INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

ISTRUZIONI DI INSTALLAZIONE, FUNZIONAMENTO E MANUTENZIONE

INSTRUCTIONS D'INSTALLATION, D'UTILISATION ET DE MAINTENANCE

INSTRUCCIONES DE INSTALACIÓN, USO Y MANTENIMIENTO

"ROLL-IN SMART" ELECTRONIC CONTROL

CONTROLLO ELETTRONIC0 "ROLL-IN SMART"

CONTRÔLE ÉLECTRONIQUE "ROLL-IN SMART"

CONTROL ELECTRÓNICO DEL "ROLL-IN SMART"

USA Page 07 - 19

IT Pagina 20 - 32

FR Page 33 - 45

ES Página 45 - 58

PART NO. 5957 411 01

VERSION 2 2005.12

"

660 mm

"

600 mm

"

630 mm

"

870 mm

"

m

"

50 mm

"

m

"

85 mm

"

m

"

9

m

"

m

"

m

"

315

INSTALLATION DIAGRAM

SCHEMA DI INSTALLAZIONE

SCHÉMA D'INSTALLATION

DIAGRAMA DE INSTALACIÓN

FRONT VIEW

VISTA FRONTALE

83 5/64

2110 m

VUE DE FACE

VISTA FRONTAL

29 17/32

750 m

SIDE VIEW

VISTA LATERALE

VUE DE CÔTÉ

VISTA LATERAL

38 25/64

75 m

12 13/32

mm

3 11/32

30 5/16

770 m

1 31/32

TOP VIEW

VISTA SUPERIORE

