Page 1

(/(&752/8;+20(352'8&761257+$0(5,&$

SERVICE MANUAL

24" BUIL T -IN DISHWASHERS

2001 MECHANICAL MODELS

PRECISION WASH SYSTEM

5995355186

:KLWH : HVWLQJKRXVH

June 2001

Page 2

TABLE OF CONTENTS

SAFE SERVICING PRACTICES ................................................................................ 3

WHAT'S NEW ............................................................................................................. 4

MODEL TECHNICAL SPECIFICATIONS

Frigidaire .................................................................................................................................................. 5 - 8

Universal - Multiflex ................................................................................................................................... 9

Amana ..................................................................................................................................................... 10 - 11

Crown ...................................................................................................................................................... 11

Gibson ..................................................................................................................................................... 12

CONSTRUCTION AND OPERATION

Water Distribution System ...................................................................................................................... 13

Water Distribution Components ............................................................................................................... 13

Wash Pump ...................................................................................................................................... 13

Upper Spray Arm .............................................................................................................................. 14

Lower Spray Arm .............................................................................................................................. 14

Lower Spray Arm with Collapsible Tower ..........................................................................................14

Filter ................................................................................................................................................. 14

Polyprolene Filter .............................................................................................................................. 14

Stainless Steel Filter ........................................................................................................................ 14

Drain Pump ...................................................................................................................................... 15

Drying System ........................................................................................................................................ 15

Static Dry System ............................................................................................................................15

Active Vent System ......................................................................................................................... 15

Power Vent System..........................................................................................................................15

Drying System Components ................................................................................................................... 16

Lower Vent Housing .......................................................................................................................... 16

Vent Valve........................................................................................................................................ 16

Vent Actuator ................................................................................................................................... 16

Blower .............................................................................................................................................. 16

Upper Vent Housing .......................................................................................................................... 16

Dispensing System ................................................................................................................................. 17

Detergent & Rinse Aid Dispenser...................................................................................................... 17

Dispenser Operation ......................................................................................................................... 17

Door Latch Assembly.............................................................................................................................. 17

Selector Switch and Thermostats ........................................................................................................... 18

Heated Dry ....................................................................................................................................... 18

Hi-Temp Wash .................................................................................................................................. 18

Hi-Temp Rinse .................................................................................................................................. 18

High Limit Thermostat ...................................................................................................................... 18

Dishwasher Leveling ............................................................................................................................... 19

DISASSEMBLY

Safety Precautions ................................................................................................................................. 20

Control Panel .......................................................................................................................................... 20

Timer ...................................................................................................................................................... 20

Disassembly Tip ...............................................................................................................................20

Selector Switch ....................................................................................................................................... 20

Door Panels (All Models)......................................................................................................................... 20

Page 1

Page 3

TABLE OF CONTENTS

Door Vent Assembly ............................................................................................................................... 20

Vent Valve .............................................................................................................................................. 21

Vent Actuactor ........................................................................................................................................ 21

Vent Blower .................................................................................................................... ........................21

Door Latch Assembly.............................................................................................................................. 21

Detergent / Rinse Aid Dispenser ............................................................................................................. 21

Inner Door Panel ..................................................................................................................................... 21

Door Seal ................................................................................................................................................ 21

Upper Rack ............................................................................................................................................. 22

Upper Water Tube ............................................................................................................... ....................22

Upper Spray Arm .................................................................................................................................... 22

Water Distributor ..................................................................................................................................... 22

Kick Plate ............................................................................................................................................... 22

Heating Element ................................................................................................................ ..................... 22

Float Switch and Bracket ........................................................................................................................ 23

Water Valve ............................................................................................................................................ 23

Drain Pump ............................................................................................................................................. 23

Lower Spray Arm .................................................................................................................................... 23

Glass Trap .............................................................................................................................................. 23

Lower Spray Arm Support ....................................................................................................................... 23

Filter ....................................................................................................................................................... 24

Pump and Motor Assembly ..................................................................................................................... 24

Motor Mounting Bracket .......................................................................................................................... 24

Motor and Impeller .................................................................................................................................. 24

Thermostats............................................................................................................................................25

High Limit Thermostat ............................................................................................................................. 25

Indicator Lamps ...................................................................................................................................... 25

TROUBLESHOOTING

Troubleshooting Tips ........................................................................................................................ 26 - 27

APPENDIX A - Diagrams - Exploded Views .............................................................A - 1

APPENDIX B - Service Data Sheets (Wiring Diagrams & Timer Charts)................B - 1

Page 2

Page 4

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe

Servicing Practices be observed. The following are some limited examples of

safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

Remove the power cord from the electrical outlet, trip the circuit breaker to

the OFF position, or remove the fuse.

Turn off the gas supply.

Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN,

or GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a hazard.

6. Prior to returning the product to service, ensure that:

All electrical connections are correct and secure

All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts

All non-insulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels

All safety grounds (both internal and external) are correctly and securely

connected

All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechnical

training and a level of knowledge of these subjects generally considered acceptable in the

appliance repair trade. Electrolux Home Products cannot be responsible, nor assume any

liability, for injury or damage of any kind arising from the use of this manual.

© 2001 White Consolidated Industries

Page 3

Page 5

WHAT'S NEW

Ö COLLAPSIBLE TOWER - Single wash arm on low end models with collaspsible tower that is molded into the

spray arm. This tower retracts completely into the lower arm giving added area in the lower rack.

Ö VENT COVER- The vent cover has the gasket molded into the cover to prevent water leaks.

Ö PUMP AND MOTOR ASSEMBLY - The wash pump and motor are in one piece and is not repairable. The new

design motor does not have nor need a seal to prevent water leaks. In the end of this motor is a small circuit

board that is designed to make sure that the motor will always start in the proper direction. This new motor is

mounted with a new mounting bracket that only requires two screws.

Ö SANITIZE RINSE - On the higher end models, a sanitize rinse setting has been added and the rinse temperature

will reach 150°F.

Page 4

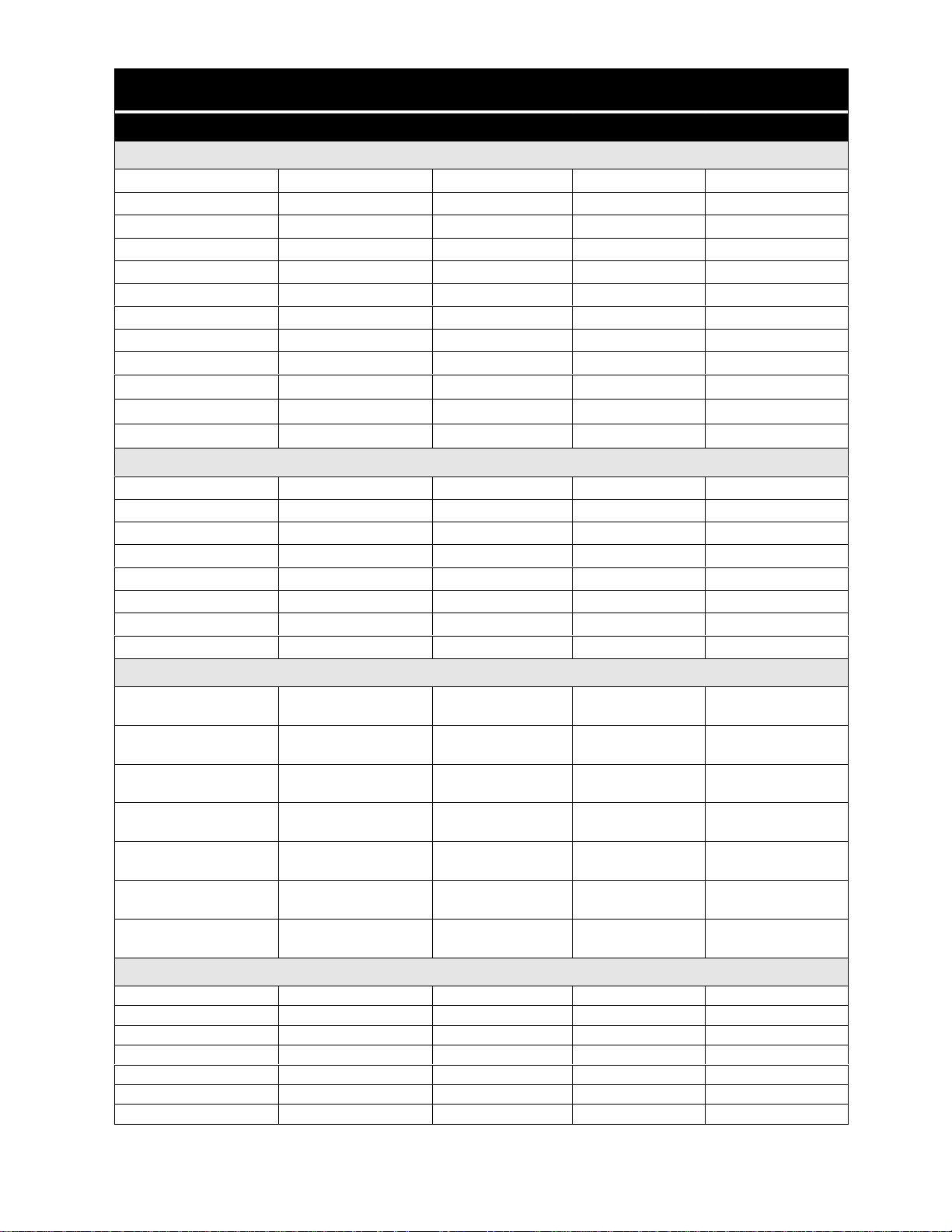

Page 6

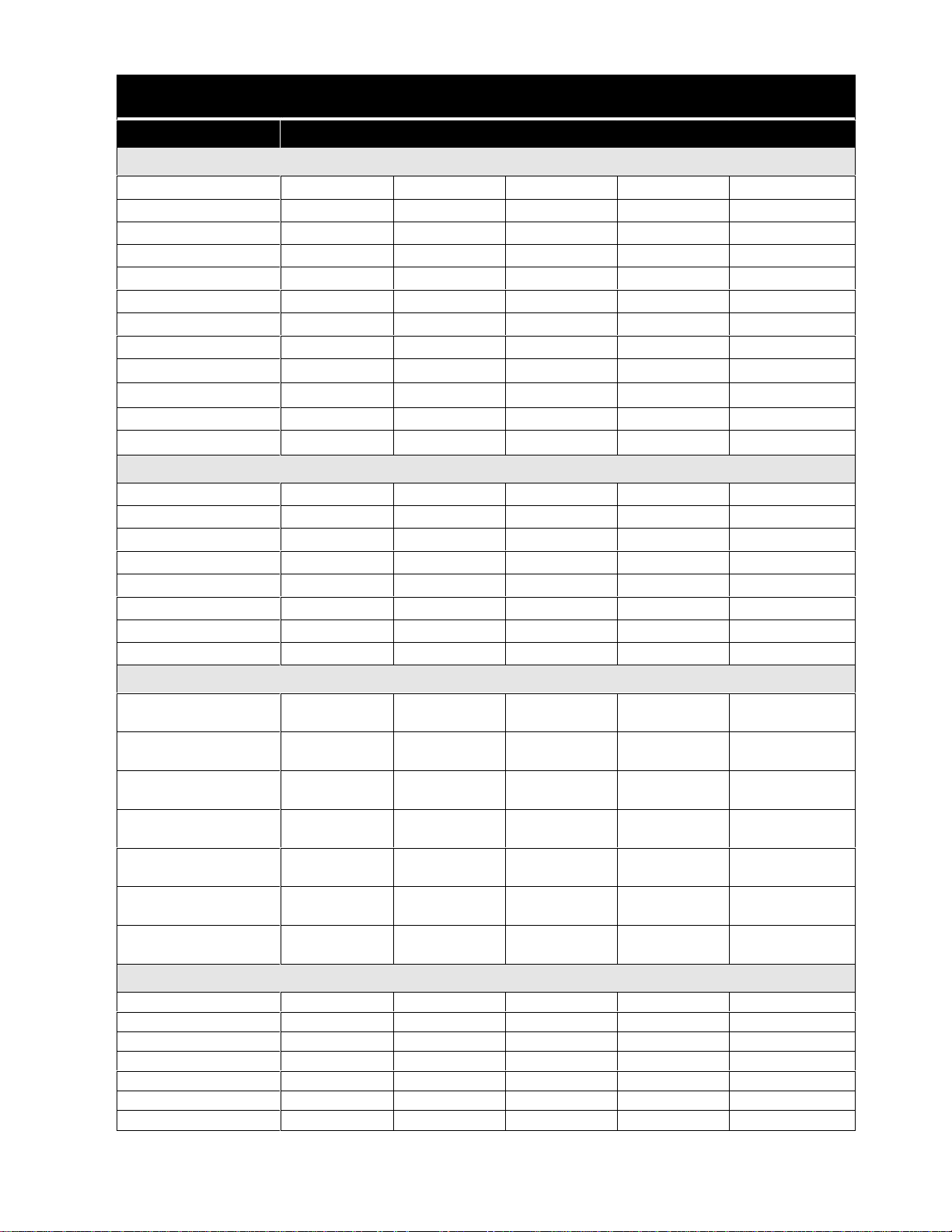

FRIGIDAIRE

MODEL FDB125RH*2 FDB345LF*2 FDB421RF*6 FDB421RF*7 FDB435RFR*6

ELECTRICAL

Service Data Sheet 154395901 154400501 154370901 154405901 154385401

Voltage 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

th

Motor (Amps) 1.1 1.1 1.1 1.1 1.1

Heater (Watts) 900 900 900 900 900

Total Amps 10 10 10 10 10

Temp Assure

Temp Boost

117°F

127°F (53

Sanitize N/A N/A N/A N/A

Hi-Limit Thermostat

200°F (93

COMPONENT RESISTANCE (ohms)

Timer Motor 2357 2357 7700 7700 2357

Heating Element 13.5 9.28 9.28 9.28 9.28

Pump Motor

Vent Actuator N/A 1893 1893 1893 1893

Dispenser 1928 1928 1928 1928 1928

Drain Motor 28 28 28 28 28

Water Valve Solenoid 699 699 699 699 699

Blower N/A N/A N/A N/A N/A

1/12

th

± 5°F

th

1/12

1/12

N/A N/A

th

°C) 122°F (50°C) 122°F (50°C) 127°F (53°C)

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

1/12

117°F

th

± 5°F

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8" 3/8"

7.2 6 6 6 6

12 12 12 12 12

DIAGRAMS (Located in Appendix A or B)

