Electrolux 901EN Service Manual

SERVICE MANUAL

WASHING

© ZANUSSI ELETTRODOMESTICI

VIA GIARDINI CATTANEO, 3

I - 33170 PORDENONE (ITALY)

Fax (0434) 394096

599 33 49-01/7 1/27

Pubblication No,

599 33 49-01/7

980220

EN/SERVICE/EB

WASHING MACHINES

WITH TIMERS

124 92000.. / 124 92010..

FUNCTIONS:

VA30J - VB30J - VC30J

599 33 49-01/7 2/27

INDEX

General characteristics page 4/27

Operating principles page 5/27

Configuration of functions page 6/27

Safety features page 7/27

Washing programmes page 9/27

Washing cycle options page 11/27

Washing programme tables page 14/27

Basic circuit diagram page 22/27

Timer diagram page 24/27

Timer and electronic control board connections page 25/27

Troubleshooting page 26/27

599 33 49-01/7 3/27

GENERAL CHARACTERISTICS

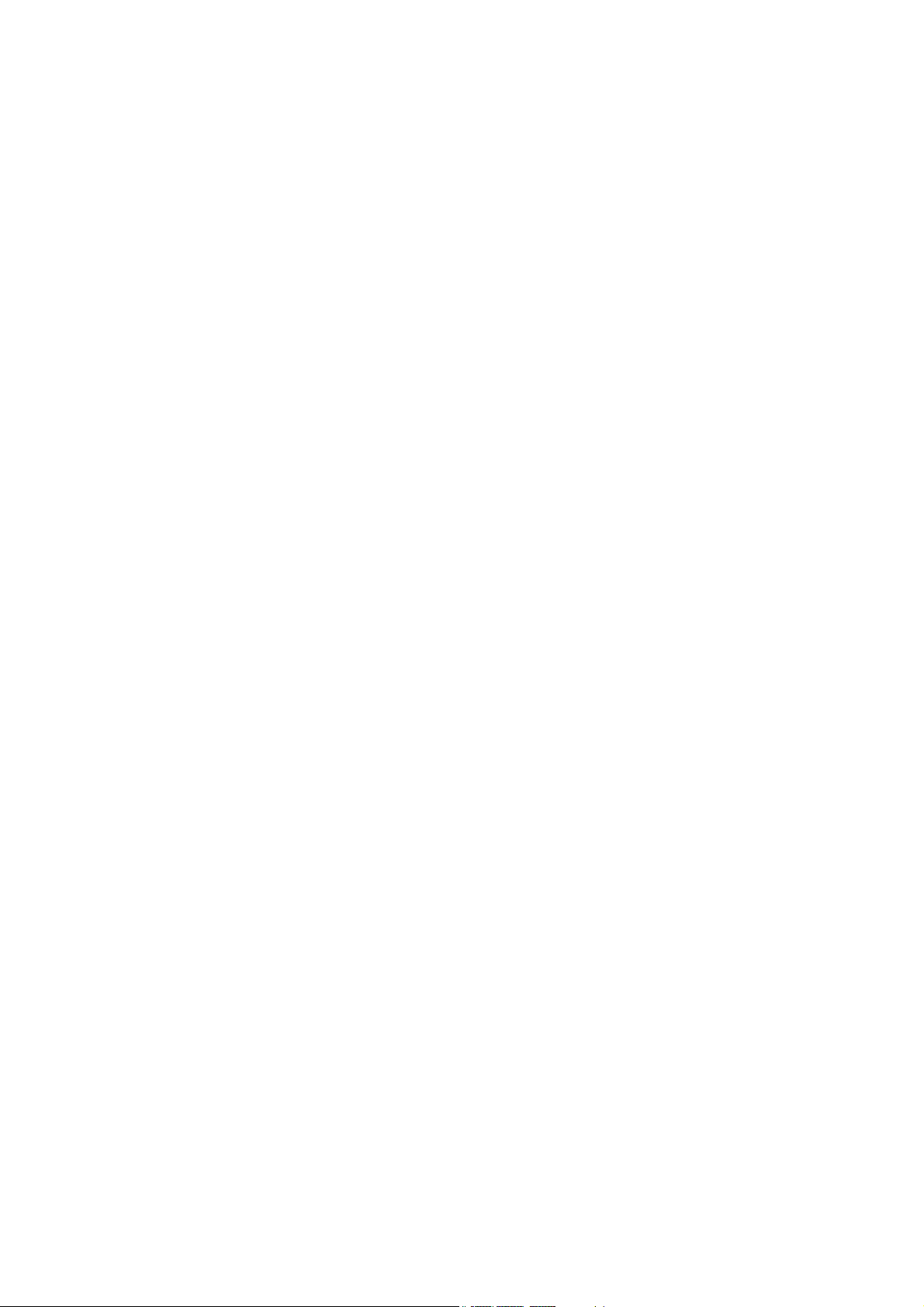

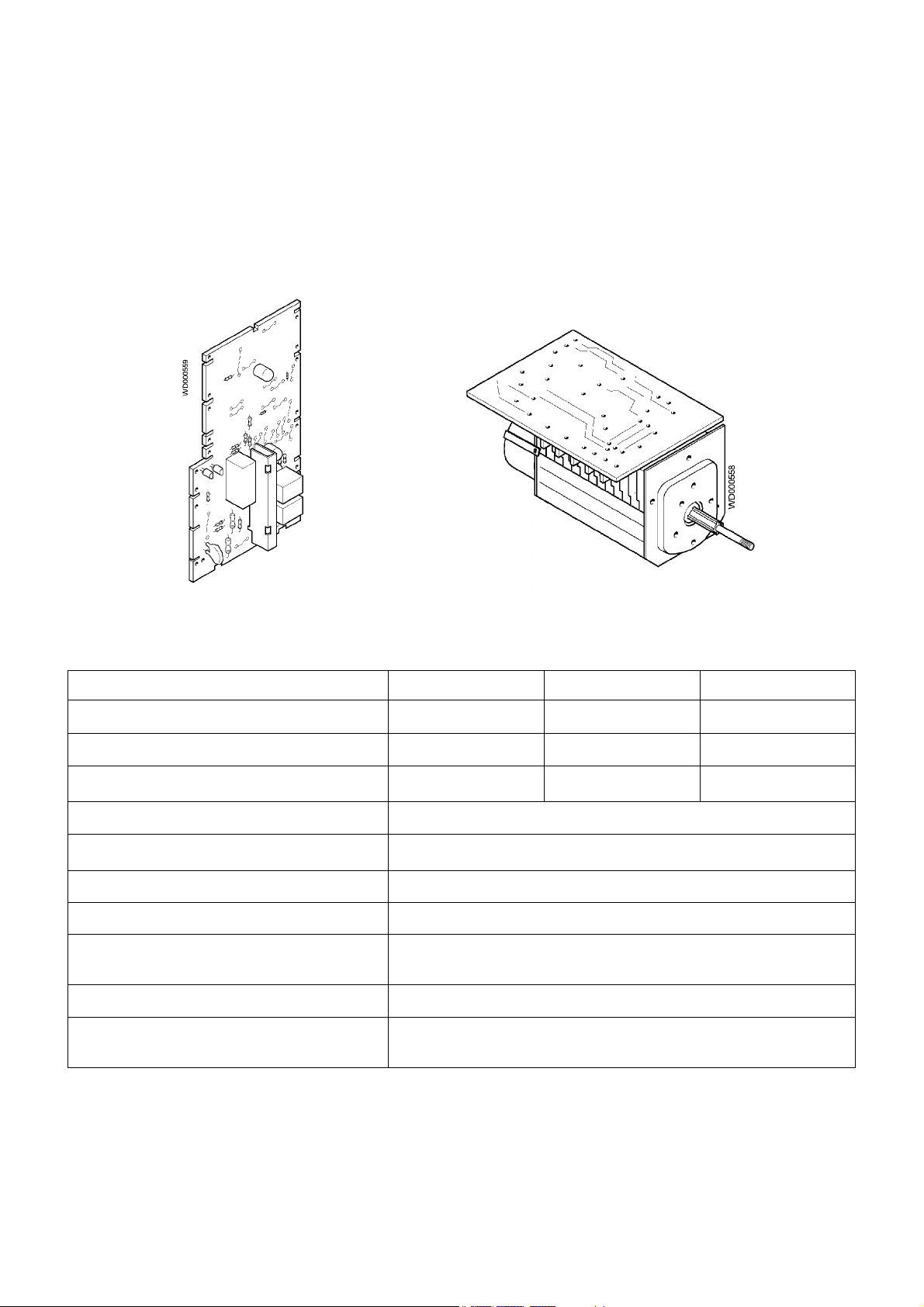

The VA30J - VB30J - VC30J timers manufactured by AKO are used in certain washing machine models with spin

speeds from 900 rpm to 1500 rpm.

