Electro Industries/GaugeTech Shark NEMA 1, Shark NEMA 4X Installation & Operation Manual

V.1.09

May 3, 2018

This page intentionally left blank.

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Shark® Meter In Enclosure Assembly Installation and Operation Manual Version 1.09

Published by:

Electro Industries/GaugeTech

1800 Shames Drive

Westbury, NY 11590

All rights reserved. No part of this publication may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying, recording, or information storage or retrieval systems or any future forms of duplication, for

any purpose other than the purchaser's use, without the expressed written permission

of Electro Industries/GaugeTech.

Copyright Notice

All rights reserved. No part of this publication may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying, recording, or information storage or retrieval systems or any future forms of duplication, for

any purpose other than the purchaser's use, without the expressed written permission

of Electro Industries/GaugeTech.

© 2018 Electro Industries/GaugeTech

Shark® is a registered trademark of Electro Industries/GaugeTech. The distinctive

shapes, styles and overall appearances of all Shark® meters are trademarks of

Electro Industries/GaugeTech.

Doc# E173701 i

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Customer Service and Support

Customer support is available 9:00 am to 4:30 pm, Eastern Standard Time, Monday

through Friday. Please have the model, serial number and a detailed problem description available. If the problem concerns a particular reading, please have all meter

readings available. When returning any merchandise to EIG, a return materials

authorization number is required. For customer or technical assistance, repair or

calibration, phone 516-334-0870 or fax 516-338-4741.

Product Warranty

Electro Industries/GaugeTech warrants all products to be free from defects in material

and workmanship for a period of four years from the date of shipment. During the

warranty period, we will, at our option, either repair or replace any product that

proves to be defective.

To exercise this warranty, fax or call our customer-support department. You will

receive prompt assistance and return instructions. Send the instrument, transportation prepaid, to EIG at 1800 Shames Drive, Westbury, NY 11590. Repairs will be made

and the instrument will be returned.

This warranty does not apply to defects resulting from unauthorized modification,

misuse, or use for any reason other than electrical power monitoring. The Shark

Meter in Enclosure assembly is not a user-serviceable product.

®

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. ELECTRO INDUSTRIES/

GAUGETECH SHALL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES ARISING FROM ANY AUTHORIZED OR

UNAUTHORIZED USE OF ANY ELECTRO INDUSTRIES/GAUGETECH

PRODUCT. LIABILITY SHALL BE LIMITED TO THE ORIGINAL COST OF

THE PRODUCT SOLD.

Doc# E173701 ii

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Use of Product for Protection

OUR PRODUCTS ARE NOT TO BE USED FOR PRIMARY OVER-CURRENT PROTECTION.

ANY PROTECTION FEATURE IN OUR PRODUCTS IS TO BE USED FOR ALARM OR

SECONDARY PROTECTION ONLY.

Statement of Calibration

Our instruments are inspected and tested in accordance with specifications published

by Electro Industries/GaugeTech. The accuracy and a calibration of our instruments

are traceable to the National Institute of Standards and Technology through

equipment that is calibrated at planned intervals by comparison to certified standards.

For optimal performance, EIG recommends that any metering device, including those

manufactured by EIG, be verified for accuracy on a yearly interval using NIST traceable accuracy standards.

Disclaimer

The information presented in this publication has been carefully checked for reliability; however, no responsibility is assumed for inaccuracies. The information contained

in this document is subject to change without notice.

Symbols Used in This Manual

This warning symbol indicates that the operator must refer to an

important explanation in the operating instructions. The word following the symbol indicates the type of warning being given.

Ce symbole d'avertissement indique que l'opérateur doit se référer à

une explication importante dans les instructions d'utilisation. Le mot suivant le symbole

indique le type d'avertissement ne soit donné.

CAUTION! The instructions given must be followed to prevent damage to

equipment.

Les instructions doivent être respectées pour éviter

d'endommager l’équipement.

WARNING! The instructions given must be followed to prevent serious

injury to people.

Les instructions doivent être respectées pour d’éviter de graves

blessures aux personnes.

