application of a transparent or stainless steel panel mask.

The following components are screwed or pressure-fitted to the inside of the control panel:

- The timer or electronic board

- The door aperture handle

- The pushbutton array

- The pilot lamp diffusers.

The inner door is in and is secured by two lateral hinges (using four screws), which are secured to

the two front uprights of the tub.

The following components are fitted to the interior of the inner door:

- The door latch with a built-in door aperture microswitch

- The integrated dispenser (detergent and rinse-aid)

- In the lower section, a seal with the bottom of the tub.

The door is in enamelled sheet steel, and is secured to the inner door by six screws around the

perimeter and two lateral screws.

- On certain stylings (free-standing) a perimetral surround is fitted for application of a front décor

panel.

- The doors of built-in appliances have holes, slots and shaped sections for application of an outer

door in wood.

SOI/TD - PR 12/32 599 38 72-30

Page 13

B

A

C

2.2.4 DOOR HINGE

In galvanized pressed steel, with a series of mechanisms (springs, levers, spindles) which form the

system of movement for aperture/closure of the door.

- Secured externally to the two lateral uprights (D) by pressure-fitted

couplings and screws with metric thread.

- Hinges with different functional characteristics and settings are used,

depending on the styling of the appliance.

2.2.4.1 CHARACTERISTICS & FUNCTIONS

Aperture and closure of the door is by means of a pair of self-adjusting

hinges (A) and a tensioning spring (B). The movement is self-balancing

and features an automatic "braking" system.

The self-balancing system consists of a helical spring which is

calibrated to a fixed setting.

- The calibration depends on the overall weight of the door fitted to the

appliance.

- The helical spring is secured to the upper extremity of the upright

and to the hinge mechanism.

The automatic "braking" system consists of a mechanical clutch.

- The clutch consists of a sliding element (C) fitted to the hinge

mechanism which, during aperture and closure of the door, slides

vertically along the surface of the hinge.

- Some hinges are fitted with a double clutch system (two sliding

elements) in order to provide a greater "braking" effect, so that doors

of greater weight are balanced in the same way.

D

SOI/TD - PR 13/32 599 38 72-30

Page 14

C

2.3 TUB

The tub assembly consists essentially of a stainless steel tub and a series of sub-assemblies which

form the load-bearing structure of the dishwasher.

Two basic tubs have been designed, to suit the type of drying to be performed by the dishwasher.

- The difference between the two lies in the presence or absence of a hole (*) in the rear section of

the tub ceiling, to which the drying duct can be fitted.

- Other differences concern the type of soundproofing, which depends on the number and thickness

of the tar-coated panels.

2.3.1 STRUCTURAL CHARACTERISTICS

The tub is produced by press-forming using steel.

- Side and rear panels produced in a single production cycle (pressing, drilling, forming)

- Tub ceiling (pressing, drilling).

- Tub bottom (pressing, drilling).

The side and rear panels are then crimped to the ceiling and the bottom of the tub.

A silicone-based adhesive is inserted between the parts to provide a seal.

Two ducts in stainless steel (in the shape of an inverted "L"), welded around the internal perimeter of

the front section of the tub to the ceiling and the two sides, are used as a seat for the perimetral door

seal.

The tub is soundproofed by applying tar-coated panels, which are hot-glued on the external sides (all

or some of the sides). These panels are of different thicknesses, according to the level of noise

generated by the appliance.

2.3.2 STRUCTURAL SUB-ASSEMBLIES

The structure of the tub is completed by the installation of a

number of additional components

Lateral uprights (A), which support the tub on all four sides.

Three of these (the two rear uprights and the RH lateral upright)

are inserted into the base.

- Two rear uprights, produced automatically using the

"clinching" system (cold deformation welding).

- Two front uprights, secured manually using three screws.

Rear cross-member (B), in plastic, secured to the lateral uprights

by two screws.

- The rear cross-member is a structural support for the side

panels and work-top, and also supports the various hoses.

Front cross-member (C) in enamelled sheet metal, pressurefitted to the two lateral uprights and secured using two screws.

- The front cross-member is a structural support for the side

panels and work-top, and also for the door closure

mechanism.

2.3.2.1 COMPONENTS BUILT INTO THE TUB

The tub is then fitted with a number of functional components.

Externally:

- On either side, the four supports for the upper basket guides.

- On the RH side, the vertical manifold which ducts water to the upper spray arm.

- On the LH side, the water fill tank.

- On the upper side, the drying duct and (if featured) the fan.

- On the bottom, the sump assembly and the water softening system, if featured.

Internally:

- On either side, the two guides in which the upper basket slides.

- At the rear, the horizontal manifold which ducts water to the upper spray arm.