These are "hybrid" timers which consist of an electromechanical timer and an electronic control board (fitted to the

base of the washing machine).

FUNCTIONS VA30J VB30J VC30J

WASHING SYSTEM

RINSING SYSTEM

POSSIBILITY OF DELAYED START

TUB

JETSYSTEM JETSYSTEM JETSYSTEM

ANTI-FOAM ANTI-FOAM ANTI-FOAM

YES

STAINLESS STEEL AND CARBORAN

WATER FILL:

- "EUROPE" VERSION COLD

- "GB" VERSION HOT AND COLD

LEVELS

3 WATER FILL LEVELS CONTROLLED BY PRESSURE

SWITCHES

TYPE OF MOTOR

TEMPERATURE CONTROL

BY NTC SENSOR. THE WASHING TEMPERATURES MAY BE

COMMUTATOR

FIXED OR ADJUSTABLE USING A KNOB

599 33 49-01/7 4/27

LEVEL CONTROL

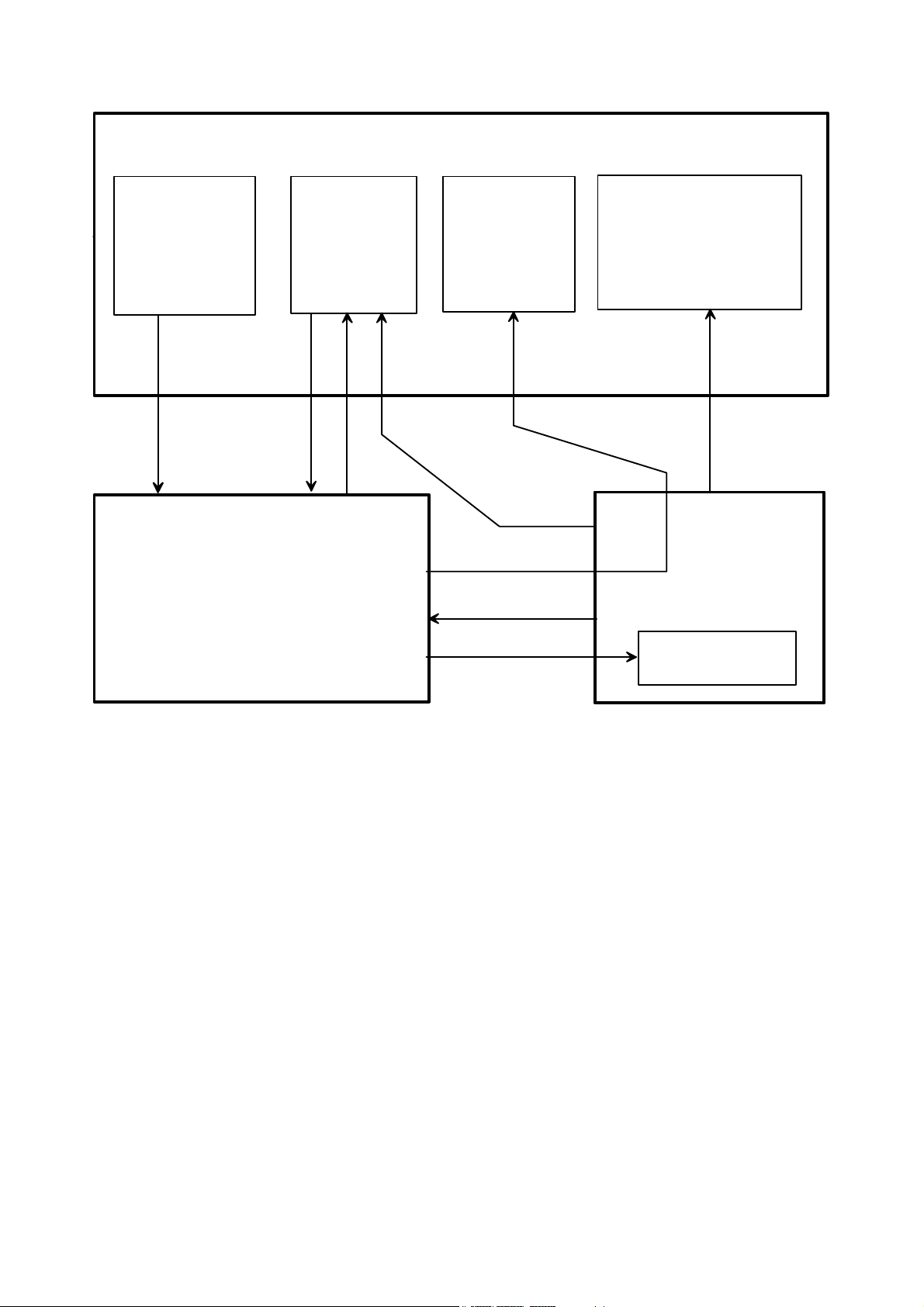

OPERATING PRINCIPLES

TEMPERATURE

SENSOR

g h

MOTOR

d

c

e

ELECTRIC

VALVES

f

WASHING MACHINE

COMPONENTS

ELECTRONIC CONTROL BOARD

CODES

a

b

TIMER

TIMER

MOTOR

a. The electronic control board (with microprocessor) powers the timer motor (via a TRIAC) so that it advances

through the various steps.

b. The duration and type of each washing phase depend on the closure of a series of timer contacts (codes).

The phases also depend on the configuration (different functions) and on the options selected using the keys

or potentiometers.

c. The drum motor is powered directly by the electronic control board via a TRIAC. Reversal of the direction of

rotation of the drum is performed by two relays fitted to the electronic board.

d. The electronic control board controls the speed of rotation of the motor according to a signal received from

the tachymetric generator.

e. A timer contact selects half the stator during the final spin cycles.

f. The hot (if featured) and cold water fill solenoids are powered by the electronic control board via a TRIAC and

selected by one of the timer contacts.

g. The temperature of the washing solution is controlled directly by the electronic control board via an NTC

sensor. The board also detects the closure of the contacts of the level pressure switch and the anti-foam

pressure switch.

h. All the other components of the washing machine are powered directly by the timer.

