Page 1

Affinity Front Load Washer

Service and Diagnostics

Page 2

Teardown and Component Operation

Page 3

Dispenser Drawer

Pull out the detergent drawer and push down on the “Push” tab.

Page 4

Main Top

•

Remove the two screws on

the rear of the main top.

•

Slide back

Page 5

Console

Remove the two screws, one

on each end, holding the

console to the top of the side

panels

Page 6

Console

Remove the three

screws located

behind the dispenser

drawer

Page 7

Console

Lift the three tabs on the top of

the console from the mounting

plate and roll the console

forward, while lifting up to

release the bottom tabs from

the front panel.

Top tabs

Bottom tabs

Page 8

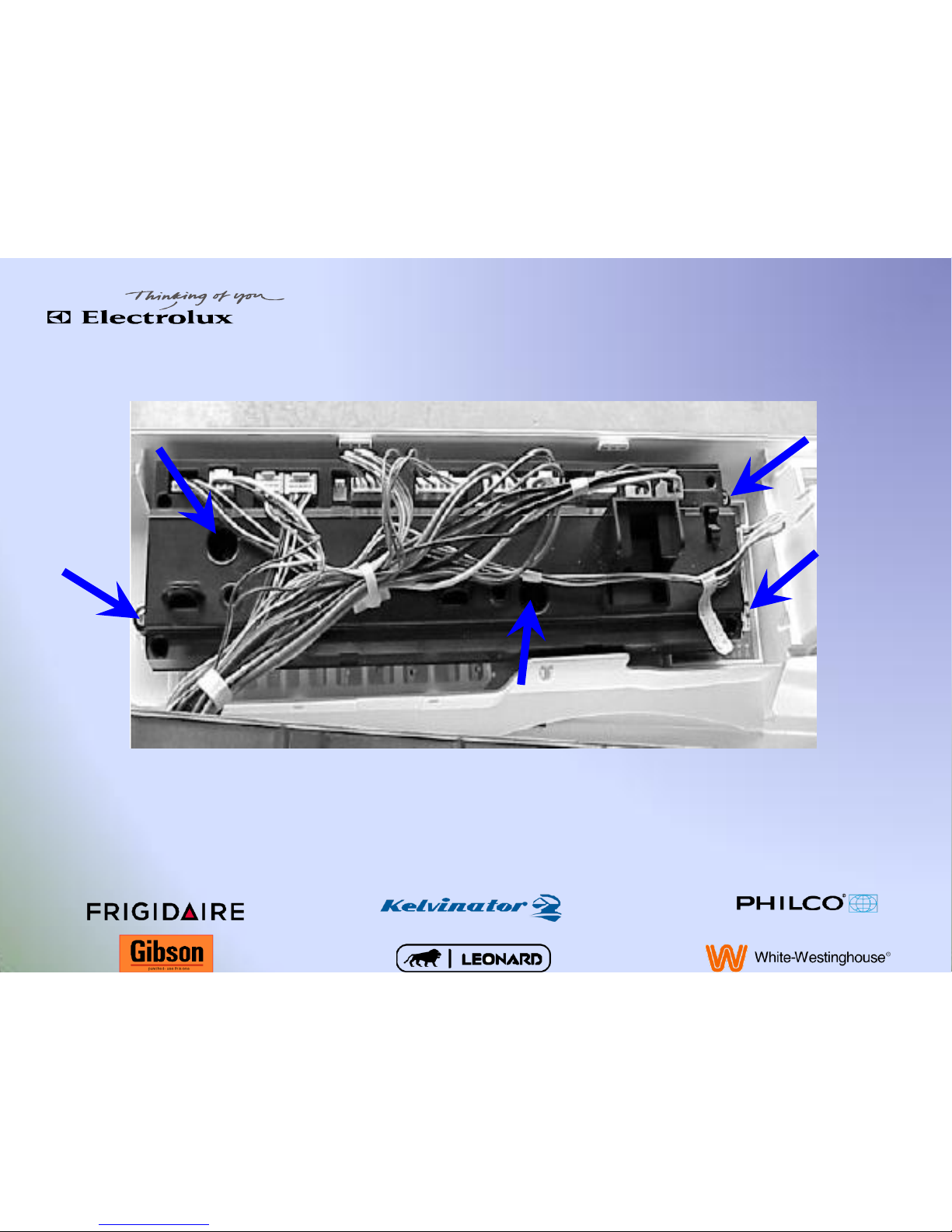

Electronic Control

Remove the five screws and disconnect wires

Page 9

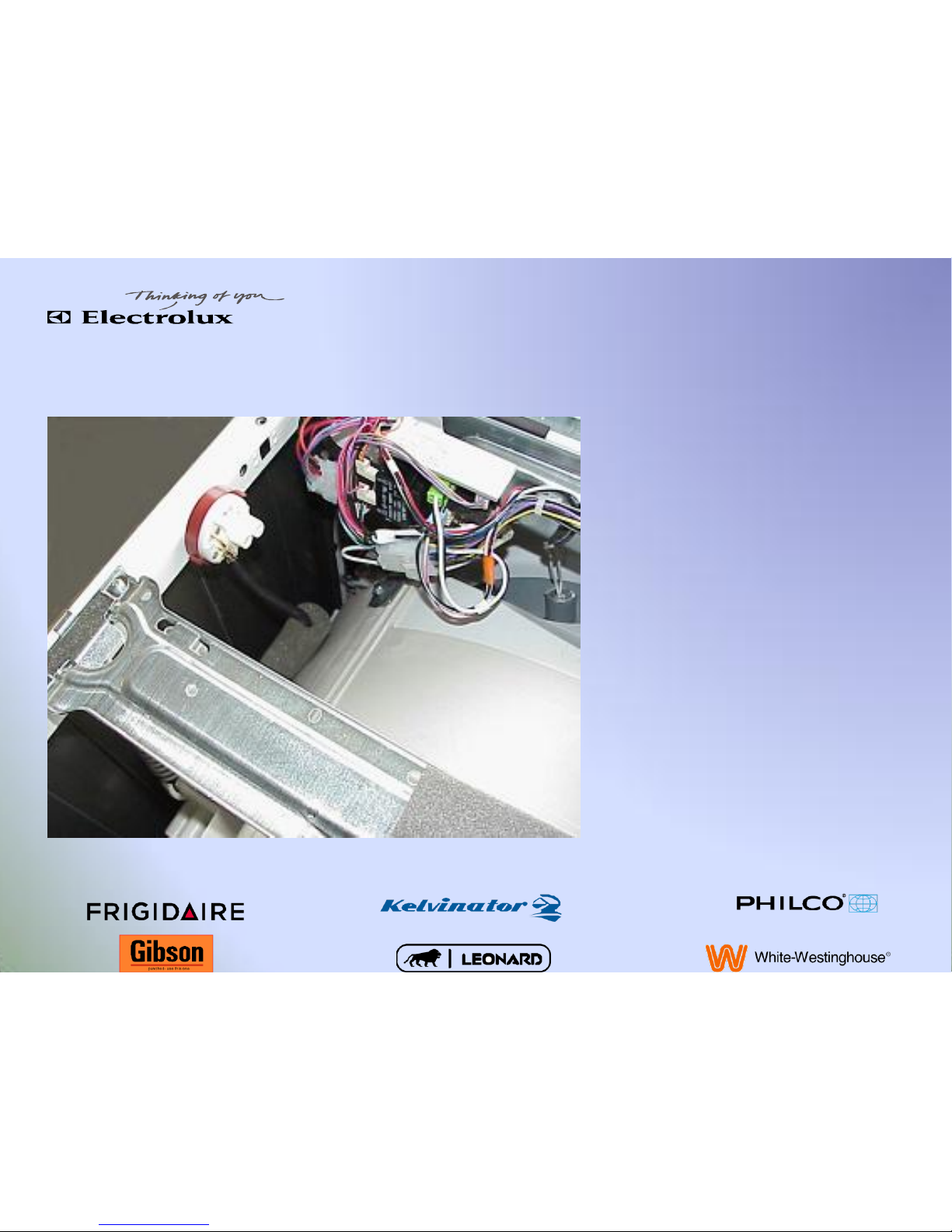

Pressure Switch

Disconnect pressure hose and

wires

Turn the pressure switch one