B

A

SOI/TD - PR 14/32 599 38 72-30

Page 15

Short

tank

Long

Drying

2.4 HYDRAULIC SYSTEM

The hydraulic system is common to all versions of the dishwasher, since its specific water softening

function consists of a number of specific components.

The only difference is the featuring or not of the water softening system.

2.4.1 HYDRAULIC PATH

WATER INTAKE HOSE

- Water intake from the mains supply circuit.

FILL TANK

- Passage of water into and out of the appliance.

- Water deposit for regeneration, if featured.

SOFTENING SYSTEM (if featured)

- Passage of water for softening process.

- Passage of water for regeneration process.

SUMP

- Collects water for the washing process and deposits for drainage.

FILTER GROUP

- Filters the washing water in circulation and retains any dirt.

LOWER SPRAY ARM DUCT

- Ducts water to the lower basket.

UPPER SPRAY ARM

- Ducts water to the upper basket.

2.4.2 DIFFERENCES IN THE HYDRAULIC CIRCUIT ACCORDING TO THE TYPE OF DRYING SYSTEM

Although the functional principle of the hydraulic system is identical for all versions, the single

exception is the fill tank, which differs according to the type of drying system.

TRADITIONAL ACTIVE & ACTIVE TURBO

duct

tank

SOI/TD - PR 15/32 599 38 72-30

Page 16

Drying duct

Turbo fan

LONG TANK

SHORT TANK

3 HYDRAULIC AND FUNCTIONAL CHARACTERISTICS

Softener

(if featured)

Fill tank

Sump

Fill tank + Condenser

Counter-weight

(if featured)

Drain pump

Base

Heating

element

Washing pump

SOI/TD - PR 16/32 599 38 72-30

Page 17

3.1 WATER FILL TANK

The water fill tank is a container in transparent moulded plastic consisting of two

sections that are welded together.

- Inside the tank, special chambers and ducts define the path taken by the

D

water during the fill phase.

- The fill tank is positioned in the left-hand section of the appliance, and is

screwed into position from inside the tub using a fixing ring.

- The softener regulation system, if featured, is built into the fixing ring, and is

actioned by a knob.

The water fill tank is one of the main functional parts of the hydraulic circuit.

TYPES OF TANK

KEY

A Water fill chamber and regeneration volume

LONG

SHORT

A

C

B

B Regulation system for softening circuit

C Steam venting chamber

A

D Steam circulation chamber

E Steam condensation chamber

The following functions are involved:

B

SYSTEM OF FILL WATER INTAKE

TREATMENT SYSTEM FOR REGENERATION WATER

CONDENSATION OF STEAM

3.2 WATER SOFTENING SYSTEM (if featured)

If featured, the water softening system consists of a monobloc container

in transparent plastic. The container is subdivided into two sections,

which communicate through internal ducts and contain the salt and the

resin. The container is positioned in the base of the appliance and

screwed to the tub from the inside by a fixing ring.

- The container is connected to the water fill tank by two O-ring

connectors.

- It is also connected to the sump by an outlet duct.

B

A

The following components are fitted externally to the container:

- The salt sensor (A)

- The regeneration solenoid valve (B)

A normally-closed separation valve (*) is installed inside the container,

and serves to separate the two sections:

- The valve opens as a result of the pressure exerted by the water

during the regeneration process, when the regeneration solenoid

valve (4) opens.

SALT reservoir

The salt reservoir contains the salt used for regeneration, and is accessible for filling.

The salt sensor (A) indicates to the user that the salt reservoir requires topping up.

The sensor consists of a reed sensor positioned externally to the reservoir, and a magnetic float inside

the reservoir.

The sensor is connected electrically to the SALT LED on the control panel in versions with

electromechanical control; in electronic versions, it is connected directly to the PCB.

RESIN reservoir

This sealed reservoir contains the resins (organic substances used to purify the water).

The regeneration solenoid valve (B), when actioned, performs the regeneration process (cleaning of the

resins)

E

SOI/TD - PR 17/32 599 38 72-30

Page 18

3.3 SUMP ASSEMBLY

The sump is a monobloc container in plastic material, and consists of three thermowelded sections:

PRESSURE, WASHING and DRAIN.

The sump is located on the bottom of the tub, with a perimetral

sealing ring, and is secured from the inside by four screws.

PRESSURE section (A)

An integral part of the WASHING section, in which a double

pressure chamber controls the level of the water.

WASHING section (B)

A

Located beneath the main stainless steel filter, this section collects

the filtered water, which is then re-introduced (clean) into the circuit

B

and ducted to the spray arms.

- Direct hydraulic connection to the lower spray arm.

C

DRAIN section (C)

Located beneath the circular filter in the bottom of the sump, where

the dirt is deposited before being drained.

- Housing for the drain filter.

Four ball valves built into the sump perform a number of specific

functions.

Pressure switch pressure valves (2):

- Positioned inside the respective pressure chambers.

