Page 1

© ELECTROLUX ITALIA S.p.A.

Spares Operations Italy

Corso Lino Zanussi, 30

I - 33080 PORCIA /PN (ITALY)

Fax +39 0434 394096

Publication no.

599 72 40-80

Edition: 12-2009

EN

SERVICE MANUAL

WASHING

WM-WD

Front loader

Platform

EWM1000

EWM1000plus

EWM2000evo

EWM3000new

ENV06

11xx21xx

25xx/35xx

Page 2

QUICK GUIDE AND APPLIANCES LIST 2/176 599 72 40-80

Page 3

Content

EWM1000 ............................................................................................................................................5

1

1.1 Access to the diagnostic cycle ....................................................................................................5

1.2 Rapid reading of alarms..............................................................................................................5

1.3 Cancelling the last alarm.............................................................................................................5

1.4 Phases of the diagnostics test.....................................................................................................6

1.5 Reading the alarms.....................................................................................................................7

1.5.1 Display ing th e alarm..............................................................................................................7

1.5.2 Examples of alarm display.....................................................................................................7

1.5.3 Status of alarms during the diagnostics cycle ......................................................................... 7

1.6 Table of alarms codes EWM1000 ...............................................................................................8

1.6.1 Notes concerning cer tain alarm codes...................................................................................9

1.7 Elementary diagram..................................................................................................................10

1.7.1 With instantaneous door l oc k ing device...............................................................................10

1.8 With PTC door locking dev ic e ...................................................................................................11

1.8.1 Key to circuit diagram..........................................................................................................12

1.9 Connectors on circ uit board EWM1000.....................................................................................13

1.10 Burning on the ci rcuit boar d EWM 1000 ..................................................................................... 14

1.10.1 EWM1000...........................................................................................................................14

1.10.2 Components side (common)................................................................................................ 14

1.10.3 Pushbutton – led side (horizontal buttons)...........................................................................15

1.10.4 Pushbutton – led side (vertical buttons) ............................................................................... 15

2 EWM1000plus 2000ev o 3000new.....................................................................................................16

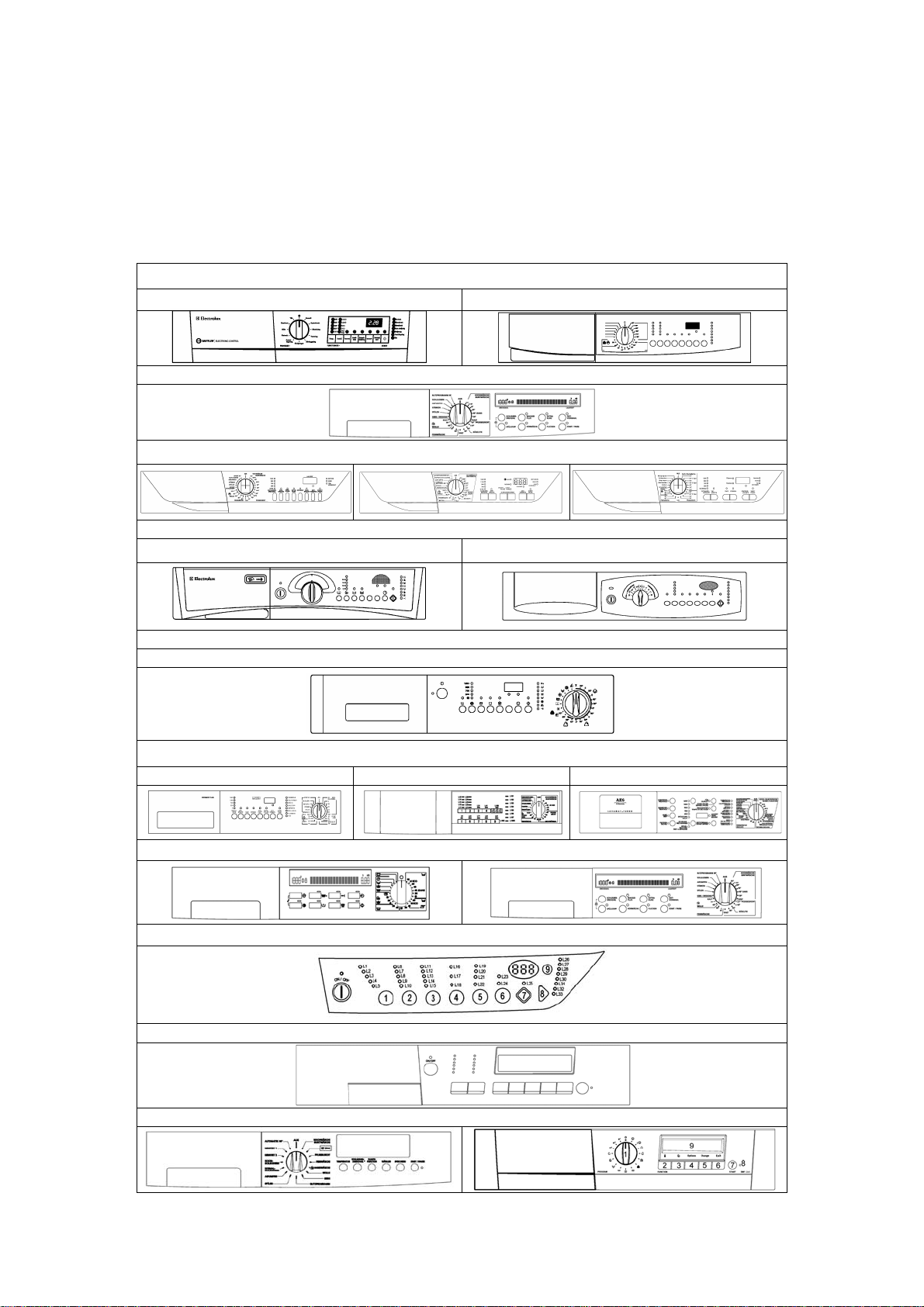

2.1 Control panel ............................................................................................................................ 16

2.2 Sigma/Alpha/Ellipse//Multipanel Built-In/Sigm a- ZK/Jewel with or without selector......................17

2.2.1 Access to diagnostic s system.............................................................................................. 17

2.2.2 Rapid reading of alarm codes.............................................................................................. 17

2.2.3 Cancelling the last alarm.....................................................................................................17

2.3 AEG NexXxt Version wit h sel ec tor and incorporated ON/OFF swit c h......................................... 18

2.3.1 Access to diagnostic s system.............................................................................................. 18

2.3.2 Rapid reading of alarm codes.............................................................................................. 18

2.3.3 Cancelling the last alarm.....................................................................................................18

2.4 AEG New Version with right selector and incorporat ed ON/OFF switc h ..................................... 19

2.4.1 Access to diagnostic s system.............................................................................................. 19

2.4.2 Rapid reading of alarm codes.............................................................................................. 19

2.4.3 Cancelling the last alarm.....................................................................................................19

2.5 DELTA Version without selector and button ON/OFF switch......................................................20

2.5.1 Access to diagnostic s system.............................................................................................. 20

2.5.2 Rapid reading of alarm codes.............................................................................................. 20

2.5.3 Cancelling the last alarm.....................................................................................................20

2.6 CLUB DISPLAY Version with selector and incorpor ated ON/OFF switch...................................21

2.6.1 Access to diagnostic s system.............................................................................................. 21

2.6.2 Rapid reading of alarm codes.............................................................................................. 21

2.6.3 Cancelling the last alarm.....................................................................................................21

2.7 LCD Version without sel ec tor and button ON/OFF switch..........................................................22

2.7.1 Access to diagnostic s system.............................................................................................. 22

2.7.2 Rapid reading of alarm codes.............................................................................................. 22

2.7.3 Cancelling the last alarm.....................................................................................................22

2.8 LCD Version with selector and button ON/OFF switch...............................................................23

2.8.1 Access to diagnostic s system.............................................................................................. 23

2.8.2 Rapid reading of alarm codes.............................................................................................. 23

2.8.3 Cancelling the last alarm.....................................................................................................23

2.9 Phases of the diagnostics test...................................................................................................24

2.10 Reading the alarm c odes ..........................................................................................................26

2.10.1 Display ing th e alarm............................................................................................................26

2.10.2 Examples of alarm displays ................................................................................................. 26

2.11 Table of alarms codes EWM 1000plus EWM2000EVO EWM3000NEW.................................27

2.12 Basic circuit diagr am EWM 1000P LUS....................................................................................... 31

2.12.1 Diagram (wit hout aqua control)............................................................................................31

2.12.2 Key to circuit diagram..........................................................................................................32

2.12.3 Diagram (wit h aqua c ontrol).................................................................................................33

2.12.4 Key to circuit diagram..........................................................................................................34

2.13 Basic circuit diagr am with sensor EWM2000EVO......................................................................35

QUICK GUIDE AND APPLIANCES LIST 3/176 599 72 40-80

Page 4

2.13.1 Key for circ u i t d iag r am.........................................................................................................36

2.14 Basic circuit diagr am with sensor EWM3000NEW..................................................................... 37

2.14.1 Key for circ u i t d iag r am.........................................................................................................38

2.15 Connectors on circ uit board EWM1000plus...............................................................................39

2.16 Burning on the ci rcuit boar d EWM 1000plus ............................................................................... 40

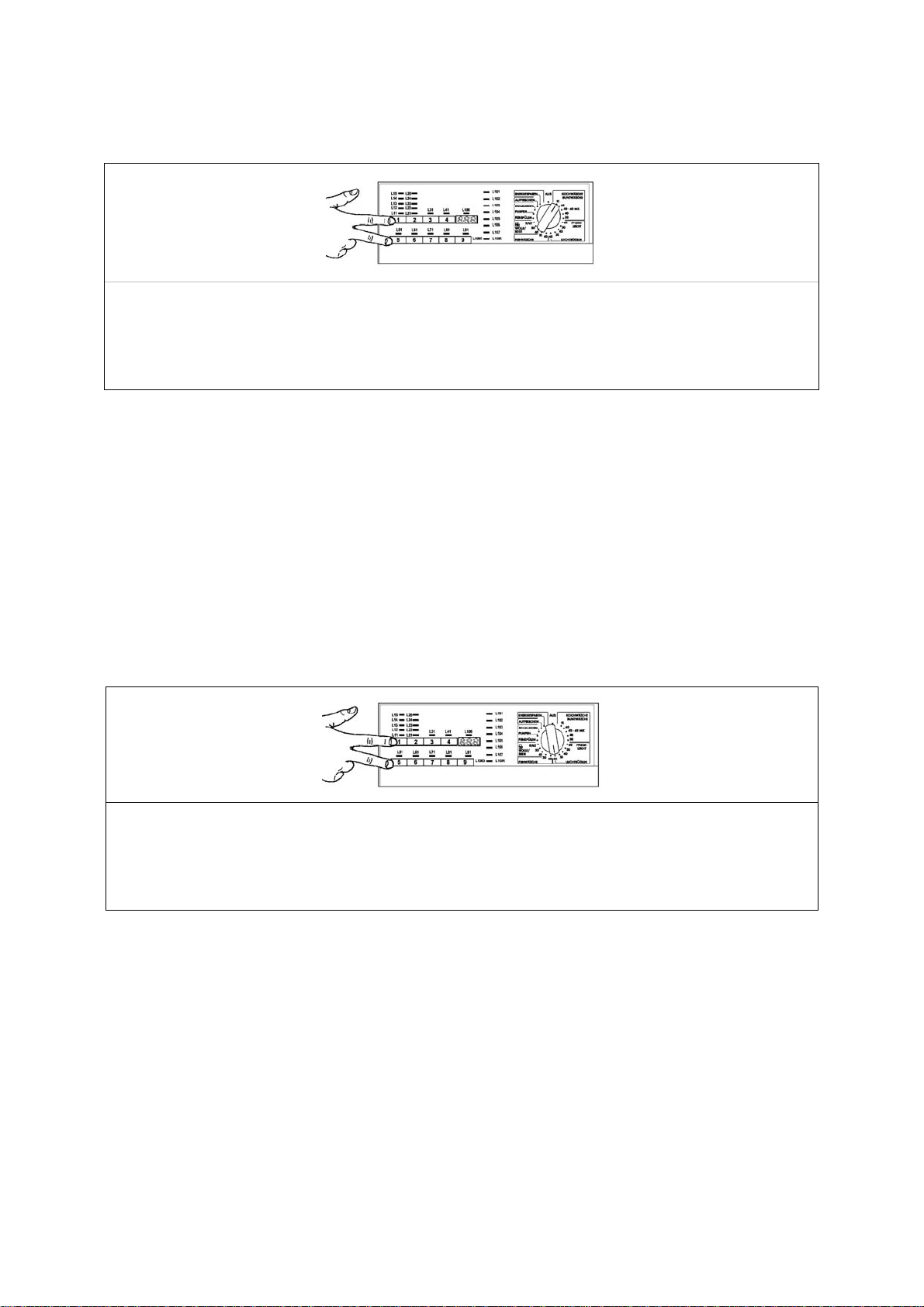

3 ENV 06...............................................................................................................................................41

3.1 Access to the diagnostic cycle ..................................................................................................41

3.1.1 All version...........................................................................................................................41

3.1.2 INPUT vers ion.....................................................................................................................41

3.1.3 Rapid reading of alarm codes.............................................................................................. 41

3.2 Cancelling the last alarm...........................................................................................................42

3.3 Phases of the diagnostic cycle..................................................................................................43

3.4 Alarm displaying.......................................................................................................................44

3.4.1 AEG Vers io n :...................................................................................................................... 44

3.4.2 Other vers io n s:....................................................................................................................44

3.4.3 Examples of alarm display...................................................................................................44

3.4.4 Operation of alarms during diagnostics................................................................................ 44

3.5 Table of alarms codes ENV06...................................................................................................44

3.5.1 Notes concerning cer tain alarm codes.................................................................................44

3.6 Basic circuit diagr am EWM 1100................................................................................................ 44

3.6.1 Key to circuit diagram EWM 1100......................................................................................... 44

3.7 Connectors on circ uit board EWM1100.....................................................................................44

3.8 Burning on the ci rcuit boar d EWM 1100 ..................................................................................... 44

3.9 Basic circuit diagr am WM EWM2100 ........................................................................................ 44

3.9.1 Key to circuit diagram WM EWM 2100.................................................................................. 44

3.10 Basic circuit diagr am WM with aqua c ontrol EWM2100 .............................................................44

3.10.1 Key to circuit diagram WM with Aqua Control EWM2100 ..................................................... 44

3.11 Basic circuit diagr am WD EWM2100......................................................................................... 44

3.11.1 Key to circuit diagram WD EWM2100.................................................................................. 44

3.12 Basic circuit diagr am WD wit h aqua c ontr ol EWM2100..............................................................44

3.12.1 Key to circuit diagram WD with aqua control EWM2100.......................................................44

3.13 Connectors on circ uit board WM/WD EWM2100 ....................................................................... 44

3.14 Burning on the ci rcuit boar d EWM 2100 WM /W D .......................................................................44

3.15 Basic circuit diagr am EWM 25xx without aqua control................................................................44

3.15.1 Key to circuit diagram EWM 25xx with Aqua Control.............................................................44

3.16 Basic circuit diagr am EWM 25xx without aqua control................................................................44

3.16.1 Key to circuit diagram EWM 25xx without Aqua Control........................................................44

3.17 Basic circuit diagr am EWM 25xx WD without aqua control .........................................................44

3.17.1 Key to circuit diagram EWM 25xx WD with Aqua Control......................................................44

3.18 Basic circuit diagr am EWM 25xx WD without aqua control .........................................................44

3.18.1 Key to circuit diagram EWM 25xx WD without aqua control ..................................................44

3.19 Basic circuit diagr am EWM 35xx with aqua control.....................................................................44

3.19.1 Key to circuit diagram EWM 35xx with Aqua Control.............................................................44

3.20 Basic circuit diagr am EWM 35xx without aqua control................................................................44

3.20.1 Key to circuit diagram EWM 35xx without Aqua Control........................................................44

3.21 Connectors on circ uit board WM/WD EWM25xx/35xx ...............................................................44

3.22 Burning on the circuit boards EWM25xx/35xx WM/WD.............................................................. 44

3.23 Burning on the ci rcuit boar d WD................................................................................................ 44

4 Appliances list....................................................................................................................................44

