Page 1

ENGLISH

S

GB INDEX

A GENERAL INFORMATION .............................................................................. Page 7

A1 Introduction ......................................................................................................................Page 7

A2 Definitions ........................................................................................................................Page 7

A3 Typographical conventions .............................................................................................. Page 7

A4 Machine and Manufacturer’s identification data............................................................... Page 8

A5 Equipment identification ..................................................................................................Page8

A6 Copyright ......................................................................................................................... Page 9

A7 Liability............................................................................................................................. Page 9

A8 Keeping the manual......................................................................................................... Page 9

A9 Users of the manual ........................................................................................................Page 9

B GENERAL DESCRIPTION OF MACHINE ....................................................... Page 10

B1 General description ......................................................................................................... Page 10

B2 Description of machine modules .....................................................................................Page 10

B2.1 Wash zone...........................................................................................................Page 11

B2.2 Rinse zone...........................................................................................................Page 11

B2.3 Prewash zone...................................................................................................... Page 11

B2.4 View of module composition................................................................................ Page 11

C TECHNICAL DATA ........................................................................................... Page 12

C1 Main technical characteristics.......................................................................................... Page 12

C2 Characteristics of power supply....................................................................................... Page 13

D TRANSPORT, HANDLING AND STORAGE.................................................... Page 14

D1 Introduction...................................................................................................................... Page 14

D1.1 Transport: Instructions for the carrier................................................................... Page 14

D2 Handling .......................................................................................................................... Page 15

D2.1 Procedures for handling operations..................................................................... Page 15

D2.2 Translation ........................................................................................................... Page 15

D2.3 Placing the load................................................................................................... Page 15

D3 Storage ............................................................................................................................Page 15

E INSTALLATION AND ASSEMBLY ................................................................... Page 16

E1 Customer responsibilities ................................................................................................ Page 16

E2 Characteristics of the site installation .............................................................................. Page 16

E3 Machine space limits ....................................................................................................... Page 16

E4 Positioning ....................................................................................................................... Page 16

E5 Disposal of packing .........................................................................................................Page 16

E6 Plumbing connections .....................................................................................................Page 16

E6.1 Plumbing circuits ................................................................................................. Page 17

E6.2 Installation diagrams............................................................................................Page 19

E7 Electrical connections......................................................................................................Page 25

E8 Installation of detergent/rinse aid dispensers .................................................................. Page 26

E8.1 Arrangement for water connection ...................................................................... Page 26

E8.1.1 Detergent concentration measurement probe...................................Page 27

E8.1.2 Liquid detergent dispensers.............................................................. Page 27

E8.1.3 Rinse aid dispensers......................................................................... Page 27

E8.2 Arrangement for electrical connection ................................................................. Page 27

3

Page 2

E9 Fitting curtains .................................................................................................................Page 28

E10 Installation of rack handling systems ...............................................................................Page 29

E10.1 Arrangement for mechanical connection .............................................................Page 29

E10.2 Arrangement for electrical connection .................................................................Page 29

E10.3 Positioning of emergency switches...................................................................... Page 29

E10.4 Emergency stop reinstatement ............................................................................ Page 30

F DESCRIPTION OF CONTROL PANEL ............................................................Page 31

F1 Basic controls ..................................................................................................................Page 31

F2 Accessory function selection controls.............................................................................. Page 31

G STARTING.........................................................................................................Page 32

G1 Preliminary checks, adjustments and operational tests...................................................Page 32

G1.1 Electrical and plumbing checks ...........................................................................Page 32

G1.2 Check the positioning of tank components.......................................................... Page 32

G1.2.1 Check the fitting of filters and overflows ............................................Page 32

G1.2.2 Check the fitting of arms and curtains............................................... Page 32

G2 Starting ............................................................................................................................Page 32

H GENERAL SAFETY RULES.............................................................................Page 33

H1 Introduction...................................................................................................................... Page 33

H1.1 Protection devices installed on the machine........................................................Page 33

H1.2 Safety signs to be displayed on the machine.......................................................Page 33

H2 Decommissioning ............................................................................................................ Page 34

H3 Instructions for use and maintenance..............................................................................Page 34

H4 Improper use.................................................................................................................... Page 34

H5 Residual risks .................................................................................................................. Page 35

I NORMAL MACHINE USE.................................................................................Page 36

I1 Correct use ......................................................................................................................Page 36

I2 Characteristics of personnel trained for normal machine use..........................................Page 36

I2.1 Characteristics of personnel enabled to operate on the machine........................Page 36

I2.1.1 Operator qualified for normal use......................................................Page 36

I3 Daily activation of machine ..............................................................................................Page 36

I3.1 Wash phase.........................................................................................................Page 36

I3.2 Rack jamming ......................................................................................................Page 37

I3.3 Wash phase stop ................................................................................................. Page 37

I3.4 Temperature display ............................................................................................ Page 37

I3.5 Loading dishes on racks ...................................................................................... Page 38

I3.6 Accessory functions.............................................................................................Page 38

I3.7 Door open ............................................................................................................Page 39

I3.8 Emergency stop...................................................................................................Page 39

I3.9 General alarm......................................................................................................Page 39

I4 Machine cleaning............................................................................................................. Page 41

I4.1 Daily internal cleaning ......................................................................................... Page 41

I4.2 Exterior cleaning .................................................................................................. Page 41

I5 Long idle periods .............................................................................................................Page 41

I6 Maintenance ....................................................................................................................Page 42

I6.1 Preventive maintenance ......................................................................................Page 42

I7 Machine disposal .............................................................................................................Page 42

I8 Troubleshooting ...............................................................................................................Page 42

4

Page 3

ENGLISH

GB INDEX OF FIGURES AND TABLES

INDEX OF FIGURES

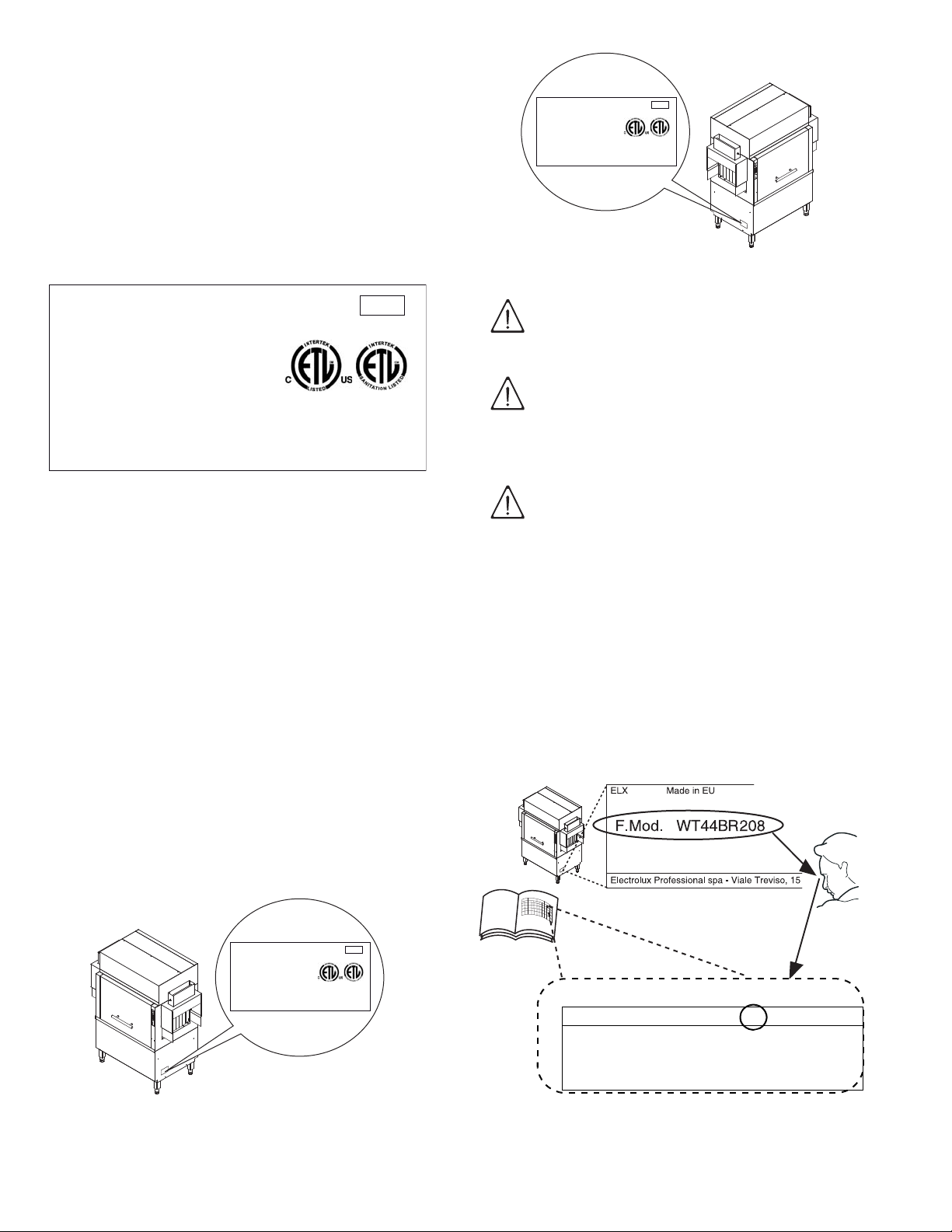

Figure 1 Reproduction of the marking/dataplate on the machine.....................................................Page 8

