Electro Industries/GaugeTech Shark 250 Installation And Operation Manual

V.1.02

October 9, 2018

This page intentionally left blank.

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Shark® 250 Meter Installation and Operation Manual Version 1.02

Published by:

Electro Industries/GaugeTech (EIG)

1800 Shames Drive

Westbury, NY 11590

Copyright Notice

All rights reserved. No part of this publication may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying, recording, or information storage or retrieval systems or any future forms of duplication, for

any purpose other than the purchaser's use, without the expressed written permission

of Electro Industries/GaugeTech.

© 2018 Electro Industries/GaugeTech

All information contained herein is, and remains the property of Electro Industries/

GaugeTech and its suppliers, if any. The intellectual and technical concepts contained

herein including, but not limited to, programming code, database structures, etc., are

proprietary to Electro Industries/Gauge Tech and its suppliers and may be covered by

U.S. and Foreign Patents, patents in process, and are protected by trade secret or

copyright law. Dissemination of this information or reproduction of this material is

strictly forbidden unless prior written permission is obtained from Electro Industries/

Gauge Tech.

Shark® is a registered trademark of Electro Industries/GaugeTech. The distinctive

shapes, styles, and overall appearances of all Shark® meters are trademarks of

Electro Industries/GaugeTech. Communicator EXT

TM

and V-SwitchTM are trademarks

of Electro Industries/GaugeTech.

Modbus® is a registered trademark of Schneider Electric, licensed to the Modbus

Organization, Inc.

Doc# E169701 i

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Customer Service and Support

Customer support is available 8:00 am to 8 pm, Eastern Standard Time, Monday

hrough Friday. Please have the model, serial number and a detailed problem descrip-

t

tion available. If the problem concerns a particular reading, please have all meter

readings available. When returning any merchandise to EIG, a return materials

authorization number is required. For customer or technical assistance, repair or

calibration, phone 516-334-0870 or fax 516-338-4741.

Product Warranty

Electro Industries/GaugeTech (EIG) warrants all products to be free from defects in

material and workmanship for a period of four years from the date of shipment.

During the warranty period, we will, at our option, either repair or replace any product

that proves to be defective.

To exercise this warranty, fax or call our customer-support department. You will

receive prompt assistance and return instructions. Send the instrument, transportation prepaid, to EIG at 1800 Shames Drive, Westbury, NY 11590. Repairs will be made

and the instrument will be returned.

This warranty does not apply to defects resulting from unauthorized modification,

misuse, or use for any reason other than electrical power monitoring. The Shark

meter is not a user-serviceable product.

®

250

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. ELECTRO INDUSTRIES/

GAUGETECH SHALL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES ARISING FROM ANY AUTHORIZED OR

UNAUTHORIZED USE OF ANY ELECTRO INDUSTRIES/GAUGETECH

PRODUCT. LIABILITY SHALL BE LIMITED TO THE ORIGINAL COST OF

THE PRODUCT SOLD.

Doc# E169701 ii

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Use Of Product for Protection

Our products are not to be used for primary over-current protection. Any protection

feature in our products is to be used for alarm or secondary protection only.

Statement of Calibration

Our instruments are inspected and tested in accordance with specifications published

by Electro Industries/GaugeTech. The accuracy and a calibration of our instruments

are traceable to the National Institute of Standards and Technology through

equipment that is calibrated at planned intervals by comparison to certified standards.

For optimal performance, EIG recommends that any meter, including those manufactured by EIG, be verified for accuracy on a yearly interval using NIST traceable accuracy standards.

Disclaimer

The information presented in this publication has been carefully checked for

reliability; however, no responsibility is assumed for inaccuracies. The information

contained in this document is subject to change without notice.

This symbol indicates that the operator must refer must to an

important WARNING or CAUTION in the operating instructions.

Please see 4.1: Considerations When Installing Meters on page 41, for important safety information regarding installation and

hookup of the Shark® 250 meter.

Dans ce manuel, ce symbole indique que l’opérateur doit se référer à un important

AVERTISSEMENT ou une MISE EN GARDE dans les instructions opérationnelles. Veuillez consulter 4.1: Considerations When Installing Meters on page 4- 1, pour des informations importantes relatives à l’installation et branchement du compteur.

The following safety symbols may be used on the meter itself:

Les symboles de sécurité suivante peuvent être utilisés sur le compteur même:

This symbol alerts you to the presence of high voltage, which can

cause dangerous electrical shock.

Ce symbole vous indique la présence d’une haute tension qui peut

provoquer une décharge électrique dangereuse.

Doc# E169701 iii

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

This symbol indicates the field wiring terminal that must be connected

to earth ground before operating the meter, which protects against

electrical shock in case of a fault condition.

Ce symbole indique que la borne de pose des canalisations in-situ qui doit être

branchée dans la mise à terre avant de faire fonctionner le compteur qui est protégé

contre une décharge électrique ou un état défectueux.