QUICK GUIDE AND APPLIANCES LIST 4/176 599 72 40-80

Page 5

EWM1000

1 EWM1000

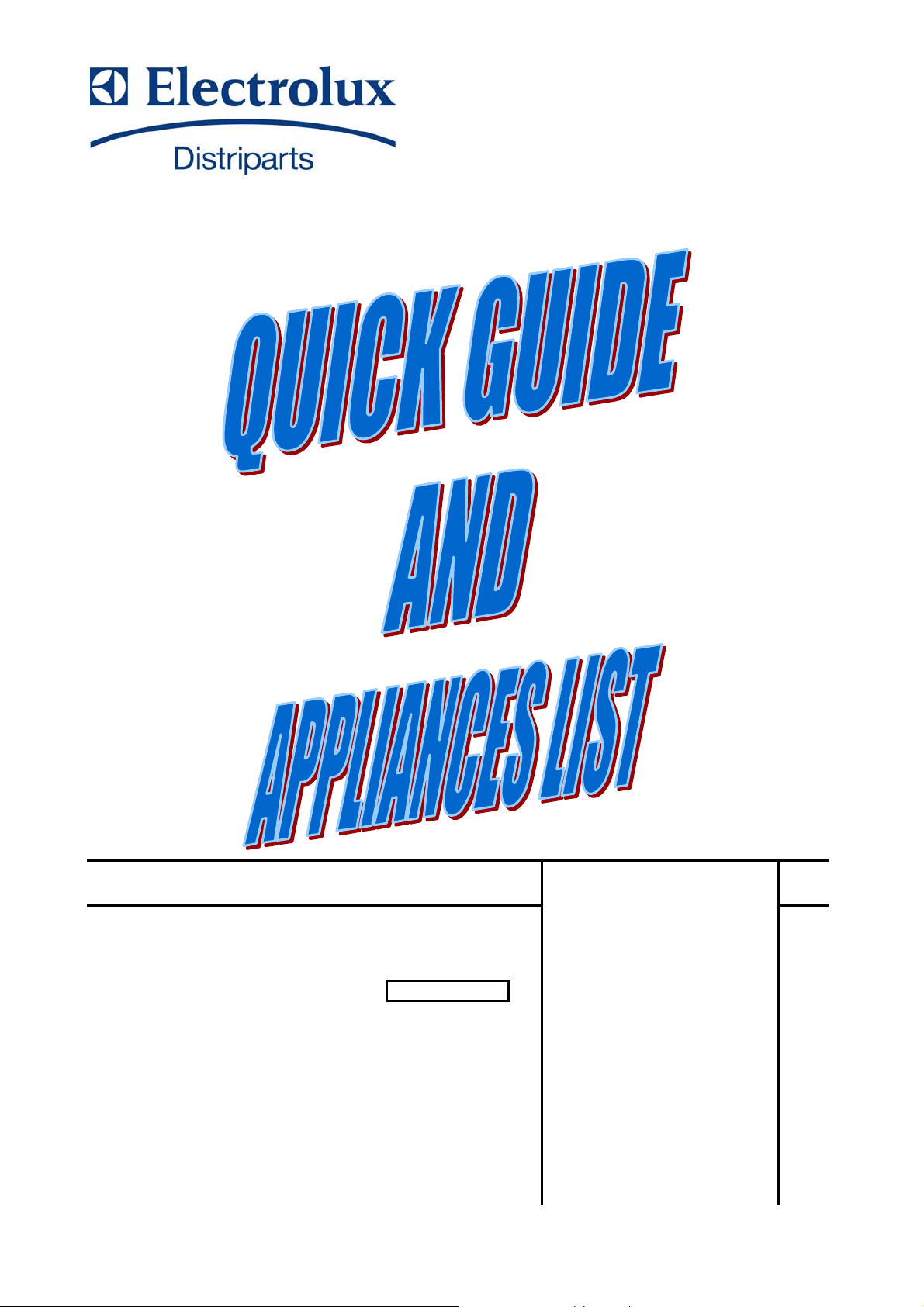

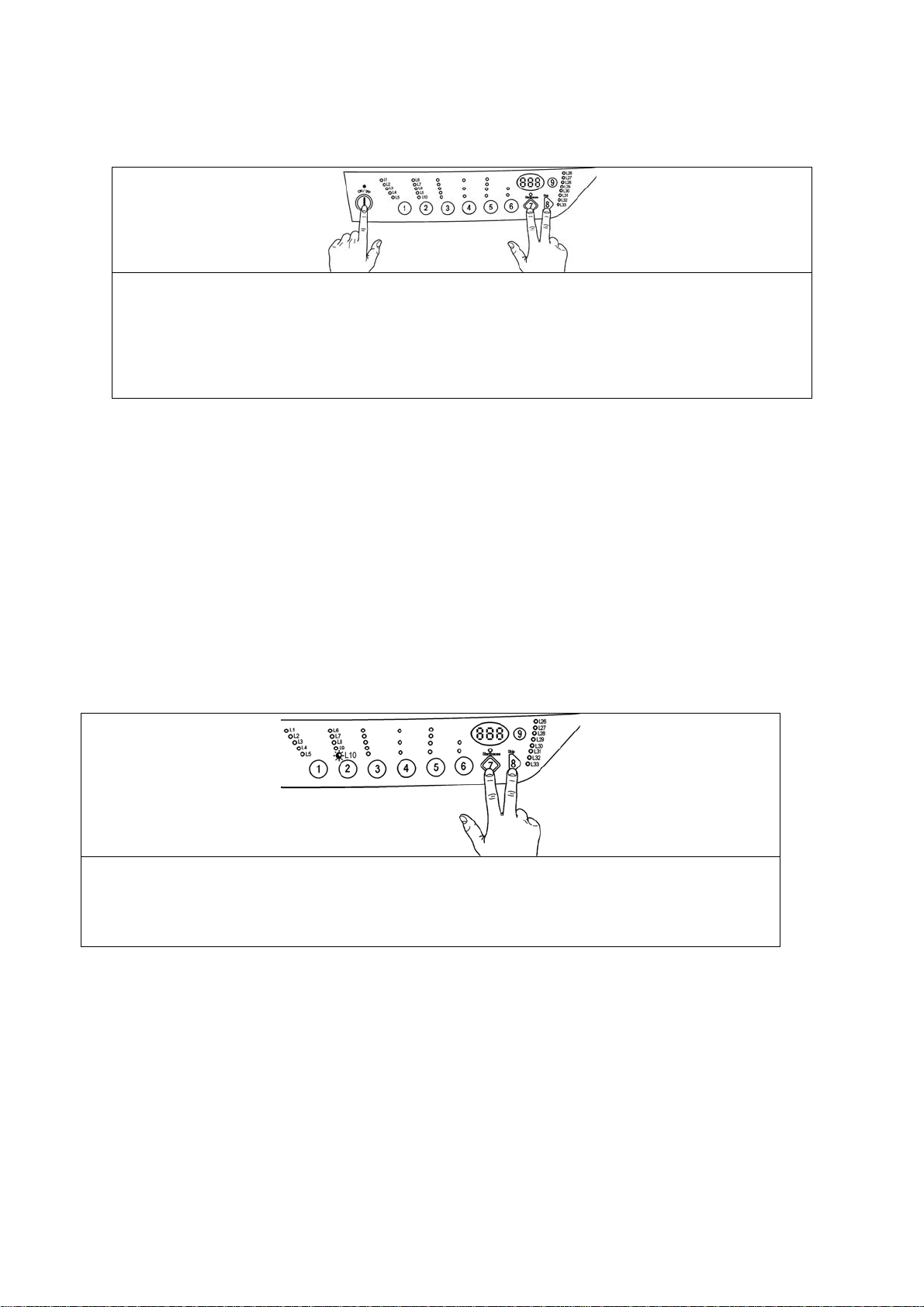

1.1 Access to the diagnostic cycle

versi on wit h horizont a l pus hbutto ns versi on wit h ve r t ic a l pus hbutto ns

1. Switch off the appliance.

2. Press and hold down the START/PAUSE button and any one of the OPTION buttons simultaneously.

horizontal version, while for vertical version pushbuttons are 2 and 3.

3. Holding down both buttons, switch the appliance on by turning the programme selector one posi tion

clockwise.

4. Continue to hold down the START/PAUSE button and the OPTION button horizontal ver si on, while for

vertic al v ersion pushbutt ons are 2 and 3, until the LEDs begin to flash (at least 2 seconds).

5. To exit the diagnostics system switch the applianc e off , on and t hen off again.

IMPORTANT: The position of the START/PAUSE button varies according to the model, and is

therefore not always the same.

1.2 Rapid reading of alarms

The last alarm can be di spl ay ed ev en if t he pr ogramme selector is not in the tenth posi tion (diagnostics) or if

the applianc e i s in normal oper ating mode (e.g. while the washing programme is in operation):

version wit h hori z ontal pushbuttons version wit h v ertic al pushbuttons

1. Press START/PAUSE and any one of the option buttons simultaneously for horizontal ver si on, while

for vertical version pushbuttons are 2 and 3, for at least two seconds: the LEDs first switch off, and then

display the flashing sequence corresponding to the alarm condition.

2. The alarm sequence continues as long as the two buttons are held down.

3. While the alarms are displayed, the current cycle being performed continues or, if the appliance is in the

programme sel ection phase, the options previ ousl y selected remain in memory.

1.3 Cancelling the last alarm

version wit h hori z ontal pushbuttons version wit h v ertic al pushbuttons

1. Access alarm reading mode (t enth sel ect or position)

2. Press and hold down START/PAUSE and any one of the option keys simultaneously for horizontal

version, while for vertical version pushbuttons are 2 and 3.

3. Hold the START/PAUSE and OPTION button down until the LEDs begin to flash (about 5 seconds)

Page 6

EWM1000

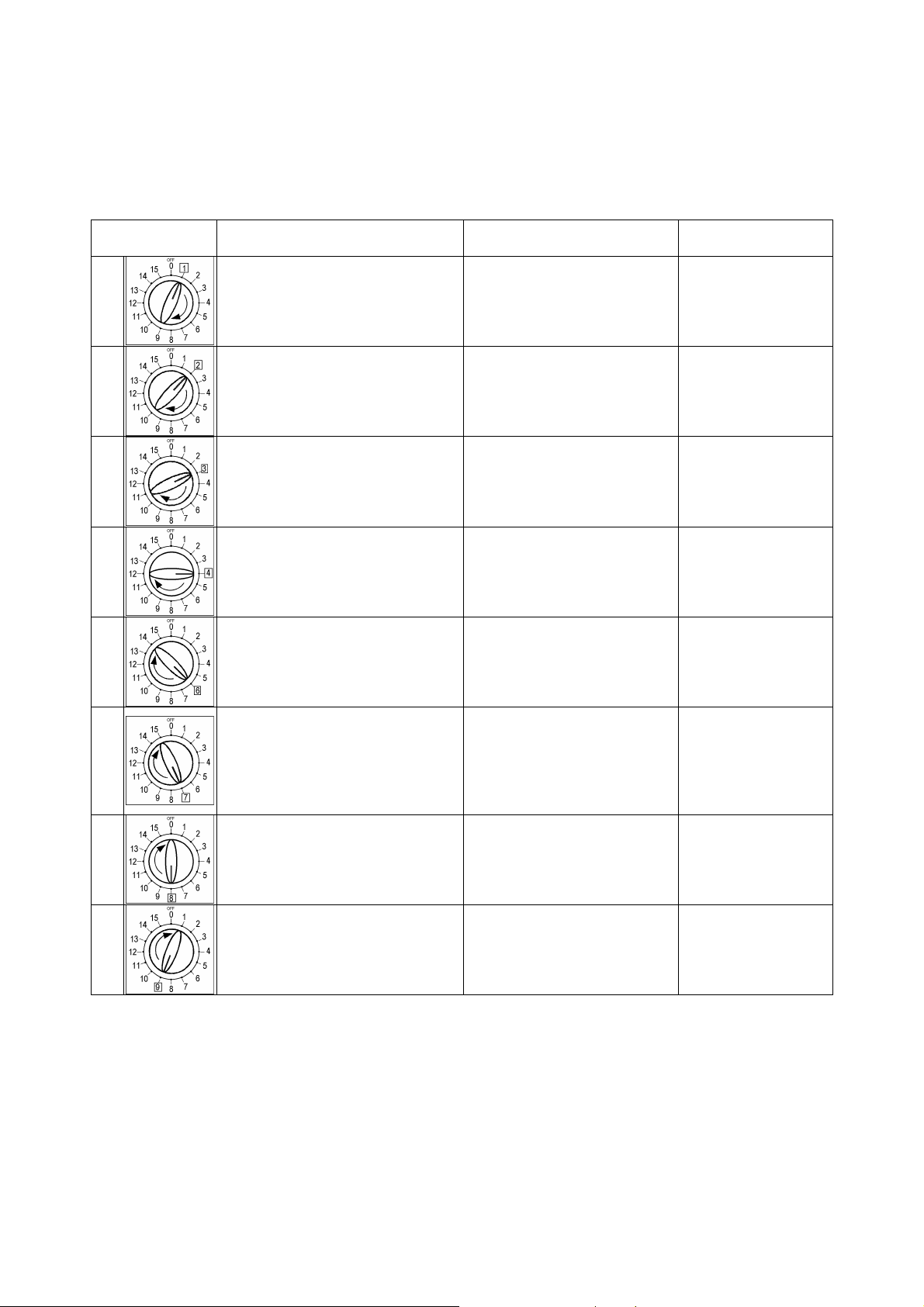

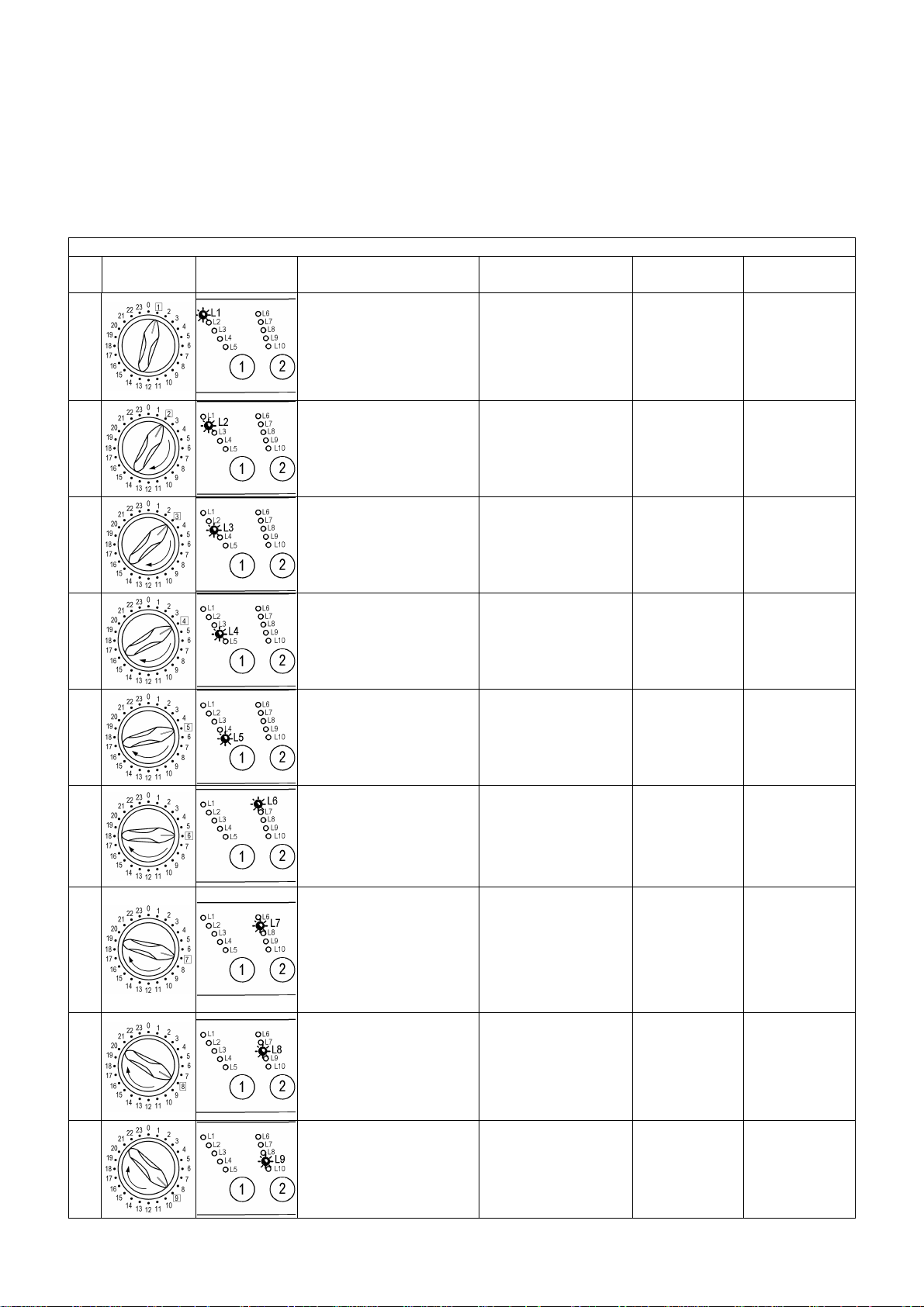

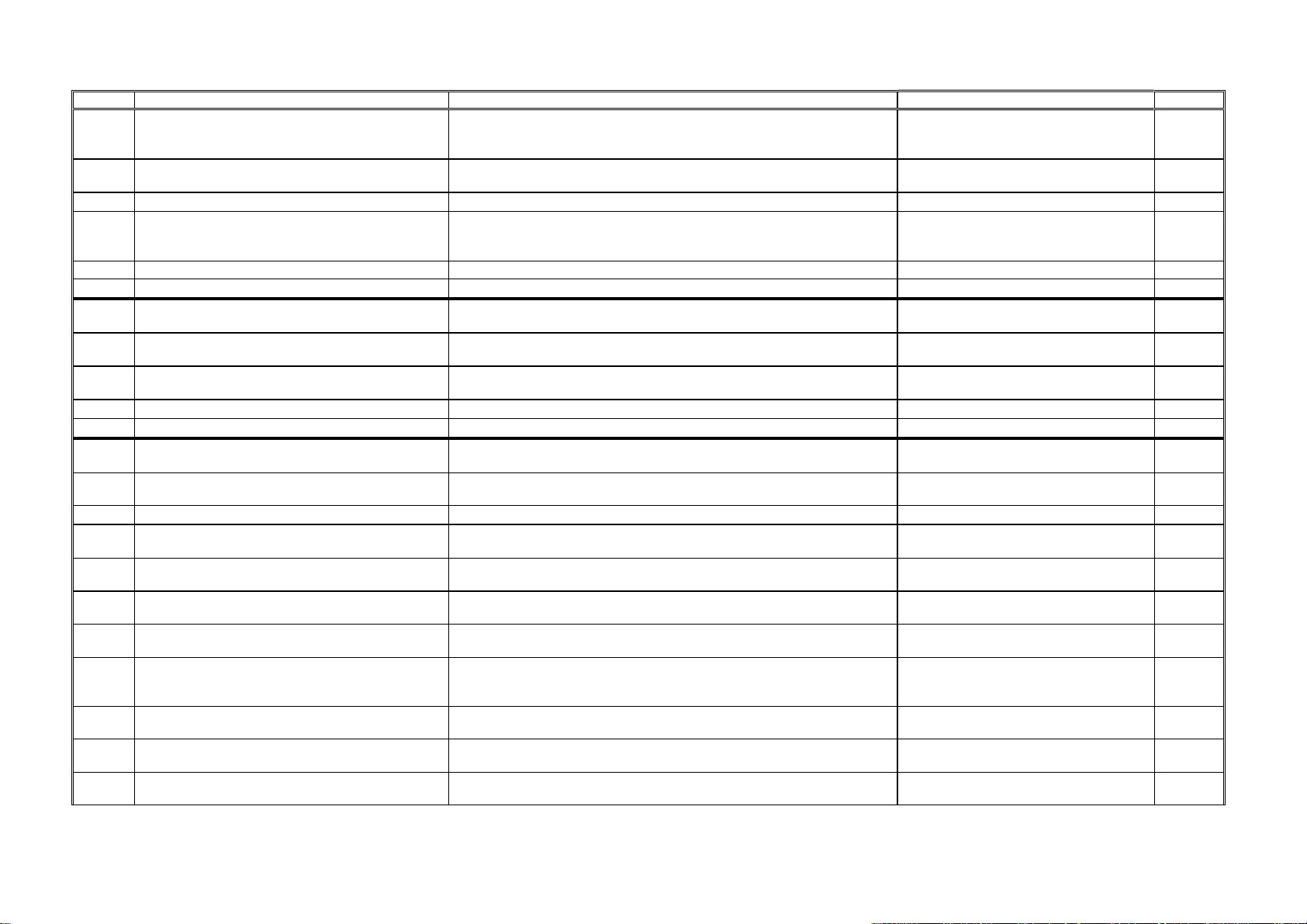

1.4 Phases of the diagnostics test

After accessing the diagnostics cycle, and irrespective of the type of control boar d fitted to the appliance

(i.e. vertical or horizontal buttons) and t he c onfiguration of the selector, turn the programme selec tor

clockwise to perform the diagnostics cycle for the various components and to read t he alarms.