- In case of tilting of the appliance, the valves prevent the

residual water in the sump from entering the connections of the

two pressure switch tubes.

Drain pump breather valve:

- This valve is located internally, near the drain pump breather.

- During the water fill phase, the valve opens and maintains the

drain circuit open so that the air is expelled. This enables the

pump to fill with water and prevents cavitation.

Sump bottom valve:

- Located internally, near the sump bottom.

- During the water fill phase, the valve closes to separate the drain section from the washing section.

- During the drain phase, the valve opens, thus connecting the drain and washing sections.

The following connections are located externally:

- Hydraulic connection to the softener via a rubber hose

- Hydraulic connection to the drain pump, via a rubber coupling

- Hydraulic connection to the washing pump, via a rubber coupling

- Housing for the thermostat or temperature/turbidity sensor

- To the level and safety pressure switches, via two small tubes of different colours.

3.4 DRYING DUCT

The drying duct is a moulded plastic container consisting of two

sections which are pressure-fitted together. The drying duct is

used in Active and Turbo drying.

During the drying phase, the function of the duct is to transfer

the steam from inside the tub into the fill tank condenser, where

it is condensed.

The drying duct is positioned externally above the tub and fixed

from the inside by a snap ring.

3.4.1 DRYING DUCT + FAN

Turbo drying is obtained by means of a fan located inside the

drying duct.

The fan consists of a small synchronous electric motor and an

elastic drive belt which actions the suction fan blade.

When the fan is in operation, it creates a forced air movement.

SOI/TD - PR 18/32 599 38 72-30

Page 19

4 ELECTRICAL COMPONENTS

4.1 TERMINAL BLOCK

The terminal block consists of a junction box to which the power

cable is connected; the wiring is then routed to the appliance's

ON/OFF switch.

The terminal block is pressure-fitted into a housing inside the

base. A suppressor is built into the terminal block.

The suppressor is an electrical device designed to filter out radio

interference.

Correct operation of the suppressor requires that the appliance

be connected to an efficient ground connection.

4.2 PUSHBUTTON

The pushbutton array consists of one or more modular buttons

(maximum 4) in a single block (the individual buttons are pressurefitted into a metal support).

The pushbutton array is located inside the control panel and

secured by two screws.

The pushbuttons are of two types, with different functions:

- Switch (two-pole) for the ON/OFF key

- Deviator (single-pole/two-pole) for the Option keys.

4.3 TIMER

4.4 LATCH ASSEMBLY

The timer is a timer-controlled electrical device which controls the duration and the

execution of the operations that comprise the washing cycle.

All the "user" components (solenoid valve, pump, heating element etc.) are

connected electrically to the timer by means of a specific wiring harness.

The signals to the user components are transmitted via the contacts (switching)

fitted to a lateral support and actioned by a series of cammes.

The movement of the cammes is transmitted by a synchronous motor via a series

of levers and gears which, in turn, advance the timer from one step to the next.

One complete rotation of the timer is subdivided into 58 steps, each with a specific

duration (step time variable between 5 sec and 24 sec).

Closure of the door is performed by a mechanical locking/release

system which also connects and disconnects the electrical components

in the appliance.

The latch is positioned inside the inner door in the upper section, and is

secured from the exterior by two screws.

The assembly consists of the latch, which also features a built-in

microswitch.

Latch:

The latch is in plastic material in which a system of levers provides the

mechanical action.

Microswitch:

The microswitch is connected electrically (in series) to the ON/OFF

switch, and opens or closes the contacts in order to connect or

disconnect the machine from the power supply. The microswitch is

pressure-fitted into a housing in the latch.

SOI/TD - PR 19/32 599 38 72-30

Page 20

Ω

Ω Ω

Ω

Ω

Ω Ω

Ω

Ω

Ω Ω

Ω

4.5 WASHING PUMP

Single-phase asynchronous two-pole motor with a single direction

of rotation.

- Counter-clockwise rotation (seen from impeller side).

- The hydraulic group (pump scroll casing, sealing rings and

impeller) is clamped to the motor shield, with an internal sealing

ring.

- Secured to the base of the appliance by two supports in

vibration-damping rubber.

- Connected to the sump by rubber couplings.

4.5.1 WASHING PUMP (versions with Electronic control)

Same functional characteristics, but with one exception:

The pump is fitted with a tachymetric sensor (G) housed

externally to the motor. The sensor is connected to the electronic

control system in order to provide variable speeds of rotation.

4.6 CAPACITOR

Capacitance 3µF - operating voltage 450 V.

The capacitor is permanently connected to the windings of the

washing pump, and is used to start up and maintain rotation in all

operating conditions.

4.7 DRAIN PUMP

Single-phase two-pole synchronous centrifugal motor.

- Rotation in both directions.

- Integrated hydraulic group (pump body and impeller).