599 33 49-01/7 5/27

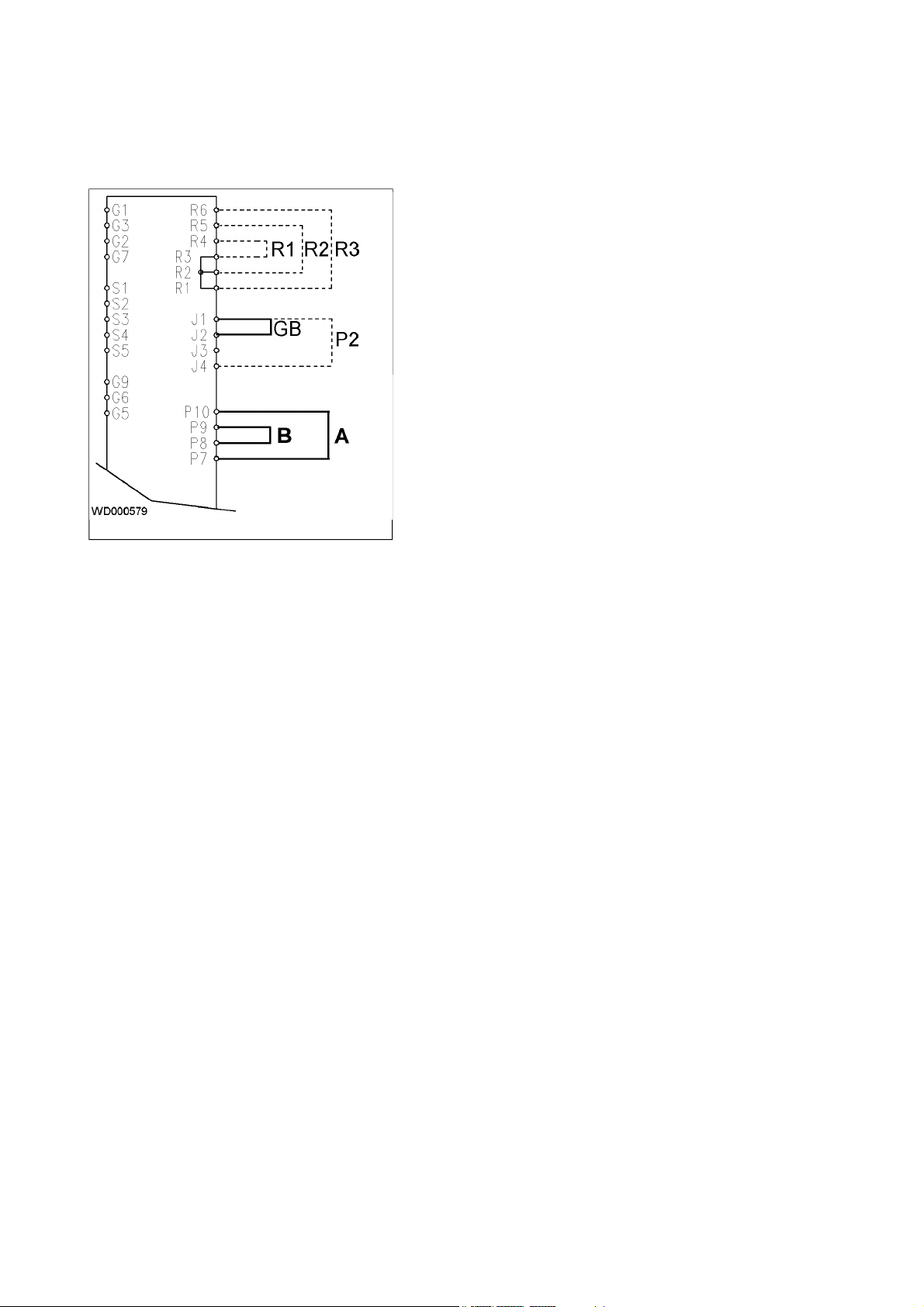

CONFIGURATION OF THE FUNCTIONS OF THE ELECTRONIC BOARD

The various functions of the washing programmes are configured according to the settings of the wiring

connectors on the electronic control board.

Configuration of functions VA30J - VB30J - VC30J

(connectors A and B)

VA30J:

Connectors A (P7 - P10) and B (P8 - P9)

connected to the board.

VB30J: Connector A (P7 - P10) connected to the board.

VC30J: Connector B (P8 - P9) connected to the board.

Selection of the "GB" function (hot and cold water)

This option can be selected for each of the different functions by connecting contacts J1-J2 on the electronic

board. If these contacts are not connected, the appliance is set to the "EUROPE" function (cold water only).

Selection of spin speed (connectors R1, R2, R3)

The configuration of the various spin speeds, which depends on the transmission ratio between the drum pulley

and the motor pulley, is by selecting the appropriate connections between contacts R1 - R6 on the electronic

board.

Configuration of the "G13" tub function (connector P2)

This function, used only for models with the "G13" stainless steel tub (54 litre drum) is configured using contacts

J1 - J4 on the electronic board.