All the alarm s are enabled during the diagnostics cycle.

Position of

selector

1

2

3

4

6

7

8

9

(*) In most cases, this time is sufficient to check the heating function. However, the time can be increased by repeating the heating

phase with out draini n g the water: p ass for a moment to a different ph as e of the diagnos t ic s c ycl e and then bac k t o th e h eati ng

check phase (if the temperature is higher than 80°C, heating does not take place).

Components activated Conditions of operation Function tested

- All the LEDs light in sequence

- When a button is pressed, the

corresponding LED l ights (and

the buzzer may sound)

- Door safety interlock

- Washing solenoid valve

- Door safety interlock

- Pre-wash solenoid valve

- Door safety interlock

- Washing and pr e- wash solenoid

valves

- Door safety interlock

- Wash solenoi d (if the water in

the tub is below 1st level)

- Heating element

- Door safety interlock

- Wash solenoi d (if the water in

the tub is below 1st level)

- Motor (55 rpm clockwise, 55

rpm anti-clock wise, impulse at

250 rpm)

- Door safety interlock

- Drain pump

- Motor up to 650 rpm then at

maximum spin speed

Only for top-loaders with drum

positioning system:

- Door safety interlock

- Motor (25 rpm)

- Drain pump

Always enabled

Door locked

Water level lower than antioverflow lev el

Maximum time 5 minutes

Door locked

Water level lower than antioverflow lev el

Maximum time 5 minutes

Door locked

Water level lower than antioverflow lev el

Maximum time 5 minutes

Door locked

Water leve l > 1st le ve l

Maximum time 10 minutes or

up to 90°C (*)

Door locked

Water leve l > 1st le ve l

Door locked

Water level lower then antiboiling level for spinning

Door locked

Water level lower then antiboiling level

Maximum time 2 minutes

Operation of the

user interfac e

Water ducted

through washing

compartment

Water ducted

through pre-wash

(bleach)

compartment

Water ducted

through conditioner

compartment

Heating

Check for leaks

from the tub

Drain and spin,

check for

congruence in

closure of pressure

switch levels

Test for positioning

of drum

QUICK GUIDE AND APPLIANCES LIST 6/176 599 72 40-80

Page 7

EWM1000

1.5 Reading the alarms

Proceed as follows to read the last alarm condition stored in the EEPROM on the

control boar d:

• Access diagnosti c s mode.

• Irrespective of the type of control board and confi gur ation, turn the programme

selector clockwise to the tenth position.

1.5.1 Di splaying the alarm

The alarm is displayed by a r epeated flashing sequence of the two LEDs (0.4

seconds ON, 0.4 seconds OFF, with a pause of 2.5 seconds between each

sequence). The buz z er (if featured) sounds a series of “beeps” in synchronization

with the flashing of the LEDs.

• END OF CYCLE indicator → indicates the first digit of the alarm code (family)

• START/PAUSE → indicates the second digit of the alarm code (number

within the family).

These two LEDs are present on all models (though confi gured in different

positions) and flash simultaneously.

Notes:

• The first letter of the alarm code “E” (Error) is not displayed si nc e it is the same for all alarm codes.

• The alarm code famili es are expressed in hexadecimal form. In other words:

→ A is repr es ented by 10 flashes

→ B is represented by 11 flashes

→ ...

→ F is represented by 15 flashes

• Configurati on er r or s are displayed by the flashing of all the LEDs (user i nterface not configured).

1.5.2 Examples of alarm display

Exam ple: Alarm E43 (problems with the door safety interlock tri ac ) will be displayed as follows:

• four flashes of t he E ND OF CYCLE LED indicat e the first digit E43;

• three flashes of t he STA RT/ P A USE LED i ndic ate the second digit E43;

END OF CYCLE LED

ON/OFF

Time

(seconds)

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

2.5 Pause

Value ON/OFF

1

2

3

4

START/PAUSE LED

Time

(seconds)

0.4

0.4

0.4

0.4

0.4

0.4

3,3 Pause

Value

1

2

3

1.5.3 Status of alarms during the diagnostics cycle

All the alarm s are enabled during the components diagnosti c s t est.

QUICK GUIDE AND APPLIANCES LIST 7/176 599 72 40-80

Page 8

EWM1000

1.6 Table of alarms codes EWM1000

Alarm Description Possible faul t Action/Machi ne status Reset

E00

Tap closed or water pressure insufficient; Drain hose

E11 Difficulty in filling during wash phase

E13 Water leakage

E21 Difficulties in dra ining

Drain pump triac faulty Drain pump faulty; Wiring faulty; Circuit board faulty. Safety drain - Cycle stopped, door open Selector on “0”

E23

Problems with «sensing» of drain pump triac Circuit board faulty. Safety drain – Cycle stopped, door released Selector on “0”

E24

Incongruence between contact closure of anti-

E33

boiling and 1st level of pressure switch

E35 Water ov e rflow

«sensing» circuit of anti-boiling pressure switch

E36

faulty

«sensing» circuit of 1st level faulty Circuit board faulty. Cycle blocked, door closed Selector on “0”

E37

HV «sensing» circuit of anti-flooding pressure

E39

switch faulty

Door open

E41

Problems with aperture of door

E42

Power triac on door interlock faulty

E43

Door interlock «sensing» faulty Circuit board faulty. Saf ety drain, door released Selector on “0”

E44

«sensing» on door interlock triac faulty Circuit board faulty. Saf ety drain, door released Selector on “0”

E45

Motor power triac short-circuited

E51

E52 No signal from motor tachimetric generator

«sensing» circuit on motor triac faulty Circuit board faulty. Cycle blocked Selector on “0”

E53

incorrectly positioned; Water fill solenoid faulty; Leaks from

pressure switch hydraulic circuit; Pressure switch faulty;

Wiring faulty; Circuit board faulty.

Drain hose incorrectly positioned; Water pressure

insufficient; Water fill solenoid faulty; Leaks or blockage in

pressure switch hydraulic circuit; Pressure switch faulty;

Circuit board faulty.

Drain hose kinked/blocked/incorrectly positioned; Drain filter

clogged or dirty; Drain pump faulty; Pressure switch faulty;

Wiring faulty; Circuit board faulty; Current leakage from

heating element to ground.

Pressure switch faulty; Current leakage from heating

element to ground; Heating element; Wiring faulty; Circuit

board faulty.

Water fill solenoid faulty; Leaks from pressure switch

hydraulic circuit; Pressure switch faulty; Wiring faulty; Circuit

board faulty.

Circuit board faulty. Cycle blocked, door closed Selector on “0”

Circuit board faulty. Cycle blocked, door closed Selector on “0”

Door safety interlock faulty; Wiring faulty;

Circuit board faulty.

Door safety interlock faulty; Wiring faulty;

Circuit board faulty

Door safety interlock faulty; Wiring faulty;

Circuit board faulty.

Circuit board faulty;

Current leakage from motor or wiring.

Motor faulty; Wiring faulty;

Circuit board faulty.

No alarm

Cycle paused, door closed Start

Cycle paused, door closed Start

Cycle paused Start

Safety drain - Cycle stopped, door open Selector on “0”

Cyc le block ed, do or closed. Safety dr ain.

Drain pump (sequence 5 min. ON - 5 min.

OFF)

Cycle paused Start

Cycle paused

Safety drain, door released Selector on “0”

Cyc le block ed, do or closed ( after 5 attempts in

diagnostics or immediate during selection)

Cyc le block ed, do or closed ( after 5 attempts in

diagnostics or immediate during selection)

Selector on “0”

Start or Selector

on “0”

Selector on “0”

Selector on “0”

QUICK GUIDE AND APPLIANCES LIST 8/176 599 72 40-80

Page 9

EWM1000

Alarm Description Possible faul t Action/Machi ne status Reset

Motor relay cont acts sticking

E54

Insufficient heating during washing

E61

Overheating during washing

E62

Power re lay for heating element faulty

E66

NTC washing sensor faulty

E71

Error in res et p o sit ion of selector Circuit board faulty. Cycle cancelled Selector on “0”

E82

Error in reading selector position Configuration data incorrect; Circuit board faulty.

E83

Incorrect machine configuration Configuration data incorrect; Circuit board faulty. Appliance blocked Selector on “0”

E93

Incorrect washing cycle configuration Configuration data incorrect; Circuit board faulty. Appliance blocked Selector on “0”

E94

Communications error between microprocesso r

E95

and EEPROM

Incongruence between hardware version and

E96

configuration.

Incongruence between programme selector and

E97

cycle configuration

Power supply frequency of appliance incorrect

EB1

Voltage too high

EB2

Voltage too low

EB3

Circuit board faulty;

Current leakage from motor or wiring.

NTC sensor faulty; Heating element faulty; Wiring faulty;

Circuit board faulty.

NTC sensor faulty; Heating element faulty; Wiring faulty;

Circuit board faulty.

Circuit boa rd faulty; Current leakage f r om hea t ing elem ent

or wiring to ground.

NTC sensor faulty; Wiring faulty;

Circuit board faulty.

Circuit board faulty. Appliance blocked Selector on “0”

Configuration data incorrect; Circuit board faulty. Appliance blocked Selector on “0”

Configuration data incorrect; Circuit board faulty. Appliance blocked Selector on “0”

Mains power supply problems (incorrect / interference);

Circuit board faulty.

Mains power supply problems (incorrect / interference);

Circuit board faulty.

Mains power supply problems (incorrect / interference);

Circuit board faulty.

Cyc le block ed, do or closed ( after 5 attempts in

diagnostics or immediate during selection)

Heating phase skipped --Safety drain (with co ol ing w ater f i ll) - Sto p with

door open

Safety drain (with co ol ing w ater f i ll) - Sto p with

door open

Heating phase skipped ---

During the cycle continues normally, switches

off completely during selection

Cycle blocked until normal power supply

conditions are restored

Cycle blocked until normal power supply

conditions are restored

Cycle blocked until normal power supply

conditions are restored

Selector on “0”

Selector on “0”

Selector on “0”

---

Selector on “0”

Selector on “0”

Selector on “0”

1.6.1 No t es concerning certain alarm codes

Configuration alarms E93-E96: If these alarm s are generated (when the appliance is switched on), operation of t he appliance is blocked and all the

LEDs light. The di agnostics procedure cannot be acc essed; t he only option is to switch the appliance OFF (by turning the selector to position “0”).

Configuration alarm E94: For this alarm code, only the family for alarm “9” is di spl ay ed; the diagnostics procedure cannot be ac c essed, and the “rapid

alarm display” function cannot be used.

Alarms EB1-EB2-EB3: In the event of problems with the mains power supply, the appliance remains in alarm mode until the mains fr equenc y or

voltage are r estor ed to the correct value or the appliance i s switched of f (by turning the programme selector to “0”). The family of alarm “B” i s di spl ay ed;

the diagnosti c s procedur e c annot be accessed, and the “rapid alarm display” function cannot be used. The complete alarm code can be read only when

the abnormal situation has ceased.

Alarms E51- E52: During the diagnostics test, all the alarms are displayed. Norm ally , when the programme selector is turned f rom one test phase to

another, the appliance exits the alarm condition and performs the phase selected. This does not take place in the case of alarm s E51 (power triac on

motor short-circuited) and E52 (no signal f r om t he tachymetric generator on the motor): in these cases, the only option to exit the alarm condition is to

switch the appliance OFF by turning the selector t o position “0” (reset).

QUICK GUIDE AND APPLIANCES LIST 9/176 599 72 40-80

Page 10

EWM1000

1.7 Elementary diagram

1.7.1 With instantaneous door locking device

QUICK GUIDE AND APPLIANCES LIST 10/176 599 72 40-80

Page 11

EWM1000

1.8 With PTC door locking device

QUICK GUIDE AND APPLIANCES LIST 11/176 599 72 40-80

Page 12

EWM1000

1.8.1 Key t o circuit diagram

Electrical compo nents – appliance Components of elect ron ic circuit board

1. Circuit board

2. Suppressor

3. Main switch (on progr amme selector)

4. Door safety interlock

5. 1st level pressure swit c h

6. Anti-boiling pressure switch

7. Anti-ov erflow pressure switch (certain models only)

8. Heating element

9. Stator (motor)

10. Overl oad circuit- breaker (m otor)

11. Tachymetric generator (motor)

12. Rotor (motor)

13. Drain pump

14. Pre-wash solenoid valve

15. Washing solenoid valve

16. “ Door c losed” lamp (certain m odels onl y )

17. Dr um posi tioning system (DSP) (top- loaders – certain models only )

DOOR_TY Triac for door saf ety interlock

DRAIN_TY Triac for drai n pum p

K1 Heating elem ent r elay

K2 Motor relay: clockwise rotation

K3 Motor relay: anti-clockwise rotation

K4 Motor relay: half-range power (certain models only)

MOTOR_TY Motor triac

ON/OFF Main switch (programme selector)

PWELW_TY Tri ac for pre-wash solenoid valve

Serial interface Asynchronous serial interface

WELV_TY Triac for washing solenoid v alv e

QUICK GUIDE AND APPLIANCES LIST 12/176 599 72 40-80

Page 13

EWM1000

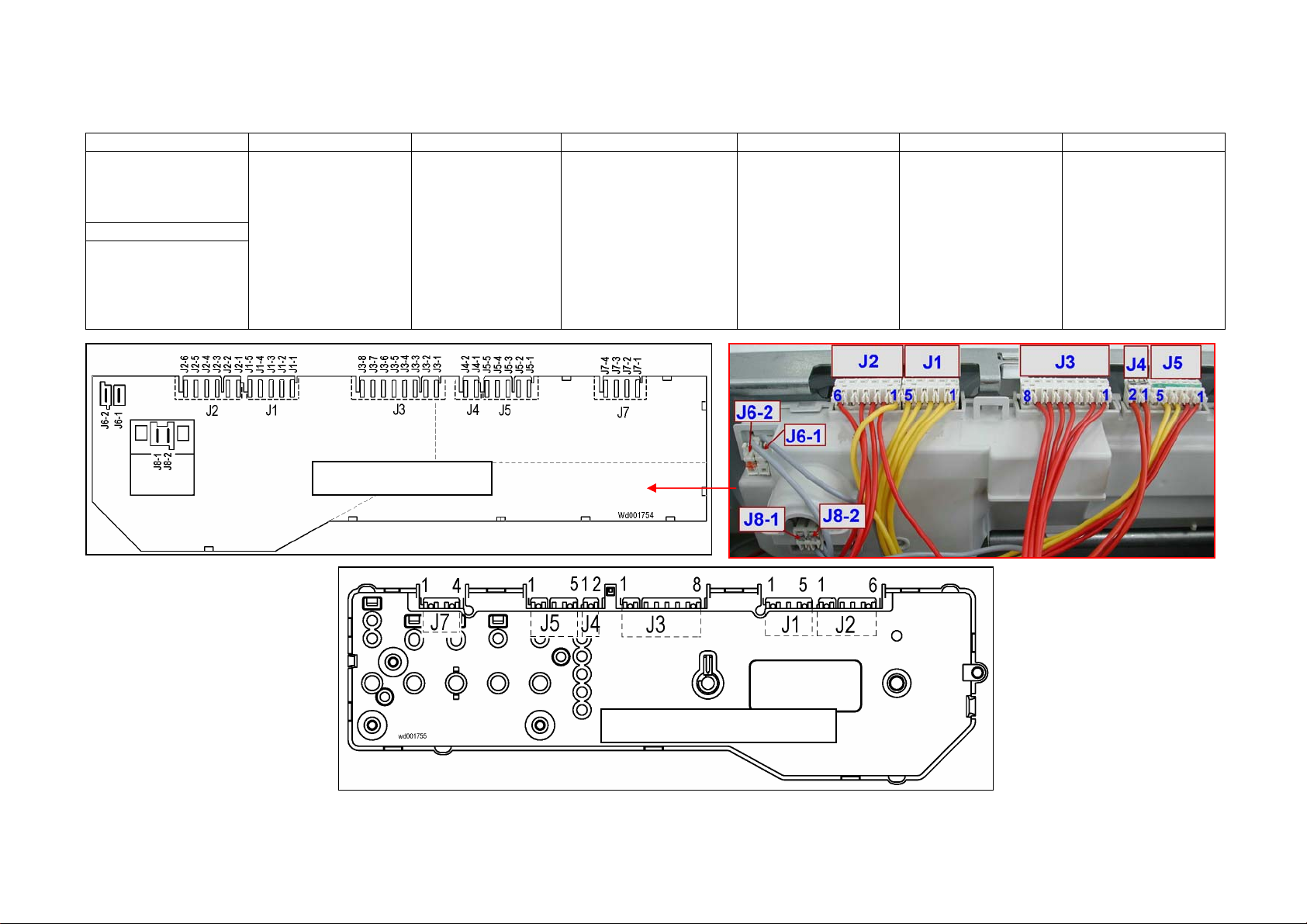

1.9 Connectors on circuit board EWM1000

J6 J2 J1 J3 J4 J5 J7

J6-1: Heati ng element

(relay)

J6-2: Door safety

int erl o ck (line)

J8

J8-1 line

J8-2 line (neutral)

J2-1 Door safety interlock

(line-sensing)

J2-2 1st level(sensing)

J2-3 (Anti-overflow

pressure switch)

J2-4 Door safety interlock

(triac)

J2-5 (Door safety

interlock)

J2-6 (Anti-overflow

pressure switch)

Rear view

J1-1 Motor (triac)

J1-2 Motor (stator – full

range)

J1-3 Motor (stator - 1/2

range)

J1-4 Motor (rotor)

J1-5 Motor (rotor)

J3-1 Drain pump (line)

J3-2 Solenoids (line)

J3-3 (line)

J3-4 Drain pump (triac)

J3-5 Pre-wash solenoid

(triac)

J3-6 Washing solenoid

(triac)

J3-7 Solenoids (line)

J3-8 (Not used)

Front view

J4-1 “Door closed” pilot

lamp

J4-2 “Door closed” pilot

lamp

J5-1 NTC temperature

sensor

J5-2 NTC temperature

sensor

J5-3 Motor (tachymetric

generator)

J5-4 Motor (tachymetric

generator)

J5-5 (DSP drum

positioning syste m)

Serial interface:

J7-1 ASY_IN

J7-2 ASY_OUT

J7-3 5V

J7-4 GND

QUICK GUIDE AND APPLIANCES LIST 13/176 599 72 40-80

Page 14

EWM1000

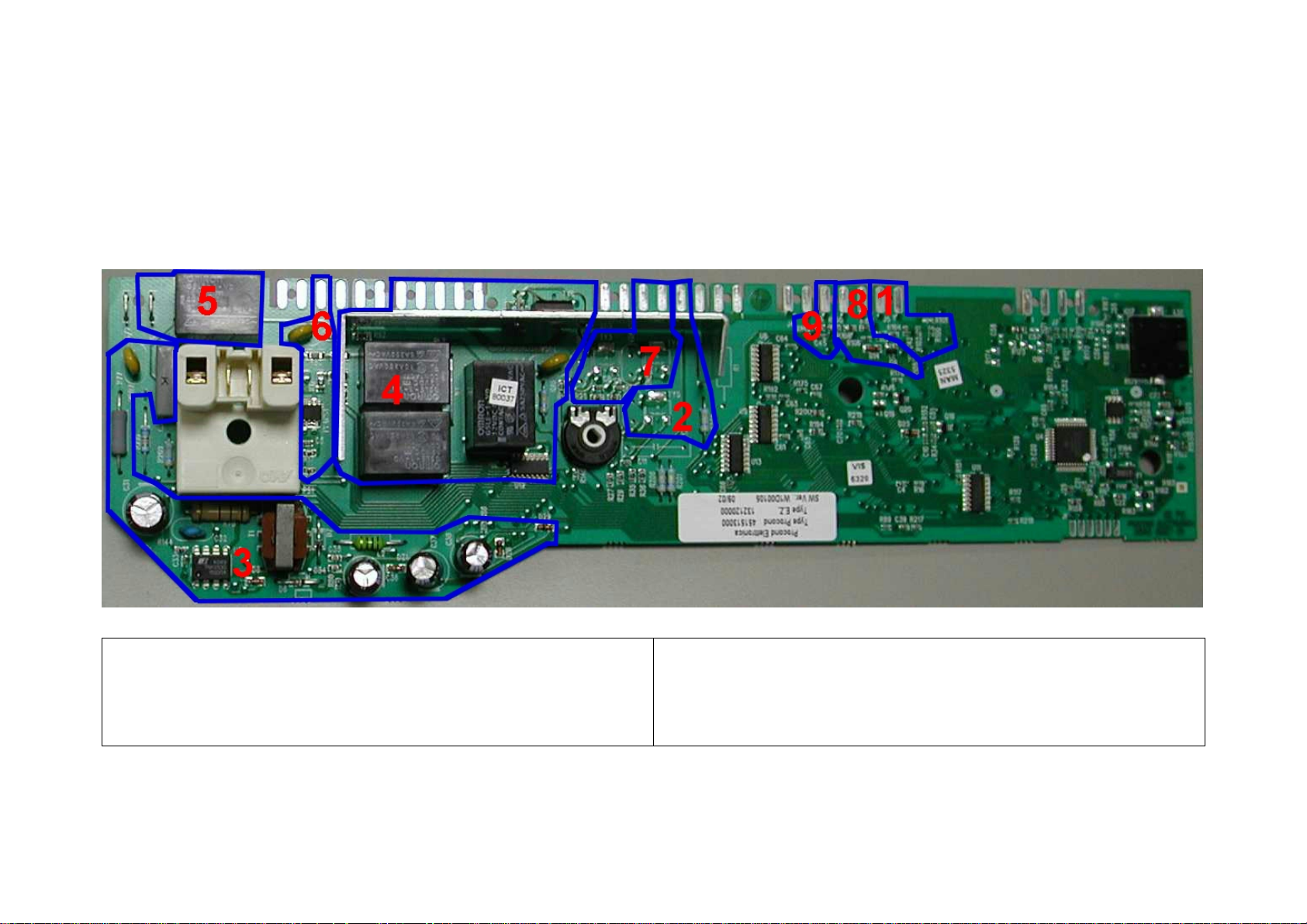

1.10 Burning on the circuit board EWM1000

1.10.1 EWM1000

In case of burning on the main ci r c uit board, check that the problem is not caused by another electrical component (short-circuits, poor insulation, water leakage).

Refer to the figures bel ow in or der to identify the component that mi ght have caused the burning according t o the posi tion of the burned area.

The circuit boar d s hown below is the version with the greatest number of components: other boards may not feature all t hes e c om ponents (relay K4 and buzzer).

1.10.2 Components side (common)

1. NTC washing temperature sensor

2. Drain pump

3. Power supply

4. Motor

5. Heating element

6. Door safety interlock

7. Water fill solenoids

8. Tachymetri c generat or (motor)

9. Drum positi oning system (top-loaders)

QUICK GUIDE AND APPLIANCES LIST 14/176 599 72 40-80

Page 15

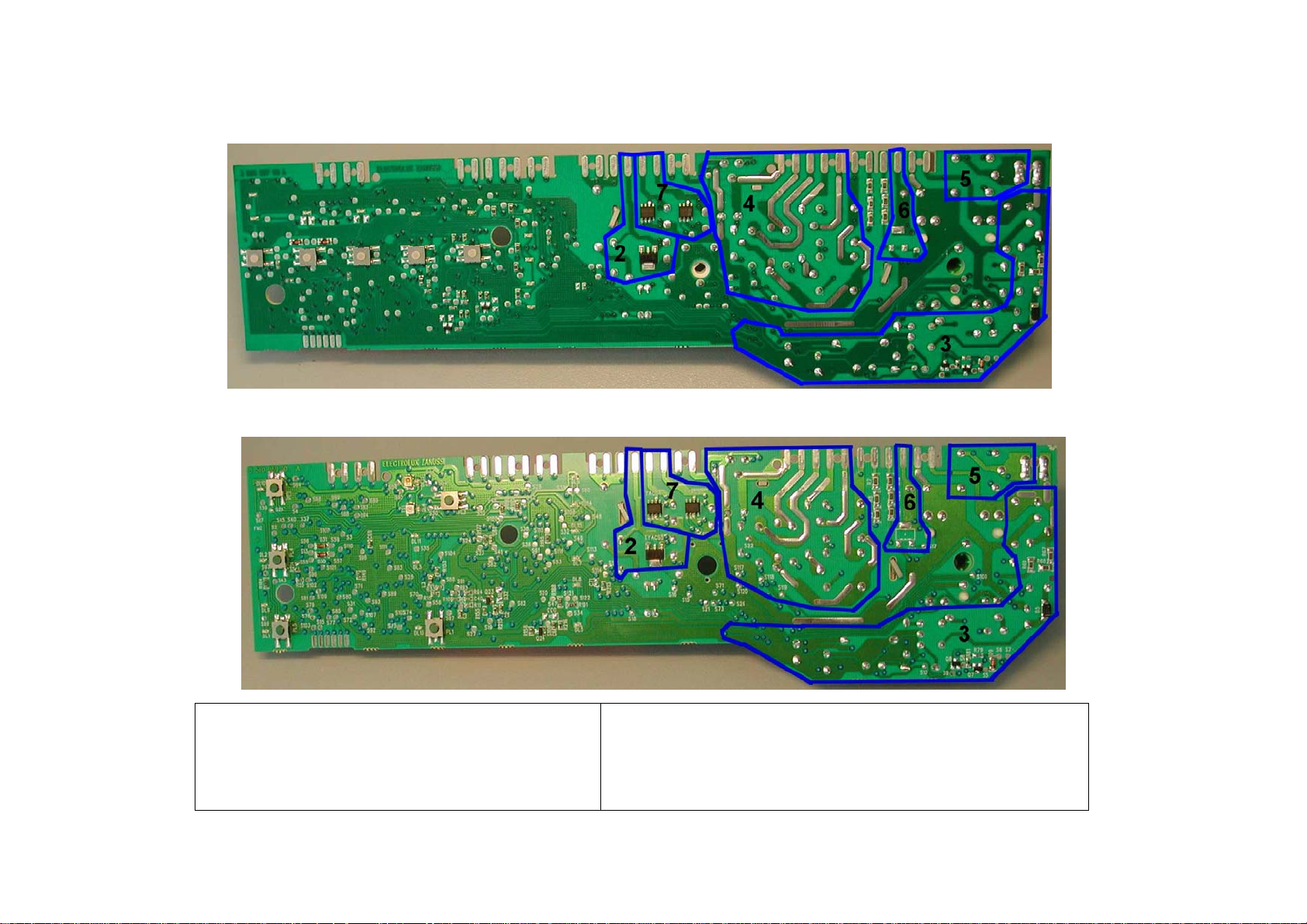

EWM1000

1.10.3 Pushbutton – led side (horizontal buttons)

1.10.4 Pushbutton – led side (vertical bu tton s)

1. ---

2. Drain pump

3. Power supply

4. Motor

5. Heating element

6. Door safety interlock

7. Water fill solenoids

8. Tachymetri c generat or (motor)

9. Drum positi oning system (top-loaders)

QUICK GUIDE AND APPLIANCES LIST 15/176 599 72 40-80

Page 16

EWM1000plus EWM2000evo EWM3000new

2 EWM1000plus 2000evo 3000new

2.1 Control panel

The configurat ion of the control panel depends on the fol lowing:

ª Type of control/ display board (with or without display)

ª Design of the cont r ol panel and posi tion of the programme selector ( ri ght or left of the buttons)

ª Number and confi gur ation of the buttons (max. 8)

ª ON/OFF switch: inc or por ated in the programme select or or wit h separated button

Version with lef t select or and incorporated ON/OFF button

Alpha-Rim Sigma

Club Display

Delta

Version with left selector and button ON/OFF switch

Alpha Ellipse

Version with righ t select or and button ON/OFF switch

Version with righ t select or and incorporated ON/OFF switch

Sigma/ZK AEG NexXxt AEG NE W

Delta Version without selector and button ON/OFF switch

Multipanel Built-in

Club Display

LCD Version without selector and button ON/OFF switch

LCD Version with left selector and incorporated ON/OFF button

QUICK GUIDE AND APPLIANCES LIST 16/176 599 72 40-80

Page 17

EWM1000plus EWM2000evo EWM3000new

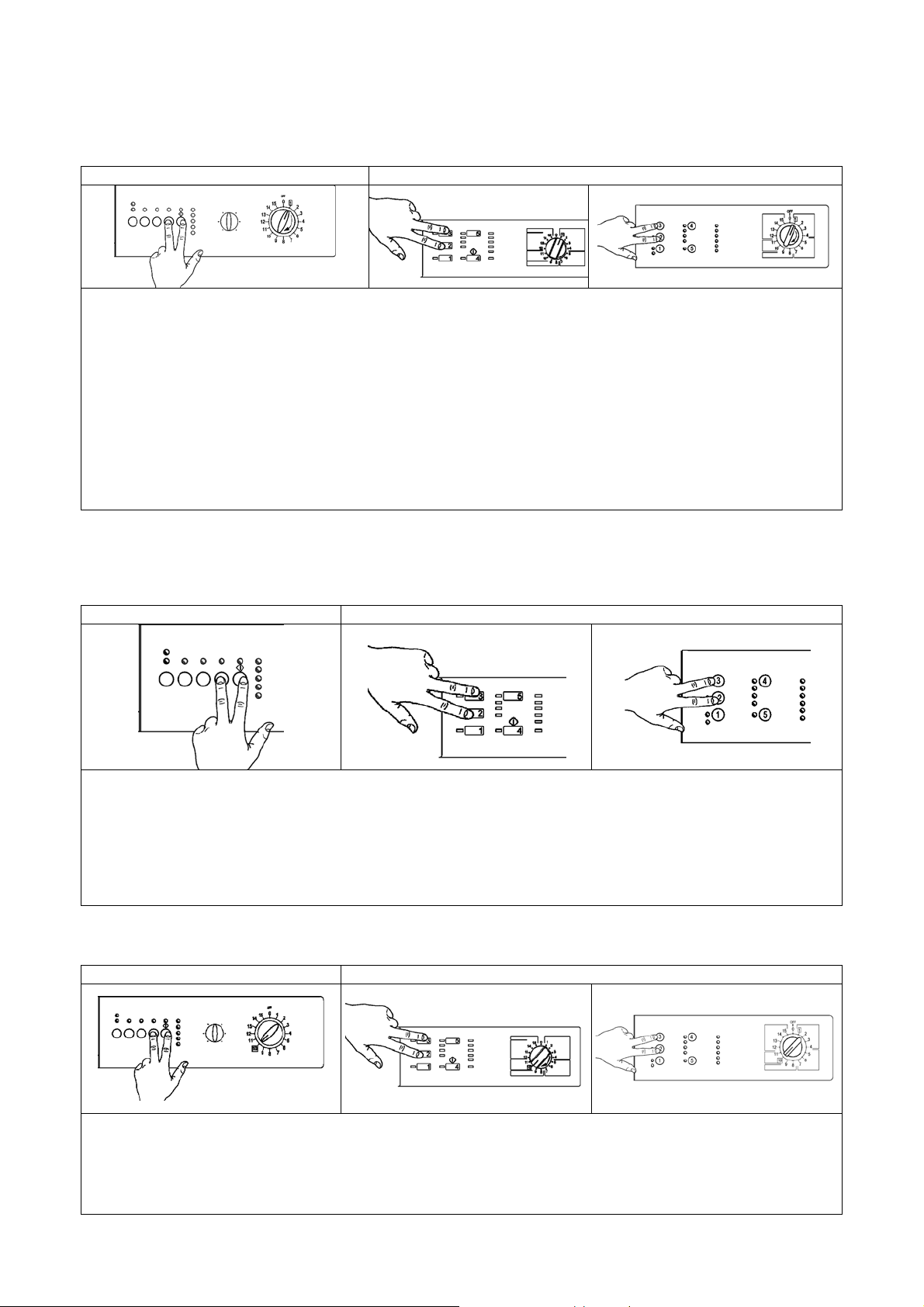

2.2 Sigma/Alpha/Ellipse//Multipanel Built-In/Sigma-ZK/Jewel with or without

selector

2.2.1 Access to diagnosti cs system

Attention: the pr ogr am m e select or is not always in the position indicated in the picture; it can be on the right

or on the left of the display boar d!

Version with selector and button ON/OFF switch

1. Cancel the set progr amme and switch the appliance off.

2. Rotate the progr amme selector of one pos itions clockwise.

3. Press the start/pause (8) button and any of t he option button simultaneously and then, keeping them

pressed, swi t ch the appliance on through the ON/OFF button (on/off).

4. Hold the start/pause and option buttons down till the LEDs start f lashing (about 5 seconds).

5. To exit the diagnostics system switch the applianc e off, on and then off again.

Version with select or and incorporated ON/OFF switch

1. Cancel the set progr amme switching the appliance off .

2. Press the start/pause (8) button and any of the option buttons simult aneousl y and then, keeping them

pressed, swi t ch the appliance on rotating the pr ogr amme selector of one position clockwise.

3. Hold the start/pause and option buttons down till the LEDs start f lashing (about 5 seconds).

4. To exit the diagnostics system switch the applianc e off, on and then off again.

2.2.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Press and hold down START/PAUSE and the option button nearest to the START/PAUSE button for at

least two seconds: the LEDs initially switch off, and then display the flashing sequence cor responding to

the alarm; if the displ ay is featured, it will display the alarm c ode

ª The alarm sequence is displ ay ed for the time in which the buttons are hold down

ª During the time t he alarm is displayed, the applianc e conti nues to perform the cycle or, if it is in the

selection phase, it keeps in memory the options previously chosen.

2.2.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r e- occurs

during the diagnostics control after the r epar ation of the appliance.

1. Select diagnostics mode and turn the programme sel ector to the tenth position (reading of alarm)

2. Press and hold down START/PAUSE and any of the option buttons at the same time for five

seconds.