- Secured to the sump by snap-on connectors and connected

hydraulically via a rubber coupling.

- A diaphragm-type non-return valve (A) positioned on the outlet

coupling reduces the quantity of water remaining in the sump at the

end of the drain cycle and prevents water from entering the

appliance from the drain system (in the sink).

4.8 FILL SOLENOID VALVE

Traditional single-coil solenoid valve with one inlet and one outlet.

- Positioned in the lower rear section of the base.

- The outlet is connected via a tube to the water fill tank.

- Rated delivery 4 litres/min. approx.

4.8.1 "AQUACONTROL" FILL SOLENOID VALVE

Integrated single-coil solenoid valve fitted upstream of the fill hose.

- The fill hose is coupled from the outlet in the lower rear section of

the base to the water fill tank.

- Rated delivery 4 litres/min. approx.

117

213

48

A

SOI/TD - PR 20/32 599 38 72-30

Page 21

4.9 TUBE-ENCASED HEATING ELEMENT

The heating element, which is encased inside a tube, is used to heat the

washing water. The heating element is not activated during the drying

phase.

- Inserted into the delivery side of the washing pump and coupled with

the duct which directs water to the upper spray arm.

- Standard version for all the appliances in the range.

- Heating power: 2,100 Watts.

Built-in safety devices:

- 1 auto-reset bi-metal thermostat calibrated to 98°C and connected in series to one branch of the

heating element.

- 1 manual-reset fuse calibrated to 206°C and connected in series to the second branch of the

heating element. If this fuse intervenes, the heating element is disconnected definitively.

4.10 TEMPERATURE THERMOSTAT

Used in versions with electromechanical control systems (timers) to

control the temperature of the washing water.

- Positioned externally on the sump, in direct contact with the water.

Available in two versions: with one temperature or two temperatures.

- 1_Tº for appliances with fixed-temperature washing (65°C).

- 2_Tº for appliances with variable-temperature washing (50 ÷ 65°C).

4.11 TEMPERATURE SENSOR

Used in versions with electronic control systems to control the temperatures of

the washing water.

- Positioned externally on the sump, in direct contact with the water.

- Constantly transmits the temperature of the water to the electronic control

system.

- Consists of an NTC sensor whose resistive value decreases as the

temperature of the water increases.

4.12 TEMPERATURE SENSOR + TURBIDITY SENSOR

If featured, it’s used in versions with electronic control (high-end appliances) to

control both the temperature and the turbidity of the washing water.

- Positioned externally on the sump in direct contact with the water.

- Fitted with an NTC sensor for control of the temperature.

- Fitted with an infra-red system for control of the turbidity of the water (i.e. the

quantity of dirt in the water).

- Constantly transmits the two signals to the electronic control system for

processing.

- By correctly combining the signals received from the two sensors (NTC and turbidity), enables the

appliance to perform "automatic" washing cycles which automatically optimize the washing cycle

according to the type of load, the quantity of the load and the degree of soiling.

4.12.1.1 TURBIDITY DETECTION SYSTEM

This consists of a reading process which takes place during the cycle according to the signals received

from the turbidity sensor by the electronic control system.

The signal is transmitted by the sensor and enables the control system to identify the status of the

cycle.

1st reading during Pre-wash phase:- Determines whether the pre-wash drain cycle is performed.

If the drain cycle is performed, the wash phase is performed at the normal temperature (65ºC).

If the drain cycle is not

performed, the wash phase is performed at 50ºC.

2nd reading during the 1st rinse:- Determines whether the 2nd rinse is performed..

SOI/TD - PR 21/32 599 38 72-30

Page 22

4.13 INTEGRATED DISPENSER

The integrated dispenser consists of a plastic container comprising

two separate sections which contain Detergent (A) and Rinse-aid

(B).

- Fitted to the interior of the inner door and secured by two screws.

- The dispenser uses a single electrical coil connected to a

mechanical system and which performs both functions.

- When the coil is energized, it actions the mechanism via a series

of levers, thus introducing the contents in sequence (first

detergent, then rinse-aid).

- The dispenser is controlled by the timer (or PCB) at predetermined steps during the cycle to ensure correct dosing.

- A window to the side of the rinse-aid sector indicates the level of detergent (when the window is

clear, the detergent requires topping up).

4.14 LEVEL & ANTI-OVERFLOW PRESSURE SWITCH

4.14.1 LEVEL PRESSURE SWITCH

4.14.2 ANTI-OVERFLOW PRESSURE SWITCH

These are two traditional pressure switches (pneumatic diaphragm type) connected to a special

support which is in turn secured to the right-hand upright by two screws.

Determines the level of water introduced into the appliance.

Operating range: Intervention/Reset = 65/ 45mm

Operating characteristics: Empty/Full = Contacts 1-2 / 1-3

Ensures that the level of water in the appliance does not exceed

the safety threshold (overflow from the door).