599 33 49-01/7 6/27

SAFETY FEATURES

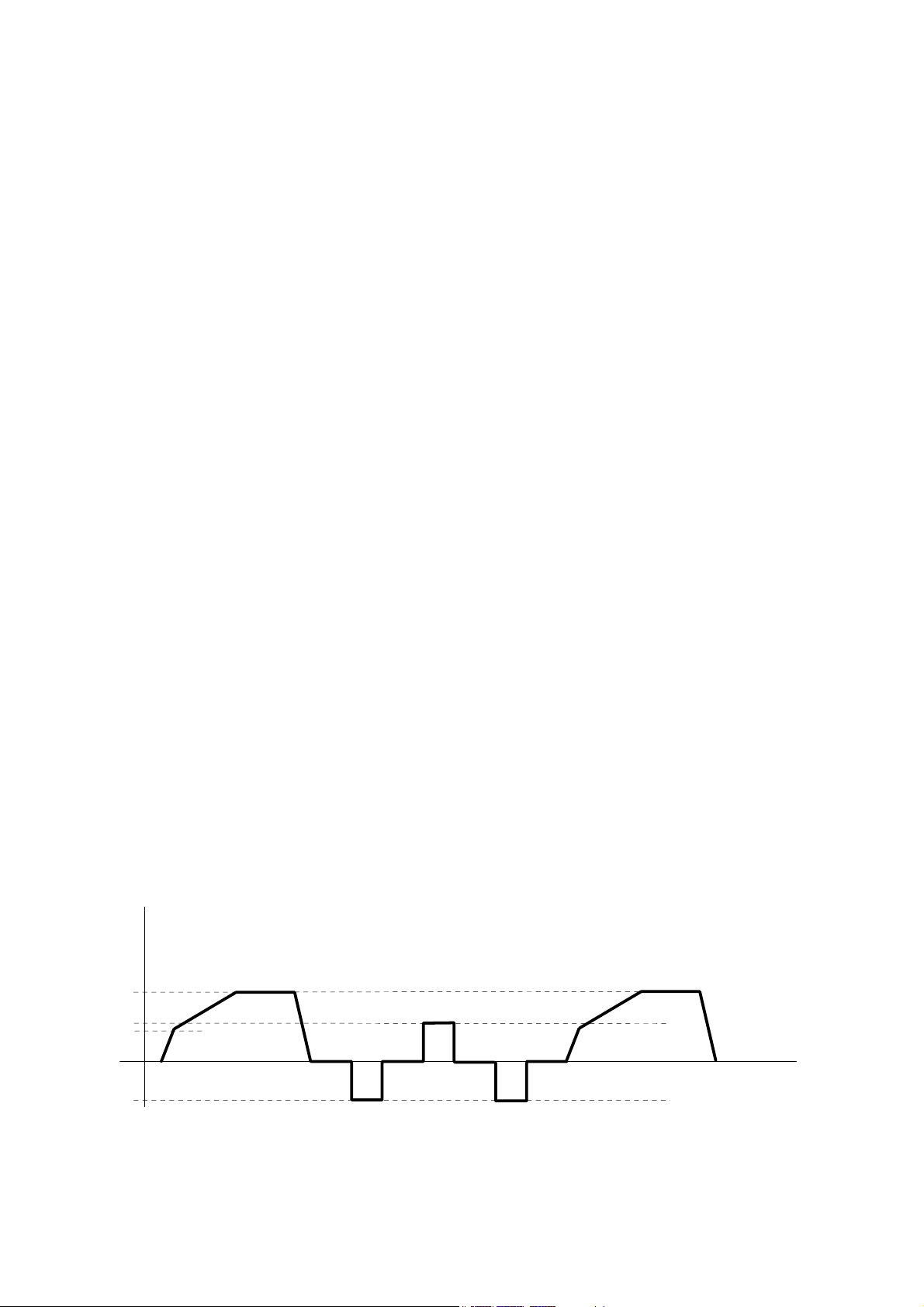

ANTI-UNBALANCING DURING SPINNING

Control of the balance of the load is performed while the drum rotates at between 45 rpm and 85 rpm, i.e. before

the spin cycle.

Final spin for COTTON cycles (CF / CFQ)

In these spin cycles, control of unbalancing is performed at two levels: 1.2 kg and 0.8 kg:

- if the unbalancing control detects unbalancing of less than 0.8 kg, the spin cycle is carried out normally.

- if the unbalancing is between 0.8 and 1.2 kg, the spin cycle is not carried out, and the drum is rotated at low

speed in an attempt to balance the load. The spin cycle is then restarted, and the unbalancing check is

repeated. If, after three attempts at balancing the load, unbalancing remains between 0.8 kg and 1.2 kg, the

spin speed is limited to 1000 rpm.

- if the unbalancing control detects unbalancing in excess of 1.2 kg, the spin cycle is not carried out, and the

drum is rotated at low speed in an attempt to balance the load. The spin cycle is then restarted, and the

unbalancing check is repeated. If the load is still unbalanced, this sequence is repeated for the entire duration

of the phase; thereafter, if the load is still unbalanced, the spin cycle is skipped.

