Page 1

thermaline S90

FRY TOP GRILL/GRIDDLE, GAS

US INSTALLATION- AND OPERATING INSTRUCTIONS page 3

FR INSTRUCTIONS D’INSTALLATION ET D’EMPLOI page 13

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

-

PLAQUE GRIL ET GRIDDLE, POUR GAZ

Doc.

62.9677.01_UL

Edition 1

05.2006

POUR VOTRE SÉCURITÉ

Ne déposez pas ou n'employez

pas l'essence ou d'autres vapeurs

in the vicinity of this or any other

appliance.

ou liquides inflammables à pro-

ximité de ceci ou d'aucun autre

appareil.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property

damage, injury or death. Read the

installation, operating and

maintenance instructions thoroughly before installing or servicing

this equipment.

AVERTISSEMENT

L'installation inexacte, l'ajuste-

ment, le changement, le service

ou l'entretien peuvent causer des

blessures matériels, des domma-

ges ou la mort. Lisez les instruc-

tions d'installation, d'opération et

d'entretien complètement avant

d'installer ou entretenir cet

équipement.

INSTRUCTION

Post in a prominent location instructions to be followed if the user smells gas. Consult

the local gas supplier to obtain the information.

Présentez dans des instructions en avant d'un endroit d'être suivi si l'utilisateur sent le

gaz. Consultez le fournisseur local de gaz pour obtenir l'information.

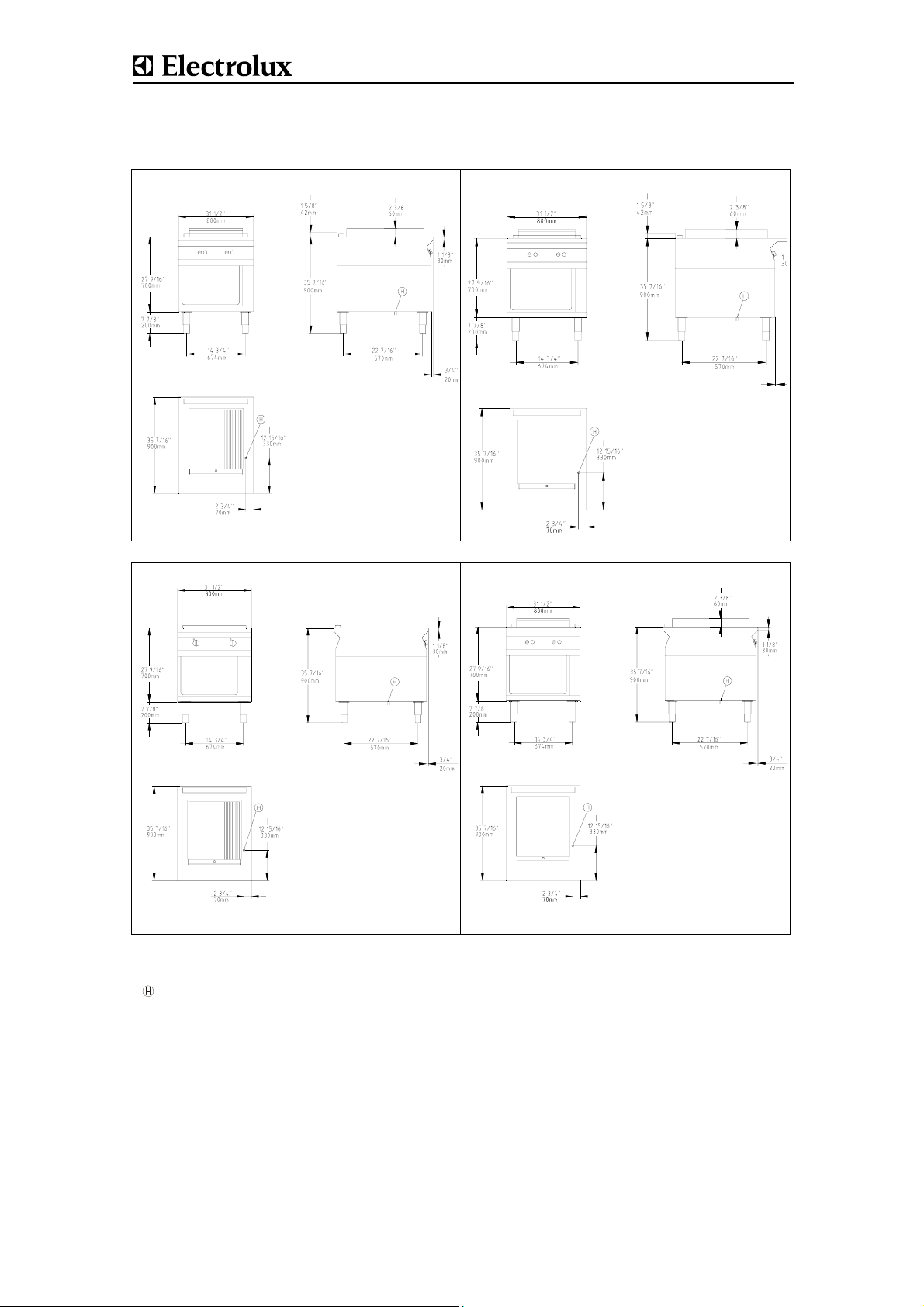

Page 2

Against wall - contre une paroi

Free standing - isolé

Connections - Raccordement

Gas - Gaz

Fig.1 INSTALLATION DRAWINGS - PLANS D'INSTALLATION

Doc. 62.9677.01_UL

Page 3

CONTENTS

I. GENERAL INFORMATION................................................................................................. 3

II. INSTALLATION INSTRUCTIONS....................................................................................... 5

III. OPERATING INSTRUCTIONS............................................................................................ 9

SOMMAIRE

IV. INSTRUCTIONS GÉNÉRALES......................................................................................... 13

V. INSTRUCTIONS RELATIVES À L'INSTALLATION......................................................... 15

VI. INSTRUCTIONS DE FONCTIONNEMENT....................................................................... 19

APPENDIX

VII. Nozzle Table - Tableau de gigleur

62.9677.01_UL Page 1

Page 4

Page 2 62.9677.01_UL

Page 5

I . GENERAL INFORMATION

GENERAL INFORMATION

1. INSTRUCTIONS FOR SAFETY AND USE

1.1 INSTALLATION AND INITIAL OPERATION

S The installation, adjustment and initial opera-

tion of the appliance must be carried out

according to the manufacturer's instructions

and may only be done by an authorised specialist.

S Installations for the supply of electricity and

gas must be carried out by approved specialists in compliance with specific national and

local regulations. They bear the responsibility.

S The installation must conform with local

codes, or in the absence of local codes, with

the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or the Natural Gas and

Propane Installation Code, CSA B1 49.1.

S The appliance and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing of

that system at pressures in excess of 1/2 psi

(3.5 kPA)

S The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure

testing of the gas supply piiping system at

test pressures equal to or less than 1/2 psi

(3.5 kPA)

S The appliance must not be placed in

operation until the user has become familiar

with its operation. The operating instructions

and the related safety precautions must be

followed precisely. Follow strictly the

attention and warning label indications on the

appliances.

1.2 OPERATOR'S OBLIGATIONS

S The manager is responsible for ensuring that

all components relevant to safety are in perfect working order at all times. The operating

condition of these components must be

examined by an authorised specialist at least

once a year and any defects remedied if

required.

S The operator of this appliance is responsible

for total observation of the national regulations concerning operating safety.

S Remain the manual for future reference.

1.3 USE AS PRESCRIBED

S Closed containers (jars, cans, bottles, tubes,

etc.) must not be heated owing to the danger

of bursting and injuries.

S The appliance is only approved for cooking

food in commercial establishments. .

1.4 SAFETY-CONSCIOUS WORKING

S

Touching the hot cooking zones can cause

burns.

S When putting oil, fat, water or ingredients in

the preheated hot frying pan, they may spit -

danger of burning!

S

Overheated oil can ignite spontaneously. Never

use water to extinguish burning oil, but smother

the flames with the lid or a damp cloth.

S Filling quantity and temperature must be sel-

ected as appropriate. At high temperatures

(above 100°C) too much liquid in the trough

can lead to boiling over and spitting. - Dan-

ger of burning!

S The escape of burnable gases represents a

fire and explosion hazard. Action in the case

of a gas leak and a smell of gas:

- No smoking, no fire

- Do not operate electric switches or bells.

- Do not operate the piezo igniter

- Close gas cylinder valves and the main

gas valve on the appliance.

- Ventilate the room thoroughly

- Place the leaking gas cylinders upright in

the open with valves closed.

S The waste-gas outlets of the fryer become

hot. Avoid touching them.

S The waste-gas outlets of the fryer are not to

be covered by any objects.

S Spraying the appliance or parts of it with a

high-pressure cleaning device may cause

malfunctions and is not to be done.

S Keep the appliance area free and clear from

combustibles

S Do not obstruct the flow of combustion and

ventilation air.