2 61/62

75 m

23 5/8

24 51/64

VUE DE DESSUS

VISTA SUPERIOR

2 61/62

75 m

34 1/4

65 23/64

1

2

I = electrical connection

Z = bolt holes for floor fastening

I = connessione elettrica

Z = fori per bulloni fissaggio a pavimento

I = branchement électrique

Z = trous de boulon pour fixation au sol

I = Conexión eléctrica

Z = Orificios para pernos de anclaje en el

suelo

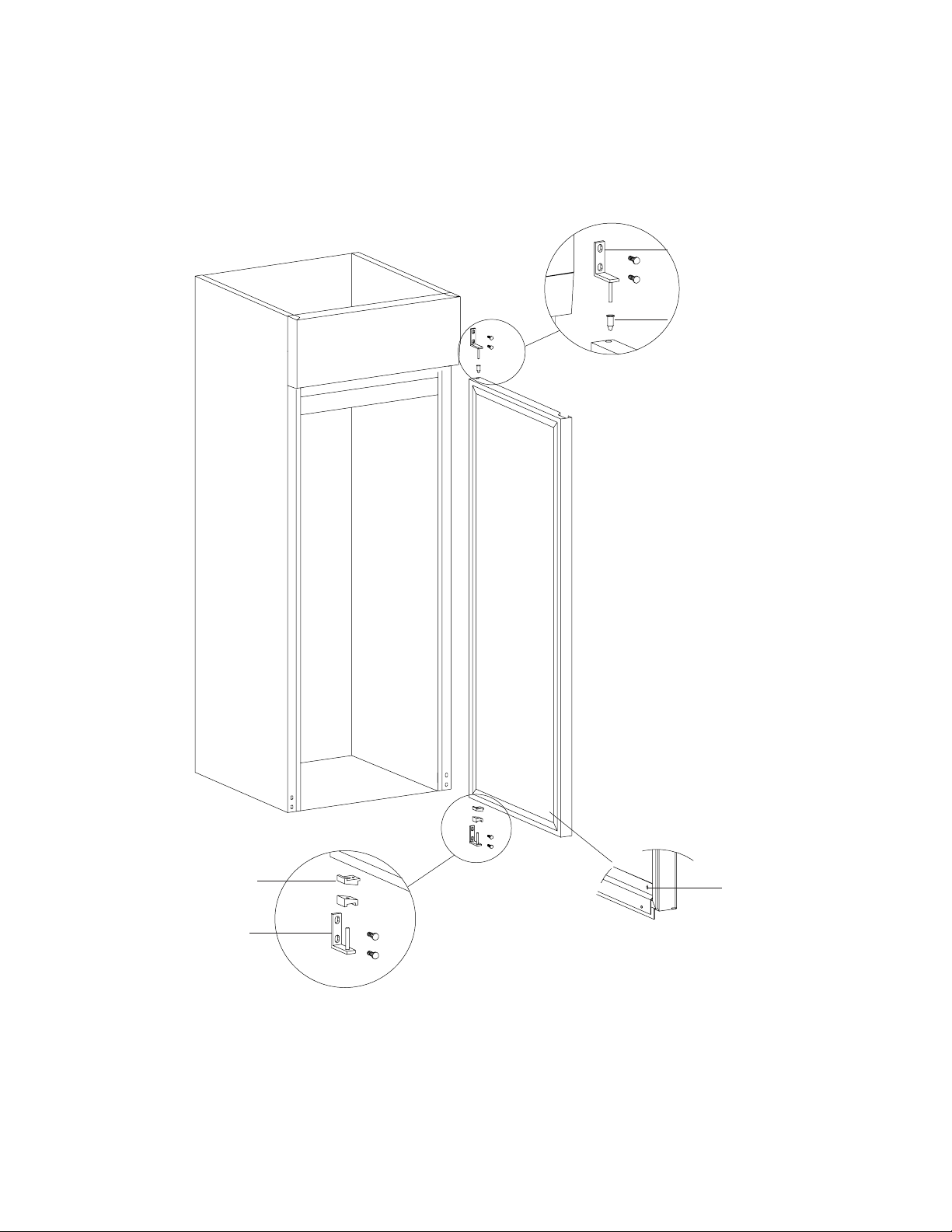

REVERSING OPENING OF THE DOOR

INVERSIONE APERTURA DELLE PORTE

INVERSION DU SENS D'OUVERTURE DE LA PORTE

CAMBIO DE DIRECCIÓN DE APERTURA DE LA PUERTA

G

H

Dett.1

F

E

Dett.3

Dett.2

L

3

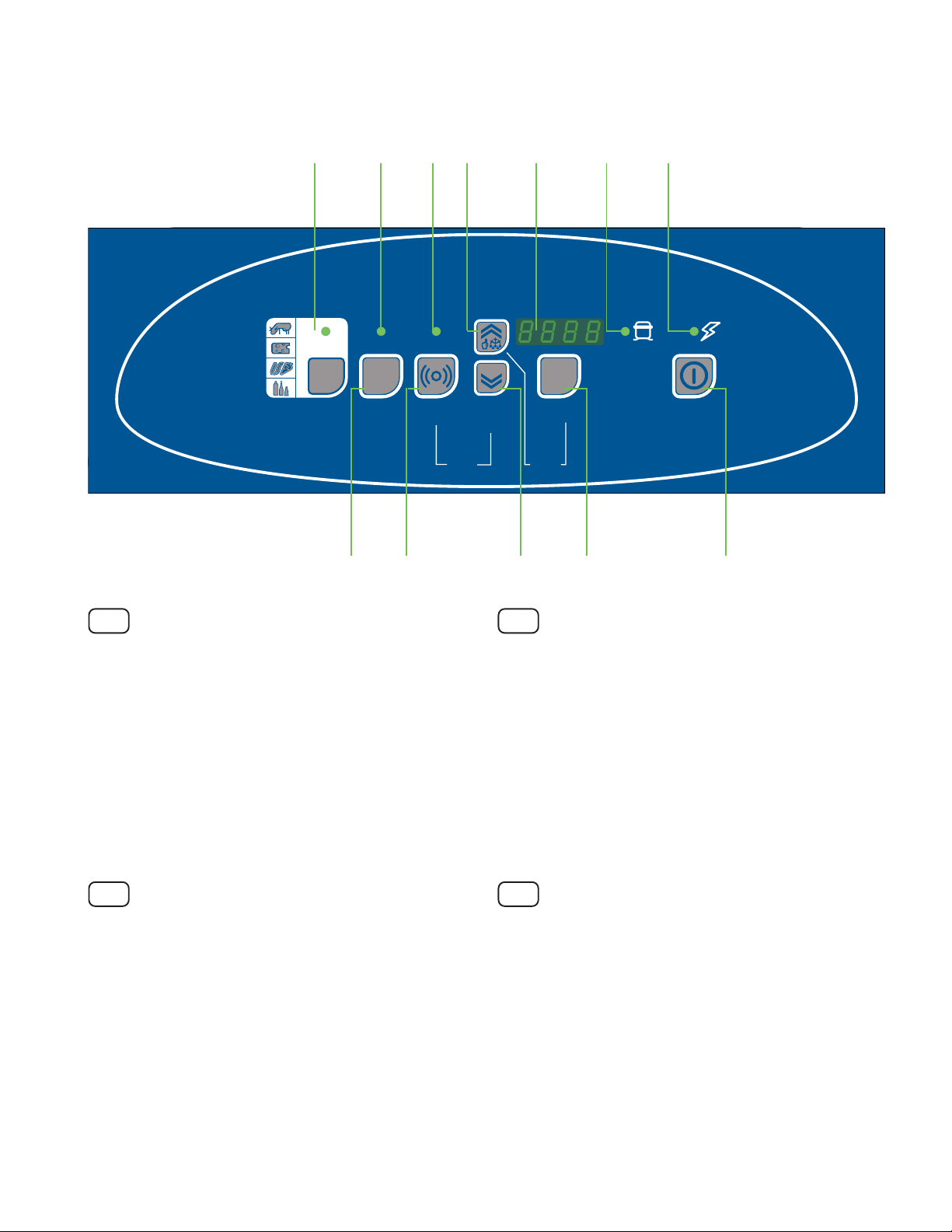

CONTROL PANEL

PANNELLO COMANDI

PANNEAU DE COMMANDE

PANEL DE CONTROL

1

1

2

3

CATEGOR Y

4

ACCESS TO

FOOD CATEGORIES

2a 3a 4 7 8 9

2

MANUAL

DEFROST

TEMPERATURE/

CATEGORY

SELECTION

PRINT

SET

HACCP

HACCP

ALARMS

7 DAYS

REPORT

%

HUM

HIGH

HIGH HUM.

