ElectrIQ eiQ-CRFC18K, eiQ-SSRFC36K, eiQ-SSRFC24K, eiQ-SSRFC48K, eiQ-SSRFC60K Instruction And Installation Manual

INSTRUCTION AND

INSTALLATION MANUAL

CEILING MOUNTED CASSETTE

AIR CONDITIONER

Compact Cassette

eiQ-CRFC18K

18,000 BTU

Round-Way Cassette

eiQ-SSRFC24K

24,000 BTU

eiQ-SSRFC36K

36,000 BTU

Round-Way Cassette

(3 Phase Outdoor)

eiQ-SSRFC48K

48,000 BTU

eiQ-SSRFC60K

55,000 BTU

Thank you for choosing an electriQ Air Conditioner

Please read this user manual before using this innovative

Air Conditioner and keep it safe for future reference.

2

CONTENTS

CONTENTS 2

SAFETY INSTRUCTIONS 3

HOW AIR CONDITIONERS WORK 5

OPERATION 6

PARTS 6

PANEL 7

OUTDOOR UNIT (DRAWINGS ARE FOR REFERENCE ONLY) 8

REMOTE CONTROL 9

MAINTENANCE 14

END OF SEASON 15

START OF SEASON 15

REPLACING THE BATTERIES 15

INSTALLATION GUIDE 16

TOOLS RECOMMENDED FOR INSTALLATION 18

INSTALLATION OF THE INDOOR CASSETTE UNIT 19

DRAINAGE PIPE INSTALLATION 24

PANEL INSTALLATION 26

INSTALLATION OF THE OUTDOOR UNIT 27

CONDENSATE DRAINAGE OF THE OUTDOOR UNIT 29

REFRIGERANT PIPE INSTALLATION 30

ELECTRICAL CONNECTION OF THE AIR CONDITIONER 36

TEST RUN 39

TROUBLESHOOTING AND SELF DIAGNOSIS 40

TECHNICAL SPECIFICATION 43

APPENDIX 46

3

SAFETY INSTRUCTIONS

IMPORTANT!

Carefully read the instructions before operating the unit

This appliance comprises of a cassette unit, a panel and an outdoor unit. The cassette is

designed exclusively for indoor installations while the external condenser can be installed

outside while still away from flood water or snow line.

Always place the unit on a dry and stable surface. Install the outdoor unit on a wall with wallmounting brackets or fix to a floor slab with special floor mounting slab bolts or brackets

away from flood or snow lines.

This appliance is intended for permanent installation into a fixed structure, and should not

be installed on vehicles.

The outdoor part of the air conditioner unit must always be stored and transported upright,

otherwise irreparable damage may be caused to the compressor; if in doubt we suggest

waiting at least 24 hours before starting the unit.

European Union regulations requires for an F-Gas trained engineer to handle any operation

where non-qualified intervention could cause fluorinated gas to escape. A commissioning

certificate must be issued with any installation.

This air conditioner contains R32 with a GWP of 675.

This air conditioner has been tested and is safe to use. However, as with any electrical

appliance - use it with care.

Disconnect the power before dismantling, assembling or cleaning.

Never connect the unit to an electrical outlet using an extension cord. Both the indoor and

outdoor units must be hardwired by a qualified electrician.

Never operate this appliance if the cord is damaged. Ensure the power cord is not stretched

or exposed to sharp objects or edges.

A damaged supply cord should be replaced by the manufacturer or a qualified electrician in

order to avoid a hazard.

Avoid touching any moving parts within the appliance.

Never insert fingers, pencils or any other objects through the guard

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities. It is also not intended for use by those with a lack of

experience and knowledge, unless they have been given supervision or instruction

concerning the use of the appliance by a person responsible for their safety. Do not leave

children unsupervised with this appliance.

Do not clean the unit by spraying it or immersing it in water.

Any service other than regular cleaning or filter replacement should be performed by an

authorized service representative or a qualified air conditioning engineer. Failure to comply

could result in a voided warranty.

This air conditioner is intended for cooling / heating a room to a suitable level for human

comfort, and should not be used for any other purpose such as cooling food.

Avoid restarting the air conditioning unit unless 3 minutes have passed since being turned

off. This prevents damage to the compressor.

Never use the mains as a switch to start and turn off the air conditioning unit. Use the

provided ON/OFF button located on the remote control.

The indoor unit should not be installed in laundry or wet rooms.

After cleaning the mesh filter, reinstall it as soon as possible; do not operate the unit without

the mesh filter; otherwise it may affect the operation of the unit.

Lightning and other electromagnetic radiation sources may affect the operation of the unit.

During these conditions, disconnect the power supply and then power on after the

4

influence has been eliminated.

The operation parameters and protection device settings have been set during production;

these settings must only be changed by a qualified engineer with understanding of their

usage as incorrect settings could disable the unit’s protection features leading to damage of

the unit.

The unit must be sited far from any fire hazard. In case of fire due to short circuit, immediately

disconnect the power and extinguish the fire with a dry powder fire extinguisher. The unit

must only be installed by a qualified F-gas registered engineer.

Decommissioning or moving of the unit must only be carried out by a qualified F-gas

registered engineer.

Do not operate or store inflammable or explosive articles around or below the unit; otherwise

it may lead to a fire hazard.

If the unit is not to be used for a while, turn off the mains supply so as to avoid accident.

Avoid moisture ingress to the electric control system; otherwise it may lead to short circuit

or damage to the machine.

Please ensure the desired temperature is set correctly, especially when elderly, children or

people with limited mobility or mental capability are within the room.

In case of breakdown, the user should report the fault to the retailer or manufacturer for

consultation and repair rather than attempting diagnosis or repair; attempted repairs of the

unit by non-professional staff may lead to personal injury or damage to the unit, and may

invalidate the warranty.

In case of refrigerant leak, the stress meter will stop the operation of unit, a qualified F-gas

engineer should be contacted to arrange service;

The refrigerant may discompose into a harmful gas if allowed into contact with an open fire.

Do not touch the exhaust side pipe fittings to avoid scalding since the temperature may be

in excess of 100°C.

Sharp edges and the fin surfaces must not be touched to prevent the risk of cuts or injury.

WARNING

Do not use means to accelerate the defrosting process or to clean,

other than those recommended by the manufacturer.

The appliance shall be stored in a room without continuously

operating ignition sources (For example: open flames, an operating

gas appliance or an operating electric heater)

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

ENERGY SAVING AND UNIT SAFETY PROTECTION TIPS

Do not cover or restrict the airflow from the outlet or inlet grills.

For maximum performance the minimum distance from a wall or objects should be 50cm.

Keep the filters clean. Under normal conditions, filters should only need cleaning once every four

weeks (approximately). Since the filters remove airborne particles, more frequent cleaning maybe

necessary, depending on the air quality.

For the initial startup set the fan speed to maximum and the thermostat to 4-5 degrees lower than

the current temperature. After, set the fan switch to low and set the thermostat to your desired

setting.

To protect the unit we recommend not using the cooling mode when the ambient indoor

temperature is higher than 35℃.

To protect the unit we recommend not using the heating mode when the indoor ambient

temperature is lower than 7℃. Performance will be reduced at lower temperatures.

Note the manufacturer operating temperature ranges at the end of this user manual.

5

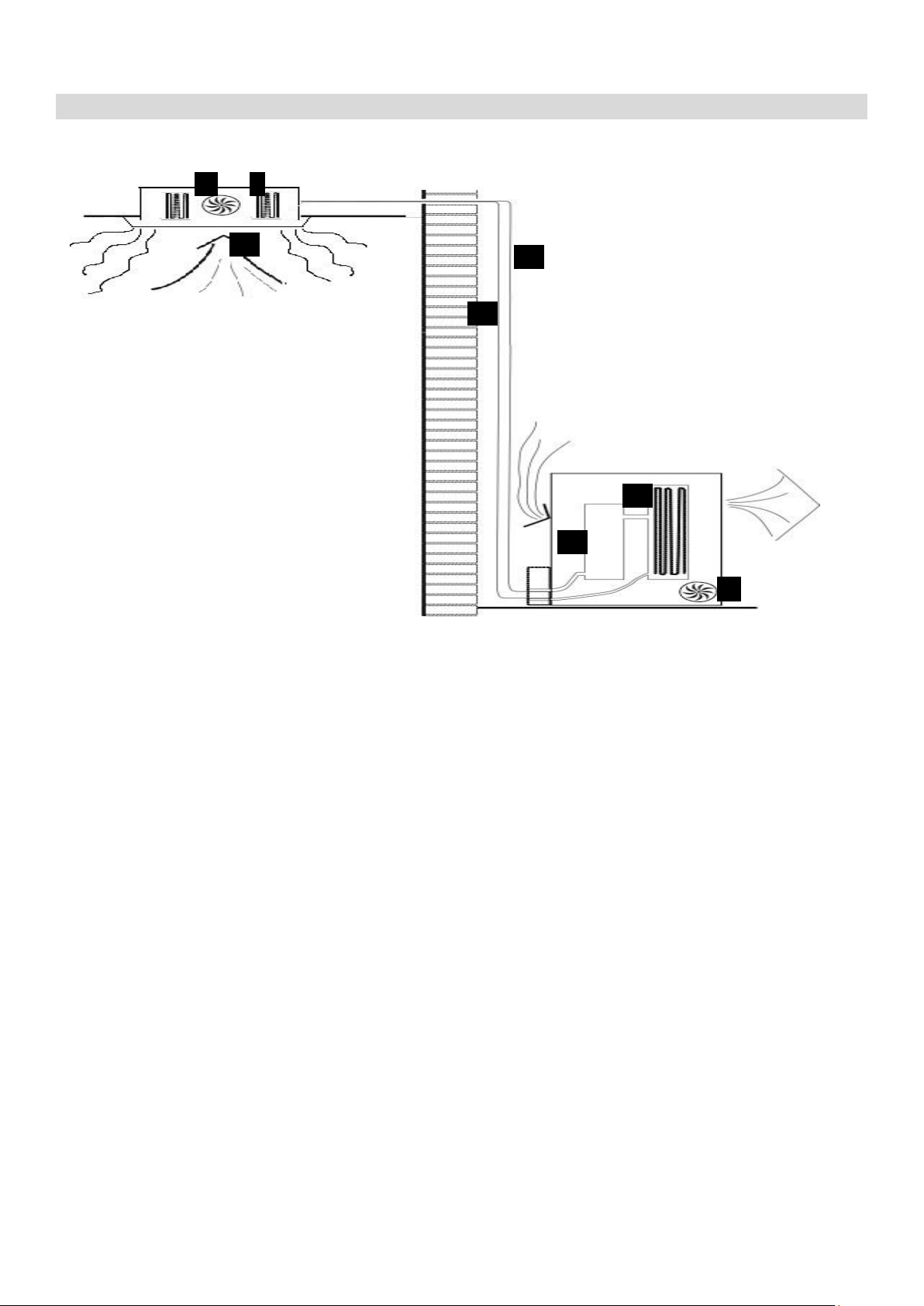

HOW AIR CONDITIONERS WORK

COOLING MODE

The compressor (6) in the external unit compresses the refrigerant into a high-temperature, highpressure gas. When this gas flows along the cooling fins of the condenser (7), heat is exuded and

the gas condenses into a liquid, which is then led to the evaporator (1) in the indoor unit. The liquid

expands into a gas at a low temperature and low pressure. This gas absorbs the warmth of the air

in the room, and a fan (3) draws the air through the filter and over the evaporator (1), blowing the

cooled air back into the room. The heat is moved to the compressor along with the gas. A fan (8)

draws air over the condenser and blows the warm air away.

1. Evaporator

2. Filter

3. Evaporator Fan

4. Gas Line

5. Liquid line

6. Compressor

7. Condenser

8. Condenser Fan

HEAT PUMP MODE

The system operates in reverse: the condenser works as an evaporator, the evaporator as

a condenser: warm air is blown into the room. It is ideal as a maintenance heating when

outside temperature is not too low and when the indoor temperature is more than 7°C.

DEHUMIDIFYING

As with cooling, the moisture in the air condenses on the cold evaporator at room temperature

acting as a powerful dehumidifier.

