Electrolux Air-O-Steam, Air-O-Steam - Touchline, Air-O-Convect - Touchline, Air-O-Convect Quick Installation Manual

Page 1

Air-O-Steam, Air-O-Steam - Touchline, Air-O-Convect, Air-O-Convect - Touchline

Quick Installation Guide

Rev: B - 12/11/2018

Page 2

Index

Page 1

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Filtration System 4

Positioning 5

Drainage Connection 6

Detergent Tray (6 Grid, 10 Grid) 7

Oven Cleaner Connection (20 Grid) 7

Water Connection 8

Electrical Oven - Power 9

Gas Oven - Power 9

Total Dissolved Solids (TDS) Test 3

Chloride Test 3

Information

Electrical and Gas Connection 2

Water Connection 2

Attention 2

Page 3

Information

Page 2

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Attention

Disclaimer:

The manufacturer and distributor cannot be held responsible or liable for any injuries or damages of any kind occurred

to persons, appliances or others, due to abuse and misuse of this appliance in regards to installation, un-installation,

operation, servicing or maintenance, or lack of conformity with the instructions indicated in this documentation.

All appliances made by the manufacturer are delivered assembled, where possible, and ready to install. Any installation,

un-installation, servicing, maintenance and access or removal of any parts, panels or safety barriers that is not

permitted, does not comply in accordance to this documentation, or not performed by a TRAINED AND AUTHORISED

SPECIALIST will result in the IMMEDIATE LOSS OF THE WARRANTY.

The manufacturer cannot be held responsible or liable for any unauthorized modifications or repairs. All modifications

or repairs must be approved by the manufacturer in writing before initiating. All modifications or repairs performed to

this appliance must be performed at all times by a TRAINED AND AUTHORISED SPECIALIST.

Read through the following instructions carefully before proceeding with the installation. Be sure to follow all relevant standard and local

codes. Please contact the Stoddart Service Department at 1300 307 289 if you are having problems with the installation of the unit.

Information

• This unit must be connected to an adequate supply of filtered potable water. (See page 3-4 for selection of an appropriate filter system)

• This unit must be connected to a waste water disposal system that:

(a) will effectively dispose of all waste water; and

(b) is constructed and located so that there is no likelihood of the waste water polluting the water supply or contaminating food.

• Regulations require that all units be installed to the appropriate Australian standards.

• Regulations require that authorised persons carry out all plumbing work.

Water Connection

IMPORTANT!

This unit must be installed in accordance with AS/NZS 3500.5

Information

• The electrical and/or gas supply must comply with the rating plate data.

• Ensure that the machine is connected to a suitably rated, dedicated and earthed power source with its own isolation switch.

Extension leads or power boards are not to be used.

• Regulations require that all units be installed to the appropriate Australian standards.

• Regulations require that authorised persons carry out all electrical and/or gas work.

• Users should also note that if the supply electricity cord is damaged in any way it should be replaced. Please contact Stoddart for parts

and we will advise how to do this in order to avoid any electrical hazard.

• The power cable should be dry and or isolated from moisture or water.

Electrical and Gas Connection

WARNING!