Service Data Sheet

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

B - 9 B - 16 B - 1 B - 21 B - 7

A - 9 A - 10 * * *

A - 17 A - 18 * * *

A - 20 A - 20 * * *

A - 23 A - 24 * * *

A - 29 A - 29 * * *

A - 35 A - 32 * * *

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

.83 .83 .83 .83

87 87 87 87

120°F

(49°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 5

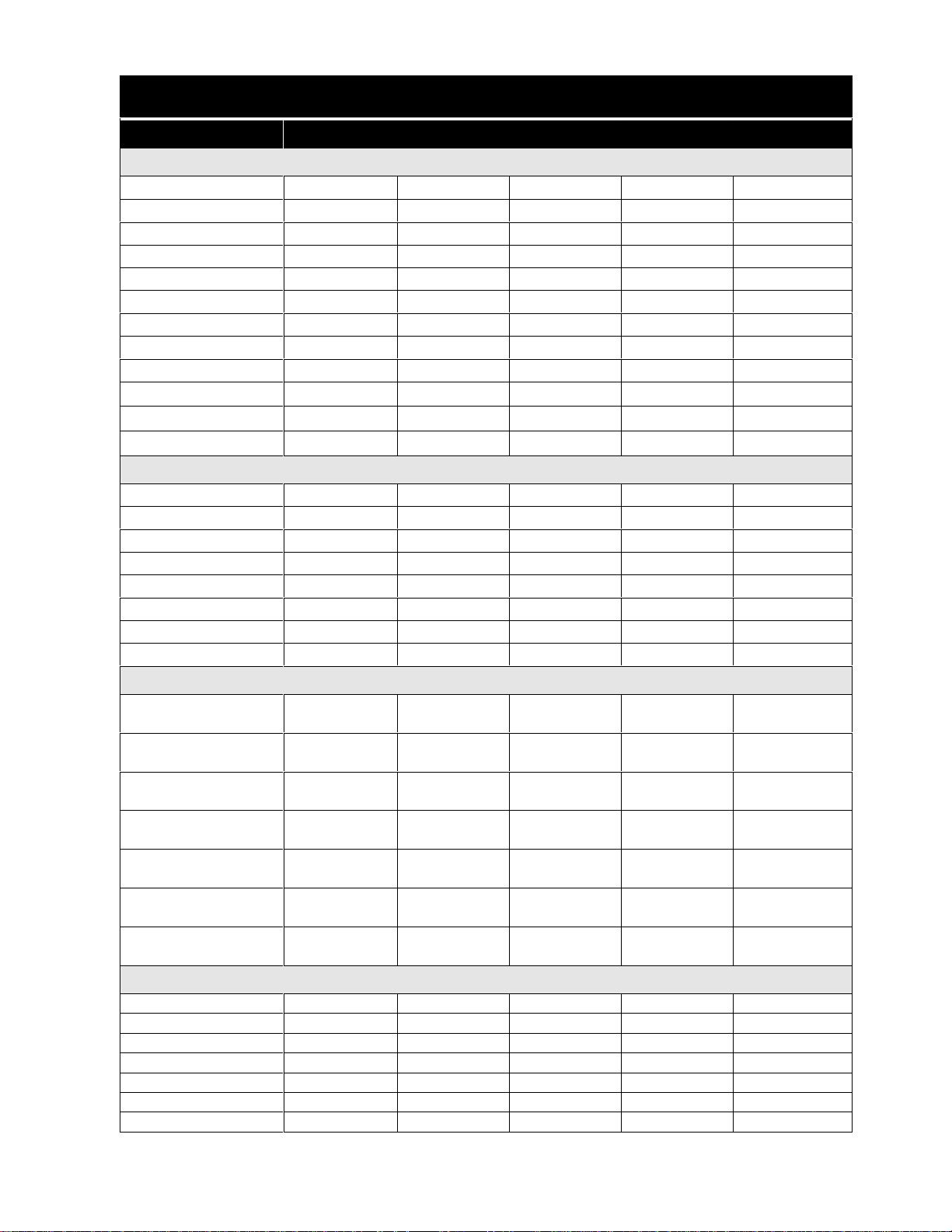

Page 7

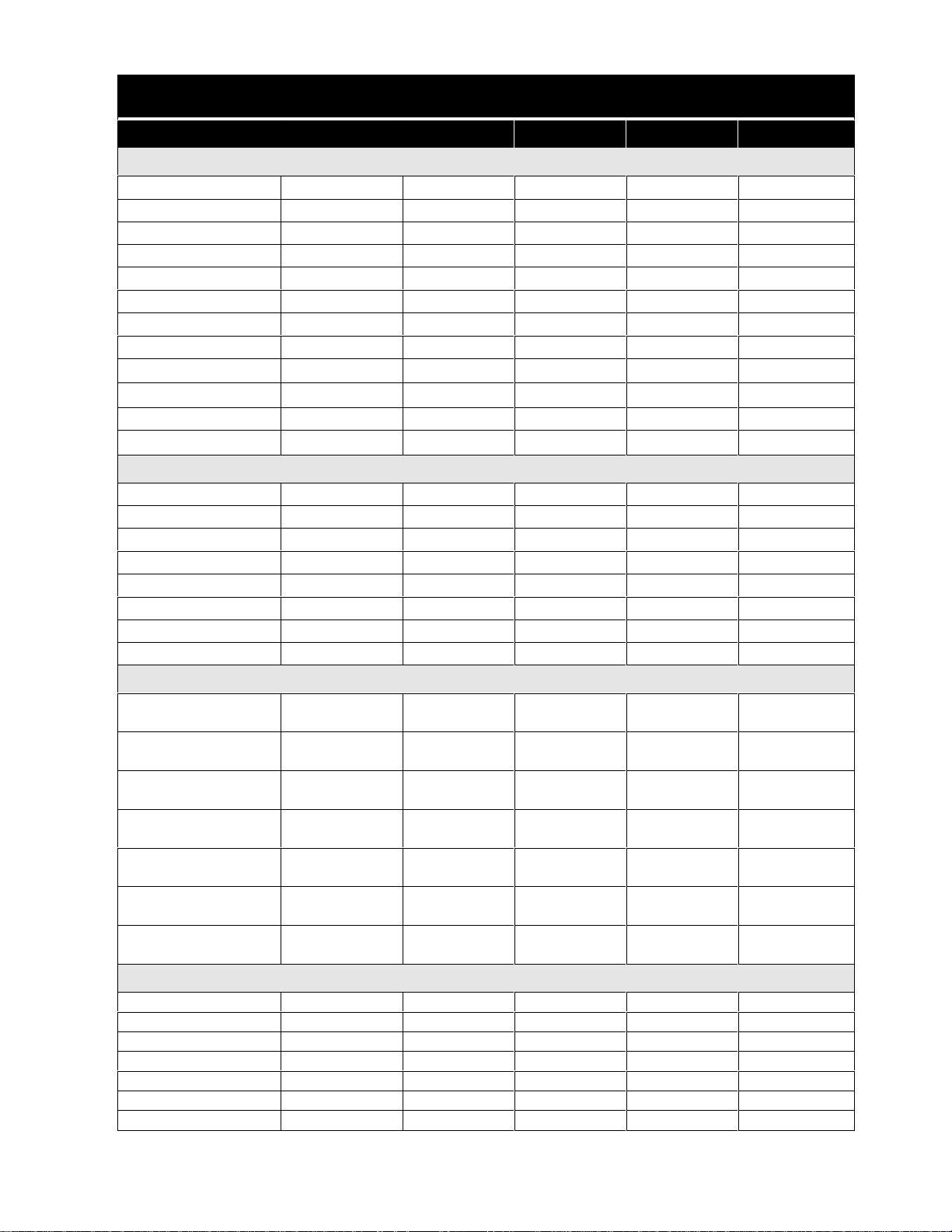

FRIGIDAIRE

MODEL FDB435RFS*4 FDB634CF*4 FDB635RF*6 FDP635RF*5 FDB641RA*0

ELECTRICAL

Service Data Sheet 154385401 154396801 154396801 154396801 154403801

Voltage 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

th

Motor (Amps) 1.1 1.1 1.1 1.1 1.1

Heater (Watts) 900 900 900 900 900

Total Amps 10 10 10 10 10

Temp Assure

Temp Boost

117°F

± 5°F

127°F (53

117°F

°C) 122°F (50°C) 122°F (50°C) 122°F (50°C) 122°F (50°C)

Sanitize N/A N/A N/A N/A N/A

Hi-Limit Thermostat

200°F (93

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

COMPONENT RESISTANCE (ohms)

Timer Motor 2357 2357 2357 2357 7700

Heating Element 9.28 9.28 9.28 9.28 9.28

Pump Motor

Vent Actuator 1893 1893 1893 1893 N/A

Dispenser 1928 1928 1928 1928 1928

Drain Motor 28 28 28 28 28

Water Valve Solenoid 699 699 699 699 699

Blower N/A N/A N/A N/A N/A

1/12

th

± 5°F

1/12

117°F

th

± 5°F

1/12

117°F

th

± 5°F

1/12

N/A

th

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8" 3/8"

66666

.83 .83 .83 .83 .83

12 12 12 12 12

87 87 87 87 87

DIAGRAMS (Located in Appendix A or B)

Service Data Sheet

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

B - 7 B - 15 B - 15 B - 15 B - 20

* A - 11 A - 11 B - 11 *

* A - 18 A - 18 A - 18 *

* A - 20 A - 20 A - 19 *

* A - 24 A - 24 A - 24 *

* A - 29 A - 29 A - 25 *

* A - 32 A - 32 A - 32 *

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 6

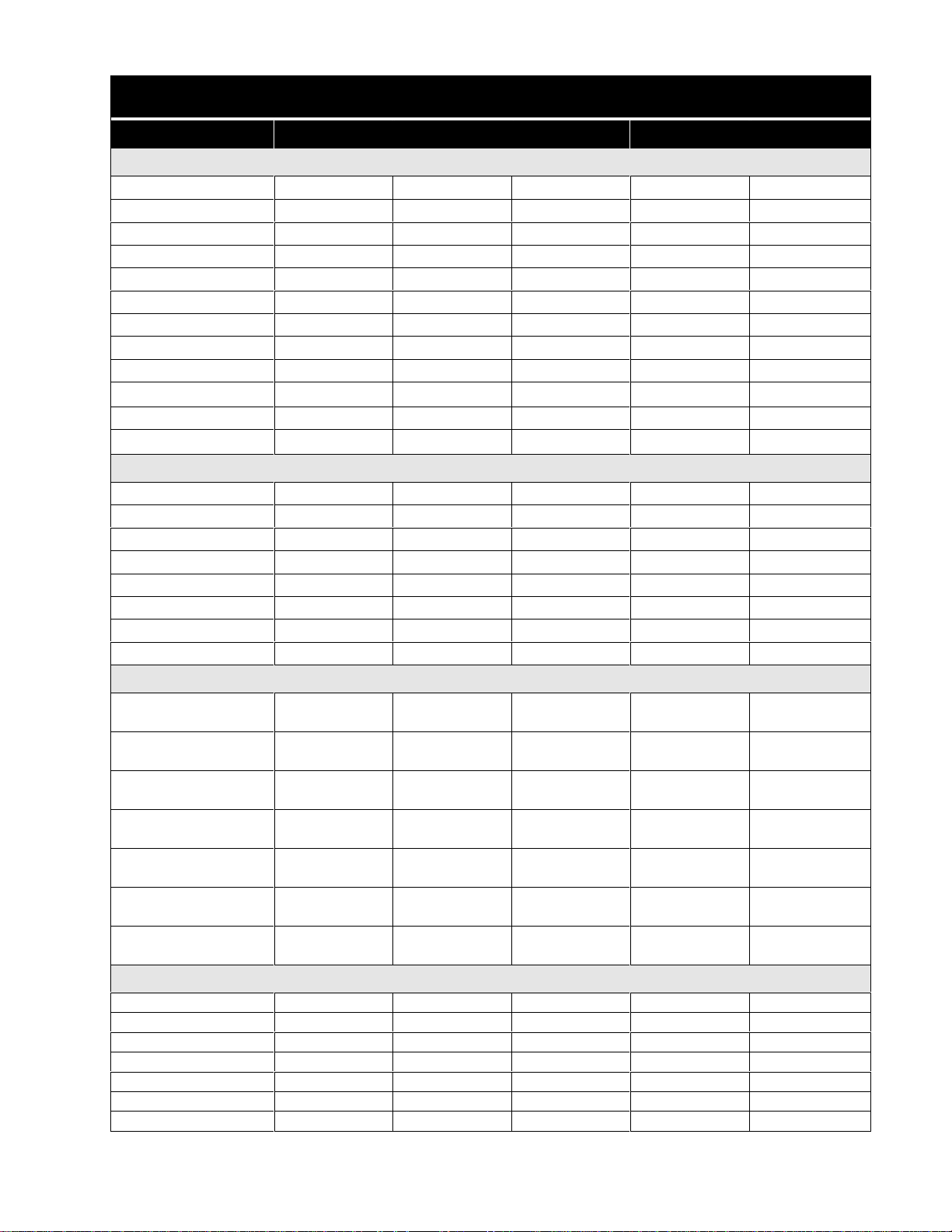

Page 8

FRIGIDAIRE

MODEL FDB641RJ*1 FDP641RA*0 FDB657RJ*1 FDB658RA*0

ELECTRICAL

Service Data Sheet 154403801 154403801 154396201 154396201

Voltage 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

Motor (Amps) 1.1 1.1 1.1 1.1

Heater (Watts) 900 900 900 900

Total Amps 10 10 10 10

Temp Assure N/A N/A N/A N/A

Temp Boost

Sanitize

Hi-Limit Thermostat

122°F (50°C) 122°F (50°C) 122°F (50°C) 122°F (50°C)

200°F (93

th

N/A N/A

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

COMPONENT RESISTANCE (ohms)

Timer Motor 7700 7700 2357 2357

Heating Element 9.28 9.28 9.28 9.28

Pump Motor

Vent Actuator N/A N/A 1893 1893

Dispenser 1928 1928 1928 1928

Drain Motor 28 28 28 28

Water Valve Solenoid 699 699 699 699

Blower N/A N/A N/A N/A

1/12

th

137°F (58

th

1/12

°C) 137°F (58°C)

1/12

th

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

DIAGRAMS

Service Data Sheet

(Located in Appendix A or B)

Control Panel

Door

Motor & Pump

Frame

Racks

Tub

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8"

6666

.83 .83 .83 .83

12 12 12 12

87 87 87 87

B - 20 B - 20 B - 11 B - 11

****

****

****

****

****

****

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 7

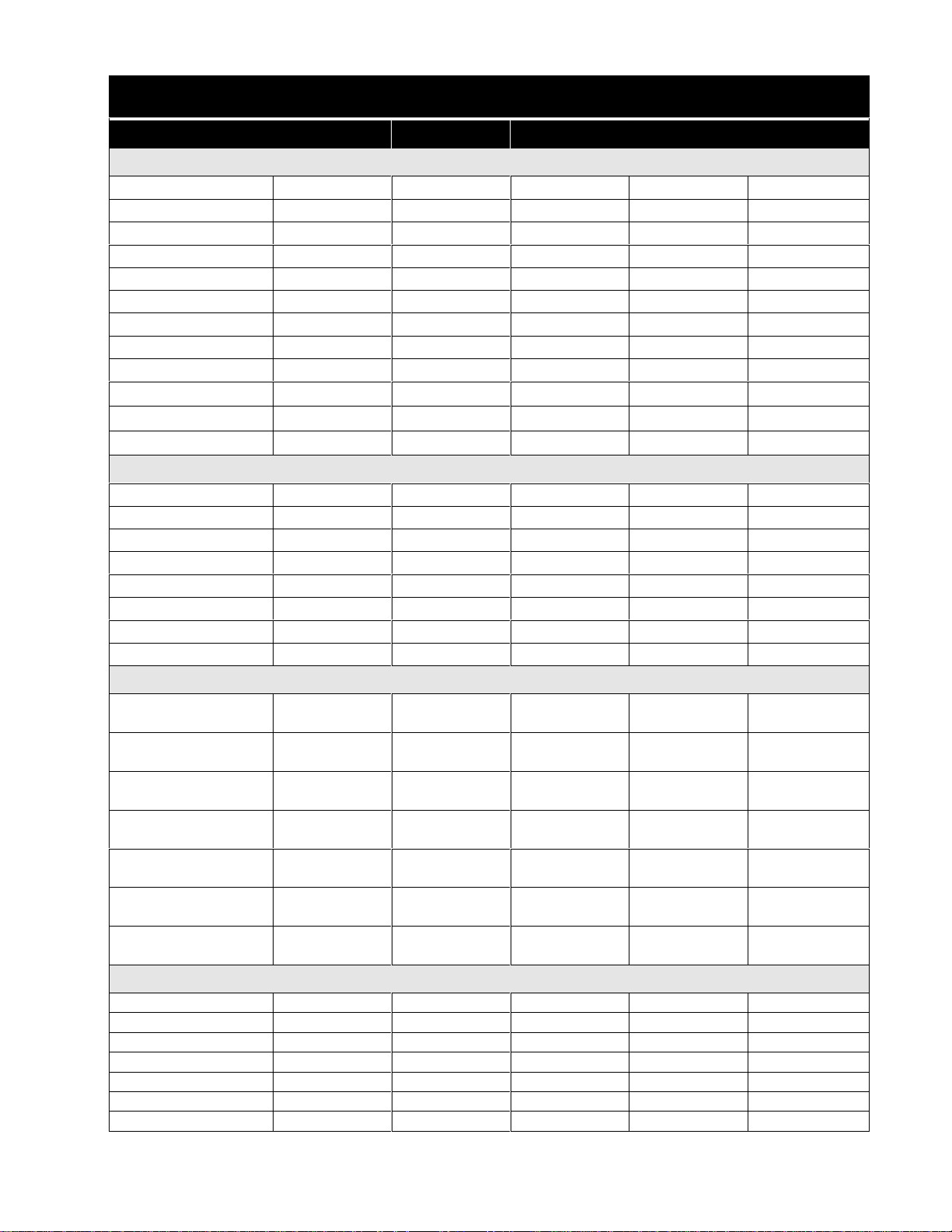

Page 9

FRIGIDAIRE

(Gallery Models)

MODEL GLDB653A*0 GLDB653J*2 GLDB656J*1 GPDB698J*1 GLDB756A*0

ELECTRICAL

Service Data Sheet 154402401 154396801 154396201 154396201 154402501

Voltage 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

Motor (Amps) 1.1 1.1 1.1 1.1 1.1

Heater (Watts) 900 900 900 900 900

Total Amps 10 10 10 10 10

Temp Assure 117°F ± 5°F 117°F ± 5°F N/A N/A 117°F ± 5°F

Temp Boost

Sanitize

Hi-Limit Thermostat

122°F (50

200°F (93

th

°C) 122°F (50°C) 122°F (50°C) 122°F (50°C)

N/A N/A

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

1/12

th

137°F (58

1/12

th

1/12

th

°C) 137°F (58°C) 137°F (58°C)

1/12

N/A

th

COMPONENT RESISTANCE (ohms)

Timer Motor 2357 2357 2357 2357 2357

Heating Element 9.28 9.28 9.28 9.28 9.28

Pump Motor N/A

Vent Actuator N/A 1893 1893 1893 1893

Dispenser 1928 1928 1928 1928 1928

Drain Motor 28 28 28 28 28

Water Valve Solenoid 699 699 699 699 699

Blower N/A N/A N/A N/A 214

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8" 3/8"

6666 6

.83 .83 .83 .83 .83

12 12 12 12 12

87 87 87 87 87

DIAGRAMS (Located in Appendix A or B)

Service Data Sheet

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

B - 17 B - 15 B - 11 B - 11 B - 18

* A - 11 A - 3 A - 6 *

* A - 18 A - 18 A - 17 *

* A - 21 A - 21 A - 21 *

* A - 25 A - 25 A - 25 *

* A - 30 A - 30 A - 31 *

* A - 33 A - 34 A - 35 *

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 8

Page 10

UNIVERSAL - MULTIFLEX

MODEL MDB12 2RF*2 MDB124BA*0 MDB124BJ*1 MDB124BH*1 MDB125RH *2

ELECTRICAL

Service Data Sheet 154396001 154407901 154396001 154396001 154395901

Voltage 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

th

Motor (Amps) 1.1 1.1 1.1 1.1 1.1

Heater (Watts) 900 900 900 900 900

Total Amps 10 10 10 10 10

Temp Assure N/A N/A N/A N/A N/A

Temp Boost

127°F (53

°C) 127°F (53°C) 127°F (53°C) 127°F (53°C)

Sanitize N/A N/A N/A N/A N/A

Hi-Limit Thermostat

200°F (93

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

COMPONENT RESISTANCE (ohms)