3 1

2

4

5

7

6

8

6

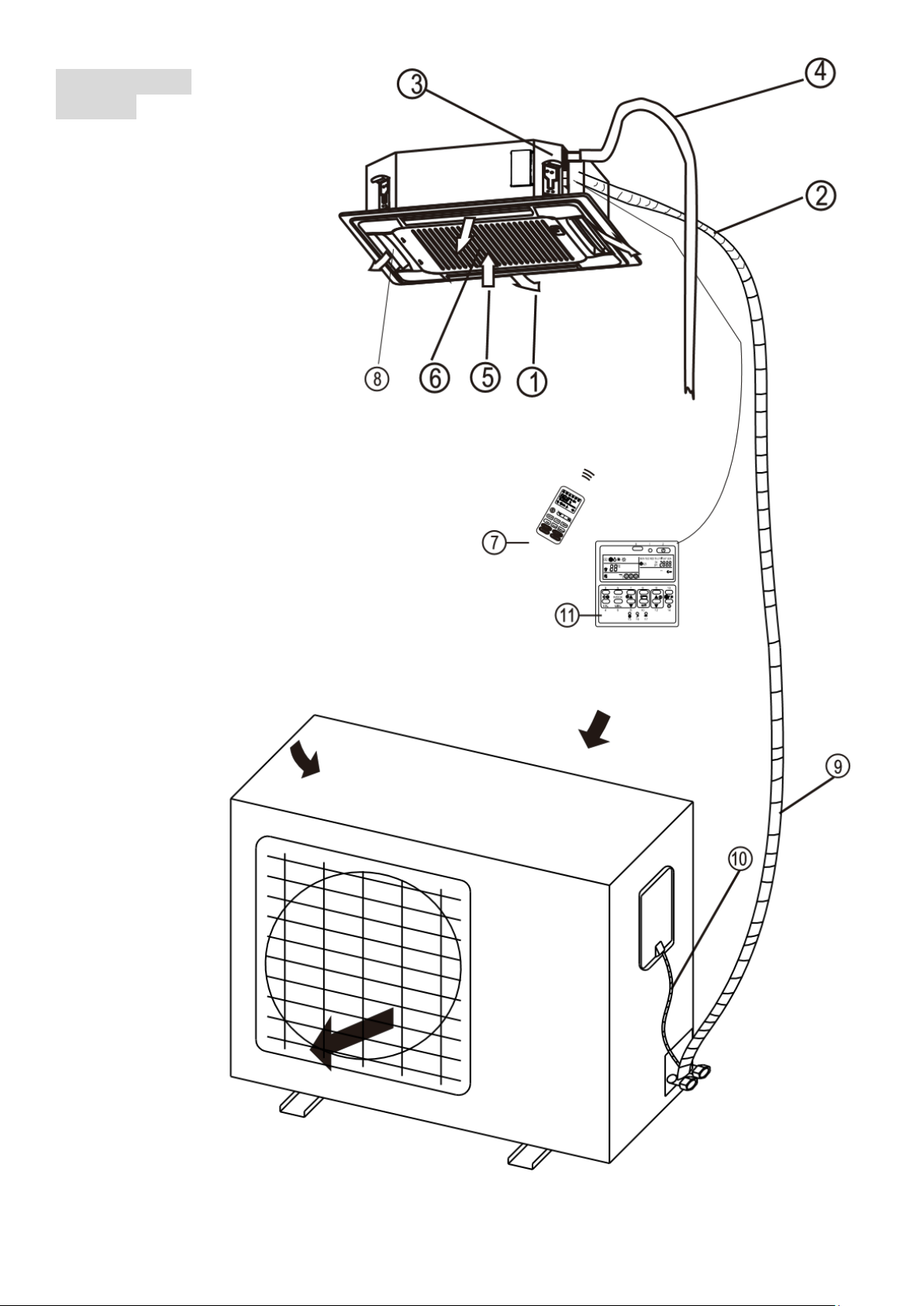

OPERATION

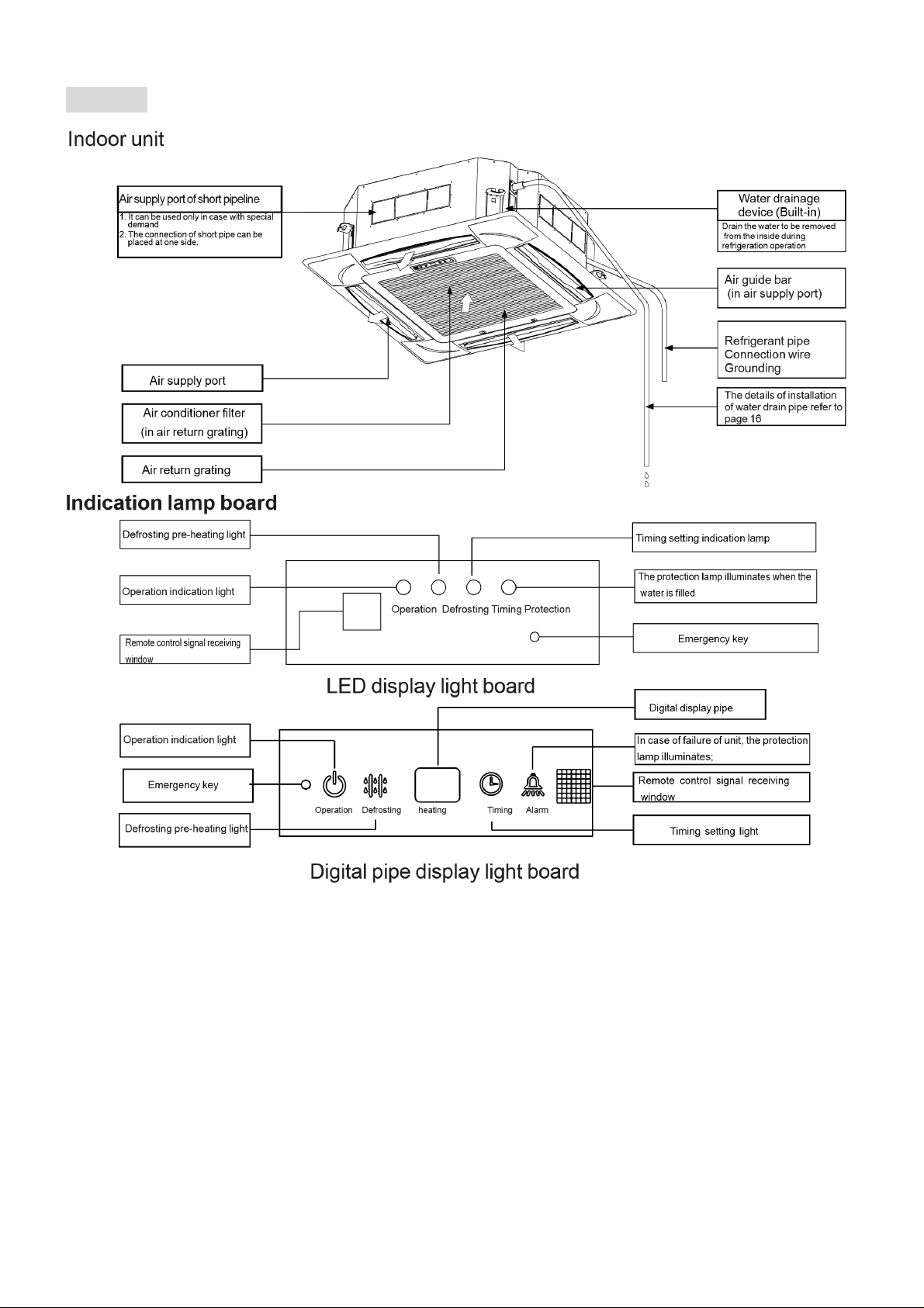

PARTS

INDOOR UNIT

1 Air Outlet

2 Refrigerant pipe junction

3 Uplift Pump

4 Drainage Pipe

5 Air Return

6 Filter

7 Remote Control

8 Louvre for airflow

9 Refrigerant pipes

10

Interconnecting Cable

11

Optional Wall Controller

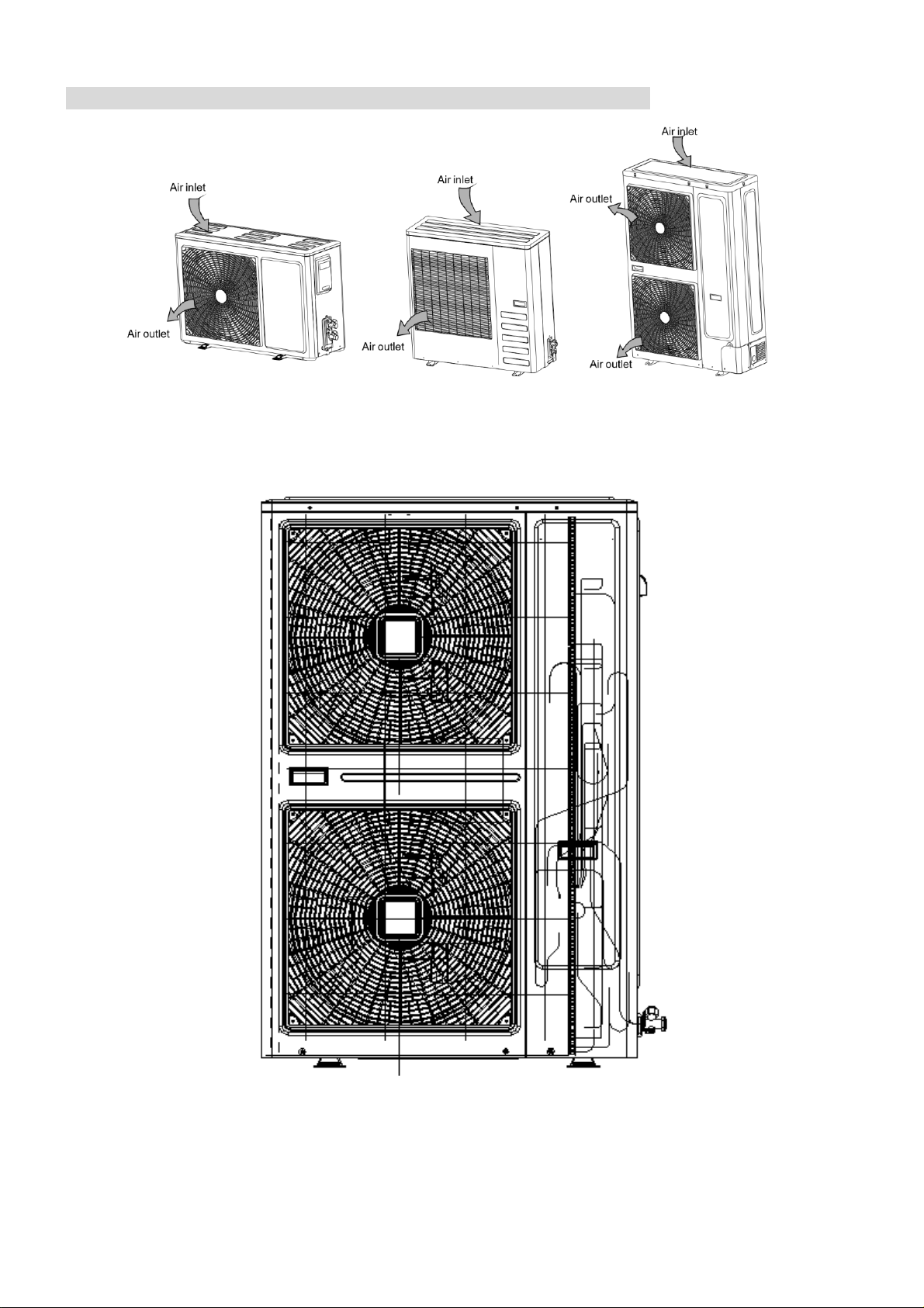

OUTDOOR UNIT

7

PANEL

8

OUTDOOR UNIT (DRAWINGS ARE FOR REFERENCE ONLY)

9

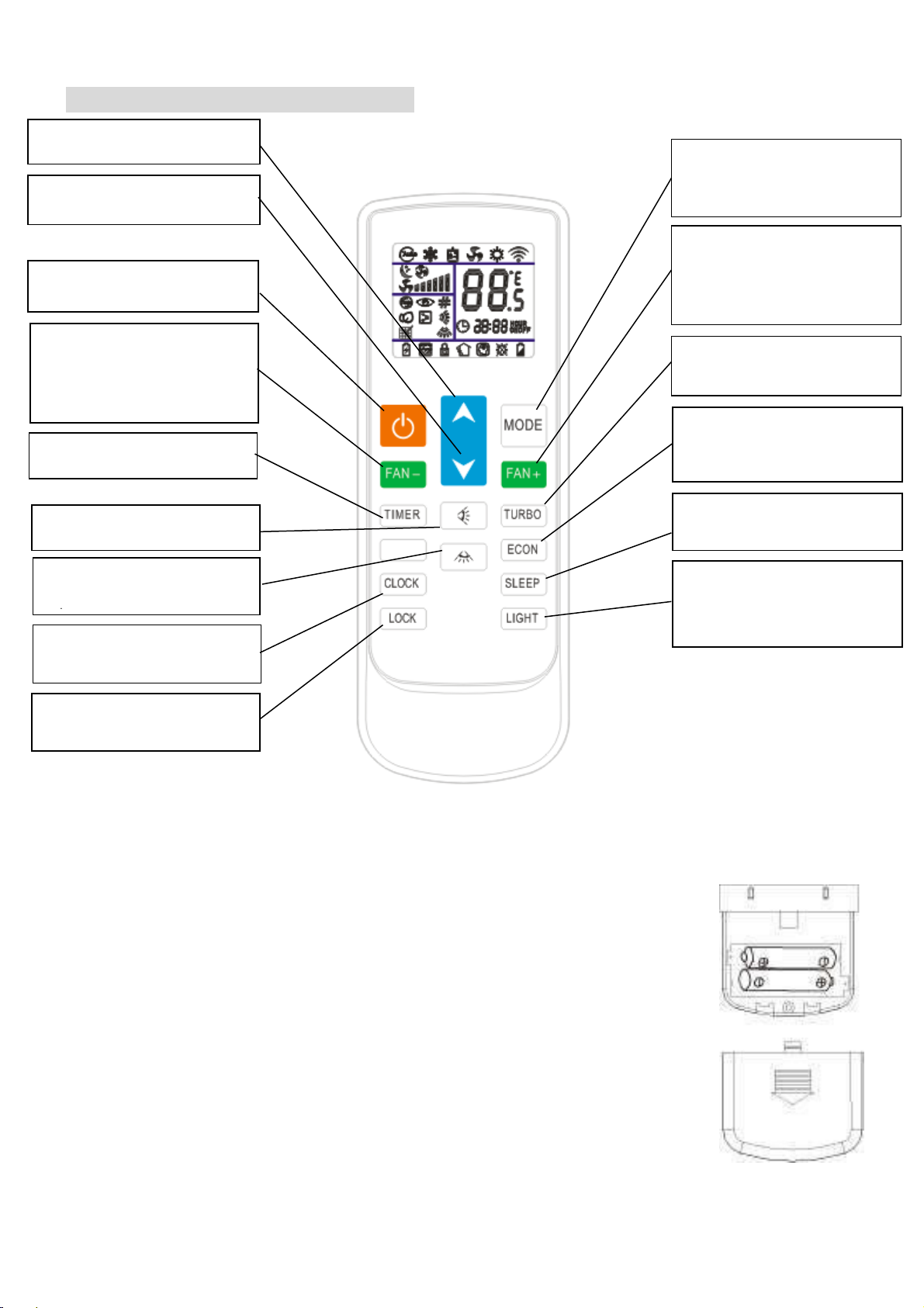

REMOTE CONTROL DIAGRAM

NOTICES FOR REMOTE CONTROL:

1.

Do not place the remote control near high temperature heat sources.

2.

Do not leave the remote control exposed to the direct sunshine.

3.

Be careful not to drop the remote as this may lead to damage.

4.

There must be no barrier between the signal receiver and remote control

as this may affect communication between them.

5.

Do not allow the remote control to be splashed or immersed in water.

6.

Do not place heavy items on top of the remote control.

Note: In case of failure of the remote control, please remove the back cover

and replace the batteries, before repeating the operation; if the failure still

exists, please run the air conditioner using the emergency operation method,

and contact the manufacturer or retailer.

POWER

Turn the appliance On / Off.