S To avoid damage to the appliance, do not let

water flow from the mixer tap onto the cooking plates.

S For appliances with a downpipe, the hose

should lead into a drain opening which is covered by a grating such that it cannot be

kicked or tipped, or a drain gutter should run

underneath the appliance.

S Devices on wheels set up in block configura-

tion must be checked before each start-up

whether the potential equalization is connected with the neighbour equipment. The

connection may be done only by authorized

technical personnel.

S Appliances on wheels must be fastened to

the building.

1.5 AFTER-SALES SERVICE AND REPAIR

S In the event of a permanent fault which inter-

feres with operation, the appliance must be

switched off and disconnected from the

power supply.

S To perform maintenance and repairs contact

the factory, the factory representative or a

local service company.

S Repair, maintenance work and other adjust-

ments are only to be carried out by an

authorised specialist. The valid local and

national regulations must be observed. This

applies especially to burners, ignition, safety

and control elements. Parts requiring

replacement are only to be replaced by original spare parts. Periodic tests for gas leaks

must be carried out. A service contract is

therefore recommended.

S Cleaning and maintenance must be done

only when the heating surfaces are cold. Do

not use inflammable liquids to clean the

appliance.

S An obligatory service check is required

annually.

62.9677.01_UL Seite 3

Page 6

GENERAL INFORMATION

2. TECHNICAL DATA

PNC Appli-

ances

9CHG584122

9CHG584123

9CHG584124

9CHG584125

Appliance type

WHGURFOOOO

WHGUSFOOOO

WHGURAOOOO

WHGUSAOOOO

inch

31.5

35.4

35.4

Width

Depth

Height

mm

800

900

900

Frying

surface

29.4“ x

25.6“

(748 x

649mm)

Power

Gas rating

17.4 kW

59000 BTU

3. PACKAGING

All the packaging materials used are environmentally friendly.

They may burnt at an incineration plant or sent for recycling.

4. TESTS / CERTIFICATES

All gas appliances are tested according to the standard ANSI

Z83.11-2002 and CSA 1.8-2002 of Gas Food Service Equipment.

5. SPECIFICATION PLATE

The specification plate (E) is located in each case inside and

outside on the right of the operator panel (C) (Seite 6 Fig. 5).

The serial number is marked on the type plate. The 8 digits

give following information:

Y last digit of the year of production

WW week of production

XXXXX running number

Seite 4 62.9677.01_UL

Page 7

INSTALLATION INSTRUCTIONS

II . INSTALLATION INSTRUCTIONS

1. INSTALLATION

The appliance is designed for connection to fixed lines. The

appliances are suitable for setting up as single appliances or as

a group of appliances. They can be set up freely in the room,

side by side, at the side and/or at the back against a w al l.

Gaps between two appliances or appliance and sidewall

should be filled with a FDA approved silicone such as Sa mco

RTV103.

1.1 DISTANCES

If an appliance is set up next to or against temperature-sensitive furniture or similar, a safety gap of approximately 6“ (150

mm) should be maintained or some form of heat insulation fitted.

The walls must be made up of non-combustible material like

tiles or steel.

1.2 HEIGHT ADJUSTMENT

Appliance on feet: Alignment is carried out by screwing the

Appliance on

steel plinth:

Appliance on feet.

lower foot parts in or out.

Irregularities or differences in height can

be equalized by inserting one or several

strips of chrome nickel steel.

D Turn the lower part of the feed to adjust the appliance high.

The feet are adjustable from 4“ to 8“ (100 to 200 mm). A high

of 8“ (200 mm) can be recommended and results in an appliance high of 35,4“ (900 mm).

Note:

Adjustment of the legs shall provide an unobstructed

clearance of minimal 6“ (150 mm) and maximal 8“ (200

mm) beneath the unit due to sanitary and stability

aspects.

The lower part of the foot must not be unscrewed too far.

The exposure of threads is prohibited.

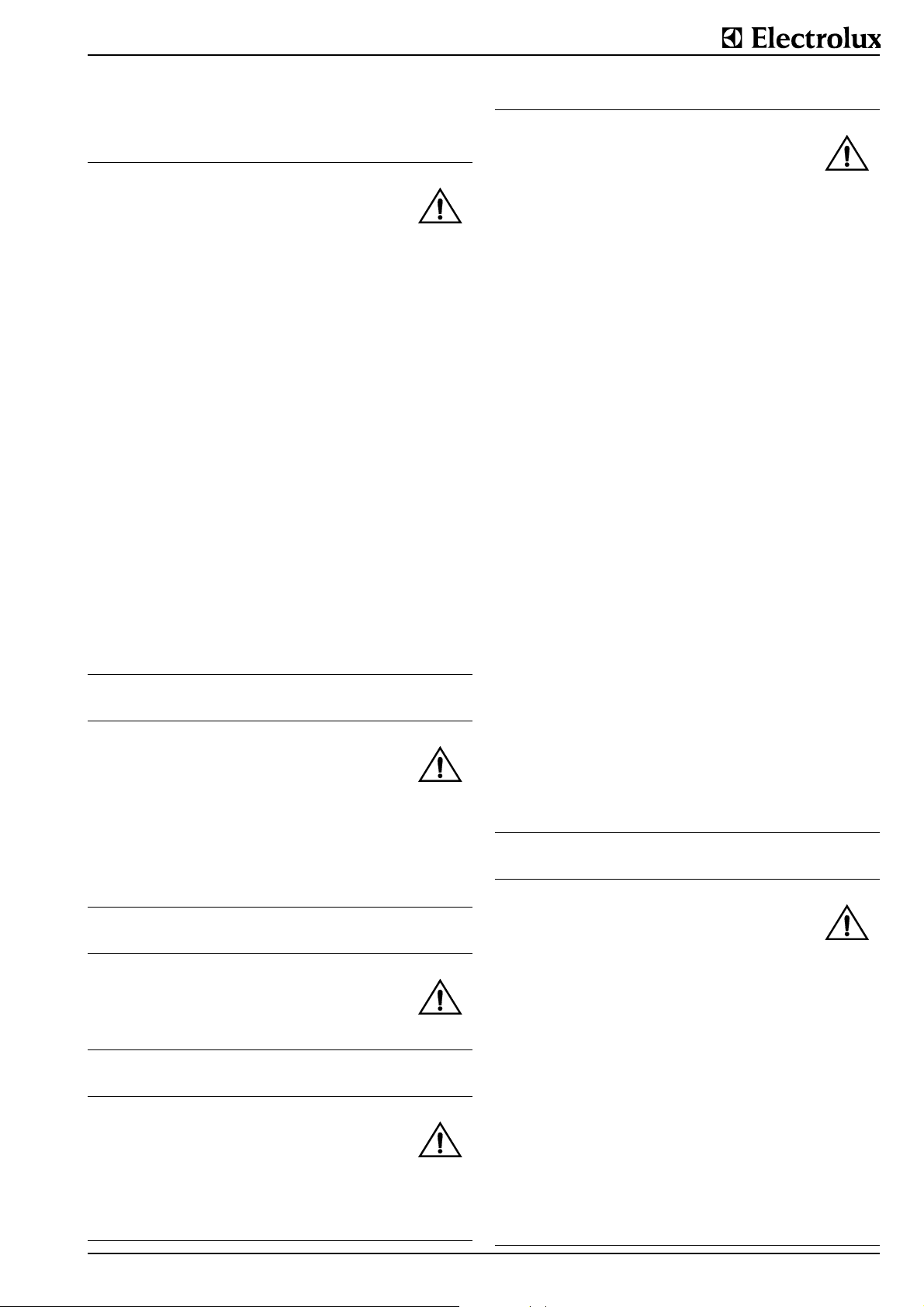

1.3 ASSEMBLING TWO APPLIANCES

(2)

(1)

(1)

(2)

a

b

1

c

Fig.1 Lateral connection

(3a)

(1)

(3b)

(2)

(3c)

(3c)

The assembly kit contains two of each of the following:

caged nuts (1 / Fig.1) pre-assembled on the right-hand side of

the appliance, hexagonal screws M8x25 (1 / Fig.1) and mounting links (2 / Fig.1)

D Remove the control panels from both appliances as in 2.2

D Remove the front panels from both appliances as in 2.1

D Keeping the screw (1 / Fig.1) loose, turn it until it is approxi-

mately 5 mm deep in the caged nut.

Positioning the appliances:

D Place the appliances next to one other.

D Align for position and height.

Connect the appliances:

D Fit the mounting link (2 / Fig.1) into the inside of the second

appliance's left connecting plate.

D Tighten the screws.

Note

If required, the caged nuts can also be fitted on the other side

of the appliance.