Timer Motor 7700 7700 7700 7700 2357

Heating Element 9.28 9.28 9.28 9.28 9.28

Pump Motor N/A N/A N/A N/A N/A

Vent Actuator 1893 1893 1893 1893 N/A

Dispenser 1928 1928 1928 1928 1928

Drain Motor 28 28 28 28 28

Water Valve Solenoid 699 699 699 699 699

Blower N/A N/A N/A N/A N/A

1/12

th

1/12

th

1/12

th

1/12

th

N/A

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8" 3/8"

66667.2

.83 .83 .83 .83 .83

12 12 12 12 12

87 87 87 87 87

DIAGRAMS (Located in Appendix A or B)

Service Data Sheet

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

B - 10 B - 22 B - 10 B - 10 B - 9

A - 15 * A - 15 A - 15 A - 9

A - 19 * A - 18 A - 18 A - 18

A - 21 * A - 21 A - 21 A - 21

A - 25 * A - 25 A - 25 A - 24

A - 28 * A - 28 A - 28 A - 30

A - 32 * A - 32 A - 32 A - 37

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

120°F

(49°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 9

Page 11

AMANA

MODEL ADW350RA*0 ADW350RA*1 ADW550RA*0 ADW5 50RA*1 ADW650RA *0

ELECTRICAL

Service Data Sheet 154382801 154396301 154382901 154396401 154383001

Voltage 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

Motor (Amps) 3.4 1.1 3.4 1.1 3.4

Heater (Watts) 900 900 900 900 900

Total Amps 11 10 11 10 11

Temp Assure N/A N/A N/A N/A N/A

Temp Boost

Sanitize

Hi-Limit Thermostat

127°F (53

200°F (93

th

°C)

N/A N/A

127°F (53

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

COMPONENT RESISTANCE (ohms)

Timer Motor 7700 7700 2357 2357 2357

Heating Element 9.28 9.28 9.28 9.28 9.28

Pump Motor 4.3 N/A 4.3 N/A 4.3

Vent Actuator 1893 1893 1893 1893 1893

Dispenser 1928 1928 1928 1928 1928

Drain Motor 28 28 28 28 28

Water Valve Solenoid 699 699 699 699 699

Blower N/A N/A N/A N/A N/A

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

DIAGRAMS

Service Data Sheet

(Located in Appendix A or B)

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8" 3/8"

66666

.83 .83 .83 .83 .83

12 12 12 12 12

87 87 87 87 87

B - 4 B - 13 B - 5 B - 14 B - 6

A - 5 A - 12 A - 7 A - 13 A - 7

A - 16 A - 18 A - 16 A - 18 A - 16

A - 21 A - 21 A - 21 A - 21 A - 21

A - 22 A - 25 A - 22 A - 25 A - 22

A - 29 A - 28 A - 29 A - 31 A - 29

A - 32 A - 32 A - 33 A - 33 A - 34

1/12

120°F

(49°C)

th

°C)

1/12

117°F ± 5

127°F (53

120°F

(49°C)

th

°F

117°F ± 5

1/12

th

°F

122°F ± 5

1/12

th

°C) 127°F (53°C) 137°F (58°C)

120°F

(49°C)

120°F

(49°C)

°F

* Information not available - Parts Catalogs not created as of this Publication date

Page 10

Page 12

AMANA CROWN

MODEL ADW650RA*1 ADW650RA*2 F71C12PH*1 F71C24RJ*1

ELECTRICAL

Service Data Sheet 154382801 154396301 154395901 154403001

Voltage 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

Motor (Amps) 3.4 1.1 1.1 31.1

Heater (Watts) 900 900 900 900

Total Amps 11 10 10 10

Temp Assure N/A N/A N/A N/A

Temp Boost

Sanitize

Hi-Limit Thermostat

122°F

137°F (58

200°F (93

th

± 5°F 122°F ± 5°F

°C) 137°F (58°C)

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

COMPONENT RESISTANCE (ohms)

Timer Motor 2357 2357 2357 7700

Heating Element 9.28 9.28 13.5 13.5

Pump Motor 4.3 N/A N/A N/A

Vent Actuator 1893 1893 N/A

Dispenser 1928 1928 1928 1928

Drain Motor 28 28 28 28

Water Valve Solenoid 699 699 699 699

Blower N/A N/A N/A N/A

1/12

th

th

1/12

N/A

N/A N/A

1/12

122°F (50

th

°C)

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8"

66 7.2 6

.83 .83 .83 .83

12 12 12 12

87 87

DIAGRAMS (Located in Appendix A or B)

Service Data Sheet

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

B - 4 B - 12 B - 9 B - 19

A - 7 A - 13 * *

A - 13 A - 18 * *

A - 21 A - 21 * *

A - 25 A - 22 * *

A - 29 A - 31 * *

A - 34 A - 34

120°F

(49°C)

120°F

(49°C)

87 87

**

120°F

(49°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 11

Page 13

GIBSON

MODEL G DP635RH*2 GDB742RJ*0 GDB742RJ*1 GDB755RJ*0 GDB755RJ*1

ELECTRICAL

Service Data Sheet 154396801 154374101 154403001 154374001 154383001

Voltage 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Cycles 60 Hertz 60 Hertz 60 Hertz 60 Hertz 60 Hertz

Circuit Rating (Amps) 15 / 20 15 / 20 15 / 20 15 / 20 15 / 20

Motor (HP) 1/12

Motor (Amps) 1.1 1.1 1.1 3.4 1.1

Heater (Watts) 900 900 900 900 900

Total Amps 10 10 10 11 10

Temp Assure

Temp Boost

Sanitize

Hi-Limit Thermostat

117°F

122°F (50

200°F (93

th

± 5°F

°C)

N/A N/A N/A

122°F (50

°C) 200°F (93°C) 200°F (93°C) 200°F (93°C) 200°F (93°C)

COMPONENT RESISTANCE (oh ms)

Timer Motor 2357 7700 7700 2357 2357

Heating Element 9.28 9.28 9.28 9.28 9.28

Pump Motor N/A N/A N/A 4.3 N/A

Vent Actuator 1893 1893 1893 1893 1893

Dispenser 1928 1928 1928 1928 1928

Drain Motor 28 28 28 28 28

Water Valve Solenoid 699 699 699 699 699

Blower N/A N/A N/A 214 N/A

WATER SUPPLY

Minimum Incoming

Water Temperature

Pressure

(min/max - psi)

Connection

(NPT)

Normal Cycle Water

Consumption (gal.)

Water valve Flow Rate

(GPM)

Water Recirculation

Rate (GPM)

Water Fill Time

(Seconds)

DIAGRAMS

Service Data Sheet

(Located in Appendix A or B)

Control Panel

Door

Tub

Motor & Pump

Frame

Racks

120°F

(49°C)

20 / 120 20 / 120 20 / 120 20 / 120 20 / 120

3/8" 3/8" 3/8" 3/8" 3/8"

66666

.83 .83 .83 .83 .83

12 12 12 12 12

87 87 87 87 87

B - 15 B - 3 B - 19 B - 2 B - 6

A - 11 A - 8 * A - 4 A - 13

A - 19 A - 18 * A - 18 A - 18

A - 20 A - 21 * A - 21 A - 21

A - 25 A - 23 * A - 23 A - 25

A - 26 A - 27 * A - 27 A - 28

A - 33 A - 32 * A - 33 A - 33

th

1/12

N/A N/A N/A N/A

°C)

120°F

(49°C)

122°F (50

1/12

120°F

(49°C)

th

°C)

1/12

122°F (50

137°F (58

120°F

(49°C)

th

°C)

122°F (50

°C) 137°F (58°C)

120°F

(49°C)

1/12

th

°C)

* Information not available - Parts Catalogs not created as of this Publication date

Page 12

Page 14

CONSTRUCTION & OPERATION

WATER DISTRIBUTION SYSTEM

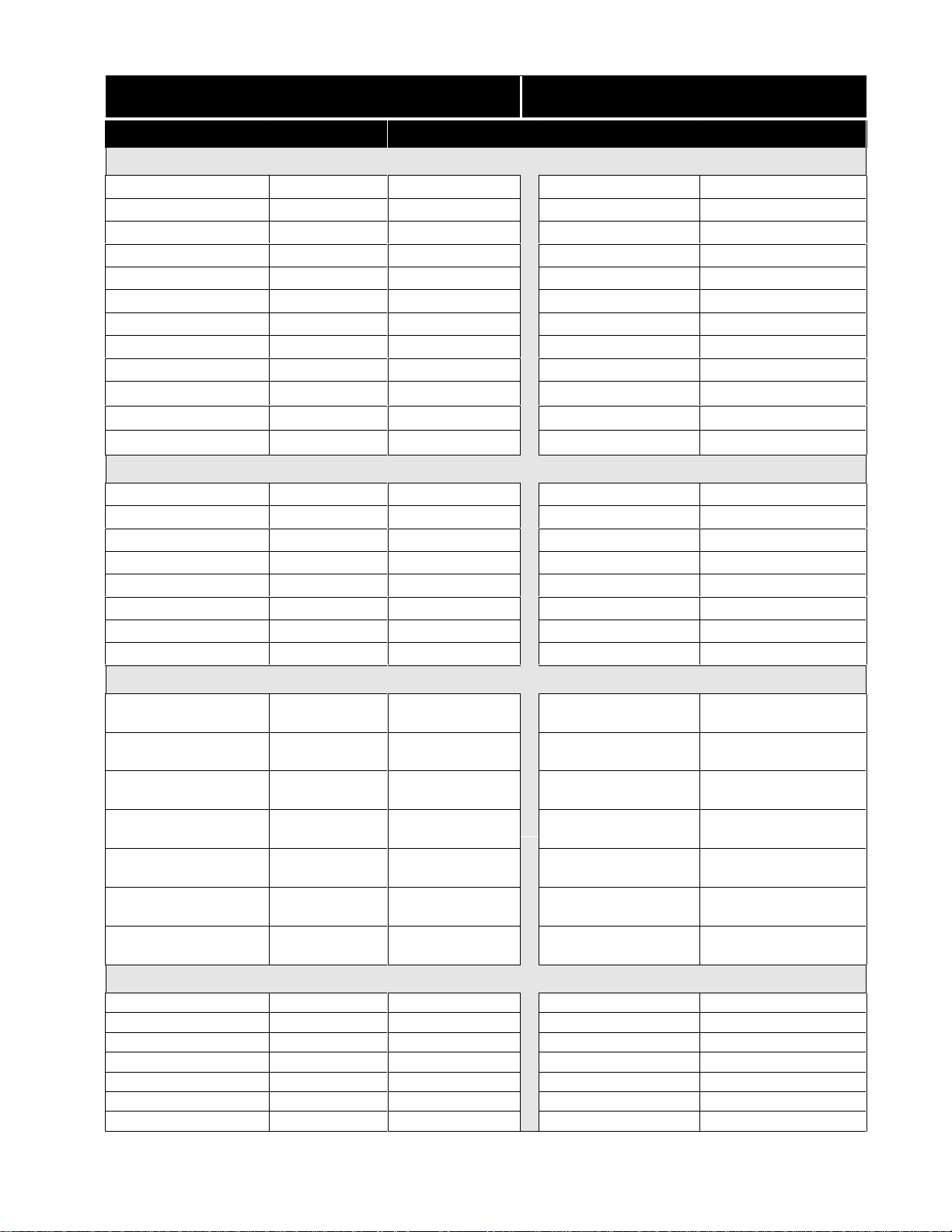

The water distribution system consists of an upper and

lower spray arm, upper (spray) arm delivery tube, filter,

soil director, pump, sump, and check ball. The system

is designed to operate only one spray arm at a time.

During the first wash and first and second rinses, only

the lower spray arm operates. In the second wash, third

and fourth rinses the spray arms alternate about every

90 seconds.

This alternating of the spray arms is achieved with a

check ball located on a ramp between two outlets of the

pump. There is an outlet to the bottom spray arm and an

outlet to the upper arm delivery tube. In the normal

position the ball is at the bottom of the ramp, in front of

the opening to the upper arm delivery tube.

the ball and enter the tube, and fills the tube at a rate of

approximately four inches a second. At the same time,

the outlet to the lower spray arm is open, so the lower

spray arm operates. When the pump stops, the pressure

is removed from the ball and the water flows down the

tube, forcing the ball up the ramp and against the outlet

to the lower spray arm. If the pump remains off for more

than 3 seconds, all the water in the tube escapes and

the ball returns to the bottom of the ramp. But, if the

pump is started in less than .6 seconds, the water from

the upper arm delivery tube is still forcing the ball up the

ramp against the outlet to the lower spray arm. The

force of the water from the pump continues to hold the

ball against the outlet to the lower spray arm which

leaves the outlet to the upper arm delivery tube open.

When the ball is in this position only the upper spray arm

operates. This momentary stopping of the pump is

controlled by a contact in the timer.

Another unique feature of the water distribution system

is the two cavities of the sump. One cavity provides

filtered water to the pump for recirculation through the

spray arms. The other, called a quiet water cavity,

allows soil to collect in the area of the macerator blade,

where it is held until the drain pump removes it.

When the pump starts, the force of the water pushes the

ball to block the opening to the upper arm delivery tube.

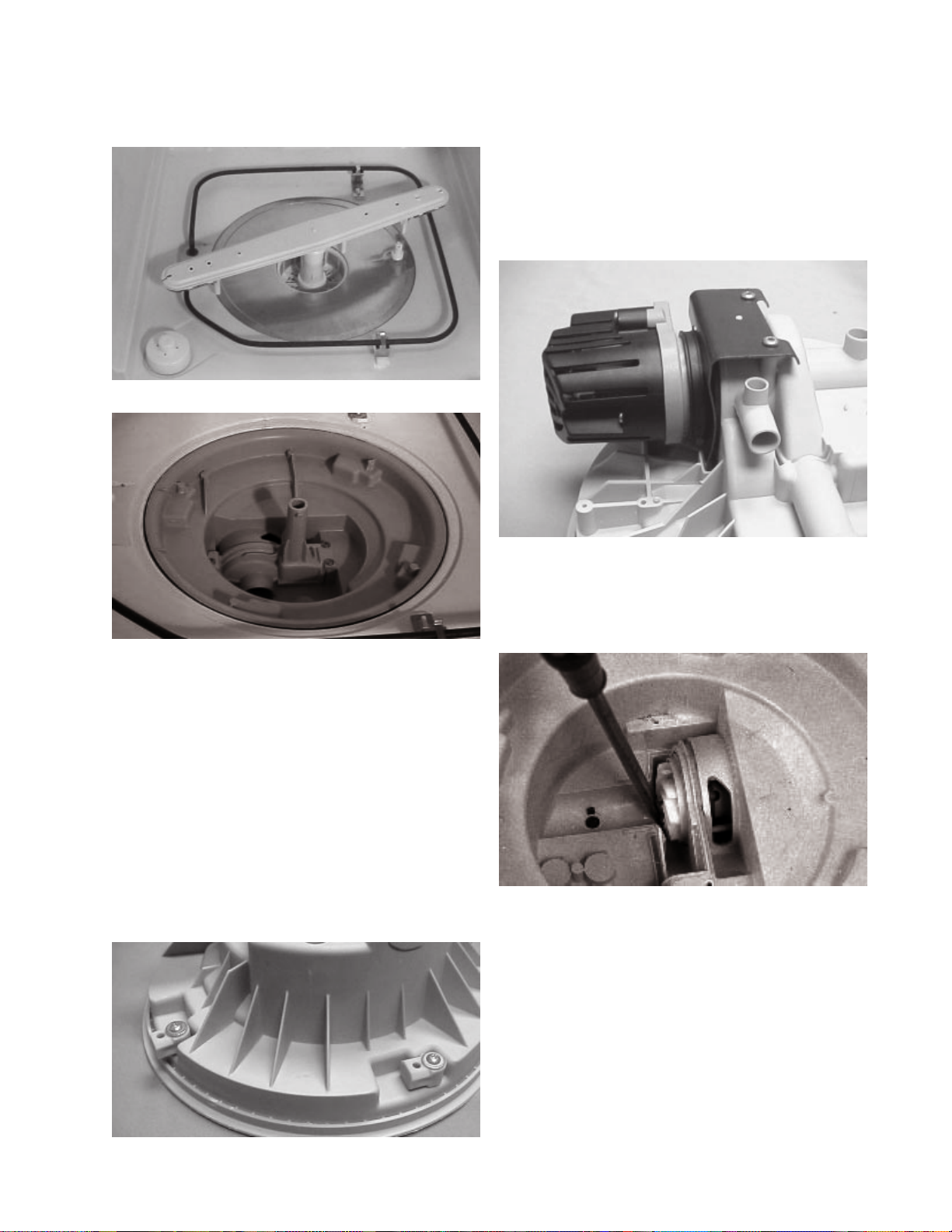

WATER DISTRIBUTION COMPONENTS

Wash Pump

The recirculation (wash) pump has three (3) functional

parts, a 1/12th HP drive motor, impeller, and macerator

blade. The pump circulates water at the rate of 12

gallons per minute. This pump is used only during the

wash cycle, a separate pump is used during the drain

cycle. The wash pump is to be replaced as a complete

assembly.