quarter turn and lift out

Page 10

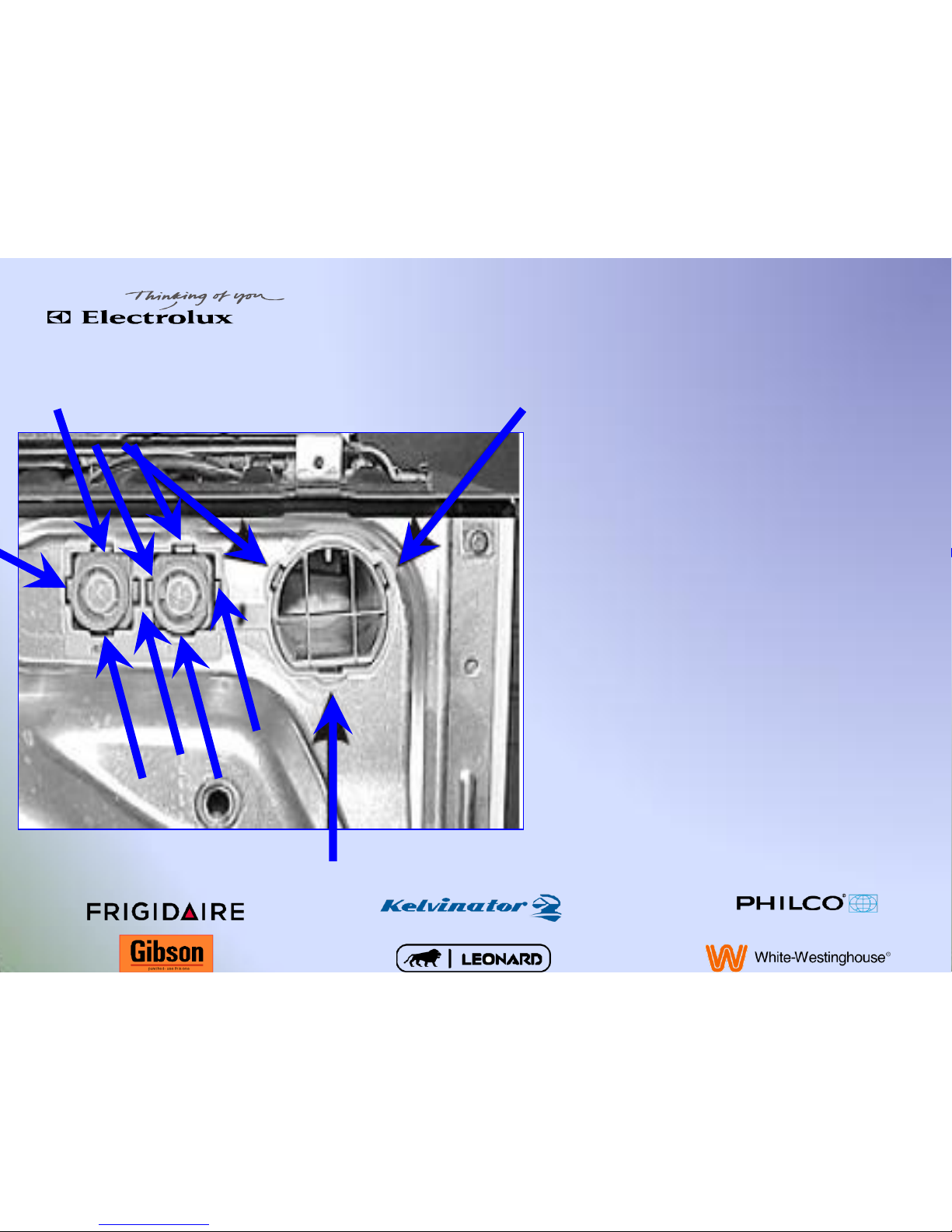

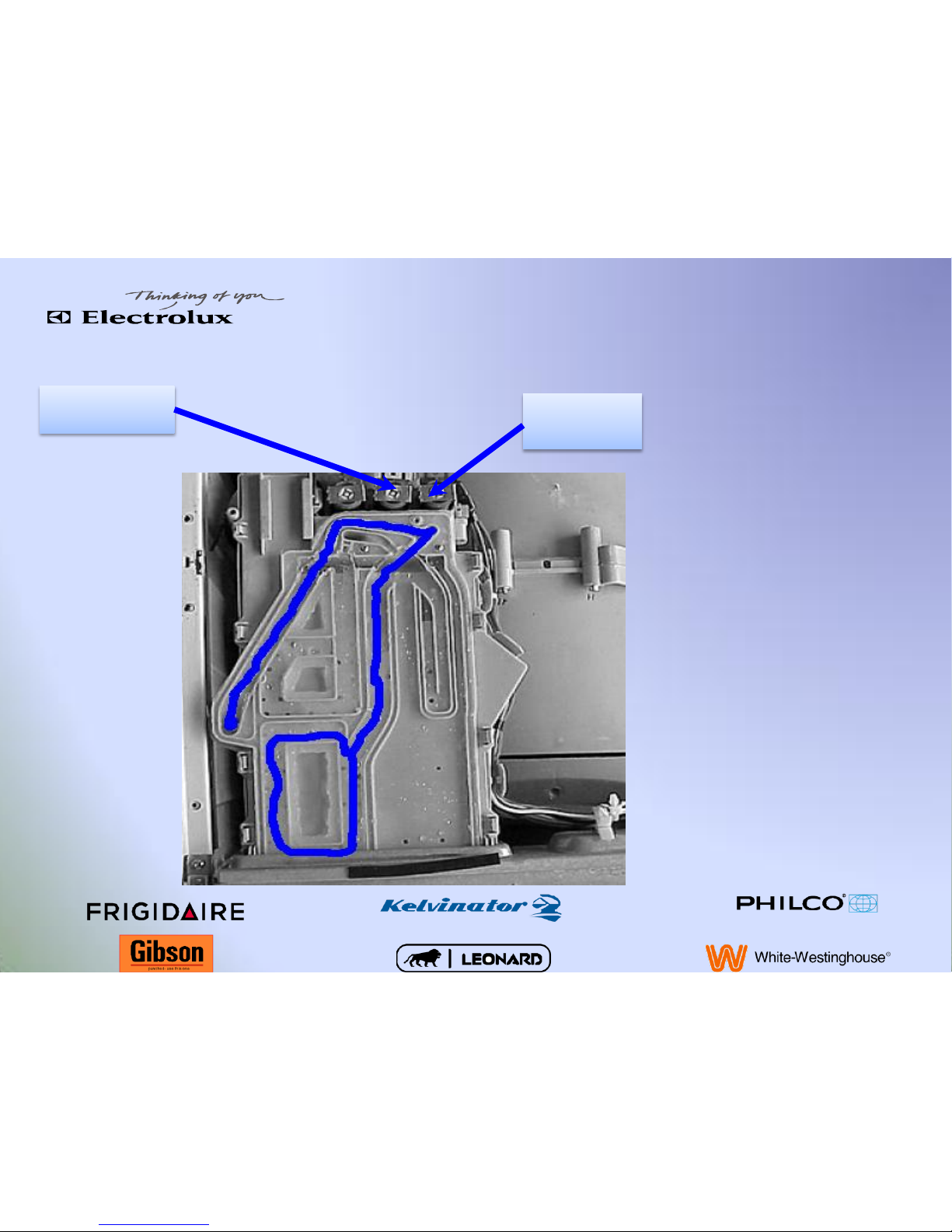

Vent Tube & Water Valve Grommet

To remove the vent tube,

water valve or dispenser first

the grommet located at the

upper right side at the back of

the washer needs to be

removed.

Release the 11 locking tabs

with a small screwdriver.

Page 11

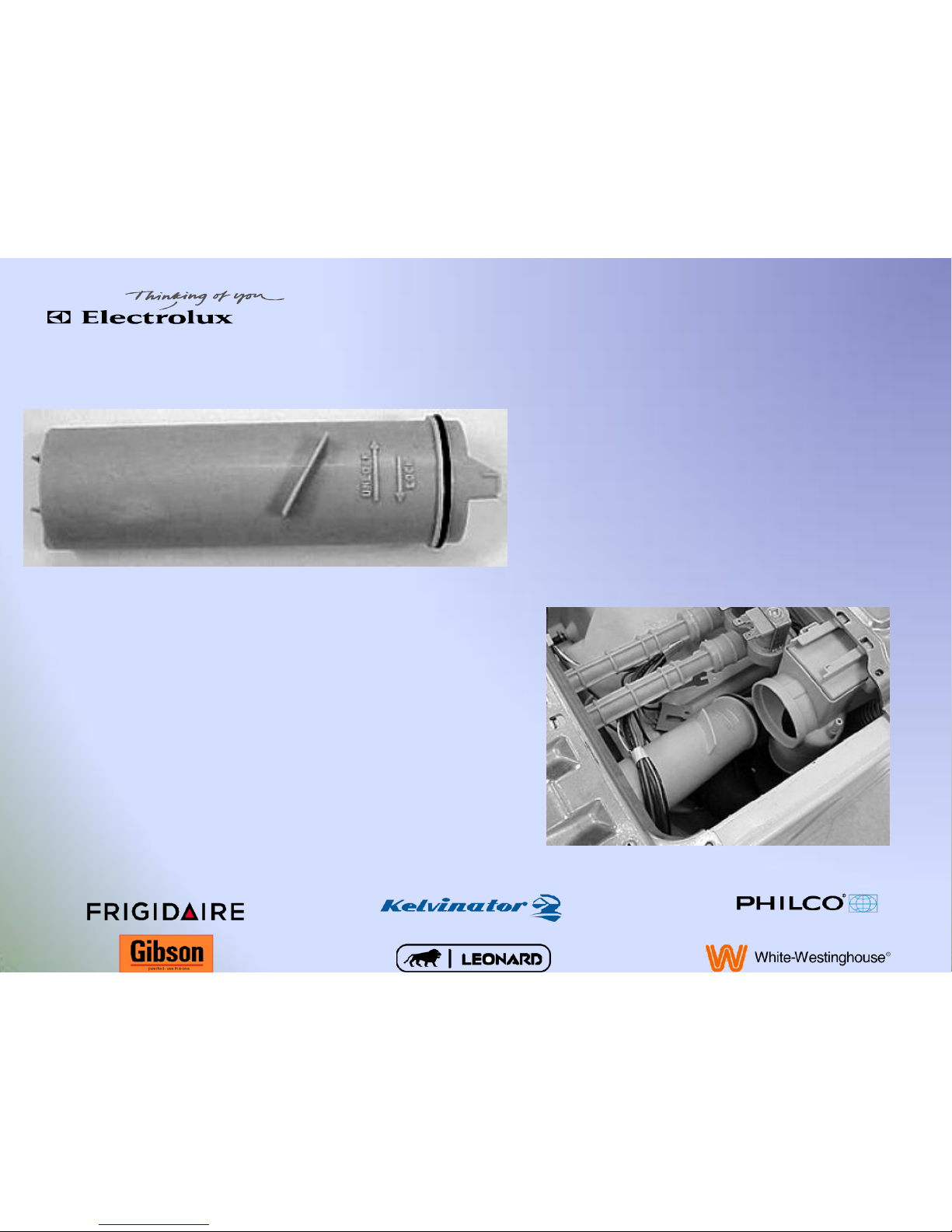

Vent Tube

Turn the vent tube counter

clockwise and pull back.