62.9677.01_UL Seite 5

Page 8

INSTALLATION INSTRUCTIONS

1.4 SIDEWALL (D)

(5)

1

a

Fig.2 Assemblage of sidewall

The assembly kit contains two of each of the following:

hexagonal screws M8x25 (1 / Fig.1), bolts with retaining rings

(2 / Fig.1), mounting links (3 / Fig.1), hexagonal screws M8x16

with serrated washers and hexagonal nuts M8, hexagonal

screws M5 with serrated washers (4 / Fig.2)

and a fastening angle (5 / Fig.2).

()

(4)

1

b

(3c)

D Insert the bolts with the retaining rings (2 / Fig.1a) from out-

side into the guide in the sidewall.

D Keeping the screw (1 / Fig.1a) loose, turn it until it is

approximately 5 mm deep in the pre-assembled caged

nuts in the sidewall.

D Attach the fastening angle (5 / Fig.2b) to the botto m of the

frame using the screws, serrated washers and nuts.

D (4 / Fig.2).

D Position the sidewall and screw it on from be low using two

hexagonal screws and the serrated washers.

D Fit the mounting link (3 / Fig.1b) in to the inside of the appli-

ance's connecting plate.

D Align the sidewall and firml y tighten all screws.

1.5 STEEL PLINTH

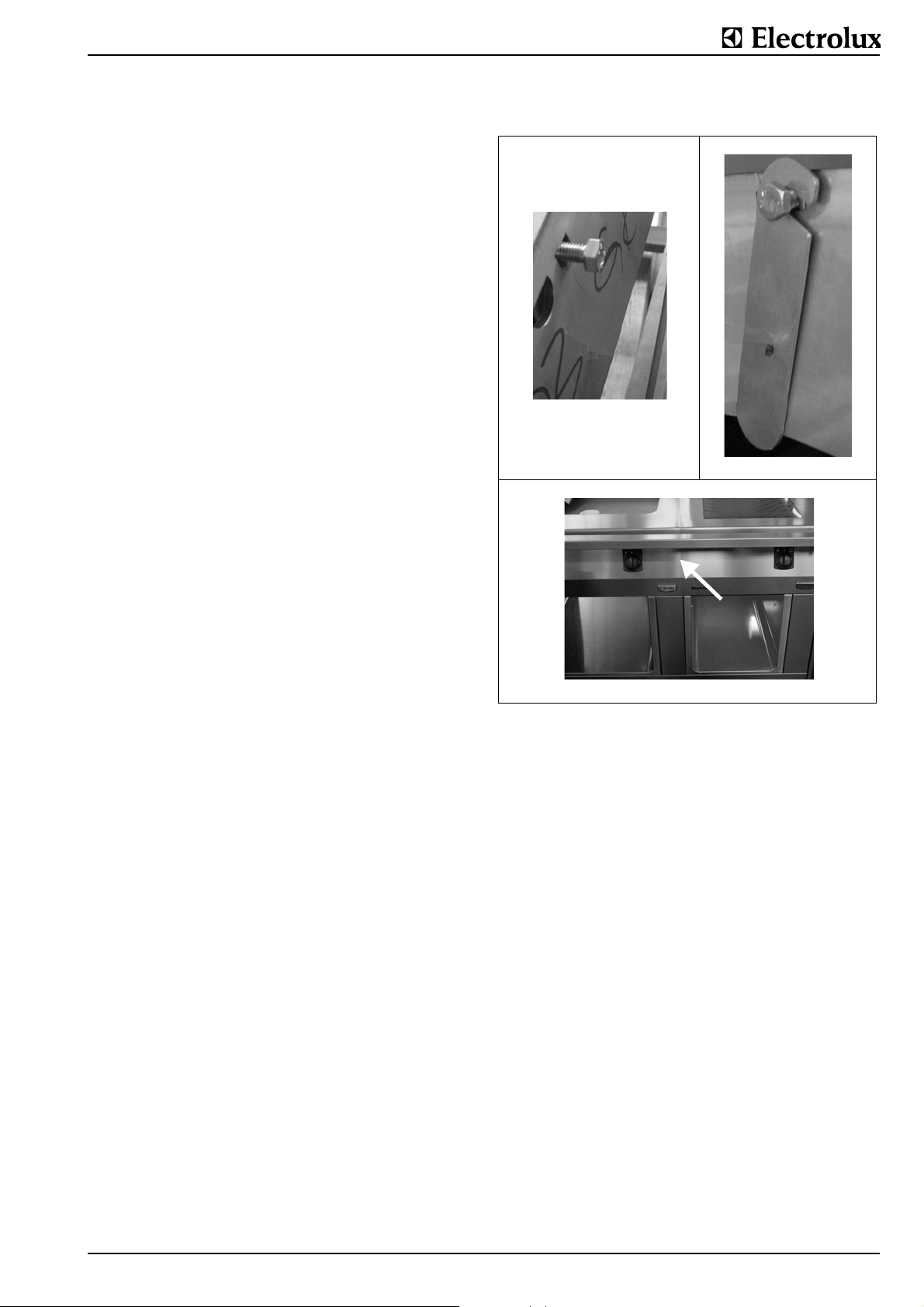

1.6 ASSEMBLING ON CASTORS

(5)

1

a

1

b

Fig.4 Assemblage on castors

The assembly kit for mounting on castors contains two cross

bars (2/Fig.4a) each with a fixed rear wheel (1/Fig.4a) a nd a

turnable front wheel (3/Fig.4a).

Mounting the castors:

(3c)

()

(4)

c

1

(3c)

D Put the appliance on supports.

D Remove the feet; each is tightened with four screws

(Fig.4b).

D Bring the two cross bars in to the correct posi tion belo w the

appliance and fasten it with 8 screws arrows (Fig.4a).

D Remove the supports.

D Fasten the appliance to the building. Use the hole to attach

a chain descending from the wall (arrow/Fig.4c). Making

sure the chain is shorter than the gas and electric connections.

(3)

()

b

(5)

1

a

Fig. 3 Plinth assembly

To assemble the plinth you will need:

• Right and left side plinth (1 / Fig.3).

• Plinth for the front and, for free-standing appliances, for the

rear also (2 / Fig.3).

(2)

(4)

b

(1)

b

(2)

1

(3)

(1)

(3c)

D Push the side plinth (1 / F ig.3) onto the legs from front to

rear using the fastener. The larger gap (b / Fig.3) on the

fastener must be at the bottom.

D Affix the fasteners (3 / Fig.3) to the plinth (2 / Fig.3).

D The larger gap (b / Fig.3) on the fastener must be at the

bottom.

D Attach the plinth with the fasteners (3 / Fig.3) onto the fee t.

Note:

Appliances on wheels must be secured by fas ten it to the

building.

2. ACCESS TO INTERIOR

Note:

Only authorized technicians may access the interior.

E

D

11

Fig. 5 General view

C

B

D

1313

Seite 6 62.9677.01_UL

Page 9

INSTALLATION INSTRUCTIONS

2.1 FRONT PANELS (A) and (B)

(1)

Fig.6 Front panel

D Unscrew screws (1 or 3). Also, in the case of a built-in oven,

unscrew screws (2 and/or 4) on the inside of the oven.

D Pull the panel away forwards and downwards.

2.2 CONTROL PANEL (C)

(2)

(3c)

1

ab

(1)

1

(3c)

3. DOWNPIPE

(3c)

1

a

Fig. 8 Downpipe

Work surfaces with a downpipe (Fig.8a) have the downpipe

opening on the right-hand side of the appliance. A flexible silicon hose when installed in the standard manner ends underneath and to the right, 0.8“ (20 mm) behind the front of the

appliance (Fig.8b).

(1)

b

(3)

c

D Alternatively, the hose can be relocated to the rear and be

routed through other pre-cut openings (Fig.8c).

(3)

Fig. 7 Control panel

c

D Remove the knob.

D Loosen the screws underneath (1 / Fig.7a) and remove the

base plate.

D Loosen the screws (2 / Fig.7b) and 3 / Fig.7c)

D Remove the panel.

2.3 OVEN, STORAGE SPACE, HOT CABINET

D Remove panels A, B and C.

D Undo screws (5).

D Pull out element.

62.9677.01_UL Seite 7

Page 10

INSTALLATION INSTRUCTIONS

4. GAS CONNECTION

The installation of the gas connection, as well as the laying of

the customer's gas line, is only to be carried out by an authorised specialist subject to the relevant national and local regulations.

NOTE

• The gas a ppliance may only be installed in an adequately

ventilated location.

• Appliances ar e set up for na tural ga s. The typ e of g as, gas

pressure and gas category are entered on the specification

plate. Prior to connection, check that the appliance is se t

up for the type of gas available on site. To do this, compare

the details on the specification plate with the existing gas

data.

• If this is not the case, the applian ce must be converted or

adapted by the service personnel responsible to suit local

conditions. The following points should be noted:

- Has the appliance been tested for the new gas data?

- Conversion in accordance with the Service Manual.

- A new specification plate or a durable marking with the

new gas data must be affixed to the appliance.

4.1 CONNECTION

Gas-only appliances as well as combination electric and gas

appliances require a gas connection.