Other spin cycles

For the intermediate spin cycles in programmes for COTTON, and spin cycles in those for SYNTHETICS,

DELICATES and WOOL, the unbalancing check is based on a single level: 1.2 kg.

- if the unbalancing control detects unbalancing of less than 1.2 kg, the spin cycle is carried out normally.

- if the unbalancing is in excess of 1.2 kg, the appliance performs the sequence described above for CF and CQ;

if the load remains unbalanced, the spin cycle is skippeed.

Drum movement with unbalanced load

rpm

85

55

45

0

sec

-55

3333

3

3

599 33 49-01/7 7/27

MOTOR PROTECTION

Power TRIAC for motor short-circuited

If the electronic control board detects a short-circuit in the TRIAC which powers the drum motor, it immediately

opens the relay contacts, thus disconnecting the motor for one minute; thereafter, power is restored to the motor.

If the malfunction persists, the electronic control board makes 4 attempts to restore power to the motor (at

intervals of 255 seconds), after which the cycle continues normally without motor movement.

Malfunction in tachymetric generator circuit

If a malfunction is detected in the tachymetric generator circuit, the electronic control board disconnects the motor;

if, after three attempts to restore power to the motor, the malfunction persists, the timer advances rapidly to

position 58.

Motor circuit-breaker open - motor windings interrupted

If one of these malfunctions should occur, the electronic control board disconnects the motor, and restores power

at periodic intervals.

If the circuit-breaker has tripped, the motor will be powered normally when the circuit-breaker is reset.

If the malfunction persists, the washing programme will be performed without movement of the motor.

PROTECTION OF HEATING ELEMENTS

Temperature sensor short-circuited or open

The heating phase is skipped.

Temperature sensor incorrectly set, heating element faulty

The heating phases have a maximum preset duration; after this period, the timer passes to the subsequent phase

even if the correct temperature has not been reached.

PROTECTION OF DRAIN PUMP

Drain pump faulty

The drain phases have a maximum duration of 3 minutes. After this period, the timer passes to the subsequent

phase even if the 1st level pressure switch is not closed in the "empty" position.

599 33 49-01/7 8/27

WASHING PROGRAMMES: "EUROPE" VERSION WITH COLD WATER

FIXED TEMPERATURES ADJUSTABLE TEMPERATURES

N° COTTON-LINEN Temp.

(°C)

Rinses COTTON-LINEN Temp.

(°C)

Rinses

1 Whites with pre-wash 95° 3 Whites/coloureds with pre-wash 30° - 95° 3

2 Whites 95° 3 Whites and coloureds 30 - 95° 3

3 Colour-fast coloureds 60° 3 - - -

4 Colour-fast coloureds,

60° 3 Whites and coloureds, light soiling 30° - 60° 3

light soiling

5 Delicate coloureds 40° 3 - - -

6 Rinses - 3 Rinses - 3

7 Conditioner - 1 Conditioner - 1

8 Spin - - Spin - -

9 Drying * - - Drying * - -

SYNTHETICS SYNTHETICS - MIXED FABRICS

10 Whites with pre-wash 60° 3 W hites / coloureds with pre-wash 30° - 60° 3

11 Whites 60° 3 W hites and coloureds 30° - 60° 3

12 Coloureds 40° 3 - - -

13 Short cycle 30° 3 Short cycle 30° 3

14 Rinses - 3 Rinses - 3

15 Conditioner - 1 Conditioner - 1

16 Drying * - - Drying * - -

DELICATES / WOOL DELICATES / WOOL

17 Wool 40° 3 W ool 40° 3

18 Delicates 40° 3 Delicates 30° - 40° 3

19 Rinses - 3 Rinses - 3

20 Conditioner - 1 Conditioner - 1

21 Short spin - - Short spin - -

22 Drain - - Drain - -

* Washer-dryers only.

Other special programmes can be selected using the keys as follows:

BIO (only for programmes 1, 2, 3, 4, 10 and 11)

-

SHORT CYCLE (only for programmes 1, 2, 3, 4, 5, 10, 11 and 12)

-

SOAK (only for programmes 1 and 10)

-

STAINS (only for programme 2 in versions with adjustable temperatures)

-

599 33 49-01/7 9/27

Loading...

Loading...