ON/OFF

SERVICE

ALARMS

356 10

COMPRESSOR

STAT US

POWER SUPPLY

STAT US

POWER ON/OFF

USA

1-Access to Food Categories button

2-High humidity ON/OFF button

2a - High humidity indicator light

3-Service alarms button

3a - Service alarms indicator light

4-Manual defrost / UP button

5-Set temperature / Category selection / DOWN button

6-HACCP alarms button

7-Display

8-Compressor status indicator light

9-Power supply status indicator light

10 - Power ON/OFF button

IT

1-Accesso al pulsante per le categorie degli alimenti

2-Pulsante ON/OFF umidità elevata

2a - Spia elevata umidità

3-Pulsante allarmi di servizio

3a - Led allarmi di servizio

4-Pulsante di sbrinamento manuale UP/ DEFROST

5-Pulsante inferiore Impostazione temperatura

/ Selezione categoria

6-Pulsante Allarmi HACCP

7-Display

8-Spia stato compressore

9-Spia stato alimentazione

10 - Pulsante ON/OFF

FR

1-Bouton ACCESS TO FOOD CATEGORIES

2-Bouton HIGH HUMIDITY ON/OFF

2a - Témoin lumineux HIGH HUMIDITY

3-Bouton SERVICE ALARMS

3a - Témoin lumineux SERVICE ALARMS

4-Bouton MANUAL DEFROST / UP

5-Bouton TEMPERATURE / CATEGORY SELECTION / DOWN

6-Bouton HACCP ALARMS

7-Affichage

8-Témoin lumineux COMPRESSOR STATUS

9-Témoin lumineux POWER SUPPLY STATUS

10 - Bouton ON/OFF

ES

1-Botón de acceso a las categorías de alimentos

2-Botón High humidity ON/OFF

2a - Luz indicadora de alta humedad

3-Botón de alarmas de servicio

3a - Luz indicadora de alarmas de servicio

4-Botón Manual defrost / UP

5-Botón Set / Category / DOWN

6-Botón de alarmas HACCP

7-Indicador

8-Luz indicadora de estado del compresor

9-Luz indicadora de estado del suministro eléctrico

10 - Botón de encendido/apagado ON/OFF

4

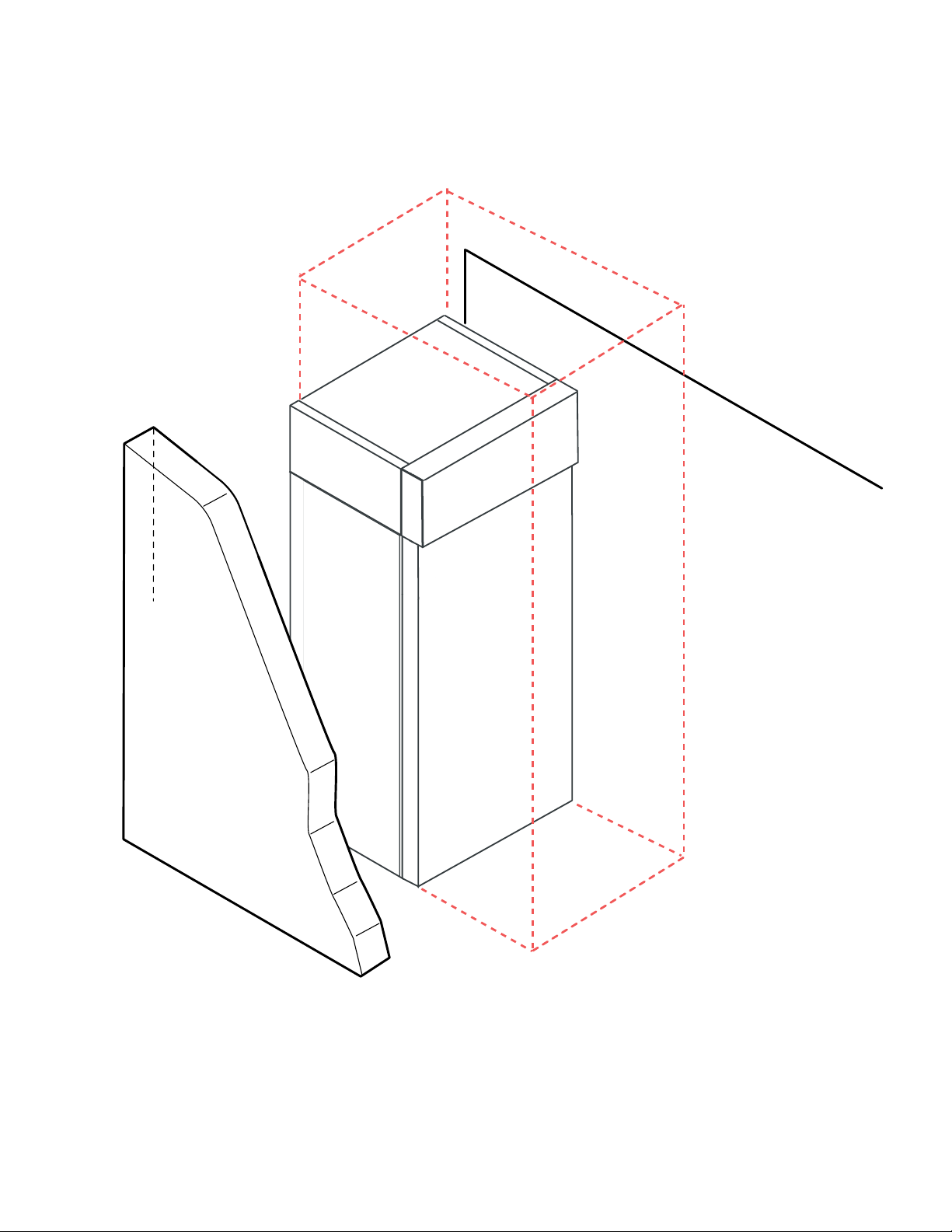

FUNCTIONAL SPACES

19.68 "

500 mm

30.31"

770 mm

102.75 "

2610 mm

SPAZI FUNZIONALI

19.68 "

500 mm

ESPACES FONCTIONNELS

ESPACIOS FUNCIONALES

102.75 "

2610 mm

30.31"

770 mm

5

This page has been intentionally left blank

Questa pagina e' stata lasciata in bianco intenzionalmente

Cette page est intentionnellement laissée blanche

Esta página ha sido dejada en blanco de manera intencional

6

USA

TABLE OF CONTENTS

SAFETY INSTRUCTIONS ......................................................... Page 9

A.1 GENERAL INFORMATION........................................................ Page 10

A.1.1 Foreword ..................................................................................................................... Page 10

A.1.2 Intended use and limitations ...................................................................................... Page 10

A.1.3 Testing ......................................................................................................................... Page 10

A.1.4 General safety rules .................................................................................................... Page 10

A.1.5 Customer’s responsibilities ....................................................................................... Page 10

A.1.6 Data plate position ...................................................................................................... Page 10

A.1.7 Physical safety features, hazards ............................................................................... Page 10

B.1 INSTALLATION ......................................................................... Page 10

B.1.1 Immediate inspect for shipping damage ................................................................... Page 10

B.1.2 Removing the packaging ............................................................................................ Page 10

B.1.2.1 Removing the packaging and handling ...................................................................... Page 10

B.1.2.2 Disposing of the packing ............................................................................................ Page 11

B.2 TECHNICAL DATA.................................................................... Page 11

B.2.1 Materials and fluids used ............................................................................................ Page 11

B.2.2 Dimensions, performance and consumption ............................................................ Page 11

B.2.3 Physical safety features, hazards ............................................................................... Page 11

B.2.4 Positioning .................................................................................................................. Page 11

B.2.5 Electrical connection ................................................................................................... Page 12

B.2.6 Reversing opening of the door ................................................................................... Page 12

B.2.7 Checking hinges ......................................................................................................... Page 13

C.1 OPERATIONS and USER INSTRUCTIONS ............................. Page 13

C.1.1 Control panel ............................................................................................................... Page 13

C.1.2 Initial switch-on and temperature adjustment ............................................................ Page 13

C.1.3 Storage using catergories button ................................................................................ Page 14

C.1.4 “High humidity ON/OFF” button ................................................................................... Page 14

C.1.5 Loading the product .................................................................................................... Page15

7

C.1.6 Defrosting .................................................................................................................... Page 15

C.1.7 Alarms ......................................................................................................................... Page 15

C.1.7.1 General description ..................................................................................................... Page 15

C.1.7.2 HACCP ........................................................................................................................ Page 15

C.1.7.3 Service alarms ............................................................................................................ Page 16

C.1.7.4 Service alarms list ....................................................................................................... Page 16

C.1.7.5 Alarm managing .......................................................................................................... Page 17

C.1.7.6 HACCP alarm reset ..................................................................................................... Page 17

C.1.7.7 Troubleshooting guide ................................................................................................ Page 17