The gas connection is located under the appliance on the right

hand side. For all types the gas connection is NPT 3/4“.

The installation of a dirt trap in the gas supply line by the owner

is recommended.

After connection, all lines carrying gas must be tested for leaks

at operating pressure by painting with non-corrosive foamforming media, (e.g. soapy water or leak spray).

D Retighten the slotted screw in the measuring nipple. Gas

pressure deviation tolerances are laid down by EN 203. If

the existing gas pressure is outside the given tolerances,

correct combustion can no longer be ensured. Compulsory

measures: pressure adjustment by the gas works or conversion of the range by the service personnel. Please refer

to "Conversion to another gas type".

Gas pressure tolerances

Gas pressure variation tolerances are as

follows: mbar

Gas type Normal

pressure

inch

water g.

Natural gas A 7 17.4 3.5 8.7

USA

Liquid gas E 11 27.4 8.0 20

Propane

USA

mbar inch

Min.

pressure

mbar

water g.

4.2 GAS PRESSURE

The current gas pressure should be measured at the Me rtik

regulator with a liquid U-tube manometer (scale at least 0.1

mbar = 1 mm water column).

D Remove the control panel. The measuring nipple is located

in downwards direction at the gas supply pipe before the

two gas valves.

D Close off the mains gas leading to the appliance.

D The measuring nipple is provided at the left side of the reg-

ulator. The incoming pressure is measured in front, the outgoing pressure behind.

D Loosen the slotted screw (1 turn) in the measuring nipple.

Then connect the pressure gauge by attaching a flexible

tube to the nipple (out-side diameter 8 mm).

D Open the main gas leading to the appliance.

D Run all burners on the appliance at full output.

D Check whether the connection pressure is i n permitted tol-

erance.

D Turn off the appliance again.

D Close the main gas valve.

Seite 8 62.9677.01_UL

Page 11

III . OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

1. GENERAL

The appliance is used for frying various types of meat, sausages, fish and vegetables on a gas-heated steel plate.

Optionally the appliance is equipped with a smooth griddle

plate or a combined grill/griddle plate with 1/3 grooved and 2/3

smooth surface.

Plate temperature control is stepless and separate for the left

and right halves of the plate.

A drawer (GN container 2/8) in the open storage space in the

base serves as a drip pan for draining liquids.

Additional equipment:

- G N container 1/1, 2/1,

- Scraper grill/griddle.

2. OPERATION

D For liquid gas operation also open the bottle or ta nk valve.

D Switch on gas burner (Chapters 2.1 and 2.2):

2

1

1Knob

2 Piezo ignition

device

Fig.9 Operating panel

Before starting to fry, moisten the plate lightly with oil so that

the food sticks less.

Each time after frying, the cooking residues must be removed

from the plate. This can be done with the scraper. If the frying

plate is not cleaned, the flow of heat into the food is reduced,

altering cooking time and quality.

2.5.1 Grill plate

The food rests only on the ridges of the grooves and gets a

dark striped pattern, or a diamond-shaped pattern by being turned. The flow of heat into the item being grilled comes mainly

from the ridges. Burnt stripes on the contact surface are a

result of excessive grilling time.

Thick pieces of meat and sausages cannot be properly grilled

with the grooved grill plate alone. To do this requires the combination of grill and griddle plate.

2.5.2 Griddle plate

The full surface of the food is in contact and the heat is transmitted intensively. Frying temperatures of 400 - 480°F (200 250°C) is no problem, even for thick pieces of meat and

sausages.

2.6 COLLECTING LIQUIDS

Draining cooking liquids can be collected in the base unit. A

drawer is provided for this purpose.

Note

D When draining oil, fat or water into the drip pan there may

be spitting - danger of burning!

2.1 IGNITING THE PILOT BURNER

The left and right plate halves are operated separately, each

by a rotary knob (1 / Fig.9) and a Piezo switch.

D Press in the knob (2/Fig.9) of the piezo igniter and tu rn it

clockwise to the stop.

D Hold the knob (2/Fig.9) pu shed in for a few seconds.

D While still pressing, turn it to the left. The gas escaping at

the pilot burner will be ignited.

D After lighting the pilot flame, keep the rotary switch pushed

in for about 10 seconds more.

D If the pilot light goes out again, repeat the whol e pr ocess.

2.2 IGNITING THE MAIN BURNER

D Turn the knob (1/Fig.9) anti-cl ockwise from position 1 pilot

burner ignition to the desired setting.

D Setting 7 equates to the maximum burner output or rated

thermal load.

2.3 TEMPERATURE SELECTION

With the knob (1/Fig.9) the temperature can be steplessly

adjusted between 195 and 570°F (90 and 300°C).

The intensity of the flame can be adjusted between the highest

setting 7 and the lowest setting 1.

2.4 INITIAL OPERATION

Wash the whole plate with hot soapy water, rinse with clean

water and allow to dry. The new appliance should then be heated up for 30 minutes at a temperature of 320°F (160°C).

2.4.1 PREHEATING

D The complete energy supply should be used for heating

up.

2.5 WORKING RULES

The temperature must be adapted to the food to be cooked:

• thin pieces require higher temperatures and shorter cooking times,

• thick pieces require lower temperatures and longer cooking

times.

62.9677.01_UL Seite 9

Page 12

OPERATING INSTRUCTIONS

2.7 SWITCHING OFF THE GRILL/GRIDDLE

2.7.1 MAIN BURNER

D Turn the knob (1/Fig.9) back clockwise from highest setting

7 to pilot burner ignition 1.

The gas supply to the main burner is stopped and the main

flame is shut down. The flame of the pilot burner keeps on

burning and is available for further main burner ignitions.

2.7.2 PILOT BURNER FLAME

D Press the knob (2/Fig.9) lightly and turn clockwise from

pilot burner ignition to Off.

The complete gas supply is cut off and the pilot light

extinguishs.

= Off

D Ignition can only start again when the heating element has

cooled down.

2.7.3 LONG SHUT-DOWNS

The following should be observed when shutting d own for a

long period:

D When operating with l iquid gas, also turn off the bottle or

tank valve.

D Never store the fryer where the temperature can drop

below 32°F (0 °C).

D Rub all chrome n ickel steel surfaces with a cloth soaked in

vaseline oil, to lay down a thin protective coating.

D Air the installation site regularly.

3. CLEANING

The appliance should be cooled before every cleaning

operation.

D Shut off all the gas taps and control valves on the range.

D Use a brush to wash the base plate with hot water to which

a fat-dissolving agent has been added, rinse with hot water

and rub dry. Do not use bleaching and chloric cleaning

agents.

D Heavy soiling can be removed with a scraper.

D Depending on utilization, the pressure tube and the drip

pan should be cleaned periodically with a small brush.

D Wash rust-resistant chrome nickel steel panels with hot

soapy water to which a fat-dissolving agent has been

added and rub them dry.

Note

D The appliance must not be sprayed with a water jet or high-

pressure cleaner.

D The floor directly in fro nt of, near and beh ind the ap pliance

must be cleaned normally without a high-pressure cleaner.

D Never use steel wool, spatulas or ordinary steel wire

brushes for cleaning the surfaces, since the deposition of

steel particles can lead to rust formation. Stainless steel

wool can possibly be used, but only in the grinding direction.

D Never use chloric products (bleaching dye, hydrogen chlo-

ride etc.) for cleaning chrome nickel steel, even if they are

diluted.

D Never use corrosive substances for cleaning the floor

under the appliance (e.g. hydrochloric acid). Clean the

appliance with commercial cleaning agents. Do not use

granular or abrasive agents.

When the flame is correctly adjusted, it must not lift off or backfire when the burner is cold as well as warm.

The flame will backfire into the inside of the burner when the

speed of the gas-air mixture through the burner outlets is too

low, particularly when the air passages are dirty.

The different ignition processes must also take place without

any delays. This concerns: ignition, arc-through and. extending

the flame over the whole burner area.

If the flame fails to meet all the requirements, cleaning or

maintenance is necessary.

4. MALFUNCTION

Malfunction Possible cause Remedy

Plate does not heat up. • The thermal limiter has

• Defective thermostat.

• The capillary tube sen-

Flame smokes. • Gas mix too rich.

Long yellow flame tips. • Mixing tube narrowed by

Flame lifts off. • Exit velocity too high due

Flame flashes back. • Mixture too lean.

No flame or flame too

small.

No flame at low setting. • Blocked low setting

No flame. • Blocked burner gaps.

Flame goes out after control valve release.

Flame too small or too

large.

• Partially blocked burner

• Pressure regulator on

• Insufficient exit velocity

• Soiled airways

• Blocked nozzle.

• Blocked nozzle or mixer

• Blocked gas tap.

•No gas.

• Insufficient gas pres-

• Blocked nozzle.

• Thermo-element insuf-

• Defective thermo-ele-

• Primary air ratio adju-

• Nozzle blocked.

tripped.

sor is damaged.

gaps.

dirt.

to blocked burner gaps.

gas cylinder not opera

ting correctly.

at burner gaps.

tube.

sure.

nozzle.