REDUCE FAN SPEED

Reduce the fan speed by one level.

Please note: When on the lowest fan

speed it will change to auto.

Pressing again will change the unit

to high

TIMER

Turn the timer ON/OFF.

CLOCK

Press to adjust the current time.

LOCK

Press to lock the buttons on the

remote.

INCREASE TEMPERATURE

Increase the desired temperature.

INCREASE FAN SPEED

Increase the fan speed by one level.

Please note: When on the highest

fan speed it will change to auto.

Pressing again will change the unit to

low.

TURBO (dependant on model)

Enter the turbo function for enhanced

short term performance.

ECON

Automatically sets the desired

temperature to 26 ℃ in cooling or

heating mode.

SLEEP (dependant on model)

The air conditioner will enter sleep

mode.

LIGHT (Dependant on model)

Forced closing or lighting of display

panel. Decide whether to have this

function according to the actual

model.

VERTICAL SWING

Press to activate the vertical swing.

HORIZONTAL SWING

(Dependant on model)

Press to activate the horizontal

MODE

Select between automatic, cooling,

dehumidification, fan and heating

modes.

REDUCE TEMPERATURE

Decrease the desired temperature.

10

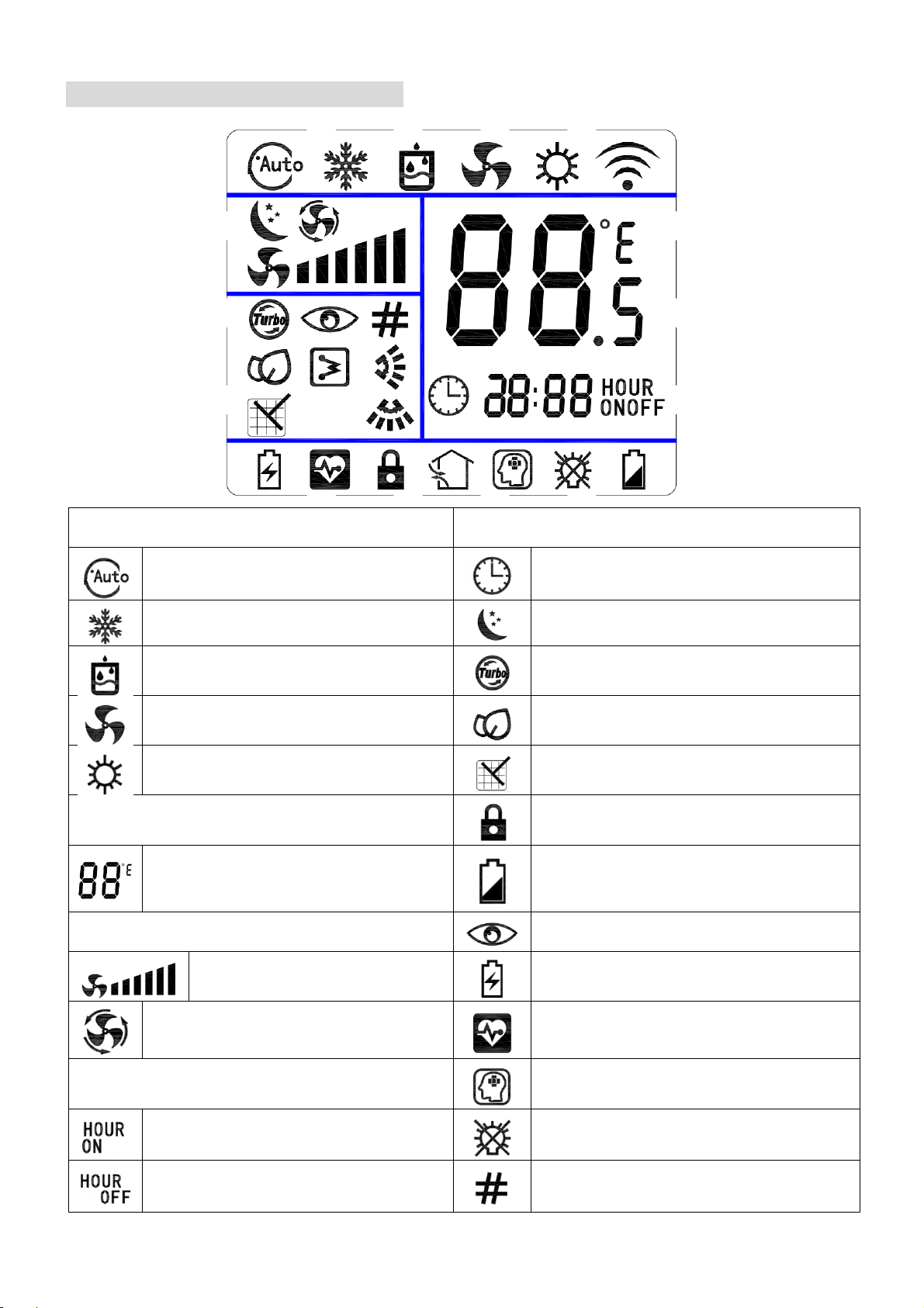

REMOTE CONTROL DISPLAY

MODES

OTHER ICONS

AUTO MODE

CLOCK

COOLING MODE

SLEEP FUNCTION

DEHUMIDIFIER MODE

TURBO FUNCTION

FAN MODE

ECON FUNCTION

HEATING MODE

CLEANING FUNCTION

TEMPERATURE DISPLAY

REMOTE LOCKED

CURRENT TEMPERATURE

Ranges between 16 - 32C

BATTERY LOW

FAN SPEED

AUTO CONFIG

LENGTH OF BAR

INDICATES FAN SPEED

POWER SAVING MODE

AUTOMATIC FAN SPEED

HEALTH MODE

TIMER

INTELLEGENT MODE

ON TIMER

BACKLIGHT OFF

OFF TIMER

ADDRESS

11

REMOTE CONTROL FUNCTIONS

POWER

This button will turn the air conditioner On and Off.

1. When first powered on, air conditioner will start with the default settings:

Desired temperature 25°C

Automatic mode and Automatic fan speed.

Vertical and Horizontal Swing.

TURBO, Sleep, Timer and lock off.

2. When powered on subsequently the unit will continue with the previously used settings but

sleep, TURBO, ECON and timer functions will be cancelled if previously activated.

MODE

1. Press this button to change between Automatic, cooling, dehumidify, fan and heating modes.

2. The dehumidification mode is set with a desired temperature of 25℃ and the temperature

cannot be adjusted.

REDUCE TEMPERATURE ▼

1. When pressing this button, the desired temperature will be reduced by 1°C. When pressing

this button in dehumidification and fan modes, the desired temperature will not be adjusted.

2. After the clock button has been pressed (The clock icon will flash), this button is used to set

the time.

INCREASE TEMPERATURE ▲

1. When pressing this button, the desired temperature will be increased by 1°C. When pressing

this button in dehumidification and fan modes, the desired temperature will not be adjusted.

2. After the clock button has been pressed (The clock icon will flash), this button is used to set

the time.

VERTICAL SWING - EXTERNAL FLAPS (Dependant on Model)

1. Press this button to change the vertical swing between fixed position and swing operation.

2. Press this button in dehumidify mode to close the external flaps.

HORIZONTAL SWING - INTERNAL FLAPS (Dependant on Model)

1. Press this button to change the horizontal swing between fixed position and swing operation.

2. Press this button in dehumidify mode to close the internal flaps.

REDUCE FAN SPEED

1. Press this button to reduce the fan speed. When going below low, the unit will enter Automatic

mode. When pressed again the fan speed will be set to high.

2. In dehumidify mode, the fan speed is fixed to low and is not adjustable.

INCREASE FAN SPEED

1. Press this button to increase the fan speed. When going above high, the unit will enter

Automatic mode. When pressed again the fan speed will be set to low.

2. In dehumidify mode, the fan speed is fixed to low and is not adjustable.

12

TIMER

The timer can be used as a start timer or a shutdown timer and can be set between 1 hour and

24 hours in 1 hour increments. This is a one use timer, and multiple timers cannot be combined.

START TIMER

1. With the air conditioner turned off, press the timer button, before using the ▲and ▼buttons

to set in how many hours you would like the unit to start.

2. The unit will operate with the settings used before the appliance was turned off.

SHUTDOWN TIMER

1. With the air conditioner running with the desired setting, press the timer button, before

using the ▲and ▼buttons to set in how many hours you would like the unit to turn off.

TURBO (Dependant on model)

1. The TURBO button will not work in Automatic, Dehumidify or fan modes.

2. Press this button in cooling or heating modes to turn the TURBO function on or off.

3. When in the TURBO mode the fan speed will not be displayed.

4. Switching modes or pressing the sleep button will turn off TURBO mode.

ECON

1. The ECON button will not work in automatic, dehumidify or fan modes.

2. Press this button in cooling or heating modes to turn on ECON mode.

3. When in ECON mode, the desired temperature is set to 26℃.

4. When ECON mode is turned off the desired temperature will return to the value before the

button was pressed.

5. Switching between modes will turn off ECON mode.

SLEEP

1. Sleep mode can be activated in all modes apart from Fan mode.

2. Switching mode will cancel the sleep function.

3. When sleep mode is activated the fan speed will automatically be set to low, but can still be

increased if necessary (except in dehumidification mode).

LIGHT (Dependant on Model)

1. Press to turn the backlight on and off.

CLOCK

1. This button is used to set the clock. Press to adjust the hour value, the hour figure on the LCD

will flash. Use the ▲and ▼ buttons to adjust.

2. When the hour is set, press the clock button again to adjust the minute value, the minute figure

on the LCD will flash. Use the ▲and ▼ buttons to adjust.

3. After adjusting, press the clock button again to confirm the time set. If no buttons are pressed

for 3 seconds, the changes will be cancelled and the remote will return to normal operation.

LOCK

1. Press the Lock button to lock the buttons on the remote control.

2. When the remote is locked, the only button still active is the lock button

BUTTON COMBINATION: FAN - + FAN +

Will change the remote from showing 3 fan speeds to 6 fan speeds. As the air conditioners only

supports 3 speeds, 1/2 is Low speed, 3/4 is Medium speed, and 5/6 is high speed.

13

IMPORTANT INFORMATION

AUTO RESTART

The air conditioner will automatically restart when electricity is restored after a power cut. If in

doubt, check the settings.

RANGE OF INTERNAL THERMOSTAT

The internal thermostat can be set at a desired temperature between 16 and 32°C. Note that

whether the desired value is achieved depends on the room size, temperature and insulation of

the room.

RANGE OF HEAT PUMP FUNCTION

The heat function can be used when the external ambient temperature is above -15°C. The

performance of the heat pump will degrade with lowering external temperatures. Please note the

performance will reduce when the outdoor temperature drops below 5°C.

CAPACITY

The required cooling or heating capacity depends greatly on the location and/or use of the room

where the air conditioner is installed. Strong sunlight and the presence of people, lights or

equipment creates an additional heat load. Normal living spaces require about 350 Btu per

square metre of floor surface. In strong sunlight or if other sources of heat are present, this may

be as much as 1200 Btu per sqm.

Tip: On warm days, let the air conditioner cool the room as much as possible during the night

and keep the temperature constant from night to daytime.

14

MAINTENANCE

FILTERS

Ensure the power is turned off to the unit before attempting to service the filters.

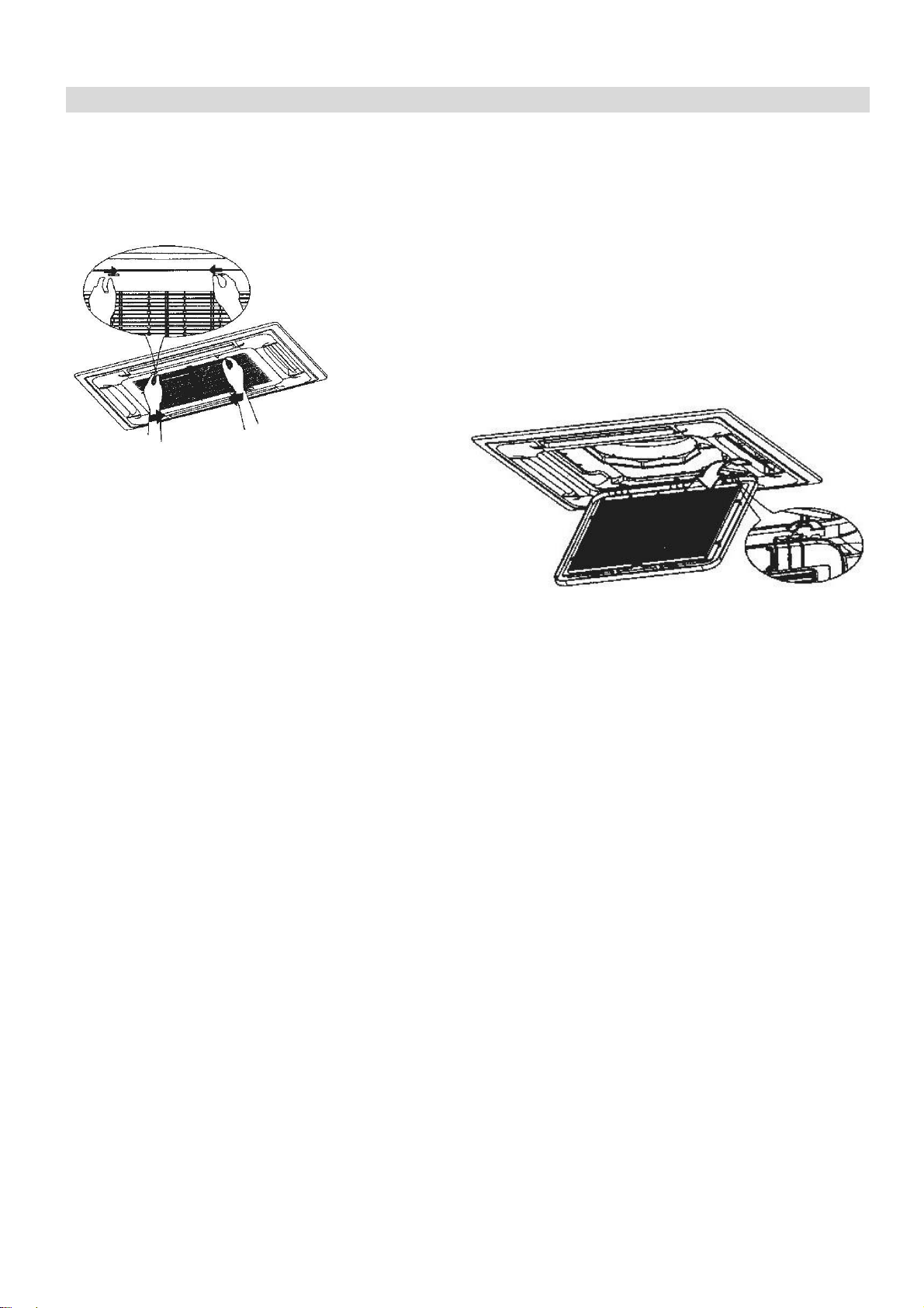

REMOVING THE GRILL

1.