This symbol indicates that the user must refer to this manual for

specific WARNING or CAUTION information to avoid personal injury or

damage to the product.

Ce symbole indique que l'utilisateur doit se référer à ce manuel pour AVERTISSEMENT

ou MISE EN GARDE l'information pour éviter toute blessure ou tout endommagement

du produit.

About Electro Industries/GaugeTech (EIG)

Founded in 1975 by engineer and inventor Dr. Samuel Kagan, Electro Industries/

GaugeTech changed the face of power monitoring forever with its first breakthrough

innovation: an affordable, easy-to-use AC power meter.

More than forty years since its founding, Electro Industries/GaugeTech, the leader in

power monitoring and control, continues to revolutionize the industry with the highest

quality, cutting edge power monitoring and control technology on the market today.

An ISO 9001

t

roind.com/about-electro-industries/), EIG sets the industry standard for advanced

certified company (certificate on the EIG website at https://elec-

power quality and reporting, revenue metering and substation data acquisition and

control. EIG products can be found on site at mainly all of today's leading manufacturers, industrial giants and utilities.

EIG products are primarily designed, manufactured, tested and calibrated at our facility in Westbury, New York.

Doc# E169701 iv

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Table of Contents

Copyright Notice i

Customer Service and Support ii

Product Warranty ii

Use Of Product for Protection iii

Statement of Calibration iii

Disclaimer iii

About Electro Industries/GaugeTech (EIG) iv

1.1: The Shark® 250 High Accuracy Revenue Meter 1 - 1

Table of Contents

1.1.1: Hookup Connections and Measurements 1 - 1

1.1.2: Ordering Codes 1 - 2

TM

1.1.3: V-Switch

1.1.4: Measured Values 1 - 6

1.1.5: Utility Demand 1 - 7

1.2: Advanced Measurement Functionality 1 - 7

1.2.1: Advanced Revenue Billing Capability 1 - 7

1.2.2: Communications and I/O Capabilities 1 - 10

1.2.3: Meter Display 1 - 12

1.3: Shark® 250 Meter Accuracy 1 - 13

1.4: Shark® 250 Meter Specifications Overview 1 - 14

Key Technology 1 - 3

1.5: DNP V 3.0 Protocol Implementation 1 - 21

1.6: Time Synchronization Alternatives 1 - 21

2: Using the Shark® 250 Meter 2 - 1

Doc# E169701 TOC - 1

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

2.1: Introduction 2 - 1

2.1.1: Understanding Meter Face Elements 2 - 1

2.1.2: Understanding Meter Face Buttons 2 - 2

2.2: Using the Front Panel 2 - 3

2.2.1: Understanding Startup and Default Displays 2 - 3

2.2.2: Using the Main Menu 2 - 4

2.2.3: Using Reset Mode 2 - 5

2.2.4: Entering a Password 2 - 7

2.2.5: Using Configuration Mode 2 - 8

2.2.5.1: Configuring the Scroll Feature 2 - 10

2.2.5.2: Configuring CT Setting 2 - 11

2.2.5.3: Configuring PT Setting 2 - 12

2.2.5.4: Configuring Connection Setting 2 - 13

2.2.5.5: Configuring the RS485 Communication Port Setting 2 - 13

2.2.6: Using Operating Mode 2 - 15

2.3: Understanding the % of Load Bar 2 - 16

3: Mechanical Installation 3 - 1

3.1: Introduction 3 - 1

3.2: ANSI Installation Steps 3 - 3

3.3: DIN Installation Steps 3 - 4

3.4: Transducer Installation 3 - 6

4: Electrical Installation 4 - 1

4.1: Considerations When Installing Meters 4 - 1

Doc# E169701 TOC - 2

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

4.2: CT Leads Terminated to Meter 4 - 4

4.3: CT Leads Pass Through (No Meter Termination) 4 - 5

4.4: Quick Connect Crimp-on Terminations 4 - 6

4.5: Voltage and Power Supply Connections 4 - 7

4.6: Ground Connections 4 - 7

4.7: Voltage Fuses 4 - 7

4.8: Electrical Connection Diagrams 4 - 8

4.9: Extended Surge Protection for Substation Instrumentation 4 - 21

5: Communication Installation 5 - 1

5.1: Shark® 250 Meter Communication 5 - 1

5.1.1: USB Port (Com 1) 5 - 1

5.1.2: RS485 / KYZ Output (Com 2) 5 - 4

5.1.2.1: Using the Unicom 2500 5 - 8

6: Using the I/O Option Cards 6 - 1

6.1: Overview 6 - 1

6.2: Installing Option Cards 6 - 2

6.3: Configuring Option Cards 6 - 4

6.4: 1 mA Output Card (1mAOS) 6 - 4

6.4.1: Specifications

6.

4.2: Default Configuration: 6 - 5

6 - 4

6.4.3: Wiring Diagram 6 - 6

6.5: 20 mA Output Card (20mAOS) 6 - 7

6.5.1: Specifications 6 - 7

Doc# E169701 TOC - 3

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

6.5.2: Default Configuration 6 - 8

5.3: Wiring Diagram 6 - 9

6.