Operating range: Intervention/Reset 129/ 105mm

Operating contacts: Empty/Full = Contacts = 1−2 / 1−3

- Connected electrically in series via contacts 1-3 to the drain pump.

- If the switch intervenes on Full (1-3), the drain pump switches on until the switch returns to Empty

(1-2)

B

A

4.15 ANTI-FLOODING DEVICE

This mechanical/electrical safety device is activated if water is

detected in the bottom of the appliance, if featured.

The device consists of a plastic container which contains a

sensor (floating type) and a microswitch.

It is fitted into a special housing inside the base of the

appliance.

Sensor (A):

- Extra-light polystyrene sensor whose position (at rest or

raised) determines the mechanical action of the microswitch.

Microswitch (B):

- This switch is connected in series to the fill solenoid, and opens or closes the contacts in order to

connect or disconnect the solenoid valve electrically.

- When at rest (solenoid valve energized), the electrical contacts are closed.

- Fitted into a housing in the container.

A

B

SOI/TD - PR 22/32 599 38 72-30

Page 23

5 WASHING SYSTEM

The washing system is of the traditional type in which the

mechanical washing action is provided by the rotation of the

washing pump. The pump ducts the water into the hydraulic

circuit, thus actioning both spray arms simultaneously.

In order to obtain the washing result, the system also requires

features such as heating of the water, change of the water,

introduction of detergent and rinse-aid etc.. All these functions

are included in the washing cycle.

5.1 DEFINITION OF THE WASHING CYCLE

The various washing cycles are known by commercial descriptions such as:- Vigorous, Normal, Short,

etc.

At design level, the cycles are based on a series of "washing phases" comprising Pre-wash, Wash,

Rinses and Drying.

Each of these phases includes a number of "phase cycles" which determine the execution of the

washing cycle in a logical sequence.

Each phase in the operation of the appliance has a pre-determined duration and temperature, though

these can be modified using the supplementary keys to create different cycles.

In other words, the functions performed during the washing cycle are variable according to the cycles

defined.

For further details regarding the definition of the washing cycles, refer to the specific Service Notes for

each model.

Basic progressive composition of the phases of the washing cycle

WASHING

PHASES

PRE-WASH

WASH

1st RINSE

2nd RINSE

3rd RINSE

DRYING

STOP

(*) The variable functions are optional, and are controlled by supplementary keys or by direct wiring

connections according to the requirements of the specific market.

Phase cycles Phase functions

Fill/Drain Resin washing

Fill Wait for pressure switch

Washing

Heating Wait for temperature

Drain

Fill Wait for pressure switch

Washing Detergent

Heating Wait for temperature

Drain

Fill Wait for pressure switch

Washing

Drain

Fill Wait for pressure switch

Wash

Drain

Fill Wait for pressure switch

Wash

Heating Wait for temperature Rinse-aid

Drain Regeneration

Pause

Fan (if featured)

Complementary

functions

(*) Variable

functions

(0º

> 50ºC)

(50º

> 65ºC)

(skip phase)

(50º

> 65ºC)

SOI/TD - PR 23/32 599 38 72-30

Page 24

6 HYDRAULIC CIRCUIT

6.1 PATH OF WATER INTAKE - "SHORT TANK"

From the solenoid valve (2/3), the water is ducted into the fill tank and across the air break (5) into the

regeneration chamber (7) until the chamber is full.

Once the chamber is full to overflowing, and the softener system is featured, the water is divided into

two parts through two separate channels.

- One channel ducts the water directly into the softening system (9) (resin container), from where the

softened water continues towards the sump.

- A smaller quantity of water is collected in one of the channels for use in the "Blending" function

(refer to section 6.6 - "Definition of the Regeneration System"), where it is ducted directly into the

tub through the steam venting ring.

With Softener

Without Softener

KEY

1 - Fill hose 10 - Level pressure switch

2 - Fill hose with "Aquacontrol" device 11 - Anti-overflow pressure switch

3 - Fill solenoid 12 - Sump assembly

4 - Regeneration solenoid 13 - Washing pump

5 - Air-Break 14 - Tube-enclosed heating element

6 - Steam condenser 15 - Drain pump

7 - Regeneration chamber 16 - Non-return valve

8 - Salt reservoir 17 - Drain hose

9 - Resin reservoir 18 - Anti-flooding device

SOI/TD - PR 24/32 599 38 72-30

Page 25

6.2 PATH OF WATER INTAKE - "LONG TANK"

From the solenoid valve (2/3), the water is ducted into the fill tank and across the air break (5) into the

steam condenser (6) until the condenser is full.

- When the condenser is full to overflowing, and the softener system is featured, the water is ducted

through a channel into the regeneration chamber (7). In this case, too, once the overflow level is

reached, the water is divided into two parts ducted through two separate channels.

