Electro Composites SDC User Manual

General information on handling

and maintenance of

Capacitor Bushings

SDCTM Solid Dielectric

Electro Composites (2008) ULC

Tel: (450) 431-2777

Web site: http://www.hubbellpowersystems.com/about/ec/

Revision 3 February 21, 2012

Foreword

This guide is intended to address issues strictly relating to ELECTRO COMPOSITES

(2008) ULC cycloaliphatic epoxy resin, dry type bushings for use on transformers, circuit

breakers and reclosers. Issues relating to any other ELECTRO COMPOSITES (2008)

ULC product should be addressed with ELECTRO COMPOSITES (2008) ULC Technical

staff.

These guidelines are presented as suggestions only and are not intended to reflect the

specific conditions of our product's usage on your equipment. As such, we recommend

that you use this information carefully and take the necessary steps to ensure that it

accommodates your particular application and operating conditions. The reader is

requested to address any questions or concerns directly with ELECTRO COMPOSITES

(2008) ULC technical staff for further information and instructions on proper installation,

use and maintenance of our bushings.

ELECTRO COMPOSITES (2008) ULC makes no warranty, representations, whether

express or implied, or representation and assumes no liability for the accuracy of the

information in this document or the use of such information. All information contained in

this guide is subject to change without prior notice. PLEASE REFER TO THE

DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITY at the end of this

document.

Page 2 of 12

This guide is intended to provide the user with information concerning the handling and

maintenance of ELECTRO COMPOSITES (2008) ULC polymeric bushings, from the

time the bushings are received until they are put into service, as well as general

maintenance guidelines after specific in-service periods. All possible contingencies,

which may arise during installation, operation, or maintenance, and all details and

variations of this equipment, are not purported to be covered in this guide. For any

questions that may arise and not covered by this guide, the reader is recommended to

contact ELECTRO COMPOSITES (2008) ULC for assistance.

GENERAL BUSHING INFORMATION

ELECTRO COMPOSITES (2008) ULC Dry Type bushings are designed for use on

transformers and oil circuit breaker applications, up to 170 kV voltage class and 5000A

current rating. Bushings can be designed to conform to the following bushing standards:

IEC 60137: Insulated Bushings for Alternating Voltages Above 1000V

ANSI/IEEE C57.19.01: Standard Performance Characteristics and

Dimensions for Outdoor Apparatus Bushings

ANSI/IEEE C57.19.00: Standard General Requirements and Test Procedure

for Outdoor Power Apparatus Bushings

CAN/CSA C88.1: Power Transformer and Reactor Bushings

(Please refer to the bushing drawing for the applicable standard)