Doc# E173701 iii

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

About Electro Industries/GaugeTech (EIG)

Founded in 1975 by engineer and inventor Dr. Samuel Kagan, Electro Industries/

GaugeTech changed the face of power monitoring forever with its first breakthrough

innovation: an affordable, easy-to-use AC power meter.

More than forty years since its founding, Electro Industries/GaugeTech, the leader in

power monitoring and control, continues to revolutionize the industry with the highest

quality, cutting edge power monitoring and control technology on the market today.

An ISO 9001:2015 certified company, EIG sets the industry standard for advanced

power quality and reporting, revenue metering and substation data acquisition and

control. EIG products can be found on site at mainly all of today's leading manufacturers, industrial giants and utilities.

EIG products are primarily designed, manufactured, tested and calibrated at our facility in Westbury, New York.

Doc# E173701 iv

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Table of Contents

Customer Service and Support ii

Product Warranty ii

Use of Product for Protection iii

Statement of Calibration iii

Disclaimer iii

Symbols Used in This Manual iii

1: Introduction 1-1

1.1: Product Handling 1-1

Table of Contents

1.2: Safety Precautions 1-2

1.3: Storage 1-2

1.4: Compliance 1-2

2: Installation 2-1

2.1: Recommended Procedures for Wire Entry Hole Cutting 2-4

2.2: Installation for the NEMA 1 Enclosure 2-8

2.2.1: Installation Steps 2-11

2.2.2: Door Locking Instructions 2-12

2.3: Installation for the NEMA 4X Enclosure 2-13

2.3.1: Installation Steps 2-17

2.3.2: Door Locking Instructions 2-18

3: Electrical Wiring 3-1

3.1: Wiring Instructions 3-2

3.2: 3 Wire Delta, 3 CT Hookup 3-6

Doc# E173701 TOC-1

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

4: Operation 4-1

4.1: Overview 4-1

4.2: Troubleshooting 4-1

5: Maintenance 5-1

6: Ordering Information 6-1

A: Removing a Meter from Service A-1

A.1: Removing the Meter A-1

A.2: Reinstalling the Meter A-4

Doc# E173701 TOC-2

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1: Introduction

The Self-Enclosed Shark® Meter Assembly lets you remotely mount Shark® power

meters. Applications include switchgear expansion, outdoor mounting capability, and

remote mounting applications. This is an ideal solution for a retrofit when there is no

metering compartment available. The unit comes standard with either a NEMA 1

indoor or a NEMA 4X outdoor enclosure and is factory wired with the meter installed.

Standard equipment includes voltage fuses, a shorting block for current transformer

connections, and a control power transformer if used with 277/480 Volt power systems.

The enclosure can be ordered with any of the following multifunction meters: Shark®

50 meter, Shark® 50B meter with native BACnet MS/TP, Shark® 100 meter, Shark®

100B meter with native BACnet/IP protocol, or Shark® 200 advanced meter with

datalogging and extensive I/O. It is offered in two voltage configurations:

1:Introduction

• 277 Volt enclosure (which comes equipped with a control power transformer)

• 120-240 Volt enclosure

1.1: Product Handling

CAUTION! READ AND UNDERSTAND THE INSTRUCTIONS CONTAINED IN

THIS DOCUMENT BEFORE ATTEMPTING TO UNPACK, INSTALL, OPERATE,

OR MAINTAIN THIS EQUIPMENT.

Every effort is made to insure that the equipment arrives undamaged and ready to be

installed. Packing is designed to protect internal components as well as the enclosure.

Do not remove protective packing until you are ready to install the equipment.

When you receive the equipment, you should inspect the shipping container for any

obvious signs of rough handling and/or external damage that occurred during transportation. Record any external and internal damage for reporting to the transportation

carrier and EIG. All claims should be as specific as possible and include general order

numbers.

You will find a plastic bag of instruction booklets and/or CDs in the shipping container.

Store these documents in a safe place.

Doc# E173701 1-1

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1.2: Safety Precautions

WARNING! All safety codes, safety standards, and/or

regulations must be strictly observed in the installation, oper-

ation, and maintenance of this device.

Hazardous voltages that can cause death or severe personal injury are present inside

enclosure. Follow proper installation, operation, and maintenance procedures to avoid

these voltages.