Pilot burner

ficiently heated (dirty?)

ment

sted.

- Inform After-sales service.

- Inform Customer Service.

- Inform Customer Service.

- Inform Customer Service.

-

- Inform Customer Service.

- Inform Customer Service.

- Check gas tap setting.

- Inform Customer Service.

- Clean pilot burner cap.

- Inform Customer Service.

- Inform Customer Service.

3.1 GAS BURNER

So far as is necessary, the pilot burner and main burner are

cleaned by after-sales service.

3.2 FLAME

In a visual check, the flames must be dark blue without any

upper yellow or orange tips; they must be stable and soot-free

and adhere firmly to the outlets.

If there is a lack of primary air, the flame has yellow streaks

and tips; if there is too much primary air, the flame is short,

transparent and tends to lift off the burner.

Seite 10 62.9677.01_UL

Page 13

OPERATING INSTRUCTIONS

5. STORAGE SPACE

The storage space (Fig.10) is incorporated into the base unit.

Recommended accessories:

- Shelf holder (1) 2 off.

- Shelves (2) 1 off.

1 Shelf holder

2 Shelves

Fig.10 Storage space

62.9677.01_UL Seite 11

Page 14

OPERATING INSTRUCTIONS

Seite 12 62.9677.01_UL

Page 15

I . INSTRUCTIONS GÉNÉRALES

INSTRUCTIONS GÉNÉRALES

1. CONSIGNES DE SÉCURITÉ ET D'UTILISATION

1.1 INSTALLATION ET MISE EN SERVICE

S Le montage, le réglage et la première mise

en service de l'appareil doivent s'effectuer

conformément aux instructions du fabricant

et être confiés exclusivement à un technicien

agréé.

S Les raccordements au réseau électrique et

de distribution du gaz doivent être réalisés

par du personnel agréé, dans le respect des

dispositions locales en vigueur dans le pays

d'installation. Celui-ci sera tenu pour responsable en cas d'installation incorrecte.

S L'installation doit être conforme aux codes en

vigueur localement, ou, en l'absence de

ceux-ci, au code national du gaz combustible, ANSI Z223.1/NFPA 54, ou au code

d'installation du gaz naturel et du propane,

CSA B1 49.1.

S Il faut que l'appareil et la vanne d'arrêt

automatique relative soient déconnectés du

système de tuyauterie d'alimentation du gaz

lors de tout test de pression effectué sur ce

système à des pressions supérieures à 1/2

psi (3,5 kPA)

S L'appareil doit être isolé du système de

tuyauterie d'alimentation du gaz en fermant

manuellement la vanne d'arrêt automatique

lors de tout test de pression effectué sur ce

système à des pressions de test équivalentes ou inférieures à 1/2 psi (3,5 kPA)

S L'utilisateur ne doit pas mettre l'appareil en

marche avant de s'être familiarisé avec son

fonctionnement. Il est impératif de suivre les

instructions et les consignes de sécurité

indiquées dans la Notice d'emploi. Respecter

rigoureusement les signaux d'avertissement

et de mise en garde appliqués sur les

appareils.

1.2 OBLIGATIONS DE L'UTILISATEUR

S Il incombe à l'utilisateur de garantir l'efficacité

permanente de toutes les pièces importantes

pour la sécurité de l'appareil. Il convient de

faire contrôler le bon fonctionnement de ces

pièces au moins une fois par an par un technicien agréé et de les remettre à neuf, si

nécessaire.

S L'utilisateur est pleinement tenu de se con-

former à la réglementation nationale en

matière de sécurité de fonctionnement de

ces appareils.

S Le mode d'emploi doit être conservé pour

toute consultation ultérieure.

1.3 UTILISATION CORRECTE

S Les récipients hermétiques ne doivent pas

être chauffés sous peine de les faire exploser

et de provoquer des blessures.

S L'appareil ne doit en aucun cas être utilisé

pour frire des aliments.

1.4 TRAVAILLER EN TOUTE SÉCURITÉ

S On peut se brûler si l'on entre en contact

avec les plaques chaudes.

S Si vous remplissez une poêle préchauffée, et

donc très chaude, avec de l'huile, de la

graisse, de l'eau ou des aliments, ceux-ci

peuvent provoquer des éclaboussures - Danger de brûlures !

S L'huile, lorsqu'elle est surchauffée, peut

prendre feu. Ne jetez jamais d'eau sur de

l'huile en feu, mais éteignez les flammes en

posant le couvercle de l'ustensile de cuisson

ou à l'aide d'un linge mouillé.

S Il faut sélectionner la température et le

volume de remplissage. Si la température est

supérieure à 100°C, le liquide dans le bac

peut bouillir et déborder. - Danger ! Risque

de brûlures !

S Les fuites de gaz combustible sont source de

risque d'incendie et d'explosion. Comportement à adopter en cas de fuite ou d'émanations de gaz :

- Évitez de fumer et d'allumer du feu

- N'actionnez ni interrupteurs ni sonneries

électriques ni piezo

- N'actionnez pas piezo-allumeur

- Fermez les valves des bouteilles de gaz

et le robinet à gaz principal sur l'appareil

- Aérez soigneusement la pièce

- Transportez les bouteilles de gaz défectueuses en plein air, fermez le robinet et

laissez-les en position verticale.

S Les orifices prévus pour les gaz d'échappe-

ment du four deviennent chauds lorsque le

four est en service ; évitez de les toucher.

S Évitez d'obstruer les orifices prévus pour les

gaz d'échappement du four avec des objets.

S L'aspersion de l'appareil ou de ses éléments

à l'aide d'appareils de nettoyage sous

pression est à proscrire, car ceux-ci peuvent

engendrer des défauts de fonctionnement.

S Ne rangez pas de matériaux combustibles à

proximité de l'appareil.

S Veillez à ce que l'évacuation des produits de

la combustion ne soit pas entravée et que les

bouches d'aération ne soient pas obstruées.

S Sur les appareils équipés d'une sortie, il con-

vient soit de raccorder le flexible à l'orifice de

sortie muni d'une grille résistante avec couvercle anti-usure et anti-basculement ou de

disposer une rigole de déversement au-dessous de l'appareil.

S Les appareils sur roues installés dans une

configuration multiple doivent être contrôlés

avant chaque démarrage si le conducteur

d'équipotentialité est reliée à l'installation du

voisin. La connexion doit exclusivement être

confiée à des techniciens agréés.

S Les appareils sur roues doivent être fixés au

mur.

62.9677.01_UL Page 13

Page 16

INSTRUCTIONS GÉNÉRALES

1.5 SERVICE-APRÈS-VENTE ET RÉPARATION

S Si un problème persistant empêche le

fonctionnement correct de l'appareil, mettezle hors tension et débranchez-le.

S Pour toute opération d'entretien ou de répa-

ration, adressez-vous au fabricant, à un

représentant agréé ou au Service Aprèsvente local.

S Toute opération de réparation, d'entretien et

de réglage doit être effectuée par un technicien agréé, en respectant les dispositions

locales en vigueur dans le pays d'installation.

Ceci concerne en particulier les dispositifs

des brûleurs, d'allumage, de sécurité et de

réglage. Les pièces défectueuses doivent

être remplacées par des pièces d'origine.

L'étanchéité du dispositif d'arrivée du gaz

doit faire l'objet de contrôles réguliers.

Par conséquent, il est recommandé de stipuler un contrat d'entretien pour votre

appareil.

S Les opérations de nettoyage et d'entretien de

votre appareil doivent s'effectuer lorsque les

surfaces chauffantes sont froides. N'utilisez

jamais de liquides inflammables pour nettoyer votre appareil.

S L'appareil doit faire l'objet d'une révision

générale à une fréquence annuelle.

3. EMBALLAGE

Tous les matériaux d'emballage utilisés sont non polluants.

Ils peuvent être brûlés dans une installation d'incinération ou

recyclés.

4. TESTS / CERTIFICATS

Tous les appareils à gaz sont testés conformément aux standard ANSI/NSF 4 - 2002, Commercial Cooking, Rethermalization, and Powered Hot Food Holding and Transport Equipment

et ANSI Z83.11-2002 et CSA1.8-2002, Gas Food Service

Equipment.

5. PLAQUE SIGNALÉTIQUE

La plaque signalétique (E) figure à l'intérieur et à l'extérieur du

panneau de commandes (C), à droite (Page 16 Fig.5).