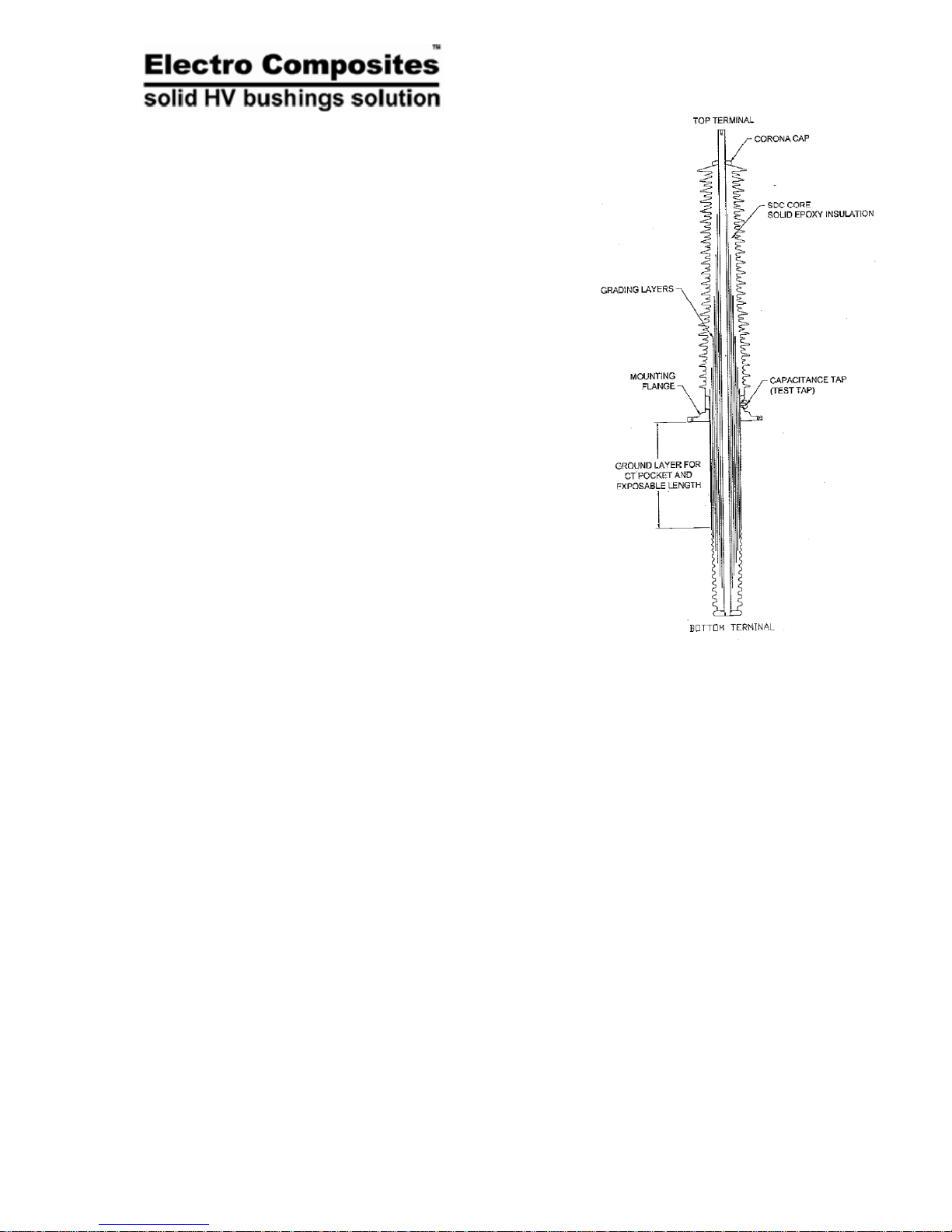

ELECTRO COMPOSITES (2008) ULC bushings

consist of a central electrolytic copper conductor,

either solid core or draw-lead type, encapsulated in

a monolithic solid rigid cycloaliphatic epoxy resin

dielectric body. External sheds are integral to the

epoxy core eliminating all interfaces through the

insulting core. A high strength aluminum flange is

bonded to the epoxy body and allows for mounting.

All working surfaces are precision machined for

optimal fit. The flange is designed to insure

maximum seal – with no leakage permitted between

the flange and the epoxy body. A non-foil

condenser shield (or series) is cast into the resin

along with the conductor, providing necessary EField grading and distribution. In the case of oil

circuit breaker type bushings, the condenser shield

is permanently connected to the metallic flange via

a setscrew insuring shield grounding. In the case of

transformer type bushings, a capacitance tap

connection is supplied. The outermost shield is

accessible through a threaded pin, insulated from

the flange when the capacitance tap button is

removed, allowing for capacitance and power factor

measurements.

THREADED HOLE

FOR EYE BOLT

TOP TERMINAL

CONDENSER SHIELD

CAPACITANCE TAP

CENTRAL CONDUCTOR

CROWN CAP

DIELECTRIC

EPOXY BODY

HIGH STRENGTH

MOUNTING FLANGE

BOTTOM TERMINAL

Page 3 of 12

There is no oil or other fluids or gases used in the

construction of ELECTRO COMPOSITES (2008) ULC

bushings.

AT ALL TIMES VERIFY THAT THE BUSHING IS

PROPERLY GROUNDED AND THAT THE

CAPACITANCE TAP SPRING AND CONTACT

WASHER ARE IN PLACE WHEN THE TAP COVER

IS CLOSED, OTHERWISE THE GROUNDING

SHIELD WILL NOT BE GROUNDED AND BUSHING

FAILURE WILL OCCUR.

After installation of the bushing on the equipment,

before the bushing is energized, proper steps must be

taken to insure the bushing is grounded. Verification

of the ground contact can be done by measuring the

resistance between the bushing flange and the

equipment on which the bushing is installed using an

ohm-meter. A maximum value of 0.5 ohm should be

measured under dry condition. If the measured value

is greater than the limit indicated, check the bushing

installation and verify the resistance again, or provide

other means to ground the bushing to the equipment.

ELECTRO COMPOSITES (2008) ULC bushings are

not supplied with a potential or voltage tap. Never

exceed 1000V when testing the bushings for

capacitance and power factor measurements.

However, test taps are insulated to 2000V.

This document does not purport to provide safe practices for use of equipment or the

performance of work around equipment where ELECTRO COMPOSITES (2008) ULC

bushings are installed. Installation and maintenance of ELECTRO COMPOSITES

(2008) ULC bushings is to be carried out by trained, certified and approved personnel

only. Although ELECTRO COMPOSITES (2008) ULC bushings present no danger to

personnel when not energized, reasonable care is to be taken when handling and

transporting bushings. Some edges may be sharp and bushings are bulky and heavy.

Page 4 of 12

Loading...

Loading...