Push the tube forward and down

to release from rear hole.

Page 12

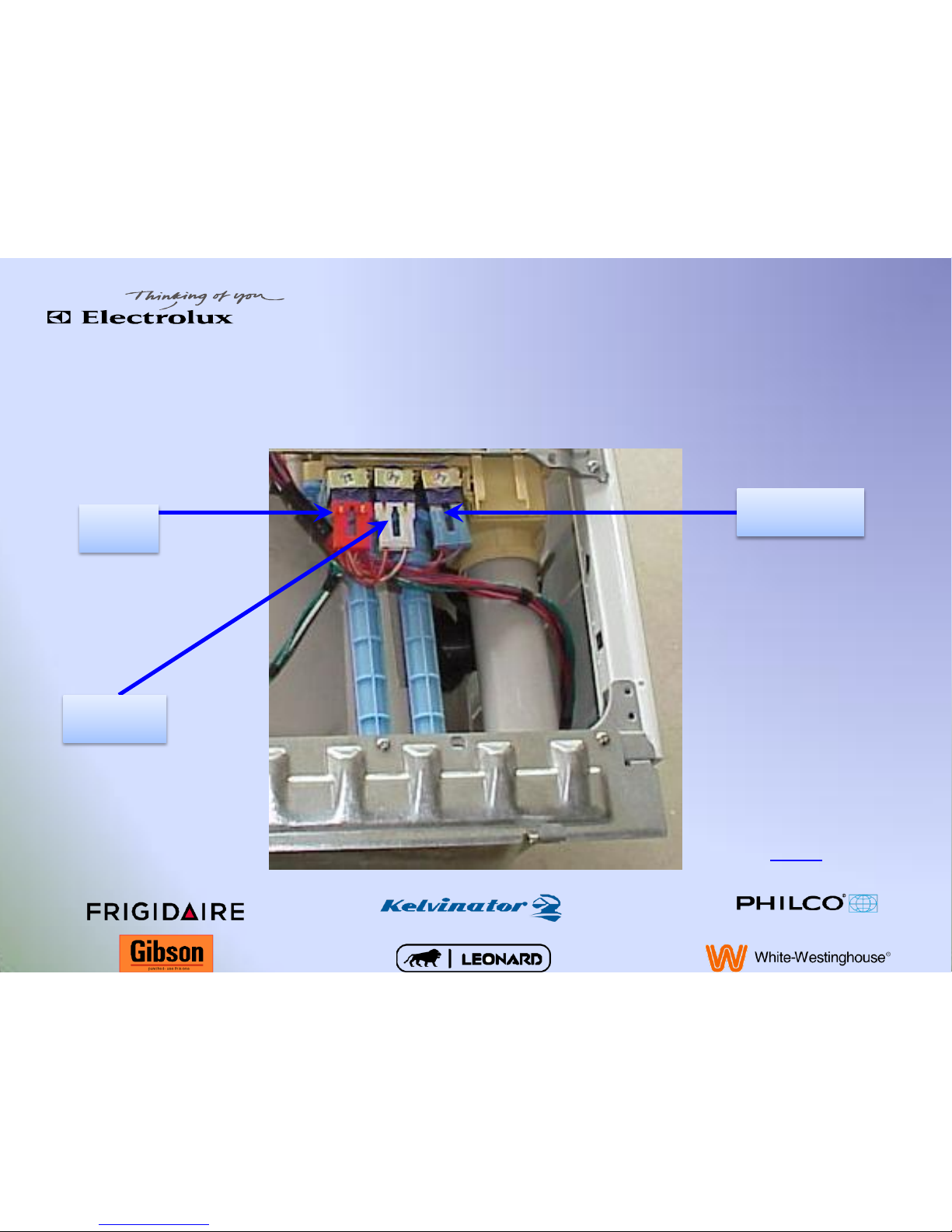

Water Valve Removal

Disconnect the electrical and

remove the two screws located

on the upper side and lower

right side of the valve.