This unit must be installed in accordance with

AS/NZS 60335.1, AS/NZS5601

Page 4

Installation

Page 3

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

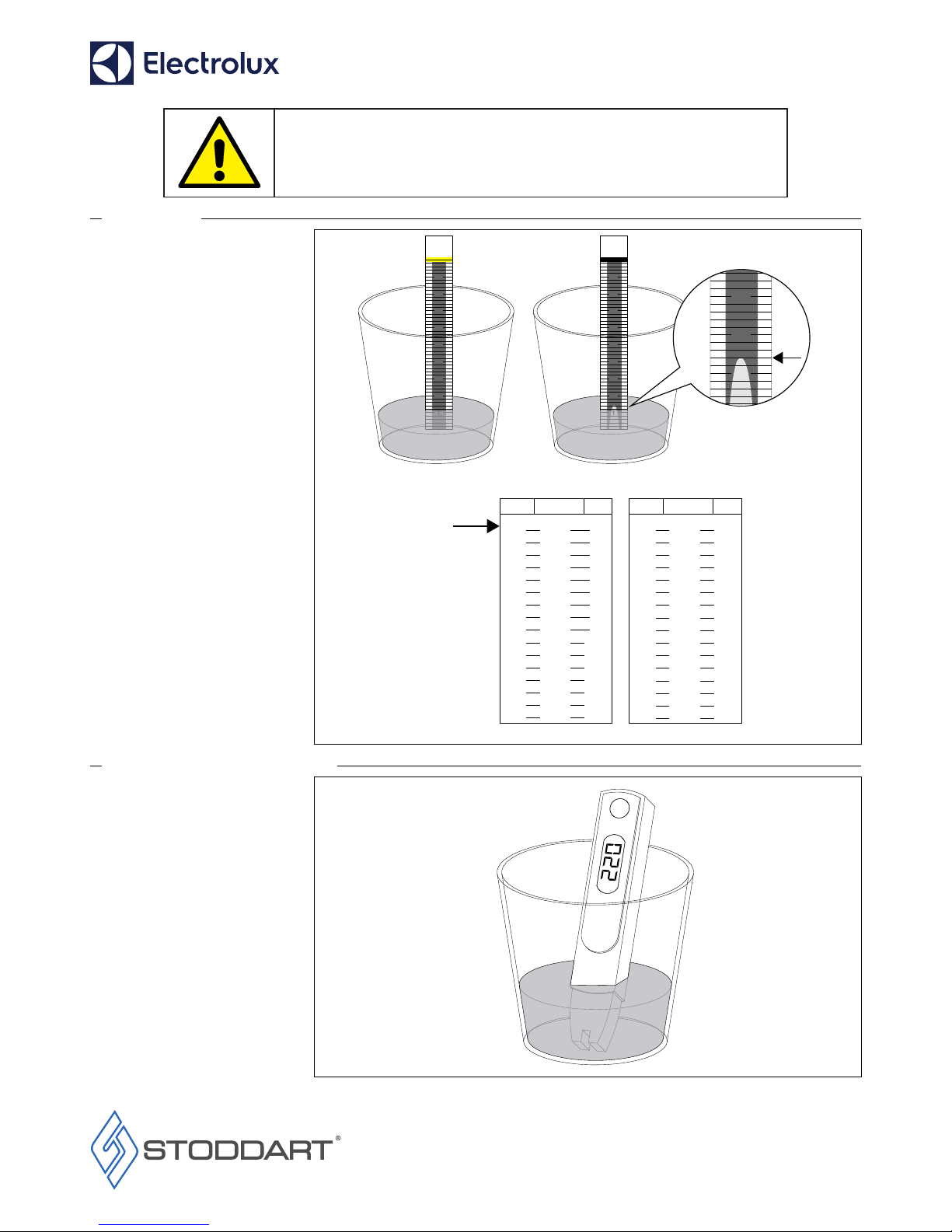

Chloride Test

1. Remove Titrator from bottle and

replace bottle cap immediately.

2. Insert lower end of the Titrator into

water to be tested (approx 20mm of

water). DO NOT allow water to touch

yellow completion band at top of

Titrator.

3. Allow water to completely saturate the

wick of Titrator. Reaction is complete

when yellow band turns dark.

4. Note where the white chloride peak

falls on the scale. This represents the

unit value.

5. Refer to the table to convert the

Titrator units into salt concentration.

* Readings higher than 1.4 (32PPM)

require a Reverse Osmosis Unit to be

installed.

Total Dissolved Solids (TDS) Test

1. Remove the cover from the TDS meter,

turn on by pressing the On/Off button.

The display should read 000.

2. Insert lower end of the TDS meter into

water to be tested (approx 20mm of

water). DO NOT completely submerge.

3. Wait 5-10 seconds.

4. The number displayed on meter is

the TDS (Total Dissolved Solids) of the

water expressed in PPM (parts per

million) e.g. TDS = 220PPM.

5. When finished, turn the TDS meter off.

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

3.6

3.8

4.0

4.2

4.4

0.005

0.006

0.007

0.009

0.010

0.011

0.013

0.014

0.016

0.017

0.019

0.021

0.023

0.025

0.027

0.030

32

39

45

53

60

68

77

86

95

106

116

128

140

152

166

180

4.6

4.8

5.0

5.2

5.4

5.6

5.8

0.032

0.035

0.038

0.041

0.044

0.048

0.051

196

212

229

248

267

288

311

6.0 0.055 335

6.2 0.060 361

6.4 0.064 389

6.6 0.069 419

6.8 0.074 452

7.0 0.080 487

7.2 0.087 525

7.4 0.093 567

7.6 0.101 613

Units %NaCI CI Units %NaCI CI

ppm(mg/L)

Limit*

ppm(mg/L)

IMPORTANT!

Selection of the correct water ltration system to suit local water

conditions is CRITICAL. Failure to install the correct system according

to the following guidelines will void warranty.

Page 5

Installation

Page 4

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Water

Supply Test

Call

Stoddart

1300 307 289

Chloride

(Cl)

TDS

Greater Than

32PPM (Parts Per Million)

BWT Unit

Reverse Osmosis Unit

Less Than

32PPM

Less Than

60PPM

Greater Than

60PPM

Filtration System

• After testing the quality of your water supply use the below chart to determine you water filter requirements.

Page 6

Installation

Page 5

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

300mm

500mm

Minimum

clearance from

non-heat source

Minimum

clearance from

heat source

Positioning

• The oven must be installed under an

extraction canopy that meets

AS 1668.2.

• To allow access to service panel and

protection of the control components,

the left hand side of the Combi oven

must have the following minimum

clearances:

Heat Source:

- 500mm clearance from another heat

source, in order to protect the oven

control components and allow access

to the service panel.

Non-Heat Source:

300mm clearance from a non-heat

source to allow access to the service

panel.

• Failure to adhere to these clearances

will potentially void the oven warranty

or add service costs due to lack of

access.