- Part of the water passes through one channel directly to the softener (9) (resin container), from

which the softened water continues towards the sump.

- A smaller quantity of water is collected in one of the channels for use in the "Blending" function

(refer to section 6,6 - "Definition of the Regeneration System"), where it is ducted directly into the

tub through the steam venting ring.

N.B. - The steam condenser (6), once full of water, remains filled. With each subsequent fill, the

incoming water replaces the water previously present in the condenser.

- The steam condenser (6) is drained through the fill hose (1/2) by a vacuum effect, after

disconnecting it from the intake tap and laying it on the floor.

With Softener

Without Softener

KEY

1 - Fill hose 11 - Anti-overflow pressure switch

2 - Fill hose with "Aquacontrol" device 12 - Sump assembly

3 - Fill solenoid 13 - Washing pump

4 - Regeneration solenoid 14 - Tube-enclosed heating element

5 - Air-Break 15 - Drain pump

6 - Steam condenser 16 - Non-return valve

7 - Regeneration chamber 17 - Drain hose

8 - Salt reservoir 18 - Drying duct/Fan

9 - Resin reservoir 19 - Anti-flooding device

10 - Level pressure switch

SOI/TD - PR 25/32 599 38 72-30

Page 26

6.3 WATER FILL SYSTEM - FUNCTIONAL DESCRIPTION

In all versions of the dishwasher (electromechanical and electronic), the water fill system is constantly

controlled by the level pressure switch, which acts as a pressure sensor.

6.3.1 DEFINITION OF WATER LEVEL

The pressure switch is connected hydraulically to the sump, inside which an air trap (pressure

chamber) is connected via a small tube in order to determine the level of water in the appliance.

In the water level circuit, the air pressure is proportional to the quantity of water present in the sump.

When this pressure exceeds the pre-determined threshold, the pressure switch (which acts as a

pressure sensor) switches the electrical contact to "full".

In order to maintain this condition, the stability of the water level is ensured during operation (washing),

which maintains the pressure switch closed on "full".

It is therefore possible to ascertain with certainty that the status of the pressure switch - i.e. its position

of "empty" or "full" - ensures that the cycle is performed correctly.

6.4 ANTI-OVERFLOW SAFETY LEVEL

In all dishwashers (electromechanical and electronic), the anti-overflow safety system is constantly

monitored by the safety pressure switch (which acts as a pressure sensor) in order to prevent water

from overflowing due to an excessively high level.

- The safety pressure switch is connected pneumatically via a small tube to the sump, which contains

a second pressure chamber (air trap), located adjacent to that of the level pressure switch. In the

safety circuit, too, the air pressure is proportional to the quantity of water present in the sump.

- Therefore, in case of a malfunction in the hydraulic circuit, and if the water level exceeds the predetermined safety threshold, the pressure switch intervenes by switching the electrical contact to

"full".

6.4.1 INTERVENTION OF THE ANTI-OVERFLOW DEVICE

The safety pressure switch commutates to "full", which immediately activates the drain pump, which is

connected electrically downstream of the circuit; the pump remains in operation until the safety

thermostat returns to "empty".

Versions with electromechanical control

The washing cycle continues in any case.

- If the malfunction is caused by a temporary fault (leakage

from the solenoid valve, excessive foam etc.) which

ceases to exist during the cycle, the user is unlikely to be

aware that the fault has occurred.

- If the fault persists, water will remain in the tub at the end

of the cycle, and the drain pump will switch on and off

alternately, since it is controlled by the pressure switch

(which cycles between "full" and "empty").

The connections for the anti-overflow system are shown in the

diagram opposite.

N.B. - If the appliance is switched off using the ON/OFF

switch at the end of the cycle, the drain pump

switches off.

- In order to ensure that the anti-overflow safety device remains in operation even when the

dishwasher is not in use, (1) the machine must remain connected to the power supply and

(2) the ON/OFF switch must be set to ON.

Versions with electronic control

Important: - If at the end of the cycle the door is opened or the appliance is switched off, the drain

pump will be disactivated.

- To ensure that the anti-overflow device remains in operation, the appliance must remain

connected to the power supply with the ON/OFF switch in the ON position and the door

closed.

N.B.:- For further details, refer to the Service Notes describing the functions of each specific model.

SOI/TD - PR 26/32 599 38 72-30

Page 27

6.5 WATER SOFTENING SYSTEM

6.5.1 SOFTENING PROCESS

If featured, this softening system is based on the use of resins (organic synthesis substances) and a

chemical process of ion exchange.

This exchange takes place rapidly, i.e. as soon as the water comes into contact with the resins.

The calcium and magnesium salts contained in the water are removed, while their sodium base is

created.