Push the two grill switched towards the centre to

unhook the grill before pulling the centre of the panel

downwards.

2.

Care must be taken with the electrical

connectors (connecting the panel to the

main cassette) If necessary these

should be disconnected.

3.

Hold the grill at a 45 angle to the unit

and lift to unhook from the rear of the

panel.

4.

The filter can then be removed from the grill for cleaning.

CLEANING THE FILTERS

Clean the air filter with a vacuum cleaner or rinse with clean water.

If the filter is heavily soiled, a soft brush should be used with mild detergent.

Ensure the filter is fully dried before reinserting back into the grill and reattaching to the unit.

CLEANING THE OUTDOOR UNIT

While the unit is disconnected from power. Remove dirt and keep the air intake and exhaust

openings free of debris, etc. Cleaning with chemicals may cause damage.

15

END OF SEASON

If the air conditioner is not going to be used for an extended period:

•

Set in fan mode on a slightly warm day so that the inside of the appliance dries out.

•

Switch off the power at the fuse box and remove the batteries from the remote control.

•

Clean the filters.

•

Remove the batteries from the remote control.

•

Disconnect the power from the appliance

START OF SEASON

If the air conditioner is to be used again after an extended period:

•

Check that the air intake and exhaust openings of the interior and exterior units are not

blocked. Remove any dirt or debris that has accumulated.

•

Check that the filter is installed within the indoor unit and is clean.

•

Check that the condensation outlet drains properly and there is no dirt or organic blockage

(otherwise leakage may occur)

•

Install 2 AAA batteries in the remote control.

•

Check that the wiring between the cassette and the panel is connected, and there is no

damage to the interconnecting wires.

•

Turn the appliance on, set the time and desired setting.

REPLACING THE BATTERIES

•

Remove the cover from the rear of the remote control.

•

Replace the AAA batteries, ensuring the correct polarity.

•

Reinstall the cover on the rear of the remote control.

•

If nothing is displayed on the remote, try pressing the power

button. If still no response, check the polarity of the batteries and

try replacing.

16

INSTALLATION GUIDE

SAFETY

Only qualified personnel should install this appliance. This installation manual is intended

for use by individuals possessing adequate backgrounds and qualifications in electrical,

electronic, refrigerant and mechanical fields. Any attempt to install or repair the appliance

may result in personal injury and property damage.

The manufacturer and retailer cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection with its use.

The units are designed for permanent installation.

The equipment is designed for domestic or office use and we are not making any

endorsements for use in industrial or maritime environment.

Do not place near sources of heat, vapours, industrial machine oil or other

flammable gases.

High-frequency waves generated by radio equipment, welders and medical equipment

will interfere with the normal operation of the unit.

Install this device only when it complies with local/national legislation, ordinances and

standards.

Check the mains voltage and frequency. The information, specifications and parameter

are subject to change due to technical modifications or improvement without any prior

notice. The accurate specifications are presented on the nameplate label.

Please read this installation manual completely before installing the product.

When the power cord is damaged, replacement work shall be performed by authorized

personnel only.

Installation work must be performed in accordance with all European, national and / or

local directives and standards and must be done by authorized personnel only.

Always make sure to wear the correct personal safety protections such as protective

eyewear, gloves, ear protection etc.

This air conditioner contains a refrigerant and can be classified as pressurized

equipment. Therefore always contact an authorized air conditioning engineer for

installation and maintenance of the air conditioner.

The air conditioner must be inspected and serviced on an annual basis by an authorised

air conditioning engineer.

Each indoor unit has a separate refrigerant circuit, and as such each circuit must be

individually pressure tested and purged during installation.

Rating: This unit must be only connected to a suitable earthed power source.

The unit should use an independent power supply switch and a separate circuit to other

electric appliances; use a power supply cable with specified section area to supply the unit

and equip the circuit with the correct rating of circuit breaker (with electric leak protection

function).

Installation must be in accordance with the regulations of the country where the unit is

used.

Diagrams and pictures provided within the manual are for guidance only. Due to continual

product development, if there is any variance between the manual and the product

received, the information provided on the product should be followed.

The outdoor unit must be mounted in an area sheltered from excessive rain and direct

sunlight; we will not be liable for problems caused by installation in an unsuitable location.

17

The appliance must be installed 2 - 3m above floor level.

The unit must be mounted with an earth wire with the specified section area and securely

mounted; do not connect the earth wire with the earth wire of gas pipelines, water pipelines,

arrester conductor or phone systems so as not to cause an electric shock risk.

The main power supply switch of unit should be placed out of reach of children so as not to

cause a hazard.

INDOOR UNIT POSITION

The air inlet and outlet vent should be away from any obstruction, ensuring that there is a good

airflow through the whole air-conditioned space. Select a position where the condensing water can

be easily drained out, and the indoor unit can be easily connected to outdoor unit. The ceiling where

the unit is fixed should be strong enough to withstand the full weight and vibration of the unit. The

unit should be accessible for service and maintenance. The height of the installed unit should be

more than 200cm from the floor. The air conditioner must not be installed in a wet environment

such as a bathroom, shower or swimming pool etc.

OUTDOOR UNIT POSITION

A convenient position, dry and well ventilated, outside of direct sunlight or strong winds, which is

not on a flood line and where noise and airflow does not cause interference or inconvenience.

Select a location where there are no obstructions to the inlet and outlet vents. The location

should be able to withstand the full weight and vibration of the outdoor unit and permit safe

installation.

Make sure that the outdoor unit is installed in compliance with the installation dimension diagram

with easy maintenance access. Select a place where it is out of reach of children. Do not block

utilities access or fire escapes.

The external unit must be lifted and put in place by two people.

NOTES:

1. Only use a power supply with the correct ratings, making sure the correct sized power cables

are used

2. The appliance shall be installed in accordance with standard wiring regulations by qualified

personnel

3. Only replace fuses according to their printed rating or corresponding pcb boards.

18

TOOLS RECOMMENDED FOR INSTALLATION

Please note this is not an exhaustive list, and is provided as guidance for the most commonly

required tools.

Electric Drill

Hammer

Screwdrivers

Tape Measure

Core Hole Cutter

Spirit Level

Number 14 (7mm)

Masonry Drill

Pencil and Chalk

4 x M10 threaded

rods

Small Stepladder

7mm Wall Plugs

Protective Glasses

and Mask

Pipe and Cable

Detector

4 inch Plastic Ties

2 Inch Pipe Clips

Circuit Breaker

Garden Gloves

Dust Sheets

Foam Filler

Silicone Sealant

19

INSTALLATION OF THE INDOOR CASSETTE UNIT

Where possible the following areas should be avoided to avoid potential problems with the

appliance and/or safety risks:

1.

Where flammable gas is likely to be in the air.

2.

Where the air has a high salt content

3.

Where caustic gasses are likely to be in the air.

4.

Which is unable to safely bear the weight of the unit

5.

With high levels of electromagnetic interference.

6.

Where the unit may be subjected to acid or alkaline solutions.

7.

With high levels of humidity.

Select the installation location taking consideration of the following:

1.

Route of the pipework / wiring

2.

Access to the upper parts of the unit for connection of the pipework/wiring after hanging

the unit

3.

Ability of the area to support the weight of the unit.

Before hanging the unit the refrigerant pipes, drain pipe and connection wires should be led to

the location of the outdoor unit. Confirm the size of the indoor unit and ceiling opening using the

supplied installation template.

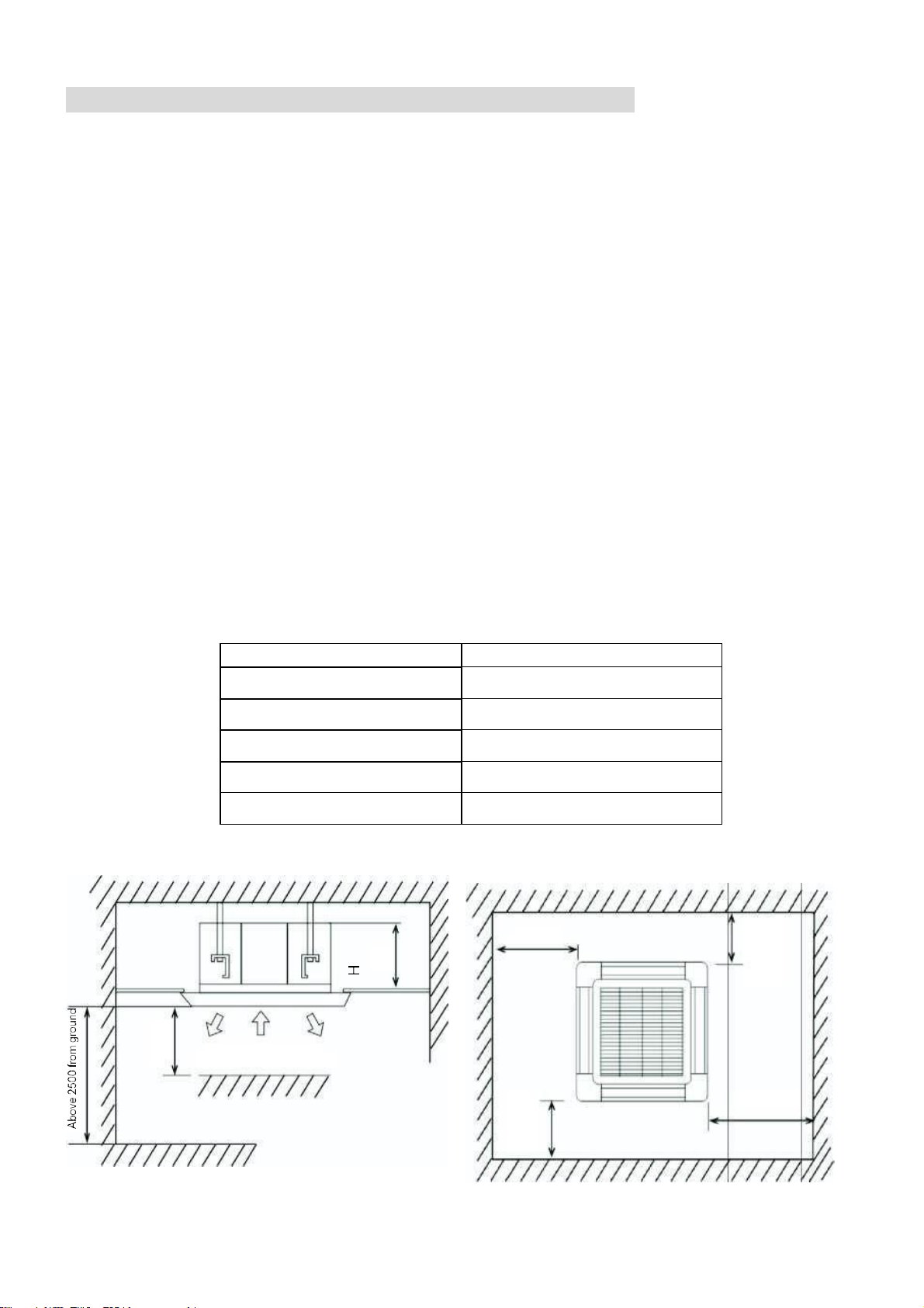

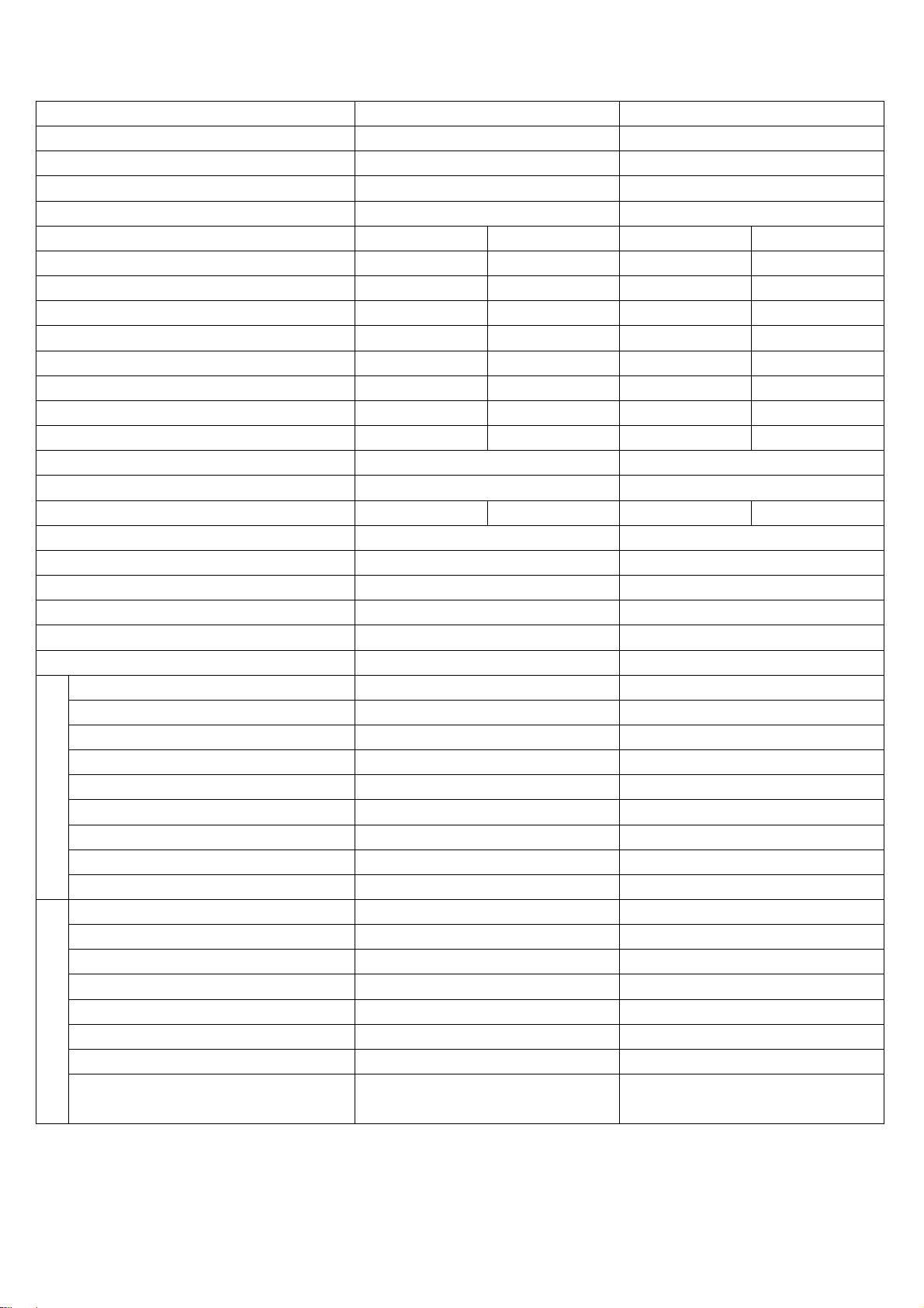

SPACE REQUIRED FOR INSTALLATION

Model

Machine body height (H) mm

eiQ-CRFC18K

267

eiQ-SSRFC24K

230

eiQ-SSRFC36K

285

eiQ-SSRFC48K

285

eiQ-SSRFC60K

285

Above1500

Above1500

Above1500

Above1500

Exhaust

Exhaust

Air inlet

20

Hoisting

bolt x4

Above

Hanging

Bracket

Refrigerant

A

Ceiling

D(

Distance between hoisting b)olts

C(indoor unit)