6.6: Digital Output (Relay Contact) / Digital Input Card (RO1S) 6 - 10

6.6.1: Specifications 6 - 10

6.6.2: Wiring Diagram 6 - 12

6.7: Pulse Output (Solid State Relay Contacts) / Digital Input Card (P01S) 6 - 13

6.7.1: Specifications 6 - 13

6.7.2: Default Configuration

6.

7.3: Wiring Diagram 6 - 15

6 - 14

6.8: Fiber Optic Communication Card (FOSTS; FOVPS) 6 - 16

6.8.1: Specifications 6 - 16

6.8.2: Wiring Diagram 6 - 17

6.9: 10/100BaseT Ethernet Communication Card (INP100S) 6 - 18

6.9.1: Specifications 6 - 18

6.9.2: Default Configuration 6 - 19

6.9.3: Wiring Diagram 6 - 19

6.10: IEC 61850 Protocol Ethernet Network Card (INP300S) 6 - 20

6.10.1: Specifications 6 - 20

6.10.2: Default Configuration 6 - 21

6.10.3: Wiring Diagram 6 - 21

6.11: RS232/RS485 Card (RS1S) 6 - 22

6.11.1: Specifications 6 - 22

6.11.2: Default Configuration 6 - 23

Doc# E169701 TOC - 4

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

6.11.3: Wiring Diagram 6 - 24

7: Using the Ethernet Card (INP100S) 7 - 1

7.1: Overview 7 - 1

7.2: Hardware Connection 7 - 1

7.3: Performing Network Configuration 7 - 2

7.4: INP100S Ethernet Card Features 7 - 2

7.4.1: Ethernet Communication 7 - 3

7.4.2: Embedded Web Server 7 - 3

7.4.2.1: Upgrading the Ethernet Card’s Firmware 7 - 14

7.4.2.2: Resetting the Ethernet Card 7 - 16

7.4.2.3: Email Notification 7 - 17

7.4.2.4: Data Push 7 - 23

7.4.3: NTP Time Server Synchronization 7 - 27

7.4.4: Modbus and DNP3 over Ethernet 7 - 27

7.4.5: Keep-Alive Feature 7 - 27

8: Data Logging 8 - 1

8.1: Overview 8 - 1

8.2: Available Logs 8 - 1

9: Using the INP300S IEC 61850 Protocol

Card 9 - 1

9.1: Overview 9 - 1

9.2: Overview of IEC 61850 9 - 1

9.2.1: Relationship of Clients and Servers in IEC 61850 9 - 3

9.2.2: Structure of IEC 61850 Network 9 - 5

Doc# E169701 TOC - 5

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

9.2.2.1: Elements of an IEC 61850 Network 9 - 7

9.2.3: Steps in Configuring an IEC 61850 Network 9 - 8

9.2.4: EIG’s Implementation of the IEC 61850 Protocol Server 9 - 10

9.2.4.1: Shark® 250 Server Configuration 9 - 12

9.2.5: Reference Materials 9 - 13

9.2.6: Free Tools for IEC 61850 Start-up 9 - 14

9.2.7: Commercial Tools for IEC 61850 Implementation 9 - 14

9.3: Using the Shark® 250 Meter’s IEC 61850 Protocol Ethernet

Network Card 9 - 15

9.3.1: Overview 9 - 15

9.3.2: Installing the IEC 61850 Protocol Ethernet Network Card 9 - 17

9.3.3: Configuring the IEC 61850 Protocol Ethernet Network Card 9 - 17

9.3.3.1: Configuring the Device Profile IEC 61850 Protocol

Ethernet Network Card Settings 9 - 17

9.3.3.2: Configuring the Meter on the IEC 61850 Network 9 - 21

9.4: Viewing the IEC 61850 Protocol Ethernet Network Card’s

System Log 9 - 27

9.5: Upgrading the IEC 61850 Protocol Ethernet Network Card’s

Firmware 9 - 28

9.6: Resetting the IEC 61850 Protocol Ethernet Network Card 9 - 29

9.7: Keep-Alive Feature 9 - 30

9.8: Testing 9 - 30

9.10: Error Codes 9 - 31

10: Time of Use Function 10 - 1

10.1: Introduction 10 - 1

Doc# E169701 TOC - 6

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

10.2: The Shark® 250 Meter's TOU Profile 10 - 3

10.3: TOU Prior Season and Month 10 - 3

10.4: Updating, Retrieving and Replacing the TOU Profile 10 - 3

10.5: Daylight Savings and Demand 10 - 4

11: Meter Calculations 11 - 1

11.1: Measurements and Calculations 11 - 1

11.2: Demand Integrators 11 - 5

12: Performing Meter Testing 12 - 1

13: Transformer Loss Compensation 13 - 1

13.1: Introduction 13 - 1

13.2: Shark® 250 Meter's Transformer Loss Compensation 13 - 3

13.2.1: Loss Compensation in Three Element Installations 13 - 5

13.2.1.1: Three-Element Loss Compensation Worksheet 13 - 6

A: Shark® 250 Meter Navigation Maps A - 1

A.1: Introduction A - 1

A.2: Navigation Maps (Sheets 1 to 4) A - 1

B: Three-Phase Power Measurement B - 1

B.1: Three-Phase System Configurations B - 1

B.1.1: Wye Connection B - 1

B.1.2: Delta Connection B - 4

B.1.3: Blondel’s Theorem and Three Phase Measurement B - 6

B.2: Power, Energy and Demand B - 8