Not all of the water is blocked however. The opening is

constructed to allow a small amount of water to bypass

Page 13

Page 15

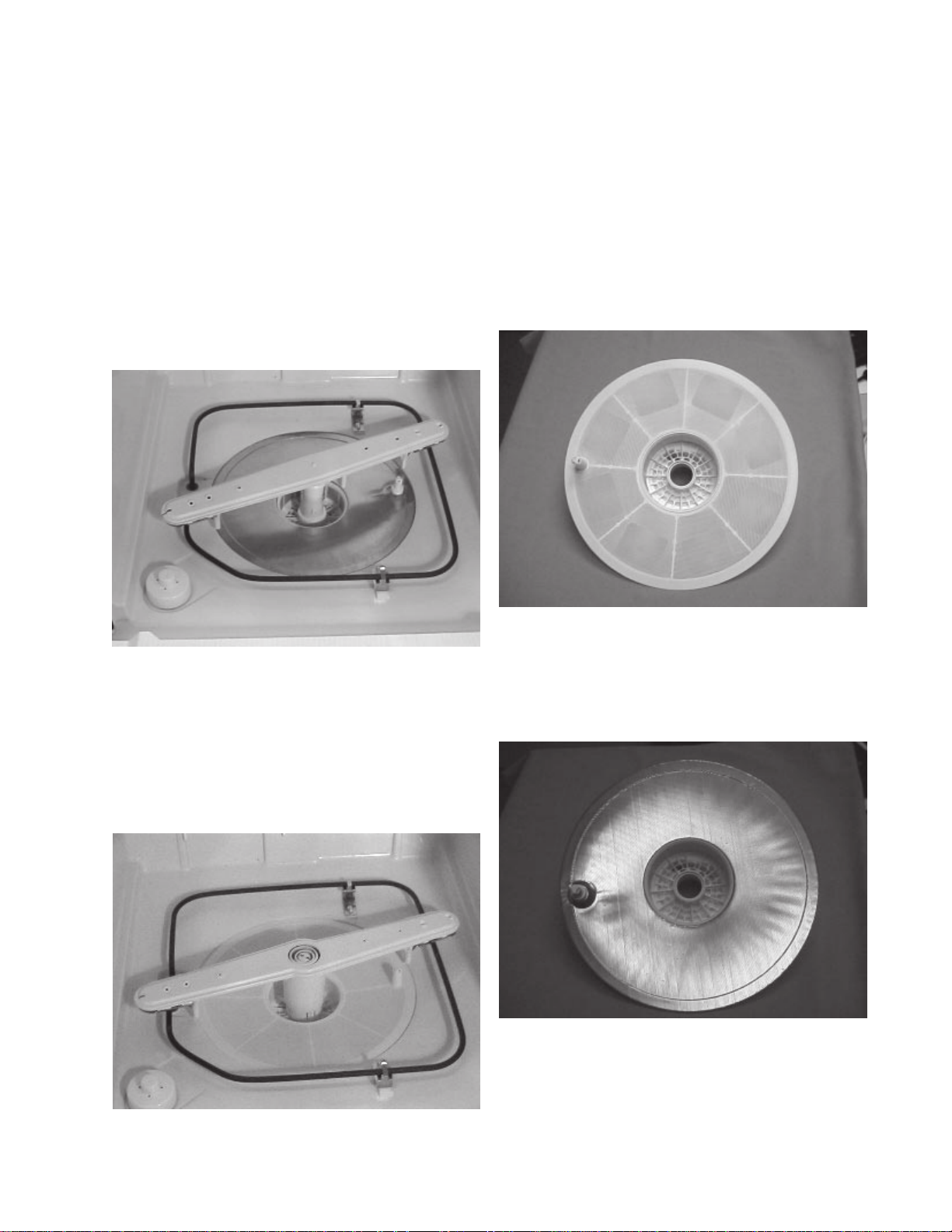

Upper Spray Arm

The upper spray arm hangs from a bracket that is

snapped to the upper rack. The water is supplied to the

arm with a nozzle and funnel arrangement. The nozzle

is located at the top of the tub and the funnel is located

directly below it and directs water into the arm. All the

spray jets but three face up.

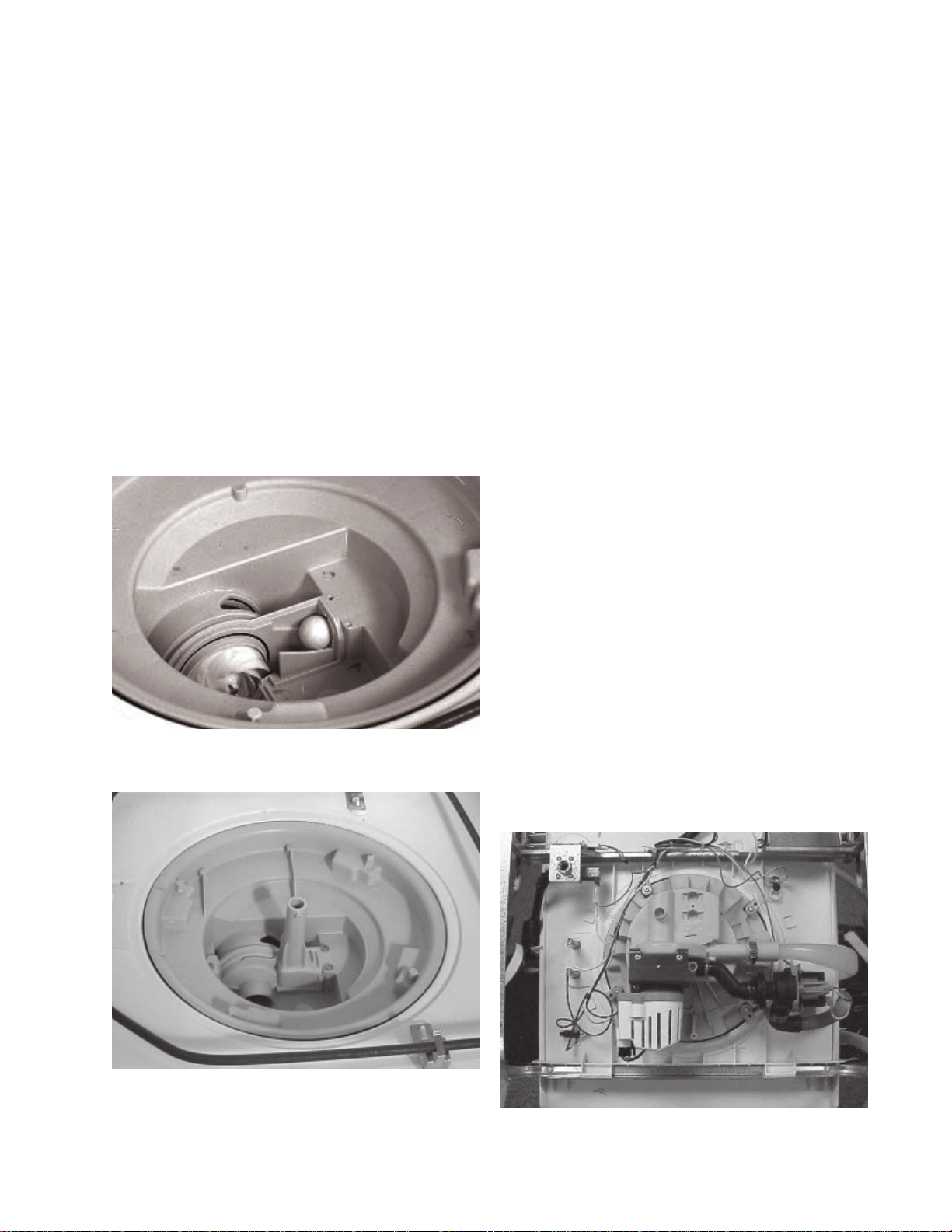

Lower Spray Arm

The lower spray arm rotates on the lower spray arm

support. It has two functions, washing the dishes and

cleaning the filter. The jets located on the top of the arm

clean the dishes and propel the arm. The three (3) jets

located on the bottom of the arm are aimed to flush the

soil on the filter toward the glass trap and soil director.

Filter

Two types of filter materials are used, molded

polypropylene and stainless steel, depending on the

model.

Polyproplene filter

This is a molded filter consisting of two parts; the filter,

which covers the entire sump, plus an inner basket,

which directs food soil to the drain portion of the pump.

The inner basket can be constructed of fine polyester

mesh or polypropylene around the sides of the basket.

The bottoms of both baskets are open to allow the soil

to enter the drain portion of the pump.

Lower Spray Arm With Collapsible Tower

The spray arm rotates 100% of the time with the tower

assembly fully extended during the wash and rinse

cycles. The arm has two functions; washing the dishes

and cleaning the filter. The jets, located on the top of the

arm, clean the dishes and propel the arm. The two jets

located on the bottom of the arm are aimed to flush the

soil on the filter toward the soil director.

Stainless Steel Filter

The stainless steel filter covers the entire sump area

with an inner basket of fine mesh polyester. The bottom

of this basket is open to allow food soil to enter the drain

portion of the pump.

Page 14

Page 16

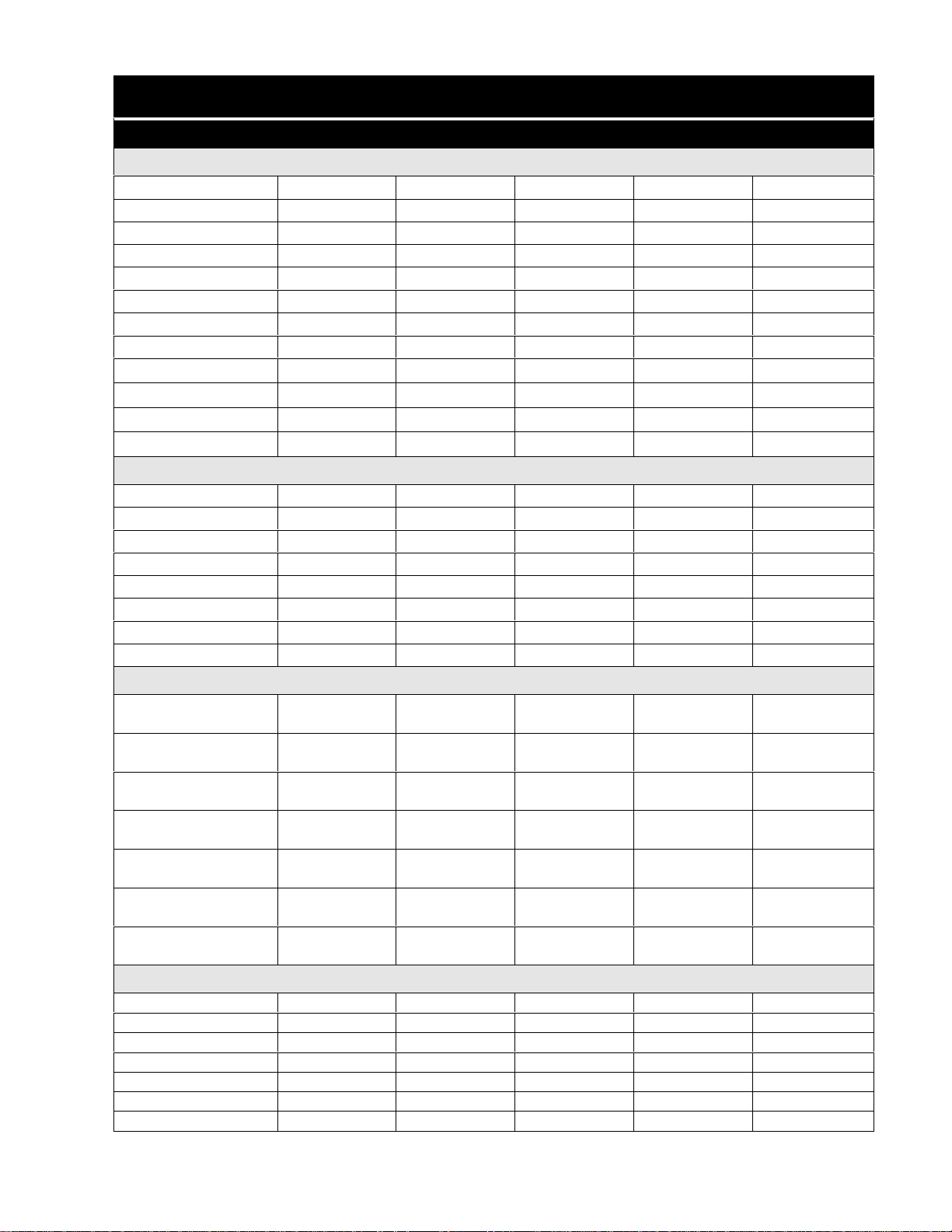

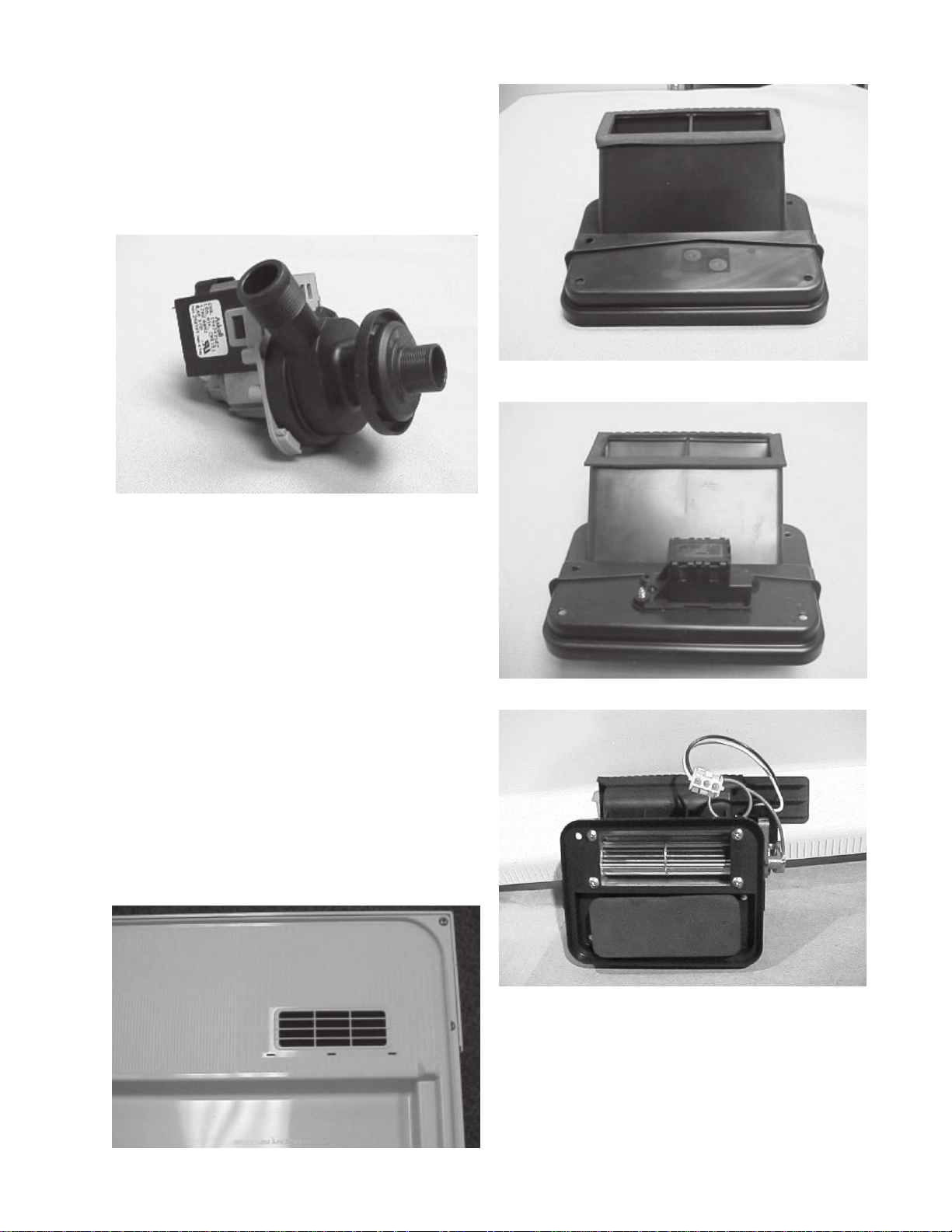

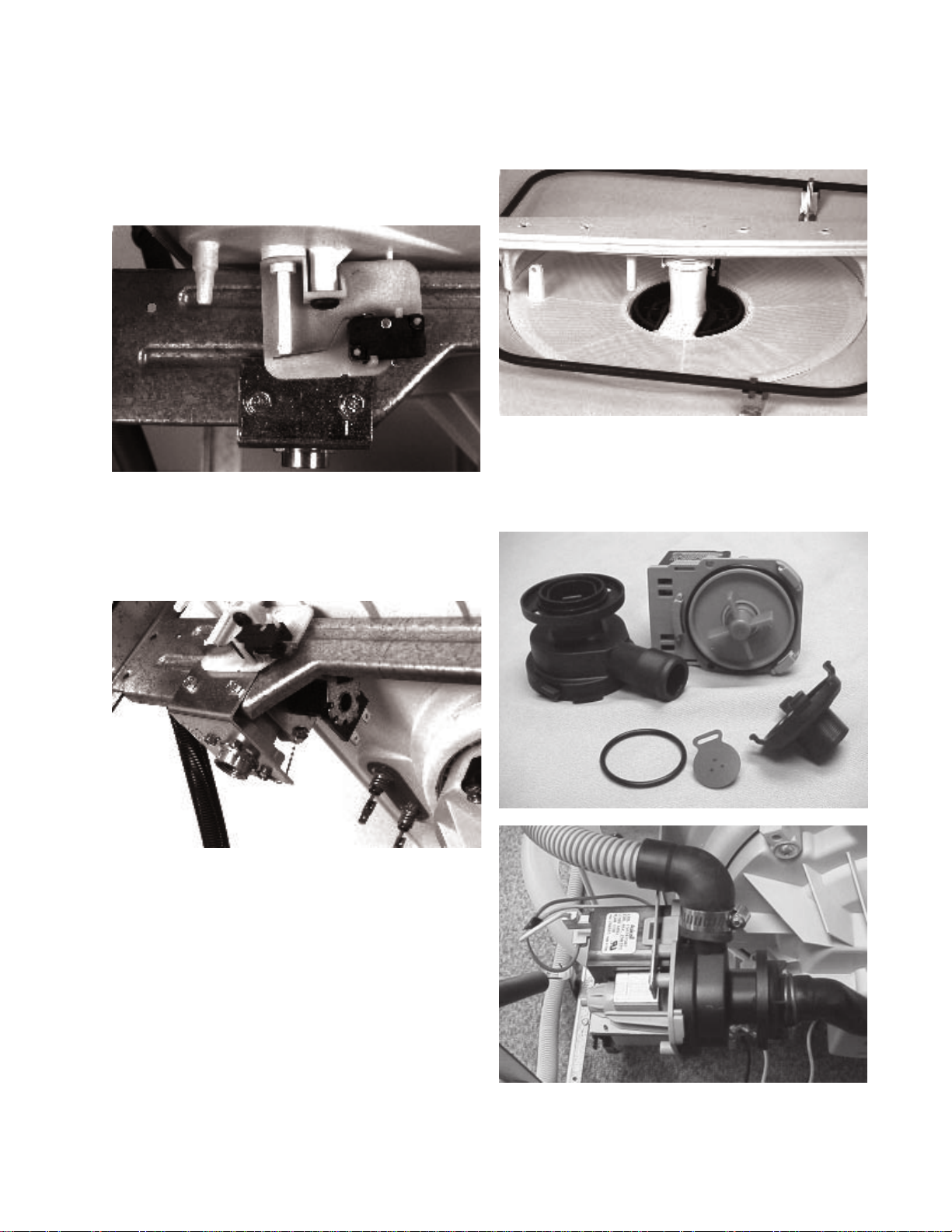

Drain Pump

The only function of the drain pump is to remove water

from the dishwasher. It is driven by a 1/25th HP drive motor.

