Page 1

ITEM #

MODEL #

NAME #

air-o-steam

SIS #

class B

LPG Gas Combi Oven 101

AIA #

Main Features

•Low temperature Steam cycle 25 °C to 99.4 °C: ideal

for sous-vide (vacuum packed) re-thermalization and

delicate cooking.

•Steam cycle 100 °C: seafood and vegetables.

•High temperature steam 100.5 °C - 130 °C.

•Combination cycle 25 °C to 250 °C: combining

convected heat and steam to obtain humidity

controlled cooking environment, accelerating the

cooking process and reducing weight loss.

•Hold function: provides an impulse ventilation ideal for

holding and light pastry.

•Variable fan speed. Radial fan.

•Reduced power cycle.

•air-o-clean™ automatic and built-in self cleaning

system (4 automatic and 1 semi-automatic cycles).

•Simple sensor core temperature probe included.

air-o-steam

class B LPG Gas Combi Oven 101

268712 (AOS101GBD2)LPG Gas Combi Oven 101 -

230V/1ph/60Hz

Short Form Specification

Item No.

Convection-steamer with dedicated steam generator guarantees a continuous

supply of fresh steam at all times.

air-o-flow: fresh air is blown into the oven from the outside, after it is pre-heated

it is pulled through the bi-functional fan, guaranteeing cooking evenness.

Humidity controlled through By-pass technology that guarantees the efficient use

of the steam generator thus reducing water and energy consumption. Manual

injection of water to add additional moisture in the cell.

air-o-clean: built-in cleaning system with four automatic pre-set cycles and one

semi-automatic cleaning cycle.

Cooking cycles: steam (100 °C), low temperature steam (25-99 °C), overheated

steam (101-130°C), hot air (25-300 °C), combi (25-250 °C), regeneration. 2-step

cooking with the possibility to combine different cycles. Half power, half speed and

pulse ventilation controls. Food probe for precise cooking. Double-glass door with

book-like opening maintains a cool external temperature and incorporates a drip

pan to collect excess condensation avoiding wet floors. Halogen lighting in the

cooking chamber. Side panels and interior in AISI 304 stainless steel.

Supplied with n.1 tray rack 1/1GN, 65mm pitch. Prearranged for LPG.

Construction

•High efficiency and low emissions burners.

•IPX 5 spray water protection certification for easy

cleaning.

•304 AISI stainless steel construction throughout.

•Seamless hygienic cooking chamber with all rounded

corners for easy cleaning.

•Double thermo-glazed door with open frame

construction, for cool outside door panel. Swing

hinged easy-release inner glass on door for easy

cleaning.

•Swing hinged front panel for easy service access to

main components.

Optional Accessories

•Couple of grids for whole chicken 1/1GN (8

per grid)

•Non-stick universal pan 1/1GN H=20mmPNC 922090 ❑

•Non-stick universal pan 1/1GN H=40mmPNC 922091 ❑

•Non-stick universal pan 1/1GN H=60mmPNC 922092 ❑

•Baking tray with 4 edges, perforated

aluminium (400x600x20)

•Baking tray with 4 edges, aluminium

(400x600x20)

•Baking tray with 4 edges, perforated

aluminium (325x530x20)

•Baking tray with 4 edges, aluminium

(325x530x20)

•Standard open base with tray support for

6&10x1/1GN

•Frying griddle GN 1/1 PNC 922215 ❑

•Double-click closing catch for doorPNC 922265 ❑

•Grid for whole chicken 1/1GN (8 per grid -

1,2kg each)

PNC 922036 ❑

PNC 922190 ❑

PNC 922191 ❑

PNC 922193 ❑

PNC 922194 ❑

PNC 922195 ❑

PNC 922266 ❑

class B LPG Gas Combi Oven 101

air-o-steam

APPROVAL:

Electrolux Professional

www.electrolux.com/foodservice

foodservice@electrolux.com

Page 2

air-o-steam

class B

LPG Gas Combi Oven 101

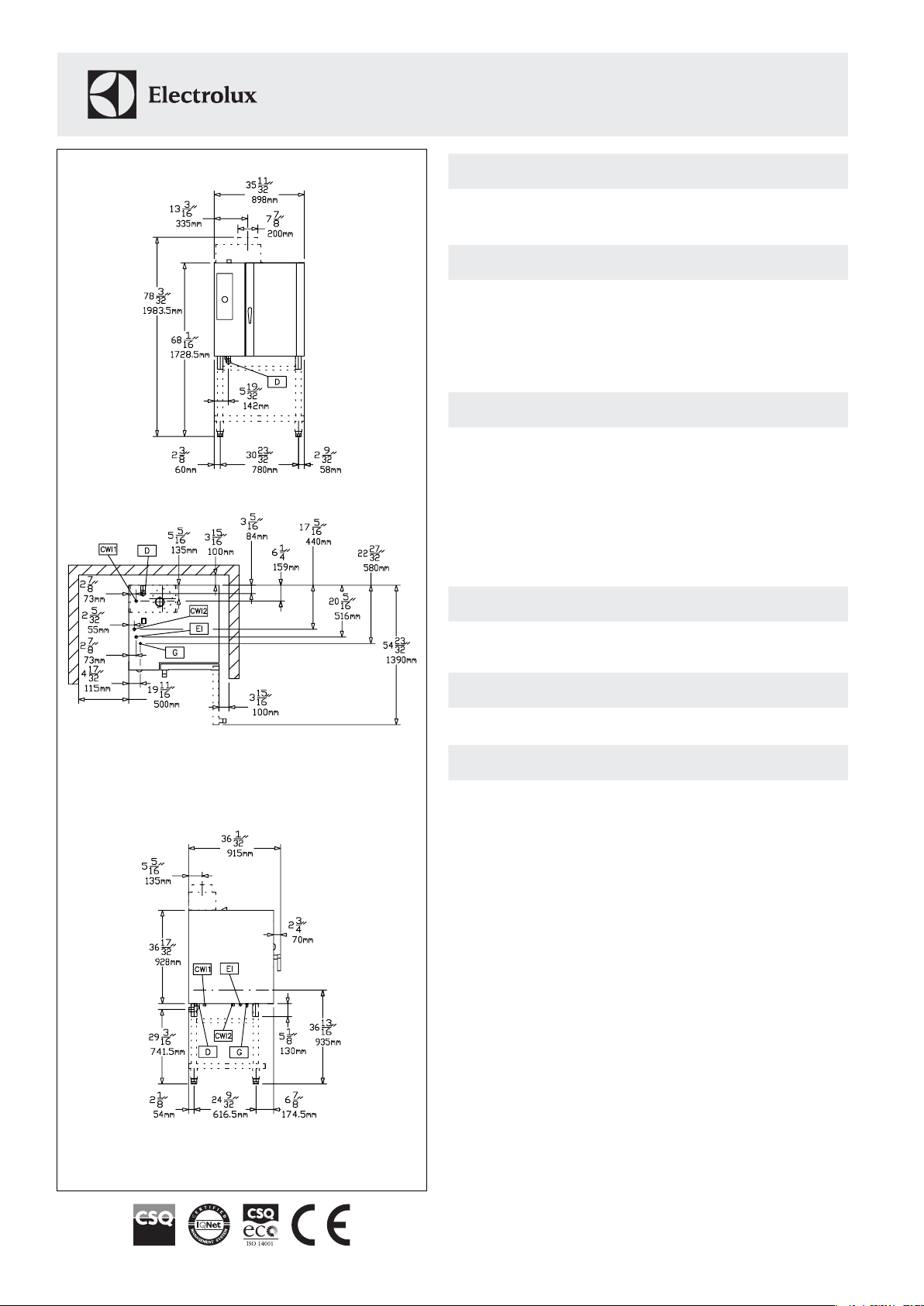

Front

Electric

Supply voltage:

268712(AOS101GBD2)230 V/1N ph/50/60 Hz

Circuit breaker required

Gas

ISO 7/1 gas connection diameter:1/2" MNPT

LPG:

Pressure:11" w.c. (27.4 mbar)

Steam generator:68180 BTU (20 kW)

Heating elements:68180 BTU (20 kW)

Total thermal load:119315 BTU (35 kW)

Water:

Water inlet "CW" connection:3/4"

Water inlet "FCW" connection:3/4"

Total hardness:5-50 ppm

Top

Pressure:1.5-4.5 bar

Drain "D":1"1/4

Electrolux recommends the use of treated water, based on

testing of specific water conditions.

Please refer to user manual for detailed water quality

information.

Installation:

Clearance:5 cm rear and right hand sides.

Suggested clearance for service

access:50 cm left hand side.