Page 13

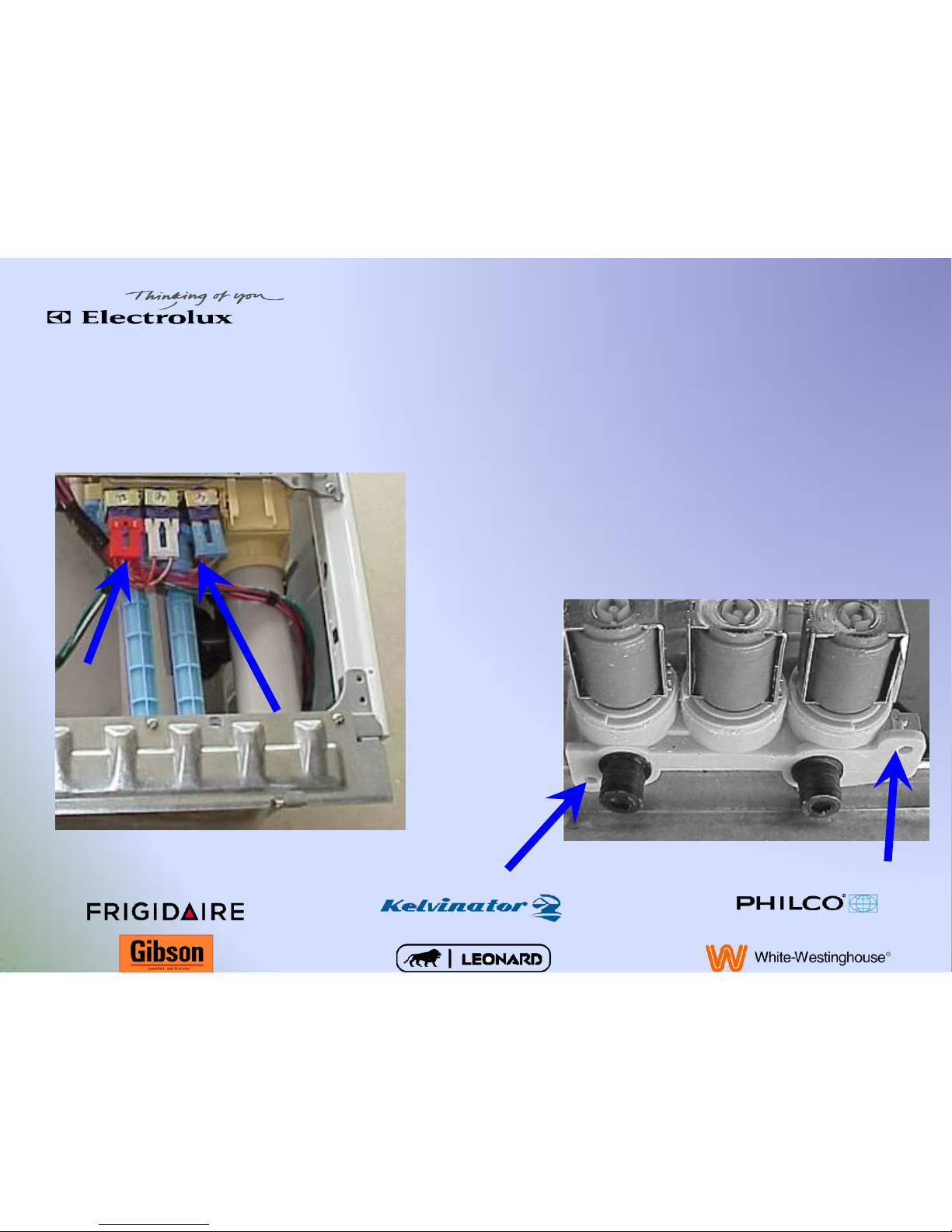

Water Valve

Bleach

Wash

Hot

Valve operation

Page 14

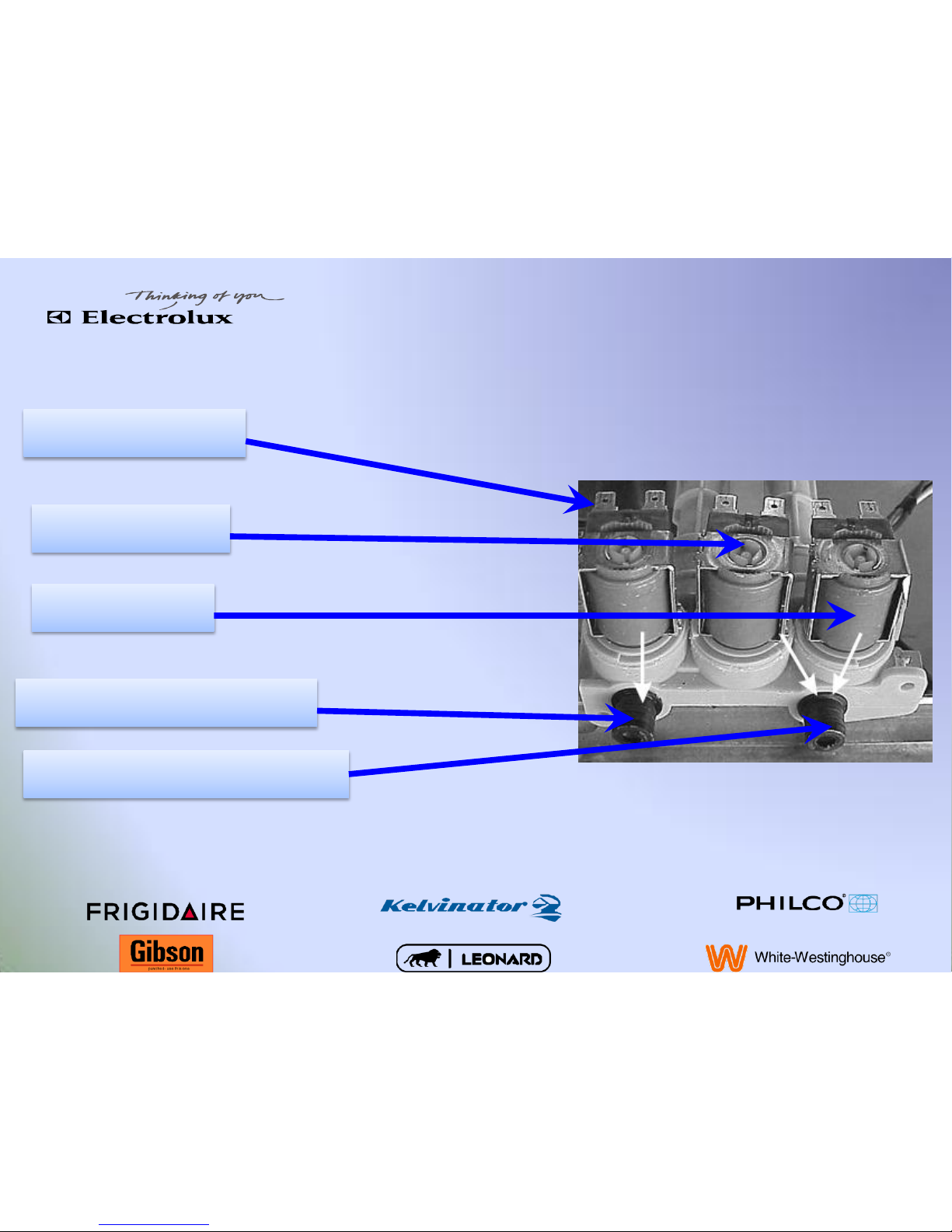

Water Valve Operation

Bleach Valve

Wash Valve

Hot Valve

Wash & Hot Port to Dispenser

Bleach Port to Dispenser

Page 15

Dispenser

During fill the wash valve

(cold) and the hot valve

are engaged depending

on what temperature

you select fill the main

dispenser and the ART

(Advanced Rinse

Technology)

Main Fill

Wash Valve

Hot Valve

Page 16

Dispenser

During the bleach fill only the bleach

valve is energized filling the bleach

compartment.