QUICK GUIDE AND APPLIANCES LIST 17/176 599 72 40-80

Page 18

EWM1000plus EWM2000evo EWM3000new

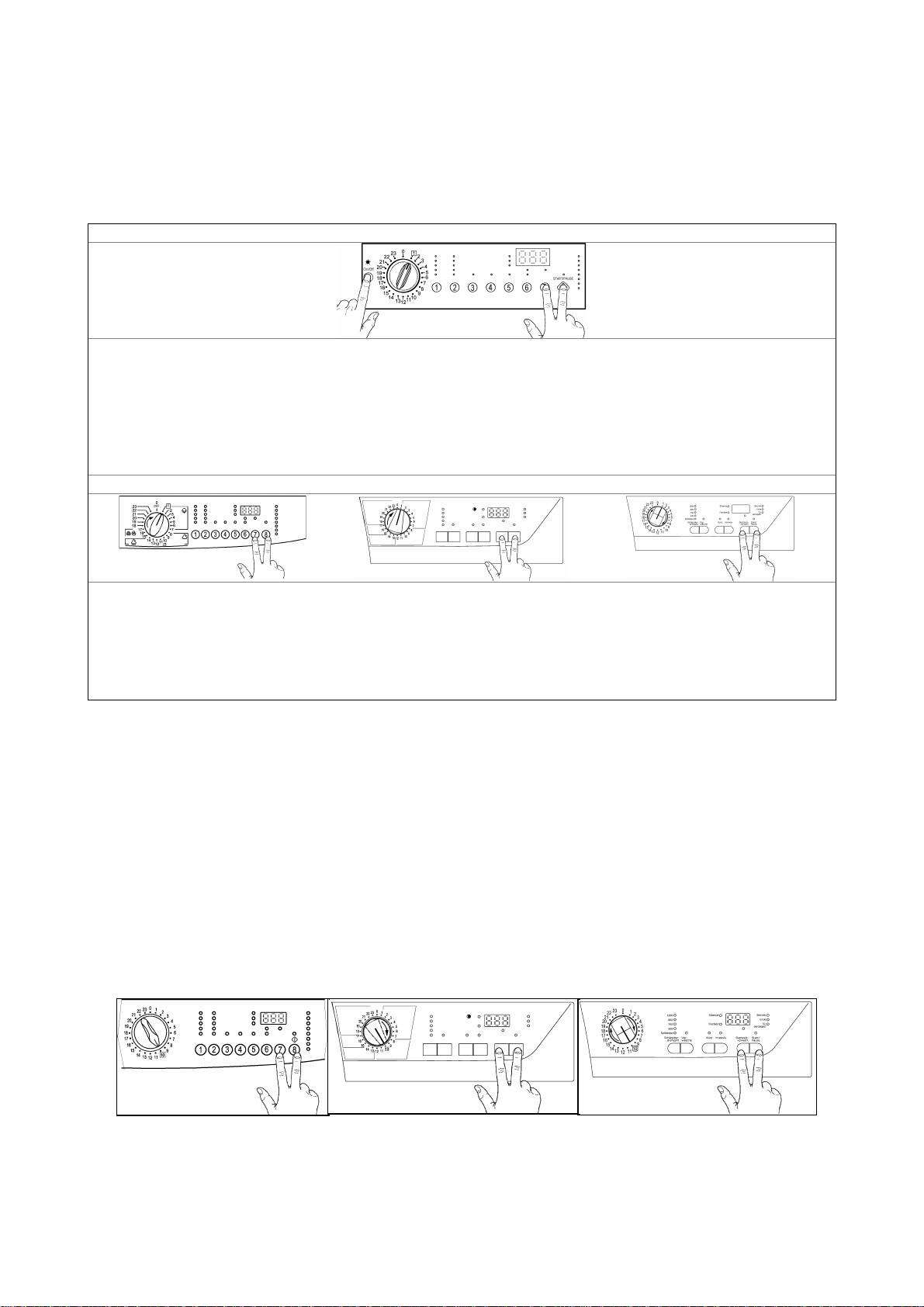

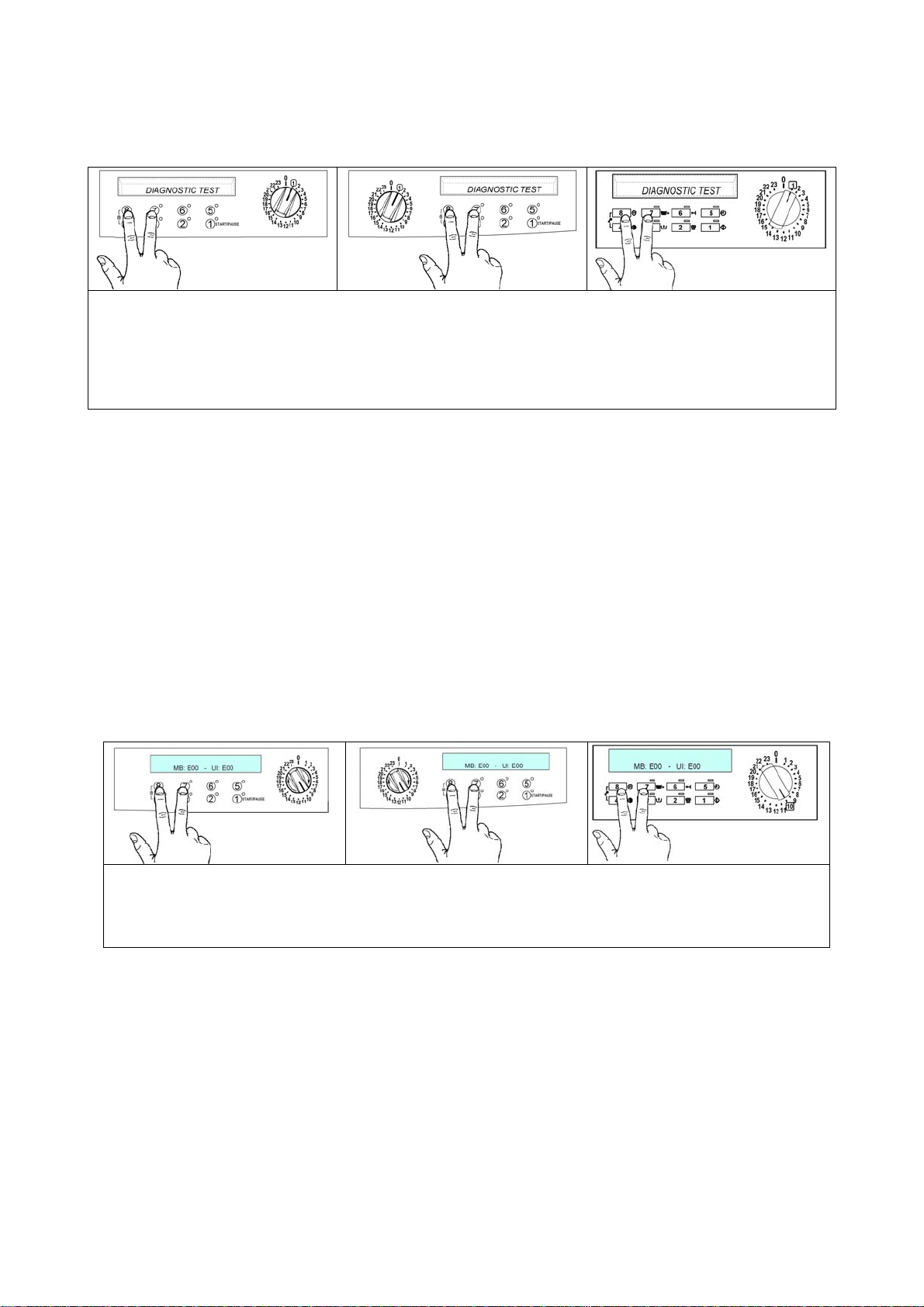

2.3 AEG NexXxt Version with selector and incorporated ON/OFF switch

2.3.1 Access to diagnosti cs system

1. Cancel the set progr amme and switch the appliance off.

2. Press buttons 1 and 5 (or butt on 2 and 6) simult aneous ly and then, holding them down, swit c h

the applianc e on by rotating the programme selector of one position cl oc k wis e.

3. To exit the diagnostics system switch the applianc e off, on and then off again.

2.3.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Press buttons 1 and 5 simultaneously f or at least 2 seconds: the LED switch off and then di spl ay the

sequence of flashes indicating the alarm.

ª The alarm sequence is displ ay ed for the time in which the buttons are hold down

ª During the time t he alarm is displayed, the applianc e conti nues to perform the cycle or, if it is in the

selection phase, it keeps in memory the options previously chosen.

2.3.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r eoccurs during the diagnostics control aft er the reparation of the appliance

1. Select diagnostics mode and turn the programme sel ector to the tenth position (reading of

alarm)

2. Press buttons 1 and 5 simultaneously.

3. Hold buttons 1 and 5 down (about 2 seconds).

QUICK GUIDE AND APPLIANCES LIST 18/176 599 72 40-80

Page 19

EWM1000plus EWM2000evo EWM3000new

2.4 AEG New Version with right selector and incorporated ON/OFF switch

2.4.1 Access to diagnosti cs system

1. Cancel the set progr amme and switch the appliance off.

2. Press buttons 1 and 2 simultaneously and then, holding them down, swit c h the appliance on

by rotating t he pr ogr amme selector of one position clockwise.

3. To exit the diagnostics system switch the applianc e off, on and then off again.

2.4.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Press buttons 1 and 2 sim ultaneously for at least 2 seconds: the LED s witch off and then display the

sequence of flashes indicating the alarm.

ª The alarm sequence is displ ay ed for the time in which the buttons are hold down

ª During the time t he alarm is displayed, the applianc e conti nues to perform the cycle or, if it is in the

selection phase, it keeps in memory the options previously chosen.

2.4.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r eoccurs during the diagnostics control aft er the r epar ation of the applianc e

1. Select diagnostics mode and turn the programme sel ector to the tenth position (reading of

alarm)

2. Press buttons 1 and 2 simultaneously.

3. Hold buttons 1 and 2 down (about 2 seconds).

QUICK GUIDE AND APPLIANCES LIST 19/176 599 72 40-80

Page 20

EWM1000plus EWM2000evo EWM3000new

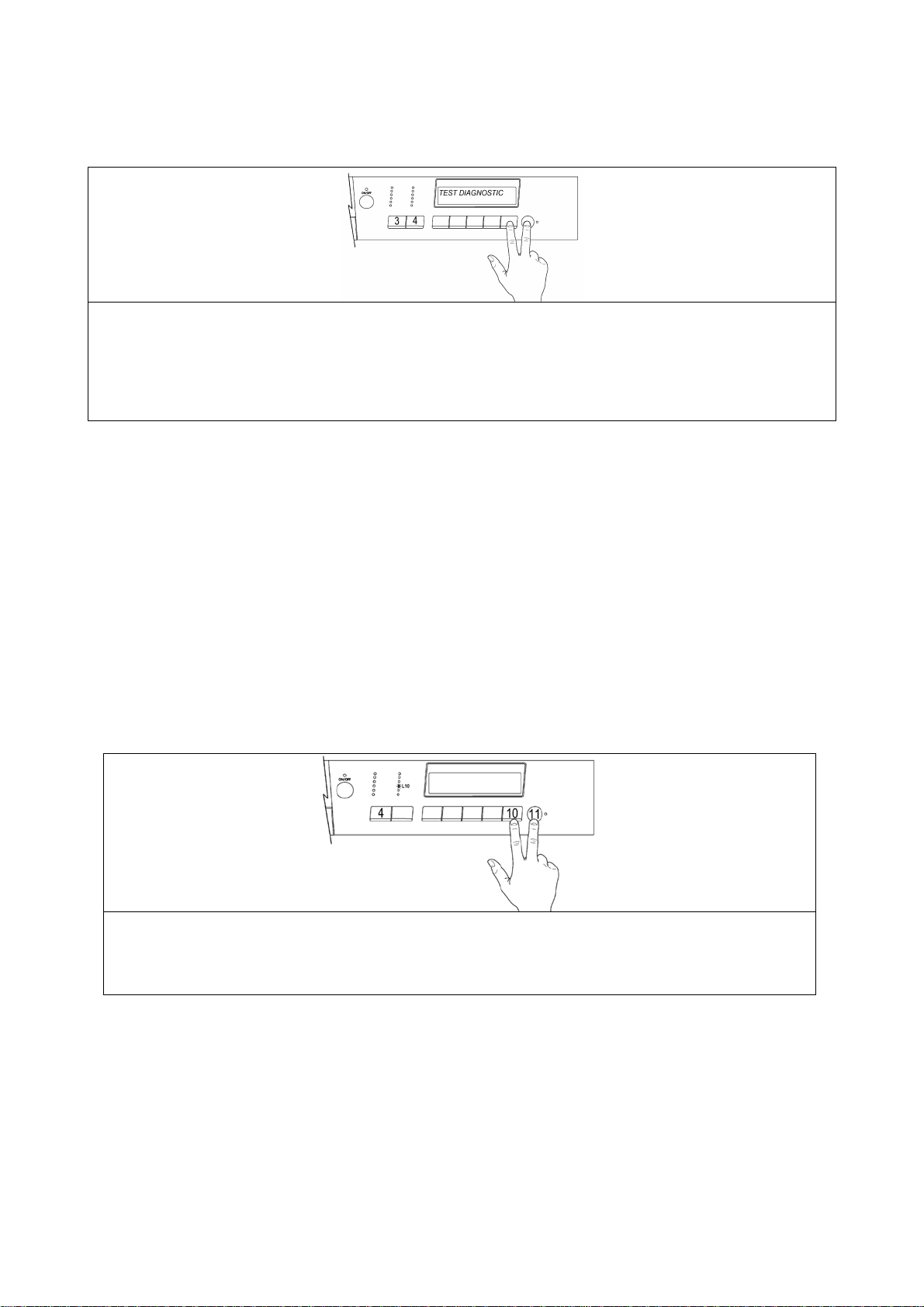

2.5 DELTA Version without selector and button ON/OFF switch

2.5.1 Access to diagnosti cs system

1. Reset the set programme with the SKIP/RESET button and then switch the appliance off.

2. Press the START/PAUSE and SKIP/RESET buttons simultaneously and then, hol ding the

buttons down, switc h the appliance on using the ON/OFF button.

3. Hold the buttons down until the buzzer sounds and the LEDs start flashing (about 4 seconds).

4. To exit the diagnostics system switch the applianc e off , on and t hen off again.

2.5.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Press START/PAUSE and SKIP/RESET buttons simultaneously f or at least 2 seconds: the LE Ds s witch

off and then display the sequence of flashes indicati ng the alarm.

ª The alarm sequence is displ ay ed for the time in which the buttons are hold down

ª During the time t he alarm is displayed, the appli ance continues to perf orm the cycle or, if it is i n the

selection phase, it keeps the options previously c hosen in memory.

2.5.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r eoccurs during the diagnostics control aft er the reparation of the appliance

1. Select diagnostics mode and Press the Fabric s (1) or Temperature (2) button until LED L10

lights (readi ng of alarm).

2. Press and hold down START/PAUSE and START/RESET.

QUICK GUIDE AND APPLIANCES LIST 20/176 599 72 40-80

Page 21

EWM1000plus EWM2000evo EWM3000new

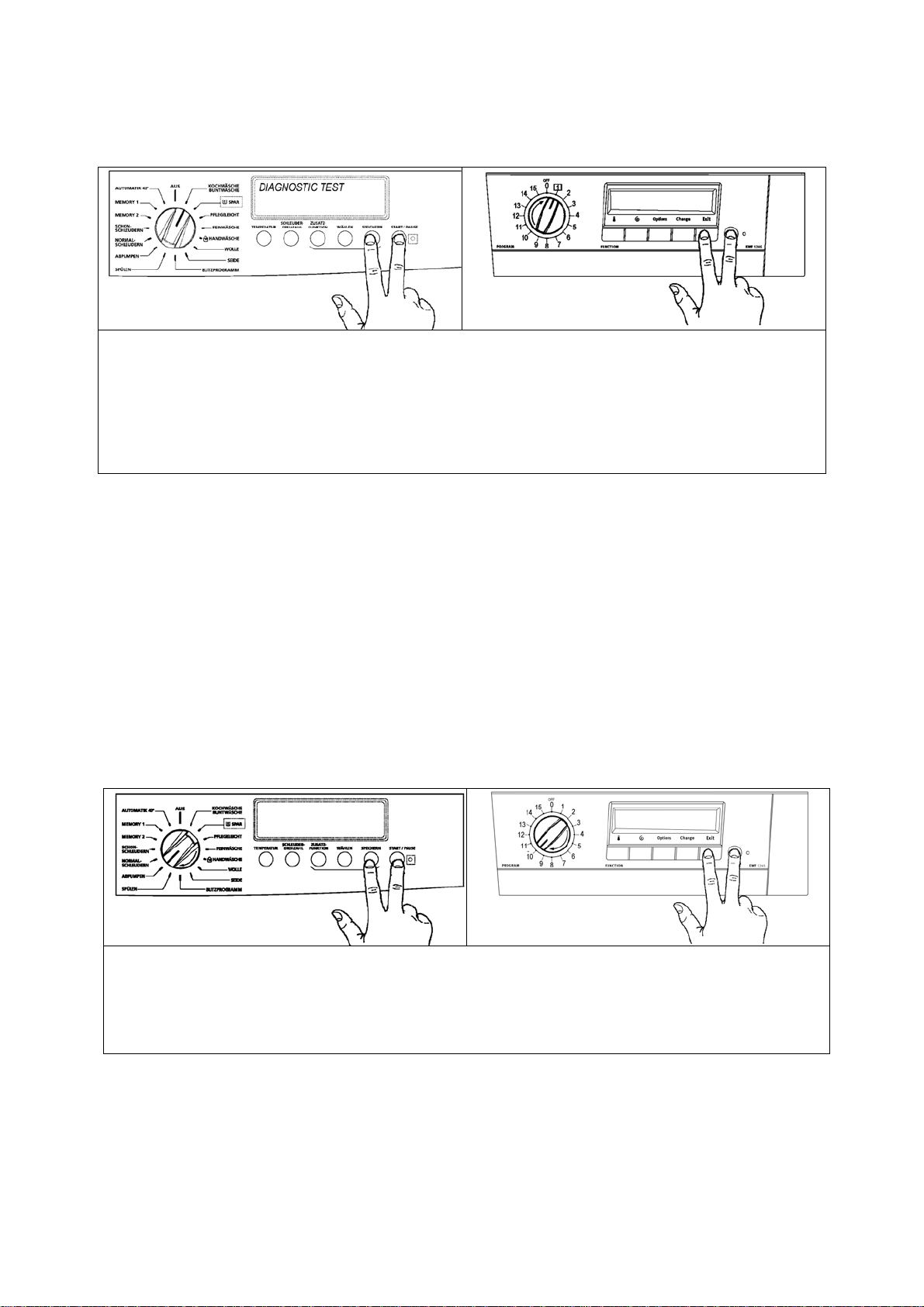

2.6 CLUB DISPLAY Version with selector and incorporated ON/OFF switch

2.6.1 Access to diagnosti cs system

1. Cancel the set progr amme and switch the appliance off.

2. Press buttons 8 and 7 simult aneousl y , then, holding them down, switc h the appliance on rotating t he

programme sel ector of one position c loc kwise.

3. Hold the buttons down up to DI AGNOSTIC MODE appears (about 5 seconds).

4. To exit the diagnostics system switch the applianc e off, on and then off again.

2.6.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Five minutes aft er the switching on, press and hold down the 8 and 7 butt ons simultaneously for 2

seconds, the LCD displ ay shows the l ast alarm codes (of the main board and displ ay boar d) . The

displayi ng of t he alarms depends on the time in which the buttons are hol d down.

ª During the time t he alarm is displayed, the applianc e conti nues to perform the cycle or, if it is in the

selection phase, it keeps in memory the options previously chosen.