CWI=Cold Water inlet

D=Drain

DO=Overflow drain pipe

Capacity:

GN:10 - 1/1 Gastronorm

Max load capacity:50 kg

EI=Electrical connection

G=Gas connection

Side

Key Information:

Net weight:160 kg

Shipping weight:180 kg

Shipping height:1058 mm

Shipping width:898 mm

Shipping depth:915 mm

Shipping volume:0.87 m³

class B LPG Gas Combi Oven 101

The company reserves the right to make modifications to the products

without prior notice. All information correct at time of printing.

air-o-steam

2012.07 .24

Page 3

Optional Accessories

•Automatic water softener for ovens PNC 921305 ❑

•Resin sanitizer for water softenerPNC 921306 ❑

•Castor kit for base for 6&10x1/1 and 2/1 GN

ovens

•Trolley for 6&10x1/1GN ovens and bcfPNC 922004 ❑

•Tray rack with wheels for 10x1/1GN ovens and

bcf, 65mm pitch (std)

•Tray rack with wheels for 8x1/1GN ovens and

bcf, 80mm pitch

•Kit 4 adjustable feet for 6&10 GNPNC 922012 ❑

•Thermal blanket for 10x1/1GNPNC 922013 ❑

•Rack for 30 plates for 10x1/1GN ovens and bcf,

65mm pitch

•Pair of 1/1 GN AISI 304 gridsPNC 922017 ❑

•Flue condenser for air-o-system gas 6x10GN1/1PNC 922018 ❑

•Tray support for air-o-steam 6&10x1/1GN open

base

•Couple of grids for whole chicken 1/1GN (8 per

grid)

•Pastry tray rack with wheels, for 10x1/1GN

ovens and bcf, 80mm pitch (8 runners).

Suitable for 400x600mm pastry trays

•Pastry kit (wheels and hinges) for air-o-system

6&10GN

•Rack for 23 plates for 10x1/1GN, 85mm pitch PNC 922071 ❑

•Slide-in rack and handle for 6&10x1/1GNPNC 922074 ❑

•Grid for whole chicken 1/2GN (4 per grid -

1,2kg each)

•Non-stick universal pan 1/1GN H=20mmPNC 922090 ❑

•Non-stick universal pan 1/1GN H=40mmPNC 922091 ❑

•Non-stick universal pan 1/1GN H=60mmPNC 922092 ❑

•Aluminium oven grill 1/1GNPNC 922093 ❑

•Cupboard base and tray support for

6&10x1/1GN ovens

•Reinforced tray rack with wheels, lowest

support dedicated to a grease collection tray,

for 10x1/1GN, 64mm pitch

•Kit HACCP EKISPNC 922166 ❑

•External connection kit for detergent and rinse

aid

•Side external spray unitPNC 922171 ❑

•Fat filter for 10 1/1 and 2/1 GN combi steamers

(gas and electric) and convection ovens

(electric)

•Water filter for ovensPNC 922186 ❑

•Baking tray with 5 rows (baguette), perforated

aluminium with silicon coating (400x600x38)

•Baking tray with 4 edges, perforated aluminium

(400x600x20)

•Baking tray with 4 edges, aluminium

(400x600x20)

•Baking tray with 4 rows (baguette), perforated

aluminium with silicon coating (325x530x38)

•Baking tray with 4 edges, perforated aluminium

(325x530x20)

•Baking tray with 4 edges, aluminium

(325x530x20)

•Standard open base with tray support for

6&10x1/1GN

•Basket for detergent tank - wall mountedPNC 922209 ❑

PNC 922003 ❑

PNC 922006 ❑

PNC 922009 ❑

PNC 922015 ❑

PNC 922021 ❑

PNC 922036 ❑

PNC 922066 ❑

PNC 922070 ❑

PNC 922086 ❑

PNC 922096 ❑

PNC 922099 ❑

PNC 922169 ❑

PNC 922178 ❑

PNC 922189 ❑

PNC 922190 ❑

PNC 922191 ❑

PNC 922192 ❑

PNC 922193 ❑

PNC 922194 ❑

PNC 922195 ❑

air-o-steam

class B

LPG Gas Combi Oven 101

class B LPG Gas Combi Oven 101

The company reserves the right to make modifications to the products

without prior notice. All information correct at time of printing.

air-o-steam

2012.07 .24

Loading...

Loading...