Figure 2 Position of marking (machine left)...................................................................................... Page 8

Figure 3 Position of marking (machine right)....................................................................................Page 8

Figure 4 Technical data identification (Machine left) ........................................................................Page 8

Figure 5 Example of document and edition identification data......................................................... Page 9

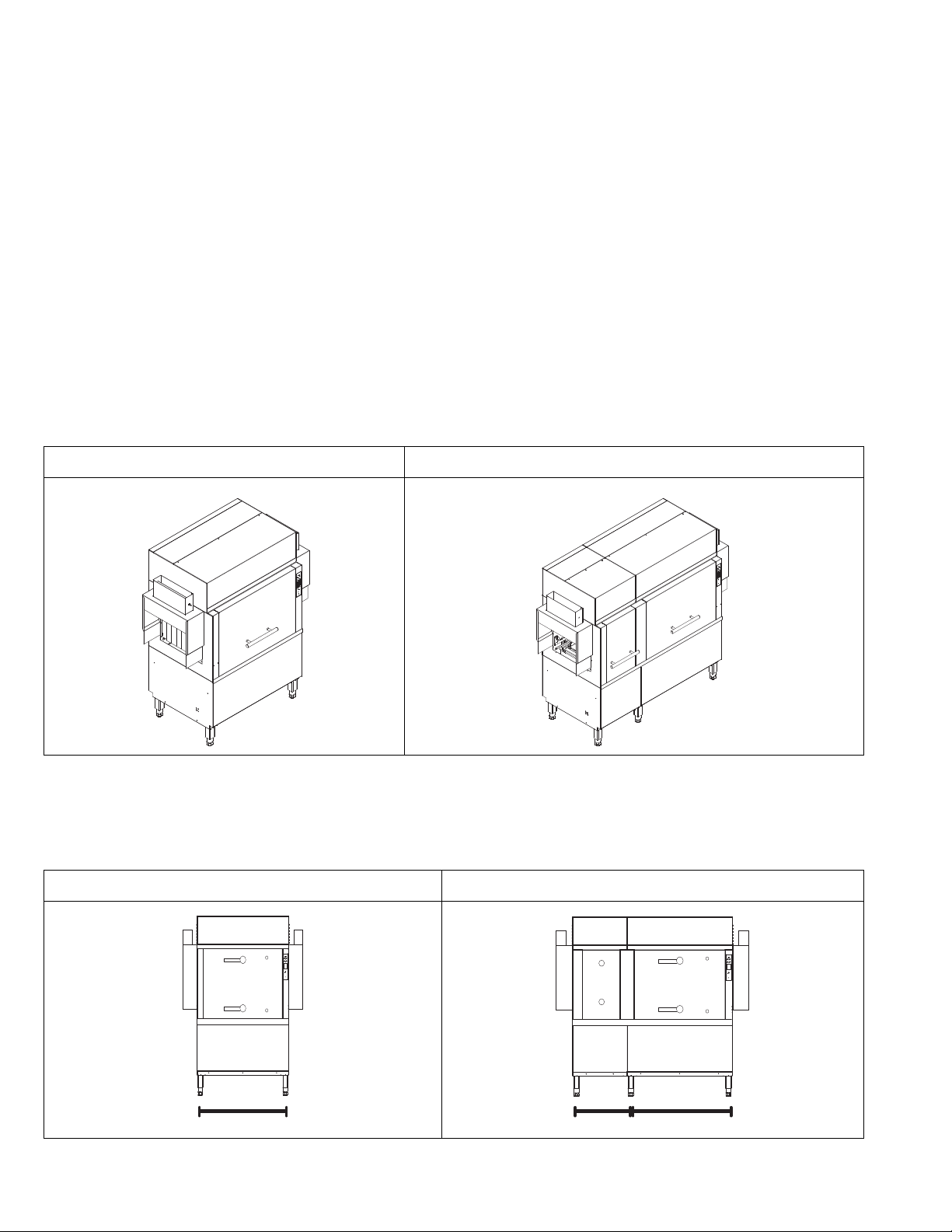

Figure 6 View of different configurations of compact rack-type dishwashers................................... Page 10

Figure 7 Feet adjustment ................................................................................................................. Page 16

Figure 8 Water connection ...............................................................................................................Page 17

Figure 9 Installation diagram - Recommended table connection and fabrication............................. Page 24

Figure 10 Electrical connections diagram .......................................................................................... Page 25

Figure 11 Hole for detergent probe .................................................................................................... Page 27

Figure 12 Arrangement for liquid detergent........................................................................................Page 27

Figure 13 Rinse aid connection..........................................................................................................Page 27

Figure 14 Diagram of curtain positioning on compact machines .......................................................Page 28

Figure 15 Handling electrical connection system............................................................................... Page 29

Figure 16 Detail of electrical connection ............................................................................................ Page 29

Figure 17 Examples of dishwasher and rack handling system couplings .......................................... Page 30

Figure 18 Prewash module tank filters ............................................................................................... Page32

Figure 19 Wash/rinse module tank filters ........................................................................................... Page 32

Figure 20 Prewash ............................................................................................................................. Page 32

Figure 21 Wash..................................................................................................................................Page 32

Figure 22 Rinse..................................................................................................................................Page 32

Figure 23 Positioning of safety signs .................................................................................................. Page 34

Figure 24 Positioning dishes .............................................................................................................. Page 38

Figure 25 Positioning pans................................................................................................................. Page 38

Figure 26 Positioning trays ................................................................................................................. Page 38

Figure 27 Remove and cleaning filters............................................................................................... Page41

Figure 28 Remove and cleaning arms ............................................................................................... Page 41

INDEX OF TABLES

Ta ble 1 Main technical characteristics, performance and consumption..........................................Page 13

Ta ble 2 Control panel...................................................................................................................... Page 31

Ta ble 3 Residual risks..................................................................................................................... Page 35

Ta ble 4 Accessory functions ........................................................................................................... Page 39

5

Page 4

Foreword

The instruction manual (hereinafter Manual) provides the operator with useful information for working correctly and

safely, facilitating him in using the machine (hereinafter “machine”, “dishwasher” or “equipment”).

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable for

improving machine performance in every respect and, above all, preventing injury to persons and animals and damage

to property due to improper operating procedures.

All persons involved in machine transport, installation, starting, use and maintenance, repair and dismantling must consult and carefully read this manual before performing the various operations, for the purpose of avoiding wrong and

improper actions that could negatively affect the machine’s integrity or endanger persons.

The manual must always be available to operators and carefully kept in the place where the machine is used so that it is

immediately at hand for consultation in case of doubts or whenever required.

If, after reading this manual, there are still doubts regarding machine use, do not hesitate to contact the Manufacturer, or

the authorized assistance centre, to receive prompt and precise assistance for better operation and maximum efficiency

of the machine.

During all phases of machine use, always respect the current regulations on safety, work hygiene and environmental

protection. It is the user’s responsibility to make sure the machine is started and operated only in optimal safety conditions for persons, animals and property.

6

Page 5

ENGLISH

A GENERAL INFORMATION

IMPORTANT

A1 Introduction

This chapter describes the symbols used (that mark and

identify the type of warning) and gives the definitions of

terms used in the manual, responsibilities and copyright.

A2 Definitions

Listed below are the definitions of the main terms used

in the Manual. Carefully read them before using the

Manual.

Operator

an operator who carries out machine installation, adjustment, use, maintenance, cleaning, repair and transport.

Manufacturer

Electrolux Professional S.p.A. or any other assistance

centre authorized by Electrolux Professional S.p.A..

Operator qualified for normal machine use

an operator who has been informed, instructed and

trained regarding the tasks and hazards involved in normal machine use.

Specialized technician or Technical assistance

an operator instructed/trained by the Manufacturer and

who, based on his professional and specific training,

experience and knowledge of the accident-prevention

regulations, is able to appraise the operations to be carried out on the machine and recognize and prevent possible risks. His professionalism covers the mechanical,

electrotechnical and electronics fields.

Danger

source of possible injury or harm to health.

Hazardous situation

any situation where an operator is exposed to one or

more hazards.

Risk

a combination of probabilities and risks of injury or harm

to health in a hazardous situation.

Guards

safety measures consisting of the use of specific technical means (guards and safety devices) for protecting

operators against dangers.

Guard

an element of a machine used specifically to provide

protection by means of a physical barrier.