D.1 ROUTINE MAINTENANCE ....................................................... Page 18

D.1.1 Cleaning the cabinet and accessories ....................................................................... Page 18

D.1.2 Precautions in the event of prolonged disuse ............................................................ Page 18

D.2 MAINTENANCE TO BE PERFORMED BY TRAINED

PERSONNEL ONLY.................................................................. Page 18

D.2.1 Periodic cleaning of condenser .................................................................................. Page 18

D.2.2 Replacing the power supply cable ............................................................................. Page 18

D.3 HACCP CONNECTIONS (ACCESSORIES) ............................. Page 19

D.3.1 HACCP connections ................................................................................................... Page 19

D.4 TROUBLESHOOTING .............................................................. Page 19

D.4.1 Quick troubleshooting guide ....................................................................................... Page 19

D.5 WASTE DISPOSAL AND DEMOLITION ................................... Page 19

D.5.1 Waste storage ............................................................................................................. Page 19

D.5.2 Procedure for preliminary dismantling of the appliance ............................................ Page 19

D.6 ENCLOSED DOCUMENTS ...................................................... Page 19

8

SAFETY INSTRUCTIONS

To reduce the risk of fire, electrical shock, or injury when using your appliance, please follow these basic

precautions including the following:

• Read all instructions before using your appliance.

• This Manual does not cover every possible condition and situation that may occur. Use common sense and caution

when installing, operating and maintaining this appliance.

• FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

• The installation of this unit must conform to local codes or, in the absence of local codes, to all National Codes

governing plumbing, sanitation, safety and good trade practices.

• BEFORE SERVICING, DISCONNET THE ELECTRICAL SERVICE AND PLACE A RED TAG AT THE DISCONNECT

SWITCH TO INDICATE WORK IS BEING DONE ON THAT CIRCUIT.

• NOTICE: CONTACT YOUR AUTHORIZED SERVICE COMPANY TO PERFORM MAINTENANCE AND REPAIRS.

• NOTICE: Using any parts other than genuine factory manufactured parts relieves the manufacturer of all warranty and

liability.

• NOTICE: Manufacturer reserves the right to change specifications at any time without notice.

• WARNING: The equipment warranty is not valid unless the appliance is installed, started and demonstrated under

the supervision of a factory trained installer.

• WARNING: The unit must be installed by Personnel who are qualified to work with electricity and plumbing. Improper

installation can cause injury to personnel and/or damage to the equipment. The unit must be installed in accordance

with applicable codes.

SAVE THESE

INSTRUCTIONS

9

A.1 GENERAL INFORMATION

A.1.1 FOREWORD

The purpose of this manual is to provide the necessary

information for the correct installation, operation, use and

maintenance of the appliance.

Consequently, the manual and all the technical documentation

enclosed with the appliance must be kept with the appliance at

all times so that they can be consulted by the technician or end

user. It is important to inform the appliance user about regulations

concerning safety during and after installation.

Read the instructions in the manual carefully before carrying out

any operation whatsoever on the appliance, as they give important

information about the standards and rules governing its

installation and safe use. Improper installation, adjustment,

alteration, service or maintenance can cause property

damage, injury or death. Failure to observe the instructions

in this manual when carrying out any operations on the

appliance will relieve the manufacturer of all liability. Also, the

manufacturer declines any responsibility in the event of

problems caused by the use of non-original spare parts.

No part of this of this manual may be reproduced.

serial number located underneath the logo.

A.1.7 PHYSICAL SAFETY FEATURES, HAZARDS

The appliance has no sharp or projecting parts.

DANGER! DO NOT REMOVE. There are guards on the units to

prevent access to components which require air movement.

B.1 INSTALLATION

WEAR PROTECTIVE GLOVES WHEN

UNPACKING AND INSTALLING THE

APPLIANCE.

Read these instructions carefully before

attempting installation. Installation and initial

startup should be performed by a qualified installer. Unless the

installation instructions for this product are followed by a qualified

service technician (a person experienced in and knowledgable

with the installation of commercial equipment) then the terms

and conditions on the Manufacturer's Warranty will be rendered

void and no warranty of any kind shall apply.

A.1.2 INTENDED USE AND LIMITATIONS

This appliance has been designed for the refrigeration and

preservation of foodstuffs. Any other use is to be considered

improper.

ATTENTION: these appliances are not suitable for installation

outdoors and/or in environments subject to natural elements

(rain, direct sunlight, etc.).

The manufacturer declines all liability for any improper use of

the product.

A.1.3 TESTING

Our appliances have been designed and optimised with

laboratory testing to give high performance and efficiency. The

product has gone through 100% testing and is ready for use.

The certificates guaranteeing that the tests (visual inspection electrical test - functional test) have been passed are included

with the appliance and are included in specific enclosures

(section D.6).

A.1.4 GENERAL SAFETY RULES

The appliance is manufactured in compliance with following

directives:

- Hygiene: ANSI / NSF 7

- Safety: UL 471

- CAN / CSA C22.2 No.120 - M91

For models:

RI93RE1FEU, RI17RE1FU.

A.1.5 CUSTOMER’S RESPONSIBILITIES

A fused disconnect switch or a main circuit breaker (customer

furnished) MUST be installed in the electric supply line for the

appliance. It is recommended that this switch/circuit breaker

have lockout/tagout capability. Before making any electrical

connections to this appliance, check that the power supply is

adequate for the voltage, amperage, and phase requirements

on the rating plate. The customer also must provide a grounded

electrical line cord of suitable capacity for the input specified

on the data plate.

A.1.6 DATA PLATE POSITION

The data plate with all the appliance specifications is located

on the refrigeration unit compartment at the top right hand side.

There is also a plate bearing the appliance’s PNC code and

IF IN DOUBT PLEASE CONTACT LOCAL SERVICE

AGENCY.

B1.1 IMMEDIATE INSPECT FOR SHIPPING DAMAGE

The container should be examined for damage before and

during unloading. The freight carrier has assumed responsibility

for its safe transit and delivery. If damaged equipment is

received, either apparent or concealed, a claim must be made

with the delivering carrier. Apparent damage or loss must be

noted on the freight bill at the time of delivery. The freight bill must

then be signed by the carrier representative (Driver). If the bill

is not signed, the carrier may refuse the claim. The supplier can

supply the necessary forms. A request for inspection must be

made to the carrier within 15 days if there is concealed damage

or loss that is not apparent until after the equipment is uncrated.

