Page 1

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

PROJECT NAME #

CUSTOMER CONTACTS

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

510705 (EFT4)

Four Tank Flight Type

Dishwasher 400V/3N/50 Hz.

Direction of Operation:

Right to Left Left to Right

Version:

Electric Steam

OPTIONS AT EXTRA COST

Different loading section:

1.100 mm 1.500 mm 1.800 mm

2.400 mm 3.000 mm 4.000 mm

2.900 mm Cross-over

Different unloading section:

700 mm 1.100 mm 1.800 mm

2.400 mm 3.000 mm 4.000 mm

Other types of conveyor:

Multi-purpose conveyor

Multi-purpose conveyor with blue plastic sticks

Conveyor for insulated trays (Temp-Rite and

Aladin)

Conveyor for insulated trays (MDS and Rieber)

Conveyor for small items

Conveyor for big items (shall be specified)

Standard Features

Item No.

Electronic control of all temperatures, statistics and alarms with

read out display.

Pumped rinse (Duo Rinse) uses fresh nal rinse water twice.

Drying tunnel (1.100 mm) with inspection door.

Water consumption of 450 liters per hour.

Insulated doors with safety switch guarantee that the machine

cannot be operated with the doors open.

Energy saving auto start ensures that the machine is only

operated when crockery is loaded.

Charging hole 660 mm wide and 420 mm clearance, effective

conveyor width of 600 mm.

Conveyor belt operated with 2 speeds with automatic overload

protection.

Large loading section (700 mm) to facilitate the loading of

tableware.

Unloading section (1.500 mm) with an automatic conveyor stop,

avoids damage to clean items if not removed in time.

Approval:

Other features:

Condensing unit (Energy saving device)

Energy Saving Device + Water heat exchanger +

Eco pre-scrap arm in pre-wash tank

Heat pump

Stainless steel pump

400 mm neutral section

(dimension of item LxWxH_____________ mm)

600 mm neutral section

(dimension of item LxWxH_____________ mm)

Variable speed with 3 speed switch (DIN10510)

Variable wash pressure

Side wash arms

Sloping belt (4° slightly towards the back)

Additional dryer (1.100 mm)

Rinse booster pump with integrated Air gap

Thermo disinfection

Sanitization cycle

Reversible conveyor

Strainer from side in loading section

Other voltages (400V/3N/50Hz standard)

Heavy duty pre-wash section (900 mm)

Split of machine for delivery,

max length_________mm

Note: limitations may exist when combining all the above

options - consult an Electrolux representative.

Flight Type Dishwasher

Warewashing

EFT4 - 4 Tank

Electrolux Professional

www.electrolux.com/foodservice

foodservice@electrolux.com

Page 2

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

Functional Zones:

Considerable reduction in detergent consumption is

achieved by diverting part of the fresh rinsed water

(220litres/hour) to the pre-wash tank, with the remaining

being used for the regeneration of the main wash tank.

The water that is diverted to the pre-wash tank is then

pumped to both the upper and the lower arms to pre-clean

the soiled products, ensuring that larger food particles and

liquid residues such as gravy and sauces are washed from

the items, thereby reducing greatly the soil level on the

items entering the machine’s main wash tank. An optional

Eco pre-scrap arm positioned just after the inlet in the

pre-wash tank, will immediately start to “soften” and “wet”

items as they enter the machine so it is especially useful

to wash heavily soiled items or when the machine is used

mainly on fast speed.

The water in the main wash tanks is pumped with detergent

and is sprayed over the items from both the upper and

the lower wash arms, guaranteeing a uniform distribution

of the washing solution and allowing all the areas of the

washing chambers to be covered. An option of variable

pressure gives the possibility to increase up to 30% the

pressure towards the lower wash arms and at the same

time to slow down the belt speed in order to better wash

boxes or heavily soiled items.

Rinse area equipped with the DUO-rinse system: the first

rinse arm is filled with re-circulated rinse water to eliminate

any trace of detergent, while the second ramp is filled with

hot clean water to guarantee the sanitation of the items.