It consists of 3 function parts; a pump cover, impeller and

armature, and stator. The pump only comes as an

assembly. The pump cover can be removed for easy

cleaning of the pump.

Drying System

Static Vent

The drying system on the dishwasher can employ one

of three types of systems:

1. Static Dry System - The vent is located on the

upper left-hand side of the door and is open at all

times. This allows the warm, moist air to escape out

the vent grill. Air is drawn into the dishwasher tub

through the opening across the bottom of the door.

2. Active Vent System - The vent is closed up until the

start of the dry cycle, at which time the vent is

opened and the warm, moist air is allowed to escape.

Also, the air is brought into the tub through the

bottom of the door.

3. Power Vent System - This system is the same as

the Active Vent System but with the addition of a

blower motor. At the beginning of the dry cycle, the

vent opens and a small motor with a centrifugal

blower starts, accelerating the movement of air

from the dishwasher.

Active Vent

Power Vent

The door vent actuator opens the vent only during the

dry cycle. It is closed during all other cycles to minimize

heat loss and to prevent noise from being transmitted

into the kitchen.

Page 15

Page 17

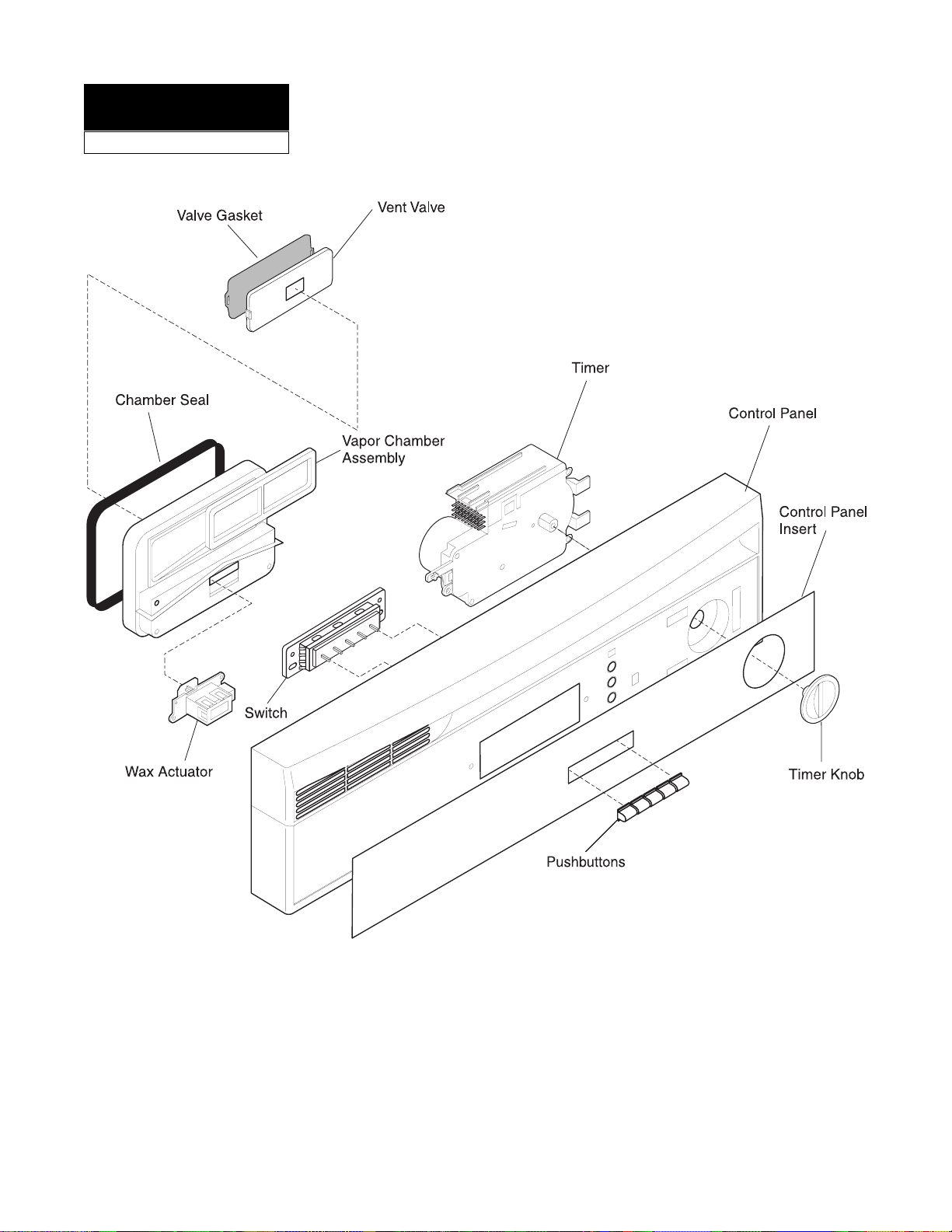

DRYING SYSTEM COMPONENTS

Lower Vent Housing

The lower vent housing is located between the inner

door assembly and control housing and is mounted to

the inner door panel. It surrounds an opening in the

inner door panel. The opening is covered with a moveable

vent valve.

Vent Valve

The vent valve is a rectangular rubber covered pad

slightly larger than the opening. The vent valve is

attached to the vent actuator which is electrically

operated.

Vent Actuator

The actuator is made up of a rod, slide, wax motor , and

spring. The valve is attached to one end of the rod and

the slide is inserted in the other. The spring pushes in

on the slide forcing the rod to push the valve against the

opening in the door panel.

When the timer enters the dry cycle, 120 VAC is applied

to the wax motor. The wax motor is made up of a heating

disk, wax chamber and piston. When voltage is applied

to the heating disk, the wax in the chamber heats

causing the wax to expand, driving the piston out. The

piston forces the slide out causing the vent valve to

open.

The vent actuator is replaced as a complete assembly.

No individual replacement parts are available.

Blower

Models that feature Fan Assisted Dry use a small motor

and centrifugal blower assembly which is mounted to

the top section of the lower vent housing.

Upper Vent Housing

The upper vent Housing is screwed to the blower and

directs air from the blower to the outlet in the console.

Models that do not have a blower use a different upper

vent housing which connects directly to the lower vent

housing.

Upper

Vent

Lower Vent Housing

Lower Vent

Vent Actuator

Blower

Vent Valve

Page 16

Page 18

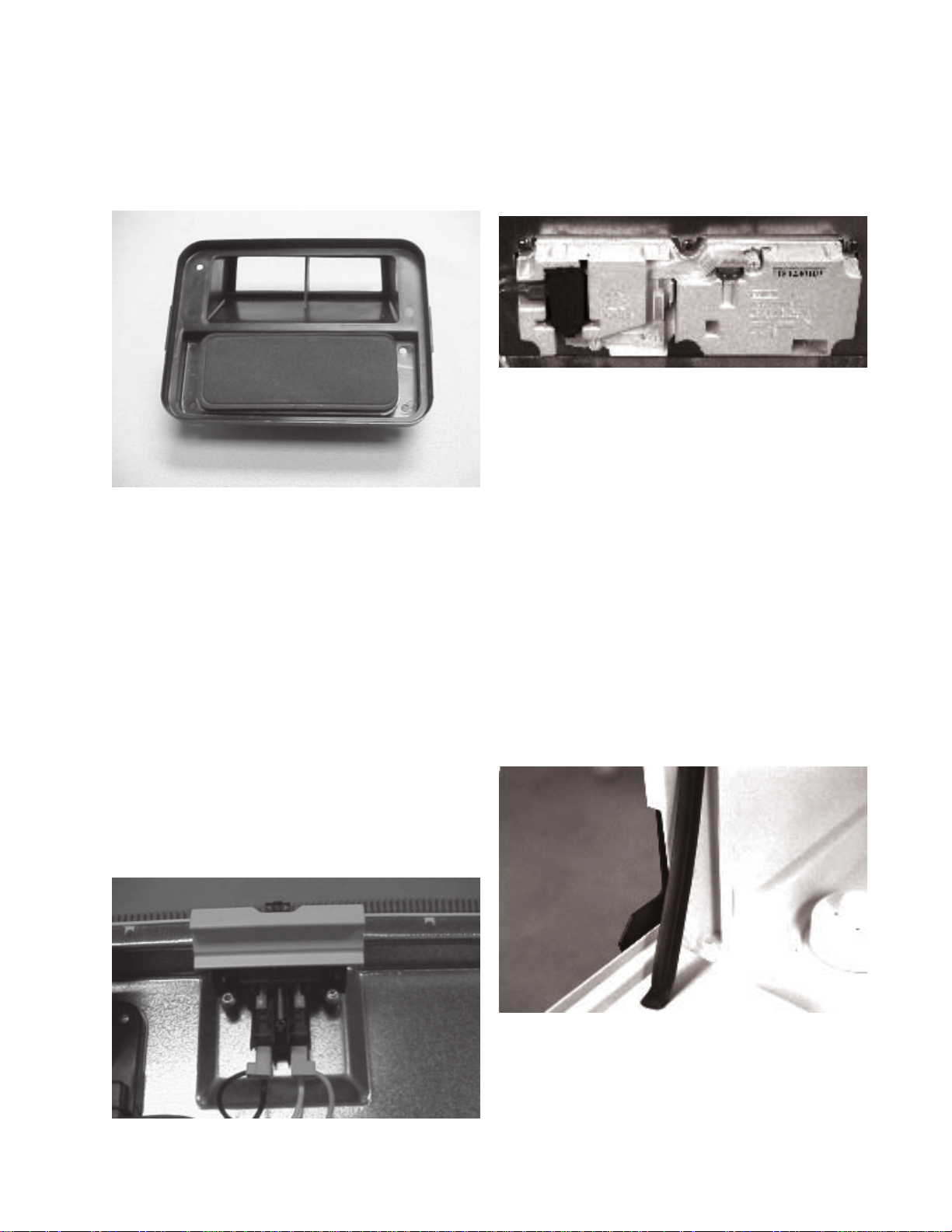

DISPENSING SYSTEM

Detergent & Rinse Aid Dispenser

The detergent & rinse aid dispenser consists of two

dispensers combined in one housing that are controlled

with one wax motor actuator. The first time the actuator

is energized in a cycle, it dispenses detergent. The

second time the actuator is energized, it dispenses

rinse aid. The amount of rinse aid dispensed can be

adjusted from one to four (1 - 4) by using a pointer under

the fill cap. The dispenser is replaced as a complete

assembly. No individual replacement parts are available.

Dispenser Operation

The dispenser has two detergent cups:

1. A cup with a spring loaded cover with a

manual or automatic release latch.

2. A cup formed in the inner door panel without

a cover.

Prior to starting the dishwasher, detergent is added to

the dispenser cup and the cover is latched close. The

open cup is also filled but empties into the tub as soon

as the door is lifted to the upright position.

The detergent in the covered cup is held until the start

of the second wash. The timer then supplies 120 VAC

to the dispenser actuator for one minute. It takes 30

seconds for the actuator to move the pivot arm far

enough to release the cover. When power is applied to

the actuator, the actuator plunger pushes the end of the

pivot arm down. The pivot arm rotates on the shaft of the

detergent dispenser door latch. As the shaft rotates, it

turns the door latch , releasing the spring loaded cover.

The pivot arm is spring loaded so that when power is

removed, it returns to the normal (horizontal) position.

The other end of the pivot arm has a pin that moves in

a slot(s) of the rinse injector pump arm. The rinse

injector pump arm is slotted in such a way that when the

actuator pushes the lever down the first time to release

the detergent cup cover, the pin moves up but does not

raise the rinse injector pump arm. When the timer

removes power from the actuator, the spring forces the

rinse injector pump arm end of the pivot armdown. The

compond slot in the rinse injector pump arm directs the

pivot arm pin down the front of the rinse injector pump

arm and under a shorter slot in the center of the arm.

When the timer reaches the middle of the final rinse

cycle, it again applies 120 VAC to the dispenser actuator

which forces the pivot arm up at the rinse injector end.

As the pin engages the shorter slot, it raises the rinse

injector pump arm which operatesthe pump. When the

power is removed, the pivot arm spring forces the pin to

the bottom of the slot. A leaf spring pushes the rinse

injector pump arm to the left so that the pin returns to the

original starting position.

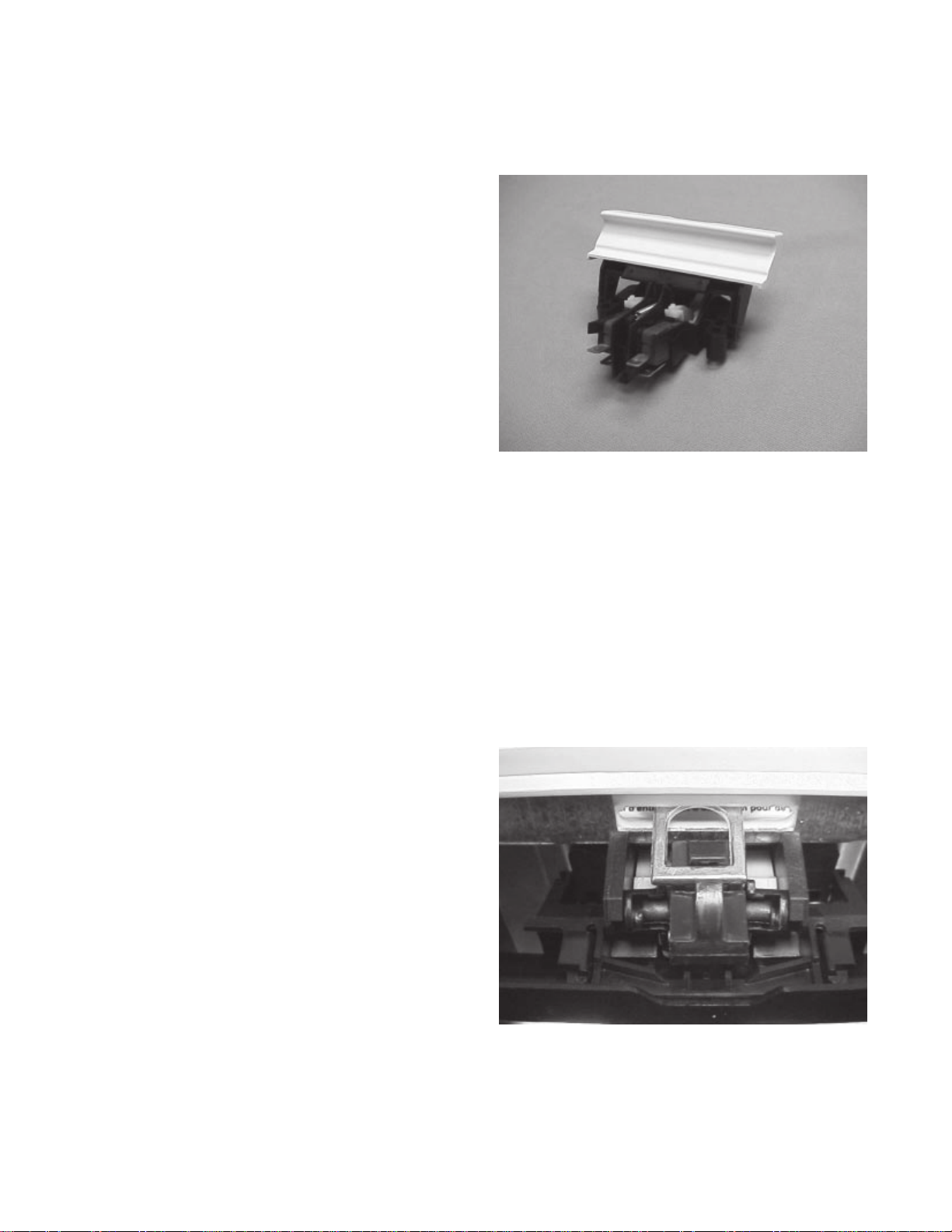

DOOR LATCH ASSEMBLY

The door latch assembly has two functions; one is to

lock the door in a closed position and the other is to

operate the door switches.

The door latch assembly consists of the door handle,

door handle bracket, door catch, door switch bracket,

and door switches. The assembly is secured to the

inner door panel with two locater pins and two screws.