B(ceiling opening)

A(trim plate)

Unit: (mm)

Model

Size

A

B C D

E

eiQ-CRFC18K

650

610

565

528

528

eiQ-SSRFC24K

890

890

840

680

780

eiQ-SSRFC36K

eiQ-SSRFC48K

eiQ-SSRFC60K

21

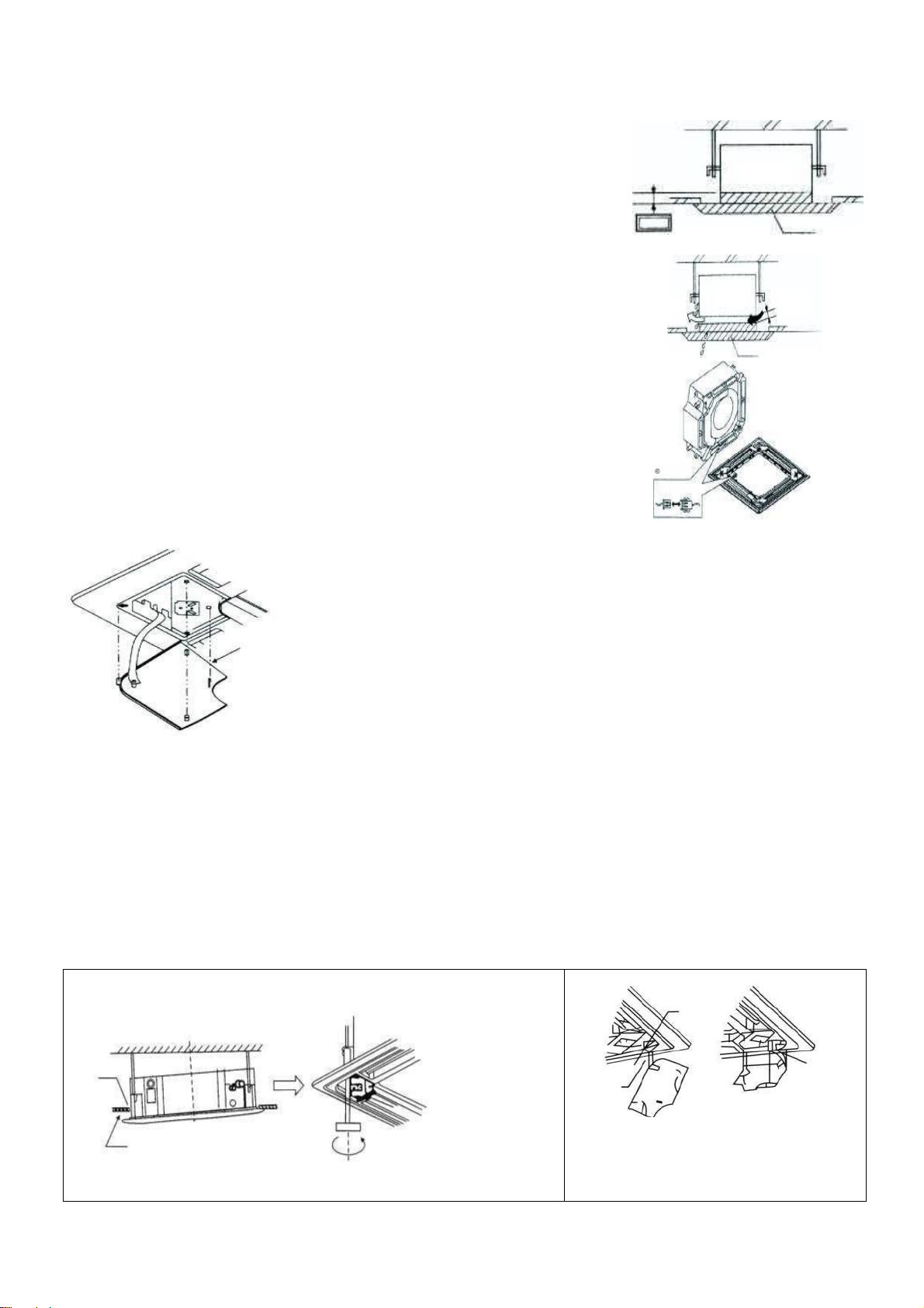

PREPARATION WORK ON THE CEILING

The indoor cassette unit is designed to be supported by 4 x threaded rods, connecting it to a solid

structure above.

The unit must be installed in accordance with current building regulations and the Installation

method should be adjusted depending on the structure of the ceiling. If in any doubt about what

installation method is suitable, independent advice should be sought.

After opening a hole, ensure that the ceiling is horizontal and strong to prevent vibration during

operation. Reinforcement of the ceiling around the opening may be necessary.

If beams require cutting to accommodate the unit, the remaining beams around the area should

be reinforced to compensate for the extra weight they are now supporting.

WOODEN CONSTRUCTION

Fix a square length of timber over the roof

beam and install the hanging screw bolts into it.

Timber over the beam

Roof beam

Ceiling

Hanging Screw Bolt

NEW CONCRETE PANELS

Blade shape

Slide insertion

Steel bar

Pipe hanging and

embedding screw bolt

FINISHED CONCRETE PANELS

Install the hanging hook using expandable bolts

into the concrete to a depth of at least 45mm to

prevent them coming use during operation.

STEEL ROOF BEAM STRUCTURE

Hanging screw bolt

Supporting

Hanging bolts

angle steel

22

HANGING THE CASSETTE UNIT

WHEN THERE IS NO INSTALLATION POSITION ON THE CEILING

1. Attach the hanging bracket seat to the hoisting bolt; be sure to use bolt and nut separately at

upper and lower head of the hanging bracket seat to firmly fix the hanging bracket seat; use

locating plate 7 to avoid the washer coming-off.

2. For the dimensions of the ceiling opening please refer to the installation drawings. The details

refers to the building agent or carpenter. The indoor unit centre is marked on the attached

installation drawing. As shown in the figure below, the screws 6 (3 pcs) mount the installation

label on the unit; fix the angle of the drain channel at the pipeline outlet with a screw.

3. Adjust the unit to the correct installation position.

4. Check whether the unit is level. The indoor unit is equipped with an embedded drain and float

switch. Check whether the four angles of unit are level.

5. Remove the washer fixing plate 7 ensuring the water-proof washer remains in position and

tighten the upper nut.

6. Remove the installation label.

WHEN THERE IS INSTALLATION POSITION ON THE CEILING

1. Temporarily install the indoor unit Attach the hanging bracket on the hoisting bolts. Be sure

to use bolt and nut separately at upper and lower head of the hanging bracket seat to firmly

fix the hanging bracket seat; use locating plate 7 to avoid the washer coming-off.

2. Adjust the height and position of unit.

23

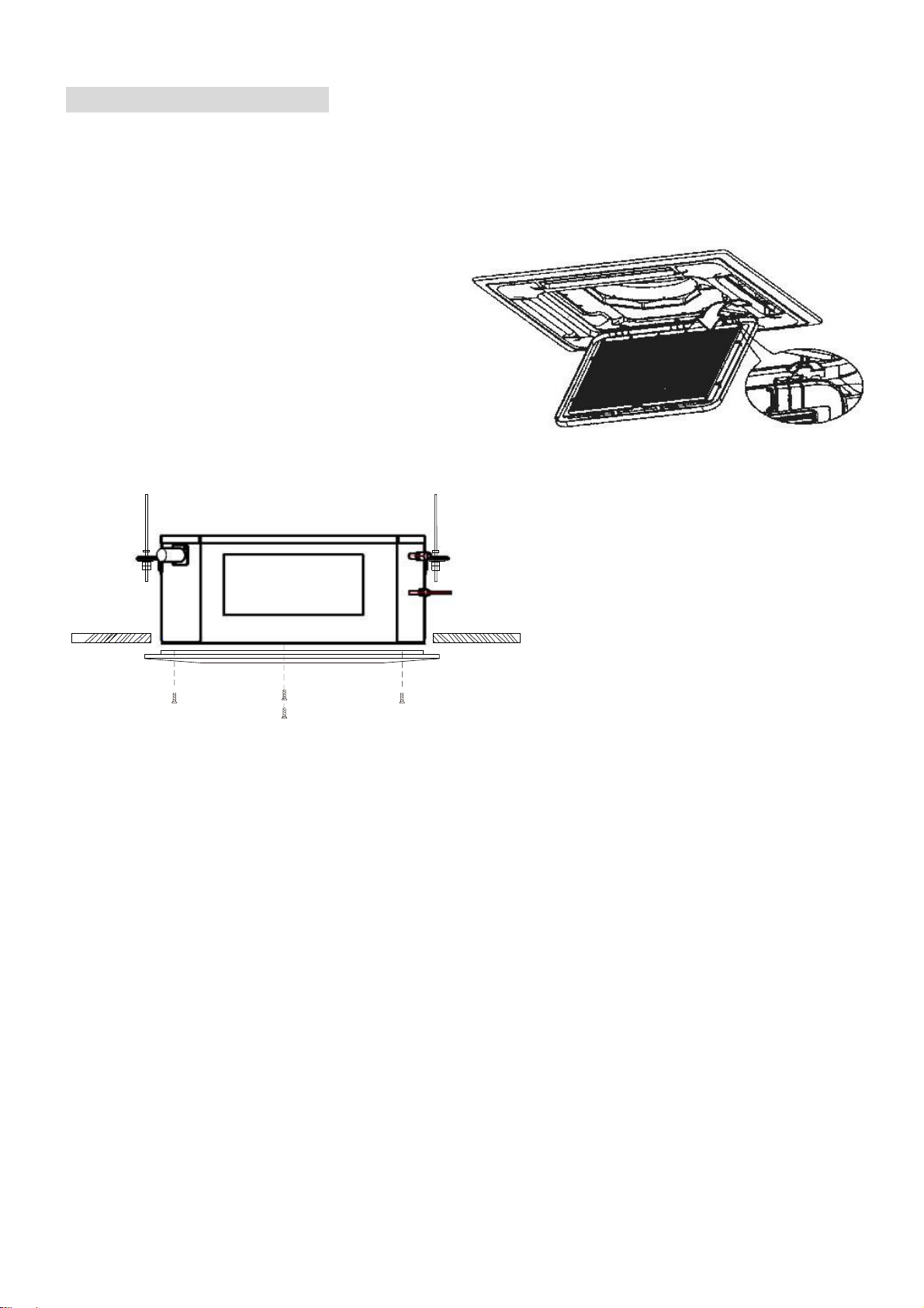

HOISTING HEIGHT OF INDOOR UNIT

Please adjust the hoisting height of indoor unit to make the

dimensions of indoor unit under the ceiling.

1. When there is gap between indoor unit and panel, condensation

may occur.

2. Line of trim panel (see right figure)

a. Connect the cable for the louvre motor (on the trim

panel).

b. If the connector is not connected, the louvres will not

function. Properly connect the joint.

c. Confirm the wires for the louvre motor are not clamped

between indoor unit and trim panel.

INSTALLATION OF AIR RETURN GRATING AND CAP

A. Install the air return grating

B. Install in reverse sequences to "Preparation of trim panel".

1013

Indoor unit

Panel

Install in reverse sequences to "Preparation of trim panel". While

rotating the air return grating, it can be installed in 4 directions. If

necessary to adjust the installation direction of the air return grating

as required by the user, the installation direction can be changed.

1. Firstly hang the air inlet grating onto the panel and then separately connect the connectors

from the louvre motor and control box on panel to related connectors of body.

2. Re-install the air inlet grating in reverse sequence to those when removing the air inlet grating;

3. Re-install the mounting cover plate.

4. Fix the mounting cover plate rope onto the lug (see the right figure); Gently press the mounting

cover plate in the panel.

①

First loosen the

Upper nut

No gap allowed

②

Adjust the

Lower nut

Install the cover plate

When installing the cover plate,

using a self tapping screw

mount the 4 slide fasteners into the

related slots.

~

Cool air

leak

Indoor

unit

Air guidance

clearance

Panel

Locationofindoorunit Attrimplate

24

DRAINAGE PIPE INSTALLATION

Please confirm there are enough space at unit installation position to mount the drainage

pipeline, and ensure the drain pipe diameter is no less than that of connection pipe.

(Polyethylene pipe, dimension: 25mm; outer diameter; 32mm)

1. The drain pipe should be short, and the slope of sagging should be equal to and

more than 1%, to. ensure drainage smoothness and avoid condensate lag

2. If impossible to ensure adequate slope for the drainage hose, a drainage lift pipe shall be

installed.