Avertissement! tous les codes de sécurité, normes de sécurité et règlements

doivent être suivis strictement dans l'installation, le fonctionnement et la

maintenance de cet appareil.

Des tensions dangereuses peuvent provoquer la mort ou des blessures graves. suivre

l'installation adéquate, le fonctionnement et les procédures de maintenance pour

1:Introduction

éviter ces tensions.

Completely read and understand the material presented in this document before

attempting installation, operation, or application of the equipment. In addition, only

qualified persons should be permitted to perform any work associated with the

equipment. Any wiring instructions presented in this document must be followed

precisely. Failure to do so could cause permanent equipment damage.

All possible contingencies that may arise during installation, operation, or maintenance, and all details and variations of this equipment do not purport to be covered by

these instructions. If further information is desired by purchaser regarding a particular

installation, operation, or maintenance of particular equipment, contact an Electro

Industries/GaugeTech (EIG) representative.

1.3: Storage

Although it has been well packaged, this equipment should not be stored outdoors. If

the equipment is to be stored indoors for any period of time, it should be stored with

its protective packaging in place. Refer to the Shark

®

50/50B100/100B and Shark®

200 Installation and Operation manuals, on the enclosed CD, for the meter’s storage

requirements.

The temperature rating for enclosure storage is (-20 to +50)

1.4: Compliance

UL / cUL Listed, file number: E358101.

o

C.

Doc# E173701 1-2

2: Installation

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

2: Installation

WARNING!

All safety codes, safety standards, and/or regulations shall be

strictly observed in the installation, operation, and maintenance of

this device. This device shall be installed in an un-energized condition and as

per the National Electric Code.

AVERTISSEMENT! Tous les codes de sécurité, normes de sécurité et règlement

doivent être suivis strictement pour l'installation, le fonctionnement et la maintenance

de cet appareil. Cet appareil doit être installé hors tension conformément au

code électrique national (National Electric Code).

Choose a mounting location that offers a flat, rigid mounting surface capable of

supporting the weight of the equipment. The unit weighs 25 lbs (11.4 kg) maximum.

Mount the equipment in a suitable environment. These enclosures are designed for

NEMA 1 or NEMA 4x environments, depending on the enclosure ordered, and are

manufactured of painted steel.

Check to make certain that there are no pipes, wires, or other mounting hazards in

the immediate mounting area that could create a problem. Also make sure you have

enough clearance around the enclosure to run wiring to it safely. EIG recommends at

least 2 feet of clearance around the enclosure.

Carefully remove all packing material from the unit. Even though an equipment

inspection was made when the equipment was received, make another careful inspection of the enclosure and the devices inside as packing material is removed. Be

especially alert for distorted metal, loose wires, or damaged components. This is

important because wiring can come loose in shipping and could cause a short circuit

or voltage to be on the wrong terminal. Please inspect to make sure all the wiring is in