B.3: Reactive Energy and Power Factor B - 12

Doc# E169701 TOC - 7

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

B.4: Harmonic Distortion B - 14

B.5: Power Quality B - 18

C: Shark® 250 Meter DNP Mapping C - 1

C.1: Overview C - 1

C.2: Configuration C - 1

C.3: Communication C - 1

C.4: Classes C - 3

C.5: Events C - 3

C.6: Time Synchronization C - 4

Table of Contents

C.7: Link Layer Functions C - 5

C.8: Application Layer Functions C - 5

C.9: Errors C - 5

C.10: Object Specifics C - 6

C.10.1: Object 0 - Device Attributes C - 6

C.10.2: Object 1 - Binary Inputs Status C - 8

C.10.3: Object 2 - Binary Input Change C - 9

C.10.4: Object 10 - Binary Output States C - 10

C.10.5: Object 12 - Relay Output Block C - 11

C.10.6: Object 20 - Binary Counters C - 13

C.10.7: Object 21 - Frozen Counters C - 14

C.10.8: Object 22 - Binary Counter Event C - 15

C.10.9: Object 30 - Analog Inputs C - 16

C.10.10: Object 32 - Analog Inputs Change C - 17

Doc# E169701 TOC - 8

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

C.10.11: Object 34 - Analog Input Dead-Band C - 18

C.10.12: Object 50 - Time C - 19

C.10.13: Object 60 - Class Objects C - 20

C.10.14: Object 80 - Internal Indications C - 21

C.10.15: Object 110 - Strings C - 22

C.11: Default Values C - 22

C.12: Use Cases C - 29

C.12.1: Case 1 - Primary of 14.4 KV and Secondary of 120 V C - 29

C.12.2: Case 2 - Primary of 138 KV and Secondary of 120 V C - 36

C.12.3: Case 3 - Read Power in the Range of 6000 Kilowatt C - 40

C.12.4: Case 4 - Read Power in the Range of 60000 Kilowatt C - 44

C.12.5: Case 5 - Read Power in the Range of 120000 Kilowatt C - 45

C.12.6: Case 6 - Reading Energy of Approximately 12345.678 kWh C - 46

C.12.7: Case 7 - Frequency of 59.95 Hz C - 50

D: Transformer Loss Compensation Spreadsheet and Examples E - 1

D.1: Calculating Values E - 1

D.2: Excel Spreadsheet with Example Numbers E - 1

Doc# E169701 TOC - 9

Table of Contents

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

This page intentionally left blank.

Doc# E169701 TOC - 10

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1: Meter Overview

1.1: The Shark® 250 High Accuracy Revenue Meter

The Shark® 250 is a multifunction, datalogging revenue meter for both critical

meter applications and basic commercial/

industrial metering applications. The

Shark® 250 meter is a full four quadrant,

bidirectional revenue meter that can also

be used for inter-tie metering. Its 0.2%

metrology accuracy meets all the accuracy requirements of ANSI C12.20 Class

0.2% and IEC 62053-22 CL 0.2S. The

meter has advanced revenue metering

features that allow it to be used not only

for measuring basic energy, but also for

providing a full complement of necessary

tools, such as instrument transformer compensation, CT/PT compensation, advanced

test mode, perpetual TOU, and extensive logging for interval energy storage.

There is also a transducer only version of the meter, the Shark® 250T transducer,

which has the same functionality as the meter, except that it doesn’t have the faceplate or the USB port.

1.1.1: Hookup Connections and Measurements

See 1.4: Shark® 250 Meter Specifications Overview, on page 1-14.

Doc# E169701 1-1

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1.1.2: Ordering Codes

1: Meter Overview

Pack

V1

V2

V3

V4

TM

Power

Supply

D2

Universal,

(90 to

265) V AC

@ 50/60

Hz

D

(18-60) V

DC

Option Card 1

Type*

X

None

PO1S

4 Pulses/4

Status Inputs

RO1S

2 Relay Out-

puts/2 Digital

Inputs

1mAOS

4 Channel

Analog Output

0-1 mA

bi-directional

20mAOS

4 Channel

Analog Output

4-20 mA

INP100S

100BaseT

Ethernet

FOSTS

Fiber Optic

Output ST

Term in ate d

Option Card

2 Type*

None

PO1S

4 Pulses/4

Status Inputs

RO1S

2 Relay Out-

puts/2 Digital

Inputs

1mAOS

4 Channel

Analog Output

0-1 mA

bi-directional

20mAOS

4 Channel

Analog Output

4-20 mA

INP100S

100BaseT

Ethernet

FOSTS

Fiber Optic

Output ST

Term in ate d

Model Frequency

Option

Numbers:

E.g: Shark250 - 60 - 2 - V2 - D - INP100S - X

Shark® 250

Revenue Meter

Shark® 250T

Trans duc er O nly

50

50 Hz System

60

60 Hz System

Current

Class

2

2 A

Secondary

10

10 A

Secondary

V-Switch

Multifunction

Meter

V1 + 2 MB

Memory

V2 + 10 MB

Memory and 128

Samples/Cycle

Waveform

Recording

V3 + 128 MB

Memory and 512

Samples/Cycle

Waveform

Recording

X

FOVPS

Fiber Optic

Output

Versatile Link

Term in ate d

INP300S

IEC 61850

Protocol

Ethernet

RS1S

RS232/RS485

Card

FOVPS

Fiber Optic

Output

Versatile Link

Term in ate d

INP300S

IEC 61850

Protocol

Ethernet

RS1S

RS232/RS485

Card

Doc# E169701 1-2

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

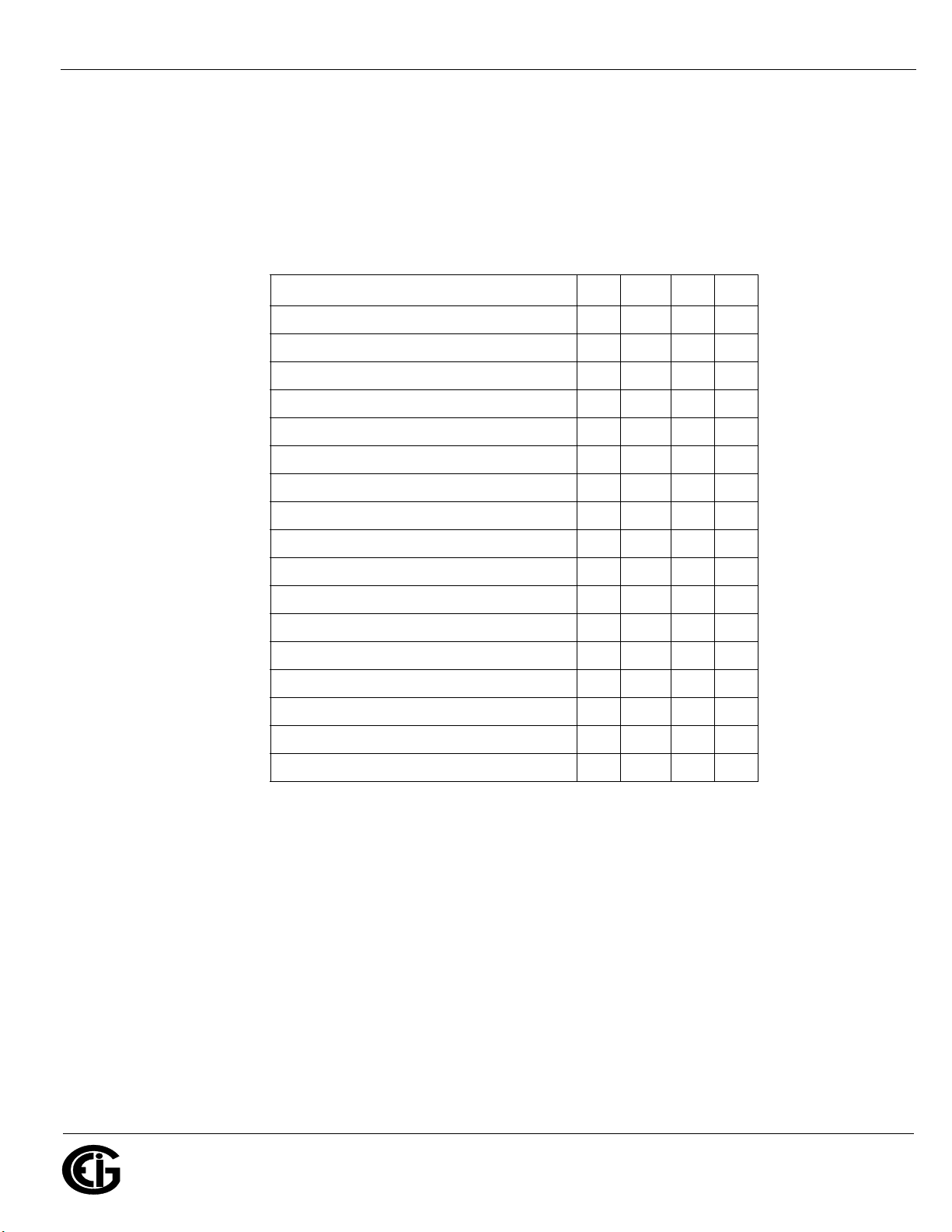

1.1.3: V-SwitchTM Key Technology

The Shark® 250 meter is equipped with V-SwitchTM key technology, a virtual

firmware-based switch that lets you enable meter features through software

communication. V-Switch

without removal from service.