3. To avoid bending of drainage hose, it will keep 1 to 1.5m distance between hanging

bracket.

Slope above 1/100

4. Use the attached drainage pipe ① and clamp ②.

Insert the drainage hose into drainage socket till the white rubber belt. Tighten the clamp

until the distance of screw head from hose is less than 4mm.

5. Condensation may lead to water leak, so it is necessary to fulfil thermal insulation

construction for following two components.

1.

Drainage pipe in room;

2.

The drainage socket refers to the figure below; insulate the thermal for clamp and

drainage pipe with attached large sealing pad ⑩.

Large sealing pad

⑩ (accessories)

Clamp ② (accessories)

Water drain pipe ①

Notice for the drainage lift pipe:

Clamp ②

Below 4mm

(accessories)

1. The installation height of drainage lift pipe shall be less than 550mm.

2. The exhaust lift pipe shall be perpendicular to the unit and be no more than 300mm from the

unit.

Ceiling

Within 300mm

1 -1.5 m

Hanging bracket seat

Below 550mm

Drainage hose

①

( accessories )

Clamp ② ( accessories )

Drainage lift pipe

200 mm

0.8 to 1 m

Adhesive tape (white)

25

Notes:

1.

Do not make the attached drainage hose subjected to excess force or bending and

twisting. (It may lead to water leak)

2.

Please install according to following procedure if several drainage pipes converge.

T- Joint

converge

drainage pipe

Above 100mm

The specification of selected converge drainage pipe shall be suitable for operation

capacity of unit. After completed the installation, slowly fill 2000cc water in the exhaust

port or inspection hole and check whether the drainage is smooth; after installation of

electric circuit, check the drainage conditions during refrigerant operation and the

detailed instructions refer to "test run". Water injection method

Access hole

Drainage pipe

Inspection hole

Service hood

Drainage outlet for

Maintenance (with rubber

plug)(discharge the water in

( Fill water from inspection hole )

Plastic spraying pot

( The pipe shall be about 100mm long

)

( Injection from exhaust port )

26

PANEL INSTALLATION

The panel should be installed after the pipework and wiring have been connected.

Following installation ensure that the gaps between the panel and the ceiling are sealed to

prevent air and liquid leakage.

1. Push the two grill switched towards the

centre to unhook the grill before pulling the

centre of the panel downwards to remove it

from the panel.

2. Hold the grill at a 45 angle to the unit and lift

to unhook from the rear of the panel.

3. Hold the panel against the cassette

unit, lining up the red arrow on the

electrical box with the one on the

panel, before loosely fastening with

the M6 bolts.

4. Connect the cables for the step

motors and display panel to the

cassette following the wiring diagram

provided, ensuring that the cables will

not get trapped when tightening the

panel.

5. If the optional wired display panel is also to be installed, it should be also be connected to the

cassette at this point.

6. Check the position of the panel before fully tightening the bolts, so that the panel is flush to the

cassette unit.

7. Reattach the Grill to the panel following the reverse of removal.

8. If there is a gap between the panel and the ceiling after tightening the screws, readjust the

height of the cassette, ensuring it is kept level.

27

INSTALLATION OF THE OUTDOOR UNIT

In order to ensure the correct working of the air conditioner, in the choice of installation

location, the following guidelines must be followed:

1.

Upon installation of the outdoor unit, the air discharged outdoors should not return, and

enough space for maintenance must be left around the machine.

2.

The ventilation must be excellent in mounting points, so that the machine can intake and

discharge sufficient air. Make sure there are no obstacles for air inlet and outlet; any

obstacles should be removed.

3.

The installation location is strong enough to withstand the weight of the outdoor unit, and

has the effect of sound insulation and vibration reduction. And to ensure that outlet air

and noise of the unit will not affect the neighbours.

4.

Avoid direct sunlight, it's best to put up an sunshade for protection.

5.

In the mounting position, rain and condensate water must be drained.

6.

In the installation position, it must be ensured that the machine will not be buried in the

snow, and not subject to the effects from garbage and mists.

7.

In the installation position, it must be ensured that the air outlet is not facing the strong

wind.

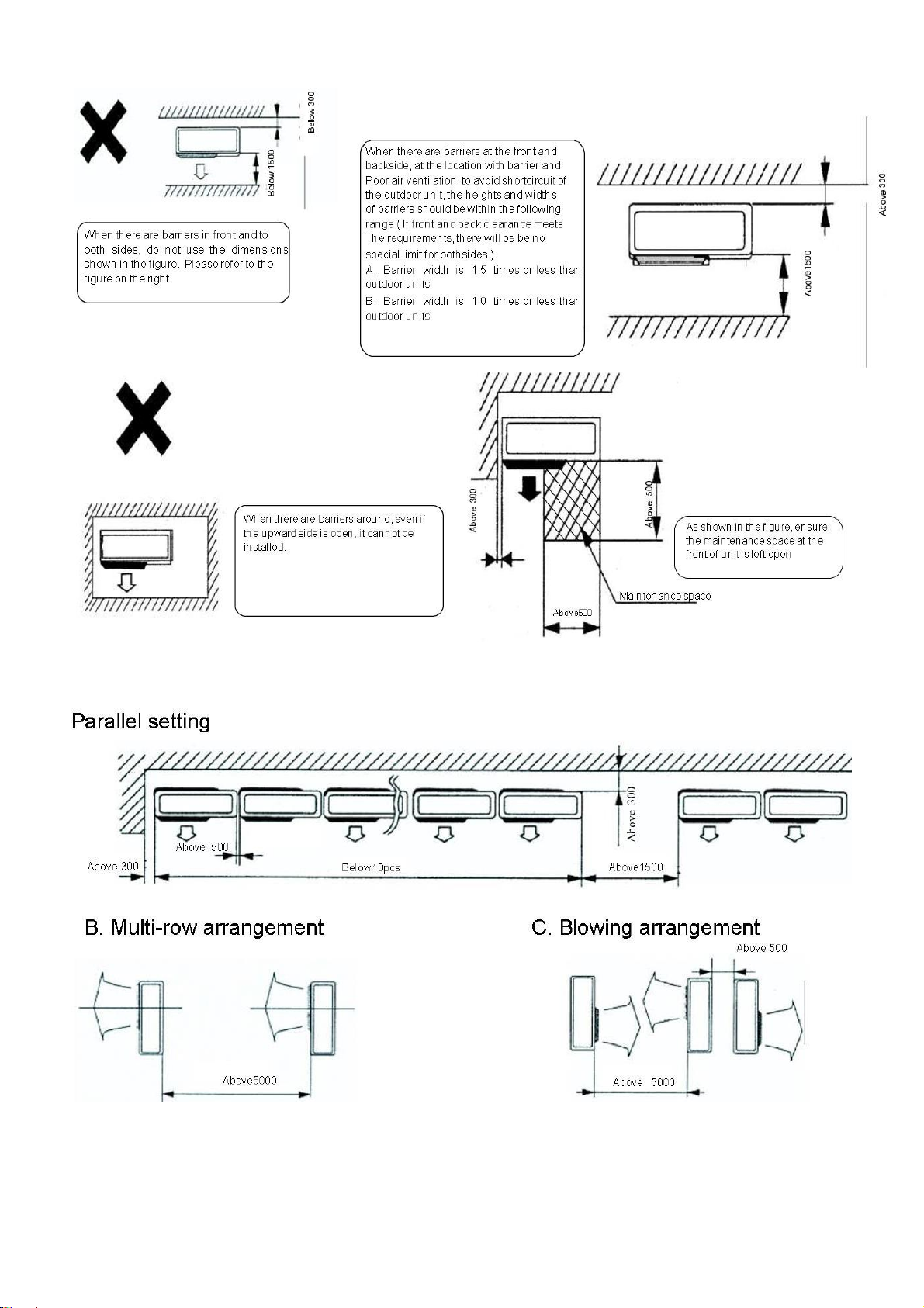

INSTALLATION REQUIREMENTS AND MAINTENANCE SPACE (OUTDOOR UNIT)

1.

Single unit installation (unit: mm)

28

MULTI UNIT INSTALLATION

29

MOUNTING ON A ROOF OR OTHER WINDY POSITIONS

When the outdoor unit is to be mounted on the roof or place around which there is no building, it

is necessary to avoid strong winds directly blowing into the air outlet of the outdoor unit. To avoid

impairing the heating or cooling effect and failure of the outdoor unit heat exchanger due to

inadequate air flow.

A. When there is wall nearby, please locate the air exhaust facing the wall and keep about

500mm distance from the wall.

B. When the air exhaust is affected by strong wind or wind direction, it is necessary to

change the air intake unit position to make the exhaust port perpendicular to the wind

direction.

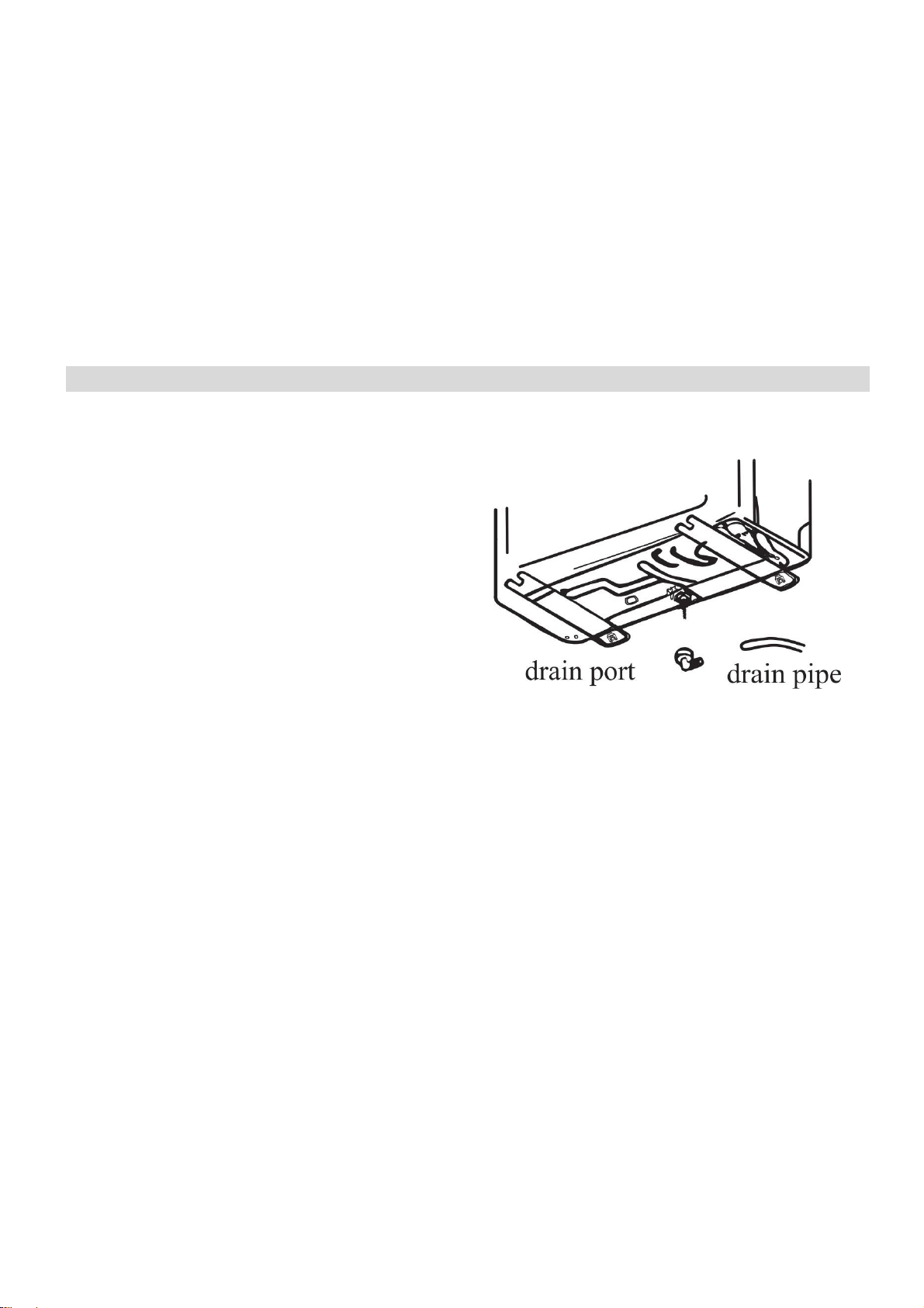

CONDENSATE DRAINAGE OF THE OUTDOOR UNIT

When operating in heating mode condensate

will collect and drain through the base of the

outdoor unit. The air conditioner is supplied with

an elbow joint which can be connected to the

underside of the outdoor unit for drainage.

1. Connect the elbow joint to the drainage hole

on the underside of the outdoor unit.

2. Connect a drain hose (not supplied) to the

elbow joint and run downhill to your chosen

drainage point.

Please note: The drainage is gravity fed, and so

must run downhill.

30

REFRIGERANT PIPE INSTALLATION

Note:

1.

Refrigerant pipe is not supplied with the unit, but a selection are available from the same

retailer as the air conditioner.

2.

A thermal insulation sleeve of more than 9mm thick and with favourable thermal

insulation performance should be used to avoid condensation when selecting the

refrigerant pipe.

3.

When installing the drainage hose (not supplied), additionally procure the cable tray

connection exhaust pipe with inner diameter of φ16, and bind up with the thermal insulation

sleeve of 9mm thick to avoid condensation.