Safety device

a device (other than a guard) that eliminates or reduces

the risk; it can be used alone or in combination with a

guard.

Customer

the person who purchased the machine and/or who

manages and uses it (e.g. company, entrepreneur, firm).

Emergency stop device

a group of components intended for the emergency stop

function; the device is activated with a single action and

prevents or reduces damage to persons/machines/property/animals.

Electrocution

an accidental discharge of electric current on a human

body.

A3 Typographical conventions

For best use of the manual, and therefore the machine, it

is advisable to have good knowledge of the terms and

typographical conventions used in the documentation.

The following symbols are used in the manual to mark

and identify the various types of hazards:

WARNING!

DANGER FOR THE HEALTH AND

SAFETY OF OPERATORS.

WARNING!

DANGER OF ELECTROCUTION - DAN-

GEROUS VOLTAGE.

Machine guards and protection devices marked with this

symbol must only be opened by qualified personnel,

after disconnecting the power to the machine.

WARNING!

DANGER OF DAMAGE TO THE

MACHINE.

Before servicing, disconnect the electrical service

and place a red tag at the disconnect switch to indicate work is being done on that circuit.

Words and safety warnings further explaining the type of

hazard are placed next to the symbols in the text. The

warnings are intended to guarantee the safety of personnel and prevent damage to the machine or the product

being worked.

The drawings and diagrams given in the manual are not

in scale. They supplement the written information with

an outline, but are not intended to be a detailed representation of the machine supplied.

The numerical values given in the machine installation

diagrams refer to measurements expressed in mm (see

par. E6.2 “Installation diagrams”).

7

Page 6

Conventionally, the machines are depicted with the rack

feed side on the right (RH); machines with left rack feed

(LH) are depicted only if necessary, in which case the

side will be expressly specified.

Due to its size, the machine is sometimes shown schematically divided into its functional modules in order to

provide a complete view.

A4 Machine and Manufacturer’s identification

data

A reproduction of the marking or dataplate on the

machine is given below.

ELX

F. Mod. WT44BR208 Comm. Model WT44BR208

PNC 534071 00 / 9CGX P63096

Electrolux Professional SpA - Viale Treviso, 15 - 33170 Pordenone (Italy)

Figure 3

Made in EU

Ser. Nr. 64500001

AC 208 V - 3ph

60 Hz 44.7 kW

3048424

CONFORMS TO ANSI/ UL 921

CONFORMS TO ANSI/ NSF 3

CONFORMS TO CSA C 22.2 No. 168

Position of marking (machine right)

2008

ELX

F. Mod. WT44BR208 Comm. Model WT44BR208

PNC 9CGX 534071 00

AC 208 V - 3ph

Min. Supply Ampacity: 67A

Made in EU

Ser. Nr. 64500001

60 Hz 44.7 kW

CONFORMS TO ANSI/ UL 921

CONFORMS TO ANSI/ NSF 3

CONFORMS TO CSA C 22.2 No. 168

3048424

2008

Electrolux Professional SpA - Viale Treviso, 15 - 33170 Pordenone (Italy)

Figure 1 Reproduction of the marking/dataplate

on the machine.

The dataplate gives the product identification and technical data; the meaning of the information given on it is

listed below.

F. Mod.................. factory description of the product

Comm. Model........ trade description

PNC:...................... production code number

Ser. No.................. serial number

AC 208V -3ph....... power supply voltage

60 Hz.................... power supply frequency

44.7 kW................. max. power absorbed

2008..................... year of construction

Electrolux Professional S.p.A.

Viale Treviso, 15

33170 Pordenone

(Italy) ................... Manufacturer

The marking plate is located on the left or right side

panel of the equipment, depending on the feed side.

WARNING!

Do not remove, tamper with or make the

machine “CE” marking illegible.

IMPORTANT!

Refer to the data given on the machine

“CE” marking for relations with the Manufacturer (e.g. when ordering spare

parts, etc.).

IMPORTANT!

When disposing of the machine the “CE”

marking must be destroyed.

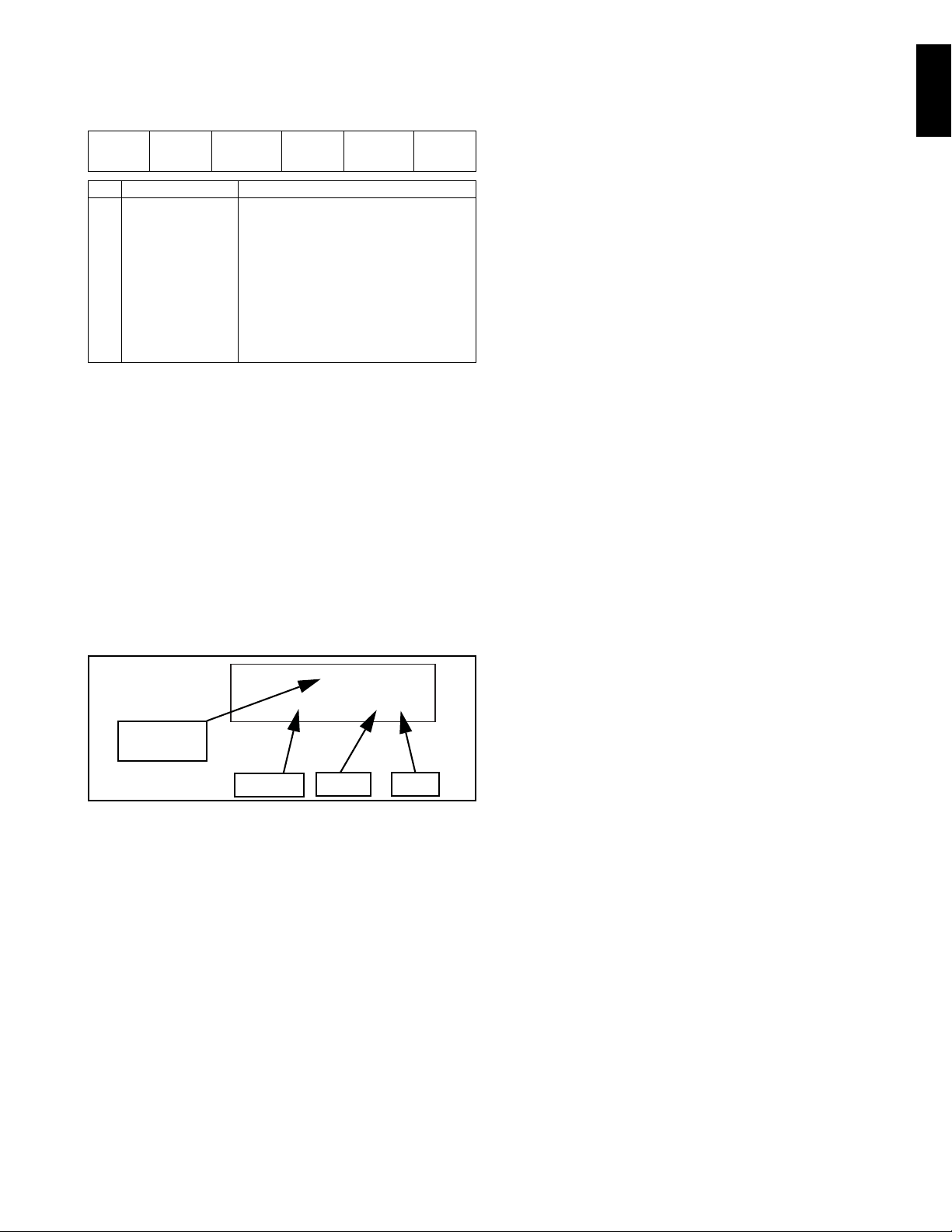

A5 Equipment identification

This manual refers to various rack-type dishwasher

models. For further details regarding your model, refer to

Table 1 “Main technical characteristics, performance

and consumption”.

How to identify the technical data

To identify the technical data (Figure 4) read the factory

description of the product (F.Mod.) on the dataplate,

identify the main machine data and consult the Table 1

“Main technical characteristics, performance and consumption”.

AC 208 V - 3ph

Made in EU

Ser. Nr. 64500001

60 Hz 44.7 kW

ELX

F. Mod. WT44BR208 Comm. Model WT44BR208

PNC 534071 00 / 9CGX P63096

Electrolux Professional SpA - Viale Treviso, 15 - 33170 Pordenone (Italy)

2008

3048424

CONFORMS TO ANSI/ UL 921

CONFORMS TO ANSI/ NSF 3

CONFORMS TO CSA C 22.2 No. 168

C1 Main technical characteristics

MODEL 44” (208V)

Power supply Electric

Power supply

voltage

Frequency Hz 60

V 208 3ph

Figure 2 Position of marking (machine left)

Figure 4 Technical data identification (Machine left)

8

Page 7

ENGLISH

How to interpret the factory description

Month YearEdition

Number

Document

The factory description on the dataplate has the following meaning:

(1) (2) (3) (4) (5) (6)

WT 44 B R 208

Description Possible variables

(1) Mark WT ...