• Using a spirit level, ensure that the

Combi oven is level. Adjust the foot

height to level Combi oven.

• If using a stand, level the stand by

adjusting the feet, then level the Combi

oven.

Page 7

Installation

Page 6

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Drainage Connection

• Drain kit is supplied with oven as

illustrated. Any modification or

extension to the kit must be able to

resist temperatures up to 100°C.

• Plumb supplied waste pipes to the

Tundish.

• Tundish needs to be a minimum of

300mm left or right from the oven

waste outlet.

• Tundish should never be located

directly below the waste outlet, or

close to or under the oven control

compartment. Steam from drainage

should not be allowed to rise

up underneath the oven control

compartment.

• Waste pipe must sit 25mm above the

Tundish.

• Secure waste pipe to the Combi oven.

Securing bracket is attached to top

of the Combi oven. Remove screw,

reposition bracket, then secure in

place with previously removed screw.

25mm

300mm

300mm

Oven Waste Outlet

25mm

300mm

300mm

Oven Waste Outlet

Page 8

Installation

Page 7

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Oven Cleaner Connection (20 Grid)

• Connect the oven cleaner and rinse aid

hoses to oven.

- Rinse aid (blue) on left side.

- Oven cleaner (red) on right side.

• Attach correct hoses directly to oven

cleaner and rinse aid bottles.

Detergent Tray (6 Grid, 10 Grid)

• Connect locking pin to underside of

oven.

• Insert bracket into holes located on

underside of oven.

• Slide detergent tray between bracket

and oven. Secure by rotating the

locking pin clockwise 90°.

• Detergent tray is split into two

compartments:

- Rinse aid (blue) on left side.

- Oven cleaner (red) on right side.

Optional Storage Rack

Oven Cleaner

(Red)

Rinse Aid

(Blue)

90°

Page 9

Installation

Page 8

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

CWI-1

Filtered Water

CWI-2

Non Filtered Water

Water Supply

With

Isolation Valve

Water Flow

Direction

Filtration

System

150-350 kPa

(22-65 psi)

150-350 kPa

(22-65 psi)

No Filtration

System

Minimum Flow Rate

Refer to specific

installation guide

supplied with the

water filter

10LPM flow rate

6,10,10x2 tray oven

20LPM flow rate

20,40 tray oven

F

E

D

Supplied

Connectors

RO Filter

BWT Filter

B

C

A

Water Connection

• Water connections are labelled on the

service panel.

• Isolation valve must be installed at the

water supply outlet.

• CWI-1: The Combi oven requires

filtered water supplied to its steam

generation system.

Water pressure must be150-350 kPa

(22-65 psi) at oven connection.

• CWI-2:The Combi oven requires

unfiltered water supplied to its wash

system.

Water pressure must be150-350 kPa

(22-65 psi) at oven connection.

Minimum flow rate:

10LPM - 6,10,10x2 tray oven.

20LPM - 20,40 tray oven.

BWT Filter Supplied Connectors:

• A: Manifold fitting with 1 cap x1

• B: Non-Return Valve x1

• E: 3/4 BSB Hex Nipple x1

RO Filter Supplied Connectors:

• D: Manifold fitting with 2 caps x1

• E: Non-Return Valve x1

• F: 3/4 BSB Hex Nipple x1

Page 10

Installation

Page 9

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Electric Oven - Power

• Oven is to be wired to the electrical

supply by a licensed technician in

accordance with AS/NZS60335.1.

• Supply must have an isolation switch.

• Remove the two screws at the base

of the service panel, remove service

panel.

• Correctly wire the oven to terminal.

• Re-install service panel.

Electric Oven

Electric Oven

Gas Oven - Power

• Gas ovens only.

• Oven is to be connected to the gas

supply by a licensed technician in

accordance with AS/NZS5601.

• Supply must have an isolation valve.

• Connect gas line to gas connection on

underside of oven.

• Stoddart is to be contacted for the gas

setting adjustment. Ph:1300307289

• No external appliance gas regulator is

required.

• The ovens electrical connection is

supplied via a 10Amp plug and lead,

for connection to an appropriately

rated GPO.

Gas

Supply

Page 11

Notes

Page 10

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 12

Page 11

www.stoddart.com.au

International

Sales

Tel: +617 3440 7600

Email: sales@stoddart.com.au

Service / Spare Parts

Tel: +617 3440 7600

Email: service@stoddart.com.au

Email: spares@stoddart.com.au

www.stoddart.co.nz

New Zealand Business Number: 6837694

New Zealand

Sales

Tel: 0800 79 1954

Email: sales@stoddart.co.nz

Service / Spare Parts

Tel: 0800 935 714

Email: service@stoddart.co.nz

Email: spares@stoddart.co.nz

www.stoddart.com.au

Australian Business Number: 16009690251

Australia

Sales

Tel: 1300 79 1954

Email: sales@stoddart.com.au

Service / Spare Parts

Tel: 1300 307 289

Email: service@stoddart.com.au

Email: spares@stoddart.com.au

Loading...

Loading...