The panel is hidden by and accessed through the

control panel.

When the door is closed, the door strike (mounted on

the tub) forces the spring loaded catch to rotate back

until the bottom of the catch clears the door handle

bracket. At that time, the spring forces the door handle

bracket to rotate. The bar at the top of the door handle

rotates back under the door catch locking the door. The

plunger on the bottom of the bracket rotates forward,

closing the door switches.

The door is released by lifting up on the door handle.

When the handle is lifted up, the door handle bracket

rotates in at the top, allowing the door catch to rotate

open, and out at the bottom to open the door switches.

When the catch is rotated to the open position, it holds

the door handle bracket away from the door switches.

Page 17

Page 19

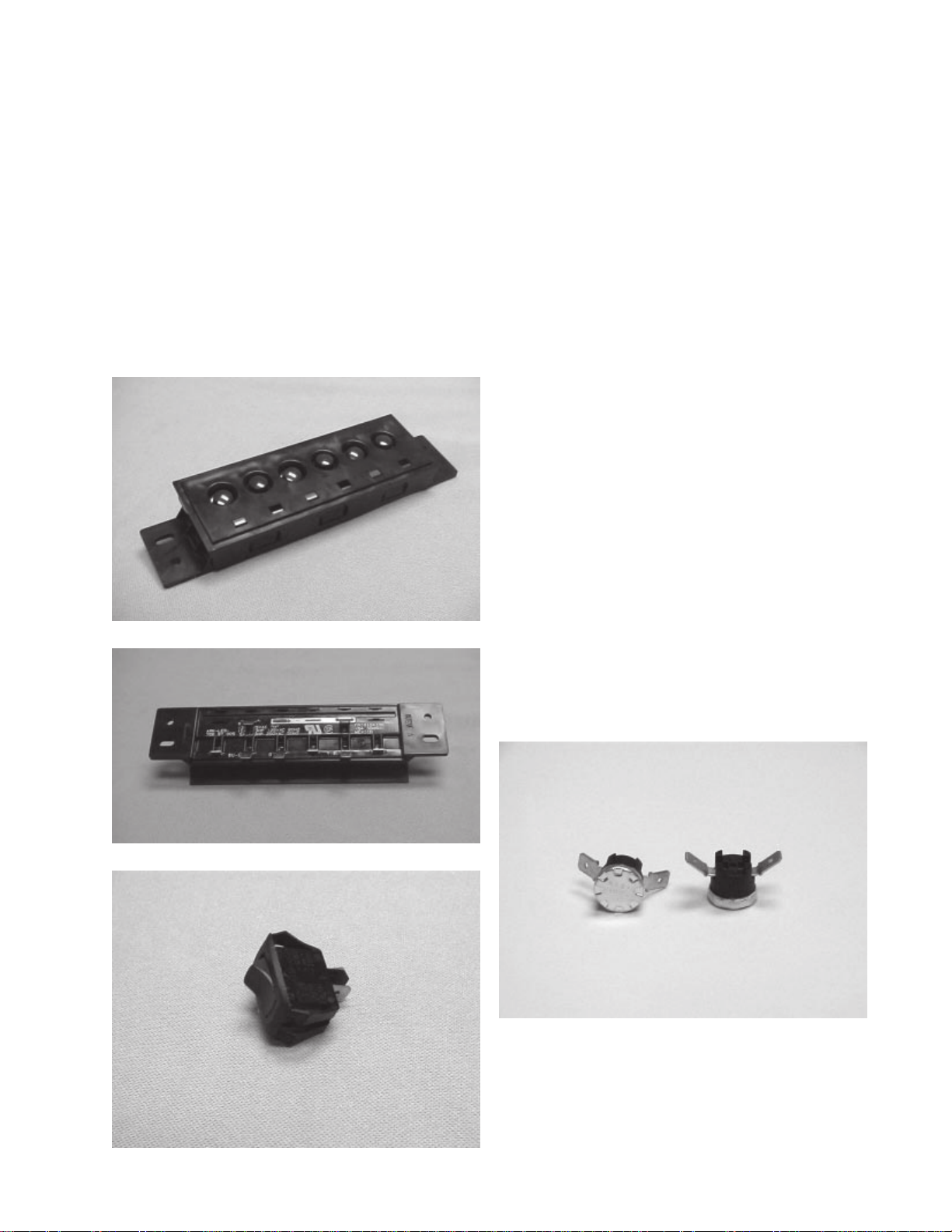

Selector Switch and Thermostats

(Mechanical Timer Models)

Depending on the model, the selector switch could be

a rocker selector switch with two selections or a push

button selector switch with from two to eight buttons and

consisting of from one to four switches.

Heated Dry

If the dishwasher has an option for "Heated Dry", this

switch will be in series with the element. When the timer

advances to the dry portion of the cycle, contacts will

close to apply power to the heating element. When

"ON" is selected, the contacts in the switch will be

closed, applying power to the element. If "OFF" is

selected, the contacts in the switch will be open.

Hi-Temp Wash

The selector switch has a selection for Hi-Temp Wash;

the switch is in parallel with a thermostat mounted on

the bottom of the tub and with a contact in the timer. The

selector switch, temp assure thermostat, and the temp

boost thermostat are all in series with the timer motor.

Both thermostats are normally open thermostats. When

the timer reaches the end of the second wash cycle, the

contact in the timer supplying power to run thetimer

motor will open. At which time, if the selector switch for

the Hi-Temp Wash has been selected, power to run the

timer motor must come through the thermostats. The

temperature of the water in the tub must rise to 137° ±

5° F for the thermostat to close and the timer motor to

advance. If the water temperature is below 137° ± 5° F,

the timer will pause until the heating element raises the

temperature of the water in the tub and allow the

thermostat to close.

Hi-Temp Rinse

If the selector switch was a selection for a Hi-Temp

rinse, the switch is in parallel with a thermostat mounted

in the tub, and the contact in the timer, the same as the

Hi-Temp wash. The operation for the Hi-Temp rinse will

be the same as for the Hi-Temp wash with the exception,

on some models, the temperature of the water in the tub

will be 150° ± 5° F for the thermostat to close to give a

sanitizing rinse.

High Limit Thermostat

The High Limit Thermostat is mounted on the bottom of

the tub in the left rear. This thermostat is a normally

closed thermostat. It is used as a safety in the event of

a component failure in the dishwasher. The thermostat

will open at 200°F and will reset at 100°F.

Page 18

Page 20

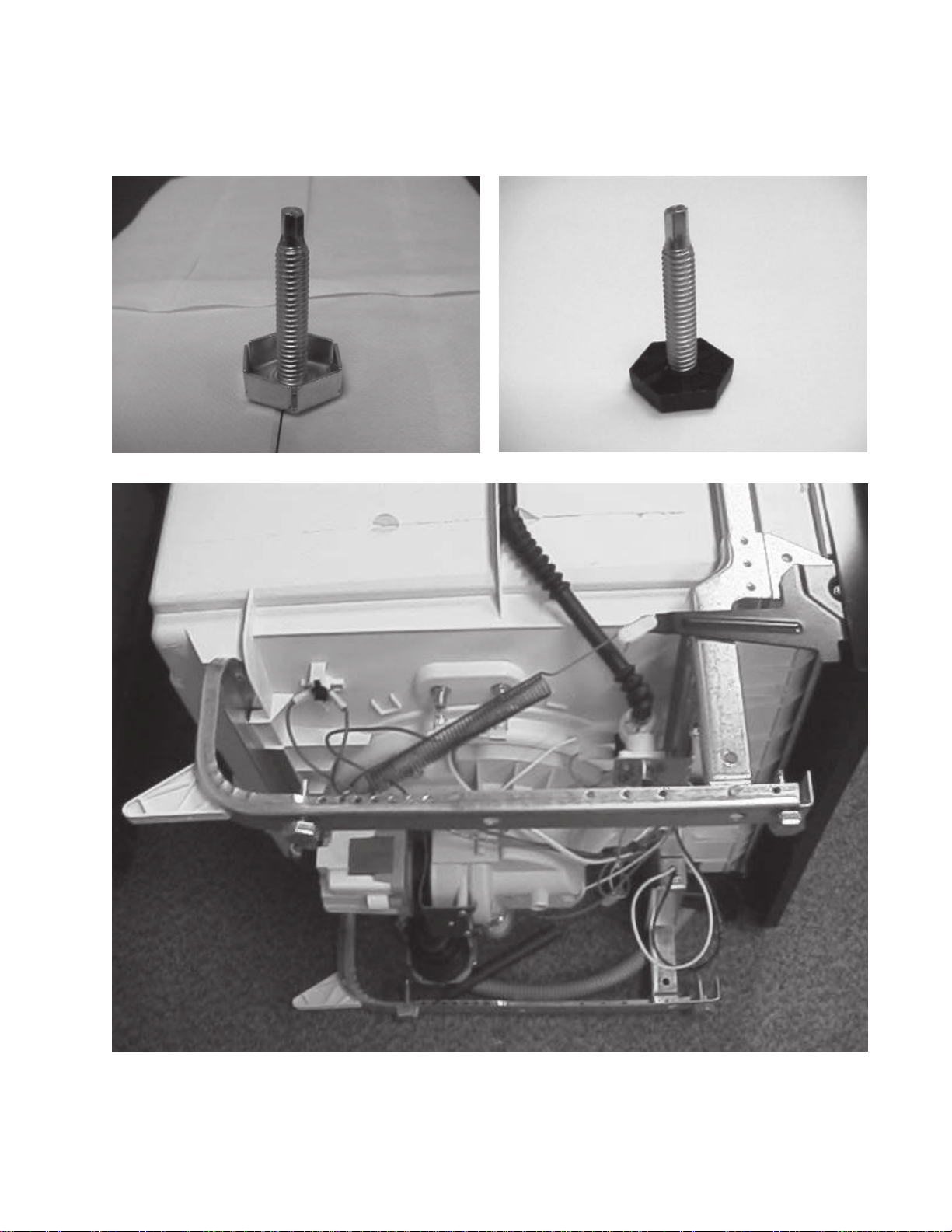

DISHWASHER LEVELING

The dishwasher used four hex shaped leveling legs. They allow the dishwasher to be leveled to any type of

flooring. The tops of the legs are tapered to 3/16" hex so a wrench or socket may be used to adjust the legs from

the top of the leveler.

Page 19

Page 21

DISASSEMBLY

SAFETY PRECAUTIONS

Always turn off the electric power supply before

servicing any electrical component, making ohmmeter

checks, or making any parts replacement. Refer to safe

servicing procedures at the front of this service manual

before servicing the dishwasher.

All voltage checks should be made with a voltmeter

having a full scale range of 130 volts or higher.

After service is completed, be sure all safety grounding

circuits are complete, all electrical connections are

secure, and all access panels are in place.

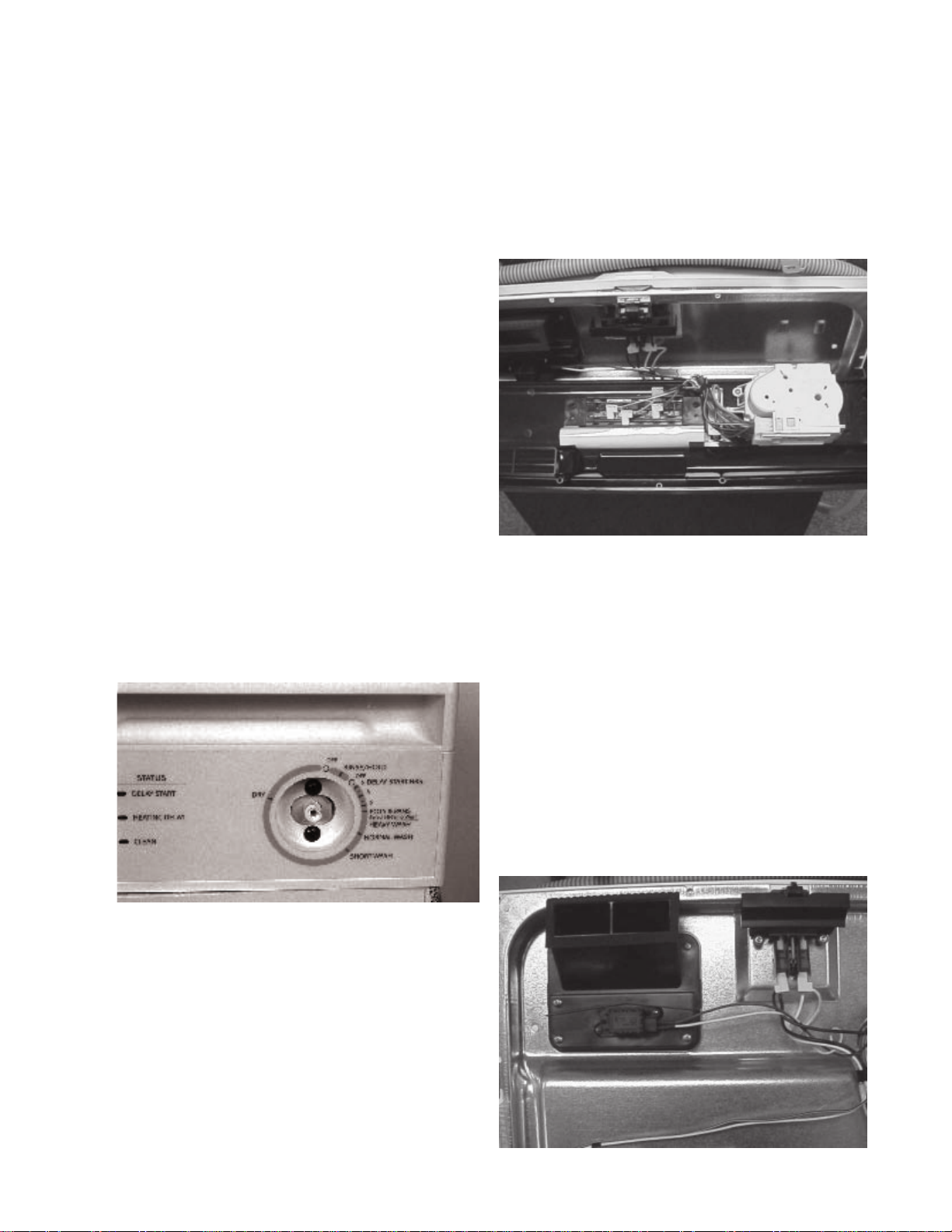

CONTROL PANEL - Mechanical Timer Models

1. Disconnect the dishwasher from electrical supply.

2. Remove six (6) Phillips screws from top of inner

door panel.

TIMER

1. Disconnect dishwasher from electrical supply.

2. Pull timer knob off of timer shaft.

3. Remove control panel.

4. Remove two Phillips screws securing timer to control

panel.

SELECTOR SWITCH

1. Disconnect the dishwasher from electrical supply.

2. Remove control panel.

3. Remove two Phillips screws, one on each end and

lift off switch.

DOOR PANELS - All Models

1. Disconnect dishwasher from electrical supply.

2. The outer door panel is held to the inner door panel

with two locking tabs and two screws. Loosen two

lower screws securing control panel.

3. Remove two screws securing door panel to door

(located at the lower section of the inner door

panel).

4. Slide door panel down and outward to remove.

.

4. Unplug wiring harness plug connector to test or

replace timer.

5. When replacing timer, be sure to transfer protective

plastic covering to new timer.

DISASSEMBLY TIP

When removing the timer knob, slide a lightweight

handerchief between the timer knob and the control

housing. Then work the handkerchief all the way around

the backside of the knob. Then pull on the handkerchief,

pulling the knob off from the rear.

DOOR VENT ASSEMBLY

1. Disconnect dishwasher from electrical supply.

2. Remove outer door panel.

3. Remove control panel.

4. Disconnect wiring to blower motor and vent actuator.

5. Remove four Phillips screws securing vent to inner

door panel.

Page 20

Page 22

VENT VALVE

1. Disconnect the dishwasher from electrical supply.

2. Remove outer door panel.

3. Remove control panel.

4. Slide the vent valve upward to remove from the

actuator arm.

VENT ACTUATOR

1. Remove the door vent assembly..

2. Remove vent valve.

3. Remove two Phillips screws. Slide actuator from

vent housing.

VENT BLOWER

1. Remove the door vent assembly.

2. Remove the two (2) screws securing the top vent

piece.

3. Remove the four (4) screws securing the lower

vent to the blower motor.

DOOR LATCH ASSEMBLY

1. Disconnect dishwasher from electrical supply.

2. Remove outer door panel.

3. The door latch is held to the inner door panel

with two screws and two locator pins. Remove

screws and pull to remove.

DETERGENT / RINSE AID DISPENSER

1. Disconnect dishwasher from electrical supply.

2. Remove outer door panel.

3. Disconnect wiring.

4. Remove six Phillips screws and carefully push

dispenser into tub.

INNER DOOR PANEL

1. To replace inner door panel, remove control

panel, door vent, dispenser and latch.

2. Remove two bolts (T-25 TORX®) from each

hinge and lift off.

3. Remove two bolts and nuts holding "C" arms to

inner door panel.

DOOR SEAL

1. To remove seal, lift one end and pull entire seal

out.

2. To replace or reinstall seal, center white mark on

back of seal into center top of seal recess and

press seal into place.

3. Go to bottom and form seal into seal recess

making the "L" in the tub. Repeat for remaining

side.

4. Push seal into recess in 5 places up one side to

center top. Repeat for remaining side.