(2) Machine dimension 44 = 44” 66 = 66”

(3) Functional level B = Atmospheric plumbing circuit with boiler,

(4) Rack loading L = from left to right

(5) Power supply

voltage

(6)

without CU

C= Atmospheric plumbing circuit without

boiler, without CU

R = from right to left

208 = 208V 240= 240V

A6 Copyright

This manual is intended for consultation only by the

operator and can be given to third parties only with the

written permission of Electrolux Professional S.p.A..

A7 Liability

The instructions supplied with the machine take into

account the Electrolux Professional S.p.A. experience

and knowledge acquired to date. The instructions are

updated to the month and year given in the box located

at the bottom right of the cover. The edition corresponds

to the manual revision number. Every new edition

replaces and cancels the previous ones.

DOC. NO. 5956.583.01

EDITION: 1 01.2008

• use of the machine by uninformed and untrained personnel;

• non-application of the current provisions in the country of use, concerning safety, hygiene and health in

the workplace.

The Manufacturer declines any liability for damage

caused by arbitrary modifications and conversions carried out by the user or the Customer.

The employer or workplace manager is responsible for

identifying and choosing adequate and suitable personal

protection equipment to be worn by operators, in compliance with current regulations in the country of use.

Electrolux Professional S.p.A. declines any liability for

possible inaccuracies contained in the manual, if due to

printing or translation errors.

Any supplements to the instruction manual the Customer

receives from the Manufacturer must be kept together

with the manual, of which they will form an integral part.

A8 Keeping the manual

The manual must be carefully kept for the entire life of

the machine until decommissioning.

The manual must stay with the machine in case of transfer, sale, hire, granting of use or leasing.

A9 Users of the manual

This manual is intended for:

• the carrier and handling personnel;

• installation and start-up personnel;

• the employer of machine users and the workplace

manager;

• operators in charge of normal machine use;

• specialized technicians - technical assistance (see

wiring diagram and service manual).

Figure 5 Example of document and

edition identification data.

The Manufacturer declines any liability for damage and

malfunctioning caused by:

• non-compliance with the instructions contained in this

manual;

• repairs not carried out in a workmanlike fashion, and

replacements using spare parts different from those

specified in this manual (the fitting and use of nonoriginal spare parts and accessories can negatively

affect machine operation);

• operations by non-specialized technicians;

• unauthorized modifications or operations;

• inadequate maintenance;

• improper machine use;

• unexpected extraordinary events;

9

Page 8

B GENERAL DESCRIPTION OF MACHINE

B1 General description

The rack-type dishwasher is suitable for washing dishes, glasses, cups, cutlery, trays, containers and receptacles in

plastic and/or steel used for preparing, cooking and serving; as well as various cooking utensils in ceramic and/or metal.

The machine is designed for the above-mentioned applications. Under no circumstances may the machine be used for

other applications or ways not provided for in this manual.

This equipment has been produced to meet the needs for a better work environment and economical efficiency. These

dishwashers are used in restaurants, cafeterias, cooking centres and large institutions.

The special dish racks, that can be equipped with various inserts, offer practical and easy use for obtaining excellent

washing results. Rack handling inside the machine occurs automatically. The electronic system enables complete

supervision of the washing process. The control panel also has a display that shows the operating parameters and signals any anomalies.

In this type of machine the rack is taken from the loading point to the unloading point, through the various washing functions. Systems for scraping and wetting the dishes (e.g. manual prewash spray) and areas for sorting and arranging

them in the racks must be arranged ahead of the dishwasher.

The possible configurations of compact rack-type dishwashers, classified according to the maximum number of racks

washed in one hour, are as follows:

44” 66”

Figure 6 View of different configurations of compact rack-type dishwashers

B2 Description of machine modules

Rack-type dishwasher - 44” Rack-type dishwasher - 66”

Wash + Rinse Prewash Wash + Rinse

10

Page 9

ENGLISH

The machine consists of the following zones:

• wash zone

• rinse zone

and can be integrated with the following units:

•prewash zone

B2.1 Wash zone

Water with the addition of detergent is sprayed on the dishes in the wash zone through an upper and lower wash arm

system. The purpose of this function is to remove all residuals of food from the dishes. Washing is carried out with water

circulating at a temperature of 71-78 °C / 160-172 °F.

B2.2 Rinse zone

Water with the addition of rinse aid is sprayed on the dishes in the rinse zone through a system of arms equipped with

special nozzles. The purpose of this function is to remove all residuals of detergent deriving from the previous wash

phase.

Rinsing is carried out with clean water coming from the water system, heated to a max. temperature of 82-90 °C / 180194°F.

The high temperature ensures satisfactory drying and careful neutralization of bacteria. The addition of rinse aid allows

the water to easily run off the dishes, thus favouring the drying process.

B2.3 Prewash zone

Water is sprayed on the dishes in the prewash zone through an upper and lower prewash arm system. The purpose of

this function is to remove the larger food residuals, preparing the dishes for the subsequent wash phase.

Prewash is carried out with water circulating at a max. temperature of 40°C / 104°F in order to prevent food residuals (in

particular proteins) from sticking to the dishes.

B2.4 View of module composition

In rack-type dishwashers the various zones just described are thus applied to the various previously defined configurations.

11

Page 10

C TECHNICAL DATA

C1 Main technical characteristics

MODEL 44” (208V) 44” (240V) 66” (208V) 66” (240V)

Power supply Electric Electric Electric Electric

Power supply voltage V 208 3PH 240 3PH 208 3PH 240 3PH

Frequency Hz 60 60 60 60

Max. power. absorbed with boiler

( rise 56 °C / 100 °F)

Max. power. absorbed with boiler

( rise 39 °C / 70 °F)

Max. power. absorbed with boiler

( rise 22 °C / 40 °F)

Max. power. absorbed without boiler kW 20.7 20.7 21.0 21.0

Max. current. absorbed with boiler

( rise 56 °C / 100 °F)

Max. current. absorbed with boiler

( rise 39 °C / 70 °F)

Max. current. absorbed with boiler

( rise 22 °C / 40 °F)

Max. current. absorbed without boiler A 61.7 55.0 64.0 57.5

Supply water pressure kPa/bar/PSI

Hot water supply temp. with boiler **

( rise 56 °C / 100 °F)

Hot water supply temp. with boiler

( rise 39 °C / 70 °F)

Hot water supply temp. with boiler

( rise 22 °C / 40 °F)

Hot water supply temp. without boiler °C/°F 90 / 194 90 / 194 90 / 194 90 / 194

Concentration of chlorides in water

Electric conductivity of water

Supply water hardness °fH /°dH/

MAIN TECHNICAL DATA

Rack loading/feed

No. speeds 2 2

Capacity speed 1 racks/h 100 100 100 100

Capacity speed 2 racks/h 200 200 200 200

Water consumption l/h - gal/h 300 - 79.3 300 - 79.3 315 - 83.2 315 - 83.2

Equivalent sound pressure level Leq

(1)

Minimum Supply - Circuit Ampacity

Supply Terminal box ( Boiler ) (2)

Minimum Supply - Circuit Ampacity

Supply Terminal box ( Machine ) (2)

Maximum overcurrent protective device

Supply Terminal box ( Machine ) (2)

Net weight lb/kg 1012 / 459 1012 / 459 1268 / 575 1268 / 575

Shipping weight lb/kg----

Shipping width lb/kg

Shipping height lb/kg

Shipping depth lb/kg

tank capacity l/gal - - 45/ 11.9 45/ 11.9

temperature °C/°F - - max 40 / 104 max 40 / 104

pump delivery l/min - gal/min - - 180 - 57.5 180 - 57.5

pump power kW - - 0.37 0.37

current absorbed by pump A - - 2.5 2.5

PREWASH

tank heating elementkW----

tank capacity l/gal 100/ 26.4 100/ 26.4 100/ 26.4 100/ 26.4

temperature °C/°F 71..78

pump delivery l/min - gal/min 450 - 118.9 450 - 118.9 450 - 118.9 450 - 118.9

pump power kW 1.9 1.9 1.9 1.9

WASH

current absorbed by pumps A 6.2 6.2 6.2 6.2

tank heating element kW 9.0 + 9.0 9.0 + 9.0 9.0 + 9.0 9.0 + 9.0

kW 44.7 44.7 45.0 45.0

kW 38.7 38.7 39.0 39.0

kW 32.7 32.7 33.0 33.0

A 128.3 112.7 130.6 115.2

A 111.6 98.3 113.9 100.8

A 95.0 83.9 97.3 86.4

150..700 / 1.5..7 /

22..102

°C/°F 27 / 80 27 / 80 27 / 80 27 / 80

°C/°F 44 / 110 44 / 110 44 / 110 44 / 110

°C/°F 60 / 140 60 / 140 60 / 140 60 / 140

150..700 / 1.5..7 /

22..102

150..700 / 1.5..7 /

22..102

150..700 / 1.5..7 /

22..102

ppm < 20 < 20 < 20 < 20

μS/cm < 400 < 400 < 400 < 400

14 / 8 / 140 14 / 8 / 140 14 / 8 / 140 14 / 8 / 140

ppm CaCO

RH machine

LH machine

dB(A) < 70 < 70 < 70 < 70

A67586758

A66606660

A80708070

3

From right to left

From left to right

--

--

-

/

160..172 71..78 / 160..172 71..78 / 160..172 71..78 / 160..172

From right to left

From left to right

-

From right to left

From left to right

22

--

--

--

From right to left

From left to right

12

Page 11

ENGLISH

MODEL 44” (208V) 44” (240V) 66” (208V) 66” (240V)

temperature °C/°F 82..90 / 180..194 82..90 / 180..194 82..90 / 180..194 82..90 / 180..194

delivery l/min - gal/min 5 - 1.32 5 - 1.32 5 - 1.32 5 - 1.32

pump power kW 0.32 0.32 0.32 0.32

current absorbed by pump A 1.5 1.5 1.5 1.5

boiler heating elements (with boiler

rise 100)