2.6.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r eoccurs during the diagnostics control aft er the reparation of the appliance

1. Select diagnostics mode and turn the programme sel ector to the tenth position (reading of alarm)

2. Press simultaneously buttons 8 and 7.

3. Hold them down until the alarms are cancelled.

QUICK GUIDE AND APPLIANCES LIST 21/176 599 72 40-80

Page 22

EWM1000plus EWM2000evo EWM3000new

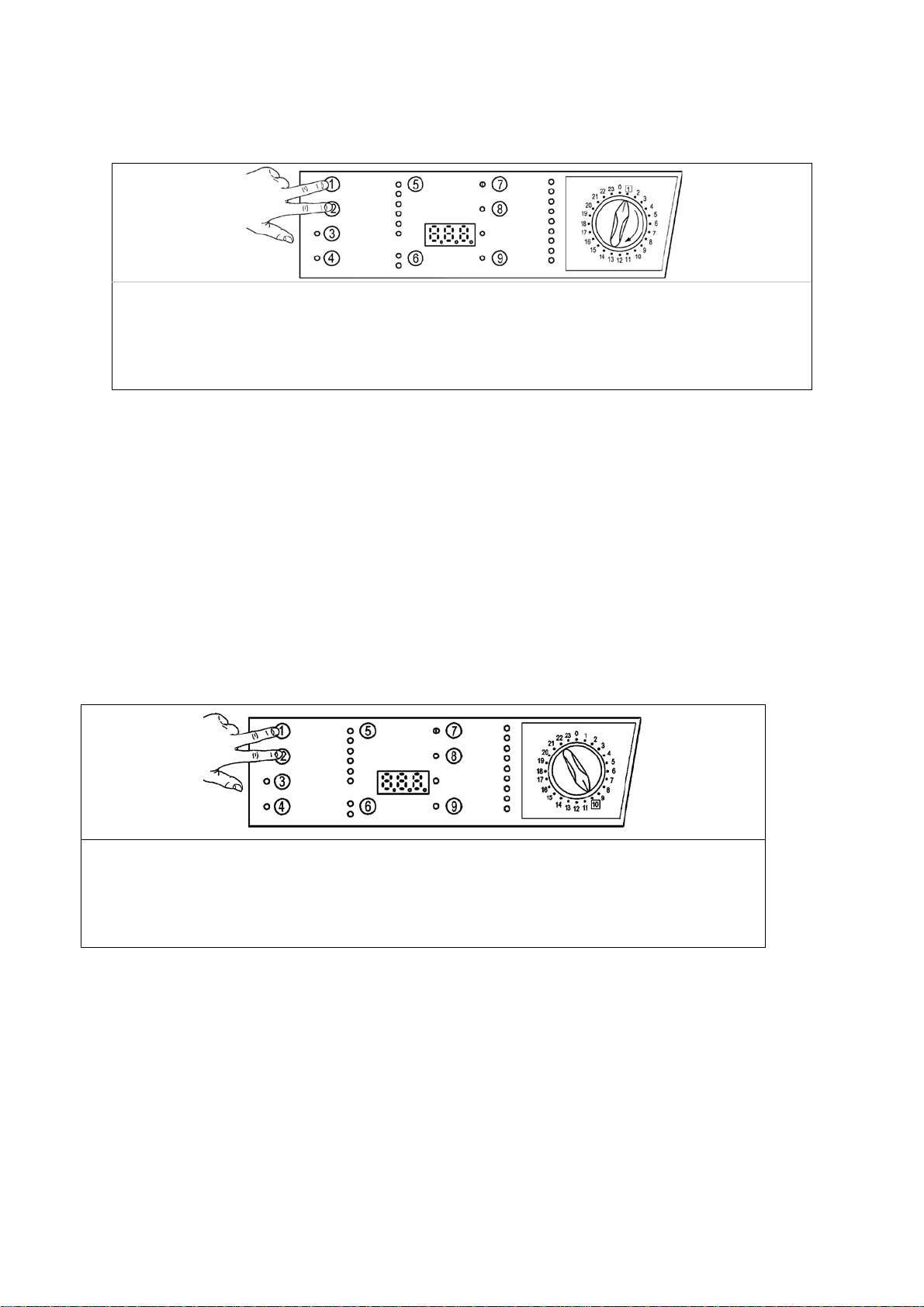

2.7 LCD Version without selector and button ON/OFF switch

2.7.1 Access to diagnosti cs system

1. Reset the set programme and switch the appliance off.

2. Press the 10 and 11 buttons, simultaneously, then, holding them down, switch the appliance on with

ON/OFF button.

3. Hold the buttons down till DIAGNOSTIC MODE appears (about 5 seconds).

4. To exit the diagnostic system switch the appli ance off, on and then off again.

2.7.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Five minutes aft er the switching on, press and hold down the 10 and 11 buttons simultaneously for 2

seconds, the LCD displ ay shows the l ast alarm codes (of the main board and displ ay boar d) . The

displayi ng of t he alarms depends on the time in which the buttons are hol d down.

ª During the time t he alarm is displayed, the applianc e conti nues to perform the cycle or, if it is in the

selection phase, it keeps in memory the options previously chosen.

2.7.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r eoccurs during the diagnostics control aft er the r epar ation of the applianc e

1. Select diagnostic mode and with button 4 go to tenth position (alarm reading)

2. Press simultaneously buttons 10 and 11.

3. Hold them down until the alarms are cancelled.

QUICK GUIDE AND APPLIANCES LIST 22/176 599 72 40-80

Page 23

EWM1000plus EWM2000evo EWM3000new

2.8 LCD Version with selector and button ON/OFF switch

2.8.1 Access to diagnosti cs system

1. Cancel the set progr amme and switch the appliance off.

2. Press the start/pause and exit buttons simultaneousl y , t hen, holding them down, switch t he

appliance on rotating the programme selector of one position clockwise.

3. Hold the START/PAUSE and EXIT buttons down up to DIAGNOSTIC MODE appears (about 5

seconds).

4. To exit the diagnostic system switch the appli ance off, on and then off again.

2.8.2 Rap id reading of alarm codes

The last alarm code can be displayed even if the programm e selector is not in the tenth position

(diagnostic s) or if the appliance is in normal operating mode (e.g. during the ex ec ution of the washing

programme):

ª Five minutes aft er the switching on, press and hold down the START/PAUSE and EXIT buttons for 2

seconds, the LCD displ ay ing shows the last alarm codes (of the main boar d and display board). The

displayi ng of t he alarms depends on the time in which the buttons are hol d down.

ª During the time t he alarm is displayed, the applianc e conti nues to perform the cycle or, if it is in the

selection phase, it keeps in memory the options previously chosen.

2.8.3 Can celling the last alarm

It is good practice to cancel the last alarm, after readi ng the alarm code to check whether the alarm r eoccurs during the diagnostics control aft er the reparation of the appliance

1. Select diagnostics mode and turn the programme sel ector to the tenth position (reading of alarm)

2. Press simultaneously START/PAUSE button and button EXIT (nearest option to START/PAUSE

button).

3. Hold down the START/PAUSE and EXIT button until the alarms are c anc elled.

QUICK GUIDE AND APPLIANCES LIST 23/176 599 72 40-80

Page 24

EWM1000plus EWM2000evo EWM3000new

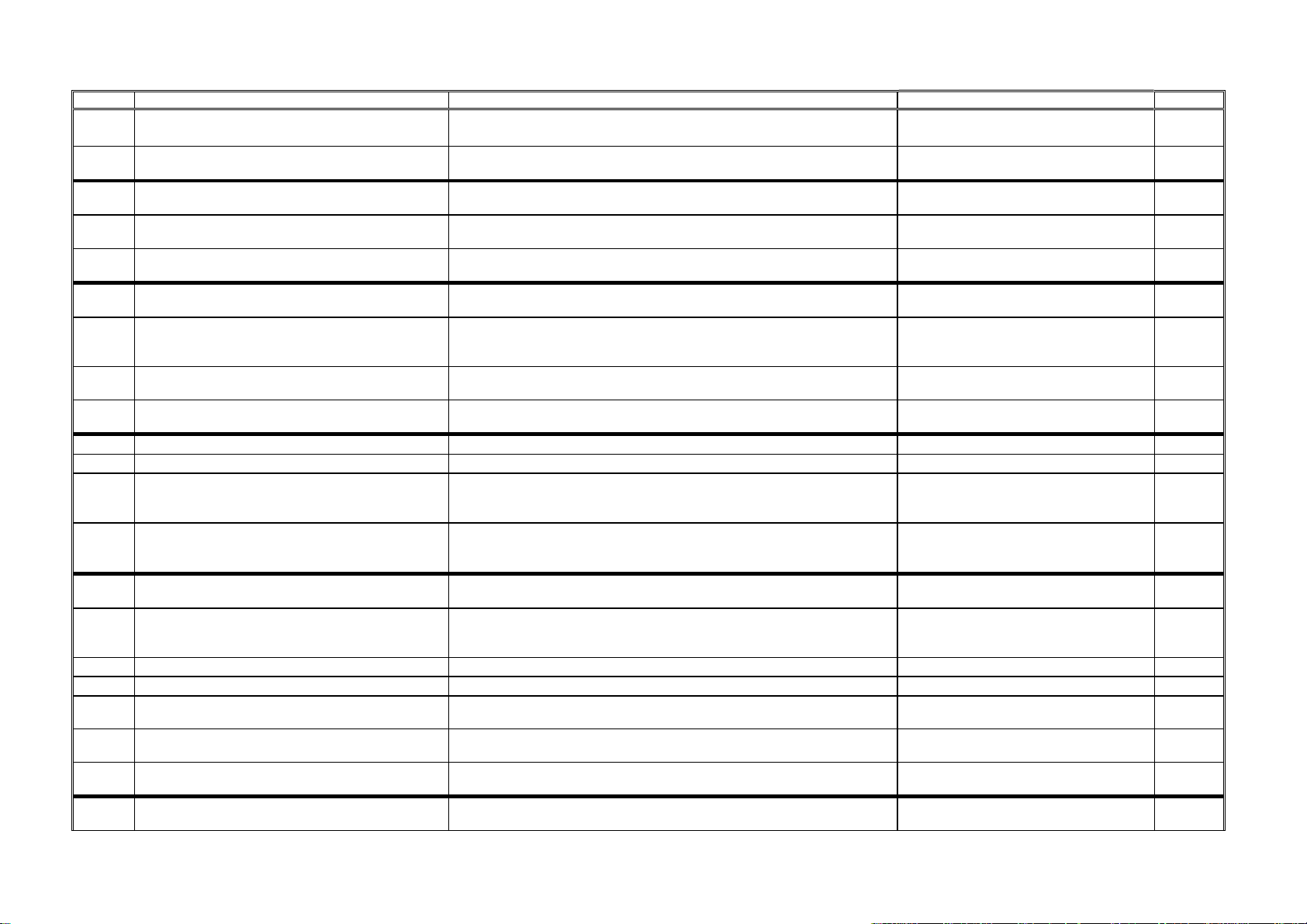

2.9 Phases of the diagnostics test

Independently of the type of selector, after activating the diagnostics system, the operation diagnostics of

the different components and the reading of the alarm s can be performed, by rotating the sel ec tor

clockwise.

In models with digit the code of the selector position is display ed for a second.

In the diagnostics cycle all alarms are activated. If duri ng the cycle operati on an alarm occurs, the appliance

blocks and the LEDs (and the display) flash indic ating the relative code.

Diagnostics phases

Selector

1

2

3

4

5

6

7

8

9

Only

pushbutton

Components actioned Operating conditions Function checked

All the LEDs light in

sequence. When a

button is pressed, the

corresponding LED

lights (and the buzz er , if

featured, sounds)

Door interloc k Washing

solenoid

Door interloc k Pre-wash

solenoid

Door interloc k

Pre-wash and wash

solenoids

Door interloc k .

Bleach/stains solenoid.

Door interloc k

Washing solenoid if the

level of water in the tub is

below 1st level Heating

element.

Door interloc k . (Washing

solenoid if the l ev el of

water in the tub is bel ow

1st level). Motor (55 rpm

clockwise, 55 rpm

counter-clockwise, 250

rpm impulse)

Always activated

Door locked

Water level below

anti-flooding level

Maximum time 5

minutes

Door locked

Water level below

anti-flooding level

Maximum time 5

minutes

Door locked

Water level below

anti-flooding level

Maximum time 5

minutes

Door locked

Water level below

anti-flooding level

Maximum time 5

minutes

Door locked.

Water at 1st level.

Maximum time 10

min. or up to 90ºC. (*)

Door locked

Water level at 1st

level.

Operation of

the user

interface

Water ducted

through

washing

compartment

Water ducted

through prewash

compartment

(bleach)

Water ducted

through

conditioner

compartment

Water ducted

through

bleach/stains

compartment

Heating

Check for leaks

from the tub

Drain and

Door interloc k

Drain pump Motor up to

650 rpm then at

maximum spin speed

Drying heater

Fan

Condensation solenoid

Drain pump

Motor

Door locked

Water leve l lowe r

than anti-boi ling

level for spinning

Door closed Drying

spin; control

of congruence

in closure of

level pressure

switches

Displayed

parameters (1 )

Button

codification

(**)Selection

position code

(**)Selection

position code

(**)Selection

position code

(**)Selection

position code

(**)Selection

position code

(**)Selection

position code

(**)Selection

position code

(**) selector

position code

QUICK GUIDE AND APPLIANCES LIST 24/176 599 72 40-80

Page 25

EWM1000plus EWM2000evo EWM3000new

10

11, 12 ...24

(*)In most cases, this time is sufficient to c heck the heating. However, the time c an be inc r eased by

repeating the phase wit hout draining the water: for a moment t o a diff er ent phase of the diagnostics cycle

and then back to the heating c ontrol phase (if the temperature i s higher than 80°C, heating does not take

place).

(**) See tables of following pages.

(1) Model s with Display.

All LEDs light i n sequence. Pres si ng a button the corresponding LED lights (and the Buzzer

sounds, if featur ed)

Reading/cancelling last alarm Alarm code

QUICK GUIDE AND APPLIANCES LIST 25/176 599 72 40-80

Page 26

EWM1000plus EWM2000evo EWM3000new

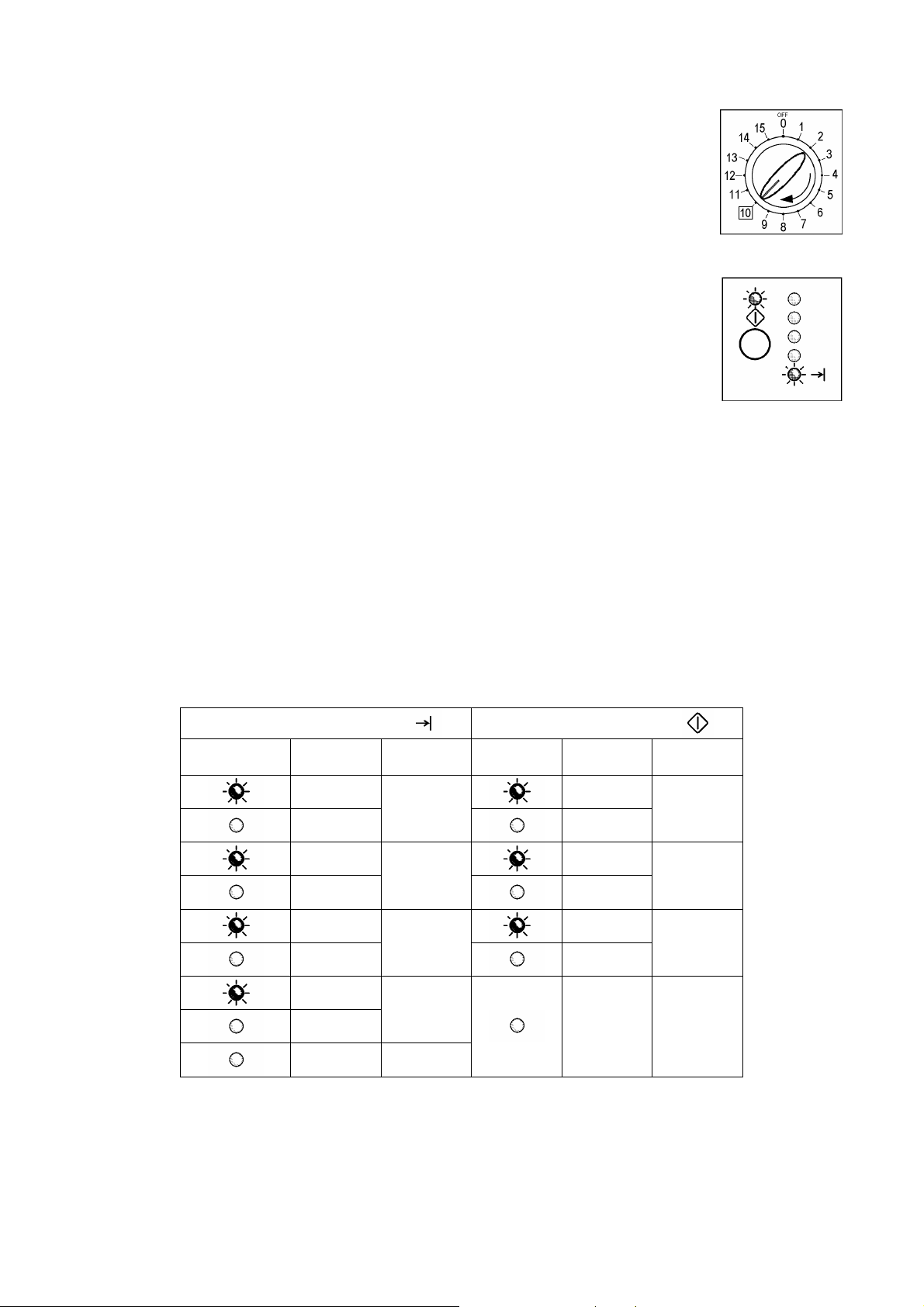

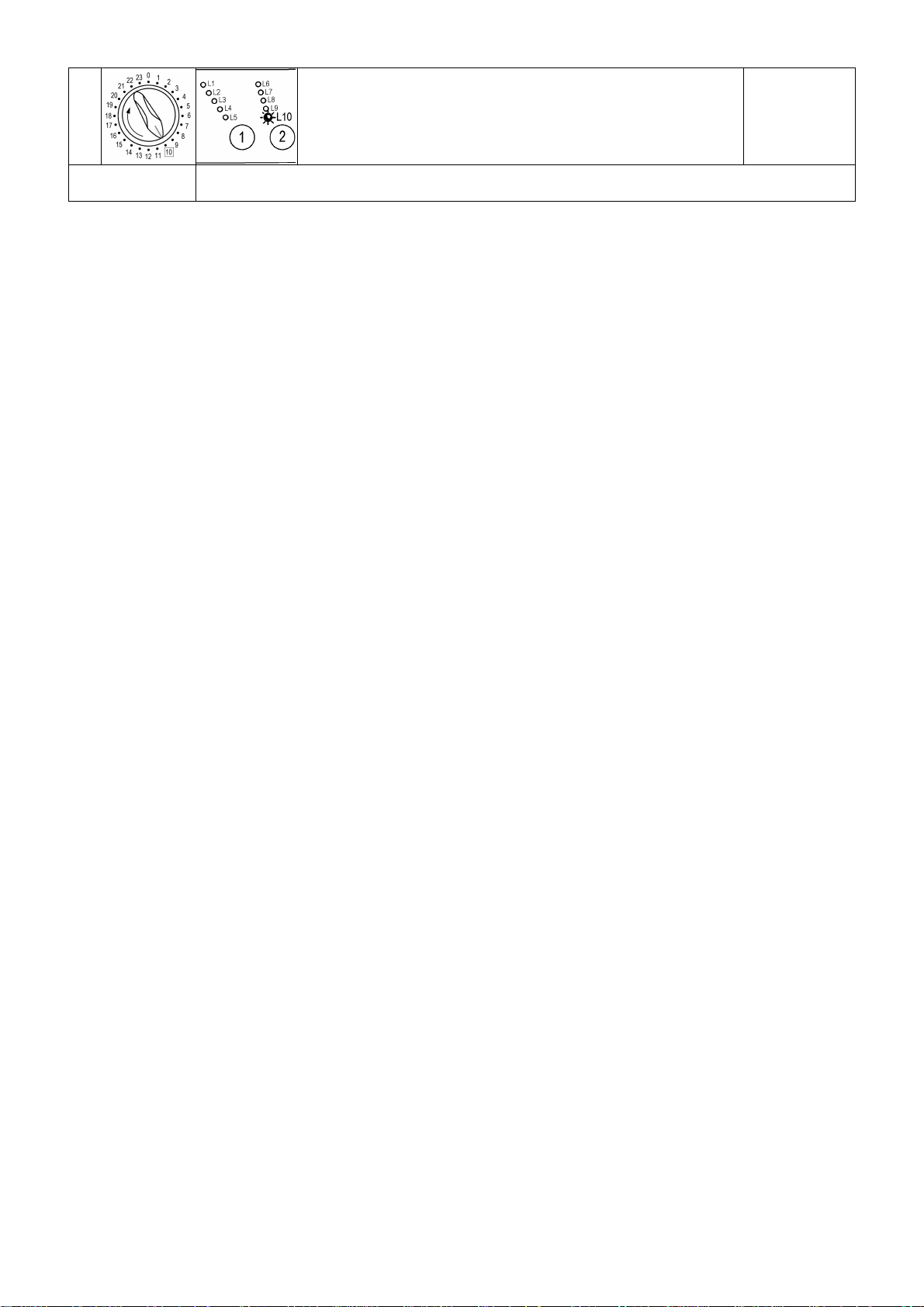

2.10 Reading the alarm codes

In order to read the last alarm code memorized in the EEPROM on the

PCB:

with knob

• Enter diagnostics mode

• Irrespective of the type of PCB and configurati on, t urn the

programme sel ector clockwise to the tenth position.

without knob

• Press the Fabrics (1) or Temper ature (2) button until LED L10

lights.