Le numéro à 8 chiffres de la plaque signalétique est composé

comme suit:

Y dernier chiffre de l'année de fabrication

WW semaine de fabrication

XXXXX numéro d'ordre

2. DONNÉES TECHNIQUES

Appareil PNC

9CHG584122

9CHG584123

9CHG584124

9CHG584125

Modèle de l'appareil

WHGURFOOOO

WHGUSFOOOO

WHGURAOOOO

WHGUSAOOOO

Largeur

Profondeur

Hauteur

inch

31.5

35.4

35.4

Superficie Puissance

mm

29.4“ x

800

25.6“

900

(748 x

900

649mm)

Consommation

de gaz

17.4kW

59000 BTU

Page 14 62.9677.01_UL

Page 17

INSTRUCTIONS RELATIVES À L'INSTALLATION

II . INSTRUCTIONS RELATIVES À L'INSTALLATION

1. MISE EN PLACE

Cet appareil est conçu pour être raccordé à des conduites

fixes. Les appareils peuvent être montés individuellement ou

en groupe. Ils peuvent être installés de façon indépendante,

côte à côte, avec un côté et/ou la partie arrière de l'appareil

reposant contre une paroi.

Les interstices entre deux appareils ou entre un appareil et le

mur latéral doivent être comblés avec du silicone homologué

par le FDA tel que Samco RTV103.

1.1 DISTANCES

Si l'appareil doit être monté au-dessus ou à côté de meubl es

sensibles à la température, il convient de prévoir un espace de

6“ (150 mm) environ entre l'appareil et le meuble ou d'appliquer un panneau d'isolation thermique.

Les parois doivent être fabriquées en un matériau non combustible, tel que carreaux ou revêtement en acier.

1.2 RÉGLAGE DE LA HAUTEUR

Appareil muni

de pieds :

Appareil installé

sur un socle en

acier :

Appareil sur des pieds.

Le réglage s'effectue en vissant ou en

dévissant la partie inférieure des pieds.

Si le sol présente des irrégularités ou des

dénivellations, corrigez celles-ci en plaçant

une ou plusieurs tôles en nichrome en dessous de l'appareil.

D Tournez la partie plus inférieure de l' alimentation pour aju-

ster la haute d'appareils.

L'alimentation sont réglable de 4“ à 8“ (100 à 200 mm). Une

haute de 8“ (200 mm) peut être recommandée et des résultats

dans une haute d'appareils de 35,4“ (900 mm).

1.3 ASSEMBLAGE DE DEUX APPAREILS

(2)

(3b)

(1)

a

(1)

(2)

(2)

(3c)

b

1

(3a)

(1)

(3c)

Note :

L'ajustement des pieds fournira un dégagement dégagé

des 6“ (150 mm) minimaux et des 8“ (200 mm) maximaux

sous l'unité due aux aspects sanitaires et de stabilité.

La partie plus inférieure du pied ne doit pas être dévissée

trop loin. L'exposition des fils est interdite.

c

Fig.1 Raccordemen t latéral

Chaque kit d'assemblage comprend respectivement deux

écrous en cage (1 / Fig.1) pré-montés à l'avant droit de

l'appareil et des éclisses (2 / fig 1),

D Retirez les panneaux de commande des deux appareils

comme indiqué en 2.2

D Retirez les panneaux avant des deux appareils comme

indiqué en 2.1

D Vissez la vis (1 /fig. 1) à env. 5 mm de profondeur dans

l'écrou en cage.

Positionnement des appareils :

D Placez les deux appareils l'un à côté de l'autre.

D Ajustez la position et la hauteur :

Assemblage des appareils :

D Insérez l'éclisse (2 / fig. 1) à l'intérieur sur la plaque

d'assemblage droite du deuxième appareil.

D Serrez fermement les vis.

N.B. :

Au besoin, les écrous en cage peuvent également être appliqués sur l'autre côté de l'appareil.

Le raccordement de deux appareils (fig. 1c, flèche) doit correspondre aux règlements hygiéniques respectifs le standard

NSF/ANSI 4. Tout le résulter joint et des coutures dans une

zone exposée aux projections seront scellées et lisser.

62.9677.01_UL Page 15

Page 18

INSTRUCTIONS RELATIVES À L'INSTALLATION

1.4 PAROI LATERALE (D)

(5)

1

a

Fig.2 Montage du paroi latérale

Chaque kit d'assemblage comprend respectivement deux

vis hexagonales M8 x 25 (1 / Fig.1), des boulons avec circlip (2

/ Fig.1), des éclisses (3 / Fig.1), des vis hexagonales M8 x 16

avec rondelles à denture intérieure et des vis hexagonales M8,

des vis hexagonales M5 avec rondelles à denture intérieure (4

/ Fig.1)

et une équerre de fixation (5 / Fig.2).

()

(4)

1

b

(3c)

D Insérez les boulons avec circlip (2 / Fig.1a) depuis

l'extérieur dans l'orifice prévu à cet effet dans la paroi

latérale.

D Vissez la vis (3 / Fig.1) à env. 5 mm d e profondeur dans

l'écrou en cage pré-monté dans la paroi latérale.

D Fixez l'équerre de fixation (5 / Fig.2b) à l'aide des vis, des

rondelles à denture intérieure et des écrous en bas du

châssis. (4 / Fig.2)

D Positionnez la paroi l atérale et vissez le bas à l'aide des

deux vis hexagonales et des rondelles à denture intérieure.

D Insérez l'éclisse (3 / Fig.1a) à l'intérieur de l'apparei l sur la

plaque d'assemblage.

D Ajustez la paroi latérale et serrez toutes les vis.

1.5 SOCLE EN ACIER

1.6 ASSEMBLAGE SUR ROULETTES

(5)

1

a

1

b

Fig.4 Assemblage sur roulettes

Le kit de montage sur roulettes contient deux barres

transversales (2/Fig.4a) respectivement fixées sur une roue

arrière fixe (1/Fig.4a) et une roue avant pivotante (3/Fig.4a).

Montage des roulettes :

(3c)

()

(4)

c

1

(3c)

D Mettre l'appareil sur des supports.

D Enlever les pieds respectivement fixés avec quatre vis

(Fig.4b).

D Mettre les deux barres transversales dans la bonne

position au-dessous de l'appareil et le fixer avec 8 vis

repérées par les flèches (Fig.4a).

D Enlever les supports.

D Fixer l'appareil a u bâtiment. Utiliser le trou pour fixer une

chaîne descendant du mur (flèche Fig.4c). S'assurer que la

chaîne est plus courte que les raccordements de gaz et

d'électricité.

(3)

()

b

(5)

1

a

Fig.3 montage du socle

Eléments requis pour le montage du socle :

• Socles latérau x droit et gauche (1 / Fig.3).

• Socle po ur panneau avant et, pour les appareils auto nomes, pour panneau arrière également (2 / Fig.3).

(2)

(4)

b

(1)

b

(2)

1

(3)

(1)

(3c)

D Poussez les pieds du socle latéral (1 / Fig.3) d'avant en

arrière à l'aide de l'attache. L'intervalle le plus grand avec

l'attache (b / fig. 3) doit se situer en bas.

D Placez les attaches (3 / fig. 3) sur le socle (2 / Fig.3).

D L'intervalle le plus grand avec l'attache (b / Fig.3) doit se

situer en bas.

D Placez le socle sur les pieds à l'aide des attaches (3 /

Fig.3).

N.B. :

Les appareils sur roulettes doivent être bloqués en les

fixant au bâtiment.

2. ACCÈS À L'INTÉRIEUR

N.B.:

Seulement les techniciens autorisés peuvent accéder à

l'intérieur.

C

E

A

B

D

D

1

1

Fig.5 Vue d´ensemble

2

55

4

33

Page 16 62.9677.01_UL

Page 19

INSTRUCTIONS RELATIVES À L'INSTALLATION

2.1 PANNEAU AVANT (A) et (B)

(1)

Fig.6 Panneau avant

D Desserrez les vis (1 et 3 Fig.6, Fig.5). Si le four est

encastré, desserrez

D Extrayez le panneau vers l'avant et le bas.

2.2 PANNEAU DE COMMANDE (C)

(2)

(3c)

1

ab

(1)

1

(3c)

3. SORTIE

(3c)

1

a

Fig.8 Sortie

(3Les plans de travail avec sortie (fig. 8a) sont pourvus d'un

orifice de sortie à droite de l'appareil. Un flexible en silicone

installé en série débouche en bas à droite, 20 mm derrière le

panneau avant de l'appareil (fig. 8b). Le flexible peut, au choix,

être placé à l'arrière.

(1)

b

(3)

c

D Dans ce cas, on le fait passer à travers d'autres orifices

pré-perforés (fig. 8.c).

(3)

Fig.7 Panneau de commande

c

D Enlever l'interrupteur rotatif.

D Dévissez les vis placées au-dessous (1 / fig. 7a) et enlevez

la plaque support.

D Dévissez les vis (2 / fig. 7b) et 3 / fig. 7c)

D Enlevez le panneau de commande.

2.3 FOUR À CUIRE, ESPACE DE RANGEMENT,

ARMOIRE DE MAINTIEN AU CHAUD

D Retirez les panneaux A, B et C.

D Desserrez les vis (5 / Fig.5).

D Extrayez l'élément.