The carrier should arrange an inspection. Be certain to hold all

contents plus all packing material. Under no circumstances

should a damaged appliance be returned to the manufacturer

without prior notice and written authorization.

CAUTION:

the operations described below should be carried out in compliance with current safety regulations, with reference both

to the equipment used and the operating procedures.

IMPORTANT: before moving the appliance, make sure that

the load-bearing capacity of the lifting equipment to be used

is suitable for the weight of the appliance.

B.1.2 REMOVING THE PACKAGING

B.1.2.1 Removing the packaging and handling

Cut the straps and remove the protective film, taking care not to

scratch the sheet metal if scissors or blades are used. Remove

the top (in cardboard), the polystyrene corners and the vertical

protection pieces. For appliances with stainless-steel cabinets,

carefully remove the protective film without tearing it, to avoid

leaving glue stuck to the surface.

Should this happen, remove the traces of glue with a noncorrosive solvent, rinsing it off and drying carefully. It is advisable

to go over all the s/steel surfaces with a rag soaked in vaseline

oil, in order to form a protective film. Use a transpallet or forklift truck to lift appliances. Inserting the forks under the pallet, lift

the appliance and carry it to the place of installation, making sure

that the load is balanced.

10

WARNING:

19.68 "

500 mm

30.31"

770 mm

102.75 "

2610 mm

during handling do not push or pull the unit: it may tip over or be

damaged.

B.1.2.2 Disposing of the packing

Packing materials should be disposed of accordance with the

binding laws in the country where the appliance is to be used.

Recyclable plastic parts are marked as follows:

polythene:outer wrapping, instructions booklet bag

PE

polypropylene: straps

PP

B.2.3 PHYSICAL SAFETY FEATURES, HAZARDS

The appliance has no sharp or projecting parts.

The guards for the mobile and live parts are bolted on to the

cabinet to prevent accidental access.

B.2.4 POSITIONING

Install the equipment, taking all the safety precautions

required for this type of operation, also respecting

the relevant fire-prevention instructions.

Place the appliance in a ventilated room and away

from heat sources such as radiators or airconditioning systems, in order to allow the cooling

of the refrigerating unit components.

Never cover the condenser, not even temporarily, as

this may jeopardise the operation of both the

condenser and the appliance.

Make sure to position the appliance taking into consideration

the space needed for door opening.

Pay particular attention to levelling of the floor on which the

appliance stands, in order to ensure its optimal operation.

polystyrene foam: protective surround elements

PS

pressed board: protective surround elements

B.2 TECHNICAL DATA

B.2.1 MATERIALS AND FLUIDS USED

All areas designed to come into contact with food are in steel

or covered in non-toxic plastic material. An HFC refrigerant, in

compliance with current legal standards, is used in the refrigerating units. The type of refrigerant gas used is stated on the

data plate.

B.2.2 DIMENSIONS, PERFORMANCE AND CONSUMPTION

External dimensions:

- Width 29.53” 750mm

- Depth with door closed 38.38” 975mm

- Depth with door open 65.35” 1660mm

- Height 83.07” 2110mm

Chamber dimensions:

- Width 24.80” 630mm

- Depth 34.25” 870mm

- Height 66.81” 1697mm

IMPORTANT:

level the appliance, otherwise its operation could be compromised. The appliance must be sealed to the floor with silicone.

ADVICE:

the part of the floor on which the cabinet is placed should be

physically insulated from the rest of the supporting surface

by means of suitable thermal insulating material, and when

possible, by means of a heat barrier.

For optimum appliance operation, please follow recommended

spacing for equipment:

19.68 "

500 mm

Gross capacity 245.68 gal 930 Iiters

Power supply 120V 1Ph 60Hz

Internal temp. range +32°F/+50°F 0°C/+10°C

Max. ambient temp. +109.4°F +43°C

Current input (°) 8 A

Refrigerant charge R134a 0.595lbs 270 gr

Refrigerant capacity (R134a) (¹) 526 W

Refrigerant capacity (R134a) (²) 1137 W

No. and type of defrostings (*) min 1 each 24h x max 30‘

(°) At room temperature 104°F/40°C.

(¹) At room temperature 89.6°F/32°C, condensation

temperature 131°F/+55°C and evaporation temperature

14°F/-10°C.

(²) ASHRAE PERFORMANCE ambient temperature 89.6°F/

+32°C, condensation temperature 131°F/+55°C and

evaporation temperature 44.96°F/+7.2°C.

(*) Auto (by electronic board)

11

30.31"

770 mm

102.75 "

2610 mm

- between top of appliance and ceiling: approx. 19.7" / 500mm:

"

660 mm

"

600 mm

"

630 mm

"

870 mm

"

m

"

50 mm

"

m

"

85 mm

"

m

- to the sides of appliance: approx. 3.9" / 100mm;

- for door opening: approx. 30.3" / 770 mm.

- from floor to ceiling: approx. 8.5 ft / 2610mm

Should the appliance be installed in rooms where there are

corrosive substances (chlorine, etc.), it is advisable to go over

all the stainless steel surfaces with a cloth coated with vaseline

oil, in order to form a protective film.

These appliances are designed to operate at ambient

temperatures of up to 109.4°F/+43 °C.

Note: the power plug should be accessible even after having

placed the appliance in its final position for installation.

tric supply line for the appliance. It is recommended that this

switch/circuit breaker have lockout/tagout capability. Before

making any electrical connections to this appliance, check

that the power supply is adequate for the voltage, amperage,

and phase requirements on the rating plate. The customer

also must provide a grounded electrical line cord of suitable

capacity for the input specified on the data plate.

- After making the connection and with the appliance running,

check that the rated level does not fluctuate by ± 10%.

The connection must be made with cable of a suitable for amperage and voltage.

ATTENTION:

the appliance must be anchored to the floor. To anchor to the

floor, drill 4 holes, as shown in the installation diagram (see

letter Z), and use metal expansion plugs.

3 11/32

30 5/16

2 61/62

75 m

770 m

1 31/32

23 5/8

24 51/64

2 61/62

75 m

34 1/4

65 23/64

1

NOTE: after anchoring the appliance to the floor, apply a silicone bead on the inside of the appliance between the bottom

and the sides.

The manufacturer will accept no liability for any damage or

injury resulting from the violation of the above rules or of the

current electrical safety standards in the country where the

appliance is used.

B.2.6 REVERSING OPENING OF THE DOOR

Roll-in appliances are normally supplied with opening to the

right.