RINSE

boiler heating elements (with boiler

rise 70)

boiler heating elements (with boiler

rise 40)

boiler capacity l/ gal 12+12 / 3.17+ 3.17 12+12 / 3.17+ 3.17 12+12 / 3.17+ 3.17 12+12 / 3.17+ 3.17

kW 6.0 + 6.0 + 6.0 + 6.0 6.0 + 6.0 + 6.0 + 6.0 6.0 + 6.0 + 6.0 + 6.0 6.0 + 6.0 + 6.0 + 6.0

kW 6.0 + 6.0 + 6.0 6.0 + 6.0 + 6.0 6.0 + 6.0 + 6.0 6.0 + 6.0 + 6.0

kW 6.0 + 6.0 6.0 + 6.0 6.0 + 6.0 6.0 + 6.0

Table 1 Main technical characteristics, performance and consumption

**

If the water supply temperature is lower than the value indicated, the machine could not comply with NSF/ ANSI 3 2003.

(1) The value could increase depending on the work station where measured.

(2) See

Figure 10 (

Electrical connections diagram ).

C2 Characteristics of power supply

The AC power supply to the machine must meet the following conditions:

• max. voltage variation ± 6% continuous ± 10% for a short period.

• max. frequency variation ± 1% continuous ± 2% for a short period.

Harmonic distorsion, unbalanced three-phase supply voltage, voltage pulses, interruption, dips and the other electric

characteristics must respect the provisions of point 4.3.2 of Standard EN 60204-1 (IEC 60204-1).

IMPORTANT!

The machine’s power supply must be protected against overcurrents (short circuits and overloads)

by fuses or suitable thermal magnetic circuit breakers.

IMPORTANT!

The dishwasher shall be installed in accordance with local codes, or in the absence of local codes,

installed in accordance with the applicable requirements in the National Electrical Code, NFPA 70,

Canadian Electrical Code (CEC), Part 1, CSA C22.1, and Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations, NFPA 96.

IMPORTANT!

Customers are requested to follow these instructions, otherwise the Manufacturer does not guaran-

tee the machine for continuous operation and/or against faults.

13

Page 12

D TRANSPORT, HANDLING AND STORAGE

D1 Introduction

Transport (i.e. transfer of the machine from one place to

another) and handling (i.e. transfer inside workplaces)

must occur with the use of special equipment of adequate capacity.

The machine can be transported by road, rail, sea or air.

Except for transport by road, the machine is placed

inside a container in which there are also other

machines. The machines can be positioned inside the

container by the Manufacturer or by the carrier.

IMPORTANT!

Due to its size, during transport one

machine cannot be stacked on top of

another, therefore possible risks of load

overturning are excluded.

The Manufacturer declines any liability for possible damage to the packing and the machine.

On receiving the machine, check that the packing and

components are not damaged. In case of damage,

immediately notify the carrier and the Manufacturer.

If the equipment received has visible or hidden damage,

a claim can be made with the carrier.

Visible losses or damage must be reported in the transport document at the time of delivery. The transport document must be signed by the carrier’s representative

(e.g. the driver). If the transport document is not signed,

the carrier can reject the claim.

The request for inspection must be submitted to the carrier within 15 days in case of non-visible damage or

losses detected only after unpacking the equipment. The

carrier shall arrange an inspection. Keep all the packing

material and contents. Under no circumstances may a

damaged appliance be returned to the manufacturer

without prior notice and written permission.

The machine must only be transported, handled and

stored by qualified personnel, who must have:

- specific technical training and experience;

- knowledge of the safety regulations and applicable

laws in the relevant sectors;

- knowledge of the general safety provisions;

- the ability to recognize and avoid any possible hazard.

The Manufacturer declines any liability whenever transport is undertaken by carriers chosen by the Customer.

IMPORTANT!

Machine transport, handling and storage

personnel must receive adequate

instruction and training on the use of lifting systems and the use of personal protection equipment suitable for the type

of operation performed (e.g. overalls,

safety shoes, gloves and helmet).

D1.1 Transport: Instructions for the carrier

During the journey the tightness of the fixing systems

must be checked several times, and in particular:

• just a few km after the start of the journey;

• in case of sudden temperature changes;

• in case of intense cold;

• in case of particularly rough roads.

When removing the anchoring systems, make sure the

stability of the machine parts does not depend on the

anchoring and, therefore, that this operation does not

cause the load to fall off the vehicle.

WARNING!

Do not stand under suspended loads

during the loading/unloading phases.

Unauthorized personnel must not

access the work zone.

IMPORTANT!

The machine’s weight alone is not suffi-

cient to keep it steady.

The transported load can shift:

- when braking;

- when accelerating;

- in corners;

- on particularly rough roads.

If slings in synthetic fibre are used to anchor the

machines, protect them from friction, abrasion and damage caused by possible sharp edges of the load. If there

are sharp edges that can damage the sling, use suitable

corner protectors or sliding tubes.

CAUTION!

When removing the anchoring systems,

make sure the stability of the machine

parts does not depend on the anchoring

and, therefore, that this operation does

not cause the load to fall off the vehicle.

Before unloading the machine components make sure all the anchoring systems are removed.

14

Page 13

ENGLISH

D2 Handling

Arrange a suitable area with flat floor for machine

unloading and storage operations.

D2.1 Procedures for handling operations

For correct and safe lifting operations:

• use the type of equipment most suitable for characteristics and capacity (e.g. lift trucks or electric pallet

truck);

• cover sharp edges;

• check the forks and lifting procedures according to

the instructions given on the packing.

Before lifting:

• send all operators to a safe position and prevent persons from accessing the handling zone;

• make sure the load is stable;

• make sure no material can fall during lifting, and

manoeuvre vertically in order to avoid impacts;

• handle the machine, keeping it at minimum height

from the ground.

CAUTION!

For machine lifting, do not use movable

or weak parts such as casings, electrical

raceways, pneumatic parts, etc., as

anchoring points.

IMPORTANT!

Machine positioning, installation and

disassembly must be carried out by a

specialized technician.

IMPORTANT!

Do not make modifications to the parts

supplied with the machine. Any missing

or faulty parts must be replaced with

original parts.

D2.2 Translation

The operator must:

• have a general view of the path to be followed;

• stop the manoeuvre in case of hazardous situations.

D2.3 Placing the load

Before placing the load make sure the path is free and

that the floor is flat and can take the load.

D3 Storage

The machine and/or its parts must be stored and protected against damp, in a non-aggressive place free

of vibrations and with room temperature of between 10°C / 14°F and 50°C / 122°F.

The place where the machine is stored must have a flat

support surface in order to avoid any twisting of the

machine or damage to the support feet.

IMPORTANT!

During the storage phase the machine

can be stacked on another as shown in

the pictogram on the packing.

15

Page 14

E INSTALLATION AND ASSEMBLY

IMPORTANT

E1 Customer responsibilities

The Customer must provide for the following:

- installation of an adequate electrical power supply

ahead of the machine, according to the equipment’s

technical specifications (Table 1 and C2 “Characteristics of power supply”);

- the equipotential ground connection of the workplace

electrical system to the metal structure of the

machine by means of a copper cable of adequate

section (see position “Q” in par. E6.2 “Installation diagrams”);

- Adducting for the electrical connection between the

workplace electric panel and the equipment;

- the water supply and drain connections and other

connections as indicated in Table 1 and par. E6

“Plumbing connections”;

- arrangement of general workplace lighting to guarantee at least 500 lx according to point 5.2.2 of EN

12464-1 or according to a value established by the

current regulations in the country of use.

E2 Characteristics of the site installation

The machine is designed for installation in professional

and not domestic-type kitchens. Water collection traps/

metal grates must be arranged in the floor at the

machine discharges (see par. E6.2 “Installation diagrams”), possibly replaceable with a single water trap

sized for a flow rate of at least 0.79 gal/s (3 l/s).