Bleach Fill

Bleach Valve

Page 17

Dispenser

During the fabric softener fill the

Bleach and Hot valve are energized

when the warm rinse is selected. The

Bleach and the Wash valves are

energized. As the water runs out

both ports the water streams meet

and colloid making a steady stream

into the fabric softener section.

Fabric Softener Fill

Wash

Valve

Bleach

Valve

Hot Valve

Page 18

Dispenser Removal

Disconnect the outlet hose Disconnect the ART Hose

Page 19

Dispenser Removal

Remove two screws at the rear

of the dispenser

Remove two screws at the

front of the dispenser behind

the drawer

Page 20

Dispenser Removal

Release the (2) tabs, one on

each side, locking the housing

to the console mounting panel

Slide the housing back until

the tabs of the center cross

bar releases and the dispenser

drops down.

Page 21

Rear Panel

Remove the 6 screws removing the

bottom one last

Access

•

Belt

•Motor

•

Motor control board

Page 22

Loosen the 10 mm nut counter clockwise which

will release metal plate and decompress rubber

gasket

Heater & Thermistor

10 mm nut

Rubber Gasket Metal Plate

Page 23

When putting heater back in place make

sure it is placed into the metal clip then

tighten down the 10 mm nut.

Heater Replacement

10 mm nut

Metal Clip

Page 24

Belt & Pulley

Belt removal:

•

Just roll belt off pulley

*Note* Look at the position of the belt on the

motor shaft for proper placement

Pulley removal

•

Use a 6 mm allen turning the bolt counter

clockwise.

•

Work the pulley back and forth to remove off

spinner support shaft.

Page 25

Motor

Remove rear panel

Disconnect wire & ground plug to the

motor

Remove four 5/16 screws located at the

front and rear of the motor. Slide motor

towards the front of the washer

Page 26

Motor Control Board

To remove controller lift up

the top and disconnect

electrical connectors

Page 27

Motor Control Board

Remove the Phillips screw located towards

the rear of the unit that secures the

controller

Page 28

Motor Control Board

Lift the side of the housing up,

slide

the assembly to the rear to

disengage

the front tab and lift the

assembly

away from the washer base

*Note*

If the upper shock pin is

removed on the motor

controller side of the outer tube

it can make removal of the

controller easier

Page 29

Light Switch

Remove electrical connections and press

side tabs and push forward

Page 30

Door Bellows Spring

Remove the spring holding the door bellows

in place

Page 31

Door Switch

1st Remove two

screws

2nd Slide switch to the left

and remove wires

Page 32

Front Panel

Remove the eight screws that

hold the panel in place

Four screws on the bottom

Four screws on the top

Page 33

Front Panel

Lift up and out

to disengage

the four nylon

pins, two on

each side.

Page 34

Boot Removal

Disconnect the ART hose

Remove light (if equipped)

Place hand under bellows of

the boot and lift up

Page 35

Boot Replacement

Align the point at the top of the boot with an alignment tab on the

outer tub at the top of the lip.

Page 36

Boot Replacement

Align boot lip into the lip of the outer tub and work it on all the way

around

If needed use water or Windex for lubrication

Do not use liquid soap or fabric softener

Page 37

Boot Replacement

Fold boot into the tub

Take boot spring and place it in the

groove at the top of the boot

Page 38

Boot Replacement

At the 12:00 position hold spring in

place by wedging an object about ¾” in

diameter between boot and counter

weight or use a clamp

Page 39

Boot Replacement

Pull spring taught in the groove to the 3:00 position wedging spring in

place or using a clamp and pull spring taught to the 7:00 position wedging

the spring in place or using a clamp. Then placing the spring in the groove

all the way around.

Page 40

Counter Weight

Remove the five 7/16 bolts

holding the weight in place

.

Page 41

Pump

Disconnect hose clamps from

sump and drain hose

Remove two screws holding

the pump to the base

Page 42

Shocks

To remove shock remove the

pins.

Depress locking tab while pulling

pin to remove.

This procedure is much easier if

a deep 1/2",6 point socket (or

13 millimeter, 6 point) is used to

compress the locking tab of the

plastic pin.

Page 43

Outer Tub & Spin Basket

Loosen clamp on the

inlet hose

Loosen clamp on the air

break

Page 44

Outer Tub & Spin Basket

Remove shock pin from

outer tub and place out

of the way

Loosen sump clamp

Page 45

Outer Tub & Spin Basket

3rd Remove

the support

springs

2nd Remove

dispenser

1st Remove

water valve

and vent

tube

Page 46

Outer Tub & Spin Basket

Lift out outer tub and lay on

protected floor and remove 23, 3/8

bolts keeping front and rear tub

together

Page 47

Page 48

Page 49

Diagnostics

Page 50

Entering Diagnostics

1. Turn the Program Knob to Spin Only. This is the start

position for the diagnostic test.

2. Press Start/Pause to start the cycle.

3. Press Cancel to stop the cycle and turn off the LEDs.

4. Press any button on the console, other than the Cancel

Button, to turn on the LEDs.

5. Within 5 seconds, press and hold the Options and

Start/Pause buttons simultaneously until all the LEDs start

sequentially flashing, then release the buttons. The unit is

now in the diagnostic test mode.

Page 51

List of Tests

Listed below in order of appearance is each test that can be performed while in

the diagnostic test mode. The program knob is used to access each test.

1. User Interface Test: At this point, all of the LEDs are sequentially flashing, pressing a button

below a cluster of LEDs will light all of the LEDs in that cluster. This test is used to check the

functionality of the LEDs as well as the user interface.

2. Wash Compartment Test: Turn the program knob one position clockwise from the start

position. This will activate the hot water solenoid. At this point, hot water will flow into the

detergent compartment. This test will check the function of the hot water solenoid and the

functionality of the detergent compartment.

3. Bleach Compartment Test: Turn the program knob two positions clockwise from the start

position. This will activate the bleach water solenoid causing cold water to flow into the

bleach compartment. This test will check the function of the bleach water solenoid and

functionality of the bleach compartment.