When changing direction of opening so that the door opens

from left to right, proceed as follows:

• disconnect from the power supply;

• unscrew the screw in the middle of the control panel, turn the

control panel;

• unscrew the two fixing bolts from bracket “G” (Detail 1);

• remove the door and turn it through 180° and reverse the

position of the lower seal “L” (Detail 3);

• remove component “F” and fix it in place in the space pro

vided under the plastic plug on the opposite side of the door;

• remove lower bracket “E” and refit it on the opposite side

in the place provided (Detail 2);

• fix bracket “G” to the structure by screwing down the fixing

bolts;

• refit the door;

• adjust the lower seal “L” (Detail 3), using the slotted holes,

to improve door closure;

• refit the control panel;

• reconnect the power supply.

B.2.5 ELECTRICAL CONNECTION

When making the electrical connection, carefully comply with

the information on the dataplate.

Detail 1

The appliance works on 120V/1ph/60Hz.

CAUTION:

Connection to the electrical mains must be carried out in

accordance with current regulations and the standards required by the National Electric Code (NEC), known as NFPA 70.

Please check:

Connection to the main power must be carried out in accordance with binding rules and standards.

Before connecting, make sure that:

- The line cord has an efficient grounding connection and the

main power frequency corresponds to that stated on the data

plate. If you have doubts on the efficiency of the grounding

connection have the circuit checked by a qualified technician.

- The appliance must be connected to the main power with a

permanent connection.

- In order to protect the appliance from possible overloads or

short-circuits, a fused disconnect switch or a main circuit

Detail 2

Detail 3

breaker (customer furnished) MUST be installed in the elec-

12

B.2.7 CHECKING HINGES

Have the hinges of the appliance checked every two years by a

technician. If necessary, adjust and grease the hinges.

C.1 OPERATIONS and USER

INSTRUCTIONS

C.1.1 CONTROL PANEL

2a 3a 4

1

MANUAL

SERVICE

ALARMS

TEMPERATURE/

PRINT

DEFROST

SET

CATEGORY

SELECTION

1

2

3

CATEGORY

4

ACCESS TO

FOOD CATEGORIES

%

HUM

HIGH

HIGH HUM.

ON/OFF

23 5 6 10

1-Access to Food Categories button

2-High humidity ON/OFF button

2a - High humidity indicator light

3-Service alarms button

3a - Service alarms indicator light

4-Manual defrost / UP button

5-Set temperature / Category selection / DOWN button

6-HACCP alarms button

7-Display

8-Compressor status indicator light

9-Power supply status indicator light

10 - Power ON/OFF button

C.1.2 INITIAL SWITCH-ON AND TEMPERATURE ADJUSTMENT

The appliance features an ON/OFF switch for activating the

appliance.

Turn on the appliance by pressing the ON/OFF button:

7

7 DAYS

REPORT

HACCP

HACCP

ALARMS

89

COMPRESSOR

POWER SUPPLY

STATU S

STATU S

POWER ON/OFF

the Unit of Measure Indicator light starts flashing.

- To change the SET temperature, press SET/DOWN button or

MANUAL DEFROST/UP button within 15 seconds

SET

or

- To store the new set value, wait until it stops flashing to exit

the program

SET

To set the chamber temperature, follow these steps:

- press and hold SET/DOWN button for 5 seconds,

SET

the SET POINT value appears on the display

if a selection is not made after 15 seconds, the last value displayed will be confirmed automatically and the chamber temperature display is restored.

Example of setting:

- switch on the appliance

13

- confirm the set temperature

Keeping button pressed down will display the selected category;

SET

- press SET/DOWN button or MANUAL DEFROST/UP button

temperature

SET

or

1

2

3

CA TEGOR Y

4

2

if “NONE” is displayed, this means that the function is disabled.

To select the category, press MANUAL DEFROST/UP or SET/

DOWN button

or

- To store the new set value, wait until it stops flashing to exit

the program

SET

Here below the temperature range for the appliances:

Position “MIN” = 32°F / 0°C

Position “MAX” = +50°F / +10°C

C.1.3 STORAGE USING CATEGORIES BUTTON

By selecting the “CATEGORY” of food to be preserved, the ap-

pliance creates the right balance between temperature and

humidity in the chamber for optimum preservation of the particular product stored.

There are 4 pre-set categories:

CATEGORY n. 1 red meat

CATEGORY n. 2 cheese and meat dishes

CATEGORY n. 3 fruit and vegetables

CATEGORY n. 4 drinks.

SET

once selected, if a selection is not made after 5 seconds, the

last category displayed will be confirmed automatically and

stored.

C.1.4 "HIGH HUMIDITY ON/OFF" BUTTON

%

HUM

HIGH

"HIGH HUMIDITY ON/OFF" button can be pressed to make the

appliance operate with a high humidity level. An indicator light

comes on when the high humidity function is selected.

With button pressed (High RU %):

- average humidity reading with ambient temperature 109.4°F/

+43°C, chamber temperature 35.6°F/+2°C:

R.H. = ~ 75%

With button released (Low RU %):

- average humidity reading with ambient temperature 109.4°F/

+43°C, chamber temperature 35.6°F/+2°C:

R.H. = ~ 65%

14

C.1.5 LOADING THE PRODUCT

Critical temperature

HACCP

Food must be evenly distributed inside the chamber (away

from the door and back wall) in order to allow proper circulation

of air.

The SERVICE ALARMS stores and manages all the alarms

available in the electronic board (except the “chamber high

temperature” alarm).

There is a sticker inside the chamber indicating the maximum

level of loading:

Cover or wrap food before placing it in the refrigerator and

avoid putting hot foods or steaming liquids inside. Do not

leave the door open longer than necessary when putting in or

taking out products.

It is advisable to keep the keys in a place accesible only to

authorized personnel. In order to avoid the use of the appliance

by non-authorized people, it is advisable to lock it.

C.1.6 DEFROSTING

- Automatic defrosting

The appliance is equipped with an automatic defrost function.

This function is indicated by the “dEFr” indicator light.

Defrost water is routed to a bowl, from where it evaporates

automatically.

- Manual defrosting

The defrost cycle can be activated manually by pressing the

MANUAL DEFROST/UP button for 5 seconds

C.1.7.2 HACCP

HACCP

· ALARM CONDITIONS

- the display shows an alarm by the label “TEMP”

- pushing

HACCP

you get information on maximum temperature, time and date

(day, month and year) alarm occured.