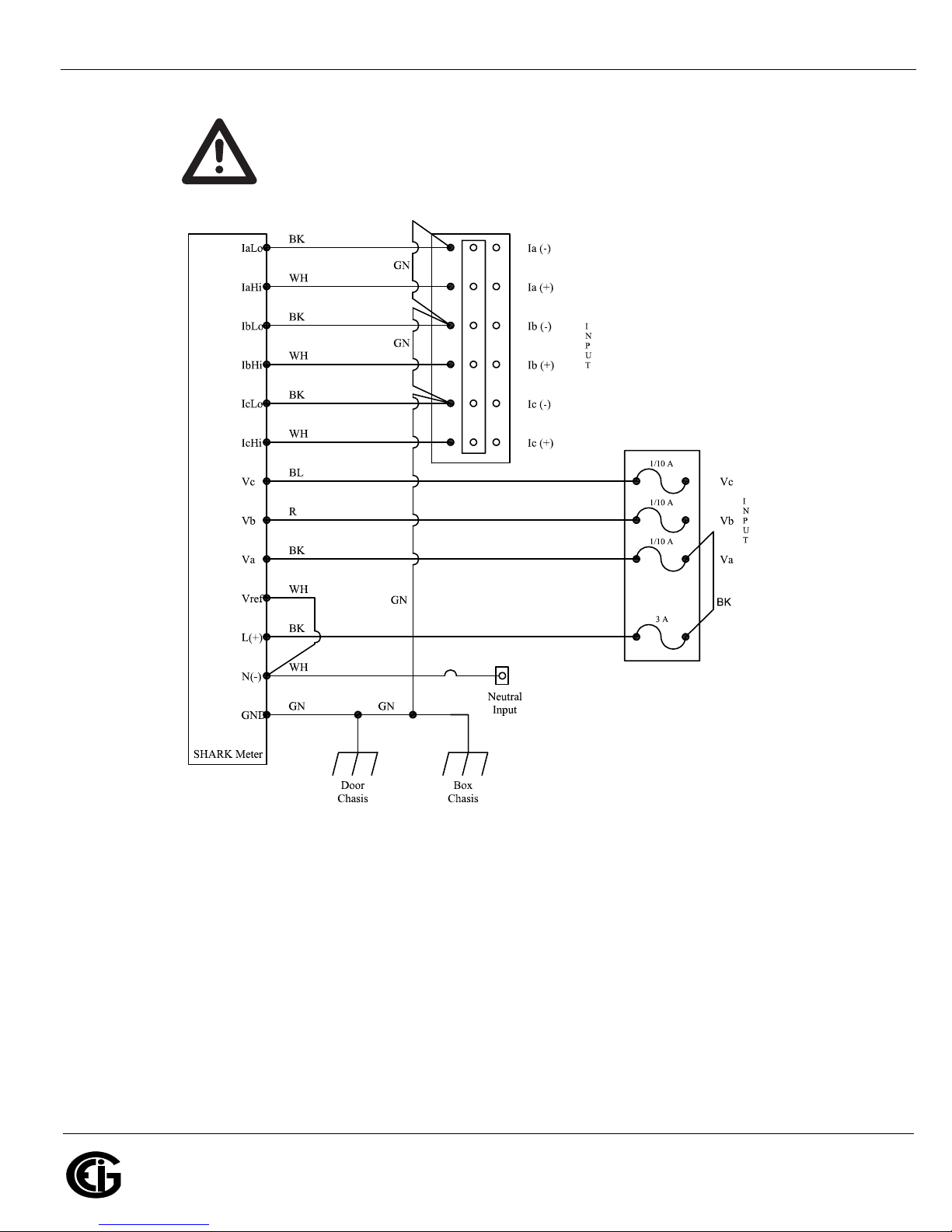

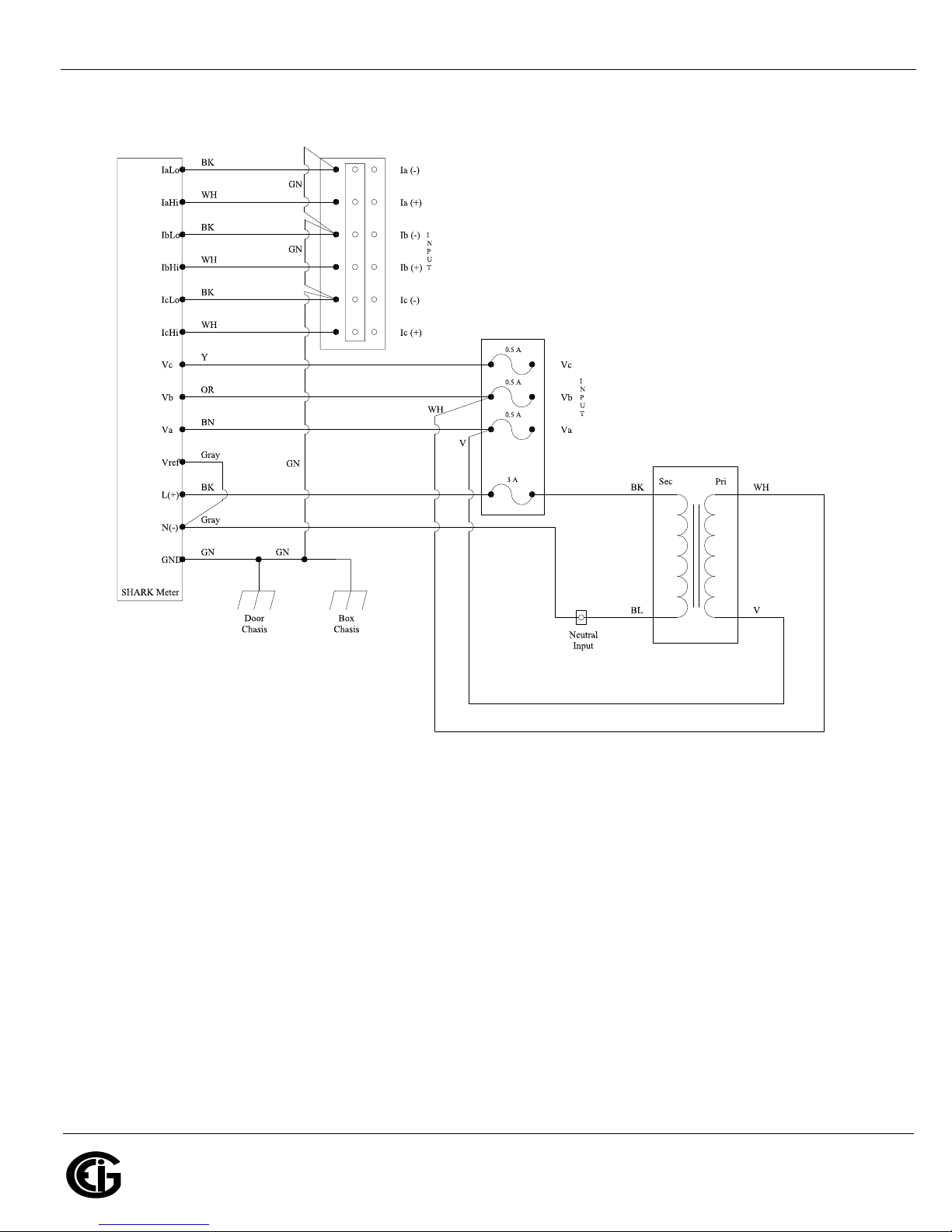

the proper place and all connections are tight. Refer to figures 2.1 and 2.2 for internal

wiring schematics.

WARNING!

Extreme care shall be taken when mounting the enclosure, and making

wire entry holes, to prevent metal chips, filings, and other

contaminants from entering the enclosure which may damage the equipment and

create a hazardous condition.

Doc# E173701 2-1

2: Installation

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

AVERTISSEMENT! Attention extrême lors de la monture de l'enceinte

et lors de la mise à terre pour prévenir les articules métalliques, remplissage et autre contaminant de l'entrée de l'enceinte qui peuvent

provoquer une condition dangereuse de l'équipement.

Figure 2.1: 120V Internal Wiring Schematic

Doc# E173701 2-2

2: Installation

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Figure 2.2: 277V Internal Wiring Schematic