E3 Machine space limits

A suitable space must be left around the machine (for

operations, maintenance, etc.).

The passages enabling personnel to operate on the

machine must be at least 27.55’’ ( 70cm) wide, except at

the rear of the machine (see par.

E6.2 “Installation dia-

grams”).

The size must be increased in case of use and/or trans-

fer of other equipment and/or means or if exit routes are

necessary inside the workplace.

E4 Positioning

Unless otherwise agreed, the machine is supplied in a

single unit.

The machine must be taken to the place of installation

and the packing base removed only when being

installed.

Arranging the machine:

• Position the machine in the required place.

• Adjust the equipment by turning the special adjustable feet and making sure it is perfectly level, both

lengthwise and crosswise.

• Wear protective gloves and unpack the machine.

• Carefully remove the protective film from the outer

panels without tearing it, to avoid leaving traces of

glue.

E5 Disposal of packing

All materials used for packing are environmentally compatible. They can be safely kept, and recycled or burnt in

a special waste incineration plant. Plastic parts subject

to possible recycling are marked as follows:

polyethylene: outer wrapping, instruc-

PE

polypropylene: roof packing panels,

PP

polystyrene

foam:

PS

Parts in wood and cardboard can be disposed of

respecting the current regulations in the country of use.

E6 Plumbing connections

Install the machine water filling and drain pipes according to the plumbing circuit and installation diagrams

given below.

Before servicing, disconnect the electrical service

and place a red tag at the disconnect switch to indicate work is being done on that circuit.

Figure 7 Feet adjustment

IMPORTANT!

Machine installation operations must only

be carried out by specialized Technicians

provided with all the appropriate personal

protection equipment (safety shoes,

gloves, glasses, overalls, etc.), tools, utensils and ancillary means.

tion booklet bag.

straps.

corner protectors.

16

Page 15

ENGLISH

E6.1 Plumbing circuits

Cold water connection ISO 228/1 DN 20 (G3/4”).

4-15°C 39°F-59°F 150 - 700 kPa (21.7 - 101.5 PSI / 1.5 - 7 bar) at 0.07 gal/sec (0.3 l/sec).

Hot water connection ISO 228/1 DN 20 (G3/4").

150 - 700 kPa (21.7 - 101.5 PSI / 1.5 - 7 bar) at 0.07 gal/sec (0.3 l/sec).

The supply water temperature is related to the machine setup.

MACHINES WITH BOILER:

RISE 40°F/ 22°C Inlet water temperature min. 140°F/ 60°C for RINSE and WASH CIRCUIT

RISE 70°F/ 39°C Inlet water temperature min. 110°F/ 43.3°C for RINSE and WASH CIRCUIT

RISE 100°F/ 56°C Inlet water temperature min. 80°F/ 26.6°C for RINSE and WASH CIRCUIT

MACHINES

WITH BOILER

MACHINES WITHOUT BOILER:

Inlet water temperature min. 194°F/ 90°C for RINSE CIRCUIT

Inlet water temperature 80-140°F/ 27-60°C for WASH TANK

Inlet water temperature 39-59°F/ 4-15°C for PREWASH TANK

MACHINES

WITHOUT BOILER

If the water pressure is less than 150 kPa (21.7 PSI - 1.5

bar) a booster pump must be installed ahead of the

machine.

This pump can be requested as an optional, and if

ordered together with the machine it is supplied already

installed on the water connection fitting. If the pressure

at one of the unions exceeds 700 kPa (101.5 PSI - 7bar),

a pressure reducing valve must be installed on the inlet

piping. Connection pipes with anti-return protection and

check valve and stop cock are available as optional

accessories.

If the water hardness exceeds 14°fH/8°dH/10°cH, install

a softener filter on the dishwasher inlet connection piping to ensure efficient machine operation.

IMPORTANT!

Connect the prewash zone to the cold

water inlet and connect the rinse zone to

the hot water inlet

Connect the appliance water supply to the mains, fitting

a cut-off cock, a filter and a pressure gauge between the

appliance and the mains.

.

!

Figure 8 Water connection

17

Page 16

Atmospheric plumbing circuit diagram,

dishwashers - 44” ( with boiler )

Atmospheric plumbing circuit diagram,

dishwashers - 44” ( without boiler )

LEGEND

A = Hot water inlet (related to boiler rise)

B = Hot water inlet 80-140F (26-60°C)

C = Hot water inlet min 194°F (90°C)

D = Cold water inlet

M2 = Rinse pump

M4 = Wash pump

M8 = Prewash pump

ABV = Air Break Valve

YV1 = Filling / Air-Gap filling solenoid valve (5.28 gal/min - 20 l/min)

YV5 = Wash tank drain solenoid valve

YV6 = Wash tank water filling solenoid valve (

YV9 = Prewash tank water filling solenoid valve (5.28 gal/min - 20 l/min)

YV11 = Prewash tank drain solenoid valve

5.28 gal/min - 20 l/min

)

18

Page 17

ENGLISH

Atmospheric plumbing circuit diagram,

dishwashers - 66” ( with boiler )

Atmospheric plumbing circuit diagram,

dishwashers - 66” ( without boiler )

LEGEND

A = Hot water inlet (related to boiler rise)

B = Hot water inlet 80-140F (26-60°C)

C = Hot water inlet min 194°F (90°C)

D = Cold water inlet

M2 = Rinse pump

M4 = Wash pump

M8 = Prewash pump

ABV = Air Break Valve

YV1 = Filling / Air-Gap filling solenoid valve (5.28 gal/min - 20 l/min)

YV5 = Wash tank drain solenoid valve

YV6 = Wash tank water filling solenoid valve (

YV9 = Prewash tank water filling solenoid valve (5.28 gal/min - 20 l/min)

YV11 = Prewash tank drain solenoid valve

5.28 gal/min - 20 l/min

)

E6.2 Installation diagrams

The following installation diagrams give the machine overall dimensions and position of water and electrical connections, as well as the position of the surround elements such as walls and extractor hoods.

In particular, make sure to position the possible extractor hood at a distance of not less than 15.74’’ ( 400mm) from the

machine so as not to compromise machine operation.

IMPORTANT!

The extractor hood is installed to remove the steam emitted by the machine. The hood air delivery

must be calculated taking into account the machine model, the type of installation and the work environment where installed. However, an air delivery of not greater than 300 m

3

/h - 177 cfm is recom-

mended.

The hood is represented in the diagrams with the symbol:

Also, the equipment must be installed at a distance of not less than 1.96’’ ( 50 mm) from the wall so as not to affect correct ventilation of internal components.

The wall is represented in the diagrams with the symbol:

19

Page 18

Installation diagram - rack-type dishwasher, 44” left

LEGEND

A Hot water inlet G 3/4”

B Cold water inlet G 3/4”

C Drain outlet G 1 1/2“

I Power supply entry

Q Equipotential screw

S Pipe inlet for detergents

S1 Detergent probe arrangement

20

Page 19

ENGLISH

Installation diagram - rack-type dishwasher, 44” right

LEGEND

A Hot water inlet G 3/4”

B Cold water inlet G 3/4”

C Drain outlet G 1 1/2“

I Power supply entry

Q Equipotential screw

S Pipe inlet for detergents

S1 Detergent probe arrangement

21

Page 20

Installation diagram - rack-type dishwasher, 66” left

LEGEND

A Hot water inlet G 3/4”

B Cold water inlet G 3/4”

C Drain outlet G 1 1/2“

I Power supply entry

Q Equipotential screw

S Pipe inlet for detergents

S1 Detergent probe arrangement

22

Page 21

ENGLISH

Installation diagram - rack-type dishwasher, 66” right

LEGEND

A Hot water inlet G 3/4”

B Cold water inlet G 3/4”

C Drain outlet G 1 1/2“

I Power supply entry

Q Equipotential screw

S Pipe inlet for detergents

S1 Detergent probe arrangement

23

Page 22

24

Figure 9 Installation diagram - Recommended table connection and fabrication

Page 23

ENGLISH

E7 Electrical connections

B

A

- Configuration of the electrical box according to the supply water temperature -

ELECTRICAL BOX (BOILER)

SUPPLY TERMINAL BOARD (BOILER)

SUPPLY TERMINAL BOARD (MACHINE)

POWER CABLES

POWER CABLE

(Boiler terminal board)

POWER CABLE

(Machine terminal board)

Figure 10 Electrical connections diagram

25

Page 24

Connection to the power supply must be carried out in

IMPORTANT

IMPORTANT

IMPORTANT

conformity with the current regulations and provisions in

the country of use.

Before servicing, disconnect the electrical service

and place a red tag at the disconnect switch to indicate work is being done on that circuit.

For supply connections, use suitable wires for at

least 167°F (75°C). Use copper conductors only.

IMPORTANT!

Work on the electrical systems must only

be carried out by a qualified electrician.