A drying section with inspection door (1100 mm wide) will

be provided as an integral part of the machine. This allows

the operator to remove practically dried items immediately,

without them being too hot to handle.

Optional Energy Saving Device (ESD) utilizes heat and

steam generated from the machine to pre-heat the

incoming water. This reduces energy consumption by

13 kWh by eliminating the need for an external boiler

or water heater and allows the machine to be supplied

with cold water up to 10° C. In addition, the double pipe

in the optional Water Heat Exchanger will have a further

energy saving of about 2 kWh as a result of the exchange

in temperature between the used rinse water and the

incoming fresh water.

Thanks to the Energy Saving Device, the outgoing air from

the machine will be cooler and less humid, eliminating the

need for a ventilation hood, if the incoming water is about

10 °C and the room has frequent air changes or is well

ventilated.

Optional Heat pump operating in conjunction with the

Energy Saving Device plus the Water Heat Exchanger, will

heat up incoming cold final rinse water up to 65 °C before

entering the boiler.

The introduction of the Heat pump system allows 19

kWh of energy savings; also the heating element in the

boiler can also be reduced by 8kW. The exhaust air will

be cooled down to about 15°C with very low humidity so

that no ventilation hood is needed over the machine.

Construction:

304 AISI stainless steel frame, door, strainers, wash and

rinse arms.

No legs in loading area (700-1.100 mm).

Wash tanks in 316 AISI acid proof stainless steel with

rounded corners to facilitate cleaning.

Double-skinned construction and insulated counter

balanced doors provide silent operation and low heat

emission.

Wash/rinse arms and filters easy to remove.

Double tank filters (flat and deep box) cover the entire

width of the wash tank.

Simple service from the front.

Operation:

The conveyor belt is driven by means of a gear motor

which will be protected against overcharge (as a result

of blockage or for any other impediment), by a safety

device mounted at the end of the unloading side.

Individual drain valves for each tank. Drain valves are

automatically closed when the door is closed, so there is

no risk of tank filling with open drain valves.

Counter balanced doors with safety switch and easy-to-

grip handle.

The machine incorporates a safety stop switch at the top

of the discharge section which will automatically stop

the conveyor in case that dishes, trays, containers, etc…

have not been removed after cleaning.

Flat panel with electronic control that, thanks to the auto

diagnostic control and the 32 digits window, is able to

communicate in every moment, the working conditions

of the appliance.

Electronic control panel incorporates the plug-in

connection to link basic and integrated HACCP systems.

Pre-arrangements for external automatic detergent

dispenser.

Two speeds, a fast speed for normal soiled items and

a slow speed for heavily soiled items. As option the

machine can be equipped with three variable speed

selector: normal speed, slow speed for heavily soiled

items and a third speed for 2 minute contact time

according to DIN 10510. Each speed is individually

adjustable.

Page 3

Electric Technical Specifications:

Speed min/max - m/min 1,8/3,6

Capacity baskets/hour 1st /2nd speed 216/432

Capacity dishes/hour 1st /2nd speed 3600/7200

Capacity trays/hour 1st /2nd speed 1800/3600

Prewash

Temperature - °C 30-50

Tank capacity - lt. 57

Pump flow - l/min 450

Pump power - kW 0,88

st

1

wash

Temperature - °C 55-65

Tank capacity - lt. 113

Pump flow - l/min 750

Pump power - kW 2,7

Tank heater - kW 15

2nd wash

Temperature - °C 55-65

Tank capacity - lt. 119

Pump flow - l/min 750

Pump power - kW 2,7

Tank heater - kW 12

3rd wash

Temperature - °C 65-75

Tank capacity - lt. 125

Pump flow - l/min 750

Pump power - kW 2,7

Tank heater - kW 15

Rinsing

Temperature - °C 80-90

Boiler capacity - lt. 16

Boiler power - kW 22

Rinse water consumption - l/h 450

Drying

Air temperature - °C 40-65

Fan power - kW 0,55

Heater - kW 9

Fan capacity - m3/h 2400

Total power*

Without energy saving system 83,3

With energy saving device (ESD) 83,3

With ESD and Water heat exchanger 83,3

With Heat pump 79,7

Air emission - m3/h 450

Air temperature - °C

Without energy saving system 45-55

With energy saving device (ESD) 22-25

With ESD and Water heat exchanger 22-25

With Heat pump 15-20

Noise level - dBA <70

Water supply

Cold water - °C 10-15

Hot water - °C 50-65

Water hardness - max °dH/ °fH 8/ 14

Pressure - bar 3-9

Relative humidity - % 75-85

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

EFT 4 - 4 Tank Flight Type Dishwasher

* The total power may change due to optional equipment.

Page 4

Steam Technical Specifications:

Speed min/max - m/min 1,8/3,6

Capacity baskets/hour 1st /2nd speed 216/432

Capacity dishes/hour 1st /2nd speed 3600/7200

Capacity trays/hour 1st /2nd speed 1800/3600

Prewash

Temperature - °C 30-50

Tank capacity - lt. 57

Pump flow - l/min 450

Pump power - kW 0,88

st

1

wash

Temperature - °C 55-65

Tank capacity - lt. 113

Pump flow - l/min 750

Pump power - kW 2,7

Tank heater - kW 0

2nd wash

Temperature - °C 55-65

Tank capacity - lt. 119

Pump flow - l/min 750

Pump power - kW 2,7

Tank heater - kW 0

3rd wash

Temperature - °C 65-75

Tank capacity - lt. 125

Pump flow - l/min 750

Pump power - kW 2,7

Tank heater - kW 0

Rinsing

Temperature - °C 80-90

Boiler capacity - lt. 16

Boiler power - kW 0

Rinse water consumption - l/h 450

Drying

Air temperature - °C 40-65

Fan power - kW 0,55

Heater - kW 0

Fan capacity - m3/h 2400

Total power*

Without energy saving system 10,3

With energy saving device (ESD) 10,3

With ESD and Water heat exchanger 10,3

With Heat pump 14,7

Air emission - m3/h 450

Air temperature - °C

Without energy saving system 45-55

With energy saving device (ESD) 22-25

With ESD and Water heat exchanger 22-25

With Heat pump 15-20

Noise level - dBA <70

Water supply

Cold water - °C 10-15

Hot water - °C 50-65

Water hardness - max °dH/ °fH 8/ 14

Pressure - bar 3-9

Relative humidity - % 75-85

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

EFT 4 - 4 Tank Flight Type Dishwasher

* The total power may change due to optional equipment.

Page 5

Electric or Steam - Right to Left

B

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

C

A

Legend

EI Electrical Connection

D Drain

EQ Equipotential Screw

SI Steam Inlet

SO Steam Outlet

V Vents

HWI Hot Water Inlet

CWI Cold Water Inlet

For different loading zone (A), unloading zone (B) and total length (C), please refer to the loading and unloading zone table on the last page.

Page 6

Electric or Steam - Left to Right

C

A

Warewashing

EFT4 - 4 Tank

Flight Type Dishwasher

B

Legend

EI Electrical Connection

D Drain

EQ Equipotential Screw

SI Steam Inlet

SO Steam Outlet

V Vents

HWI Hot Water Inlet

CWI Cold Water Inlet

For different loading zone (A), unloading zone (B) and total length (C), please refer to the loading and unloading zone table on the last page.