5. Close door and let door set seal into recess.

Page 21

Page 23

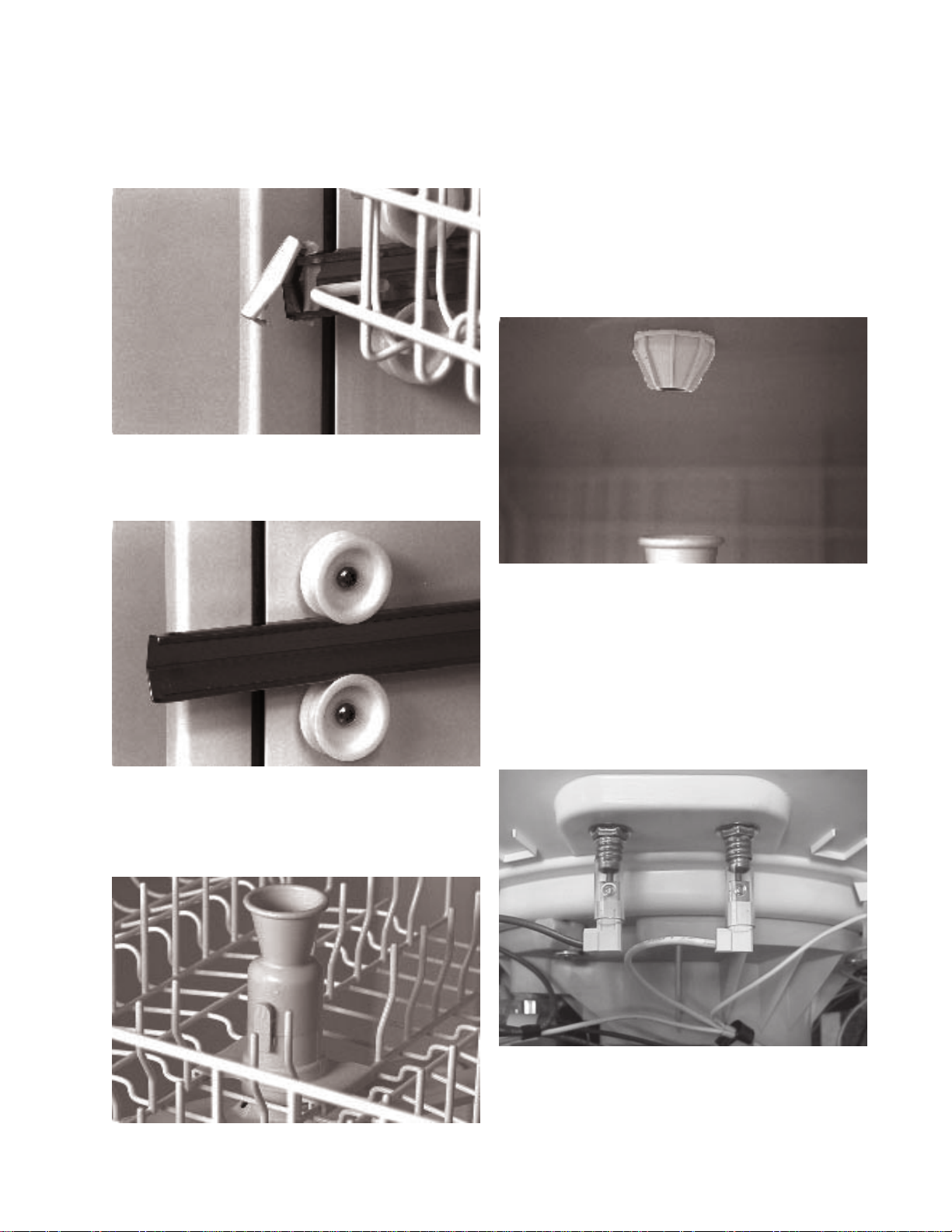

UPPER RACK

1. To remove rack, unsnap and remove retainers at

end of metal track. Once retainers are removed,

pull rack straight out.

2. Each rack roller is secured with a T-25 TORX®

bolt.

UPPER SPRAY ARM

1. To remove upper spray arm, unscrew plastic nut

securing it to support.

WATER DISTRIBUTOR

1. The water distributor (nozzle) is screwed to the

top of the upper arm delivery tube. A rubber seal

is used on the top side of the tub to eliminate

leaks.

2. Water distribtor (nozzle) is a right-hand thread

that screws counterclockwise.

UPPER WATER TUBE

1. To remove upper water tube, press in on top of

two clips and lift up.

KICK PLATE

1. To remove kick plate and insulation (some models)

remove two Phillips screws and pull out on bottom

of kick plate.

HEATING ELEMENT

1. Disconnect dishwasher from electrical supply.

2. To remove element, disconnect wiring and remove

two element mounting nuts.

3. Lift terminal ends of element into tub and rotate

element sideways, out of retainers.

Page 22

Page 24

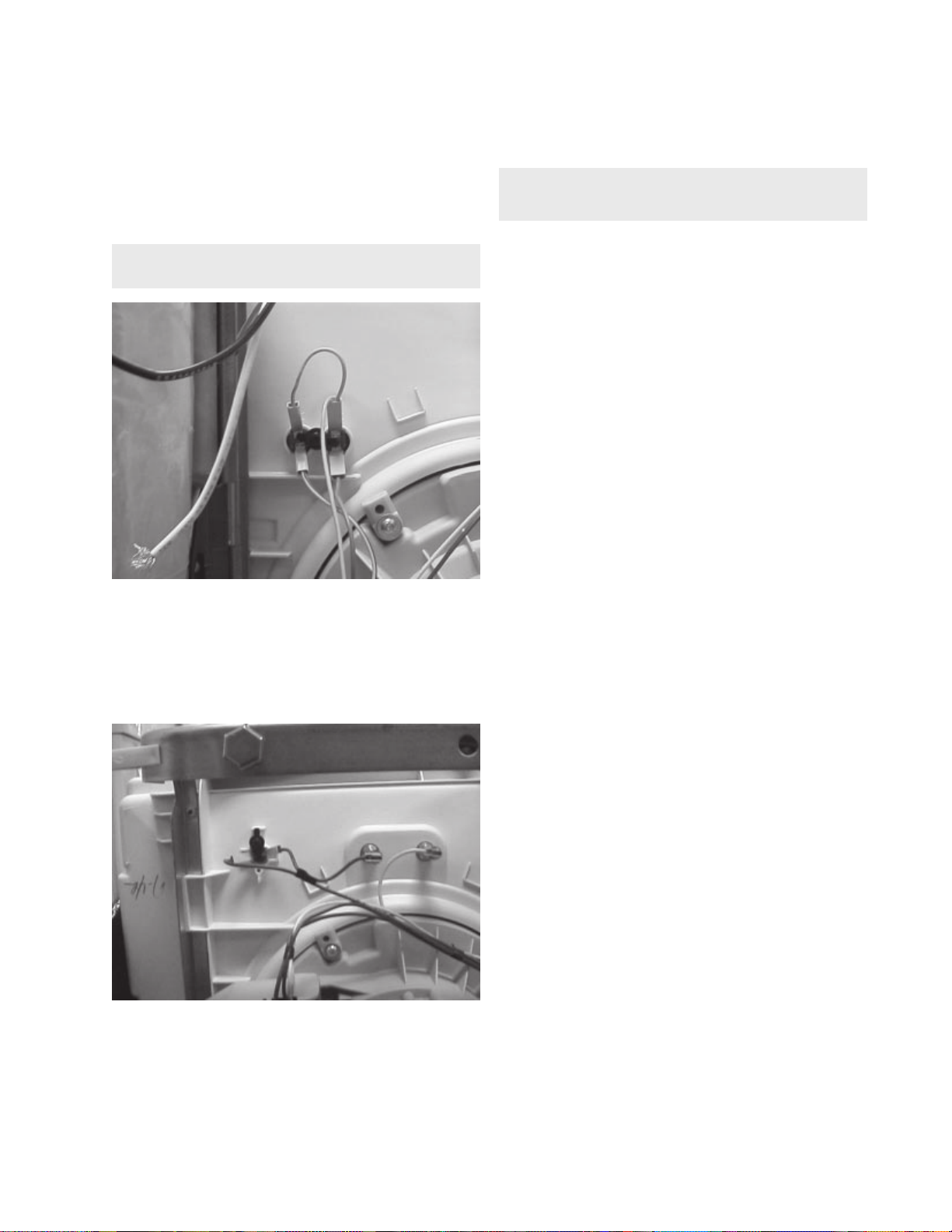

FLOAT SWITCH AND BRACKET

1. Disconnect dishwasher from electrical supply.

2. To remove float switch bracket, remove outer door

panel, kick plate, and wires to float switch. A single

Phillips screw secures the bracket to the tub.

3. Remove float switch by spreading mounting clips.

WATER VALVE

1. Disconnect dishwasher from electrical supply.

2. Remove outer door panel, kick plate, and wires.

3. Water valve is secured with two 5/16" hex screws.

GLASS TRAP

1. To remove glass trap, lift handle up and raise

trap up and out of sump.

LOWER SPRAY ARM SUPPORT

1. To remove lower spray arm support, remove

spray arm and glass trap, then turn support 90°

clockwise and lift up.

DRAIN PUMP

1. Disconnect dishwasher from electrical supply.

2. Remove outer door panel and kick plate.

3. Remove hoses and wiring to drain pump.

4. Remove two screws securing drain pump to

mounting bracket.

5. Front housing can be removed by lifting lock tab

and turning housing counterclockwise about 45°

and lifting off.

LOWER SPRAY ARM

1. To remove lower spray arm, pull out on retaining

clips and lift up.

Page 23

Page 25

FILTER

1. To remove filter, remove glass trap, spray arm and

spray arm support. Lift filter up to remove.

PUMP COVER

1. To remove pump cover, remove glass trap, spray

arm, spray arm support and filter.

2. Remove three T-20 TORX

® bolts and lift cover off.

3. Remove two T-20 TORX® screws on bottom of

bracket.

4. Place flat blade screwdriver between bracket and

sump, then lift bracket out of sump.

MOTOR AND IMPELLER

1. Disconnect dishwasher from electrical supply.

2. To remove motor, remove pump housing, motor

mounting bracket, and pump cover.

PUMP AND MOTOR ASSEMBLY

1. To remove pump and motor assembly, disconnect

dishwasher from electrical supply. Remove glass

trap, spray arm, spray arm support and filter.

2. Remove outer door panel and kick plate.

3. Disconnect delivery tube and sump drain hose.

4. Pump and motor assembly is secured in place

using four retainers that rotate easily. Turn retainers

90° and lift assembly from inside of tub.

5. Remove electric wires from motor.

MOTOR MOUNTING BRACKET

1. Disconnect dishwasher from electrical supply.

2. To remove motor and motor mounting bracket, first

remove pump and motor assembly.

3. Place large screwdriver between housing and

impeller and force impeller and motor out of housing.

DO NOT ROCK MOTOR TO RELEASE.Lubricate

with Vaseline® when reinstalling.

Page 24

Page 26

THERMOSTATS

1. Disconnect dishwasher from electrical supply.

2. To remove either thermostat, remove outer door

panel and kick plate.

3. Thermostats are located behind electrical junction

box. To remove thermostat, loosen single Phillips

screw, turn retainer, and drop thermostat from tub.

4. Remove wire from thermostat.

NOTE: When reinstalling thermostats, apply

thermal mastic to the face of the thertmostat.

INDICATOR LAMPS - Mechanical Timer Models

1. Disconnect dishwasher from electrical supply.

2. To remove an indicator lamp, drop control panel

and rotate indicator. Lift out of mounting bracket.

NOTE: Indicators are part of the wiring harness

and are not available separately.

HIGH LIMIT THERMOSTAT (ON TUB BOTTOM)

1. Disconnect dishwasher from electrical supply.

2. Disconnect wires from thermostat and remove single

Phillips screw.

3. Determine failure causing high limit thermostat to

open before replacing.

Page 25

Page 27

TROUBLESHOOTING TIPS

SYMPTOM

Dishwasher will not operate

when turned on.

Motor hums but will not start or

run.

Motor trips out on internal

thermal overload protector.

CHECK THE FOLLOWING

1. Fuse (blown or tripped).

2. 120 VAC supply wiring

connection faulty.

3. Motor (inoperative, check

resistances).

4. Door Switch (open contacts).

5. Door latch not making contact

with door switch.

1. Motor (bad bearings or locked

rotor).

2. Motor stuck due to prolonged

non-use.

3. Motor fan blocked.

1. Improper voltage.

2. Seal faces binding.

3. Motor windings shorted.

4. Glass or foreign items in pump.

REMEDY

1. Replace fuse or reset breaker.

2. Repair or replace wire

fasteners at dishwasher

junction box.

3. Replace motor / impeller

assembly.

4. Replace door switch.

5. Replace latch assembly.

1. Replace motor.

2. Rotate motor fan or impeller.

3. Check/clear fan area.

1. Check voltage.

2. Rotate motor fan or impeller, or

replace.

3. Replace motor/pump

assembly.

4. Clean and clear blockage.

Dishwasher runs but will not

heat.

Detergent cover will not latch or

open.

Dishwasher will not pump out.

1. Hi-limit thermostat open.

2. Heater element (open).

3. Wiring or terminal defective.

1. Excess detergent on lid catch.

2. Latch mechanism defective.

3. Wiring or terminal defective.

4. Broken spring(s).

5. Defective actuator.

1. Drain restricted.

2. Defective drain pump.

3. Air lock in drain hose.

4. Blocked impeller.

5. Open windings.

6. Wiring or terminal defective.

Page 26

1. Replace thermostat.

2. Replace heater element.

3. Repair or replace.

1. Clean catch area.

2. Replace dispenser.

3. Repair or replace.

4. Replace dispenser.

5. Replace actuator.

1. Clear restrictions.

2. Replace pump.

3. Drain hose must slope upward

to side of tub. Hose must be

attached on side of tub.

4. Check for blockage and clear.

5. Replace windings.

6. Repair or replace.

Page 28

SYMPTOM REMEDY

CHECK THE FOLLOWING

Dishwasher will not fill with

water.

Dishwasher water siphons out.

Detergent left in dispenser.

1. Water supply turned off.

2. Defective water inlet valve.

3. Check fill valve screen for

obstructions.

4. Defective float switch.

5. Wiring or terminal defective.

6. Float stuck in "UP" position.

1. Drain hose not connected to

side of tub.

2. Drain hose (high) loop too low.

3. Drain line connected to a floor

drain not vented.

1. Detergent allowed to stand too

long in dispenser.

2. Dispenser wet when detergent

was added.

3. Detergent cover held closed or

blocked by large dishes.

4. Improper incoming water

temperature to properly

dissolve detergent.

5. See "Detergent Cover Will Not

Open."

1. Turn water supply on.

2. Replace water inlet fill valve.

3. Disassemble and clean screen.

4. Repair or replace.

5. Repair or replace.

6. Clean float.

1. Reattach drain hose.

2. Repair to proper height.

3. Install air gap at counter top.

1. Instruct customer/user.

2. Instruct customer/user.

3. Instruct customer/user on

proper loading of dishes.

4. Incoming water temperature

of 120°F is required to properly

dissolve dishwashing

detergent.