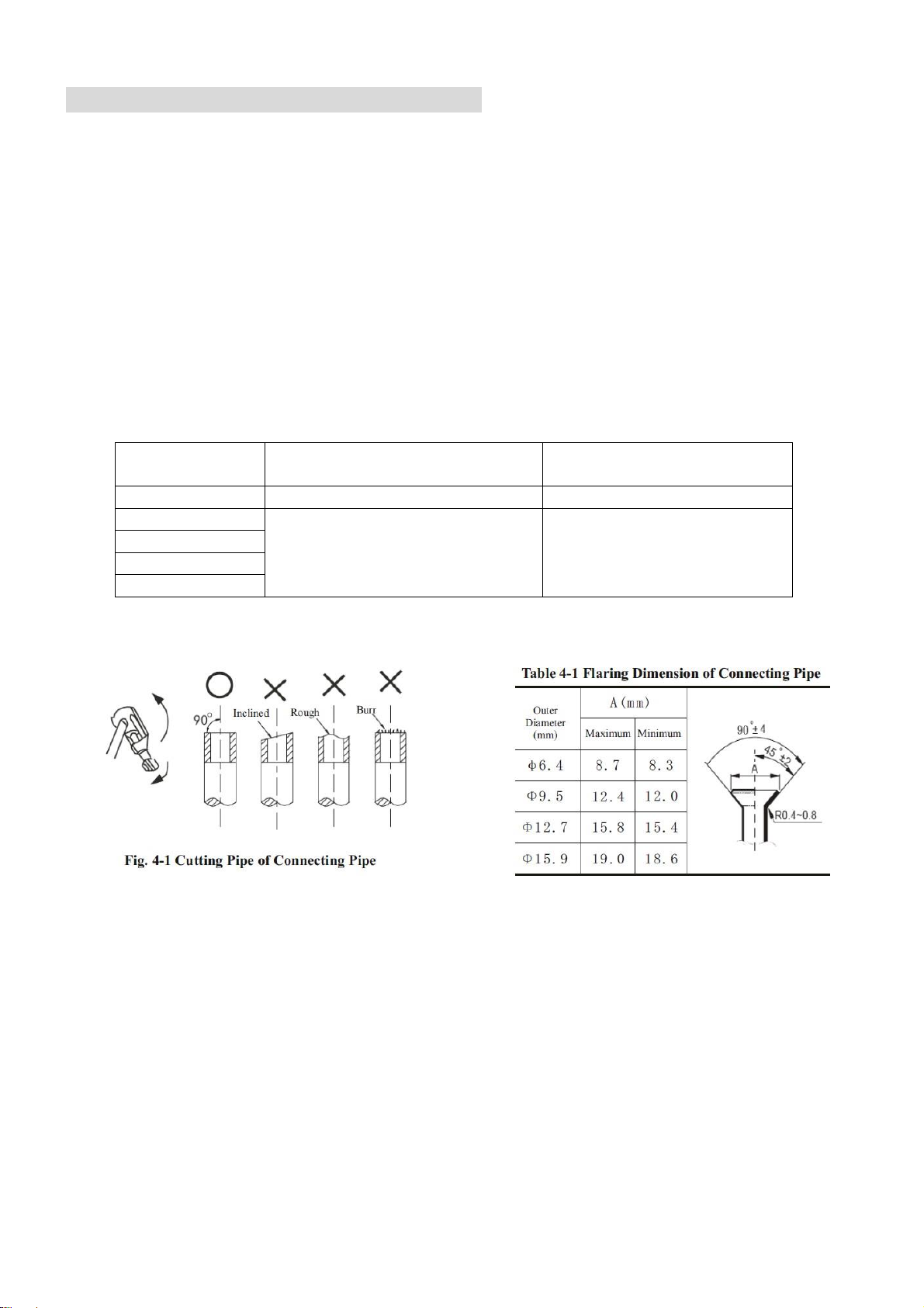

DIMENSION OF REFRIGERANT PIPE

Model

Refrigerant Liquid Pipe

Diameter

Refrigerant Gas Pipe

Diameter

eiQ-CRFC18K

6.4 (1/4”)

12.7 (1/2”)

eiQ-SSRFC24K

9.52 (3/8”)

15.88 (5/8”)

eiQ-SSRFC36K

eiQ-SSRFC48K

eiQ-SSRFC60K

FLARING THE PIPES

31

LENGTH AND HEIGHT DIFFERENCE OF ULTRA-LONG PIPING OF AIR CONDITIONING

UNIT

eiQ-

CRFC18K

eiQ-

SSRFC24K

eiQ-

SSRFC36K

eiQ-

SSRFC48K

eiQ-

SSRFC60K

Max Pipe

Length

15M

20M

50M

50M

50M

Max Height

Difference

8M

10M

20M

20M

20M

Max Pipe

bends

10

10

15

15

15

Note: When the height is more than 5m, set the oil trapping bend and non-return bend according

to relative positions of outdoor unit and indoor unit.

Outdoor unit Indoor unit

When the installation position

of indoor unit is higher than

outdoor unit

When the installation position

of indoor unit is higher than

outdoor unit

Indoor unit

32

NOTES:

The copper pipe used in the refrigeration lines are very soft, high pressure copper and prone to

get damaged if not handled correctly. Try to avoid bending or stretching the pipework. Always

ensure the pipes are protected when running through the wall to help prevent damage to the

pipes.

To keep the allowed

bending radius please

make the packed soft

pipes vertical before

extending

Please do not extend only

one side of the packed soft

pipes.

Please make use of

semicircle pulley to keep the

allowed bending angle

Extreme bending could

damage the pipes

Please use a twisting

wheel to avoid improper

bending.

Over bent soft pipes will lead

to irregular bending

Please use rigid elbow to

keep the bending angle

while soft pipes operating.

Undersize bending will

damage the soft pipe.

Please keep the minimum

bending angle while

installing

Do not use short sharp

angle bends.

33

STANDARD PIPELINES CONNECTION & AIR PURGING

No dust or any other particles, air or moisture should be allowed to enter the air conditioning

system. Careful attention should be paid when pipeline connection for outdoor unit is made. Try

to avoid repeated curves as much as possible; otherwise damage to the copper pipes may occur.

Suitable wrenches should be used when the pipeline connection is done so as to ensure

appropriate torque (refer to following torque table).

Excessive torque action might damage the joints while too little torque might lead to leakage.

Torque based upon the wrench to be used

Follow the procedures below:

1. Remove the dust caps from the indoor and outdoor units and the connecting pipe.

2. Align the joint of the connecting pipe between the indoor and outdoor and tighten the

connecting nut by hand to prevent cross threading. Secure them with a wrench, applying

the maximum torque as shown in the table above.

3. Pressure test and vacuum pump the pipework for each refrigerant circuit.

4. Remove the two valve core caps from the outdoor unit and turn on the high and low

pressure valve cores with an socket wrench, then tighten the two valve core caps of the

outdoor unit. Finally you can wrap hot insulating tape around the joints of indoor and

outdoor units

Copper pipe diam.

Tightening torque

Strengthened tightening torque

6.35(1/4")

160kgf.cm(63kgf.inch)

200kgf.cm(79kgf.inch)

9.52(3/8")

300kgf.cm(118kgf.inch)

350kgf.cm(138kgf.inch)

12.7(1/2")

500kgf.cm(197kgf.inch)

550kgf.cm(216kgf.inch)

15.88(5/8")

750kgf.cm(295kgf.inch)

800kgf.cm(315kgf.inch)

34

AIR PURGING WITH VACUUM

PUMP

1.

Check that pipelines connection

have been properly connected,

remove the charging port cap, and

connect the manifold gauge and

the vacuum pump to the charging

valve using service hoses as

shown

2.

Open the valve on the lowpressure side of the manifold

gauge, then run the vacuum

pump. Vacuum the indoor unit and

the connecting pipes until the

pressure in them lowers to below

1.5mmHG (The operation time for

vacuuming is about 10 minutes).

When the desired vacuum is

reached, close the low pressure

valve on the manifold and stop the

vacuum pump.

3.

Disconnect the service hoses and

fit the cap to the charging valve.

4.

Remove the blank caps, and fully

opens the spindles of the 2-way

and 3-ways valves with a service

valve wrench.

5.

Tighten the blank caps of the 2way and 3-ways valves, applying

the torque listed in the table

above.

35

PRESSURE TEST, VACUUMING AND LEAK TEST OF CONNECTING PIPE AND

INDOOR UNIT PIPELINE:

After installed the connecting pipe and indoor unit, firstly charge the nitrogen into the

connecting pipe and indoor unit pipe to 3.0Mpa and keep the pressure for 24h; at

same time, check for leaks with soap bubble at the connectors and welding

positions; if no leak detected, discharge the nitrogen and vacuum with a

vacuum pump (the vacuum degree shall be less than 30Pa), and then open the

main machine valve for a test run ; if the refrigerant pipe length is more than 5m,

refill the refrigerant and refer to following table:

eiQ-CRFC18K

eiQ-SSRFC24K

eiQ-SSRFC36K

eiQ-SSRFC48K

eiQ-SSRFC60K

Refrigerant to be

added per metre of

liquid pipework above

5m.

0.012Kg

0.024Kg

0.024Kg

0.024Kg

0.024Kg

i.e. If liquid pipe on an eiQ-SSRFC24K is 7m, amount of refrigerant to be added would be (7 –

5)*0.024Kg, so 0.048kg should be added.

When refilling the refrigerant, use the needle valve on low pressure valve body of

outdoor unit in refrigeration mode.

GAS LEAKAGE INSPECTION

After the pipeline connection is done, use a leakage inspection device to carefully check

if there is any leakage at the joints. This is an important step to ensure the quality of

installation. Once a leak is detected, proper action should be taken immediately.

36

ELECTRICAL CONNECTION OF THE AIR CONDITIONER

The electrical connections can be found under the protective plastic cover. Remove

this from the side of the outdoor unit to gain access to the electrical connections.

Connect the indoor power and control wires with the matching outdoor wire as per

the electrical diagram.

Do not attempt to connect the wires in a different way to the diagram on the air

conditioner as this could damage the unit and invalidate the warranty.

Secure the wires and replace the cover before operating the unit.

The appliance should be installed in accordance with national wiring regulations.

If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or a suitably qualified person in order to avoid a hazard.

The unit is designed to be hard wired and a suitable switch with a contact separation

of at least 3mm in all poles must be added to the fixed wiring.

The air conditioner electrical wiring must follow the specific country regulations. If

power cord is damaged must be replace by a qualified electrician.

Schematic wiring diagram of power supply (according to user power supply conditions

and different models, execute wiring according to the schematic diagram shown in the

figure below)

eiQ-CRFC18K

eiQ-SSRFC24K

eiQ-SSRFC36K

Indoor

Unit

Outdoor

Unit

37

Outdoor

Unit

Indoor

Unit

SIMPLIFIED PANEL WIRING DIAGRAM

eiQ-SSRFC48K

eiQ-SSRFC60K

38

ELECTRIC CONNECTION OF INDOOR UNIT:

1.

Remove the cover plate of indoor unit electric appliance box.

2.

Connect the power supply line and signal line with related terminals ash shown

in the figure.

3.

Open the wire pressing clip, pass the power supply line and signal line through

the valve plate and firmly hold in the pressing clip.

4.

Install the electric appliance box board.

A

Note: Only the wiring methods of signal line and power supply line are shown in in the

figure; the wiring methods please refer to the wiring schematic diagram of power

supply.

Outdoor

Power

Supply

Line

H05RM-

F

Indoor

Power

Supply

Line

H05VV-

F

Indoor /

Outdoor

Connection

Line( no of

Cores,

Diameter)

Power Supply

Method

Outdoor

Min Fuse

(A)

Indoor

Min

Fuse

(A)

eiQ-

CRFC18K

3 x

2.5mm

2

N/A

4 x 2.5mm

2

Outdoor Power

Supply

16

N/A

eiQ-

SSRFC24K

3 x

2.5mm

2

N/A

4 x 2.5mm

2

Outdoor Power

Supply

16

N/A

eiQ-

SSRFC36K

3 x

4.0mm

2

N/A

4 x 2.5mm

2

Outdoor Power

Supply

40

(Single

Phase)

N/A

eiQ-

SSRFC48K

5 x

2.5mm

2

N/A

4 x 2.5mm

2

Outdoor Power

Supply

20

(Three

Phase)

N/A

eiQ-

SSRFC60K

5 x

2.5mm

2

N/A

4 x 2.5mm

2

Outdoor Power

Supply

20

(Three

Phase)

N/A

* For lengths 20 – 50M 3 x 4mm2 should be used

39

TEST RUN

CONFIRMATION BEFORE TEST RUN

After installation of indoor and outdoor units,

piping and wiring, please confirm there is no

refrigerant leak, loss of power supply line and

signal line, and no mistaken polarity.

Note: The compressor will not run in case of

incorrect connection of the power supply line.

Note: Before test run, be sure to take out 4 air

wheel damper blocks (A) and fixing tape!

TEST RUN

1.

Connect the main power supply of unit.

2.

Press the emergency operation switch (refrigeration or heating) and the air

conditioner starts; the operation indication lamp will illuminate; check whether the

operation of unit is normal; when the emergency operation switch is pressed again, it

will stop the operation.

3.

Press the "ON/OFF" button on the remote control and confirm whether the indoor

unit emits a sound; if heard, the remote control functions and the emergency

operation will be canceled; then operate the buttons of remote controller to observe

whether the operation modes of unit changes correspondingly.

A.

Press "mode" key and select "air supply" mode; check whether there is air

blowing out from the airconditioner.

B.

Press "mode" key and select refrigeration mode; check whether there is cool

air blowing out of the airconditioner.

C.

Press "mode" key and select heating mode; check whether there is hot air

flowing out of the airconditioner (without this mode for single cold type unit)

D.

Press "wind speed" mode and select high speed mode; check whether there

is strong wind blowingout of the air conditioner.

E.

Press the "swing" mode, and observe if wind grate is normal swing.

TEST THE DRAINAGE DEVICE

1.

After installation of the unit, it is necessary to check the drainage device.

2.

During test run, it is necessary to correctly drain out and ensure no leak of connector.

After installation and test run, the installation personnel shall introduce the operation

method and safety notices to the user according to the operation instructions.

40

TROUBLESHOOTING AND SELF DIAGNOSIS

MALFUNCTION

POSSIBLE CAUSE

The appliance

does not

operate

Power failure

Damaged indoor/outdoor unit fan motor

Faulty compressor thermomagnetic circuit breaker

Faulty protective device or fuses

Loose connections

Self protection in adverse conditions

Voltage higher / lower than the voltage range

Active TIMER-ON function

Damaged electronic control board

Strange odour

Air filter dirty

Noise of running

water

Back flow of liquid in the refrigerant circulation

A fine mist

comes from

the air outlet

This occurs when the air in the room becomes very cold, for example

in the COOLING or DEHUMIDIFYING modes.

A strange noise

can be heard

This noise is made by the expansion or contraction of the front panel

due to variations in temperature and does not indicate a problem.