Page 7

Flight Type Dishwasher

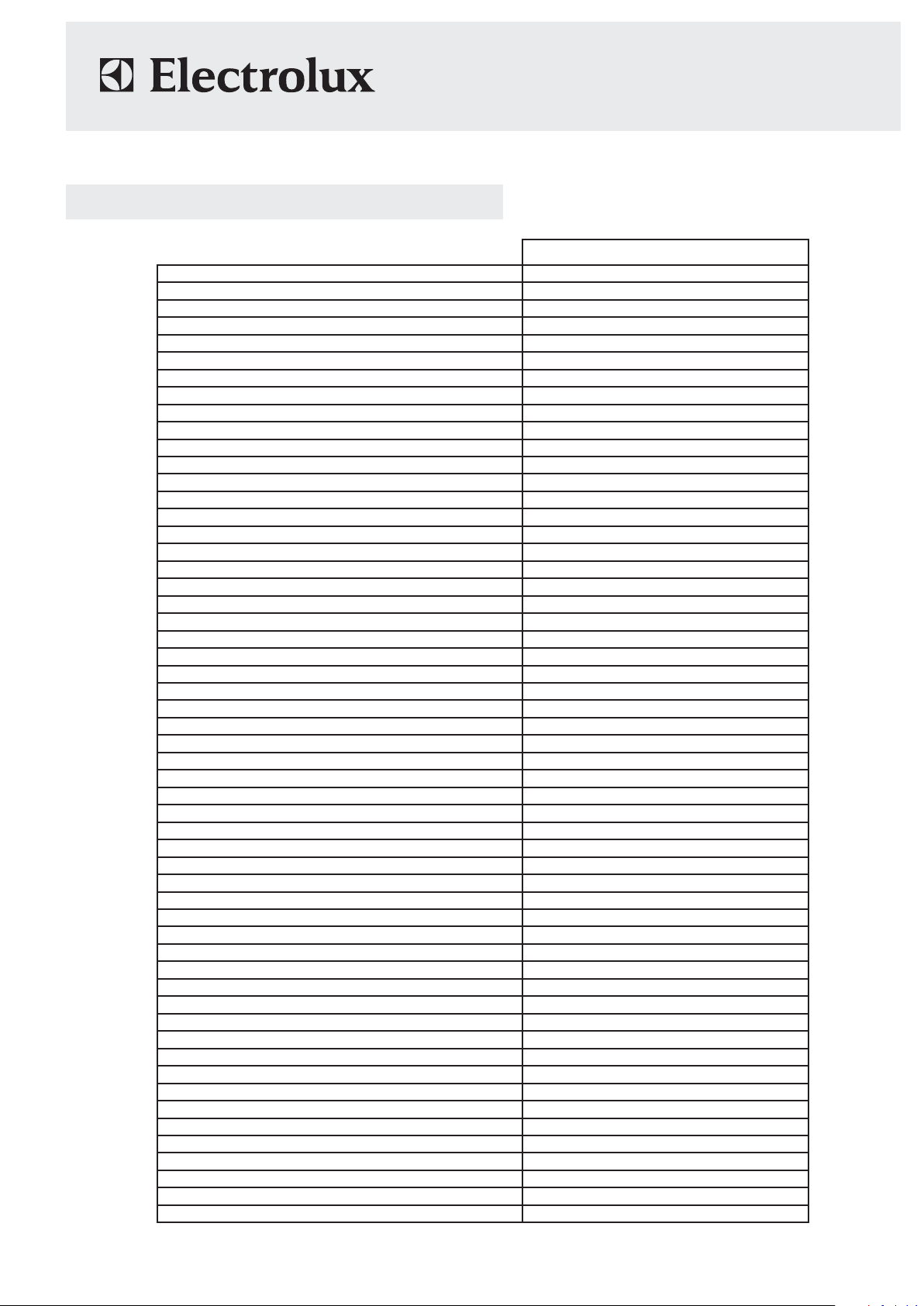

Overall length of machine with different loading/unloading options:

A = Loading size (mm)

700 1.100 1.500 1.800 2.400 3.000 4.000

700 6.300 6.700 7.100 7.400 8.000 8.600 9.600

1.100 6.700 7.100 7.500 7.800 8.400 9.000 10.000

1.500 7.100 7.500 7.900 8.200 8.800 9.400 10.400

1.800 7.400 7.800 8.200 8.500 9.100 9.700 10.700

(mm)

2.400 8.000 8.400 8.800 9.100 9.700 10.300 11.300

B = Unloading size

3.000 8.600 9.000 9.400 9.700 10.300 10.900 11.900

Warewashing

EFT4 - 4 Tank

Loading Zone

Unloading Zone

Loading...

Loading...