Multifunction Measurement * * * *

Programmable Display * * * *

Time of Use ****

System Events * * *

Input Status Change * * * *

Limits ****

Harmonics * * * *

TM

key technology allows meter upgrades after installation

Features V1 V2 V3 V4

1: Meter Overview

2 MB Memory** (3 Historical logs) *

10 MB Memory** (6 Historical logs) *

128 MB Memory** (6 Historical logs) *

Waveform 128 samples *

Waveform 512 samples *

CT/PT Compensation * * * *

TLC Compensation * * * *

IEC 61850 Protocol * * *

DNP3 ****

Modbus Protocol*** * * * *

** Note that some memory is reserved for internal operations.

*** See the Shark® 250 Meter Modbus Protocol Application Guide for instructions on

using Modbus with the meter.

Doc# E169701 1-3

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Obtaining a V-SwitchTM Key:

Contact EIG’s inside sales staff at sales@electroind.com or by calling (516) 334-0870

(USA) and provide the following information:

1. Serial number(s) of the meter(s) you are upgrading. Use the number(s), with leading zeros, shown in the Communicator EXT

TM

Communicator EXT

2. Desired V-Switch

Main screen, click Tools>Device Status).

TM

key.

3. Credit card or Purchase Order number. EIG will issue you the V-Switch

TM

Enabling the V-Switch

1. Open Communicator EXT

Key:

TM

software.

TM

Device Status screen (from the

TM

key.

2. Power up your meter.

TM

3. Connect to the Shark® 250 meter through Communicator EXT

software.

4. Download all meter logs and then reset them - see chapters 16 and 20 in the

Communicator EXT

TM

4.0 and MeterManager EXT Software User Manual for instruc-

tions on doing this; you can access the manual by clicking Help>Contents from the

Menu Bar at the top of the software’s Main screen.

5. Click Tools>Change V-Switch from the Menu Bar. A screen opens, requesting the

encrypted key.

6. Enter the V-Switch

TM

key provided by EIG.

Doc# E169701 1-4

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

7. Click the Update button. The V-SwitchTM key is enabled and the meter resets.

TM

8. Configure the log sizes - see Chapter 28 in the Communicator EXT

4.0 and Meter-

Manager EXT Software User Manual for instructions.

Doc# E169701 1-5

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1.1.4: Measured Values

The following table shows the primary measurements of the Shark® 250 meter.

Measured Values Instantaneous Avg Max Min

Voltage L-N X XXX

Voltage L-L X XXX

Current per Phase X XXX

Current Neutral X X X X

Watt (A,B,C,Total) X X X X

VAR (A,B,C,Total) X X X X

VA (A,B,C,Total) X X X X

PF (A,B,C,Total) X X X X

+Watt Hour (A,B,C,Total) X

-Watt Hour (A,B,C,Total) X

Watt Hour Net X

+VAR-Hour (A,B,C,Total) X

-VAR-Hour (A,B,C,Total) X

VAR-Hour Net (A,B,C,Total) X

VA-Hour (A,B,C,Total) X

Frequency X X X

Harmonics to the 40th Order X

THD X X X

Voltage Angles X

Current Angles X

Waveform Scope X

TDD X X X

K Factor X X X

Q X XXX

Q-Hours X

Symmetrical Components X X X

Voltage Unbalance X X X

Current Unbalance X X X

Doc# E169701 1-6

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1.1.4.1: Update Rate

Instantaneous power W, VA, VAR

and energy Wh, VAh, VARh readings: Every 6 cycles.

All other parameters: Every 60 cycles.

1.1.5: Utility Demand

The Shark® 250 meter provides user-configured Block (Fixed) window or Rolling

window Demand modes. This feature lets you set up a customized Demand profile.

Block window Demand mode records the average demand for time intervals you

define (usually 5, 15 or 30 minutes). Rolling window Demand mode functions like

multiple, overlapping Block windows. You define the subintervals at which an average

of Demand is calculated. An example of Rolling window Demand mode would be a 15minute Demand block using 5-minute subintervals, thus providing a new Demand

1: Meter Overview

reading every 5 minutes, based on the last 15 minutes. Utility Demand features can

be used to calculate W, VAR, VA and PF readings.

NOTES:

• If the meter loses power, average for the Demand interval is computed based on

energy readings for the time the meter was online.

• If there are multiple instances of power loss during an Demand interval, Cold Load

functionality is available only once for Demand computation for that interval. See

page 9 for an explanation of cold Load.

1.2: Advanced Measurement Functionality

The following sections describe the Shark® 250 meter’s measurement features in

detail.