There are two possible situations:

a) the alarm is running

b) the alarm has occured

a) the alarm is running

77˚/25˚

68˚/20˚

59˚/15˚

50˚/10˚

Temperature ˚F/˚C

Critical temperature

41˚/5˚

17:05

HOW TO CHECK IT?

display: rolling label

i.e. “TEMP 78.8F / 26C”

During this function the “dEFr” indicator light stays on.

C.1.7 ALARMS

C.1.7.1 General description

We have available in the electronic board 2 type of alarm system:

- the HACCP

- the SERVICE ALARMS

The HACCP stores and manages the MAXIMUM CHAMBER

HIGH TEMPERATURE ALARMS.

buzzer: ON sound alarm

WHAT IS RECORDED?

HACCP

Press

: the buzzer is going OFF; then press

again for 5 seconds and the alarm is showed (AL1).

Press

again: temperature, starting time and

date are shown by a rolling label: “TEMP 78.8F/26C Start 17.05

10-10-99 End----”.

15

b) the alarm has occured

Critical temperature

77˚/25˚

68˚/20˚

59˚/15˚

50˚/10˚

41˚/5˚

Temperature ˚F/˚C

18:00

17:00

16:00

Critical temperature

19:00

20:00 21:00

time

22:00

HOW TO CHECK IT?

display: is showing the label “TEMP”

buzzer: ON sound alarm

WHAT IS RECORDED?

HACCP

Press

: the buzzer is going OFF; then press

again for 5 seconds and the alarm is showed (AL1).

HACCP

Press

again: maximum temperature inside,

starting and ending time and date of the alarm are shown by a

rolling label: “TEMP 78.8F/26C Start 17.05 10-10-99 End----”.

To have access to recorded HACCP alarms press

HACCP

button for 4 seconds; now the display visualizes

HISt and then AL_1 (symbol of the alarm); this shows the last

maximum chamber temperature alarm stored in the PCB.

HACCP

Press

button to visualize the value of last

press .

· HOW LONG ARE THE ALARMS RECORDED?

Forever, or better, until the memory is out of space (maximum

number of recorded alarms: 99).

C.1.7.3 SERVICE ALARMS

To have access to SERVICE ALARMS press

button for 4 seconds; now the display visualizes the first

SERVICE ALARM stored in the electronic board, for example

“b1” (door open). Press the

button to visualize

the next SERVICE ALARM stored in the electronic board. If the

electronic board has not stored other SERVICE ALARMS, the

display visualizes “----”. If nothing is pressed within 5 seconds

we go out from SERVICE ALARMS.

· HOW LONG ARE THE ALARMS RECORDED?

Until you have seen the complete alarms list recorded. After

that, they will remain stored ‘till a new alarm occurs: the reset

will be automatic.

· HOW TO FIND AN ALARM?

- blinking led of alarm button

- buzzer ON (sound alarm)

· HOW TO CHECK THE ALARMS?

Keep pressed the button

: the display is showing

maximum chamber temperature alarm. Now in the display we

visualize:

- TEMP 78.8F/26C (type and value of maximum chamber

temperaturealarm)

- Start time and date (starting date and time of alarm)

- End time and date (ending date and time of alarm)

HACCP

Press

the alarm (AL1). Press

button to return to visualize the symbol of

HACCP

button to visualize the

next maximum chamber temperature alarm. If nothing is

pressed within 10 seconds we go out from HACCP section.

· HOW TO CHECK THE OLD ALARMS?

HACCP

Keep pressed the button

: the display shows

AL1 (the last alarm); to select all the other alarms (AL2, AL3, ...)

the last alarm (a label) occured and the buzzer is going OFF. In

order to reset the alarm, press

until the display

shows “----”.

C.1.7.4 SERVICE ALARMS LIST

· Type “b” service alarms

b1

b2

b3

b4

Door is open

Microswitch is broken

Reset HACCP memory

The condenser is dirty

Condenser fan is broken

Missing supply

Wrong plug positioning

16

· Type “E” service alarms

· keep pressed together

RES

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

Sensor short-circuited

Sensor is broken or disconnected

Sensor short-circuited

Sensor is broken or disconnected

Sensor short-circuited

Sensor is broken or disconnected

Sensor short-circuited

Sensor is broken or disconnected

Low chamber temperature

Low evaporator temperature

C.1.7.5 ALARM MANAGING

· Whenever a high chamber temperature alarm occurs the

display shows the label “TEMP” and the buzzer is active.

HACCP

· To reset the buzzer press the

button for 1

SET

HACCP

until the display shows “RES”.

C.1.7.7 TROUBLESHOOTING GUIDE

(problems which can be solved immediately)

PROBLEM

b1

b2 Reset HACCP mem ory

b3

b4

or

microswitch

is broken

HACCP

memory

is

full

High

temperature

condenser

Power

fail ure

if it's cleaned or uncovered,

ACTIONLABEL

Che ck the door, The door is open

if it's ok,

contact technical

assistance center

Check the condenser,

contact technical of

ass istance center

Check the power supply,

if it's ok,

contact technical

ass istance center

second.

· Whenever a type “b” service alarm occurs the display shows

the label code of the alarm and the buzzer is active.

· Whenever a type “E” service alarm occurs the display shows

the label code of the alarm and the buzzer is active. IT IS

NECESSARY TO CONTACT THE TECHNICAL ASSISTANCE.

· To reset the buzzer press the button for 1

second.

C.1.7.6 HACCP ALARM RESET

The maximum number of high chamber temperature recording

alarms is 99.

Whenever the memory is full and a “b2” alarm occurs or at the

end of the year, it is necessary to reset the memory in the

following way:

HACCP

· press the

button until the label “HiSt” will

appear;

17

D.1 ROUTINE MAINTENANCE

Routine maintenance tasks can be performed by non-specialised personnel. When performing maintenance please follow

the instructions closely, keeping safe at all times. The manu-

facturer declines any responsibility for injury sustained from

unsafe acts.

ATTENTION:

do not touch the appliance if hands and/or feet are wet. Before

performing any cleaning or maintenance disconnect the

appliance from the electrical source and carefully unplug the

appliance. It is DANGEROUS AND UNADVISEABLE to remove

the safety guards, AND IS NOT REQUIRED for routine

maintenance. Wear protective gloves. Do not use scissors,

screwdrivers and sharp objects on the cooling circuit.