Doc# E173701 2-3

2: Installation

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

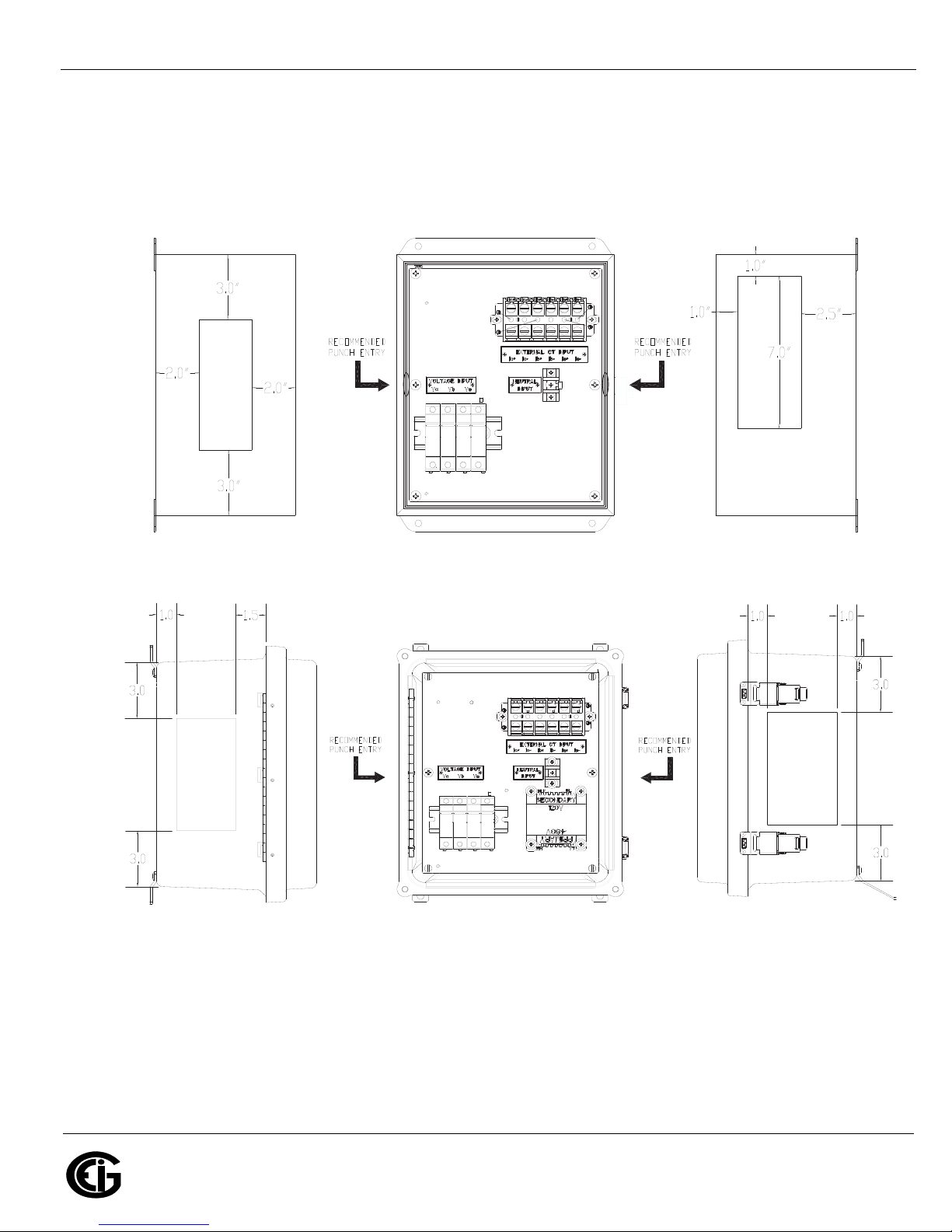

NEMA 1 Enclosure

NEMA 4X Enclosure

2.1: Recommended Procedures for Wire Entry Hole Cutting

The enclosure does not come with wire entry holes (punch entries). They must be cut

in the location you want depending on the installation. See Figure 2.3 for the locations

that EIG recommends. See CAUTIONS on next page.

Figure 2.3: Location of Recommended Punch Entries

Doc# E173701 2-4

2: Installation

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

CAUTIONS!

• There are numerous methods for making wire entry holes in the enclosure but it is

imperative that no loose material generated during the process remains in the

enclosure. During installation and cutting the wire holes, all equipment mounted

inside or on the enclosure shall be protected from loose material.

• No matter what procedure is used the installer shall verify that the hole cutting

process will not damage any of the wiring or components installed inside or on the

enclosure.

The two recommended procedures for cutting the wire entry holes are as follows:

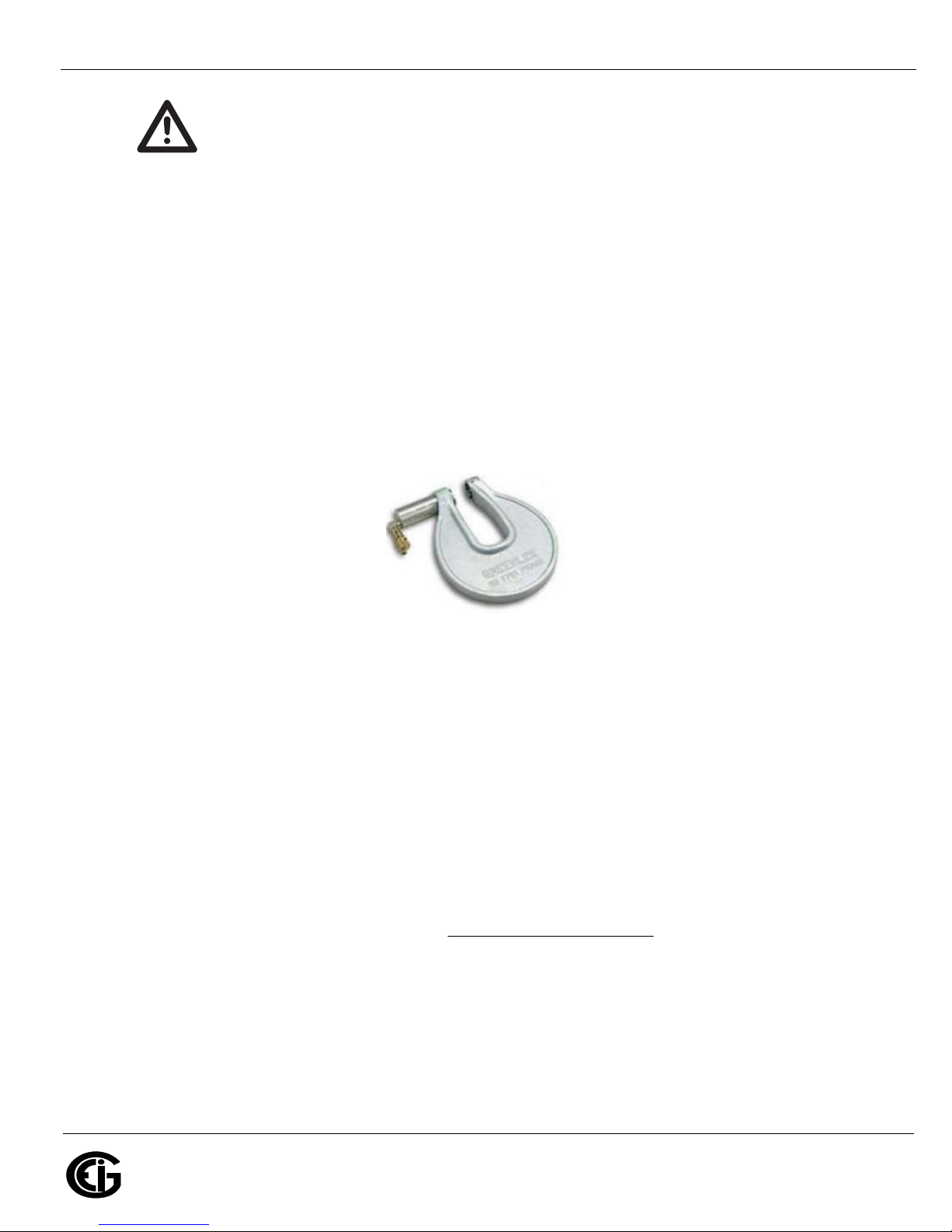

• Use a "C" frame punch to cut the wire entry holes. This type of punch does not

require a pilot hole. A typical "C" frame punch is shown below.

Figure 2.4: “C” Frame Punch

• Regular punch:

1. Place a magnet inside the enclosure where the pilot hole is to be cut and: for

the NEMA 1 enclosure, completely cover the area with masking tape (or other

very sticky tape); for the NEMA 4X enclosure, use sticky tape, only.

2. Drill the pilot hole from the outside and do not let the drill pass more than ¼"

into the enclosure.

3. Remove the tape, magnet, and cuttings and punch the hole.

After wiring and before energizing, vacuum the inside of the enclosure to make sure

that it is free of foreign material. If a vacuum is not available use an alternate method

to clean the inside of the enclosure. Do not use compressed air

(or pressurized gas) to

clean the inside of the enclosure as this may force cuttings into areas that cannot be

seen, creating a hazardous condition.

IMPORTANT!

• All wire entry into the enclosure shall be accomplished with the use of recognized

fittings or strain reliefs. Bare holes shall not be used.

Doc# E173701 2-5

Loading...

Loading...