1.2.1: Advanced Revenue Billing Capability

The Shark® 250 device is a full four-quadrant power and energy meter with 0.2

Accuracy class. Energy measurements include: kWh Delivered & Received, kVARh

Delivered & Received, kVAh, kVARh, kWh in each quadrant and Total kVAh. The meter

measures instantaneous power and provides multiple, simultaneous demand measurements, including time-stamped maximum and minimum readings.

Doc# E169701 1-7

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Time of Use

The Shark® meter’s Time of Use functionality offers the following standard

capabilities:

• 16 TOU schedules.

• Bidirectional consumption and Demand.

• 4 seasons/year and up to 12 months/year.

• Season may be customized for daily or weekly use.

• Perpetual calendar.

• 4 accumulation rates and a totalizer rate.

• Prior month and prior season readings for each schedule.

• Prior month and prior season for each accumulation rate, for each defined data set.

• Current month and current season readings for each schedule.

• Current month and current season for each accumulation rate, for each defined

data set.

• Total-to-date readings for each month.

• Total-to-date readings for each season.

• Cumulative Demand with continuous Cumulative Demand option.

• Configurable auto self-read for season and months, or manual read.

NOTE: If you make changes to either the current/voltage ratio, energy scaling or

similar format settings in the meter's profile; or the configuration of TOU datasets,

rates, schedules or day types, the data in the meter may no longer be consistent with

the previous accumulated data. Any time you change these values you should reset

the TOU data by performing a Master TOU reset action (see the Communicator EXT

TM

4.0 and MeterManager EXT Software User Manual for instructions.)

Doc# E169701 1-8

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Multiple Demand Windows

The Shark® 250 meter simultaneously calculates four quadrant demand with the

following features:

• Block Window Demand or Rolling Window Demand averaging, divided into of up to

4 subintervals.

• Cumulative Demand.

• Continuous Cumulative Demand.

• Total Demand Distortion.

• Cold Load Pickup.

• Programmable Interval length of 5 minutes, 15 minutes, 30 minutes and 60

minutes.

• End of Interval Pulse Output (with optional 4PO1 card).

• End of Interval Pulse Input (with optional 4PO1 or 4RO1 card).

Cold Load Pickup/Demand Forgiveness

The meter offers Cold Load Pickup/Demand Forgiveness, so that in case a power system outage or excessive power system voltage drop occurs, when normal service is

resumed, the customer will not be billed for the initial surge or in-rush of power to

feed its “cold loads.” During the initial time period immediately following the return of

normal electric service, the demand is not computed in the Demand Registers if the

two threshold conditions described below are met, so the customer is not billed for

possible excessive demand due to “cold load pickup.”

• A power system outage which drops the metering potential inputs to the meter (to

below a programmed threshold) and also drops the meter’s power.

• A power system outage which drops the metering potential inputs to the Meter (to

below a programmed threshold), but the meter’s external power remains supplied

by an alternate source (e.g., station battery, station service, etc.), that is, the

meter continues to operate.

Doc# E169701 1-9

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Note that energy is always continuously measured and is also recorded in the Power

Profile Logs, if so configured. See Chapter 28 in the Communicator EXT

TM

4.0 and

MeterManager EXT Software User Manual, for instructions.

Time Stamped Max/Min Readings

The unit gathers time stamped Max/Min Demands for all power values. Each of the

following values is date/time stamped:

• W Demand, Delivered & Received, Max/Min.

• VAR Demand, Delivered & Received, Max/Min.

• VA Demand, Max/Min.

• Amps Demand, Max/Min.

• Voltage, Max/Min.

Transformer Loss Compensation

Transformer Loss Compensation adjusts for both copper and iron losses with a simple

user setup.

1.2.2: Communications and I/O Capabilities

The Shark® 250 meter features advanced communication which utilizes multiple Com

ports using open protocols. The meter’s multi-port design allows multiple communication connections simultaneously. The Shark® 250 meter’s system provides a direct

digital link, allowing selected data to be gathered without affecting the meter or your

data. All of the advanced features of the 250 are made available through industrystandard Modbus or DNP3 protocols. No proprietary or closed protocols are used.

Standard Communication

• USB port, supporting Modbus ASCII, fixed at 57600 bps, 8 data bits, 1 stop bit,

parity set to None.

• RS485 serial port, supporting Modbus RTU/ASCII, DNP3 Level 2, speeds from 1200

bps through 57600 bps, 8 data bits, 1 stop bit, configurable parity.

Doc# E169701 1-10

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Optional Communication

The Shark® 250 meter allows you to select up to two optional cards for the following

uses:

• INP100S optional Ethernet Option card communicating Modbus TCP and DNP3 over

Ethernet.

• INP300S optional Ethernet card with Modbus TCP and embedded IEC 61850 Protocol server.

• FOSTS: Fiber Optic Output ST Terminated.

• FOVPS: Fiber Optic Output Versatile Link Terminated.

• RS1S: RS485/RS232 Serial Communication Option card.

Both the INP100S and the INP300S cards offer enhanced security through the

Exclusive Client feature. This feature lets you Whitelist an IP and/or MAC address.