The exchange process takes place during every fill phase, each time water is introduced into the

circuit by energizing the solenoid valve.

6.5.1.1 SOFTENING CIRCUIT

The fill water from the solenoid valve (2/3), after filling the

regeneration chamber (7), continues its path until it reaches the resin

reservoir (9).

The water then slowly passes upwards through the resin bed, where it

is softened; from here, the water continues its route towards the sump.

Obviously, after a certain period, the resins lose their softening power

(i.e. are no longer able to perform the sodium exchange) because

they are saturated with calcium and magnesium. In this case, it is

necessary to regenerate the resins by introducing sodium chloride

(salt).

6.5.2 REGENERATION PROCESS

In order to regenerate the resins and restore their efficacy, it is necessary to use a salt (sodium

chloride) solution, which should be allowed to pass slowly through the resins or, preferably, left to soak

the resins for a period.

In this case, too, the ion exchange takes place. The sodium contained in the salt solution eliminates

the calcium and magnesium salts that have been deposited on the resins, which thus regain their

softening power.

The regeneration phase is performed at a pre-determined point in the washing cycle by energizing the

regeneration solenoid valve for a given time.

The quantities of water and salt used are optimized according to the level of regeneration selected by

the user, which in turn depends on the hardness of the water coming from the mains.

6.5.2.1 REGENERATION CIRCUIT

The volume of water utilized for the regeneration process depends on the

degree of inclination of the separation baffle (A).

The water is ducted through the separation baffle via an internal channel

which is open at one extremity.

The inclination of the separation baffle determines the quantity of water

used: as the baffle moves towards the horizontal position, more water is

used, since only the water above the overflow level is introduced.

When the regeneration solenoid (4) is energized, the volume of water

contained in the regeneration chamber (7) (280 cc max.) descends by

gravity into the salt reservoir; at this point, the internal valve (*) opens,

allowing the corresponding quantity of salty water to pass into the resin

reservoir (9).

After draining, the internal valve (*), which is no longer pressurized,

closes the circuit.

When the solenoid is de-energized, the salt solution remains in the resin

reservoir until the subsequent resin washing procedure is performed.

A

SOI/TD - PR 27/32 599 38 72-30

Page 28

6.5.3 WASHING THE RESINS

On completion of the regeneration process, it is necessary to clean the softening circuit by washing

the resins in order to remove any residual impurities.

The water in the resin reservoir (9), which contains alkaline salts (calcium and magnesium) and

sodium chloride, must be cleaned before the subsequent fill phase in order to ensure that it does not

come into contact with the dishes or the internal parts of the appliance, since it is corrosive.

In this case, too, the fill solenoid and the drain pump switch on simultaneously at a certain point in the

cycle and for a pre-determined period, to circulate a quantity of water (about 2 litres) which flushes the

softening circuit.

6.5.3.1 RESIN WASHING CIRCUIT

During this phase, the two functions (fill and drain) are performed simultaneously.

Fill solenoid [2/3]

When the solenoid is energized, water is circulated through the resin reservoir (9) and from there to

the sump (the circuit described in sections 4.1/4.2 "Path of the fill water" is repeated).

Drain pump [15]

When the drain pump is switched on, the water ducted to the bottom of the sump (12) is immediately

drained as it arrives, without coming into contact with the dishes.

6.5.3.2 RESIN WASHING PROCEDURE

In all versions of the dishwasher (electromechanical and electronic), the resin washing procedure

(duration 30 seconds approx.) is performed at the beginning of each washing cycle.

- In effect, the salty water solution (regeneration water) remains deposited in the resin reservoir

from the end of the last cycle until the beginning of the subsequent cycle.

SOI/TD - PR 28/32 599 38 72-30

Page 29

6.6 DEFINITION OF THE REGENERATION SYSTEM

In all versions of the dishwasher (electromechanical and electronic), regeneration of the softener

(duration 3 minutes approx.) is performed towards the end of the cycle, during the drying phase.

6.6.1 “BLENDING” FUNCTION

This function is performed inside the fill tank during the water fill phase which, depending on the

position of the selector, automatically blends the softened water with the unsoftened water present in

the appliance.

- In practice, the softened water is introduced into the appliance through the softening system, while

the unsoftened water flows via an open by-pass duct directly through the steam venting ring.

- If the mains water supply is very soft, this function optimizes the hardness of the washing water in

order to prevent the possibility of corrosion of glass recipients.

- The quantity of unsoftened water that is introduced into the appliance is expressed as a

percentage of the total quantity of water utilized.

SELECTOR ON TANK

“BLENDING” FUNCTION

Position of

selector

1 20 %

2 10 %

3 ÷ 5

Water

blending

--

6.6.2 SELECTING THE LEVEL OF REGENERATION

Electromechanical versions

On electromechanical dishwashers, regeneration is performed during every washing cycle.

