Page 1

Electrolux Thawing Cabinet

Thawing cabinet 650 lt

In order to achieve the best results in the kitchen it is necessary to consider two fundamentals principles:

carefulness and prime products. Fresh products have always been considered the only alternative in the strive

to achieve high quality cooking results but, thanks to the new freezing techniques, frozen products have now

to be considered an excellent alternative. With the thawing process of the cabinet, Electrolux has succeeded in

retaining the freshness of the pre-frozen products with a high quality comparable to the one of the fresh

products thanks to an unique combination of high airflow, low temperature and extremely high temperature

uniformity. The model detailed in this sheet is a thawing cabinets with a capacity of 650lt.

MATERIALS

• Full construction in A304

stainless steel including

back and bottom panels for

everlasting operation in all

working environments

• A304 stainless steel air

conveyors to guarantee for

sturdiness and reliability

• Rounded corners, fully

pressed bottom plate for

ease of cleaning

• Single sheet construction

to avoid dirt traps

• 75mm thick sides and

door insulation for

maximum energy efficiency

EASY TO USE

• Even airflow ensured by

air conveyors and ducts

ensuring consistent results

on products to be thawed in

a single load.

• The openings on air

conveyors change

dimensions and positions

optimising the thawing time

and ensuring the

temperature uniformity

• No food probe needed

thanks to the time

controlled process: safer

and easier to use

• 4 factory-preset programs

to cope with loads from

727125

approx 20Kg to 80Kg. All

programs are customisable

in time, temperatures and

thaw/preservations split of

phases

• The electronic control

switches automatically from

thawing into preservation

phases to avoid bacteria

proliferation

• 2 powerful fans to ensure

a quick and uniform thawing

process.

Page 2

Electrolux Thawing Cabinet

Thawing cabinet 650 lt

• The air conveyors are

dishwasher safe and can be

removed without tools to

speed up cleaning

operations

• All parameters are fully

customisable to suit every

customer need

• Temperature display

showing the real

temperature evolution allow

quick, visual checks by the

operator during thawing and

preservation phases

• 10 rilsan grids GN 2/1

supplied as standard to use

all internal space available

• 4 wheels (front ones with

brakes) are supplied as

standard to ease cleaning

operations

• Cooling unit on the top of

the unit, fully outside of the

thawing area for maximum

capacity and ease of service

• Unit features an internal

water drain.

EASY ON THE

ENVIRONMENT

• Fully HACCP compliant

thanks to the temperature

control, visualisation and

alarm management

• CFC, HCFC, HFC free

insulation using

Cyclopentane and CFC and

HFCF free refrigerant gas

• Built in ISO9001 and

ISO14001 compliant

manufacturing facility

TC651DEW

727125

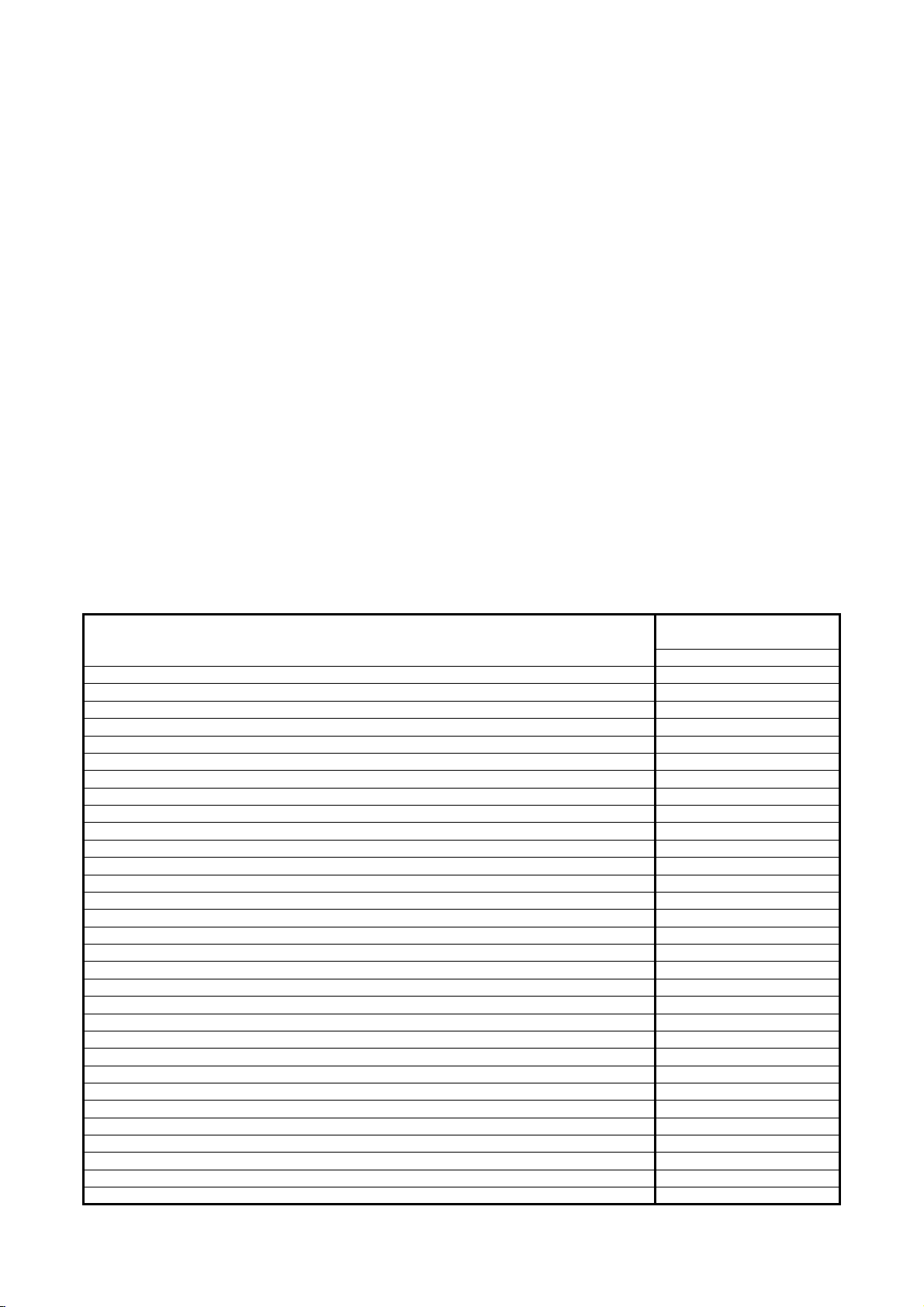

TECHNICAL DATA

Type B - 650Lt

Operating temperature - min/max °C -2/10

Gross capacity (D.I.N. 8952) - l. 650

Cooling unit Built-In

Control type Digital

Thermostat Electronic

Thermometers Digital

External dimensions - mm

width 750

depth/with open doors 810, 1475

height 2080

Internal dimensions - mm

width 600

depth 665

height 1300

Cell dimensions - inch

height 51 3/16"

N° and type of door 1

Door hinges Right Side

Compressor power - HP 3/8

N° defrost in 24 hrs. 4/20'

Refrigerant type R134a

Refrigerant quantity - g. 290

Refrigeration power - W 378

Refrigerant power

at evaporation temperature - °C -10

Power - kW

installed-electric 1.9

Noise level - dBA 54

Net weight - kg. 138

Supply voltage 230 V, 1N, 50

EF00202012-07-27Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Loading...

Loading...