62.9677.01_UL Page 17

Page 20

INSTRUCTIONS RELATIVES À L'INSTALLATION

4. RACCORDEMENT AU GAZ

Le raccordement au gaz, de même que la pose de la conduite

d'arrivée de gaz doivent être réalisés exclusivement par un

spécialiste agréé, dans le respect des dispositions nationales

et locales en vigueur.

INSTRUCTIONS

• L'appareil à gaz doit i mpérativement être installé dans une

pièce suffisamment ventilée.

• Les appareils sont prévus pour fonctionner avec du gaz

naturel. Le type, la pression et la catégorie du gaz sont

spécifiés sur la plaque signalétique. Avant d'effectuer le

raccordement, il y a lieu de contrôler si l'appareil est réglé

pour le type de gaz disponible. Pour ce faire, comparez les

données figurant sur la plaque signalétique avec celles

relatives au gaz.

• Si les données ne correspondent pas, le personnel du Service Après-Vente responsable devra procéder à la conversion ou à l'adaptation de l'appareil en fonction des

conditions locales. Il conviendra dans ce cas de respecter

les points suivants :

- L'appareil est-il homologué par rapport aux nouvelles

données du gaz ?

- La conversion doit être réalisée conformément au

manuel d'entretien.

- Une nouvelle plaque signalétique ou une indication

indélébile présentant les nouvelles caractéristiques du

gaz doit être appliquée sur l'appareil.

D Resserrer la vis à fente dans la prise de mesure. Les

écarts de tolérance de la pression de gaz sont stipulés

dans l'EN 203. Si la pression de gaz existante dépasse les

tolérances prescrites, une combustion correcte ne peu plus

être garantie. Mesures obligatoires : ajustement de la pression par l'usine à gaz ou conversion de la cuisinière par le

personnel qualifié. Veuillez vous référer au point " Conversion à un autre type de gaz ".

Tolérances pour la pression de gaz

Les tolérances pour les variations de pression

de gaz sont les suivantes : mbar

Type de gaz Pression

normale

inch

water g.

Gaz naturel A 7 17.4 3.5 8.7

USA

Gaz liquide E 11 27.4 8.0 20

Propane

USA

mbar inch

Pression

min.

mbar

water g.

4.1 RACCORDEMENT

Les appareils fonctionnant uniquement au gaz tout comme les

appareils mixtes fonctionnant à l'électricité et au gaz doivent

être branchés au gaz.

Le raccordement de gaz se trouve sous l'appareil, à droite.

Pour tous les modèles, le raccordement de gaz est de type

NPT 3/4“.

Nous vous conseillons de demander à l'installateur de poser

un collecteur d'impuretés à l'intérieur de la conduite de gaz.

Une fois le raccordement effectué, toutes les tuyauteries du

gaz doivent être contrôlées à la pression de fonctionnement

afin de s'assurer de leur étanchéité, en les badigeonnant

d'agents mousseux non corrosifs (eau savonneuse ou vaporisateur de détection des fuites, par ex.).

4.2 PRESSION DE GAZ

La pression instantanée de gaz devrait être mesurée au régulateur Mertik à l'aide d'un manomètre à tube en U (échelle minimum 0 .1 mbar = colonne d'eau de 1 mm).

D Retirer le panneau de contrôle. La prise de pression est

située vers le bas, sur le conduit d'arrivée du gaz, avant les

deux robinets de gaz.

D Fermer le conduit de gaz principal menant à l'appareil.

D La prise de pression est située sur le côté gauche du régu-

lateur. La pression d'entrée est mesurée à l'avant et la

pression de sortie à l'arrière.

D Desserrer la vis à fente (1 tour) dans la prise de pression.

Connecter ensuite la jauge de pression en fixant un tube

flexible à la prise (diamètre externe 8 mm).

D Ouvrir le conduit de gaz principal menant à l'appareil.

D Faire fonctionner tous les brûleurs de l'appareil à plein

débit.

D Vérifier si la pression de connexion ne dépasse pas le seuil

de tolérance admis.

D Eteindre à nouveau l'apparei l.

D Fermer le robinet de gaz principal.

Page 18 62.9677.01_UL

Page 21

INSTRUCTIONS DE FONCTIONNEMENT

III . INSTRUCTIONS DE FONCTIONNEMENT

1. GÉNÉRALITÉS

Cet appareil est destiné à griller et à rôtir différents types de

viande, de la saucisse, du poisson et des légumes.

L'appareil peut être équipé au choix d'un plat à cuire plat ou

des deux utensiles 1/3 d'un plat à grillade à rainures, 2/3 d'un

plat à cuire plat.

Le réglage de la température de la base s'effectue graduellement et de manière séparée pour les moitiés gauche et droite

du plat.

Un tiroir (récipient GN 2/8), situé dans l'espace de rangement

prévu dans la partie inférieure de l'appareil, récolte les liquides

qui s'écoulent des plats.

Équipement auxiliaire :

- Récipient GN 1/1, 2/1,

- G rattoir Gril/Plat à cuire.

2. COMMANDE

D En cas d'utilisation de gaz liquide, ouvrez la valve de la

bouteille ou du réservoir de gaz :

2

1

1 Poignée

2 Piézo-élec-

trique

2.4.1 PRÉCHAUFFAGE

D Pour préchauffer votre appareil, un apport maximum

d'énergie est nécessaire.

2.5 RÈGLES DE TRAVAIL

La température doit être adaptée à l'aliment à cuire :

• les pièces de faible épaisseur nécessitent des températures élevées et des temps de cuisson courts,

• les pièces épaisses nécessitent des températures plus

basses et des temps de cuisson plus longs.

Il est nécessaire de badigeonner le plat d'huile avant de commencer à rôtir l'aliment pour éviter que celui-ci n'adhère au

fond du plat.

Dès que le processus de rôtissage est terminé, il convient

d'éliminer tous les résidus alimentaires du plat, éventuellement

à l'aide du grattoir fourni avec l'appareil. Si vous ne le faites

pas, le flux de chaleur dirigé vers l'aliment à cuire sera réduit,

ce qui modifiera le temps de cuisson et la qualité de celle-ci.

2.5.1 Plat à grillade

L'aliment à cuire repose uniquement sur les crêtes des rainures et acquiert un motif à lignes foncées, ou en forme de

losange lorsqu'on retourne l'aliment. La chaleur pénètre dans

l'aliment à griller principalement à travers les crêtes des rainures. Si des lignes brûlées apparaissent sur la surface du

revêtement, cela signifie que le temps de cuisson a été trop

long.

Il n'est pas possible de cuire à point de gros morceaux de

viande et des saucisses en utilisant uniquement le plat à grillade à rainures. Dans ce cas, il est nécessaire d'utiliser conjointement le plat à grillade et le plat à cuire plat.

Fig.9 Panneau de commande

2.1 ALLUMAGE DU DISPOSITIF D'ALLUMAGE

Les moitiés gauche et droite du plat sont actionnées séparément à travers une poignée tournante (1 / Fig.10) et un bouton

piézo-électrique uniques.

D Appuyez sur la poignée (2/Fig. 10) pou r déclencher l'allu-

mage piézo-électrique et tournez-la dans le sens des

aiguilles d'une montre jusqu'à la butée.

D Maintenez la poignée (2/Fig. 10 ) enfoncée pendant quel-

ques secondes.

D Tournez-la vers la gauche tout en la mainten ant enfoncée.

Cette opération provoquera l'allumage du gaz qui

s'échappe du dispositif d'allumage.

D Maintenez la poignée enfoncée pen dant encore 10 secon-

des environ jusqu'à ce que la flamme pilote soit allumée.

D Si la flamme s'éteint, répétez l'opération décrite ci-dessus.

2.2 ALLUMAGE DU BRÛLEUR PRINCIPAL

D Tournez la poignée (1/Fig. 10) de la position 1 de l'allu-

mage du dispositif d'allumage dans le sens inverse des

aiguilles d'une montre jusqu'à la position souhaitée.

D La position 7 correspond à la puissance maximale du

brûleur ou à la puissance calorifique nominale.

2.3 SÉLECTION DE LA TEMPÉRATURE

La température peut être réglée graduellement entre 195°F et

570°F (90 et 300°C) au moyen de la poignée tournante

(1/Fig.10).

L'intensité de la flamme se règle entre la position haute 7 et la

position basse 1.

2.4 PREMIÈRE MISE EN SERVICE

Nettoyez soigneusement l'ensemble du plat à l'eau savonneuse, rincez à l'eau claire et laissez sécher. Ensuite, réglez la

température sur 320°F (160°C) et faites chauffer le nouvel

appareil pendant 30 minutes.

2.5.2 Plat à cuire

L'aliment à cuire repose sur toute la surface du plat et la chaleur est diffusée avec davantage d'intensité. Il vous est possible de rôtir de gros morceaux de viande et des saucisses à

des températures comprises entre 200 et 250°C sans aucun

problème.