The level of regeneration is selected using the selector located inside the tub (on the left-hand side,

near the steam venting ring).

- The quantity of water utilized depends on the position of the selector.

- The knob can be set to one of ten different settings as shown in the table below.

- If the selector is set to (L1) or (L2), the "Blending" function is performed automatically, thus

blending softened water with unsoftened water.

To select a different level of regeneration (according to the hardness of the mains water supply),

open the door and adjust the position of the selector from inside the appliance as follows:

- Turn the selector until the correct level (1 - 10) is aligned with the marker.

- If the water is hard, turn the selector clockwise; if it is soft, turn the selector counter-clockwise.

Selection of the appropriate level of regeneration will ensure efficient washing.

Level

1

2

3

4

* 5

6

7

8

9

10

Set up of Softener

Manual Eletronichal

1

1

1

1

2

2

2

2

2

2

1

2

3

4

* 5

6

7

8

9

10

TABLE OF REGENERATION LEVELS

Number of

acoustics

signal (if

featured)

1 - - - 0 0 > 7 0 > 4

2 130 240 8 > 18 4 > 10

3 94 240 19 > 25 11 > 14

4 70 240 26 > 32 15 > 18

5 53 240 33 > 39 19 > 22

6 37 240 40 > 50 23 > 28

7 20 240 51 > 64 29 > 36

8 15 240 65 > 75 37 > 42

9 10 240 76 > 90 43 > 50

10 3 2x240 91 > 125 51 > 70

Water filled in

between two

regenerations

litres sec º F (TH) º D (dH)

Opening of

Regeneration

solenoid

HARDNESS OF

TREATED WATER

6.6.3 SELECTING THE LEVEL OF REGENERATION

Electronic versions

In electronic dishwashers, regeneration is performed as and when necessary.

For further details regarding this process, refer to the "function" Service Manuals for these versions of

the dishwasher.

SOI/TD - PR 29/32 599 38 72-30

Page 30

7 DEFINITION OF THE DRYING CIRCUIT

In these dishwashers, the dishes are dried by means of a steam condensation process.

Depending on the type of appliance, one of three drying systems is used:

- "NORMAL - DRY" drying

- "ACTIVE - DRY" drying

- "TURBO - DRY" drying

7.1 "NORMAL - DRY" DRYING

DEFINITION OF THE SYSTEM

The "Normal Dry" system is characterized by an integrated circuit which draws in and expels air to

the exterior of the appliance.

- This is the classic, traditional drying system, based in the natural circulation of hot air.

- The steam (hot, humid air) produced during the hot rinse enters from the lower section through the

steam venting ring, and circulates slowly inside the chamber of the fill tank. Here, it is condensed

and expelled from the upper section towards the exterior.

SOI/TD - PR 30/32 599 38 72-30

Page 31

7.2 "ACTIVE - DRY" DRYING

DEFINITION OF THE SYSTEM

The "Active Dry" system is characterized by an integrated closed circuit in which the hot air is

circulated in a bi-directional convection movement onto a cold wall; no air is drawn in from the exterior.

- This drying system is based on the natural circulation of the hot air produced during the hot rinse,

where the steam (hot, humid air) circulates inside the condenser of the fill tank through two

connector ducts, thus generating the process of condensation.

- Part of the steam enters from the lower section through the steam venting ring and circulates

slowly inside the chamber of the condenser.

- The remaining part of the steam circulates in the same way, entering from the upper section of the

tub through the external upper duct, which communicates with the chamber of the condenser.

- The condenser is a condensation chamber filled with water (cold wall) against which the hot air is

ducted. This contact between the hot air and the cold wall generates the process of condensation.

This forms a closed condensation circuit which does not expel steam to the exterior, from which the

circuit is isolated.

The drying time is variable and pre-defined for each washing cycle.

SOI/TD - PR 31/32 599 38 72-30

Page 32

7.3 "TURBO - DRY" DRYING SYSTEM

The "Turbo Dry" system is characterized by an integrated closed circuit in which the hot air is

circulated in a mono-directional convection movement onto a cold wall; no air is drawn in from the

exterior.

- This drying system is based on the forced circulation of the hot air produced during the hot rinse,

where the steam (hot, humid air) is drawn in by the fan located inside the upper duct and then

ducted towards the condenser in the fill tank, from where it returns to the tub via the steam venting

ring.

- The condenser is a condensation chamber filled with water (cold wall) against which the hot air is

ducted. This contact between the hot air and the cold wall generates the process of condensation.

- This forms a closed condensation circuit which does not expel steam to the exterior, from which the

circuit is isolated.

The fan is not switched on continuously, but pauses at intervals.

The drying time is variable and pre-defined for each washing cycle.

SOI/TD - PR 32/32 599 38 72-30

Loading...

Loading...