Before servicing, disconnect the electrical service

and place a red tag at the disconnect switch to indicate work is being done on that circuit.

• Make sure the machine power supply voltage specified on the rating plate (Table 1) matches the mains

voltage.

• Make sure the system power supply is arranged and

able to take the actual current load and that it is executed in a workmanlike manner according to the regulations in force in the country of use.

• In case of doubts regarding the efficiency of the equipotential earth connection, or aspects concerning

electrical safety, have the system checked by a qualified electrician.

To connect the power cable to the equipment, proceed

as follows:

- remove the front panel “A” of the wash and rinse

zone (

Figure 10

- connect the power cable to the terminal block as indicated in the wiring diagram attached to the equipment, and secure it with the special cable gland;

IMPORTANT!

The connection cable must be H07RN-F

type, oilproof.

- close the front panel “A” of the wash and rinse zone

(

Figure 10

IMPORTANT!

All electrical interventions ahead of the

machine must be carried out by qualified

electricians and with the power to the

equipment being wired disconnected.

E8 Installation of detergent/rinse aid dispensers

The machine is arranged for installation of detergent and

rinse aid dispensing devices.

The dispensers must be fitted in a way that does not

compromise machine operation or safety.

);

).

IMPORTANT!

Do not start the machine if the dispenser

devices do not meet the safety requirements of EC Directives or current regulations in the country of use.

CAUTION!

Contact with chemical substances (e.g.

detergent, rinse aid, scale remover, etc.)

without taking appropriate safety precautions (e.g. personal protection equipment) can involve exposure to chemical

risk and possible damage to health.

Therefore always refer to the safety

cards and labels on the products used.

E8.1 Arrangement for water connection

Described below are all the possible plumbing connections that can be made in the machine for installing

detergent or rinse aid dispensing devices.

IMPORTANT!

Carry out all the following plumbing con-

nections with particular care, in order to

avoid any leaks of liquid inside the

machine and near the electrical connections.

IMPORTANT!

Faulty plumbing connections can cause

low machine performance due to pressure losses in the system.

NOTICE!

This machine must be operated with an

automatic detergent feeder and, if applicable, an automatic chemical sanitizer

feeder, including a visual means to verify

that detergents and sanitizers are delivered or a visual or audible alarm to signal

if detergents and sanitizers are not available for delivery to the respective

washing an sanitizing systems. Please

see instructions for electrical and plumbing connections located in this manual

and in the feeder equipment manual.

26

Page 25

ENGLISH

E8.1.1 Detergent concentration measurement

S1

S

S

probe

For positioning the detergent concentration measurement probe there is a hole “S1” (Ø 0.86’’ - 22 mm)

closed with a plug (Figure 11) in the wash tank, as

already indicated also in par. E6.2 “Installation diagrams”.

Figure 11 Hole for detergent probe

E8.1.2 Liquid detergent dispensers

Inside the wash tank there are two indents “S” (Ø

5 mm

) to be perforated for fitting a liquid detergent injec-

tor (Figure 12)

as already indicated also in par.

grams”

.

,

E6.2 “Installation dia-

0.19’’ -

Figure 13 Rinse aid connection

• connect the rinse aid dispenser pipe, unscrewing

plug “T” (

potential plumbing leaks (tighten the clamps

securely);

• refit the upper panel “B” (

E8.2 Arrangement for electrical connection

The electrical connection of the dispenser devices must

be carried out by a specialized technician according to

that indicated in the wiring diagram on the machine.

Figure 13)

IMPORTANT!

Do not make direct connections on the

printed circuits.

, always paying attention to

Figure 10

).

Figure 12 Arrangement for liquid detergent

E8.1.3 Rinse aid dispensers

The machine is supplied with a nipple, a piece of pipe

and two clamps for connecting the rinse aid dispenser.

Carefully follow the instructions given below to correctly

carry out the connection for the rinse aid:

• remove the upper panel “B” (

Figure 10

);

27

Page 26

E9 Fitting curtains

1

2

33

33

1 11

2 22

With the machine switched off and cold, fit or refit the curtains as illustrated below. The machines are represented in the

assembly diagrams firstly in the version with left rack loading and then in the version with right rack loading.

Types of curtains on the machine

Double long (1) Quadruple long (2) Single short (3)

Important:

fasten the curtains with the flat part against the hook.

Rack-type dishwasher - 44”

Rack-type dishwasher - 66”

22 3 2 23

28

Figure 14 Diagram of curtain positioning on compact machines

Page 27

ENGLISH

E10 Installation of rack handling systems

IMPORTANT

CAUTION!

Machine installation operations must

only be carried out by specialized Tech

nicians provided with all the appropriate

personal protection equipment (safety

shoes, gloves, glasses, overalls, etc.),

tools, utensils and ancillary means.

Before servicing, disconnect the electrical service

and place a red tag at the disconnect switch to indicate work is being done on that circuit.

IMPORTANT!

Work on the electrical equipment must

only be carried out by a qualified electrician.

E10.1 Arrangement for mechanical connection

See Figure 9 (

table connection and fabrication

Installation diagram - Recommended

).

-

A

Figure 15 Handling electrical connection system

Whatever the type of system (motor-operated or not) to

be connected to the dishwasher, proceed as follows:

• unscrew plug “A” (Figure 15) anticlockwise;

• connect the rack handling system connector “C”

(Figure 16) to connector “B” of the dishwasher,

according to electrical wiring diagram.

•

B

B

C

E10.2 Arrangement for electrical connection

The left and right side panels of the dishwasher have a

connector “B” (Figure 15), closed with a plug “A”

(Figure 15), to be used for carrying out the electrical connection of the rack handling systems.

IMPORTANT!

The rack handling system electrical con-

nection power lines are protected

against short circuits as shown in the

wiring diagram. The dishwasher shall be

installed in accordance with local codes,

or in the absence of local codes,

installed in accordance with the applicable requirements in the National Electrical Code, NFPA 70, Canadian Electrical

Code (CEC), Part 1, CSA C22.1, and

Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations, NFPA 96.

Figure 16 Detail of electrical connection

If a type “C” connector is not available for carrying out

the connection, follow the indications in the machine wiring diagram: make sure to pass the external cable

through the special cable gland, avoiding zones where

the connection can be damaged (e.g. lower part of the

machine, due to periodical cleaning of the floor with

sweepers).

E10.3 Positioning of emergency switches

If rack handling systems are connected at the infeed or

outfeed of a rack-type dishwasher, install on such systems emergency switches that are clearly visible and

identifiable and easily accessed by the operator “R”

(Figure 17) who must use them.

Described below are possible couplings of dishwashers

“L” (Figure 17) with rack handling systems “M”, with the

corresponding positions of the emergency switches “E”

and work stations “R” (Figure 17).

IMPORTANT!

The emergency switches installed on the

machine do not exempt operators from

diligent and careful use of the machine.

The function of these devices guarantees

prompt intervention in case of emergency.

29

Page 28

IMPORTANT!

Operators must know the position of the

emergency switches installed on the

machine. The paths to reach and operate

them must be kept free of obstacles.

IMPORTANT!

Emergency switches must be installed,

otherwise the machine cannot operate

(see wiring diagram).

IMPORTANT!

Anyone detecting a danger for persons

must immediately operate one of the

emergency stops; the same applies in

case of operation anomalies and/or

damage to parts of the machine requiring

it to be stopped immediately.

E10.4 Emergency stop reinstatement

When an emergency switch is operated, restart the

machine only after making sure that:

- the cause requiring operation of the emergency

switch has been eliminated;

- restarting machine operation does not involve any

hazard.

If the EMERGENCY SWITCH is operated during

machine operation, the entire machine is deactivated.

To reinstate machine operation, proceed as follows:

- release the previously operated red emergency

mushroom push button, turning or pulling it in order to

disconnect its interlock;

- restart the machine according to what is described in

par. I3 “Daily activation of machine”.

R

L

MM

M

EE

R R

M

L

M

M

M

E

E

R

Figure 17 Examples of dishwasher and rack handling system couplings

E

R

L

R

M

E

M

E

30

Page 29

ENGLISH

F DESCRIPTION OF CONTROL PANEL

LEGEND

A = On/Off

B = Stop

C = Start at speed 1

D = Start at speed 2

F = Prewash temperature or

machine status

G = Wash temperature

H = Boiler temperature

M = Accessory functions

O = Increase key

Q = Decrease key

R = Confirmation key

The possible control panel configurations for compact rack-type dishwashers are as follows:

A

C

Q

O

B

D

F

G

H

R

M

Table 2 Control panel

Described below are all the single keys and functions present in the various control panel models listed above. Some

functions are shared by all models of the range, whereas others are available only on several versions.

F1 Basic controls

Stop

On/Off

This key is used to stop a wash phase or drain/cleaning

cycle.

This key indicates the status of the equipment: on or off.

When the appliance is on, the key is lit.

F2 Accessory function selection controls

Start at speed 1 (low speed)

This key is used to start a wash cycle at speed 1. This

speed is recommended for washing very dirty dishes.