Insufficient

airflow, either

hot or cold

Inappropriate temperature setting.

Air inlet or outlet of indoor or outdoor unit has been blocked.

Air filter is blocked.

Fan speed set at minimum.

Other sources of heat in the room.

No refrigerant.

The appliance

does not

respond to

commands

Remote control is not near enough to indoor unit.

Battery in Remote controller may have been exhausted..

Obstacles between remote control and signal receiver in indoor unit.

The display is

off

Active LED function

Power failure

Remote cannot

select heating

mode.

Remove the batteries from the remote and follow the guide for

setting up the remote.

Switch off the air conditioner immediately and cut off the power supply in the

event of:

Strange noises during operation.

Faulty electronic control board

Faulty fuses or switches.

Spraying water or objects inside the appliance.

Overheated cables.

Very strong smells coming from the appliance.

41

SELF DIAGNOSIS FUNCTION

Table 1: Failure code list of indoor unit

Fault Description

4LED fault indication

Digital display

Wired remote display

Three-phase power phase sequence fault

E0

E0

Indoor and outdoor unit communication failure

Timing lights flash

E1

E1

Temperature sensor (T1) fault

Running lights flash

E2

E2

Pipe temperature sensor in the evaporator (T2) fault

Running lights flash

E3

E3

Pipe temperature sensor in the evaporator (T2B) fault

Running lights flash

E4

E4

Outdoor unit failure

Warning lights flash slowly

E5 E5

The indoor unit EEPROM fault

Defrost lights flash slowly

E7

E7

Water over protection

Warning lights flash

EE

EE

Indoor unit with line controller communication failure

E9

E9

Note: The flash frequency for each of the above indicator is 2.5Hz, slow flashing frequency is 1Hz

Table 2: Parameter table for spot inspection of outdoor unit

The digital tube display the indoor unit amount connected and communicated with during standby

The digital tube displays the frequency value during operation of compressor; the digital tube

displays"dF" during defrosting;

Spot check

NO.

Content

Spot check

NO.

Content

1

Indoor unit capacity

11

Opening of EXV

2

Indoor unit capacity demand

12

Running frequency of

compressor

3

Indoor demand after T4 amendment

13

Primary voltage/4

4

Indoor demand after T2 amendment

5

Indoor room temperature (T1)

temperature

6

Indoor coil middle temperature (T2)

temperature

7

Indoor coil outlet temperature (T2B)

temperature

8

Outdoor unit condenser outlet (T3)

temperature

9

Outdoor temperature (T4) temperature

10

Compressor top temperature (T5)

temperature (maximum 99℃)

42

Table 3: Failure code list of outdoor unit

Display

Error description

Display

Error description

E0

Phase protection

F0

(reserved)

E1

Communication error between outdoor unit and

indoor unit

F1 (reserved)

E2

Indoor room temperature (T1) sensor error

F2

(reserved)

E3 Indoor coil middle temperature (T2) sensor error

F3

Outdoor unit current error cannot recover

Display P3 error for 3 times within 60

minutes

E4

Indoor coil outlet temperature (T2B) sensor error

F4

Outdoor temperature (T4) sensor error

E5

Outdoor unit error

F5

(reserved)

E6

Zero speed protection

F6

Outdoor unit condenser outlet (T3) sensor

error

E7

EERPOM error

F7

Secondary side current protection

E8

Indoor fan motor speed lose protect ion

F8

Heat T2 temp. protection

E9

Wired controller communication error

F9

Outdoor unit voltage error

EE

Water level alarm error

EF

(reserved)

Display

Error description

Display

Error description

P0

(reserved)

H0

Communication error between outdoor

unit main

board and driver board

P1 (reserved)

H1 (reserved)

P2 (reserved)

H2 (reserved)

P3 Primary/secondary overcurrent protection

H3 (reserved)

P4 Exhaust temperature over-high protection

H4 3 times of P6 error within 30 minutes

P5

Outdoor unit condenser outlet (T3)

temperature

over-high protection

H5

3 times of P2 error within 30 minutes

P6 Compressor driver error or IPM protection

H6 3 times of P4 error within 100 minutes

P7 (reserved)

H7 (reserved)

P8 (reserved)

H8 (reserved)

P9 Outdoor unit DC fan motor error

H9 2 times of P9 error within 10 minutes

43

TECHNICAL SPECIFICATION

Model

eiQ-CRFC18K-V4

Indoor Rated voltage and frequency (Ph-V-Hz)

N/A

Outdoor Rated voltage and frequency (Ph-V-Hz)

1Ph/220-240V~/50Hz

Indoor Fuse Required

N/A

Outdoor Fuse Required

16A

Mode

Cooling

Heating

Rated capacity (KW)

5.3 (2.0-5.6)

5.9 (2.5-6.0)

Power input (W)

1555 (420-2100)

1445 (500-1940)

Current input (A)

2.1-10.1

2.5-9.2

SEER/SCOP(W/W)

6.1 / A++

4.0 / A+

Nominal load (kW)

5.300

4.800

Balance point temperature heating (oC)

- -7

Min. outdoor operating temperature (oC)

-15

-15

Thermostat-off mode (W)

45

11

Standby mode (W)

1 Off mode (W)

1

Annual consumption (kW)

319

1765

Copper Pipe Type length

-

Liquid side / Gas side (mm/inch)

Φ6.35/Φ12.7

Max. refrigerant pipe length

15

Max. elevation

8

Interconnecting Cable

4x2.5mm

2

Moisture Removal (L/h)

2.47

Indoor

Air Flow (m3/h)

650

Body Dimensions (L*W*H) (mm)

565x267x565

Panel Dimensions (L*W*H) (mm)

650x29.8x650

Body Packaging (L*W*H (mm)

745x375x675

Panel Packaging (L*W*H (mm)

750x95x750

Body Net / Gross weight (Kg)

16.5/21.5

Panel Net / Gross weight (Kg)

2.7/4.0

Noise – Sound pressure level (dB/A)

36-43

Noise – Sound power level (dB/A)

46-55

Outdoor

Dimension (L*W*H) (mm)

925x366x700

Packaging (L*W*H) (mm)

990x410x770

Net / Gross Weight (Kg)

45/48

Noise – Sound pressure level (dB/A)

52

Noise – Sound power level (dB/A)

63

Refrigerant type/weight

R32 / 1300g

Defrost mode

Automatic defrosting

Applicable climate types

Cooling (-15oC – 50oC)

Heating(-15oC – 30oC)

Due to continuous product development process specification may change.

These units contain a gas governed by F-Gas regulations. The gas must be handled by qualified F-Gas engineers.

44

Model

eiQ-SSRFC24K-V4

eiQ-SSRFC36K-V4

Indoor Rated voltage and frequency (Ph-V-Hz)

N/A

N/A

Outdoor Rated voltage and frequency (Ph-V-Hz)

1Ph/220-240V~/50Hz

1Ph/220-240V~/50Hz

Indoor Fuse Required

N/A

N/A

Outdoor Fuse Required

16A

40A

Mode

Cooling

Heating

Cooling

Heating

Rated capacity (KW)

7.0 (3.5-8.0)

7.7(4.5-8.5)

10.5 (6.6-12.8)

11.5(7.35-13.2)

Power input (W)

2140 (600-3000)

1920 (1500-2600)

3150 (740-3900)

3375 (1100-4000)

Current input (A)

2.5-13

5.5-11

2.8-20

4.2-20.4

SEER/SCOP(W/W)

6.1 / A++

4.0 / A+

6.1 / A++

4.0 / A+

Nominal load (kW)

7.000

6.000

10.500

7.500

Balance point temperature heating (oC)

- -7 -

-7

Min. outdoor operating temperature (oC)

-15

-15

-15

-15

Thermostat-off mode (W)

45

45

45

45

Standby mode (W)

1 1 Off mode (W)

1 1

Annual consumption (kW)

423

2512

610

3080

Copper Pipe Type length

- -

Liquid side / Gas side (mm)

Φ9.52/Φ15.88

Φ9.52/Φ15.88

Max. refrigerant pipe length

20

65

Max. elevation

10

30

Interconnecting Cable

4 x 2.5mm

2

4 x 2.5mm

2

Moisture Removal (L/h)

2.59

3.51

Indoor

Air Flow (m3/h)

1100

1800

Body Dimensions (L*W*H) (mm)

840x230x840

840x285x840

Panel Dimensions (L*W*H) (mm)

950x50x950

950x50x50

Body Packaging (L*W*H (mm)

920x265x920

920x310x920

Panel Packaging (L*W*H (mm)

1030x100x1030

1030x100x1030

Body Net / Gross weight (Kg)

25/30

30.5/36

Panel Net / Gross weight (Kg)

6.5/9.5

6.5/9.5

Noise – Sound pressure level (dB/A)

43-49

43-48

Noise – Sound power level (dB/A)

56-63

53-61

Outdoor

Dimension (L*W*H) (mm)

958x843x392

1030X788X432

Packaging (L*W*H) (mm)

1025x960x430

1120X900X485

Net / Gross Weight (Kg)

52/62

68/74

Noise – Sound pressure level (dB/A)

54

55

Noise – Sound power level (dB/A)

67

68

Refrigerant type/weight

R32 / 1700g

R32 / 2150g

Defrost mode

Automatic defrosting

Automatic defrosting

Applicable climate types

Cooling (-15oC – 50oC)

Heating(-15oC – 30oC)

Cooling (-15oC – 50oC)

Heating(-15oC – 30oC)

Due to continuous product development process specification may change.

These units contain a gas governed by F-Gas regulations. The gas must be handled by qualified F-Gas engineers.

45

Model

eiQ-SSRFC48K-V4

eiQ-SSRFC60K-V4

Indoor Rated voltage and frequency (Ph-V-Hz)

N/A

N/A

Outdoor Rated voltage and frequency (Ph-V-Hz)

380~415/3/50

380~415/3/50

Indoor Fuse Required

N/A

N/A

Outdoor Fuse Required

20A

20A

Mode

Cooling

Heating

Cooling

Heating

Rated capacity (KW)

14.0 (7.0-15.5)

15.2 (8.0-16.0)

16.0(7.5-17.0)

16.8 (8.5-17.5)

Power input (W)

4950 (1100-5800)

4920 (1200-6000)

5900 (1400-6300)

5460 (1500-6500)

Current input (A)

2.8-14.6

3.0-15.0

3.5-15.8

3.7-16.3

SEER/SCOP(W/W)

6.1 / A++

4.0 / A+

6.1 / A++

4.0 / A+

Nominal load (kW)

14.000

11.500

16.000

12.000

Balance point temperature heating (oC)

- -7 -

-7

Min. outdoor operating temperature (oC)

-15

-15

-15

-15

Thermostat-off mode (W)

101

23.9

128

23.6

Standby mode (W)

3 3 Off mode (W)

3 3

Annual consumption (kW)

795

3723

911

4046

Copper Pipe Type length

- -

Liquid side / Gas side (mm/inch)

Φ9.52/Φ15.88

Φ9.52/Φ15.88

Max. refrigerant pipe length

65

65

Max. elevation

30

30

Interconnecting Cable

4 x 2.5mm

2

4 x 2.5mm

2

Moisture Removal (L/h)

5.08

7.96

Indoor

Air Flow (m3/h)

1900

2000

Body Dimensions (L*W*H) (mm)

840x285x840

840x285x840

Panel Dimensions (L*W*H) (mm)

950x50x950

950x50x950

Body Packaging (L*W*H (mm)

920x310x920

920x310x920

Panel Packaging (L*W*H (mm)

1030x100x1030

1030x100x1030

Body Net / Gross weight (Kg)

29/34

29/34

Panel Net / Gross weight (Kg)

6.5/9.5

6.5/9.5

Noise – Sound pressure level (dB/A)

45-52

45-52

Noise – Sound power level (dB/A)

56-63

56-63

Outdoor

Dimension (L*W*H) (mm)

1014x1430x450

1014x1430x450

Packaging (L*W*H) (mm)

1095x485x1545

1095x485x1545

Net / Gross Weight (Kg)

109/123.6

112/126.6

Noise – Sound pressure level (dB/A)

58

58

Noise – Sound power level (dB/A)

70

70

Refrigerant type/weight

R32 / 3800g

R32 / 3800g

Defrost mode

Automatic defrosting

Automatic defrosting

Applicable climate types

Cooling (-15oC – 50oC)

Heating(-15oC – 30oC)

Cooling (-15oC – 50oC)

Heating(-15oC – 30oC)

Due to continuous product development process specification may change.

These units contain a gas governed by F-Gas regulations. The gas must be handled by qualified F-Gas engineers.

46

APPENDIX

Disposal: Do not dispose this product as unsorted municipal waste. Collection

of such waste must be handled separately as special treatment is necessary.

Recycling facilities are now available for all customers at which you can

deposit your old electrical products. Customers will be able to take any old

electrical equipment to participating sites run by their local councils. Please

remember that this equipment will be further handled during the recycling

process, so please be considerate when depositing your equipment. Please

contact the local council for details of your local household waste recycling

centres.

47

We recommend that you note the details of your purchase below and retain your original

proof of purchase receipt with this manual. Keep these documents safe in the event of a

warranty claim.

Purchase Date:

Retailer name:

Model number:

Serial number:

Installation Date:

Installer name:

Service Date:

Engineer/ Company name:

electriQ UK SUPPORT

Please, for your own convenience, check the troubleshooting guide before calling the service line.

If the unit still fails to operate call: 0871 620 1057 or complete the online form Office hours:

9AM - 5PM Monday to Friday

www.electriQ.co.uk/support

Unit J6, Lowfields Business Park

Lowfields Way, Elland

West Yorkshire, HX5 9DA

WARRANTY INFORMATION

electriQ guarantee provides cover against material or manufacturing faults.

This means that if your air conditioner develops a fault during the guarantee

period, we will arrange for it to be repaired or replaced.

Faults arising from a faulty installation are specifically excluded.

The system must be serviced annually by qualified personnel.

This unit must be operated under conditions as recommended in this user manual,

at voltages indicated on the unit. Any attempts made to service or modify the unit

by unqualified person, will render this WARRANTY VOID.

This warranty is in addition to, and does not affect, your statutory rights.

Our warranty is RTB warranty and cover parts and labour only.

Loading...

Loading...