2.10.1 Displaying the alarm

The alarm is displayed by a r epeated flashing sequence of the two LEDs (0.4

seconds lit, 0.4 seconds off, with an interval of 2.5 seconds between sequences).

The buzzer (if featured) will sound “bips” in synchronization with the flashing of

the LEDs.

• END OF CYCLE LED → indicates the first digit of the alarm code (family)

• START/PAUSE → indicates the second digit of the alarm code (number

within the family)

These two LEDs are featured on all models (though they are configured

differently), and flash simultaneously.

Notes:

• The first letter of the alarm code “E” (Error) is not displayed, since this letter is

common to all alarm codes.

• The alarm code “f amili es” are sho wn in hexadecimal; in other words:

→ A is represented by 10 fl ashes

→ B is represented by 11 fl ashes

→ ...

→ F is represented by 15 flashes

• Configurati on er r or s are shown by the flashing of a series of LEDs.

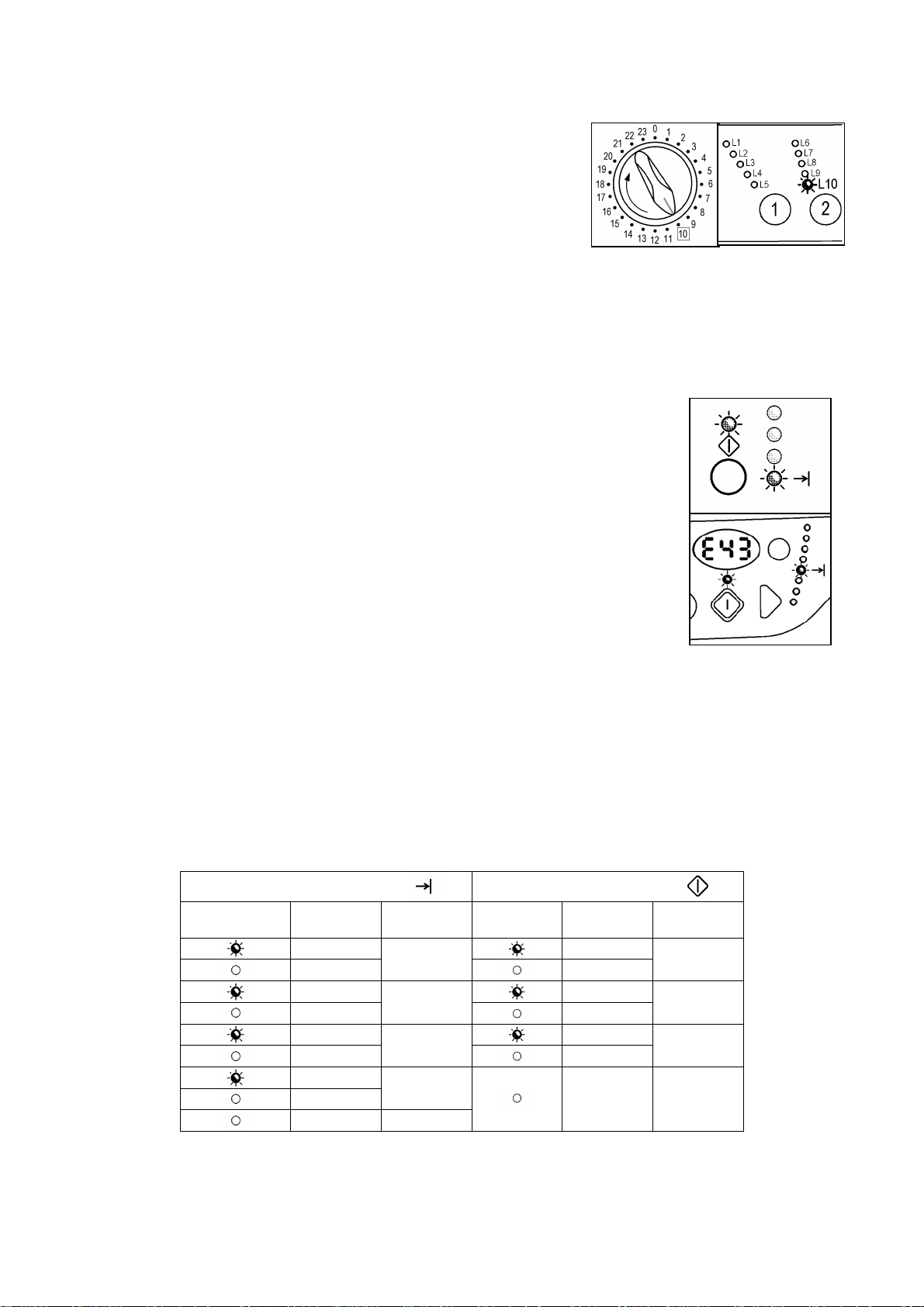

2.10.2 Examples of alarm displays

Example: Alarm E43 will displ ay the following:

• On the display, if featured, E43

• The sequence of four flashes of the End-of-cycle LED indicates the first number E

• The sequence of three flashes of the Start/Pause LED indicates the second number E4

END-OF-CYCLE LED

On/Off

Time

(Sec.)

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

2.5 Pause

Value On/Off

1

2

3

4

START/PAUSE LED

Time

(Sec.)

0.4

0.4

0.4

0.4

0.4

0.4

3,3 Pause

43;

Value

1

2

3

3;

QUICK GUIDE AND APPLIANCES LIST 26/176 599 72 40-80

Page 27

EWM1000plus EWM2000evo EWM3000new

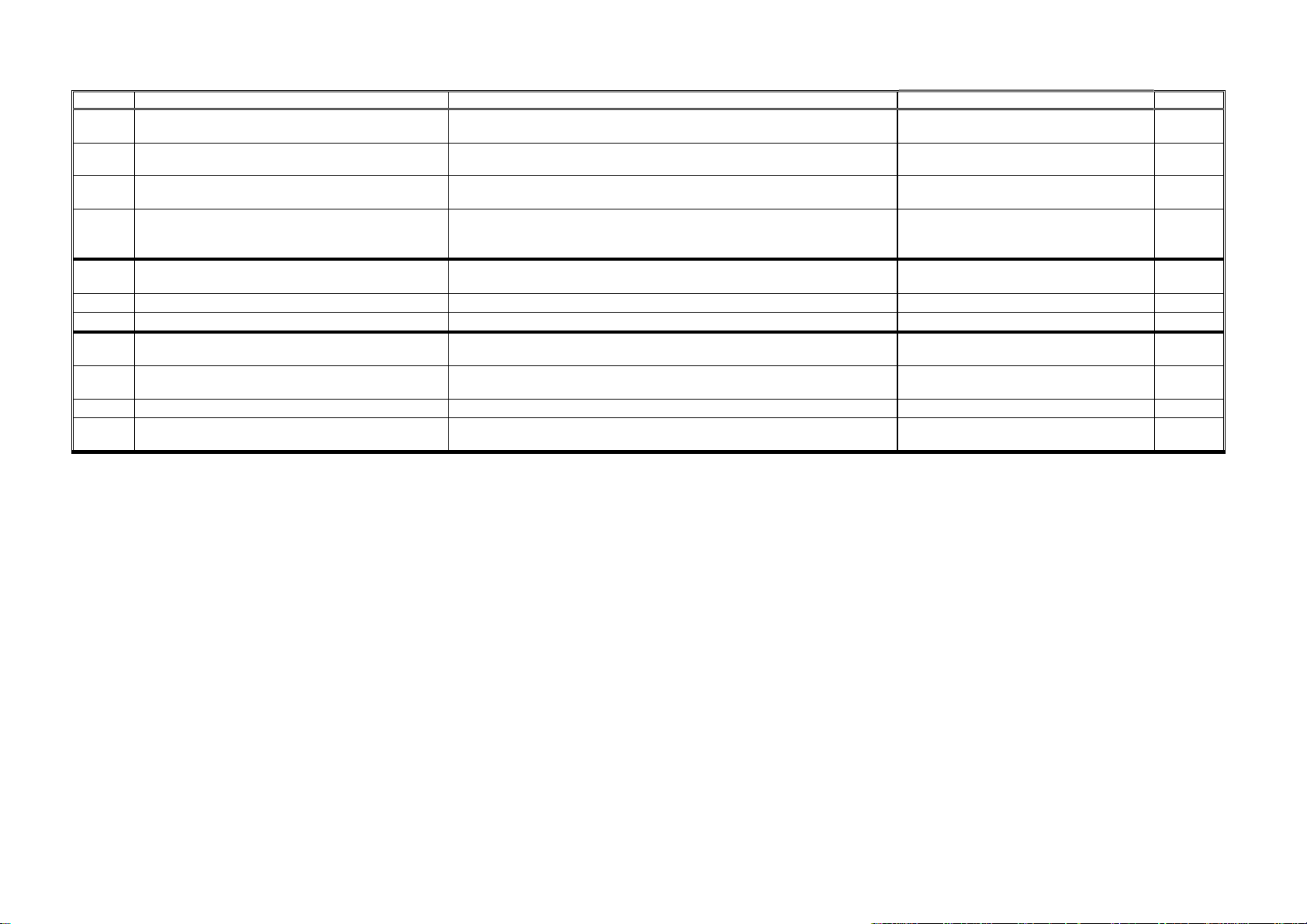

2.11 Table of alarms codes EWM 1000plus EWM2000EVO EWM3000NEW

Alarm Description Possible malfunction Action/status of machine Reset

E00

Tap closed or water pressure too low; Drain tube improperly positioned;

E11 Poor water fill before wash cycle

Difficulty in water fill during drying (maximum

E12

time 3 min. water fill in drying during the wash

load unrolling phase)

E13 Water leaks

E21 Poor draining

Difficulty in water fill during drying or drying

E22

condenser clogged (anti-boiling pressure

switch closed on “FULL”)

Defective triac for drain pump Drain pump defective; Wiring defective; Main board defective.

E23

Malfunction in sensing circuit on triac for drain

E24

pump

Malfunction in pressure switch circuit

E31

(frequency of signal from pressure switch out

of limits)

Electronic pressure switch improperly

calibrated (level on electronic pressure switch

differs from 0-66 mm after initial calibration

E32

drain and when antiboiling pressure switch is

on “empty”).

Inconsistency between level on electronic

pressure switch and level on antiboiling

E33

pressure switch 1-2 (fault persists for at least

60 sec.).

Inconsistency between level on electronic

pressure switch and level on antiboiling

E34

pressure switch 2 (fault persists for at least 60

sec.).

Water fill solenoid valve is defective; Leaks from water circuit on

pressure switch; Pressure switch defective; Wiring defective; Main board

defective.

Tap closed or water pressure too low; solenoid valve; pressure switch

water circuit; pressure switches; wiring; main board.

Drain tube improperly positioned; Water pressure too low;

Water fill solenoid valve is defective; Water circuit on pressure switch is

leaking/clogged; Pressure switch defective.

Drain tube kinked/clogged/improperly positioned; Drain filter

clogged/dirty; Drain pump defective; Pressure switch defective; Wiring

defective; Main board defective; Electrical current leak between heating

element and ground.

Drain hose kinked; filter clogged: drying condenser clogged; drain pump

faulty; pressure switches faulty; wiring; main circuit board defective;

current leakage between heater and ground.

Main board defective.

Pressure switch; Wiring; Main board; Cycle stops with door locked OFF/reset

Tap is closed or water pressure is too low;

Solenoid valve;

Water circuit on pressure switches; pressure switches;

Wiring; main board;

Pressure switch defective;

Electrical current leak between heating element and ground; Heating

element; Wiring defective;

Main board defective.

Water circuit;

Pressure switch defective;

Electrical current leak between heating element and ground; Heating

element; Wiring defective;

Main board defective.

Water circuit;

No alarm ---

Cycle is paused with door locked Start

Cyc le is paused Start

Cycle is paused with door locked Start

Cyc le is paused Start

Cyc le is paused Start

Emergency drain procedure - Cycle

stops with door unlocked

Emergency drain procedure - Cycle

stops with door unlocked

Cyc le is paused Start

Emergency drain procedure - Cycle

stops with door unlocked

Emergency drain procedure - Cycle

stops with door unlocked

OFF/reset

OFF/reset

OFF/reset

OFF/reset

QUICK GUIDE AND APPLIANCES LIST 27/176 599 72 40-80

Page 28

EWM1000plus EWM2000evo EWM3000new

Alarm Description Possible malfunction Action/status of machine Reset

Water fill solenoid valve is defective; Leaks from water circuit on

Overflow

E35

Sensing circuit on antiboiling pressure switch

E36

1 defective

1st level sensing circuit faulty PCB faulty. Cycle blocked, door locked. OFF/reset

E37

Pressure chamber blocked

E38

(water level does not vary for at least 30 sec.

during drum rotation

“HV” sensor of anti-overflow level faulty PCB faulty. Cycle blocked, door locked. OFF/reset

E39

Heating elem. relay sensi ng fa ul ty PCB faulty. Cycle blocked, door locked OFF/reset

E3A

E41 Door open

Problems of door closure

E42

Interlock power supply triac faulty

E43

Door interlock sensor faulty PCB fa ulty. ( S afety drain cycle) C ycle b locked OFF

E44

Door interlock sensing circuit triac faulty PCB faulty (Sa fety drain cycle) Cy cle block ed OFF

E45

pressure switch; Pressure switch defective; Wiring defective; Main board

defective.

Main board defective.

Electrical current leak between drying heating element and ground

Pressure switch hydraulic circuit;

Pressure switches;

Motor drive belt broken;

Door interlock faulty; wiring faulty;

PCB faulty.

Door interlock faulty; wiring faulty;

PCB faulty.

Door interlock faulty; wiring faulty;

PCB faulty.

E51 Motor power supply triac short-circuited PCB faulty; current leakage from motor or from wiring.

No signal from motor tachometric generator Motor faulty; wiring faulty; PCB faulty

E52

Motor triac sensing circuit faulty PCB faulty. Cycle blocked, door locked OFF/reset

E53

Motor relay cont acts sticking PCB faulty; current leakage from motor or from wiring

E54

Inverter is drawing too much current (>15A)

E57

Motor is drawing too much current (>4.5A)

E58

No signal from tachometric generator for more

E59

than 3 seconds

E5A Overheating on heat dissipater for inverter

Input voltage is lower than 175V Wiring defective, Inverter board defective

E5B

Input voltage is too high

E5C

Data transfer error between inverter and main

E5D

board

Motor defective; Wiring defective on inverter for motor, inverter board

defective.

Motor defective; Wiring defective on inverter for motor, inverter board

defective, abnormal motor operation (motor overloaded).

Motor defective; Wiring defective on inverter for motor;

Inverter board defective.

Inverter board defective. NTC open (on the inverter board).

Overheating caused by continuous operation or ambient conditions (let

appliance cool down)

Inverter board defective, the mains voltage is too high (meas ure the

mains voltage)

Line interference, Wiring defective, defective main board or inverter

board

Cyc le stops. Emerg ency drain

procedure. Drain pump continues to

operate (5 min. on, then 5 min. off, etc.).

Cycle stops with door locked OFF/reset

Heating phase skipped. ---

Cycle paused Start

Cycle paused Start

(Safety drain cycle) Cycle blocked OFF

Cycle blocked, door locked (after 5

attempts)

Cycle blocked, door locked (after 5

attempts)

Cycle blocked, door locked (after 5

attempts)

Cycle stops with door locked (after 5

attempts).

Cycle stops with door locked (after 5

attempts).

Cycle stops with door locked (after 5

attempts).

Cycle stops with door locked (after 5

attempts).

Cycle stops with door locked (after 5

attempts).

Cycle stops with door locked (after 5

attempts).

Cycle stops with door locked (after 5

attempts).

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

QUICK GUIDE AND APPLIANCES LIST 28/176 599 72 40-80

Page 29

EWM1000plus EWM2000evo EWM3000new

Alarm Description Possible malfunction Action/status of machine Reset

Communication error between inverter and

E5E

main board

Inverter board fails to start the motor Defective inverter board, Defective wiring, defective main board

E5F

E61 Insufficient heating during wash cycle

Overheating during wash cycle

E62

Relay supplying power to heating element

E66

defective

E71 NTC sensor for wash cycle defective

Fault in NTC sensor on drying condenser

E72

(voltage out of range = short-circuit, open

circuit)

Fault in NTC sensor on drying duct (voltage

E73

out of range = short-circuit, open circuit)

NTC sensor for wash cycle improperly

E74

positioned

Error in selector reset position PCB faulty (Wrong configuration data). Selector, wiring --- OFF/reset

E82

Error in reading selector PCB faulty (Wrong configuration data). Selector, wiring Cycl e cancelled ---

E83

Recirculation pump defective (inconsistency

between the state of the sensing circuit for the

E84

recirculation pump and the state of the triac)

Defective sensing circuit on triac for

recirculation pump (input voltage on

E85

microprocessor remains at 0 or 5 V).

Communication error between main board and

E91

display board

Inconsistency in communication between main

E92

board and display board

(versions not compatible)

Configuration error on appliance Main board defective (Improper programming). Cycle stops OFF/reset

E93

Configuration error on wash cycle Main board defective (Improper programming). Cycle stops OFF/reset

E94

Communication error between microprocessor

E95

and EEPROM

Inconsistency between list of programmes and

E97

configuration of cycle

Communication error between microprocessor

E98

and clock

Frequency of power supplied to appliance out

EB1

of limits

Defective wiring between main board and inverter board,

Defectiv e inverter board, defective m ain boar d

Defective NTC sensor for wash cycle; Heating element defective; Wiring

defective; Main board defective.