To guarantee an adequate cleanless in the washing of

the glasses it is advised the speed 1.

Start at speed 2 (high speed)

This key is used to start a wash cycle at speed 2. This

speed is recommended for washing medium dirty or not

very dirty dishes.

When a speed is selected the corresponding key is lit.

Accessory functions

This key is used to access the “accessory functions”

menu which is displayed.

When activating the accessory functions menu or executing one of these functions the corresponding light is

on.

To quit the accessory functions menu, press the accessory functions key again.

After entering the accessory functions menu, the

required function can be selected by means of the

increase (“O” - Table 2) and decrease (“Q” - Table 2)

keys.

After selecting the required accessory function, it can be

started by pressing the confirm key (“R” Table 2).

31

Page 30

GSTARTING

G1 Preliminary checks, adjustments and

operational tests

G1.1 Electrical and plumbing checks

Before starting the machine:

• check correct connection of the electrical wires that

feed the machine;

• make sure the power supply voltage and frequency

match the data given in Table 1;

• check correct connection of the water supply and

drain pipes (par. E6 “Plumbing connections”);

• make sure all the guards, safety devices and emergency switches are in place and efficient.

IMPORTANT!

These operations must only be carried

out by specialized technicians provided

with adequate personal protection equipment (e.g. safety footwear, gloves,

glasses, etc.), tools and suitable ancillary equipment.

G1.2 Check the positioning of tank components

IMPORTANT!

The following operations must be car-

ried out by operators provided with suitable personal protection equipment (e.g.

protective gloves, etc.) with the machine

switched off and cold.

2

1

Figure 19 Wash/rinse module tank filters

G1.2.2 Check the fitting of arms and curtains

Make sure the upper and lower prewash (Figure 20),

wash (Figure 21) and rinse (Figure 22) arms are correctly fitted.

Figure 20 Prewash Figure 21 Wash

Also make sure the prewash and wash arm couplings

are correctly locked and that the rinse arm ring nuts are

secured.

3

Make sure the filters, arms and curtains are fitted in the

correct position in every module making up the machine.

G1.2.1 Check the fitting of filters and overflows

Make sure the overflow “1” and the flat filters “2”

(Figure 18) are fitted in the prewash module, if present in

the machine.

•

1

Figure 18 Prewash module tank filters

Make sure the overflow “1”, flat filter/s “2” and box

strainer/s “3” (Figure 19) are fitted in the wash/rinse

module.

2

Figure 22 Rinse

Make sure all the types of curtains, provided for the

machine model, are correctly fitted according to that indicated in par. E9 “Fitting curtains”.

Close the doors of the various machine modules only

when all the parts previously described are correctly

installed, then start the dishwasher.

IMPORTANT!

The machine can be started only if

assembled in compliance with what is

established in this manual.

G2 Starting

• Open the water supply cocks.

• Connect the electrical service. Press the On/Off key

Table 2 (“A” - “Control panel”).

32

Page 31

ENGLISH

H GENERAL SAFETY RULES

CAUTION

THIS DISHWASHER HAS MORE THAN ONE POWER-SUPPLY

CONNECTION POINT. DISCONNECT ALL POWER SUPPLIES

BEFORE SERVICING.

Doc.No.: 5956.613.00

H1 Introduction

The machines are provided with electric and/or mechanical safety devices for protecting workers and the

machine itself. Therefore the user must not remove or

tamper with such devices.

The Manufacturer declines any liability for damage due

to tampering or their non-use.

H1.1 Protection devices installed on the machine

H1.1.1 Guards

The guards on the machine are:

- fixed guards (e.g. casings, covers, side panelling,

etc.), fixed to the machine and/or frame with screws

or quick-release couplings that can only be removed

or opened with tools;

- interlocked movable guards (front panels) for access

to inside the machine;

- access doors to the machine’s electrical equipment,

made from hinged panels openable with tools. The

door must not be opened during machine movement,

if inside the door there is equipment that is hazardous

when live or under pressure.

H1.2 Safety signs to be displayed on the machine

PROHIBITION MEANING

Do not oil, lubricate, repair and

adjust moving parts.

Do not remove the safety

devices.

Do not use water to extinguish

fires (shown on electrical parts).

DANGER MEANING

DANGER OF CRUSHING HANDS

DANGER OF BURNS

IMPORTANT!

Several illustrations in the manual repre-

sent the machine, or parts of it, without

guards or with guards removed. This is

purely for explanatory requirements.

Never operate the machine without the

guards or with the safety devices deactivated.

H1.1.2 Safety devices

The machine has:

- a yellow/red main switch that acts as an emergency

switch;

- interlocks on the front panels giving access to inside

the machine;

- emergency stop push buttons and stops must be

installed on the rack handling tables in case the racks

exceed their travel.

ref. A

ref. B

DANGER OF ELECTROCUTION

(shown on electrical parts with

indication of voltage).

WARNING!

Do not remove, tamper with or make the

labels on the machine illegible.

MINIMUM WASH TEMPERATURE 160°F (71°C)

MINIMUM PUMPED RINSE TEMPERATURE 180°F (82°C)

MINIMUM SANITIZING RINSE TEMPERATURE 180 °F (82 °C)

MAX. CONVEYOR SPEED 5.48 FT./MIN (1.67 M/MIN)

WAR NING

THERE ARE MOVING PARTS.

THERE IS THE POSSIBILITY OF SPRAYING

AND SPLASHING OF HOT WATER.

Doc.No.: 5956.582.00

Doc.No.: 5956.582.00

33

Page 32

ref. B

MINIMUM WASH TEMPERATURE 160°F (71°C)

MINIMUM PUMPED RINSE TEMPERATURE 180°F (82°C)

MINIMUM SANITIZING RINSE TEMPERATURE 180 °F (82 °C)

MAX. CONVEYOR SPEED 5.48 FT./MIN (1.67 M/MIN)

WARNI NG

THERE ARE MOVING PARTS.

THERE IS THE POSSIBILITY OF SPRAYING

AND SPLASHING OF HOT WATER.

Doc.No.: 5956.582.00

Doc.No.: 5956.582.00

ref. A

CAUTION

THIS DISHWASHER HAS MORE THAN ONE POWER-SUPPLY

CONNECTION POINT. DISCONNECT ALL POWER SUPPLIES

BEFORE SERVICING.

H2 Decommissioning

When the machine is no longer to be used, make it

unusable by removing the feed wiring from the power

supply and the water connections.

H3 Instructions for use and maintenance

Risks mainly of a mechanical, thermal and electrical

nature are present in the machine.

Where possible the risks have been neutralized:

• directly, by means of adequate design solutions,

• or indirectly by using guards, protection and safety

devices.

Any anomalous situations are signalled on the control

panel display.

During maintenance several risks remain, as these could

not be eliminated and which must be neutralized through

specific behaviour and precautions.

Do not carry out any control, cleaning, repair or maintenance operations on moving parts.

Workers must be informed of the prohibition by means of

clearly visible signs.

To guarantee machine efficiency and correct operation,

periodical maintenance must be carried out according to

the instructions given in this manual.

In particular, make sure to periodically check correct

operation of all the safety devices and the insulation of

electrical cables, which must be replaced if damaged.

Doc.No.: 5956.613.00

Figure 23 Positioning of safety signs

ref. A

CAUTION

THIS DISHWASHER HAS MORE THAN ONE POWER-SUPPLY

CONNECTION POINT. DISCONNECT ALL POWER SUPPLIES

BEFORE SERVICING.

IMPORTANT!

Machine maintenance operations must

only be carried out by specialized Technicians provided with all necessary personal protection equipment (safety

shoes, gloves, glasses, overalls, etc.),

tools, utensils and suitable ancillary

means.

WARNING!

Never operate the machine by removing,

modifying or tampering with the guards

and protection or safety devices.

IMPORTANT!

Before carrying out any operation on the

machine, always consult the manual

which gives the correct procedures and

contains important information on

safety.

H4 Improper use

Improper use is any use differing from that specified in

this manual. During machine operation, other types of

work or activities considered improper and that in general can involve risks for the safety of operators and

damage to the system are not allowed.

Improper use includes:

• failure to disconnect the power supply with the main

switch in “O” off position before carrying out adjustment, cleaning, resetting and maintenance operations;

Doc.No.: 5956.613.00

34

Page 33

ENGLISH

• failure to disconnect the power supply with the main

switch in off position “O” at the end of the day;

• lack of machine maintenance, cleaning and periodical checks;

• structural changes or modifications to the operating

logic;

• tampering with the guards or safety devices;

• failure to use personal protection equipment by operators, specialized technicians and maintenance personnel;

• failure to use suitable accessories (e.g. use of equipment, ladders, etc., unsuitable for carrying out maintenance on equipment positioned inside the

machine);

• keeping combustible or flammable materials, or in

any case materials not compatible with or pertinent to

the work, near the machine;