Page 52

List of Tests

4. Softener Compartment Test: Turn the program knob three positions clockwise from the

start position. This will activate the bleach and wash water solenoids and cold water will

enter the softener compartment. This test will check the function of the wash solenoid as

well as checking the functionality of the softener compartment.

5. Door Lock Test: Turn the program knob four positions clockwise from the start position.

The door lock solenoid will open, allowing the technician to open the door. This test will

check the function of the door lock assembly, as well as the interior light.

6. Movement Test: Turn the program knob five positions clockwise from the start position.

This will fill the washer with water and start a tumbling action. Once the tumbling action

has started, the heater will turn on (if equipped). The purpose of this test is to check the

operation of the motor, motor control, water level switch, and heater (if equipped).

7. Drain and Spin Test: Turn the program knob six positions clockwise from the start position.

This test will activate the drain pump, as well as activate the door lock solenoid, allowing

the machine to start a high speed spin cycle. This test checks the drain pump, motor

control, motor, and door lock.

Page 53

List of Tests

8. Error Code Display: Turn the control knob seven positions clockwise from the start

position. This will display the last five error codes stored in the control beginning with

the most recent. This provides the technician with a history of codes that will help the

technician in their diagnosis of the failure. After the fault has been repaired, the

technician should erase the fault codes. To erase the fault codes, press the Start/Pause

and Option buttons simultaneously while in diagnostic test 8.

To exit the diagnostic test mode, there are two options that can be used to

return the unit to normal operation:

Unplug the unit from its power source, wait 5 to 8 seconds, then reapply

power to the unit or turn the program knob two or three positions clockwise

from the start position. Then press the Options and Start/Pause buttons

simultaneously for a few seconds until wash cycle LEDs appear.

Page 54

Error Codes

Error Code

Error Code Description

Test

E11

Water fill exceeded allowed time

limit

Refer to test (1).

E13

Water leakage

Refer to test (2).

E21

Water not pumping out quickly enough

Refer to test (3).

E31

Pressure switch failure

Refer to test (4).

E32

Pressure switch calibration problem

Refer to test (4).

E35

Pressure switch senses water overfill

Refer to test (5).

E38

Air trap clogged

Refer to test (5).

E41

Main control board senses the door switch is

open

Refer to test (6).

E43

Door PTC circuit failure

Refer to test (15).

Page 55

Error Codes

E44

Door closed sensing failure

Replace the main control board.

E45

Line door sensing failure

Replace the main control board.

E47

Door PTC sensing open

Refer to test (7).

E48

Door PTC sensing closed

Refer to test (7).

E49

Door sensing incongruence failure

Refer to test (7).

E4A

Door PTC sensing failure

Refer to test (6).

E52

Incorrect signal from tachometer

Refer to test (8).

E53

Low voltage to motor control board

Refer to test (17).

E54

Motor over speed failure

Refer to test (9).

E55

Motor under speed failure

Refer to test (9).

Page 56

Error Codes

E57

More than 20 amps sensed on inverter

Refer to test (9).

E58

More than 8.5 amps sensed on motor phase

Refer to test (9).

E59

No signal from tachometer for 3 seconds

Refer to test (10).

E5C

Main control received high voltage

Replace the motor control board.

E5D

Communication problem

Refer to test (11).

E5F

Main control board continuously resets

Refer to test (11).

E67

Heater relay sensing failure

Refer to test (15).

E68

Ground current leakage on heater or fuse is

open.

Refer to test (14).

E71

NTC (tub heater) failure

Check wiring. If wiring checks good, replace

main control board

E91

Communication error between main board

and user interface

Check wiring.

Page 57

Error Codes

E92

User interface and main board

communications error

Refer to test (11).

E93

Console or main board problem

Replace main control board.

E94

Main control problem

Replace main control board.

E97

Console or main board problem

Replace main control board.

E98

Communication protocol is incorrect

Replace main control board.

EA1

Power supply frequency is out of limits

Refer to Test (12).

EA2

Power supply voltage is too high

Refer to Test (12).

EA3

Power supply voltage is too low

Refer to Test (12).

EA5

Main voltage sensing failure

Refer to Test (12).

EAE

Line safety relay sensing failure

Refer to Test (12).

Page 58

Error Codes

EF1

Clogged drain pump

Unclog the drain pump.

EF2

Suds warning

Advise the customer on proper detergent

use.

EF6

Control reset

Unplug the unit for 1 minute and retry. If the

problem is not corrected, replace the main

control board.

Page 59

Customer Error Codes

“SAn”

Deep clean (Sanitary Cycle)

“cd”

Cool down (Sanitary Cycle)

“do” or “dr”

Door problem

“Err”

An error has been detected

“LOC”

Child lock has been activated

“PAU”

Cycle has been interrupted

Page 60

Tests

Test (1)

1. Is the incoming water flow normal?

2. Is the water supply turned on?

3. Is the water pressure sufficient?

4. Does water continue to fill the

washer?

5. Remove power from the unit. Did the

water fill stop?

6. Check the pressure sensor.

7. Replace the control board.

Yes. Go to step (4).

No. Go to step (2).

No. Turn on water supply.

Yes. Go to step (3)

No. Have the customer correct the pressure

problem.

Yes. Check for kinked or blocked water

supply hoses. Correct if kink or blockage is

found. If there is no kink or blockage,

replace water valve assembly.

Yes. Go to step (5).

No. Go to step (6).

Yes. Go to step (6).

No. Replace water valve assembly.

Pressure sensor checks good. Go to step (7).

Pressure sensor checks bad. Replace

pressure sensor.

Test (2)

1. Is the washer leaking water?

2. Is there an air leak in the air bell

system?

3. Check the pressure sensor.

4. Replace the main control board.

Yes. Correct water leak.

No. Go to step (2).

Yes. Correct air leak.

No. Go to step (3).

Defective. Replace pressure sensor.

Pressure sensor checks good. Go to step (4)

Page 61

Tests

Test (3)

1. Check the drain hose for restrictions.

2. Start the washer and check for 230

VAC at the drain pump.

Restriction. Correct problem.

No restriction. Go to step (2).

Zero volts. Check wiring.

Wiring checks good. Replace main control

board.

230 volts is verified at the pump. Check for

blockage in pump. If there is no blockage,

replace the pump.

Test (4)

1. Inspect the wiring between the

pressure sensor and the main control

board.

Defective wiring. Correct wiring.

Good wiring. Replace the pressure sensor. If

this does not correct the problem, replace

the main control board.