Defective NTC sensor for wash cycle; Heating element defective; Wiring

defective; Main board defective.

Mai n board defective; Elec tri cal curren t lea k from heating element to

ground.

Defective NTC sensor; Wiring defective;

Main board defective.

Drying NTC sensor (condenser) defective; wiring defective; main circuit

board defective.

Drying NTC sensor (duct) defective; wiring defective; main circuit board

defective.

NTC sensor improperly positioned; Defective NTC sensor; Wiring

defective; Main board defective.

Recirc ulation p ump;

Wiring;

Main board;

Main board

Wiring defective; Control/display board defective

Main board defective.

Wrong control/display board;

Wrong main board (not right for model).

Main board defective. Cycle stops OFF/reset

Main board defective (Improper programming). Cycle stops OFF/reset

Display board faulty The cycle continues -----------

Problems with the power mains (wrong power/interference); Main board

defective.

Cycle stops OFF

Cycle stops with door locked (after 5

attempts).

Heating phase is skipped Start

Safety drain cycle - Cycle stops with door

unlocked

Safety drain cycle - Cycle stops with door

unlocked

Heating is skipped Start

Heating is skipped Start

Heating is skipped Start

Heating is skipped Start

Machin e drains and cycle stops (with

door unlocked)

Machin e drains and cycle stops (with

door unlocked)

Cycle stops ---

Cycle stops ---

Cycle stops ---

OFF/reset

OFF/reset

OFF/reset

OFF/reset

OFF/reset

QUICK GUIDE AND APPLIANCES LIST 29/176 599 72 40-80

Page 30

EWM1000plus EWM2000evo EWM3000new

Alarm Description Possible malfunction Action/status of machine Reset

Problems with the power mains (wrong power/interference); Main board

defective.

Problems with the power mains (wrong power/interference); Main board

defective.

Main board defective, defective wiring

Main board defective

Mai n board defective, Solenoi d valve def ecti ve

Drain tube clogged/kinked/placed too high;

Drain filter dirty/clogged.

Too much detergent used; Drain tube clogged/kinked;

Drain filter dirty/clogged.

Tap closed, water pressure too low --------------------------- Reset

Cycle stops --Cycle stops ---

Machin e drains and cycle stops (with

door unlocked)

Machin e drains and cycle stops (with

door unlocked)

Cycle stops with door locked (after 5

attempts).

Warning is displayed at end of cycle

(relative LE D is l it )

Warning is displayed at end of cycle

(relative LE D is l it )

OFF/reset

OFF/reset

OFF/reset

Input voltage too high

EB2

Input voltage too low

EB3

Inconsistency between safety relay and

EBE

sensing circuit

Sensing circuit on safety system defective

EBF

(input voltage on microprocessor remains at 0

or 5 V).

Solenoid valve inoperative but flow meter

EC1

operating

Signal from turbidity sensor out of limits Turbidity sensor defective, Main board defective, Wiring defective ----------------------- Start/reset

EC2

Signal from weight sensor out of limits Weight sensor defective, Main board defective, Wiring defective --- Start/reset

EC3

Drain filter clogged

EF1

(drain cycle too long)

Too much detergent

EF2

(too much foam during drain cycles)

“Water Control” system tripped Water leaks onto base frame; water control system defective. Machine drains and cycle stops OFF/reset

EF3

Water fill pressure too low, no signal from flow

EF4

meter and solenoid valve is open

---

---

QUICK GUIDE AND APPLIANCES LIST 30/176 599 72 40-80

Page 31

EWM1000plus EWM2000evo EWM3000new

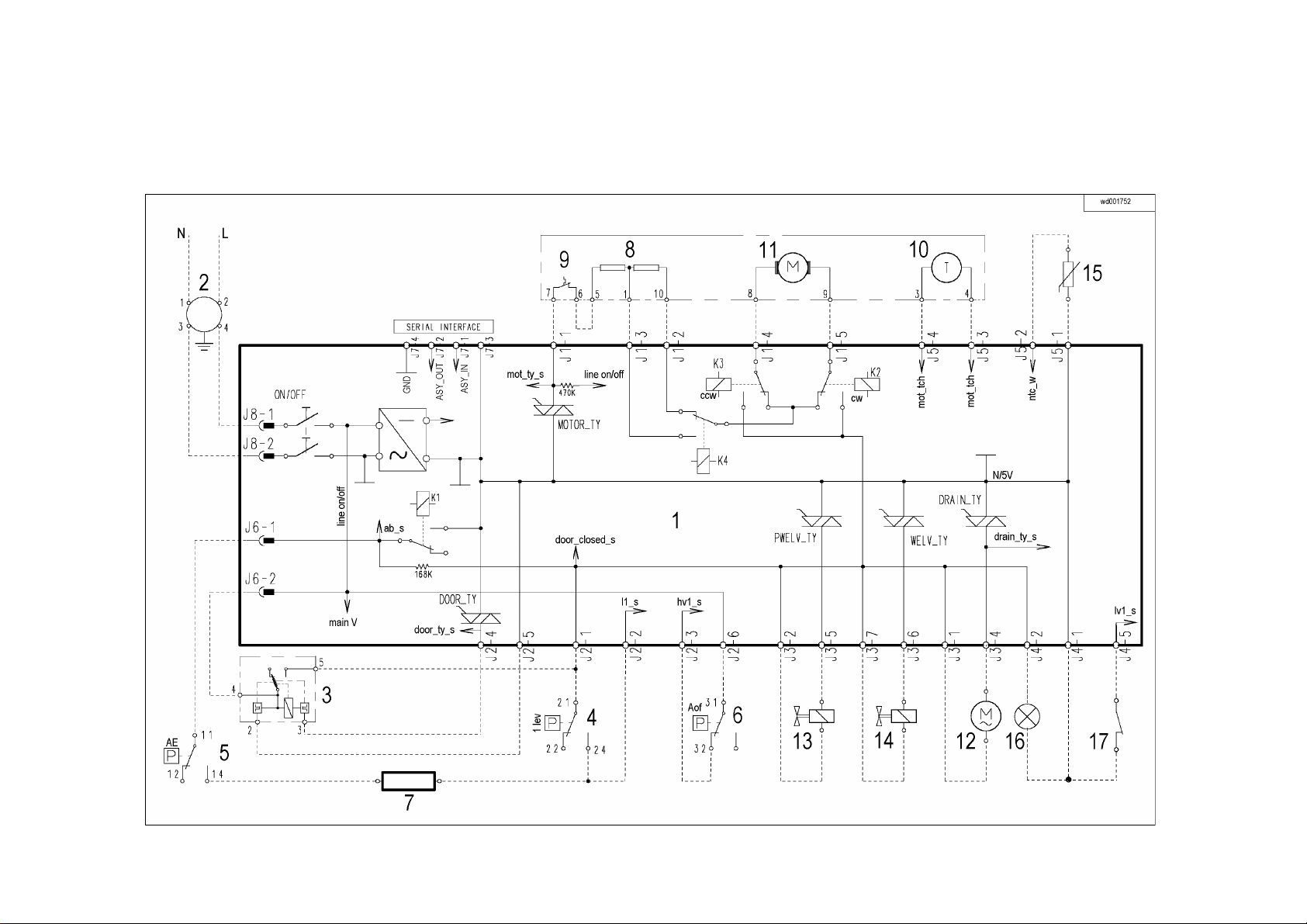

2.12 Basic circuit diagram EWM1000PLUS

2.12.1 Diagram (without aqua control)

QUICK GUIDE AND APPLIANCES LIST 31/176 599 72 40-80

Page 32

EWM1000plus EWM2000evo EWM3000new

2.12.2 Key to circuit diagram

Components in the appli ance Components of the PCB

1. Electronic board

2. Suppressor

3. ON/OFF switch

4. ON/OFF pilot lamp

5. Door interlock

6. Anti-boiling pressure switch

7. Heating element

8. 1st level pressure swit c h

9. Anti-overflow pressure switch (not all models)

10. Pre-wash solenoid valve

11. Wash solenoid valve

12. Bleach solenoid valve (not all models)

13. Drain pump

14. Closed door lamp (not all models)

15. Control/ display board

16. Thermal cut-out (motor)

17. Stator (motor)

18. Rotor (motor)

19. Tachometric generator (motor)

20. NTC temperature sensor

BELV_TY Bleach solenoid Triac

DOOR_TY Door interlock Triac

DRAIN_TY Drain pump Triac

K1 Heating elem ent r elay

K2 Motor relay: clockwise rotation

K3 Motor relay: anti-clockwise rotation

K4 Motor relay: half fi eld power supply (models with higher s pin at

1200 rpm)

MOTOR_TY Motor Triac

PWELW_TY Pre-wash sol enoid Triac

Serial interface Asynchronous serial interface

WELV_TY Wash solenoid Triac

QUICK GUIDE AND APPLIANCES LIST 32/176 599 72 40-80

Page 33

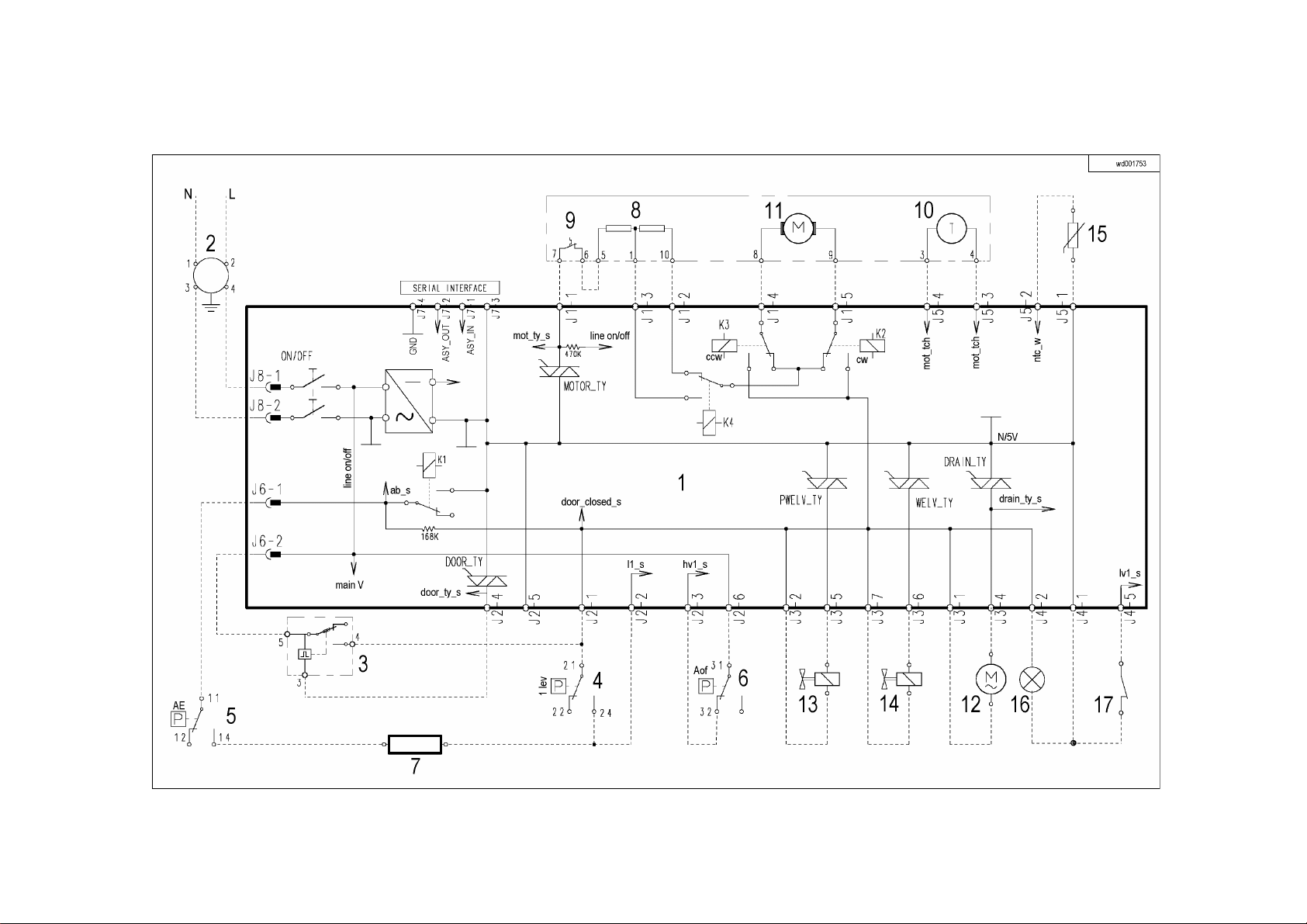

2.12.3 Diagram (with aqua control)

EWM1000plus EWM2000evo EWM3000new

QUICK GUIDE AND APPLIANCES LIST 33/176 599 72 40-80

Page 34

EWM1000plus EWM2000evo EWM3000new

2.12.4 Key to circuit diagram

Components in the appli ance Components of the PCB

1. Electronic board

2. Suppressor

3. Drain pump

4. Aqua control

5. Anti- boiling pressure switch

6. Door interlock

7. Heating element

8. 1st lev el pressure switch

9. Anti-overflow pressure switch (not all models)

10. Pre-wash solenoid valve

11. Wash solenoid valve

12. Bleach solenoid valve (not all m odels )

13. Closed door lamp (not all models )

14. Selector

15. Control/display board

16. Thermal cut- out (m otor)

17. Stator (motor)

18. Rotor (motor)

19. Tachometric gener ator (motor)

20. NTC temperat ur e sensor

BELV_TY Bleach solenoid Triac

DOOR_TY Door interlock Triac

DRAIN_TY Drain pump Triac

K1 Heating elem ent r elay

K2 Motor relay: clockwise rotation

K3 Motor relay: anti-clockwise rotation

K4 Motor relay: half fi eld power supply (models with higher s pin at

1200 rpm)

MOTOR_TY Motor Triac

PWELW_TY Pre-wash sol enoid Triac

Serial interface Asynchronous serial interface

WELV_TY Wash solenoid Triac

QUICK GUIDE AND APPLIANCES LIST 34/176 599 72 40-80

Page 35

EWM1000plus EWM2000evo EWM3000new

2.13 Basic circuit diagram with sensor EWM2000EVO

QUICK GUIDE AND APPLIANCES LIST 35/176 599 72 40-80

Page 36

2.13.1 Key for circuit diagram

Electric compon ents Components on main board

1. Main board

2. Interference filter

3. Drain pump

4. Aqua control

5. ON/OFF switch (built into selector)

6. Anti-boiling pressure switch AE2

7. Door lock unit

8. Heating element

9. Anti-boiling pressure switch AE1

10. Anti- overflow pressure switch

11. Recirc ulation pump

12. P r e- wash solenoid valv e

13. Wash solenoid valve

14. Bleach solenoid valve

15. Pilot lamp

16. Select or

17. Control/ display board

18. Turbi dity sensor

19. Flow meter

20. Analogi c pressure switch

21. NTC temperature sensor

22. Thermal cut-out (motor)

23. Stator (motor)

24. Rotor (motor)

25. Tachometric generator (motor)

EWM1000plus EWM2000evo EWM3000new

BEL_TY Bleach solenoid Triac

DOOR_TY Door interlock Triac

DRAIN_TY Drain pump Triac

REC_TY Recirculation pum p Tr iac

K1 Heating elem ent r elay

K4 Motor relay: clockwise rotation

K3 Motor relay: anti-clockwise rotation

K4 Motor relay: half fi eld power supply (models with higher s pin

than 1200 rpm)

MOTOR_TY Motor Triac

PWELW_TY Pre-wash sol enoid Triac

WELV_TY Wash solenoid Triac

QUICK GUIDE AND APPLIANCES LIST 36/176 599 72 40-80

Page 37

EWM1000plus EWM2000evo EWM3000new

2.14 Basic circuit diagram with sensor EWM3000NEW

QUICK GUIDE AND APPLIANCES LIST 37/176 599 72 40-80

Page 38

2.14.1 Key for circuit diagram

Electrical compo nents on appliance Components on main board

1. Main board

2. Interference filter

3. Drain pump

4. ON/OFF switch (built into selector)

5. Aqua Control

6. Antiboiling pressure switch AE2

7. Door lock unit

8. Heating element

9. Antiboiling pressure switch AE1

10. Recirc ulation pump

11. Solenoid valve for prewash

12. Solenoid valve for wash

13. Solenoid valve for bleach

14. Door opening lamp

15. Select or

16. Control/ display board

17. Flow meter

18. Analog pressure switch

19. Turbi dity sensor

20. NTC temperature sensor

21. Tachometric generator (on motor)

22. Windings (on motor)

23. Inverter (for motor speed control)

EWM1000plus EWM2000evo EWM3000new

BELV_TY Triac for solenoid valve for bleach dispenser

DOOR_TY Triac for door lock unit

DRAIN_TY Triac for drai n pum p

K1 Relay controll ing heating element

K2 Safety relay

PWELV_TY Triac for solenoid valve for prewash

REC_TY Triac for recirc ulation pump

WELV_TY Triac for solenoid valve for wash

QUICK GUIDE AND APPLIANCES LIST 38/176 599 72 40-80

Page 39

EWM1000plus EWM2000evo EWM3000new

2.15 Connectors on circuit board EWM1000plus

J1 J2 J3 J4

Motor

J1-1 Motor (triac)

J1-2 Motor (rotor)

J1-3 Motor (rotor)

J1-4 Motor (stator - full range)

J1-5 Motor (stator - 1/2 range)

J5 J6 J7 J8

J5-1 Drum positioning (DSP)

(sensing)

J5-2 Drum positioning (DSP)

(+5v)

J5-3 Tachometric generator

motor

J5-4 Tachometric generator

motor

J5-5 NTC temperature sensor

washing (sensing)

J5-6 NTC temper ature sensor

washing (+5v)

J10 J12 J14

J10-1 Line ON/OFF

J10-2 Door safety interlock

(triac)

Washing solenoid

J10-3

(line)

Door lamp

J2-1 Door lamp

J2-2 Door lamp

Heating element:

J6-1 Relay

J6-2 Line

J12-1 LV2 (sensing)

J12-2 Door safety interlock

J3-1 Door safety interlock

(line-sensing)

J3-2 Drain pump (line)

J3-3 Aqua Control (line)

J3-4 Anti-overflow pressure

switc h (line)

J3-5 1st level (sensing)

J3-6 Anti-overflow (sensing)

J3-7 Drain pump (triac)

DAAS Interface:

J7-1 ASY_IN

J7-2 ASY_OUT

J7-3 Vcc (+5v)

J7-4 GND

Flowmeter

J14-1 GND

J14-2 Vcc (5v)

J14-3 Flowmeter_dgt_in