2.6 RÉCOLTE DES LIQUIDES

Les liquides résultant de la cuisson peuvent être recueillis

dans la partie inférieure de l'appareil, dans un tiroir prévu à cet

effet.

N.B. :

D L'huile, la graisse ou l'eau tombant dans le tiroir peuvent

provoquer des éclaboussures - Danger de brûlures !

2.7 EXTINCTION

2.7.1 BRÛLEUR PRINCIPAL

D Tournez à nouveau la poignée (1/Fig. 10) dans le sens des

aiguilles d'une montre, de la position haute 7 vers la position d'allumage du dispositif d'allumage 1.

L'amenée de gaz vers le brûleur principal est interrompue

et la flamme principale s'éteint. La flamme du dispositif

d'allumage continue de brûler, dans l'attente d e l'allumage

éventuel du brûleur principal.

2.7.2 FLAMME DU DISPOSITIF D'ALLUMAGE

D Appuyez légèrement sur la poign ée (2/Fig. 10) et tournez-

la dans le sens des aiguilles d'une montre, de la position

d'allumage du dispositif d'allumage vers la position d'Arrêt.

L'amenée du gaz est interrompue et la flamme s'éteint.

D

= Off

D Un nouvel allumage sera possible uniquement lorsque

l'élément chauffant sera refroidi.

2.7.3 MISE HORS SERVICE

Lorsque l'appareil est mis hors service pendant une longue

période, il convient d'observer ce qui suit :

D En cas d'utilisation de gaz liquide, fermez également la

valve de la bouteille ou du réservoir à gaz.

62.9677.01_UL Page 19

Page 22

INSTRUCTIONS DE FONCTIONNEMENT

D N'entreposez jamais l'a ppareil dans un lieu où la tempéra-

ture peut descendre en dessous de 32°F (0°C).

D Appliquez un peu d'huile de vaseline à l'aide d'un torchon

humide sur toutes les surfaces en nichrome, afin de former

une fine couche de protection.

D Aérez régulièrement la pièce où est installé l'appareil .

3. NETTOYAGE

Avant de procéder au nettoyage de l'appareil, attendez qu'il

soit froid.

D Arrêtez tous les robinets de gaz et soupapes de com-

mande de l'appareil.

D Nettoyez les plaqu es à l'aide d'une brosse trempée dans

de l'eau chaude additionnée d'un peu de dé tergent à vaisselle. Rincez à l'eau chaude et laissez sécher. N'utilisez en

aucun cas de produits de blanchiment ou à base de chlore.

D Éliminez au besoin les grosses sal issures à l'aide du grat-

toir.

D Nettoyez l'orifice d'é coulement des liquides et le tiroir de

récolte des liquides après chaque utilisation avec une

petite brosse.

D Nettoyez les revêtements en nichrome anti-rouille à l'eau

savonneuse, additionnée d'un peu de détergent à vaisselle, et essuyez soigneusement.

NB:

D Ne nettoyez jamais l'ap pareil à l'ai de d'un je t d'eau ou d'un

appareil de nettoyage sous pression.

D Nettoyez le sol tout auto ur de l'appareil selon la méthode

traditionnelle, à savoir sans utiliser d'appareil de nettoyage

sous pression.

D N'utilisez en aucun cas de la laine de fer, des spatules ou

des brosses métalliques en acier non traité pour ne ttoyer

les surfaces, car les particules de fer susceptibles de s'y

déposer pourraient entraîner la formation de rouille. Vous

pouvez éventuellement utiliser de la laine en acier allié, en

la faisant toutefois glisser dans le sens de l'abrasion.

D Pour le nettoyage des parties en nichrome, n'utilisez

jamais de produits à base de chlore (eau de Javel, produit

contenant de l'eau chlorurée, etc.), même sous une forme

diluée.

D Ne nettoyez en aucun cas le fond extérieur de l'appareil au

moyen de substances corrosives (acide muriatique, par

ex.), mais utilisez les produits de nettoyage disponibles

dans le commerce.

3.1 BRULEUR

Des brûleurs d'allumage et des brûleurs principaux deviennent, pour autant que nécessairement, nettoyé du service

Après-vente.

4. PROBLÈME

Problème Cause Solution

Le plat ne chauffe plus. • Le dispositif de thermo-

La flamme produit beaucoup de suie.

La pointe des flammes est

longue et de couleur jaune.

La flamme s'éteint. • La vitesse de re foule-

Il y a des retours de

flamme.

Il n'y a pas de flamme ou

l'intensité de la flamme est

trop faible

Il n'y a pas de flamme lorsque le réglage est au

ralenti.

réglage s'est déclenché.

• Le thermostat est

défectueux.

• La sonde du tuyau

capillaire est défectu

euse.

• Le mélange gazeux est

trop épais.

• Les orifices du brûleur

sont partiellement bou

chés.

• La section du tuyau de

mélange est rétrécie en

raison de la présence de

salissures.

ment est trop élevée

suite à l'encrassement

des orifices du brûleur.

• Le régulateur de pression

du gaz en bouteille est

défectueux.

• Le mélange de gaz est

trop pauvre.

• La vitesse de refoulement au niveau des orifices du brûleur est

insuffisante.

• Les voies d'aération sont

encrassées

• L'injecteur est obstrué.

• L'injecteur ou le tuyau de

mélange est obstrué.

• Le tuyau d'arrivée du gaz

est obstrué.

• Il n'y a pas de gaz.

• La pression du gaz est

trop basse.

• L'injecteur du ralenti est

obstrué.

Dispositif d'allumage

Il n'y a pas de flamme. • Les orifices du brûleur

La flamme s'éteint après le

relâchement de la soupap e

de régulation.

La flamme est trop ou pas

assez puissante.

sont obstrués.

• L'injecteur est obstrué.

• Le thermoélément ne

chauffe pas suffisam

ment (est-il encrassé ?)

• Le thermoélément est

défectueux.

• Le rapport d'air primaire

est déréglé.

• L'injecteur est bouché.

- Adressez-vous au Service Après-vente.

-

- Adressez-vous au Service Après-vente

-

- Adressez-vous au Service Après-vente

- Adressez-vous au Service Après-vente

- Adressez-vous au Service Après-vente

- Adressez-vous au Service Après-vente

- Vérifiez l'installation du

tuyau d'arrivée du gaz.

- Adressez-vous au Service Après-vente

- Nettoyez la calotte du

dispositif d'allumage.

- Adressez-vous au Ser-

-

vice Après-vente.

- Adressez-vous au Service Après-vente.

3.2 FLAMMES

A l'œil nu, les flammes doivent être de couleur bleu foncé sans

pointe jaune ou orange et stables. Elles ne doivent pas produire de suie et doivent adhérer, en outre, correctement aux

ouvertures de sortie.

En l'absence d'air primaire, la flamme présente des vein es et

des pointes jaunes ; si la quantité d'air primaire est trop

importante, la flamme est courte, transparente et tend à se

détacher du brûleur.

Lorsque la flamme est réglée correctement, elle ne doit pas se

détacher du brûleur, que celui-ci soit froid ou chaud , et ne doit

pas donner de retours.

Un retour de flamme se produit à l'intérieur du brûleur lorsq ue

la vitesse du mélange gaz-air à travers les ouvertures du

brûleur devient insuffisante, principalement suite à l'encrassement des voies d'air.

En outre, les processus d'allumage doivent se produire sans

retards. En particulier, au moment de l'allumage du dispo sitif

d'allumage et de la propagation de la flamme sur toute la zone

du brûleur.

Si la flamme ne répond pas à tous ces critères, il est nécessaire de procéder à un nettoyage ou à un entretien.

Page 20 62.9677.01_UL

Page 23

INSTRUCTIONS DE FONCTIONNEMENT

5. Espace de rangement

L'espace de rangement (Fig.10) est installé dans la partie

inférieure de l'appareil.

Accessoires conseillés :

- Porte-tablette (1) 2 pces.

- Tablette (2) 1 pc e.

1 Porte-tablette

2 Tablette

Fig.10 Espace de rangement

62.9677.01_UL Page 21

Page 24

INSTRUCTIONS DE FONCTIONNEMENT

Page 22 62.9677.01_UL

Page 25

62.8504.01 Table of nozzle - Tableau de gigleur

Pressure after

the pressure

regulator with

burner in opera

inch Water

Gauche

Gas type

Natural

Liquid

21

22

23

24

gases

25

26

27

28

gases

Natural

gas USA

Propane

gas USA

±1%

Nominal pres

sure with burner

in operation

inch Water

Gauche

7.0 17.4 6.0 15 A 0.089 2.25 72.7801.33 fix 27 27 72.7800.02 0.59 15

11.0 27.4 10.0 25 E 0.061 1.55 72.7801.04 fix 14 14 72.7800.01 0.59 15

mbar

thermaline S90 Fry Top (17.4 kW)

±1%

Category Main flame

-

tion

mbar in mm No. in mm No. in mm

Small

flame

Ignitions burner

Air adjustment

Distance X

23

Loading...

Loading...