When that address is used to connect to the meter, all other network communication

with the meter, though the same Network card, is suspended. This ensures that anything being done, e.g., updating programmable settings, while the Whitelist address is

being used to communicate with the meter, is secure. You set up this feature through

Communicator EXT

TM

software - see Chapter 28 in the Communicator EXTTM 4.0 and

MeterManager EXT Software User Manual for instructions.

The INP100S card also supports data push of up to 15 meter readings to cloud services using the JSON structure, such as Lucid BuildingOS® Data Push. For instructions on setting up the meter to perform data push, see 7.4.2.4: Data Push, on

page 7-22.

I/O (Input and Output) capability is available in conjunction with all metering functions:

• Optional 4 high-speed status inputs for status detect or for use as load aggregation/universal metering inputs.

• Optional pulse outputs which can be programmed to pulse for any accumulated

reading. One of the pulse outputs can also be set for an End-of-Interval Sync Pulse.

Doc# E169701 1-11

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

Upgradeable Optional I/O

The user can select from the following optional I/O cards:

• Analog Outputs (0 +/- 1 mA or 4-20 mA).

• Pulse Outputs/Digital Inputs.

• Relay/Digital Inputs.

Control Options

Relay Control provides user-definable control outputs:

• Action and/or alarm on abnormal or other user-set conditions.

Doc# E169701 1-12

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1.2.3: Meter Display

The Shark 250 meter features a three line LED display for easy to use faceplate

programming and viewing of meter readings. Refer to Chapter 2 for details on the

meter’s display.

1.3: Shark® 250 Meter Accuracy

For 23 oC +/- 5 oC, 3 Phase balanced Wye or Delta load, at 50 Hz or 60 Hz (as per

order), Class 20 and Class 2 unit, accuracy as follows:

Parameter Accuracy Accuracy Input Range

Voltage L-N [V] 0.1% of reading (57 to 480) V

Voltage L-L [V]

Current Phase [A]

Current Neutral (calculated) [A]

Active Power Total [W]

Active Energy Total [Wh]

Reactive Power Total [VAR]

Reactive Energy Total [VARh]

Apparent Power Total [VA]

Apparent Energy Total [VAh]

Power Factor

0.2% of reading

0.1% of reading

2% of Full Scale

0.15% of reading

0.15% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

2

1, 3

1

1, 2

1, 2

1, 2

1, 2

1, 2

1, 2

1, 2

(100 to 720) V

(1 to 100)% of Current Class (CL)

(1 to 100)% of CL

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0.5 to 1) lag/lead

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0.5 to 1) lag/lead

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0 to 0.8) lag/lead

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0 to 0.8) lag/lead

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0.5 to 1) lag/lead

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0.5 to 1) lag/lead

I: (1.25 to 50)% of CL

V: (57 to 480) V

PF: +/-(0.5 to 1) lag/lead

Frequency [Hz] +/- 0.007 Hz (45 to 65) Hz

Harmonic Distortion (1 to

99.99)% [%]

+/- 2%

1, 4

I: (2.5 to 50)% of CL

V: (57 to 480) V

Doc# E169701 1-13

1: Meter Overview

Electro Industries/GaugeTech

The Leader In Power Monitoring and Smart Grid Solutions

1

For 2.5 element programmed units, degrade accuracy by an additional 0.5% of

reading.

• For 1 A (Class 2) Nominal, degrade accuracy to 0.5% of reading for watts and

energy; all other values 2 times rated accuracy.

• For 1 A (Class 2) Nominal, the input current range for accuracy specification is

20% of the values listed in the table.

2

For unbalanced Voltage inputs where at least one crosses the 150 V auto-scale

threshold (for example, 120 V/120 V/208 V system), degrade the accuracy to 0.4%

of reading.

3

With regard to current readings, reference Voltage applied (V A, V B, or V C).

Otherwise, degrade accuracy to 0.2%. See hookup diagrams in 4.8: Electrical

Connection Diagrams, on page 4-8.

4

At least one Voltage input (minimum 20 V AC) must be connected for THD

measurement on current channels.

1.4: Shark® 250 Meter Specifications Overview

Sense Inputs Electrical Ratings

Current

• The current inputs are transformer rated and only to be connected to external CTs.

• Programmable current to any CT ratio.

• Transformer rated.

• The meter will operate using 2, 2.5, or 3 element measurements.

• Class 10: (00.005 to 11) A, 5 A nominal.

• Class 2: (0.001 to 2) A, 1 A nominal.

• Burden: 0.005 VA per phase at 11 A.

• Pickup Current: 0.1% of nominal - Class 10: 5 mA; Class 2: 1 mA (0.2% of nominal

is using current only mode, with no connection to the voltage inputs).

• Continuous maximum ratings (for screw terminated or pass-through connections):

Class 10: 20 A AC; Class 2: 5 A AC.

Doc# E169701 1-14

Loading...

Loading...