Test (5)

1. Is the water level above 120mm?

2. Does water enter the washer

continuously?

3. Remove power from the washer. Does

the water stop coming in?

4. Check the pressure switch hose.

Yes. Go to step (2).

No. Go to step (4).

Yes. Go to step (3).

No. Replace the main control board.

Yes. Check valve wiring for shorts. If wiring

checks good, replace main control board.

No. Replace water valve assembly.

Is there a restriction of air leak? If not,

replace pressure switch.

Page 62

Tests

Test (6)

1. Is the door closing?

2. Locate plug J-2 on the main board.

Measure voltage from J2-1 to ground.

Yes. Go to step (2).

If 0 volts is measured. Check the door strike.

If the door strike checks good, replace the

door switch assembly.

If 230 volts are measured, replace the main

control board.

Test (7)

1. Remove the door lock assembly and

measure the resistance of the wax

motor.

If the wax motor is shorted or open, replace

the door lock assembly.

If the wax motor measures 800 to 1500

ohms, replace the main control board.

Test (8)

1. Disconnect the plug from the drive

motor and measure the resistance

between pins 4 and 5 on the motor.

If the measurement is between 105 and 130

ohms, replace the motor control board.

If the measurement is outside of the range

of 105 -130 ohms, replace the motor.

Page 63

Tests

Test (9)

1. Remove the belt from the motor and

spin the motor pulley. Does the motor

spin freely?

2. Remove the belt from the unit and

spin the tub pulley. Does the tub spin

freely?

3. Disconnect the motor plug. Measure

resistance of motor windings by

measuring from pin 1 to pin 2, pin 1 to

pin 3, and pin 2 to pin 3. All readings

should measure between 4 to 6 ohms.

No. Replace the motor.

Yes. Go to step (3).

No. Check the tub bearings. If tub bearings

check good, check unit for obstruction

between tub and spin basket.

Yes. Go to step (3).

If readings are correct, replace the motor

control board.

If readings are incorrect, replace the motor.

Page 64

Tests

Test 10

1. Remove the belt from the motor and

spin the motor pulley. Does the motor

spin freely?

2. Spin the tub pulley. Does the tub spin

freely?

3. Disconnect the plug from the drive

motor and measure the resistance

between pins 4 and 5 on the motor.

4. Disconnect the motor plug. Measure

resistance of motor windings by

measuring from pin 1 to pin 2, pin 1 to

pin 3, and pin 2 to pin 3. All readings

should measure between 4 to 6 ohms.

No. Replace the motor.

Yes. Go to step (3).

No. No. Check the tub bearings. If tub

bearings check good, check unit for

obstruction between tub and spin basket.

Yes. Go to step (3).

Measurement should be between 105 and

130 ohms. If meter reads outside of those

limits, replace the motor.

If the reading is between 105 and 130 ohms,

go to step (4).

If the readings are correct, replace the

motor control board.

If the readings are incorrect, replace the

motor.

Page 65

Tests

Test 11

1. Check the wiring between the main

control board and the motor control

board.

Wiring is defective. Repair or replace wiring.

Wiring checks good. Replace the main

control first. If this does not repair the error,

replace the motor control board.

Test 12

1. Contact the power supply company to

check incoming power frequency.

If the frequency is correct, replace main

control board.

Test 13

1. Check the heating element resistance.

Element resistance should be

approximately 30 ohms.

If reading is correct, replace the main control

board.

Test 14

1. Check the resistance of the tub NTC. Is

the NTC resistance approximately 4.8K

ohms.

No. Replace the heating element.

Yes. Check the wiring.

Page 66

Tests

Test 15

1. Check the wiring between the main

control board and the user interface

board.

If the wiring is defective, correct the wiring.

If the wiring checks good, and none of the

LED’s light, replace the use interface board.

If this does not correct the error, replace the

main control board.

Note: If only one of the LED’s will not light,

replace the user interface board.

Test 16

1. Does the unit shut down shortly after

coming on?

2. Does the water valve come on and then

shut off after a short period of time?

Then does the pump come on and shut

off, and then power to the unit shuts

off?

3. If nothing happens when the start

button is pushed, replace the main

control board.

Yes. Check wiring to the door lock switch. If

the wiring checks good, replace the door lock

switch.

No. Go to step (2).

Yes. Replace the door lock switch.

No. Go to step (3).

Test 17

1. Check the wiring between the main

control board and the motor control

board.

If the wiring checks good, replace the motor

control board.

Page 67

Accessing Error Codes

• Wake the washer by pressing any button other

than Cancel.

• Wait 5 seconds.

• Press and hold the Start/Pause and Cancel

buttons simultaneously. The unit will beep

and the last 5 store error codes will be

displayed as long as the Start/Pause and

Cancel buttons are pressed together.

Page 68

Clear Error Codes

• Enter the diagnostic mode as described above.

• Turn the control knob seven positions

clockwise from the start position.

• Press and hold the Options and Start/Pause

buttons for 3 seconds. This will clear the error

codes.

• Exit the diagnostic mode as described above.

Page 69

Demo Mode

Demo Mode: The demo mode is used to exhibit the

functions of the machine in a showroom setting.

When the unit is operating in demo mode it

displays the following characteristics:

Cycle times are shorter than in the operating mode.

The water fill function of the unit is disabled.

The drain function of the unit is disabled.

The heater is disabled.

The spin cycle is disabled.

Page 70

Demo Mode

To enter the demo mode, execute the following procedure:

Press the Cancel button.

Wake up the user interface by pressing any button on the console

other than the Cancel button.

Move the program to position two (rinse cycle).

Press and hold the Start/Pause and Spin Speed buttons

simultaneously for five seconds. These buttons must be pressed

exactly at the same time to enter the demo mode.

After pressing the Start/Pause and Spin Speed buttons

simultaneously the unit will beep. After the unit beeps, press the

Start/Pause button. The unit is now in demo mode.

This procedure must be completed within 7 seconds from waking up

the user interface.

Page 71

Demo Mode

Now that the washer is in demo mode, any cycle

can be selected and started and the unit will turn

on the interior drum light, count down the cycle

time in the display, and perform a tumbling

action.

The demo mode will be saved even after the unit

is disconnected from power or if there is a power

interruption. To exit the demo mode, follow the

same procedure used to enter the demo mode.

Loading...

Loading...