D.1.1 CLEANING THE CABINET AND

ACCESSORIES

Before using the unit, clean all the internal

parts and accessories with warm water and

either neutral soap or products that are over

90% biodegradable (in order

to reduce the emission of pollutants into the environment),

then rinse and dry thoroughly. Do not use solvent-based detergents (e.g. trichloro-ethylene)

or abrasive powders for cleaning. Coat the metal

panels with protective vaseline oil. The trolleys

must be cleaned with high pressure water jets.

It is advisable to clean the chamber every week;

increasing this frequency according to appliance

use.

D.1.2 PRECAUTIONS IN THE EVENT OF PROLONGED DISUSE

If the appliance is not going to be used for a long period, take

the following precautions:

• switch the appliance off using the ON/OFF button;

• disconnect the circuit-breaker installed upline of the appliance;

• remove all food from the chamber and clean the interior and

the accessories;

• leave the door ajar so that air can circulate inside the chamber, preventing the formation of unpleasant odors and mold;

• rub all the stainless steel surfaces vigorously with a cloth

slightly dampened with vaseline oil, so as to cover them

with a protective film;

• make sure that the premises is aired regularly.

D.2 MAINTENANCE TO BE PERFORMED

BY TRAINED PERSONNEL ONLY

Non-routine maintenance tasks must be performed by an

AUTHORIZED SERVICE AGENT.

USE APPROPRIATE SAFETY GEAR

(GLOVES AND MASK) WHEN CARRYING

OUT ANY MAINTENANCE OPERATION.

ATTENTION:

do not touch the appliance if hands and/or feet are wet. Before

performing any cleaning or maintenance disconnect the

appliance from the electrical source and carefully unplug the

appliance. Do not remove safety guards. Wear protective

gloves when cleaning the condenser. Do not use scissors,

screwdrivers and sharp objects on the cooling circuit.

D.2.1 PERIODIC CLEANING OF CONDENSER

Periodic cleaning of the condenser unit depends on the frequency of use of the appliance. The condenser must be

cleaned periodically to ensure the efficient operation of the

appliance and its continued high performance over time. It is

DANGEROUS AND UNADVISEABLE to remove the safety

guards. It is advisable to thoroughly clean the condenser slits

of the refrigerating unit at least once a month in a dusty environment or once every three months in a closed and clean

environment. The condenser can be cleaned with a brush,

provided the bristles are not made of steel or a material that

can compromise good operation, or a vacuum cleaner to remove the dirt. Take maximum care not to bend the condenser

fins, as this would cause a reduction in the heat exchange. Do

not use pointed objects, as they may damage the condenser.

ATTENTION: the condenser is installed on the top

of the appliance. Do not clean the appliance with

jets of water.

D.2.2 REPLACING THE POWER SUPPLY CABLE

To replace the power supply cable proceed as follows:

• disconnect from the power supply;

• remove the electrical wiring protective cover;

• replace the power supply cable;

• refit the protective cover;

• reconnect to the power supply.

NOTE: if the power supply cable has to be replaced, the

ground connection wire must be kept longer than the live

and neutral wires.

18

D.3 HACCP CONNECTIONS

(ACCESSORIES)

Example: PNC 726377 00 - Ser.No. 44600010

726377 00: Prostore Smart

44600010: manufactured in 2004, week 46, 10th item.

D.3.1 HACCP CONNECTIONS

Refer to the handbook enclosed with the kit for instructions

on installing the accessories.

Basic system connection

The printer can provide a print-out of data collected by the probe

connected to the electronic board. To do this, connect the serial cable (shielded) to the printer and the appliance itself. The

serial cable connector is located behind the control panel.

Set the print interval (see TPRN parameter); and specify the

type of report by setting the “PRND” parameter.

REPORT PRINT-OUTS

Report print-outs are produced automatically when the appliance is switched on.

The print-out contains data measured by electronic the board

and indicates:

- the date and time of start-up, repeated every 20 lines of temperature;

- the chamber temperature at pre-set intervals (TPRN user

parameter);

- the description of the type of alarm generated complete

with the exact time of the start and end of the alarm;

- time of the start and end of defrosting.

D.4 TROUBLESHOOTING

D.4.1 QUICK TROUBLESHOOTING GUIDE

In some cases faults can be remedied easily and quickly. Below

there is a list of possible faults and remedies:

D.5 WASTE DISPOSAL AND DEMOLITION

D.5.1 WASTE STORAGE

At the end of the appliance’s working life, make sure it is disposed of properly. Make sure you remove the doors before

scrapping the appliance.

Special waste materials can be stored temporarily while awaiting processing for disposal and/or permanent disposal. In

any event, the binding environmental protection laws in the

country of use must be observed.

D.5.2 PROCEDURE FOR PRELIMINARY DISMANTLING

OF THE APPLIANCE

All countries have different legislation; provisions laid down by

the laws and the authorized bodies of the countries where

demolition takes place are therefore to be observed.

In general terms, the refrigerator must be taken to a specialized collection/demolition center.

Dismantle the refrigerator and group the components together

according to their chemical characteristics (plastic parts are

marked with letters identifying the material). Bear in mind that

the compressor contains lubricant oil and coolant, which can

be recycled, and that the refrigerator components are classed

as special waste that cannot be disposed of as urban waste.

Make the appliance unusable by cutting off the power supply

cable and removing the door and or locking mechanisms in

order to avoid the risk of anyone becoming trapped inside.

DISMANTLING OPERATIONS MUST BE CARRIED OUT BY

QUALIFIED PERSONNEL.

A. The appliance doesn’t switch on:

- check that the main circuit breaker is powered.

B. The appliance does not reach the set internal temperature:

- check that the condenser is clean;

- check that the cycles have been set properly;

- check that the product has been loaded properly into

the chamber;

C. The appliance is excessively noisy:

- check that the appliance is properly levelled.

If it is unbalanced this could cause vibrations.

- check that the cabinet is not touching other units, as this may

cause resonant vibrations.

If the defect persists after having carried out the above checks,

contact the service center, remembering to give the following

details:

• the nature of the fault;

• the appliance’s PNC (production number code);

• the Ser. No. (appliance serial number).

Note: the data plate with all the appliance specifications is

located on the refrigeration unit compartment at the top right

hand side. There is also a plate bearing the appliance’s PNC

code and serial number located underneath the logo. These

are essential for identifying the type of appliance and date of

manufacture.

PNC 726377

Ser.No. 44600010

D.6 ENCLOSED DOCUMENTS

• Set of test and inspection documents

• Wiring diagram

• Installation diagram

19

Loading...

Loading...