Page 27

Page 29

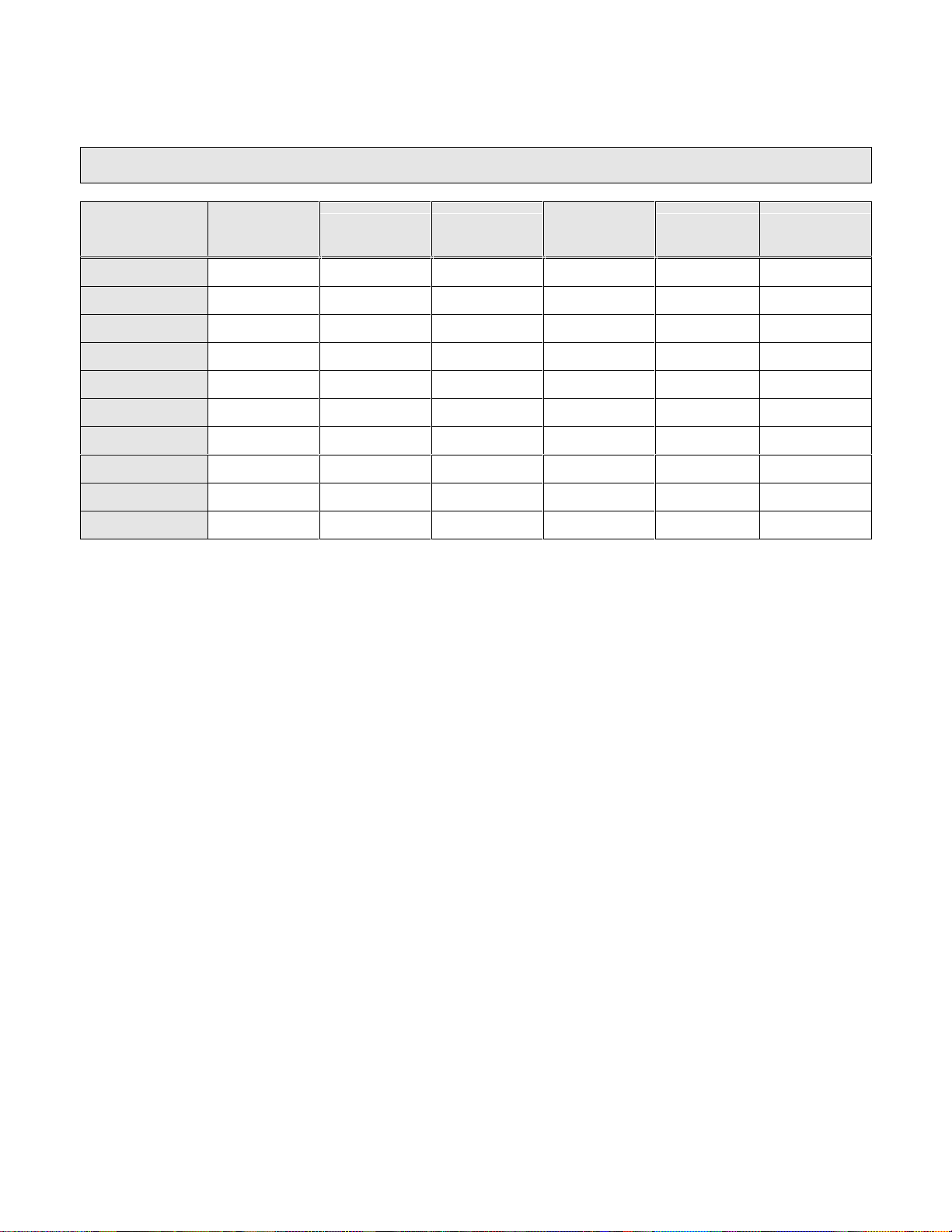

APPENDIX A

Exploded Views Location Chart

Model

Number

FDB125RH*2 A - 9 A - 17 A - 20 A - 23 A - 29 A - 35

FDB345LF*2 A - 10 A - 18 A - 20 A - 24 A - 29 A - 32

FDB421RF*6 ******

FDB421RF*7 ******

FDB435RFR*6 ******

FDB435RFS*4 ******

FDB634CF*4 A - 11 A - 18 A - 20 A - 24 A - 29 A - 32

FDB635RF*6 A - 11 A - 18 A - 20 A - 24 A - 29 A - 32

FDB641RA*0 ******

FDB641RJ*1 ******

FDB657RJ*1 ******

FDB658RA*0 ******

FDP635RF*5 A - 11 A - 18 A - 19 A - 24 A - 25 A - 32

FDP641RA*0 ******

GLDB653A*0 ******

Control

Panel

Door Tub

Motor &

Pump

Frame Racks

GLDB653J*2 A - 11 A - 17 A - 20 A - 24 A - 29 A - 32

GLDB656J*1 A - 3 A - 17 A - 20 A - 24 A - 29 A - 33

GLDB756A*0 ******

GPDB698J*1 A - 6 A - 16 A - 20 A - 24 A - 30 A - 34

MDB122RF*2 A - 14 A - 18 A - 20 A - 24 A - 27 A - 31

MDB124BA*0 ******

MDB124BJ*1 A - 14 A - 17 A - 20 A - 24 A - 27 A - 31

MDB124BH*1 A - 14 A - 17 A - 20 A - 24 A - 27 A - 31

MDB125RH*2 A - 9 A - 17 A - 20 A - 23 A - 29 A - 35

F71C12PH*1 ******

F7C24RJ*1 ******

ADW350RA*0 A - 5 A - 15 A - 20 A - 21 A - 28 A - 31

ADW350RA*1 A - 12 A - 17 A - 20 A - 24 A - 27 A - 31

* Information not available - Parts Catalogs not created as of this Publication date

A - 1

Page 30

APPENDIX A (continued)

Exploded Views Location Chart

Model

Number

ADW550RA*0 A - 7 A - 15 A - 20 A - 21 A - 28 A - 32

ADW550RA*1 A - 13 A - 17 A - 20 A - 24 A - 30 A -32

ADW650RA*0 A - 7 A - 15 A - 20 A - 21 A - 28 A - 33

ADW650RA*1 A - 7 A - 17 A - 20 A - 24 A - 28 A - 33

ADW650RA*2 A - 13 A - 17 A - 20 A - 21 A - 30 A - 33

GDP635RH*2 A - 11 A - 18 A - 19 A - 24 A - 25 A - 32

GDB742RJ*0 A - 8 A - 19 A - 20 A - 22 A - 26 A - 31

GDB742RJ*1 ******

GDB755RJ*0 A - 4 A - 17 A - 20 A - 22 A - 26 A - 32

GDB755RJ*1 A - 13 A - 17 A - 20 A - 24 A - 27 A - 32

Control

Panel

Door Tub

Motor &

Pump

Frame Racks

* Information not available - Parts Catalogs not created as of this Publication date

A - 2

Page 31

CONTROL PANEL

For Model #

GLDB656J*1

A - 3

Page 32

CONTROL PANEL

For Model #

GDB755RJ*0

A - 4

Page 33

CONTROL PANEL

For Model #

ADW350RA*0

A - 5

Page 34

CONTROL PANEL

For Model #

GPDB698RJ*1

A - 6

Page 35

CONTROL PANEL

For Model #'s

ADW550RA*0

ADW650RA*0

ADW650RA*1

A - 7

Page 36

CONTROL PANEL

For Model #

GDB742RJ*0

A - 8

Page 37

CONTROL PANEL

For Model #'s

FDB125RH*2

MDB125RH*2

A - 9

Page 38

CONTROL PANEL

For Model #

FDB345LF*2

A - 10

Page 39

CONTROL PANEL

For Model #'s

FDB634CF*4

FDB635RF*6

FDP635RF*5

GDP635RH*2

GLDB653J*2

A - 11

Page 40

CONTROL PANEL

For Model #

ADW350RA*1

A - 12

Page 41

CONTROL PANEL

For Model #'s

ADW550RA*1

ADW650RA*2

GDB755RJ*1

A - 13

Page 42

CONTROL PANEL

For Model #'s

MDB122RF*2

MDB124BJ*1

MDB124BH*1

A - 14

Page 43

DOOR

For Model #'s

ADW350RA*0

ADW550RA*0

ADW650RA*0

A - 15

Page 44

DOOR

For Model #

GPDB698J*1

A - 16

Page 45

ADW350RA*1

ADW650RA*2

ADW550RA*1

ADW650RA*1

FDB125RH*2

DOOR

For Model #'s

GLDB653J*2

GLDB656J*1

GDB742RJ*0

GDB755RJ*0

GDB755RJ*1

MDB124BJ*1

MDB124BH*1

MDB125RH*1

A - 17

Page 46

FDB345CF*2

FDB634CF*4

DOOR

For Model #'s

FDB635RF*6

FDP635RF*5

GDP635RH*2

MDB122RF*2

A - 18

Page 47

TUB

For Model #'s

FDP635RF*5

GDP635RH*2

A - 19

Page 48

ADW350RA*0

ADW350RA*1

ADW550RA*0

ADW550RA*1

ADW650RA*0

ADW650RA*1

ADW650RA*2

FDB125RH*2

TUB

For Model #'s

FDB345LF*2

FDB634CF*4

FDB635RF*6

GDB742RJ*0

GDB755RJ*0

GDB755RJ*1

GLDB653J*2

GLDB656J*1

GPDB698J*1

MDB122RF*2

MDB124BJ*1

MDB124BJ*1

MDB124BH*1

MDB125RH*2

A - 20

Page 49

MOTOR & PUMP

For Model #'s

ADW350RA*0

ADW550RA*0

ADW650RA*0

ADW650RA*2

A - 21

Page 50

MOTOR & PUMP

For Model #'s

GDB742RJ*0

GDB755RJ*0

A - 22

Page 51

MOTOR & PUMP

For Model #'s

FDB125RH*2

MDB125RH*2

A - 23

Page 52

ADW350RA*1

ADW550RA*1

ADW650RA*2

FDB345LF*2

FDB634CF*4

MOTOR & PUMP

For Model #'s

FDB635RF*6

FDP635RF*5

GDB755RJ*1

GDP635RH*2

GLDB653J*2

GLDB656J*1

GPDB698J*1

MDB122RF*2

MDB124BJ*1

MDB124BH*1

A - 24

Page 53

FRAME

For Model #'s

FDP635RF*5

GDP635RH*2

A - 25

Page 54

FRAME

For Model #'s

GDB742RJ*0

GDB755RJ*0

A - 26

Page 55

FRAME

For Model #'s

ADW350RA*1

GDB755RJ*1

MDB122RF*2

MDB124BJ*1

MDB124BH*1

A - 27

Page 56

FRAME

For Model #'s

ADW350RA*0

ADW550RA*0

ADW650RA*0

ADW659RA*1

A - 28

Page 57

FRAME

For Model #'s

FDB125RH*2

FDB345LF*2

FDB634CF*4

FDB635RF*6

GLDB653J*2

GLDB656J*1

MDB125RH*2

A - 29

Page 58

FRAME

For Model #'s

ADW550RA*1

ADW650RA*2

GPDB698J*1

A - 30

Page 59

RACKS

For Model #'s

ADW350RA*0

ADW350RA*1

GDB742RJ*0

MDB122RF*2

MDB124BJ*1

MDB124BH*1

A - 31

Page 60

RACKS

For Model #'s

ADW550RA*0

ADW550RA*1

FDB345LF*2

FDB634CF*4

FDB635RF*6

FDP635RF*5

GDP635RH*2

GDP755RJ*0

GDP755RJ*1

GLDB653J*2

A - 32

Page 61

RACKS

For Model #'s

ADW650RA*0

ADW650RA*1

ADW650RA*2

GLDB656J*1

A - 33

Page 62

RACKS

For Model #

GPDB698J*1

Page 63

RACKS

For Model #'s

FDB125RH*2

MDB125RH*2

Page 64

APPENDIX B

SERVICE DATA SHEETS

SERVICE DATA SHEET # PAGE

154370901 B - 1

154374001 B - 2

154374101 B - 3

154382801 B - 4

154382901 B - 5

154383001 B - 6

154385401 B - 7

154390501 B - 8

154395901 B - 9

154396001 B- 10

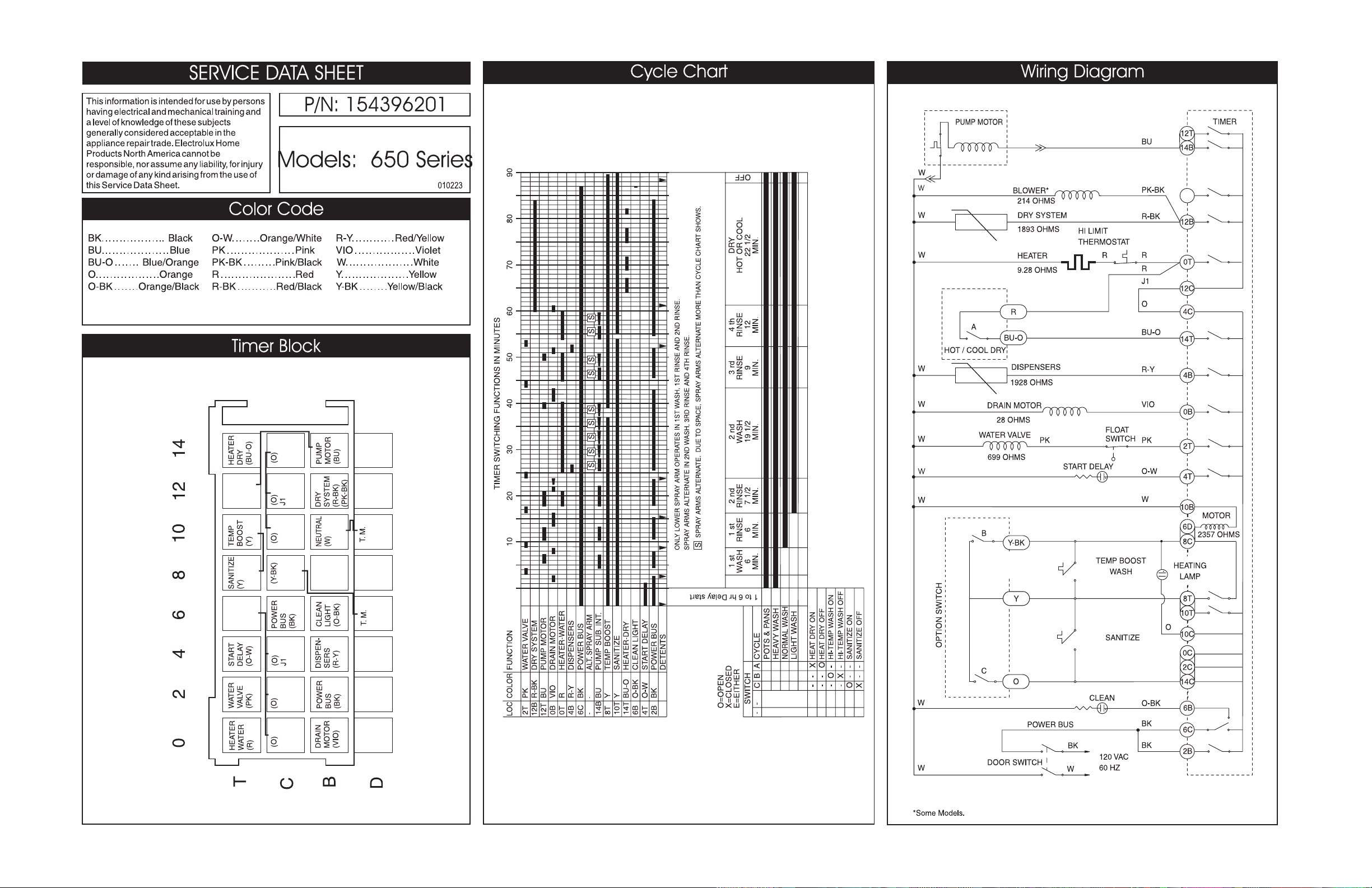

154396201 B - 11

154396301 B - 12

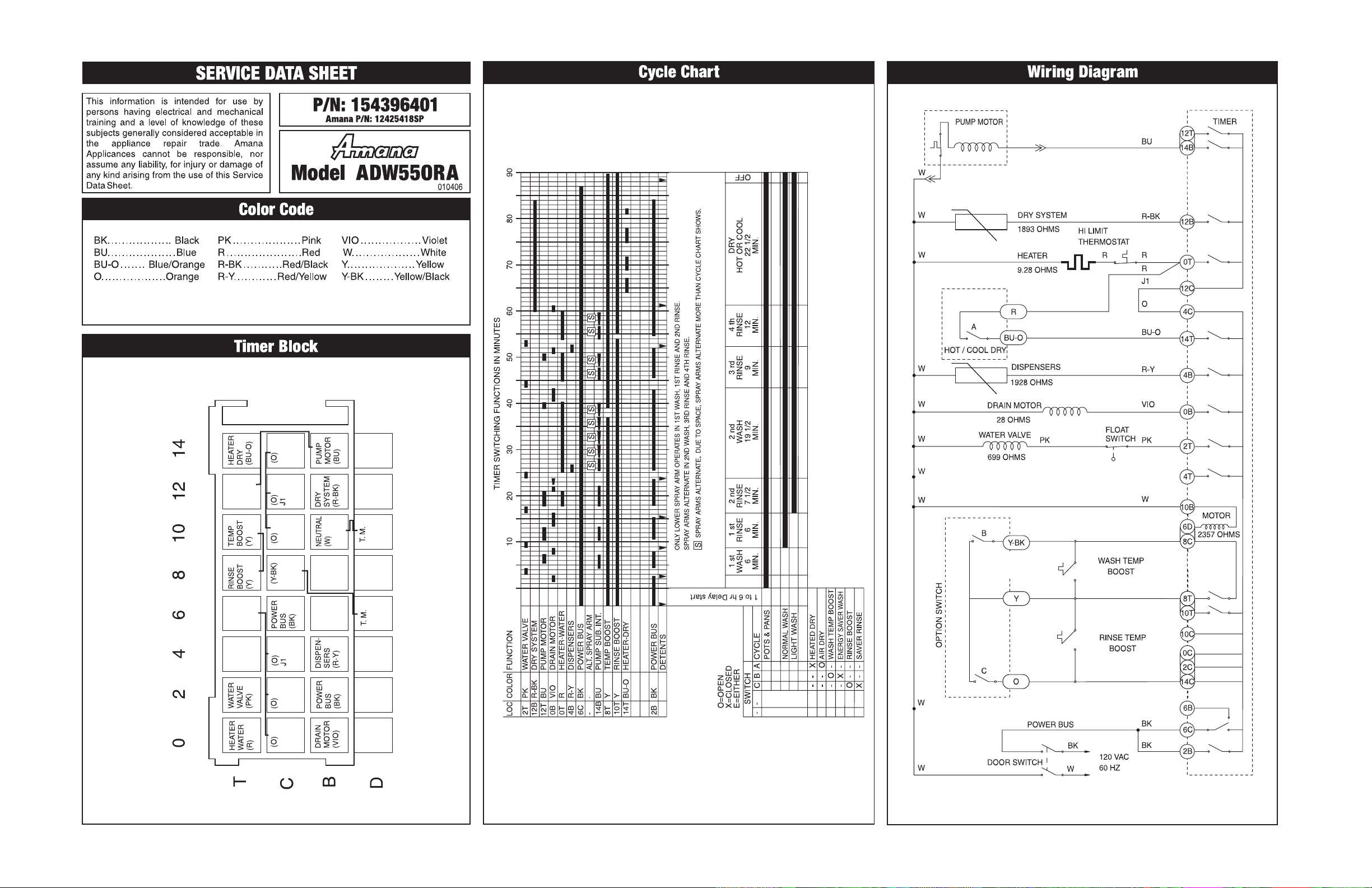

154396401 B - 13

154396501 B - 14

154396801 B - 15

154400501 B - 16

154402401 B - 17

154402501 B - 18

154403001 B - 19

154403801 B - 20

154405901 B - 21

154407901 B - 22

Page 65

B-1

Page 66

B-2

Page 67

B-3

Page 68

B-4

Page 69

B-5

Page 70

B-6

Page 71

B-7

Page 72

B-8

Page 73

B-9

Page 74

B-10

Page 75

B-11

Page 76

B-12

Page 77

B-13

Page 78

B-14

Page 79

B-15

Page 80

B-16

Page 81

B-17

Page 82

B-18

Page 83

B-19

Page 84

B-20

Page 85

B-21

Page 86

B-22

Loading...

Loading...